Patents

Literature

71 results about "Ftir pas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for non-invasive measurement of glucose in humans

InactiveUS6865408B1Efficient collectionMaximize glucose net analyte signal-to-noise ratioRadiation pyrometryDiagnostics using spectroscopyData acquisitionNon invasive

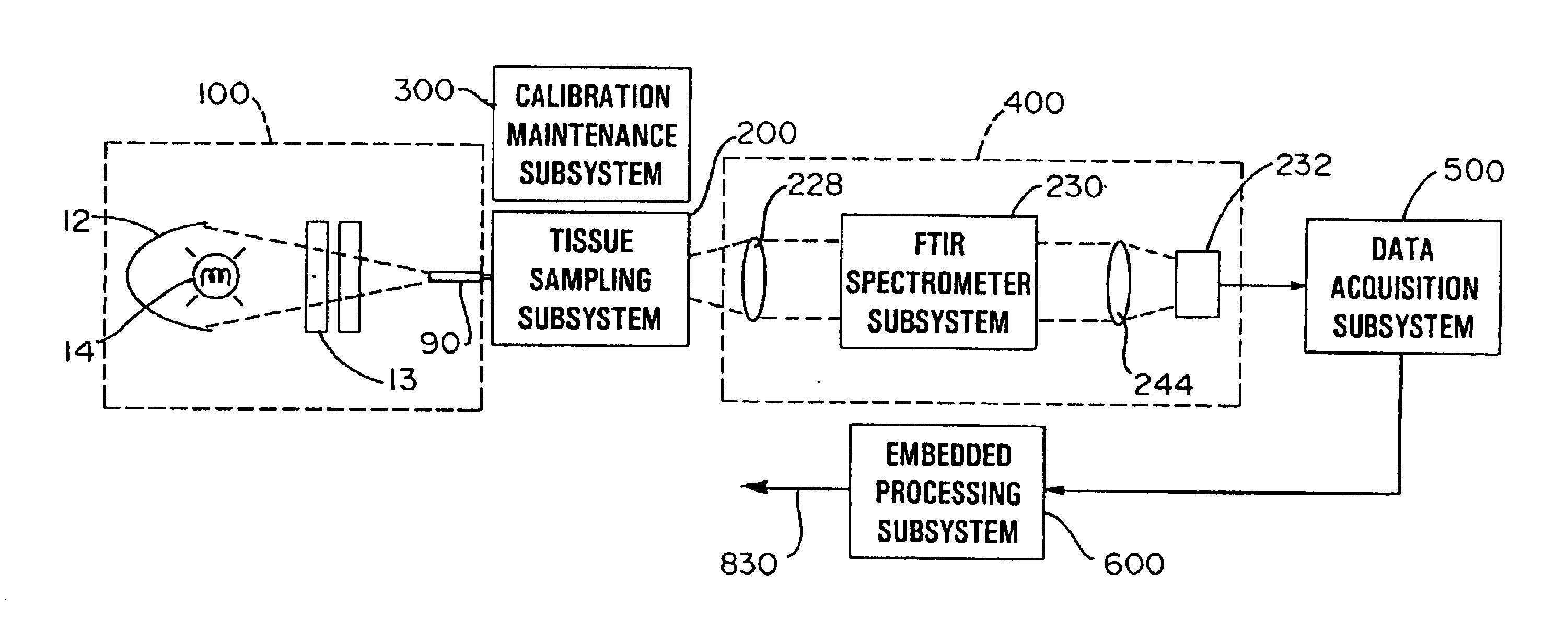

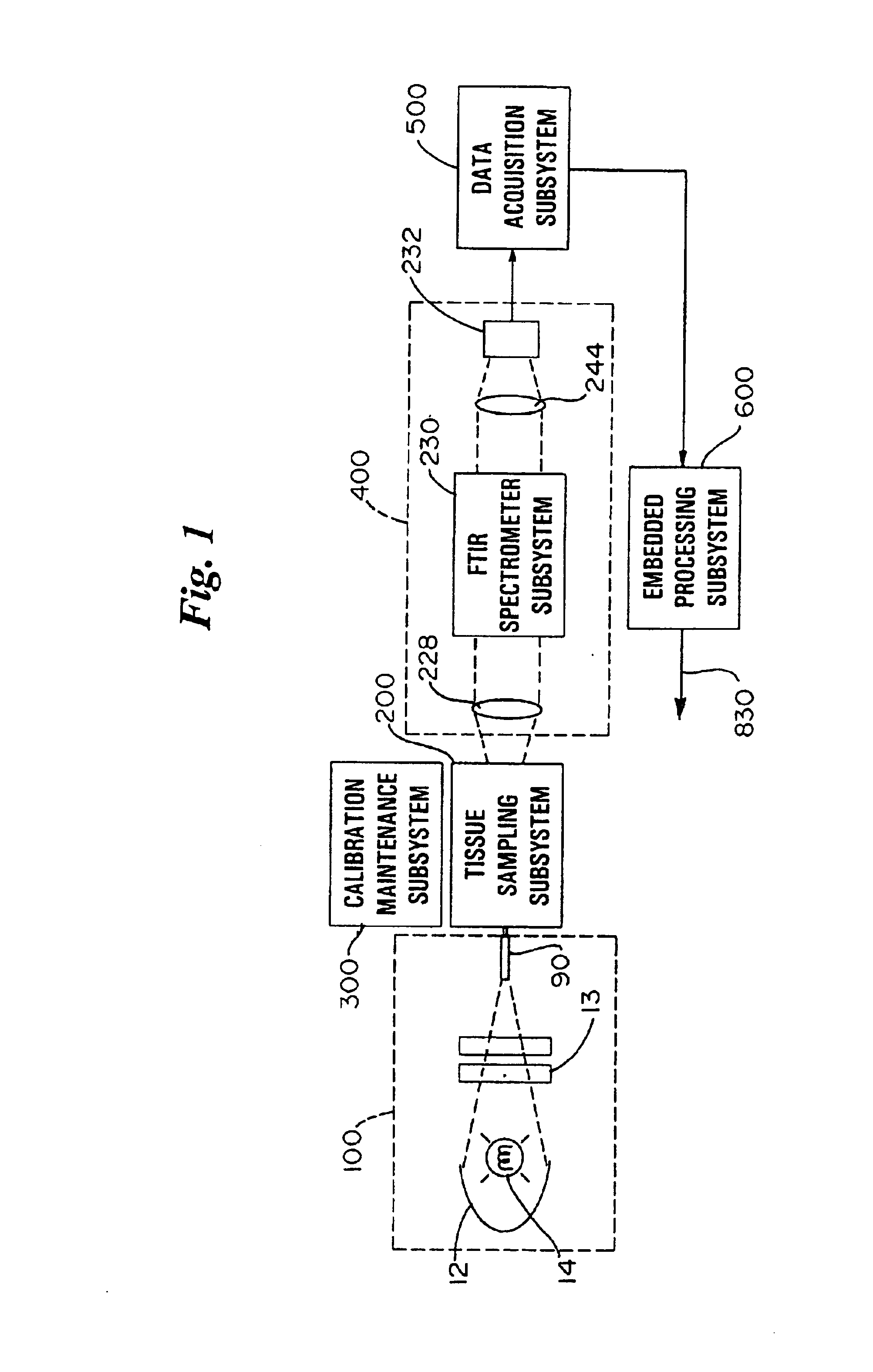

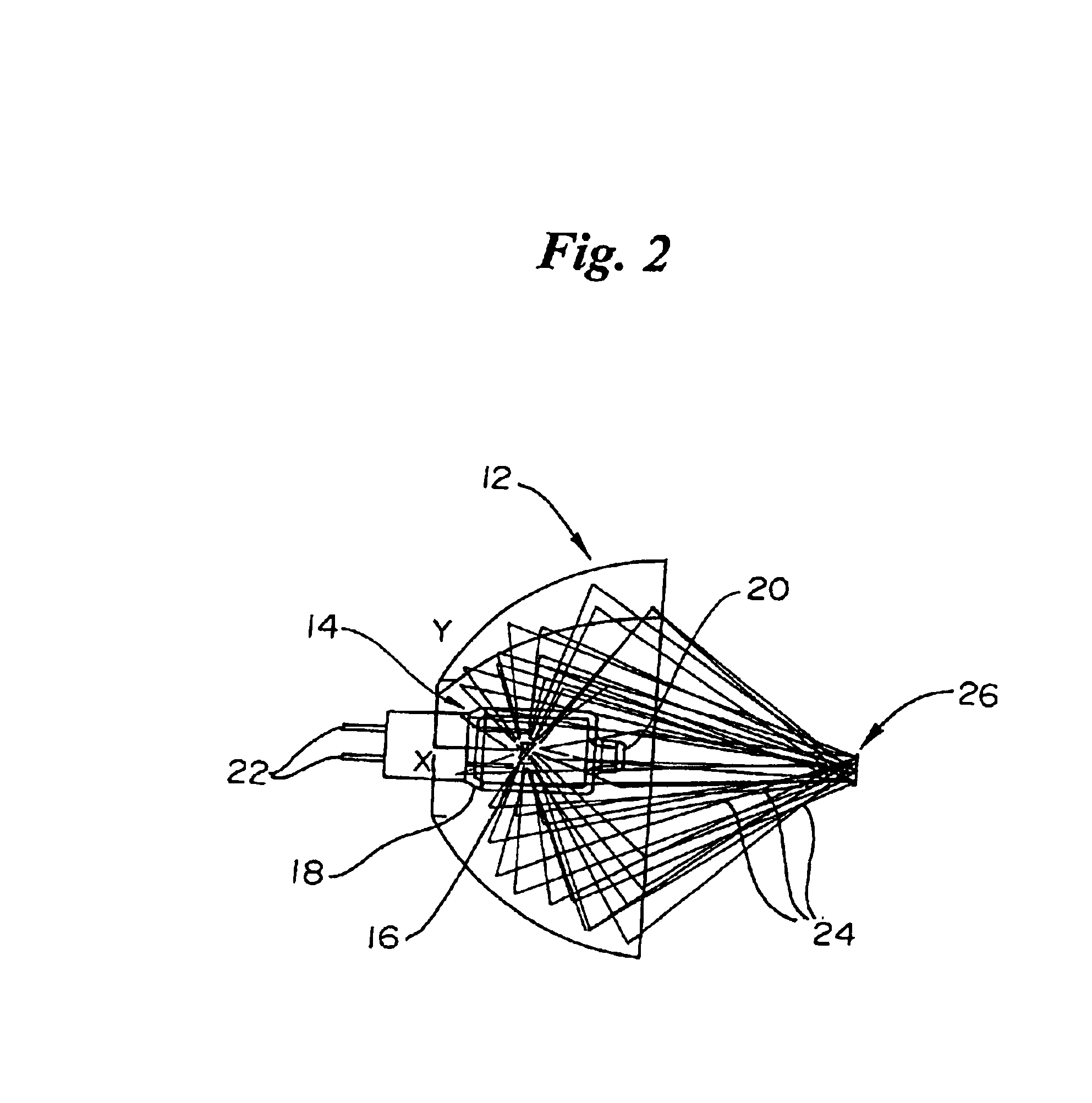

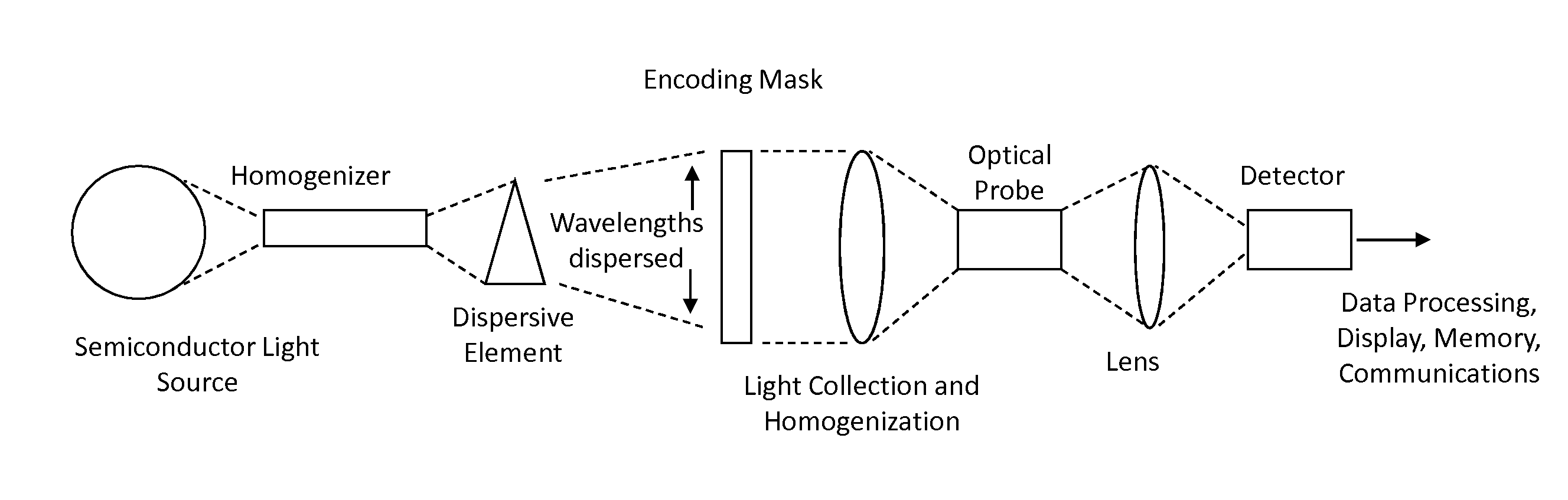

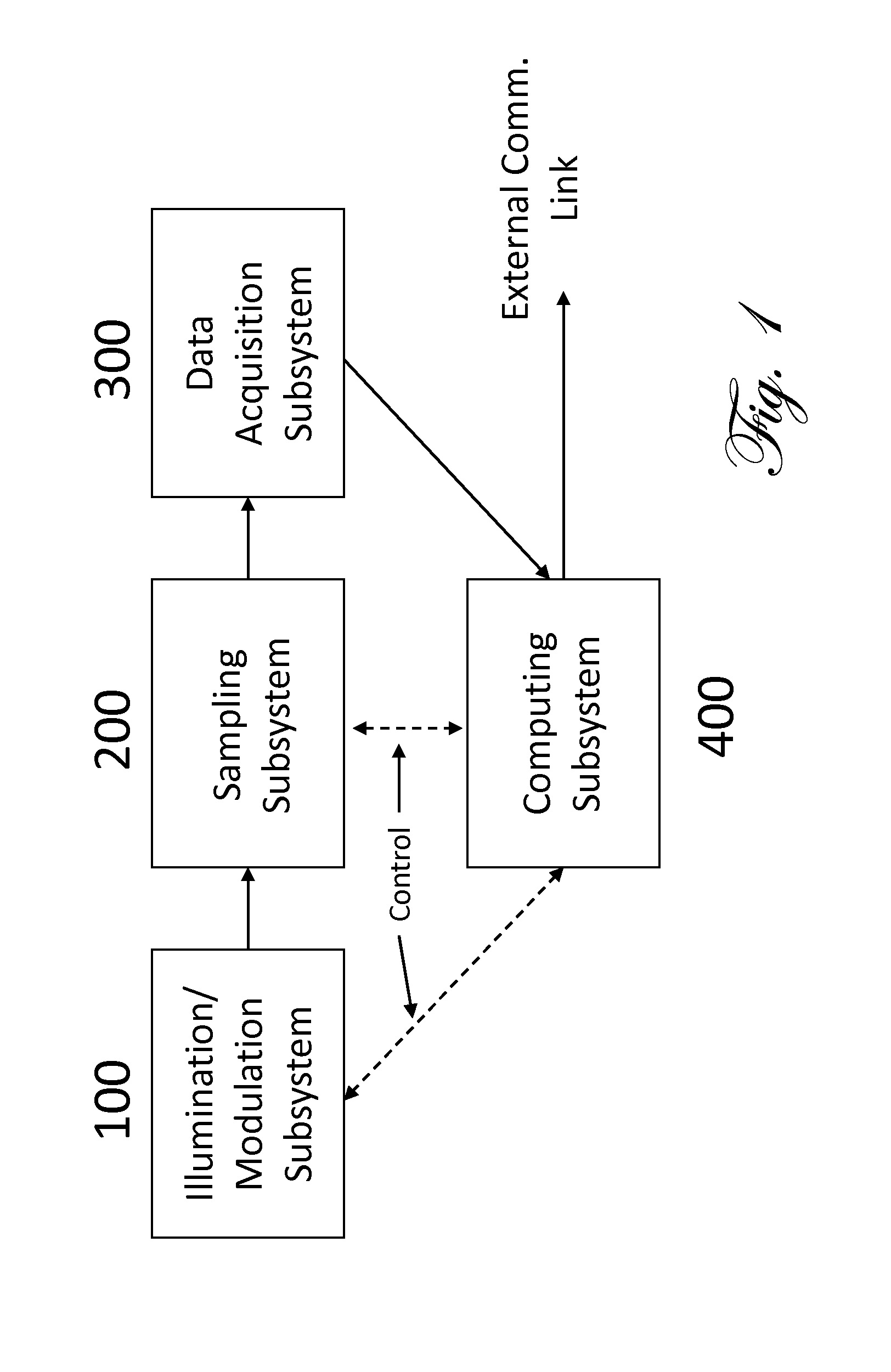

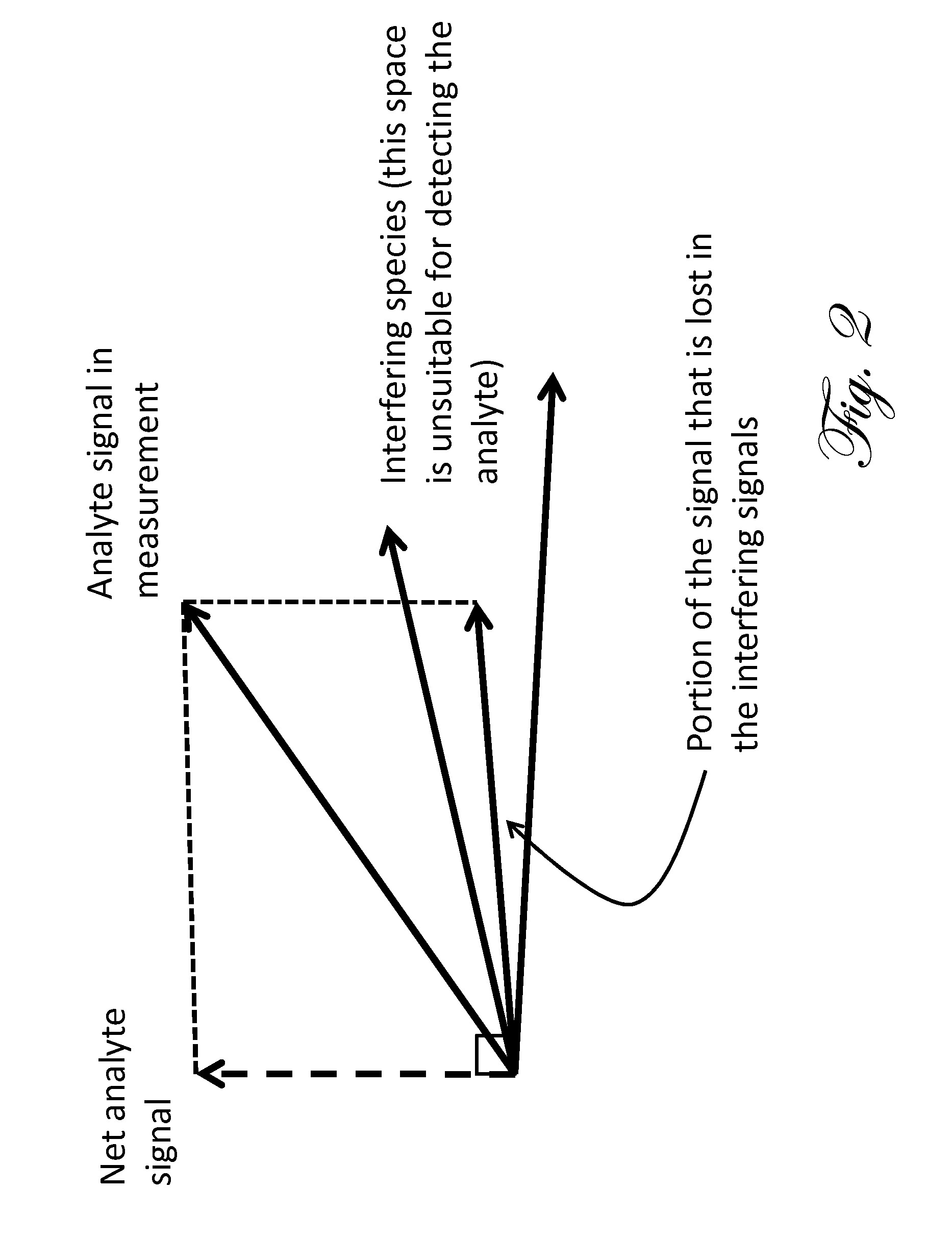

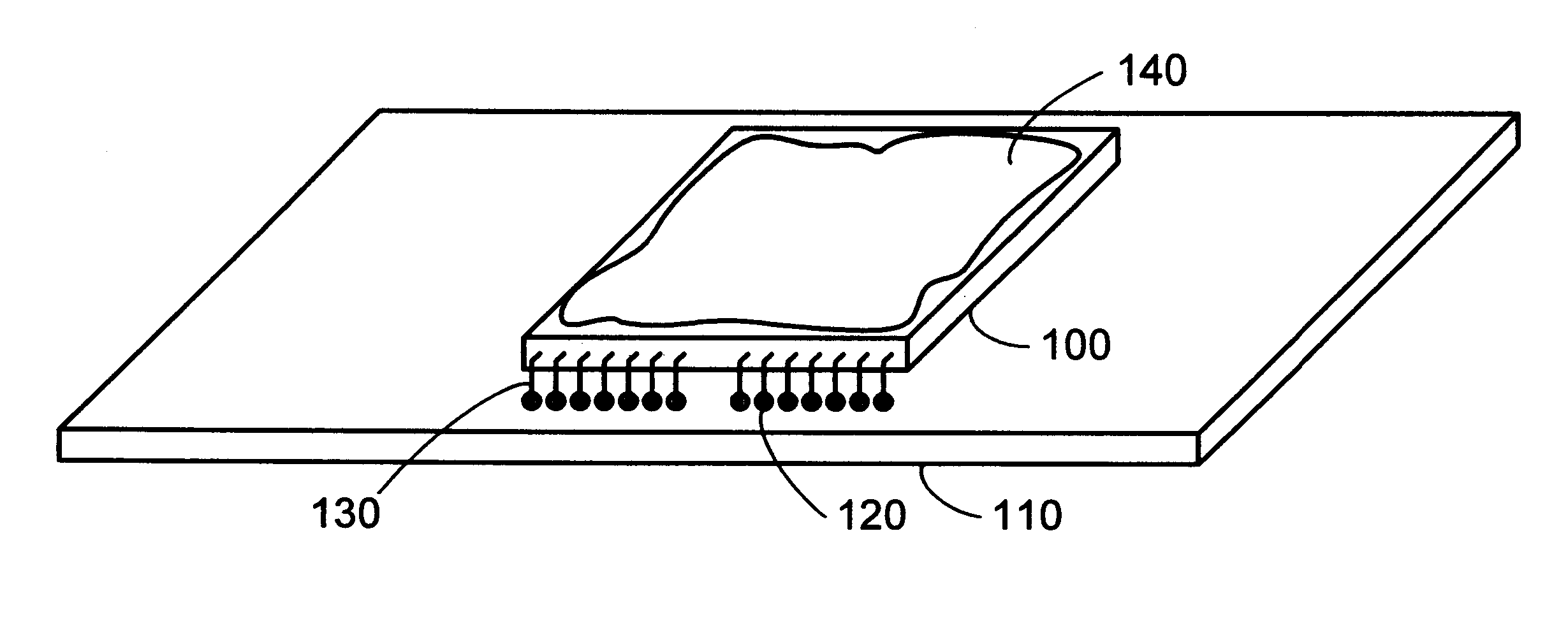

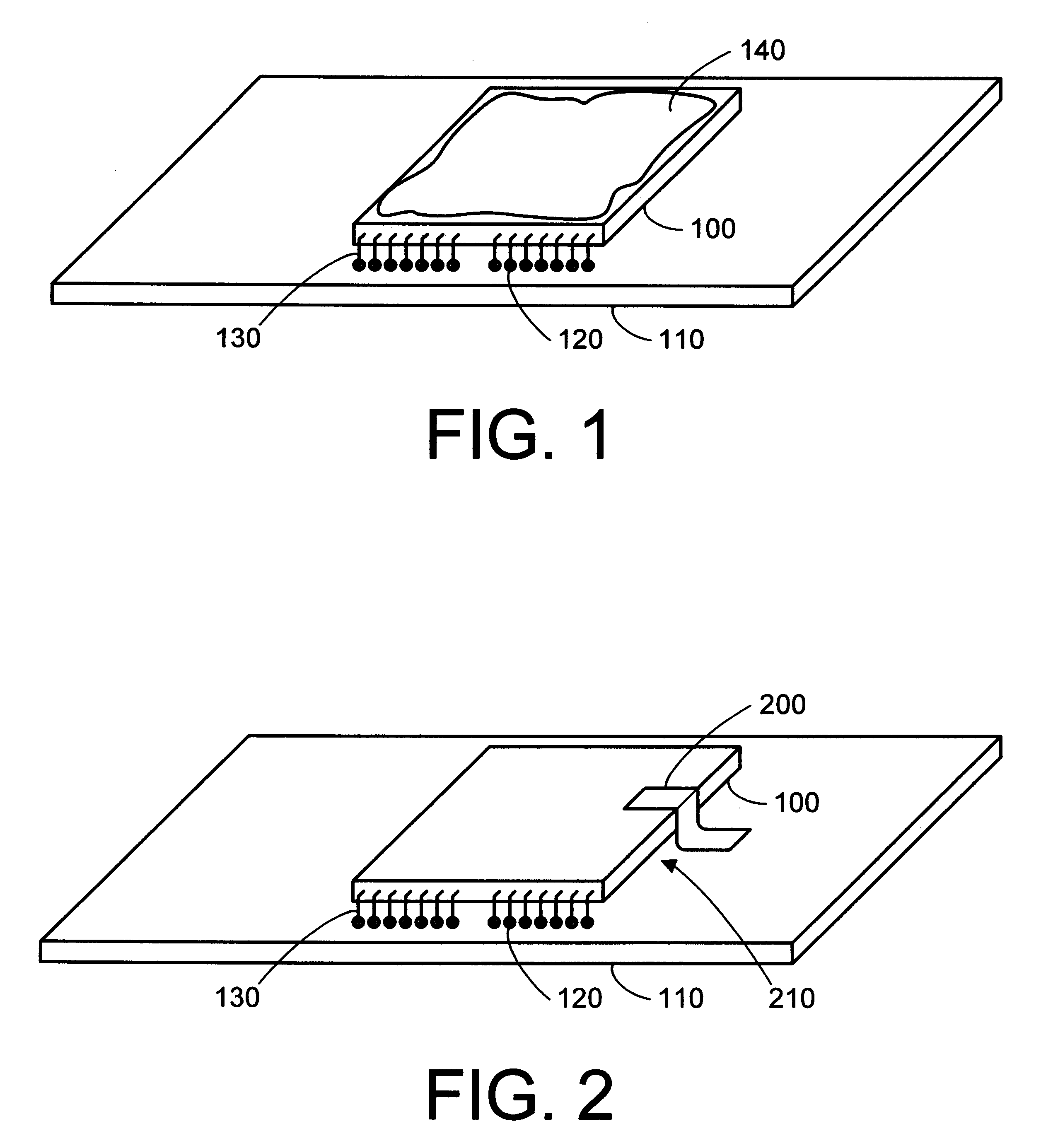

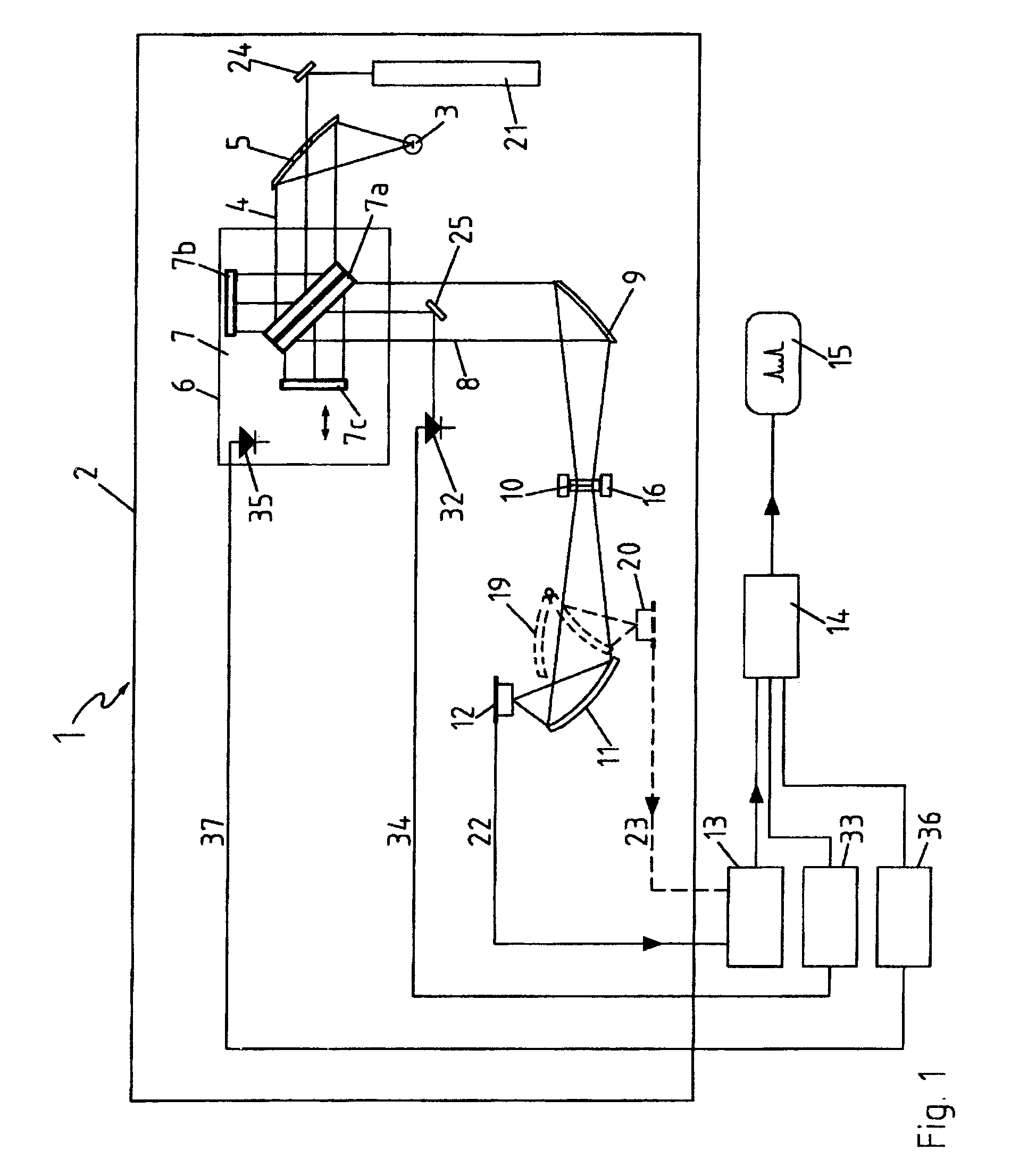

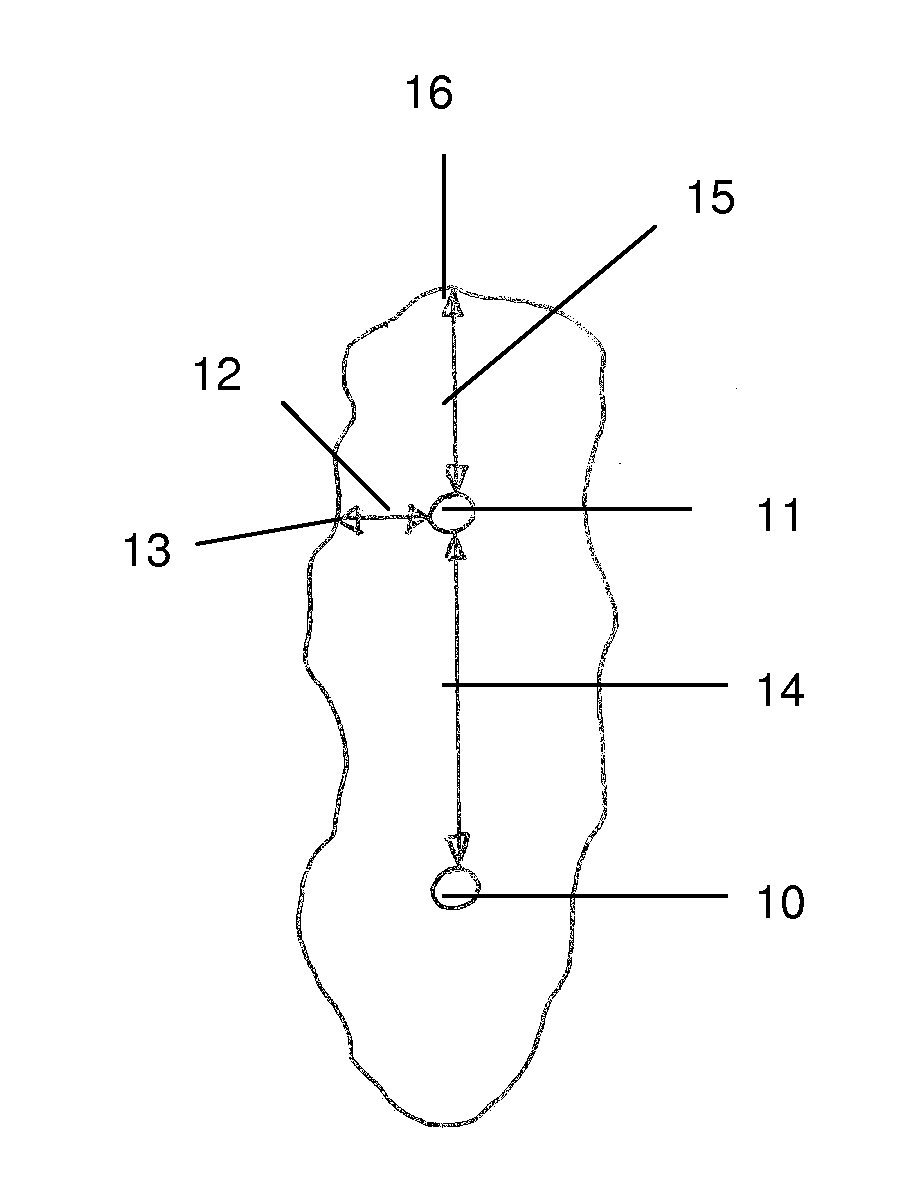

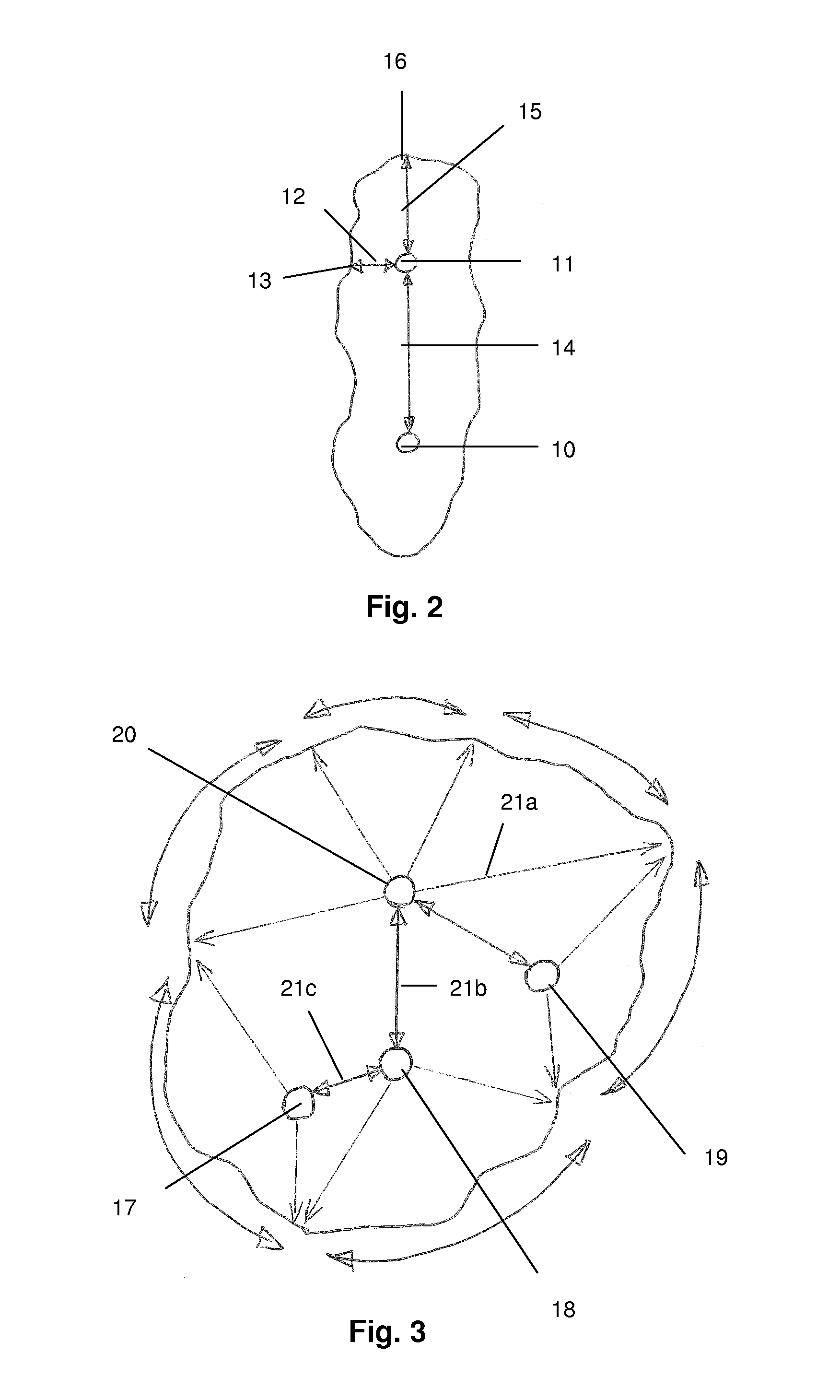

