Blasting method in reinforcing and reconstructing construction of hydraulic engineering

A technology for water conservancy projects and controlled blasting, applied in the blasting field, can solve the problems of high risk, high construction cost, bad environmental pollution, etc., and achieve the effect of obvious construction benefit and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with specific embodiment, further illustrate the present invention.

[0072] A blasting method in the reinforcement and transformation of water conservancy projects, characterized in that it comprises the following steps:

[0073] Step one, preparation work.

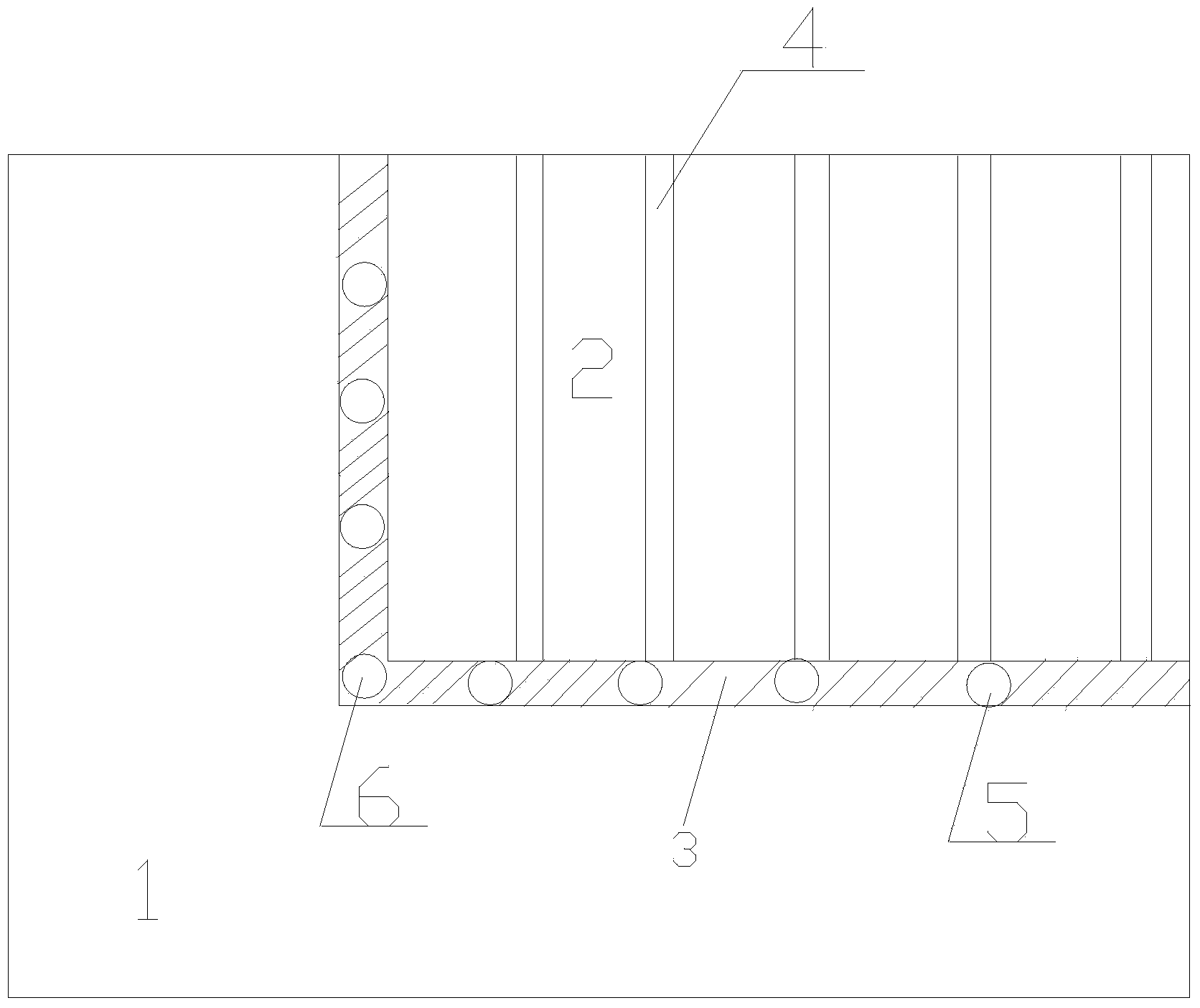

[0074] Rebar removal, along the contour line of the pre-split body (3), manually chisel out the steel bars to expose them, cut off the steel bars by oxygen welding, completely disconnect the steel bars of the demolished body (2) and the retained body (1), protect the bottom plate, and cover it on the bottom plate 50cm of soil is used as the buffer layer of the falling body to ensure the safety of the floor structure.

[0075] Step two, pre-splitting blasting.

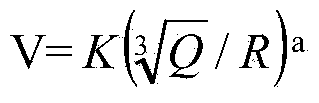

[0076] Arrange multiple pre-split blast holes (5) along the pre-split body (3) according to the position of the designed holes. The explosives in each hole are arranged at intervals of 3 sections, and the explosive packs in adjacent h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com