Construction method for reversely removing floor slab by using chain saw

A construction method and floor slab technology, applied in building maintenance, construction, building construction, etc., can solve the problems of high construction intensity, low efficiency, limited upper operating space, etc., and achieve the effect of reducing construction intensity and safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

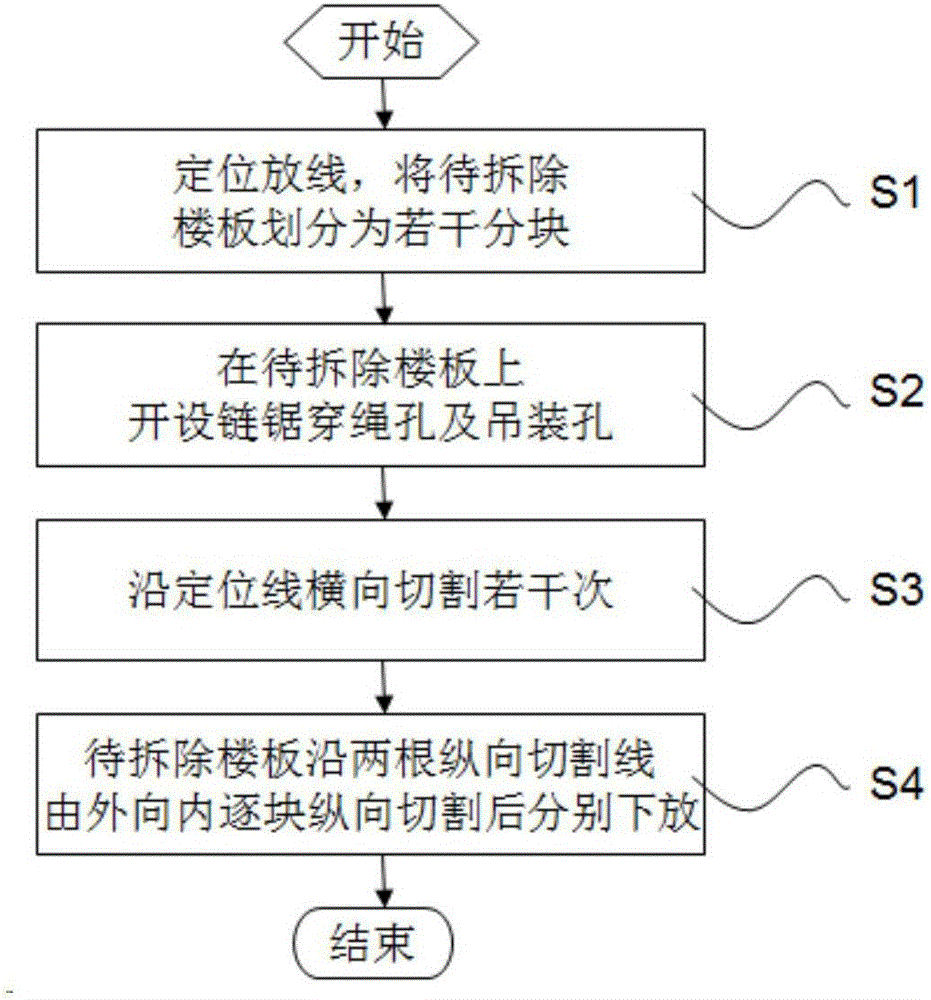

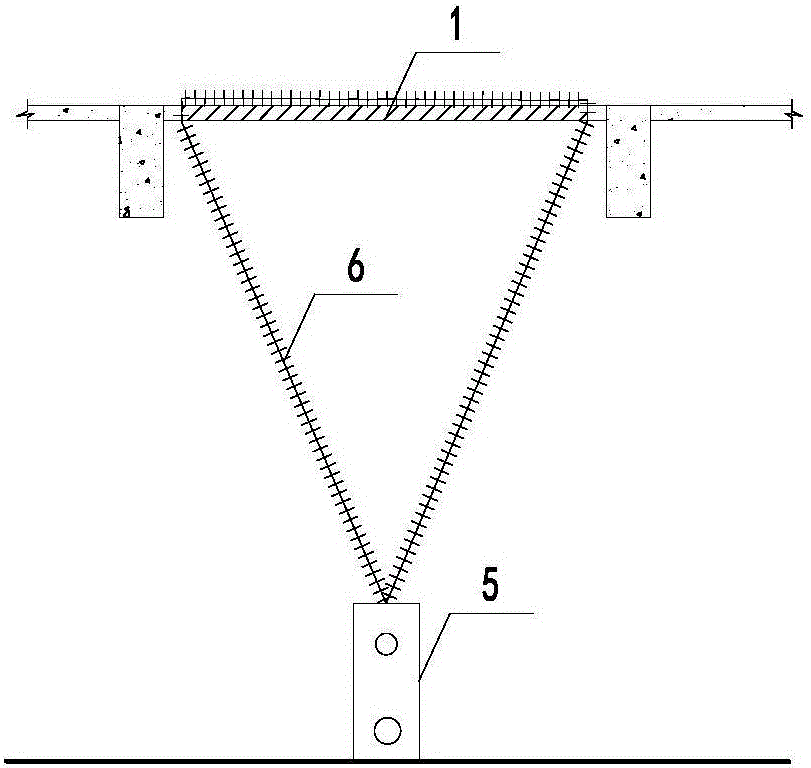

[0028] Such as Figure 1-6 As shown, the present invention provides a chain saw construction method for reverse demolition of floor slabs, comprising the following steps:

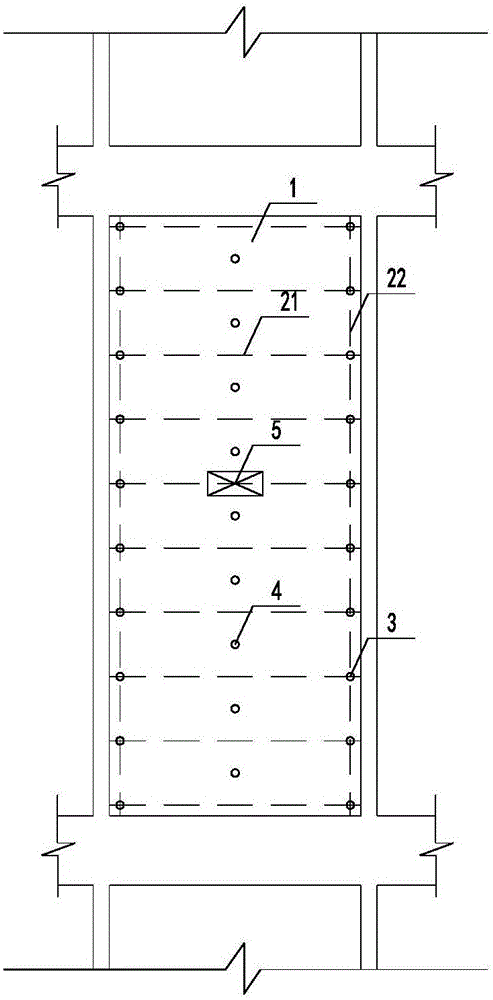

[0029] S1: positioning and setting out, parallel longitudinal cutting lines 22 are respectively set on both sides of the length direction of the floor 1 to be removed, and several transverse cutting lines 21 perpendicular to the longitudinal cutting lines 22 are arranged at intervals between the two longitudinal cutting lines 22, The floor slab 1 to be removed is divided into several sub-blocks. The block size of the floor slab 1 to be removed is jointly determined according to the carrying capacity of the spreader 8, the support frame 7 and the surrounding fixed structure 10. In this embodiment, the floor slab 1 to be demolished is rectangular, the short side of the rectangle is parallel to the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com