An apparatus and method for non-invasive measurement of glucose in human tissue by quantitative infrared spectroscopy to clinically relevant levels of precision and accuracy. The system includes six subsystems optimized to contend with the complexities of the tissue spectrum, high signal-to-noise ratio and photometric accuracy requirements, tissue sampling errors, calibration maintenance problems, and calibration transfer problems. The six subsystems include an illumination subsystem, a tissue sampling subsystem, a calibration maintenance subsystem, an FTIR spectrometer subsystem, a data acquisition subsystem, and a computing subsystem.

Owner:INLIGHT SOLUTIONS

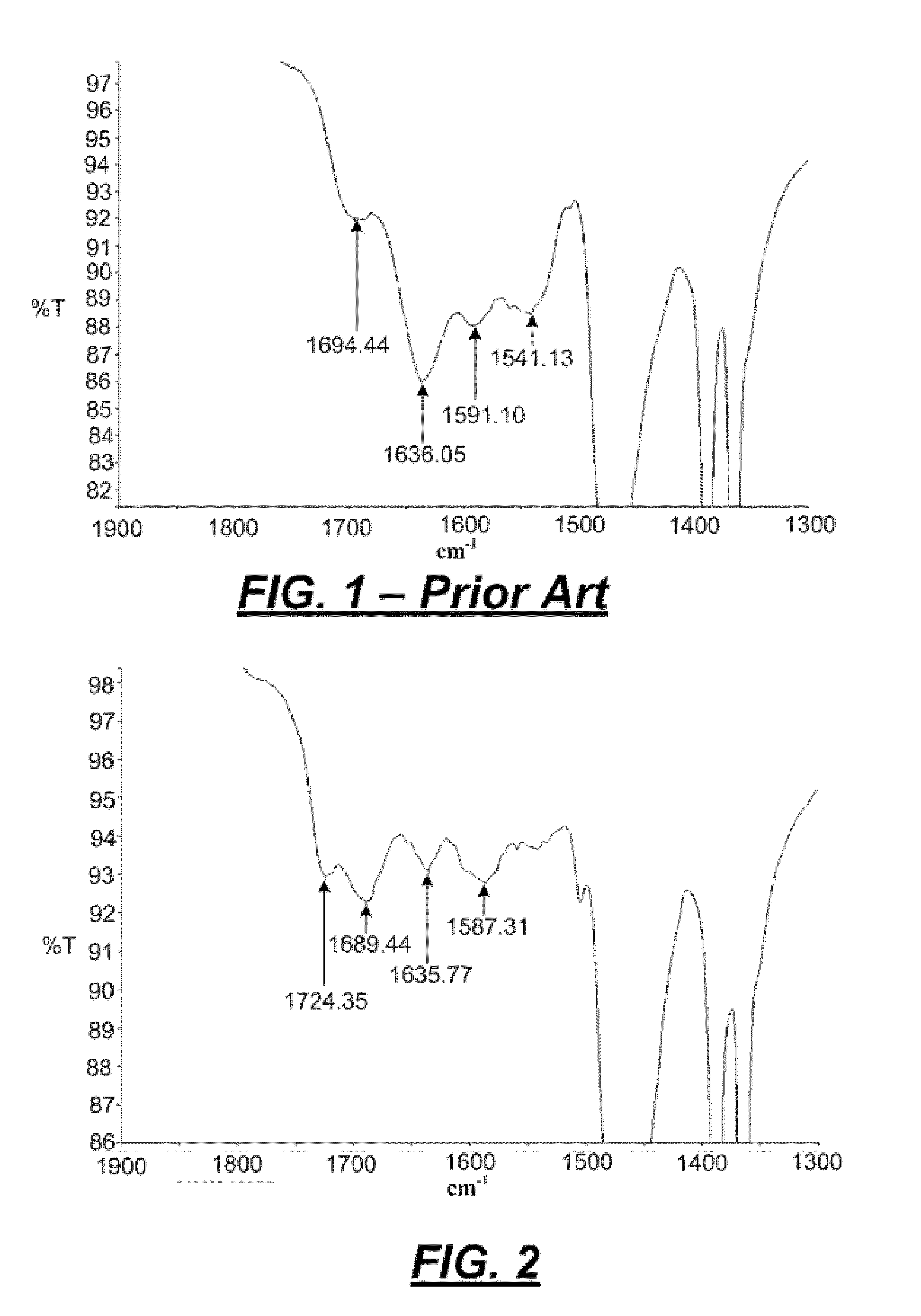

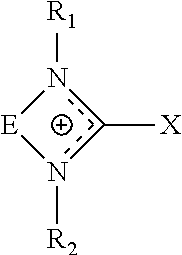

Fuel additives for treating internal deposits of fuel injectors

InactiveUS20130074794A1Reduce the amount requiredAvoid cloggingNon-fuel substance addition to fuelInternal combustion piston enginesHydrogenDicarboxylic acid

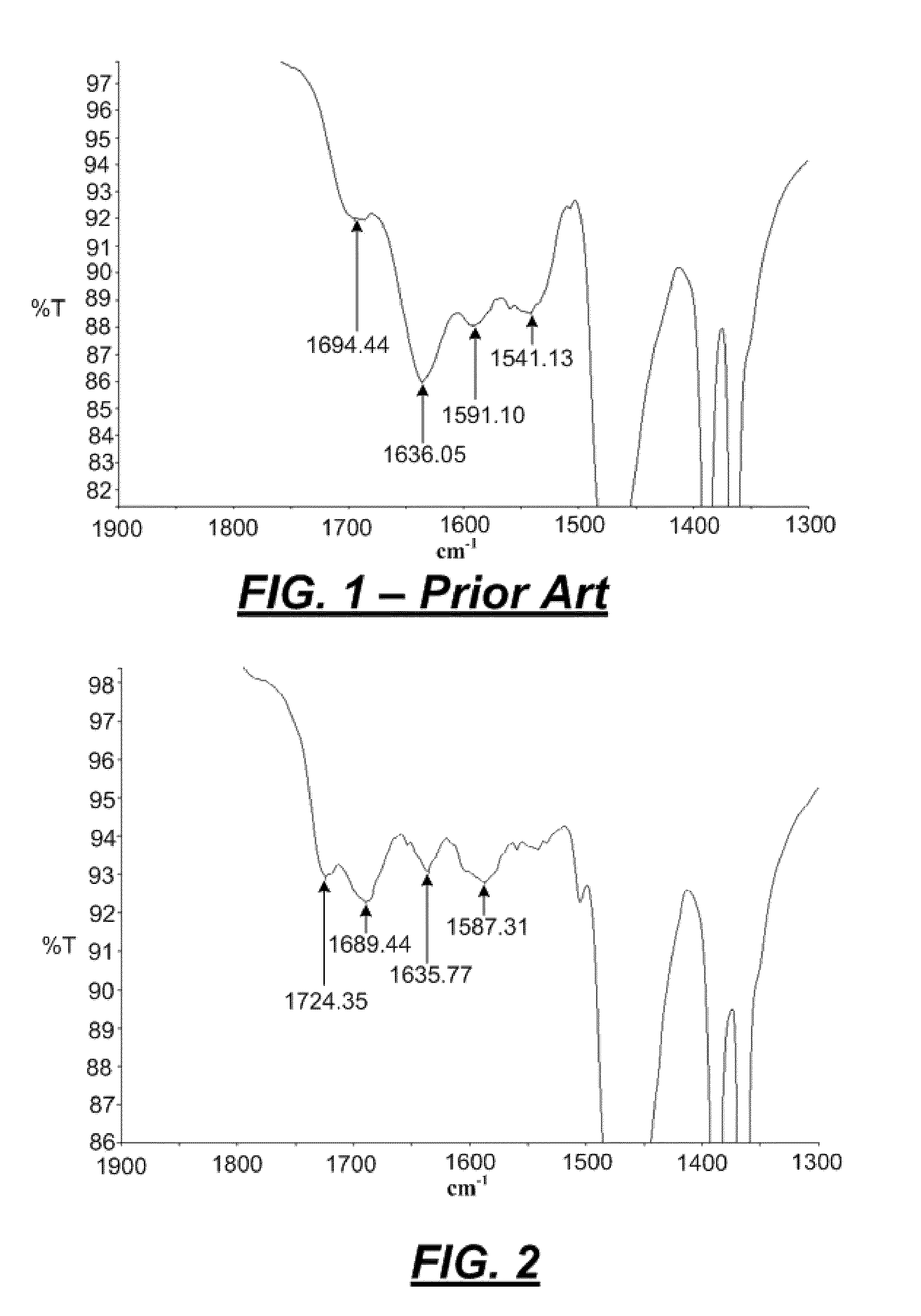

A method cleaning up internal components of a fuel injector for a diesel engine. The method includes operating a fuel injected diesel engine on a fuel composition that includes a major amount of diesel fuel and from about 5 to about 500 ppm by weight of a reaction product derived from (a) a hydrocarbyl substituted dicarboxylic acid, anhydride, or ester and (b) an amine compound or salt thereof of the formulawherein R is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product is characterized by a particular FTIR spectrum.

Owner:AFTON CHEMICAL

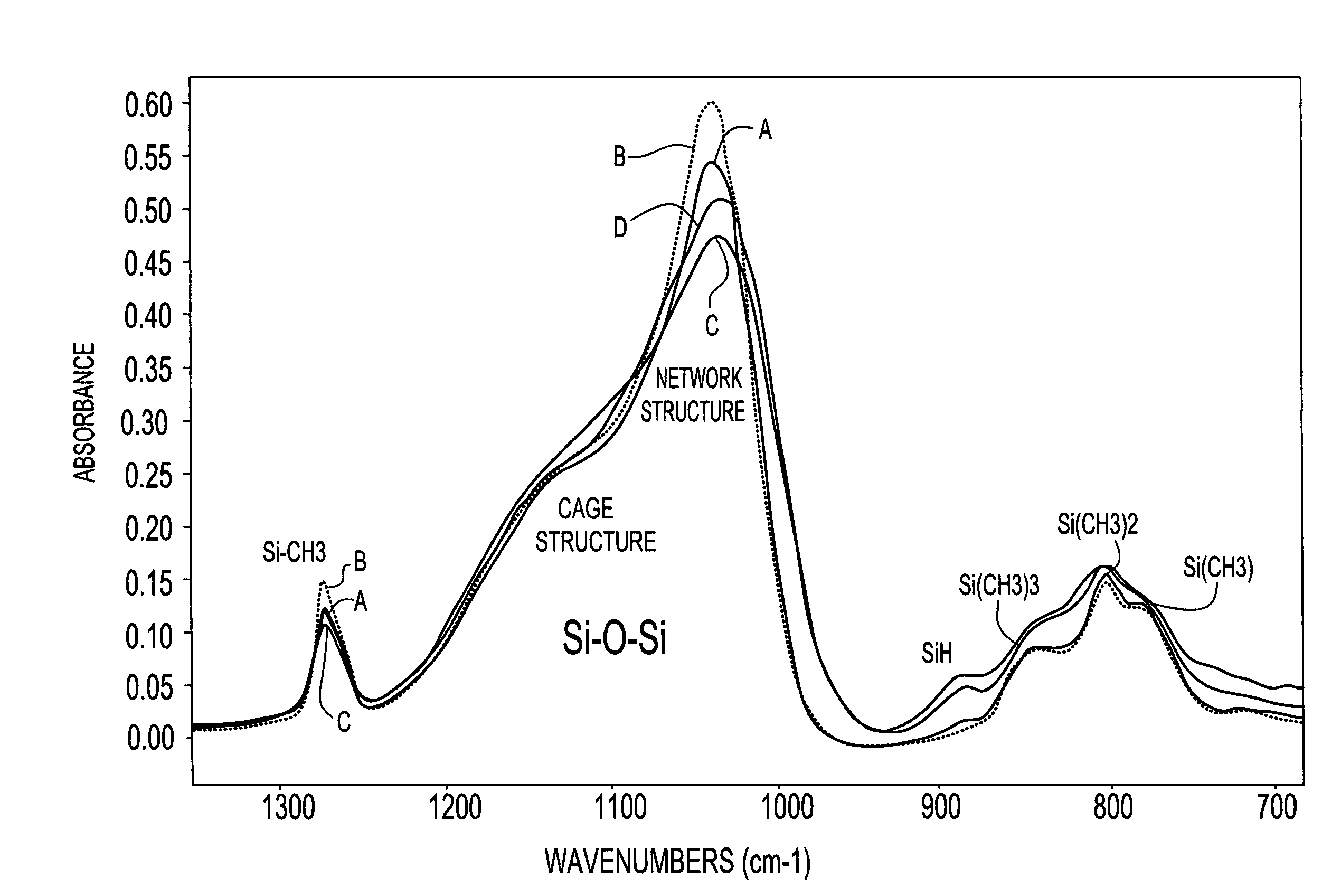

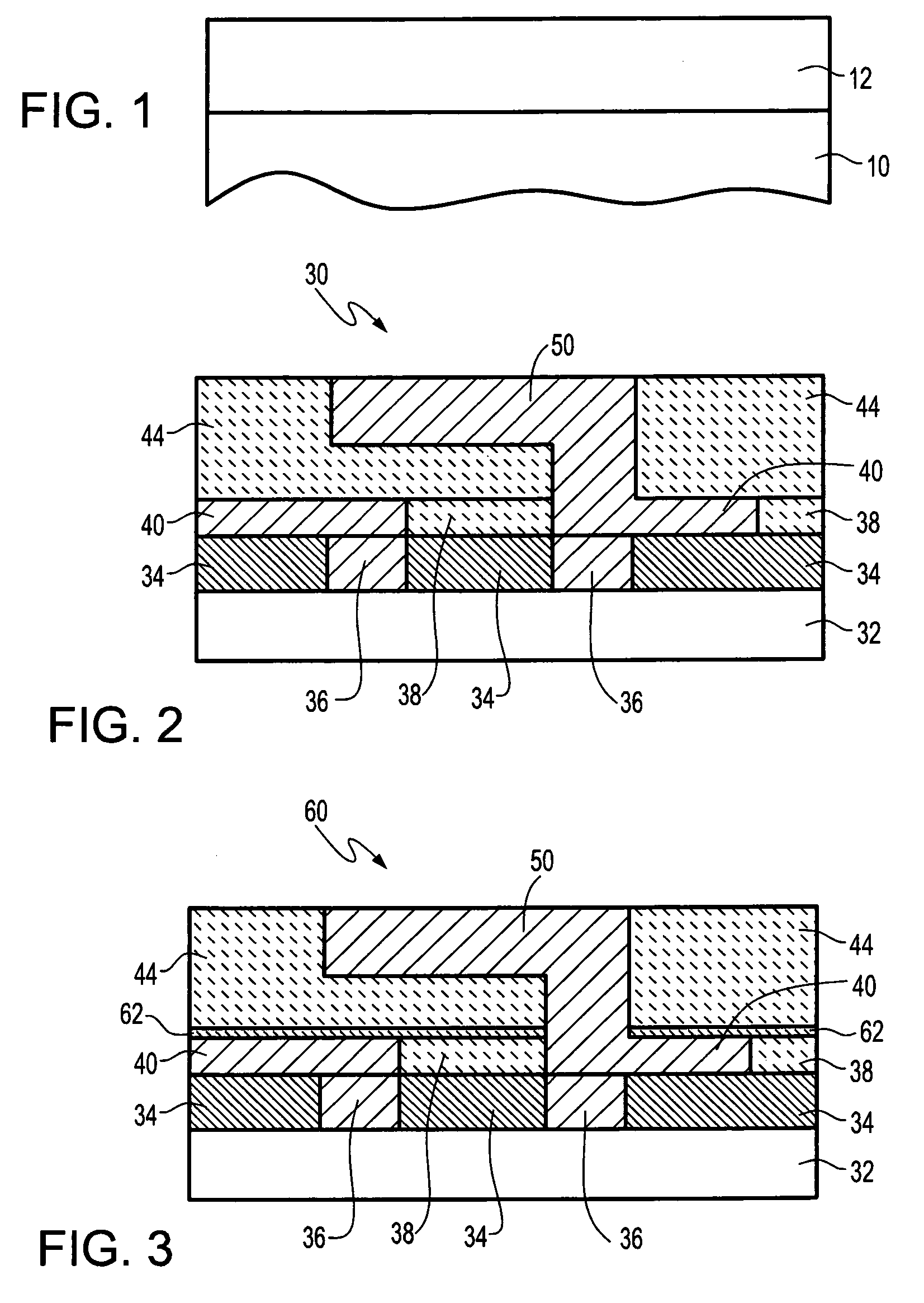

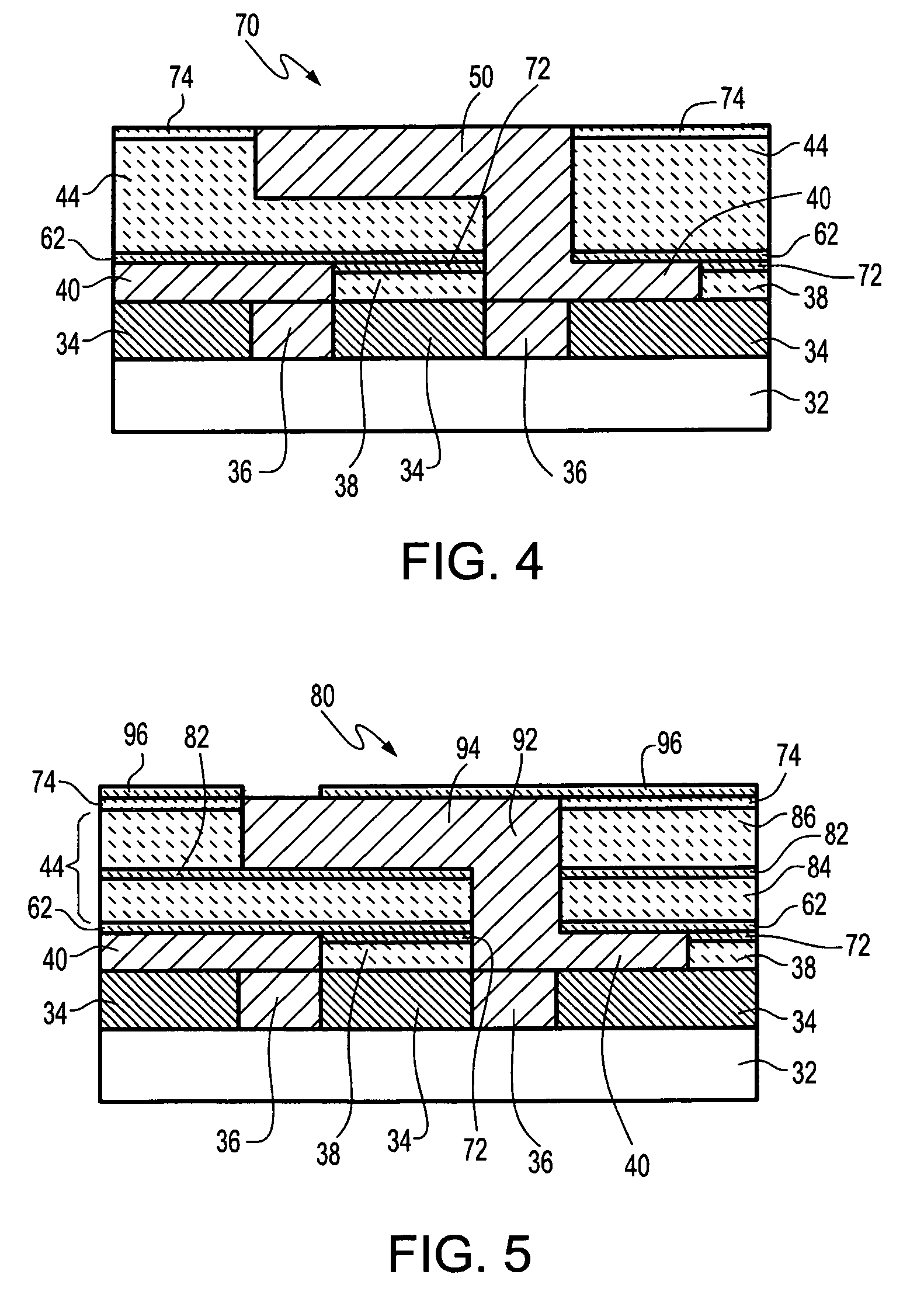

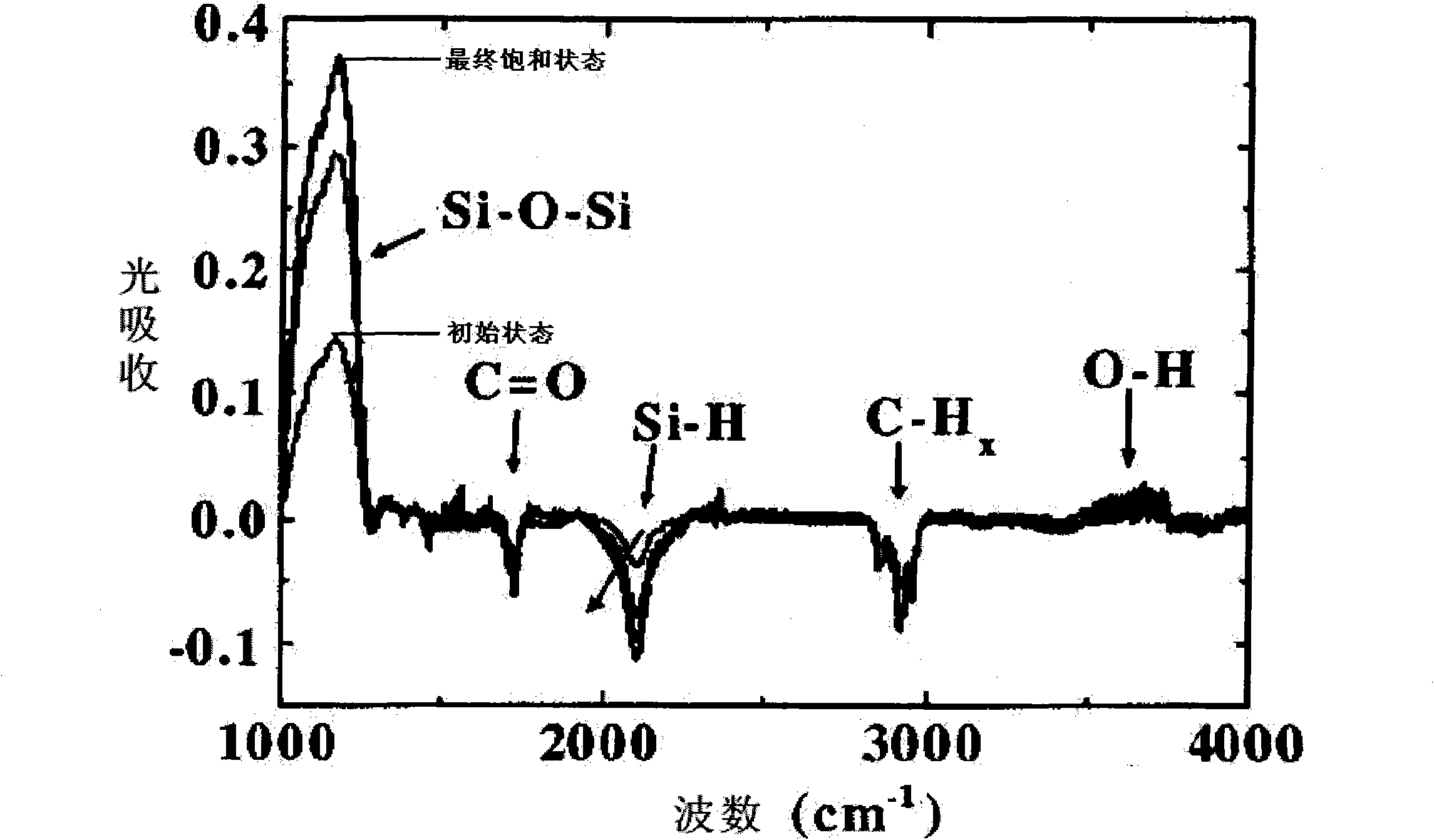

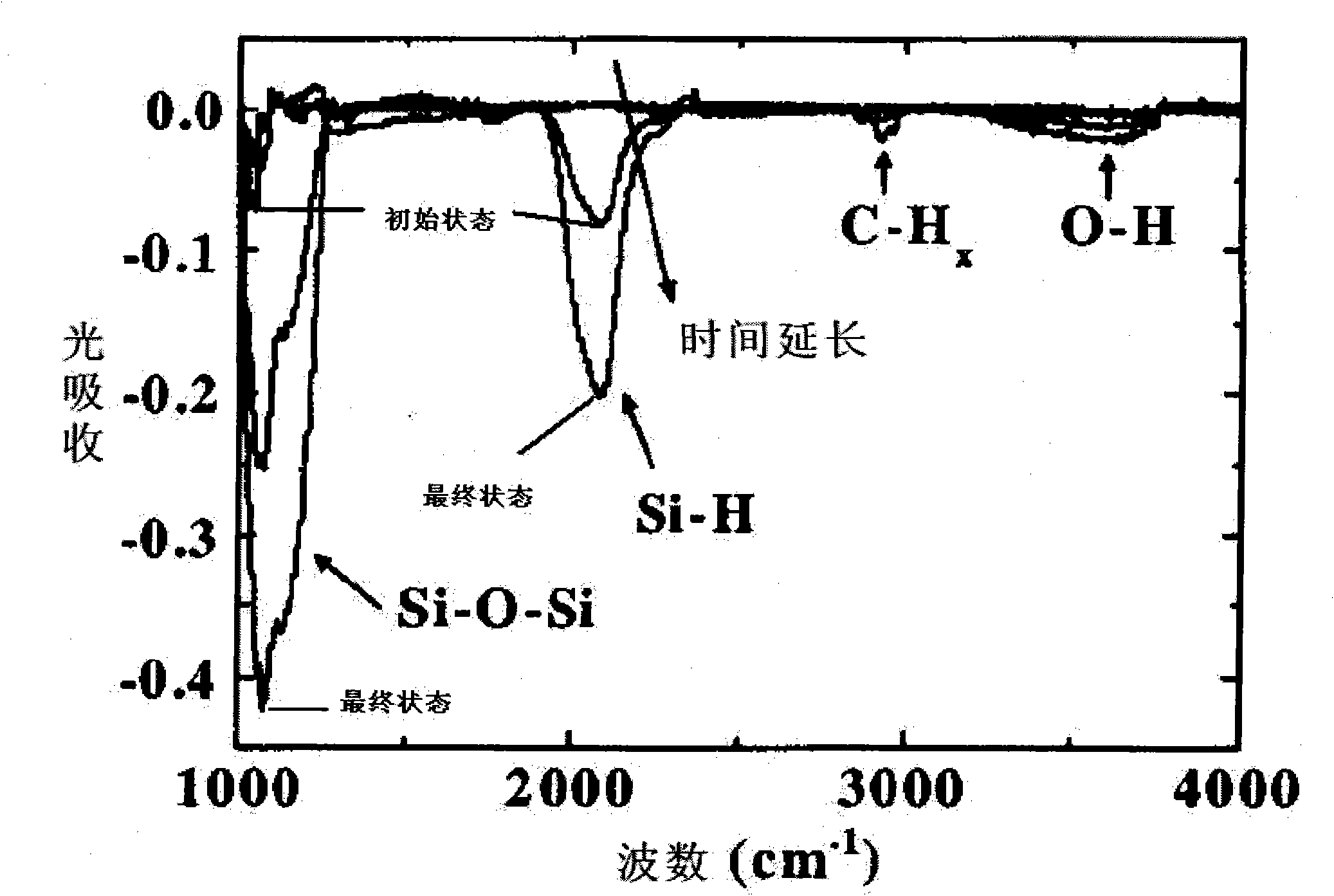

Advanced low dielectric constant organosilicon plasma chemical vapor deposition films

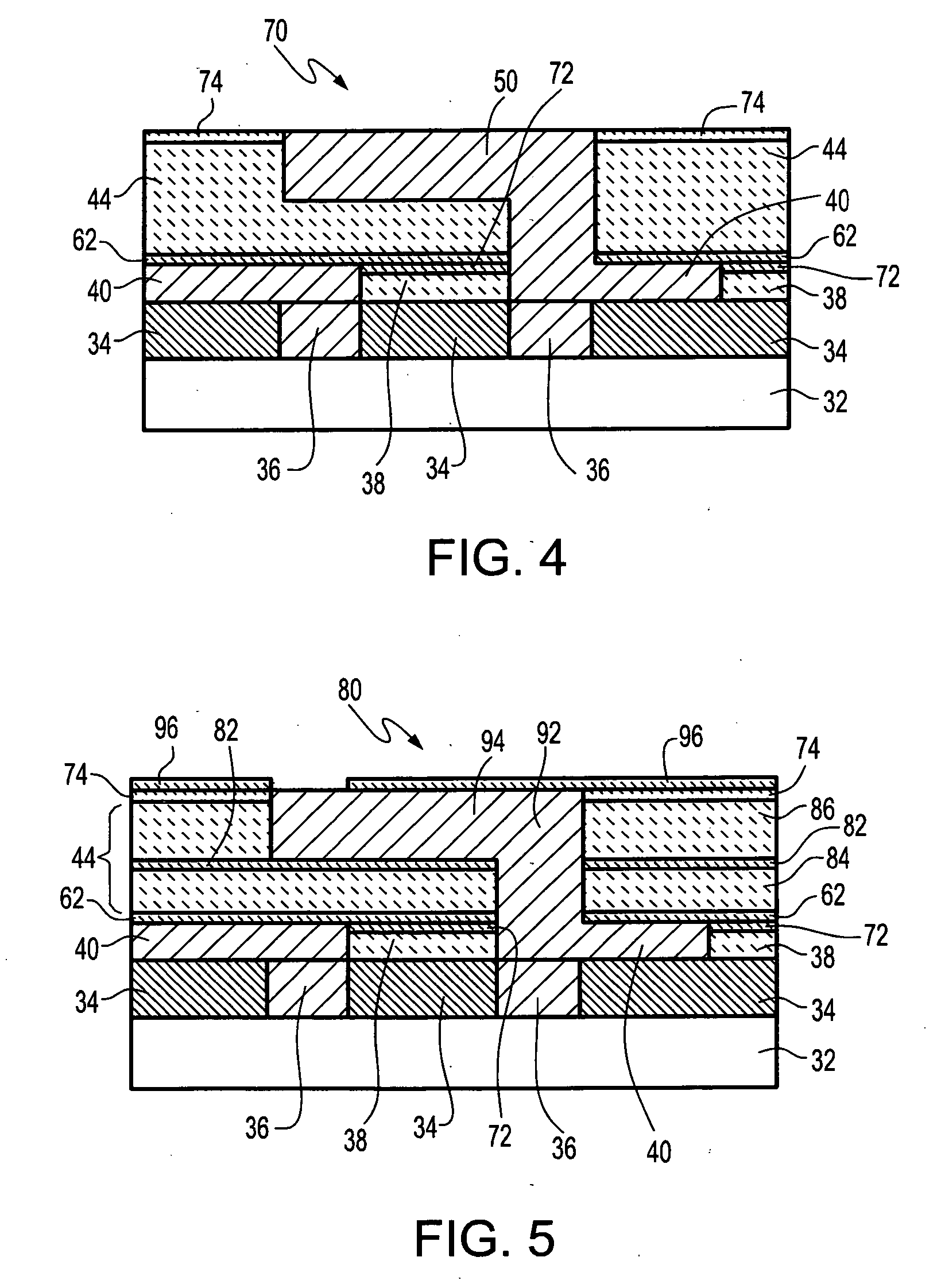

ActiveUS20060183345A1Increase Si-O-Si bondingImprove propertiesSemiconductor/solid-state device detailsSolid-state devicesPorosityNetwork structure

A porous low k or ultra low k dielectric film comprising atoms of Si, C, O and H (hereinafter “SiCOH”) in a covalently bonded tri-dimensional network structure having a dielectric constant of less than about 3.0, a higher degree of crystalline bonding interactions, more carbon as methyl termination groups and fewer methylene, —CH2— crosslinking groups than prior art SiCOH dielectrics is provided. The SiCOH dielectric is characterized as having a FTIR spectrum comprising a peak area for CH3+CH2 stretching of less than about 1.40, a peak area for SiH stretching of less than about 0.20, a peak area for SiCH3 bonding of greater than about 2.0, and a peak area for Si—O—Si bonding of greater than about 60%, and a porosity of greater than about 20%.

Owner:SONY CORP +2

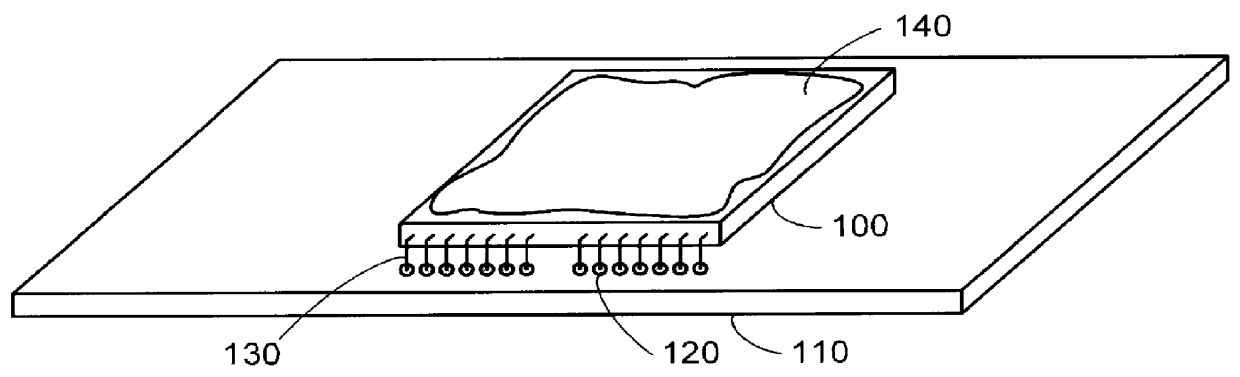

System for noninvasive determination of alcohol in tissue

InactiveUS20110282167A1Efficient collectionUniform radiationDiagnostics using spectroscopyPerson identificationAlcoholMedicine

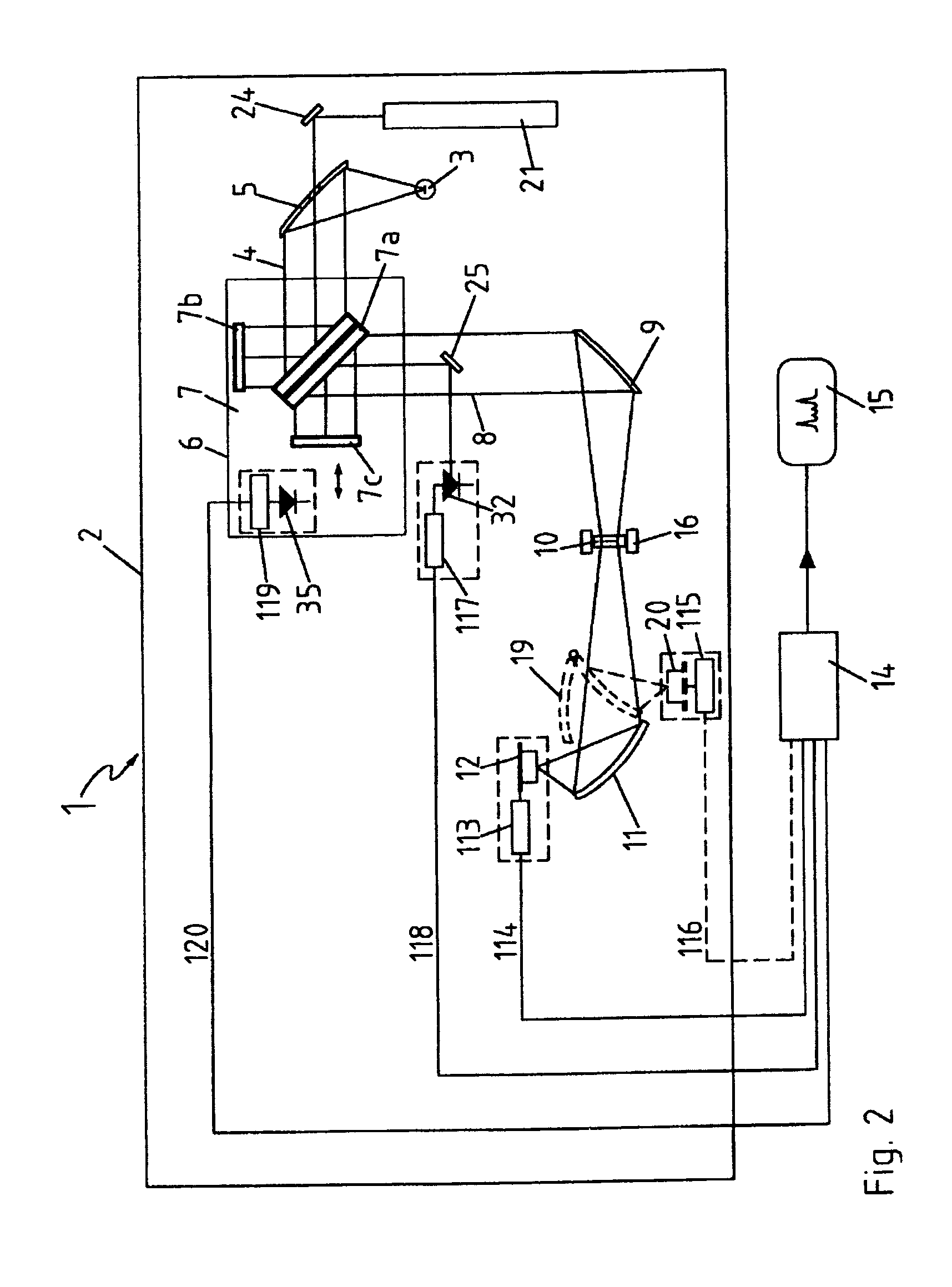

An apparatus and method for non-invasive determination of attributes of human tissue by quantitative infrared spectroscopy to clinically relevant levels of precision and accuracy. The system includes subsystems optimized to contend with the complexities of the tissue spectrum, high signal- to-noise ratio and photometric accuracy requirements, tissue sampling errors, calibration maintenance problems, and calibration transfer problems. The subsystems include an illumination / modulation subsystem, a tissue sampling subsystem, a calibration maintenance subsystem, an FTIR spectrometer subsystem, a data acquisition subsystem, and a computing subsystem.

Owner:TRUTOUCH TECH

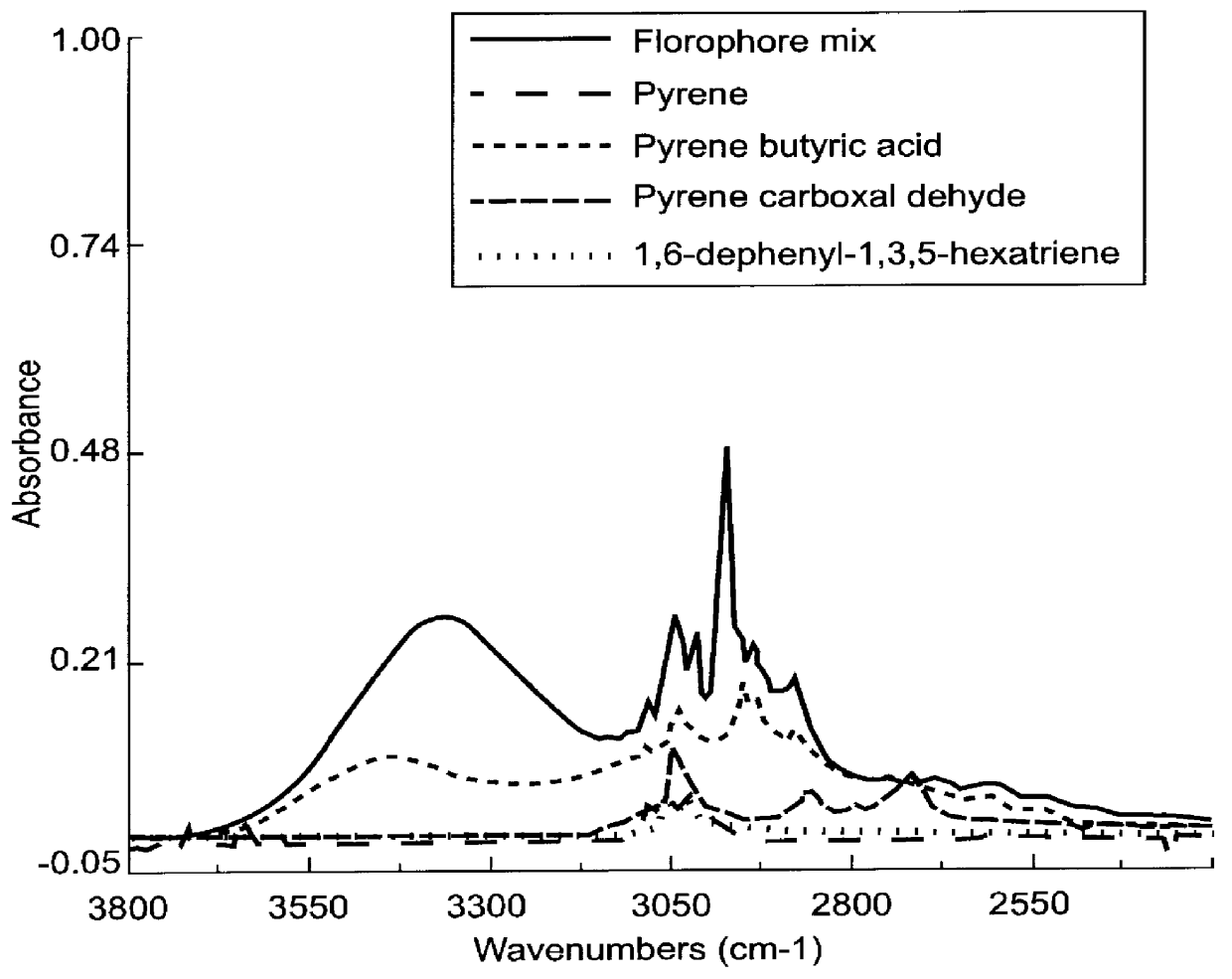

Coating material and method for providing asset protection

InactiveUS6280797B1Semiconductor/solid-state device detailsSolid-state devicesUltravioletSpectroscopy

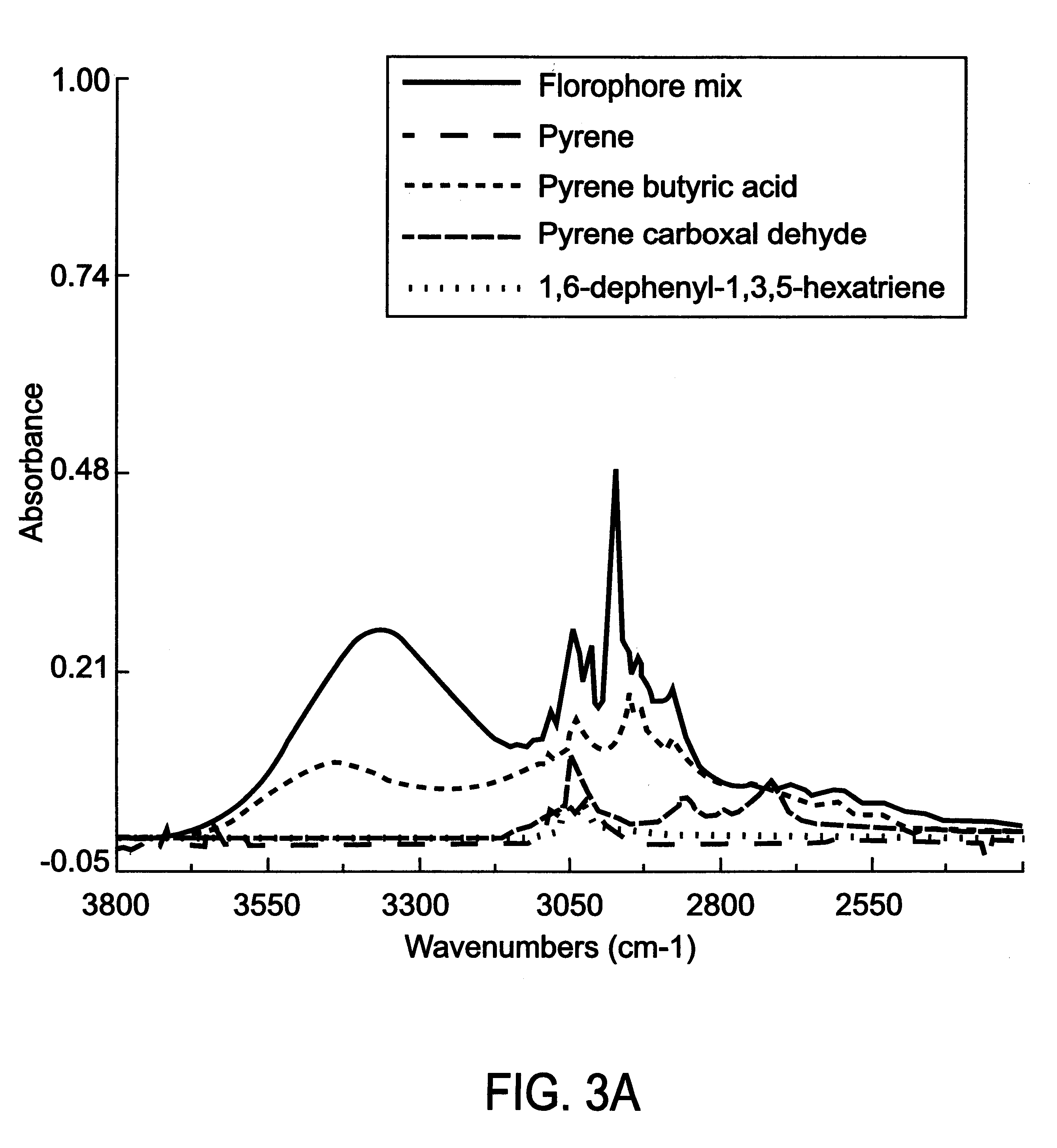

A material and a method for forming a tamper-indicating identification coating are provided. The components of the coating are selected such that the coating exhibits a characteristic absorption spectrum with distinct features in individual regions during Fourier-transform infa-red (FTIR) spectroscopy. The coating components are selected to provide a distinct spectrum while, at the same time, providing a sufficiently complex spectrum such that the coating is difficult to duplicate. Also, a blowing agent in the coating decomposes to change the FTIR spectrum due to the heat associated with resoldering of an out-of-warranty electronic part marked with the identification coating to an in-warranty circuit card. In addition, the coating may contain a fluorophore to reveal the presence of a tamper-indicating identification coating, allowing a manufacturer to check the card by exposure with ultra-violet (UV) light. Further, the coating composition may be changed periodically and tracked to provide a date marker.

Owner:INT BUSINESS MASCH CORP

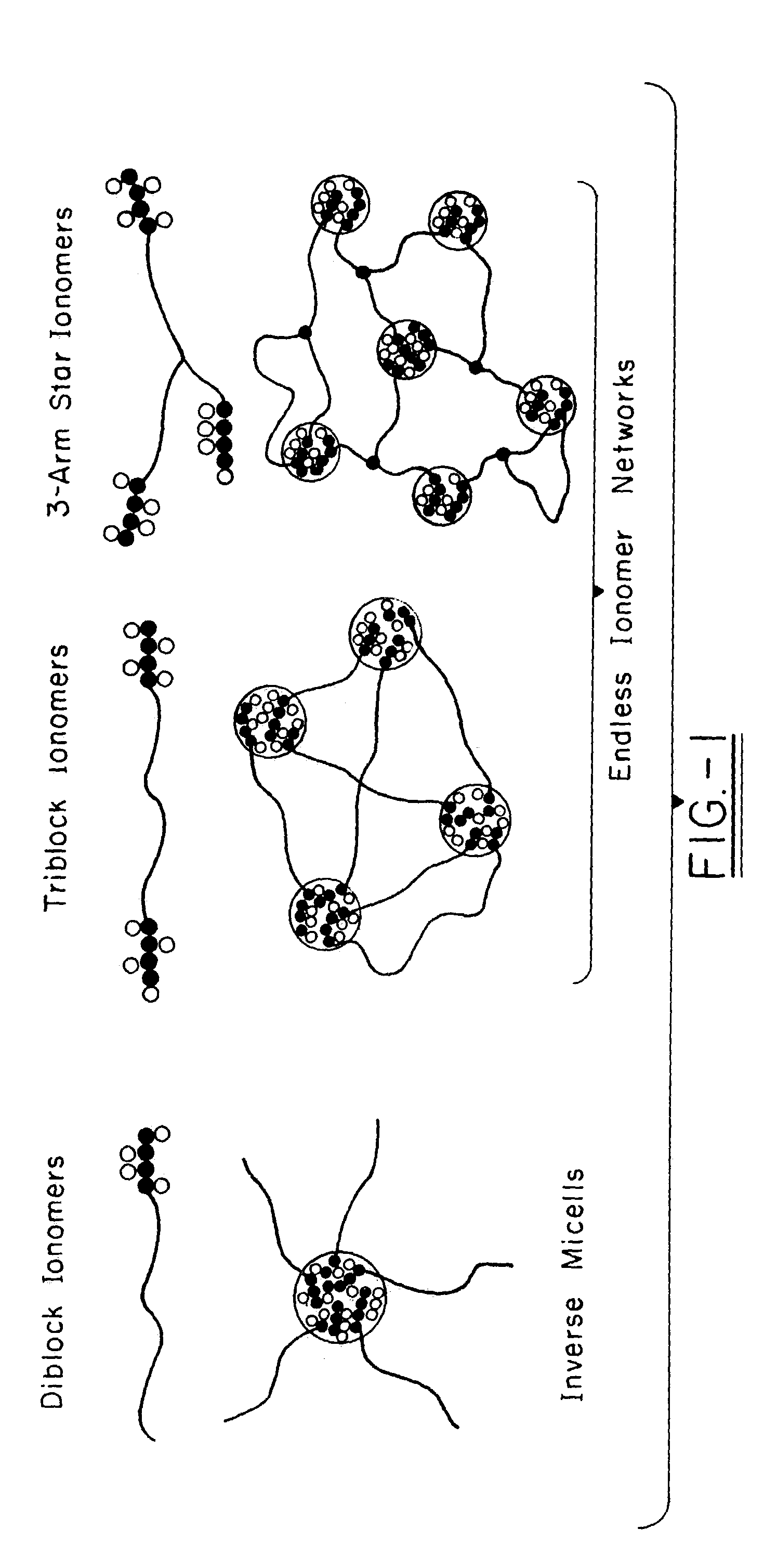

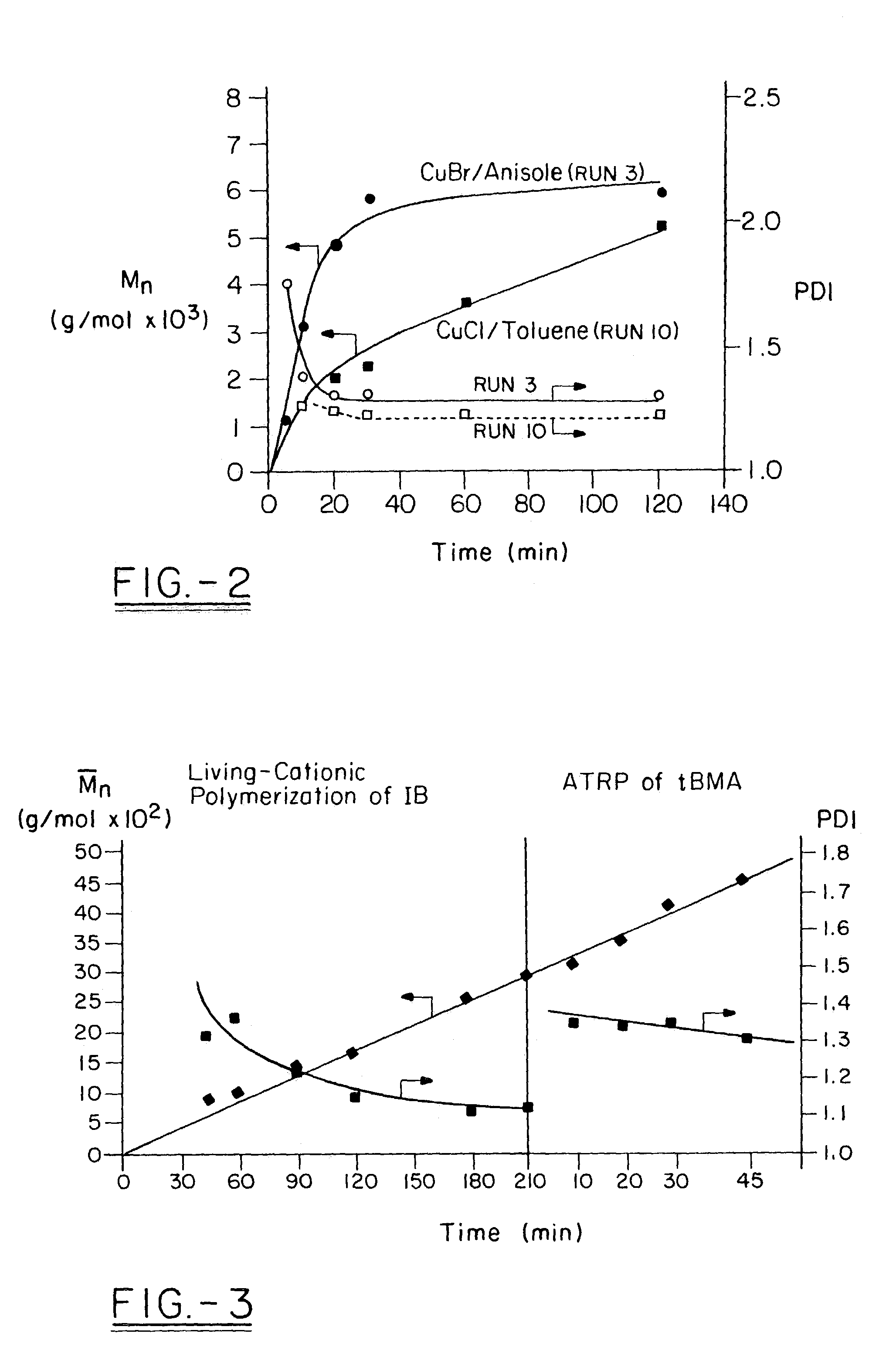

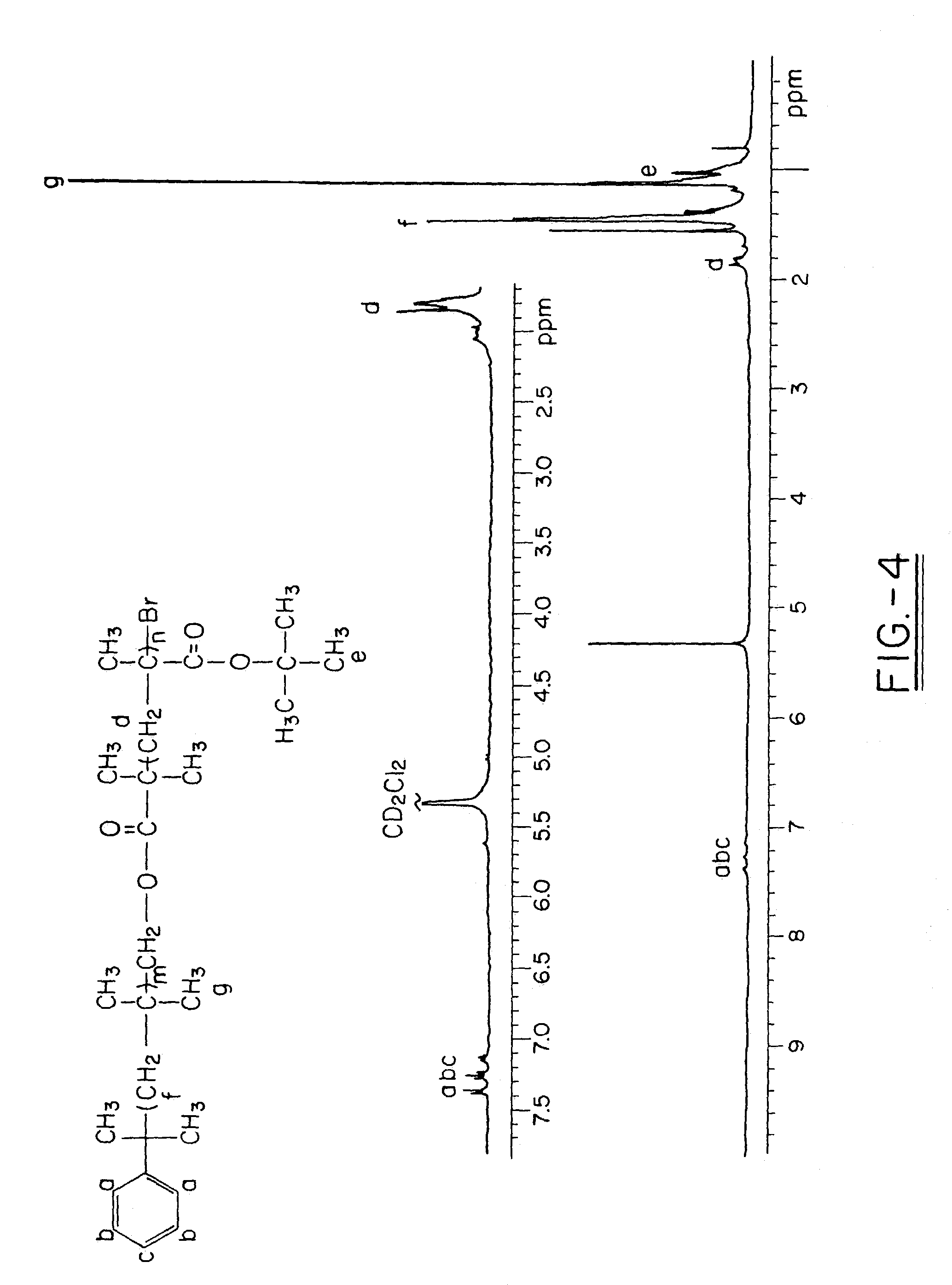

Polyisobutylene-based block anionomers and cationomers and synthesis thereof

Various novel block cationomers comprising polyisobutylene (PIB) and poly(2-dimethylamino)ethyl methacrylate) (PDMAEMA) segments have been synthesized and characterized. The specific targets were various molecular weight diblocks (PDMAEMA+) and triblocks (PDMAEMA+-b-PIB-b-PDMAEMA+) with the PIB blocks in the DPn=50–200−(Mn=3,000–9,000 g / mol) range connected to blocks of PDMAEMA+ cations in the DPn=5–20 range. The overall synthetic strategy for the preparation of these block cationomers comprised four steps: 1) Synthesis by living cationic polymerization of mono- and di-allyltelechelic polyisobutylenes, 2) End group transformation to obtain PIBs fitted with termini capable of mediating the atom transfer radical polymerization (ATRP) of DMAEMA, 3) ATRP of DMAEMA and 4) Quaternization of PDMAEMA to PDMAEMA+I− by CH3I. Kinetic and model experiments provided guidance to develop convenient synthesis methods. The microarchitecture of PIB-PDMAEMA di- and triblock and the corresponding block cationomers were confirmed by 1H NMR and FTIR spectroscopy and solubility studies.

Owner:THE UNIVERSITY OF AKRON

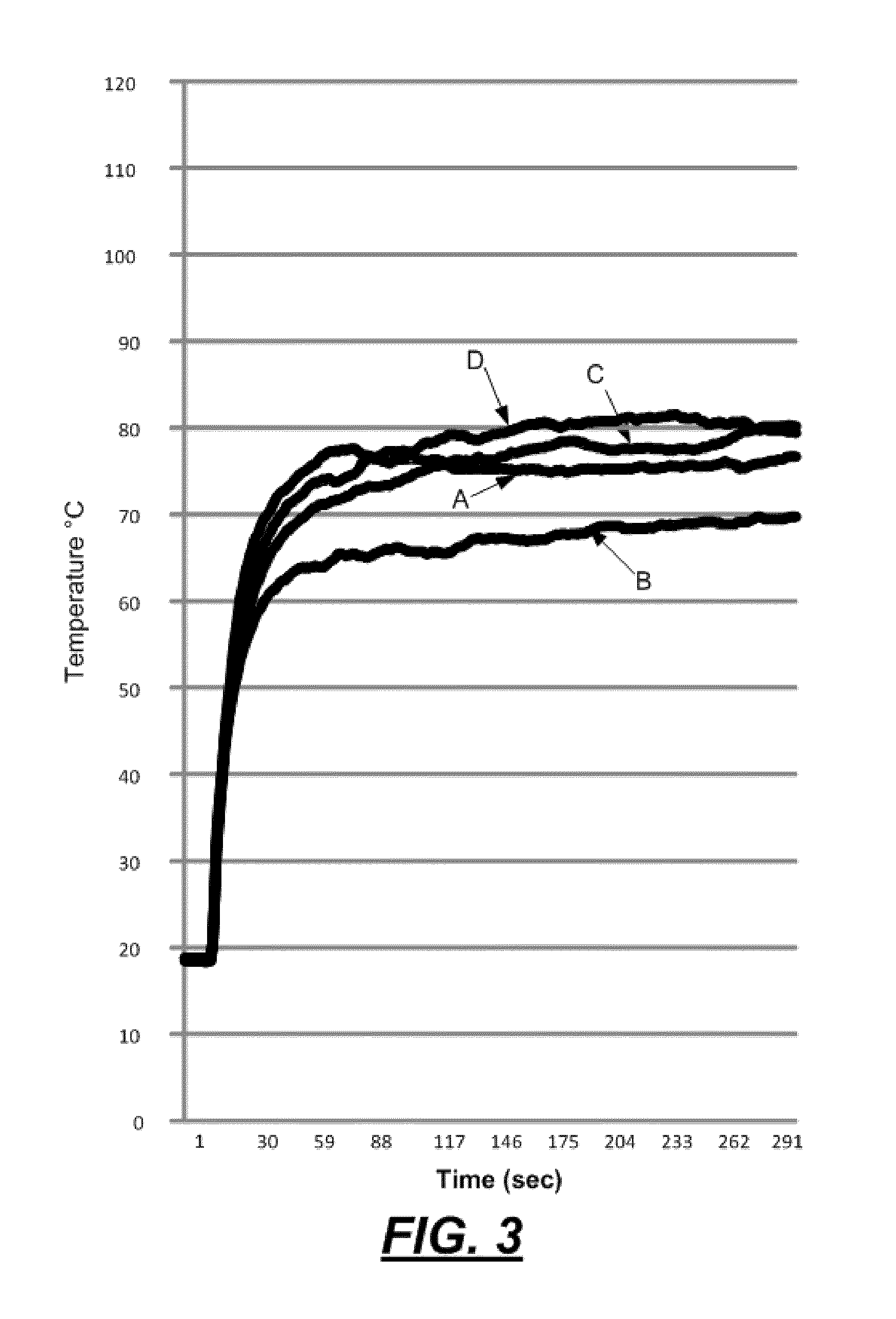

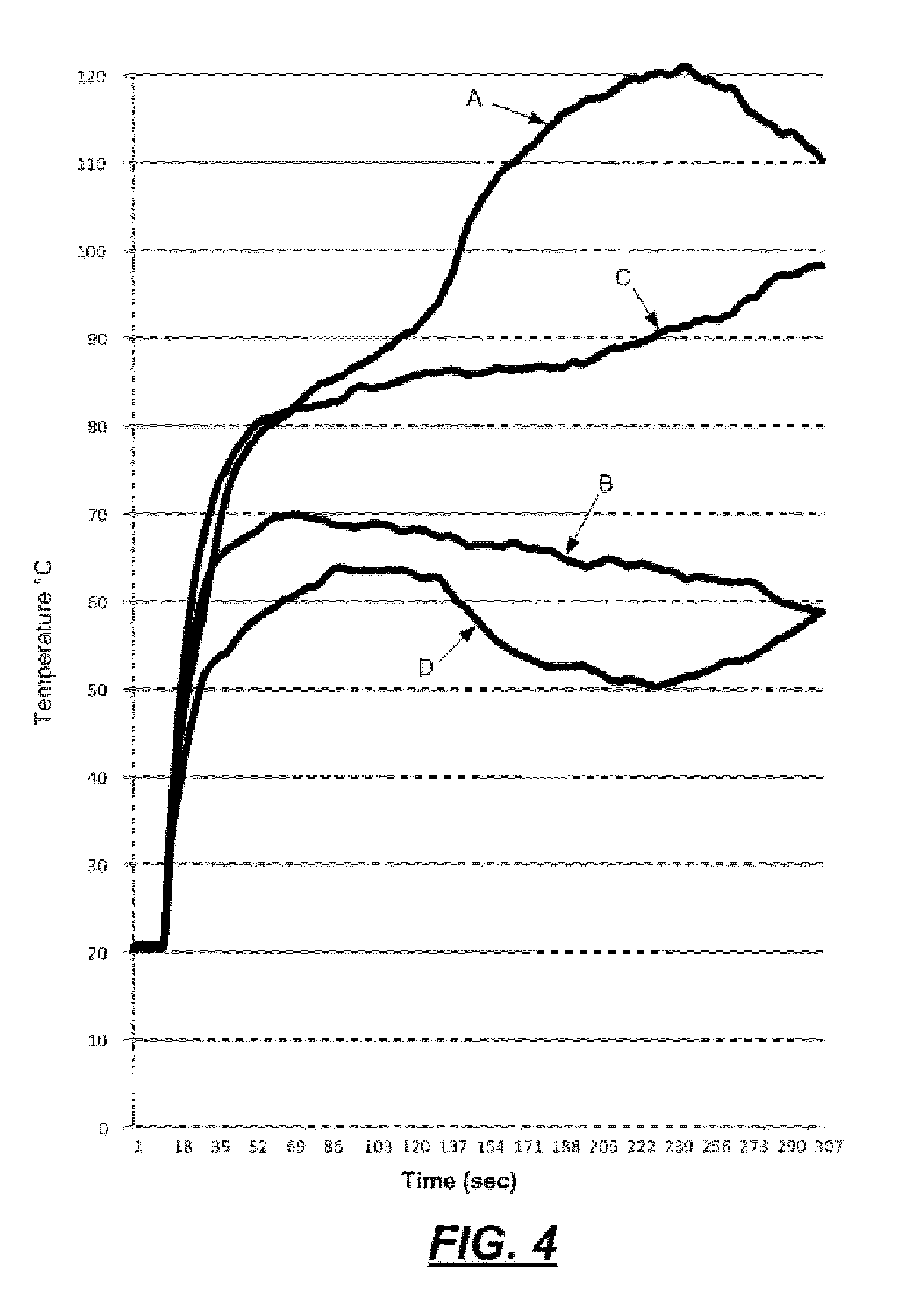

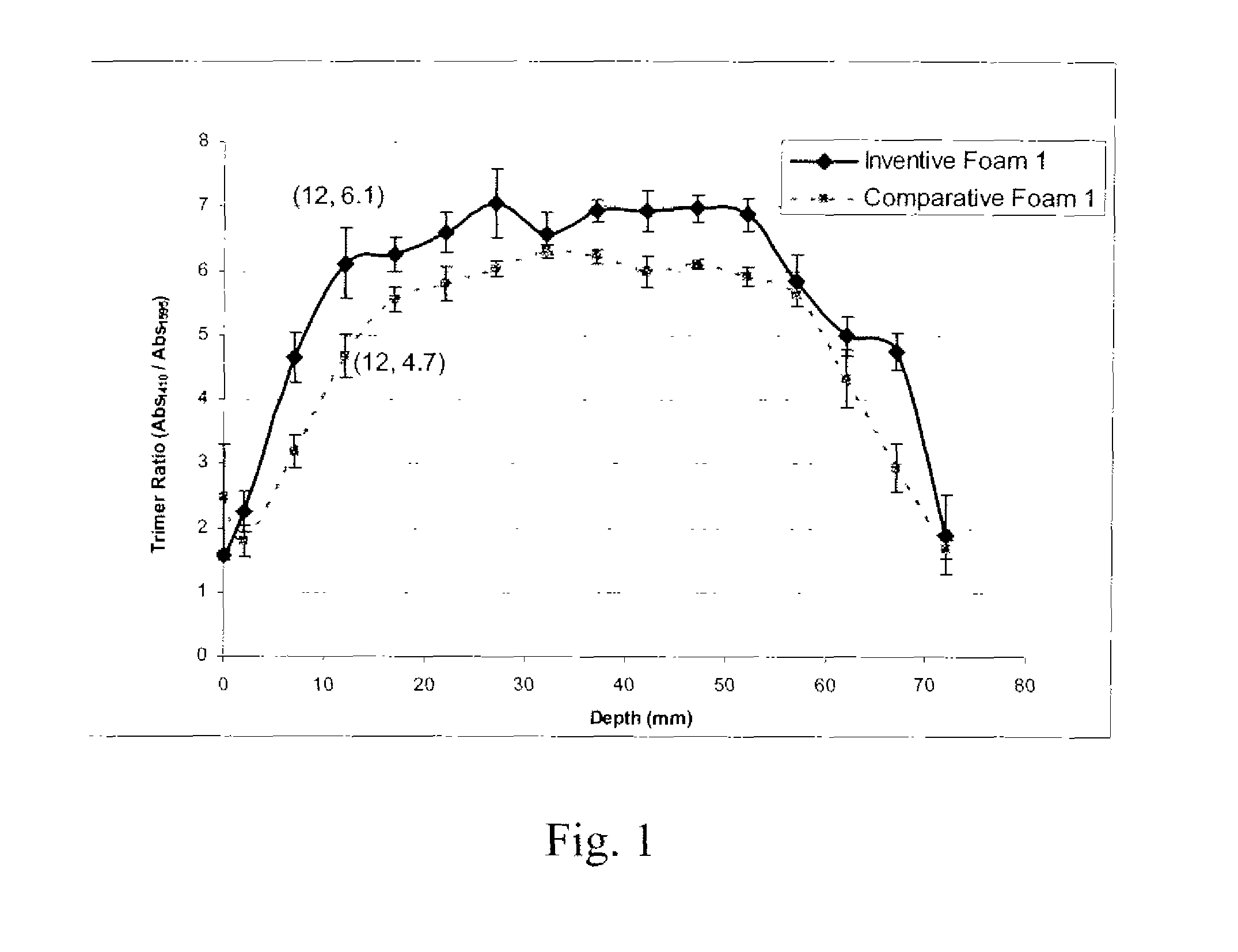

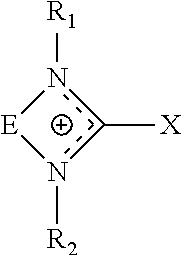

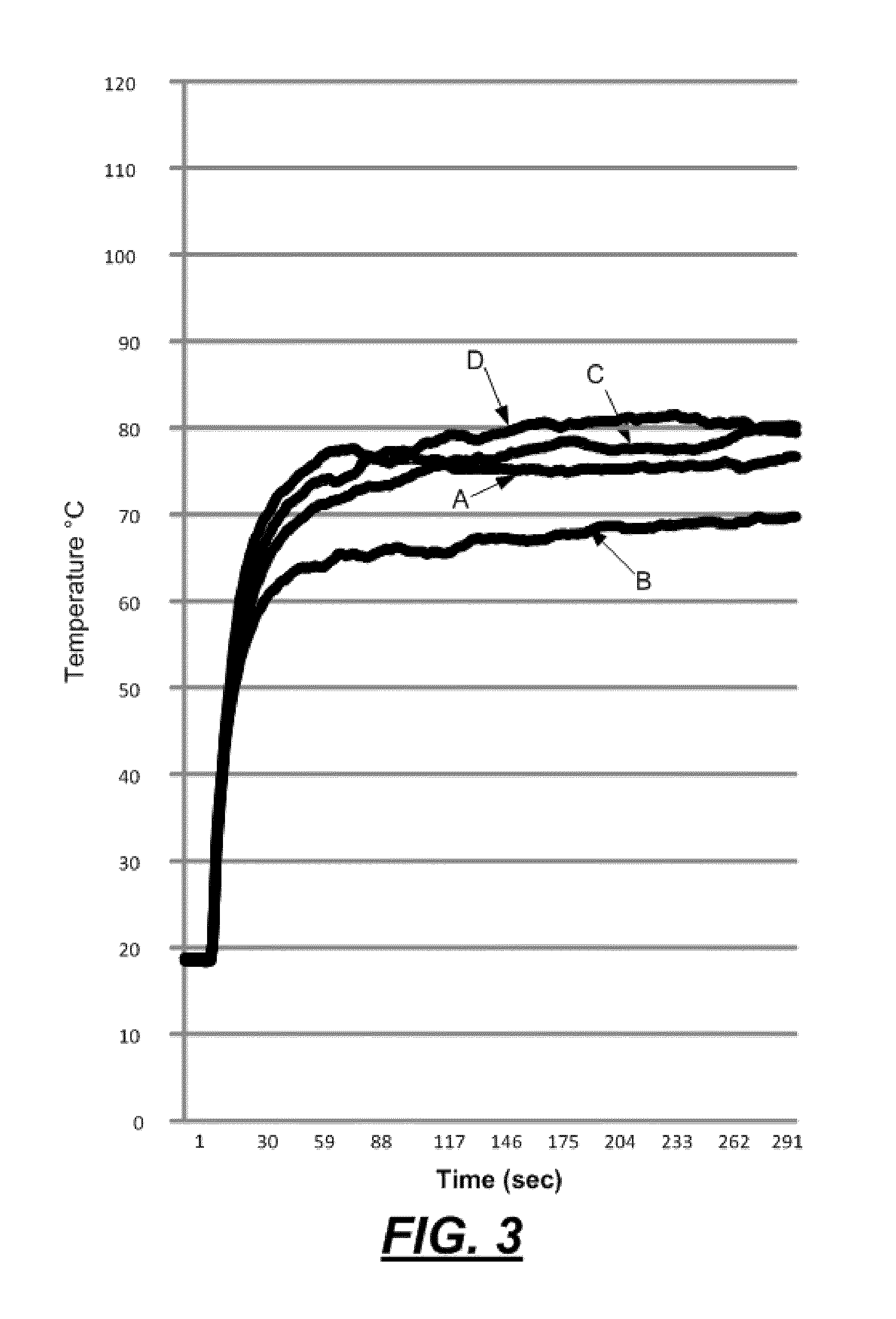

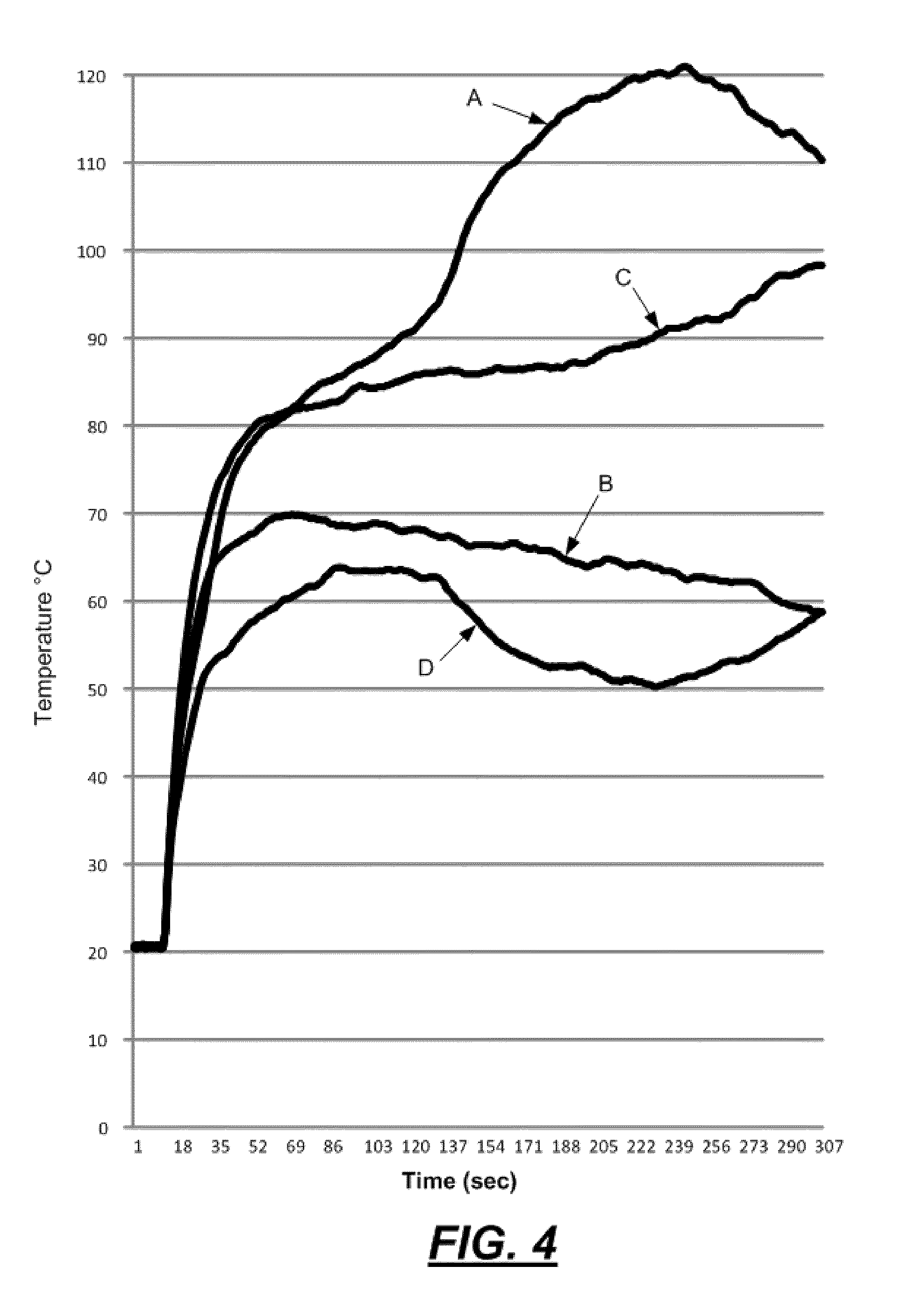

Isocyanate trimerisation catalyst system, a precursor formulation, a process for trimerising isocyanates, rigid polyisocyanurate/polyurethane foams made therefrom, and a process for making such foams

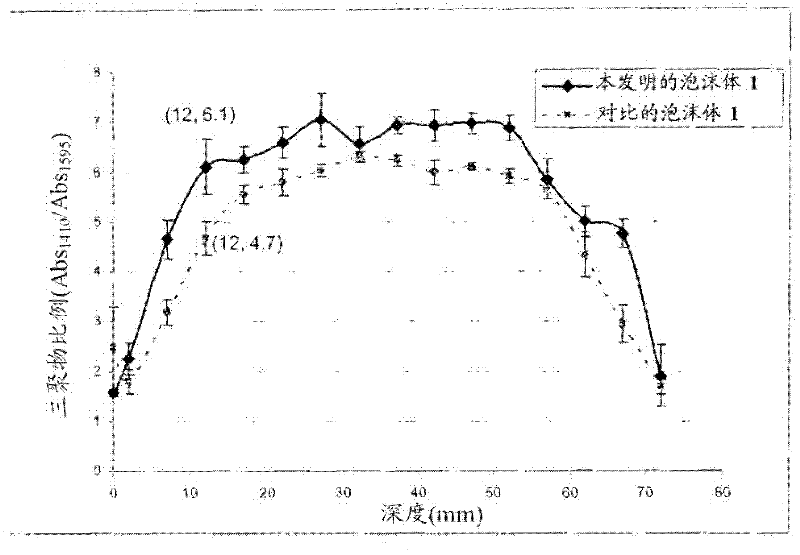

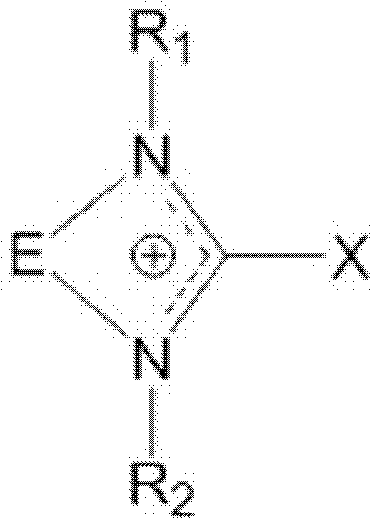

The instant invention provides an isocyanate trimerisation catalyst system, a precursor formulation, a process for trimerising isocyanates, rigid foams made therefrom, and a process for making such foams. The trimerisation catalyst system comprises: (a) an imidazolium or imidazolinium cation; and (b) an isocyanate-trimer inducing anion; wherein said trimerisation catalyst system has a trimerisation activation temperature in the range of equal to or less than 73° C. The precursor formulation comprises: (1) at least 25 percent by weight of polyol, based on the weight of the precursor formulation; (2) less than 15 percent by weight of a trimerisation catalyst system, based on the weight of the precursor formulation, comprising; (a) an imidazolium or imidazolinium cation; and (c) an isocyanate-trimer inducing anion; wherein said trimerisation catalyst system has a trimerisation activation temperature in the range of equal to or less than 73° C.; and (3) optionally one or more surfactants, one or more flame retardants, water, one or more antioxidants, one or more auxiliary blowing agents, one or more urethane catalysts, one or more auxiliary trimerisation catalysts, or combinations thereof. The process for trimerisation of isocyanates comprises the steps of: (1) providing one or more monomers selected from the group consisting of an isocyanate, a diisocyanate, a triisocyanatetriisocyanate, oligomeric isocyanate, a salt of any thereof, and a mixture of any thereof; (2) providing a trimerisation catalyst system comprising; (a) an imidazolium or imidazolinium cation; and (b) an isocyanate-trimer inducing anion; (c) wherein said trimerisation catalyst system has a trimerisation activation temperature in the range of equal to or less than 73° C.; (3) trimerising said one or more monomers in the presence of said trimerisation catalyst; (4) thereby forming an isocyanurate trimer. The process for making the PIR foam comprises the steps of: (1) providing one or more monomers selected from the group consisting of an isocyanate, a diisocyanate, a triisocyanatetriisocyanate, oligomeric isocyanate, a salt of any thereof, and a mixture any thereof; (2) providing polyol; (3) providing a trimerisation catalyst system comprising; (a) an imidazolium or imidazolinium cation; and (b) an isocyanate-timer inducing anion; wherein said trimerisation catalyst system has a trimerisation activation temperature in the range of equal to or less than 73° C.; and (4) optionally providing one or more surfactants, one or more flame retardants, water, one or more antioxidants, one or more auxiliary blowing agents, one or more urethane catalysts, one or more auxiliary trimerisation catalysts, or combinations thereof; (5) contacting said one or more monomers, and said polyol, and optionally said one or more surfactants, and optionally said one or more flame retardants, and optionally said water, and optionally said one or more antioxidants, and optionally said one or more auxiliary blowing agents in the presence of said trimerisation catalyst system and optionally said one or more urethane catalysts, and optionally said one or more auxiliary trimerisation catalysts; (6) thereby forming said polyisocyanurate / polyurethane rigid foam. The PIR foam comprises the reaction product of one or more monomers selected from the group consisting of an isocyanate, a diisocyanate, a triisocyanatetriisocyanate, oligomeric isocyanate, a salt of any thereof, and a mixture any thereof with polyol in the presence of a trimerisation catalyst system comprising an imidazolium or imidazolinium cation, and an isocyanate-trimer inducing anion, and optionally one or more surfactants, optionally one or more flame retardants, optionally water, optionally one or more antioxidants, optionally one or more auxiliary blowing agents, optionally one or more additional urethane catalysts, and optionally one or more auxiliary trimerisation catalysts, or optionally combinations thereof, wherein the trimerisation catalyst system has a trimerisation activation temperature in the range of equal to or less than 73° C. The PIR foam comprises the reaction product of one or more monomers selected from the group consisting of an isocyanate, a diisocyanate, a triisocyanatetriisocyanate, oligomeric isocyanate, a salt of any thereof, and a mixture any thereof with polyol in the presence of a trimerisation catalyst system comprising an imidazolium or imidazolinium cation, and an isocyanate-trimer inducing anion, and optionally one or more surfactants, optionally one or more flame retardants, optionally water, optionally one or more antioxidants, optionally one or more auxiliary blowing agents, optionally one or more additional polyurethane catalysts, and optionally one or more auxiliary trimerisation catalysts, or optionally combinations thereof, wherein the PIR foam has a polyisocyanurate trimer ratio (Abs1410 / Abs1595) of at least 5 at a depth of 12 mm from the rising surface of the rigid foam, measured via ATR-FTIR spectroscopy.

Owner:DOW GLOBAL TECH LLC

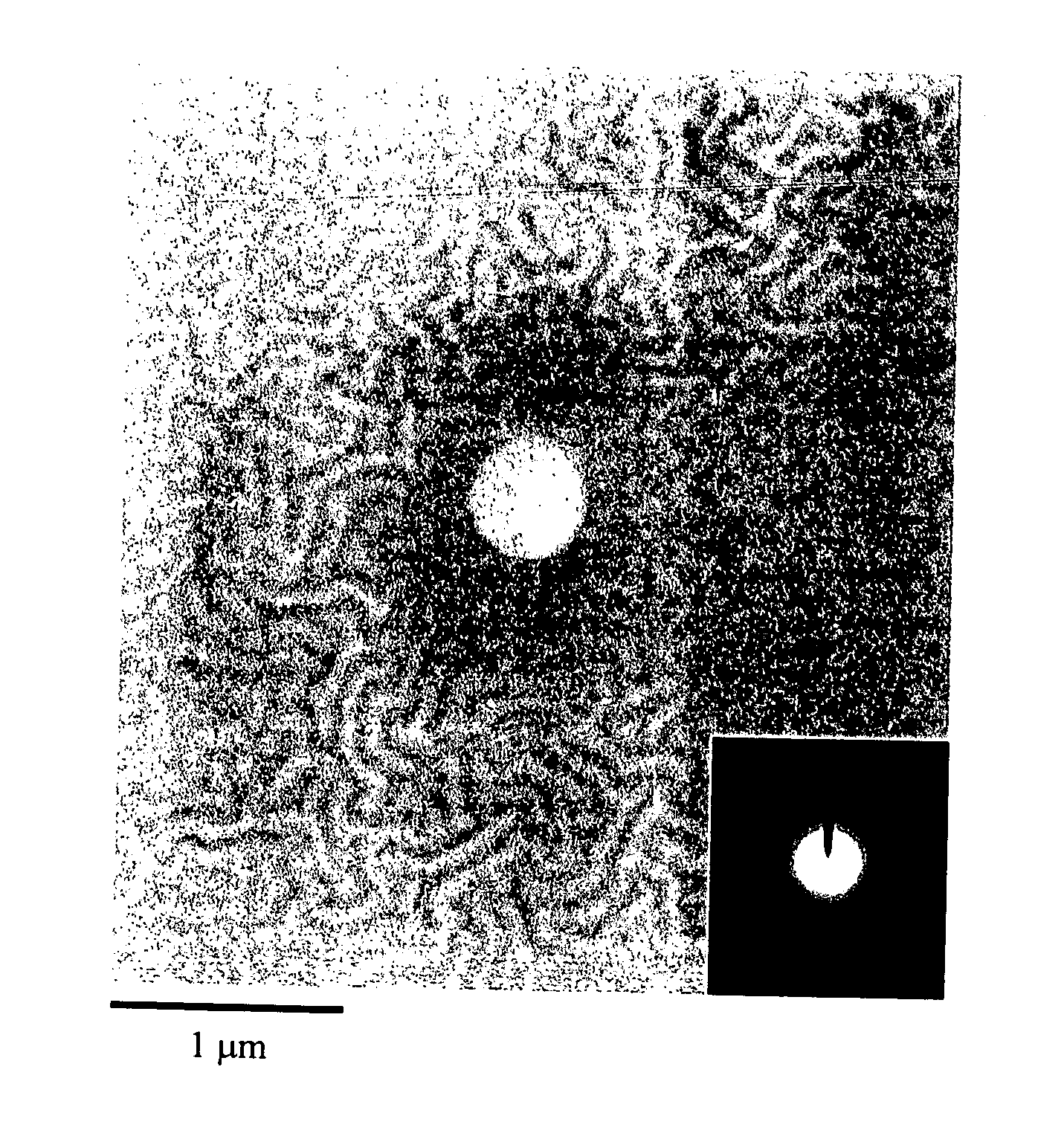

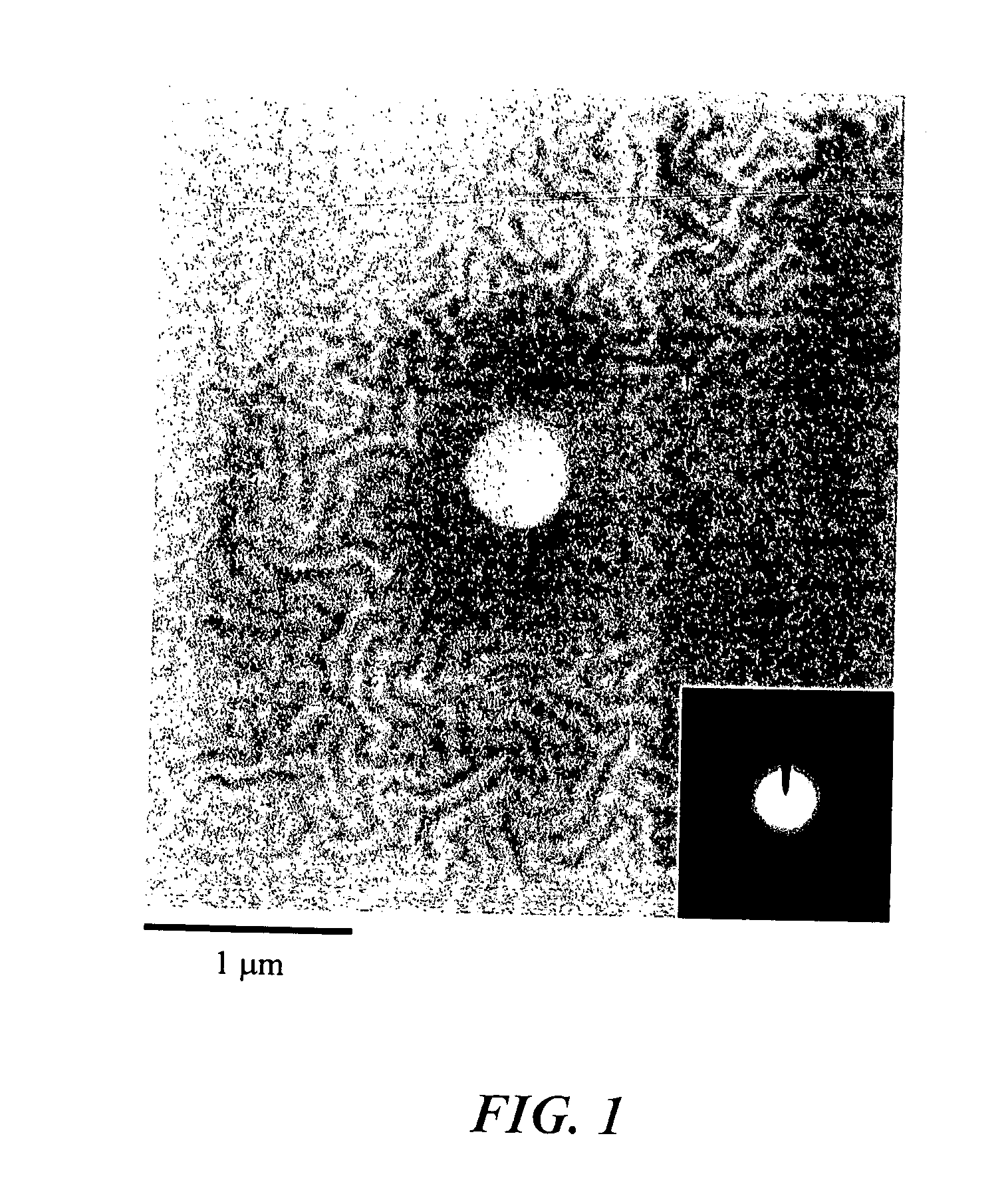

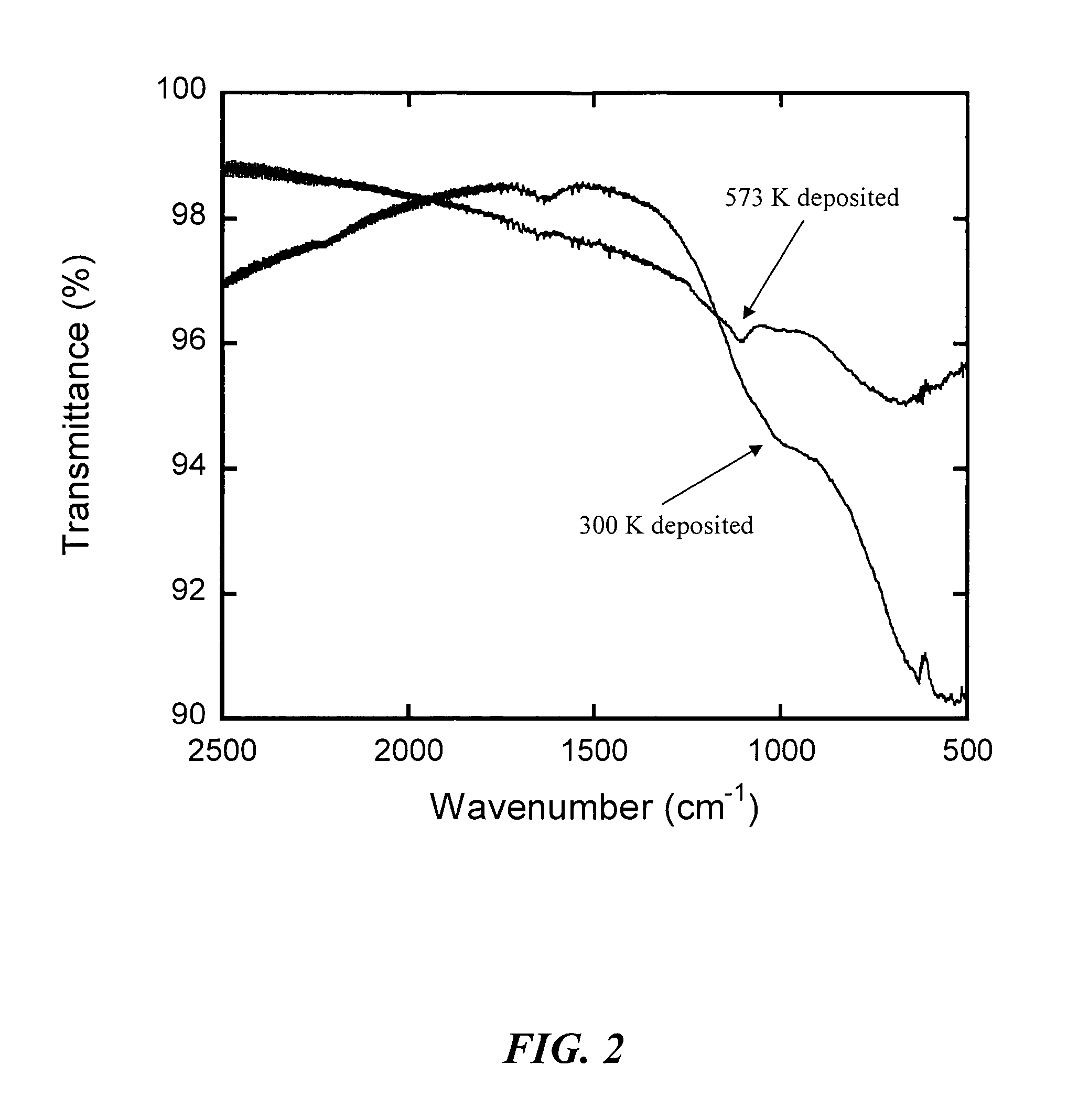

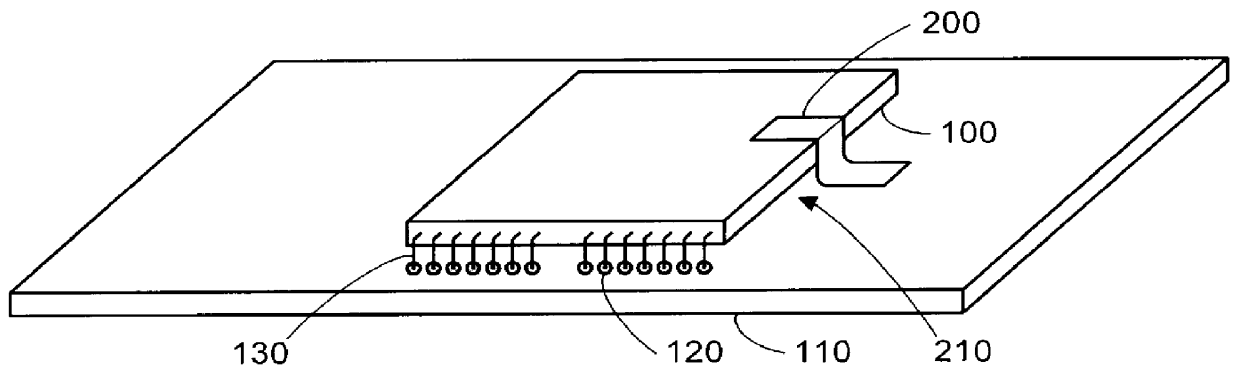

Ultra-hard low friction coating based on AlMgB14 for reduced wear of MEMS and other tribological components and system

InactiveUS20050100748A1Superior protective coatHigh hardnessVacuum evaporation coatingSolid-state devicesMicroelectromechanical systemsAlloy

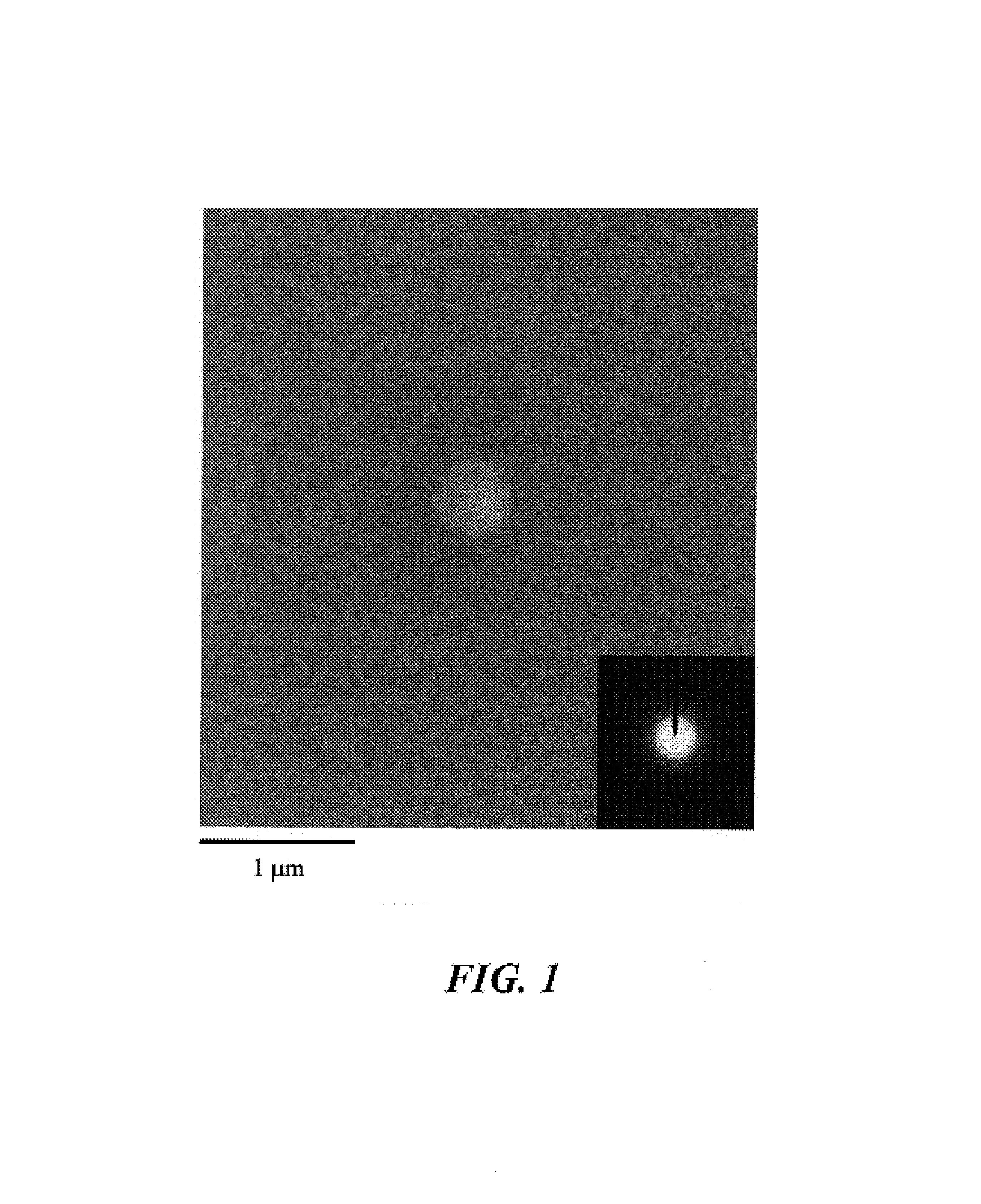

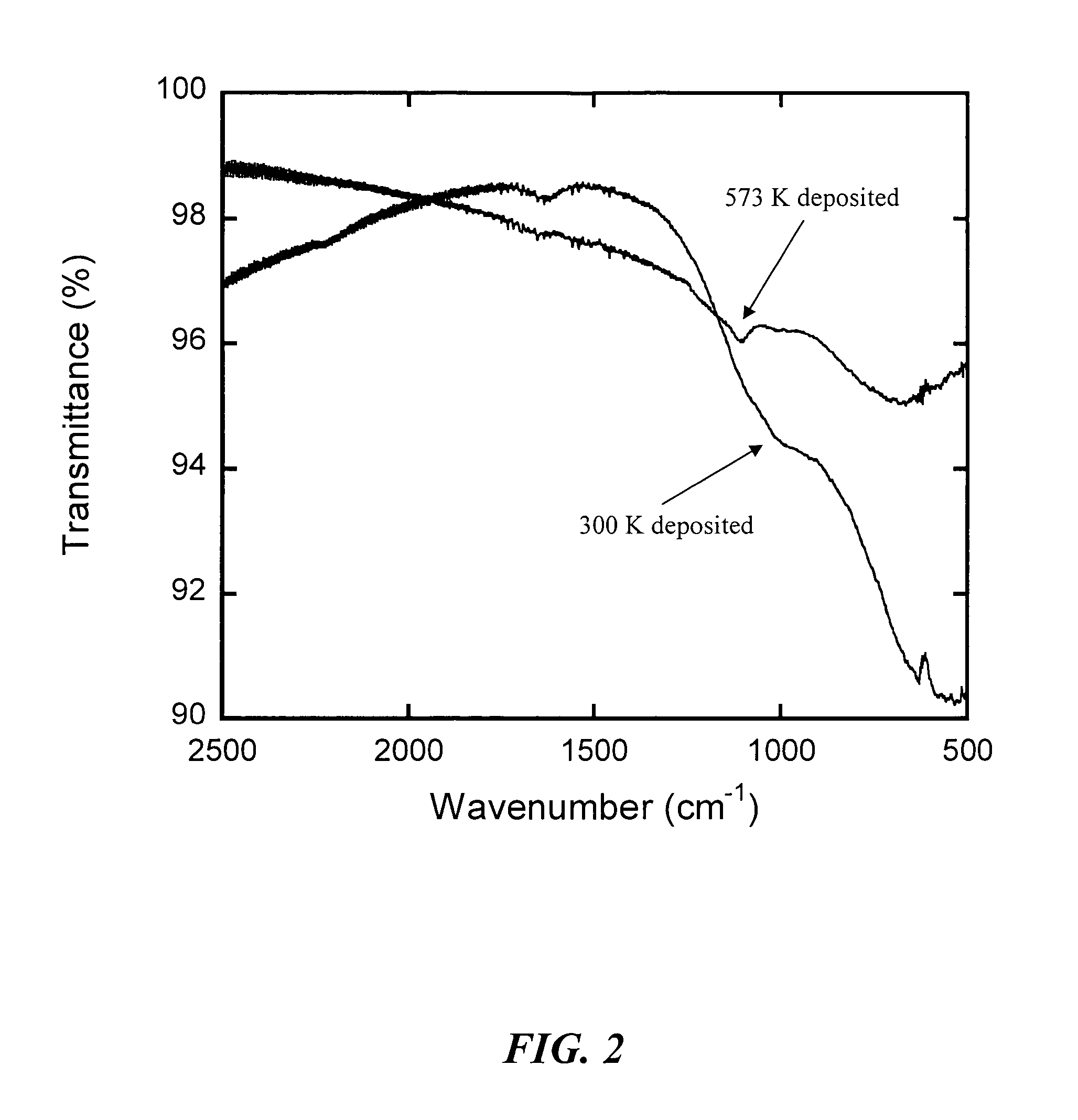

Performance and reliability of microelectromechanical system (MEMS) components enhanced dramatically through the incorporation of protective thin film coatings. Current-generation MEMS devices prepared by the LIGA technique employ transition metals such as Ni, Cu, Fe, or alloys thereof, and hence lack stability in oxidizing, corrosive, and / or high temperature environments. Fabrication of a superhard, self-lubricating coating based on a ternary boride compound AlMgB14 is described in this letter as a potential breakthrough in protective coating technology for LIGA microdevices. Nanoindentation tests show that hardness of AlMgB14 films prepared by pulsed laser deposition ranges from 45 GPa to 51 GPa, when deposited at room temperature and 573 K, respectively. Extremely low friction coefficients of 0.04-0.05, which are thought to result from a self-lubricating effect, have also been confirmed by nanoscratch tests on the AlMgB14 films. Transmission electron microscopy studies show that the as-deposited films are amorphous, regardless of substrate temperature; however, analysis of FTIR spectra suggests that the higher substrate temperature facilitates formation of the B12 icosahedral framework, therefore leading to the higher hardness.

Owner:IOWA STATE UNIV RES FOUND

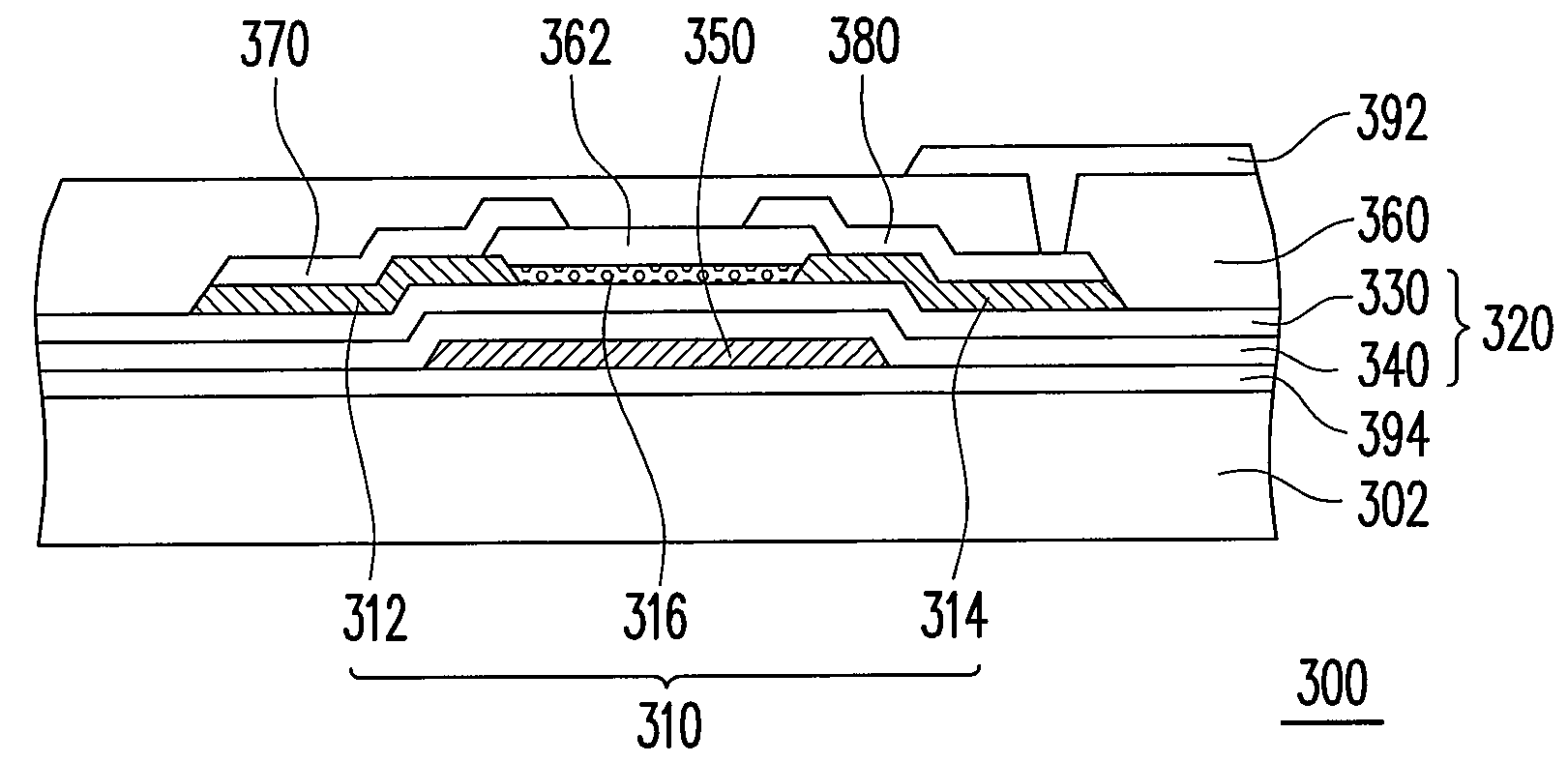

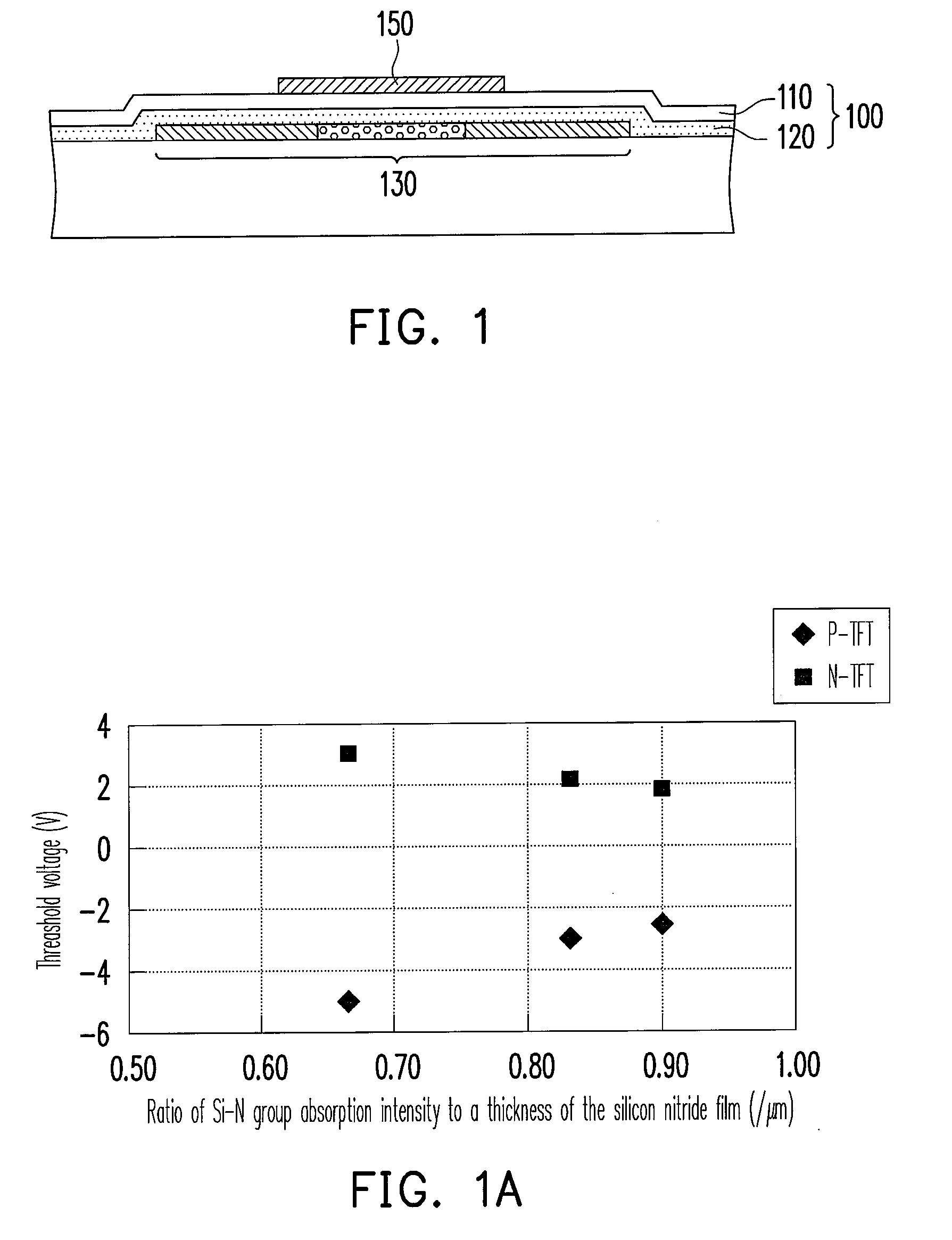

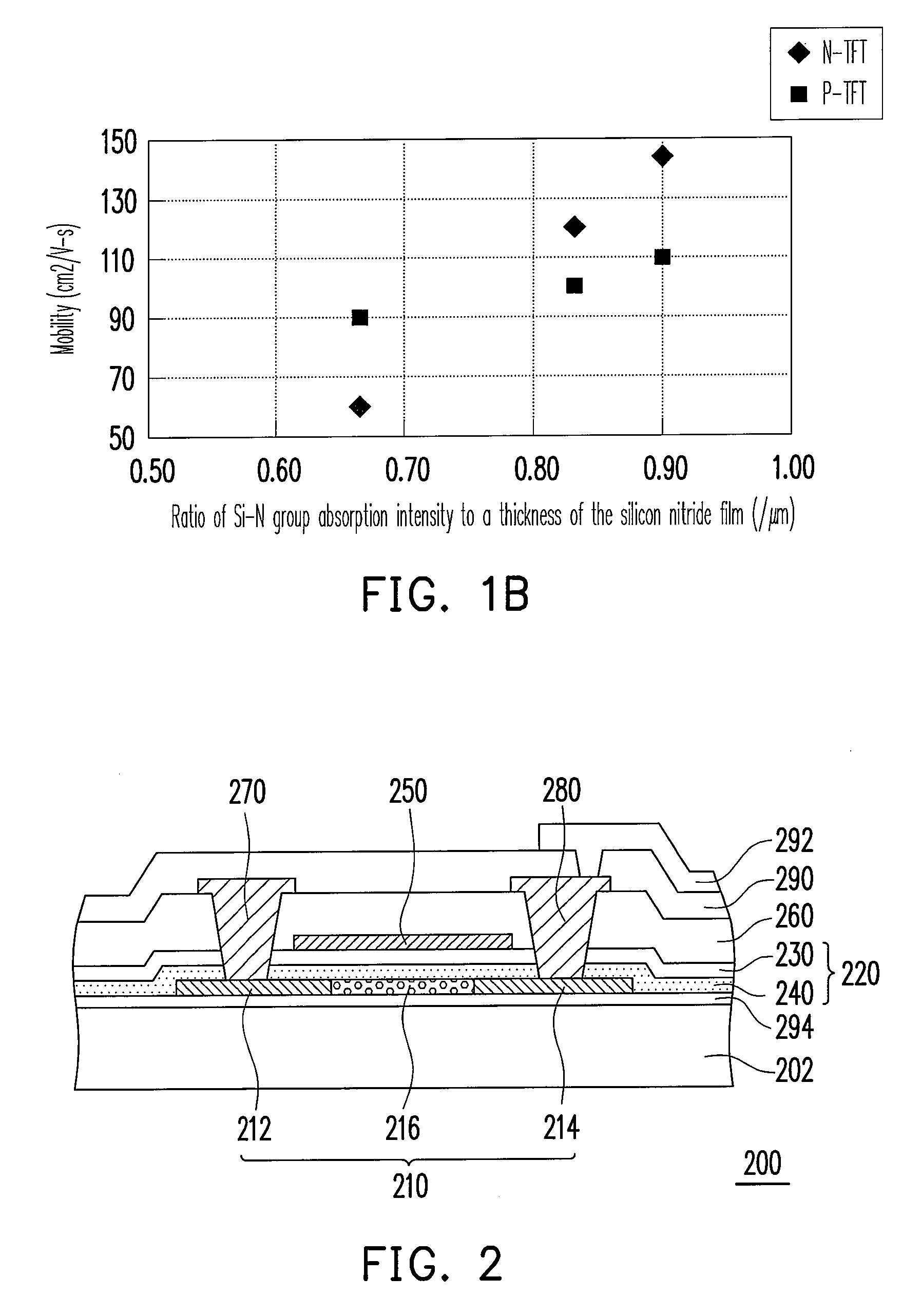

Dielectric layer and thin film transistor

ActiveUS20080308821A1Excellent electrical propertiesIncrease manufacturing costSemiconductor/solid-state device detailsSolid-state devicesNitrogenOxygen

A dielectric layer including a film with silicon compound contain oxygen and a film with silicon compound contain nitrogen is provided. A ratio of Si—N group absorption intensity to a thickness of the film with silicon compound contain nitrogen in an FTIR spectrum is substantially greater than or substantially equal to 0.67 / μm. The dielectric layer can be incorporated in switch devices.

Owner:AU OPTRONICS CORP

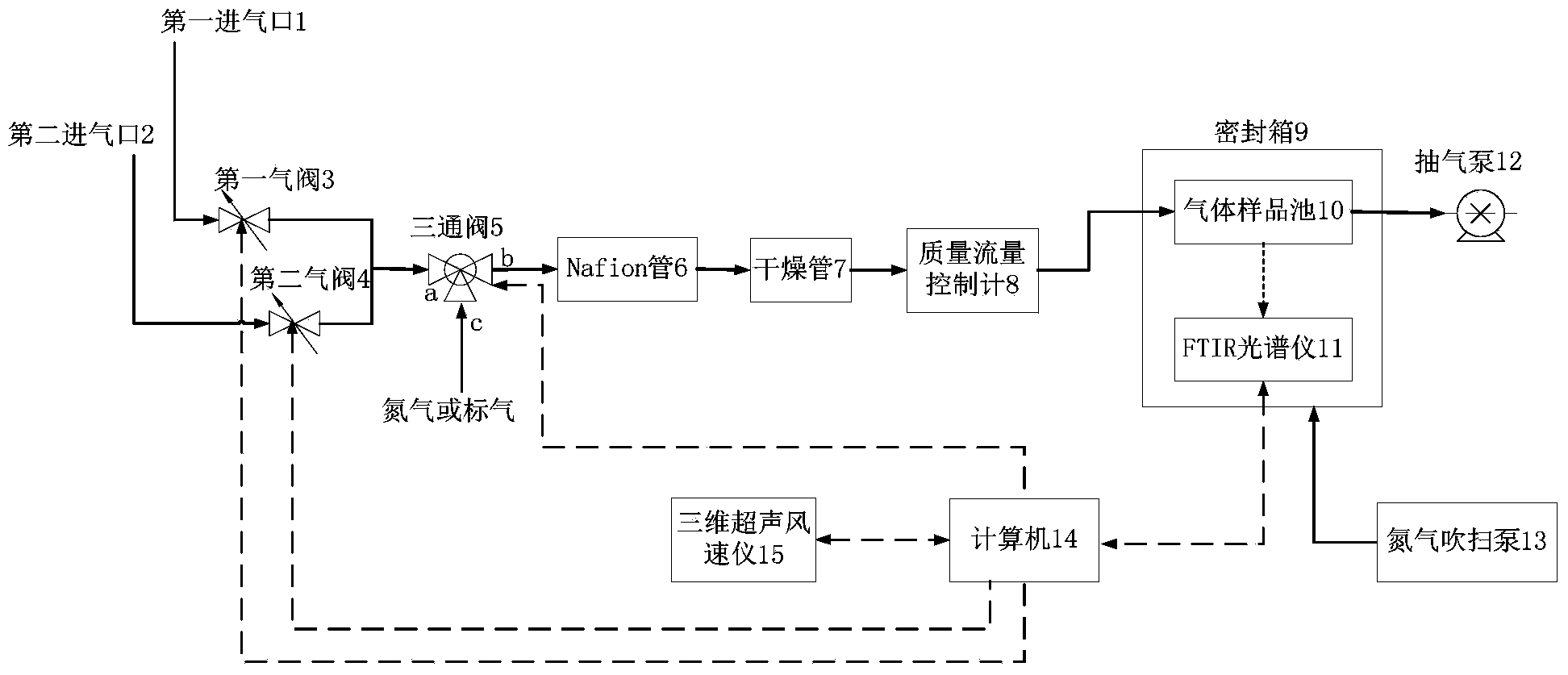

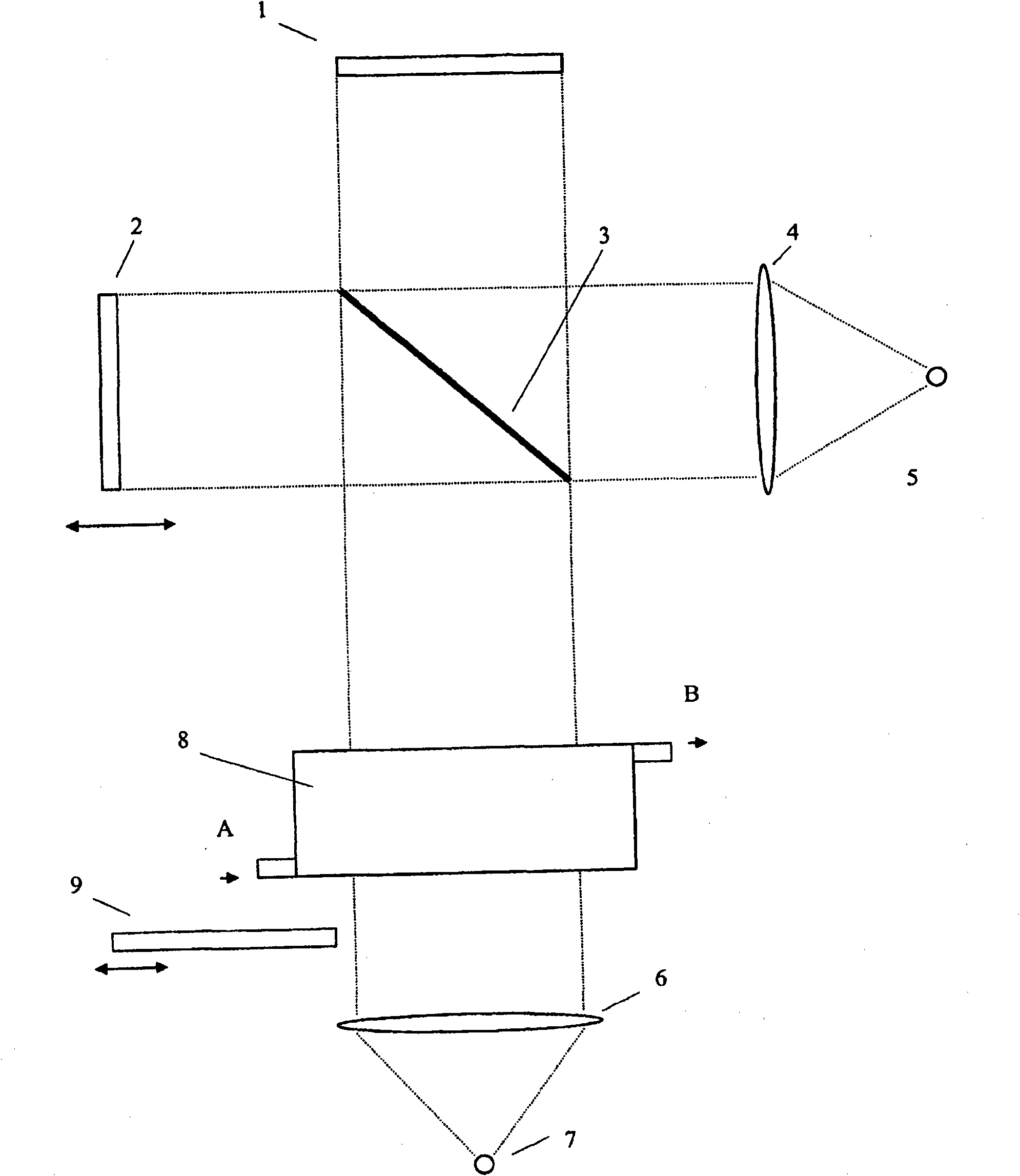

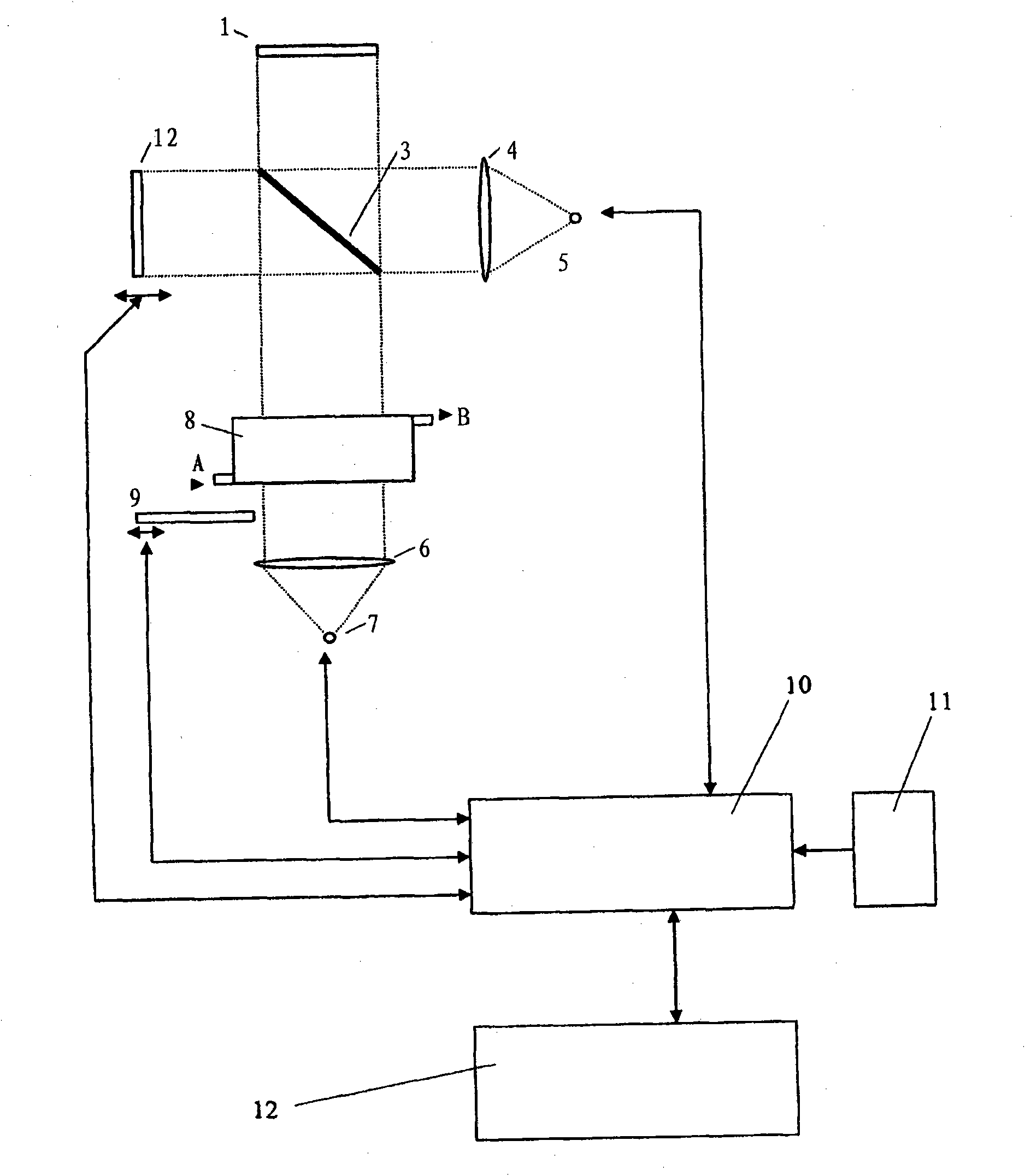

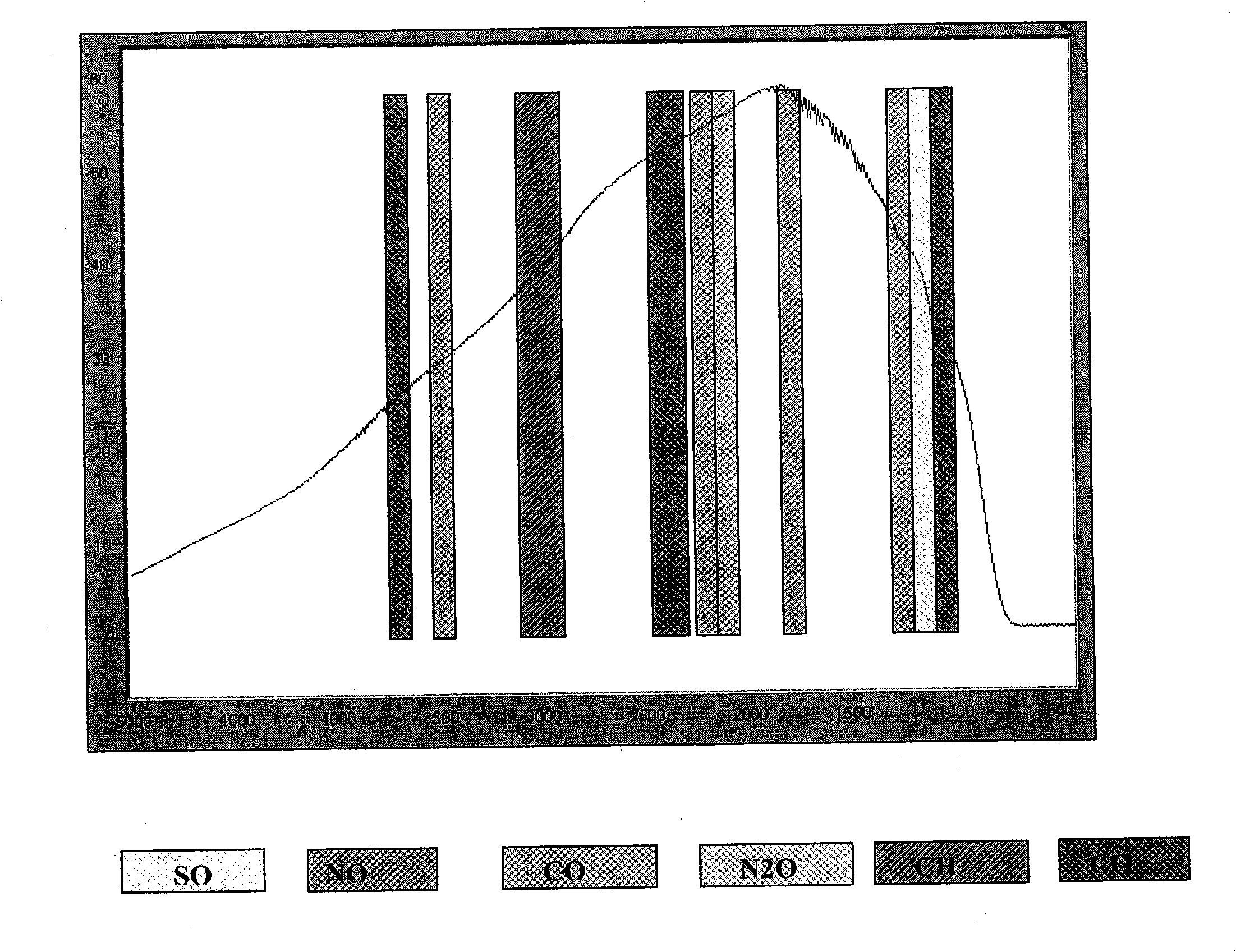

System and method for measuring infrared spectrum in greenhouse gas emission flux

ActiveCN103852437AReal-time emissionAchieve emissionsMaterial analysis by optical meansSurface layerSpectrograph

The invention discloses a system and a method for measuring an infrared spectrum in a greenhouse gas emission flux. The system mainly comprises a two-way-feeding automatic switching gas circuit, a gas sample pool, a Fourier transform infrared (FTIR) spectrograph, a three-dimensional ultrasound anemograph and a computer. According to the system, the emission flux of measured gas is obtained according to the mixing ratio concentration of greenhouse gas measured by the FTIR spectrograph as well as information of a surface layer wind field, close to a concentration measurement height, measured by the three-dimensional ultrasound anemograph.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

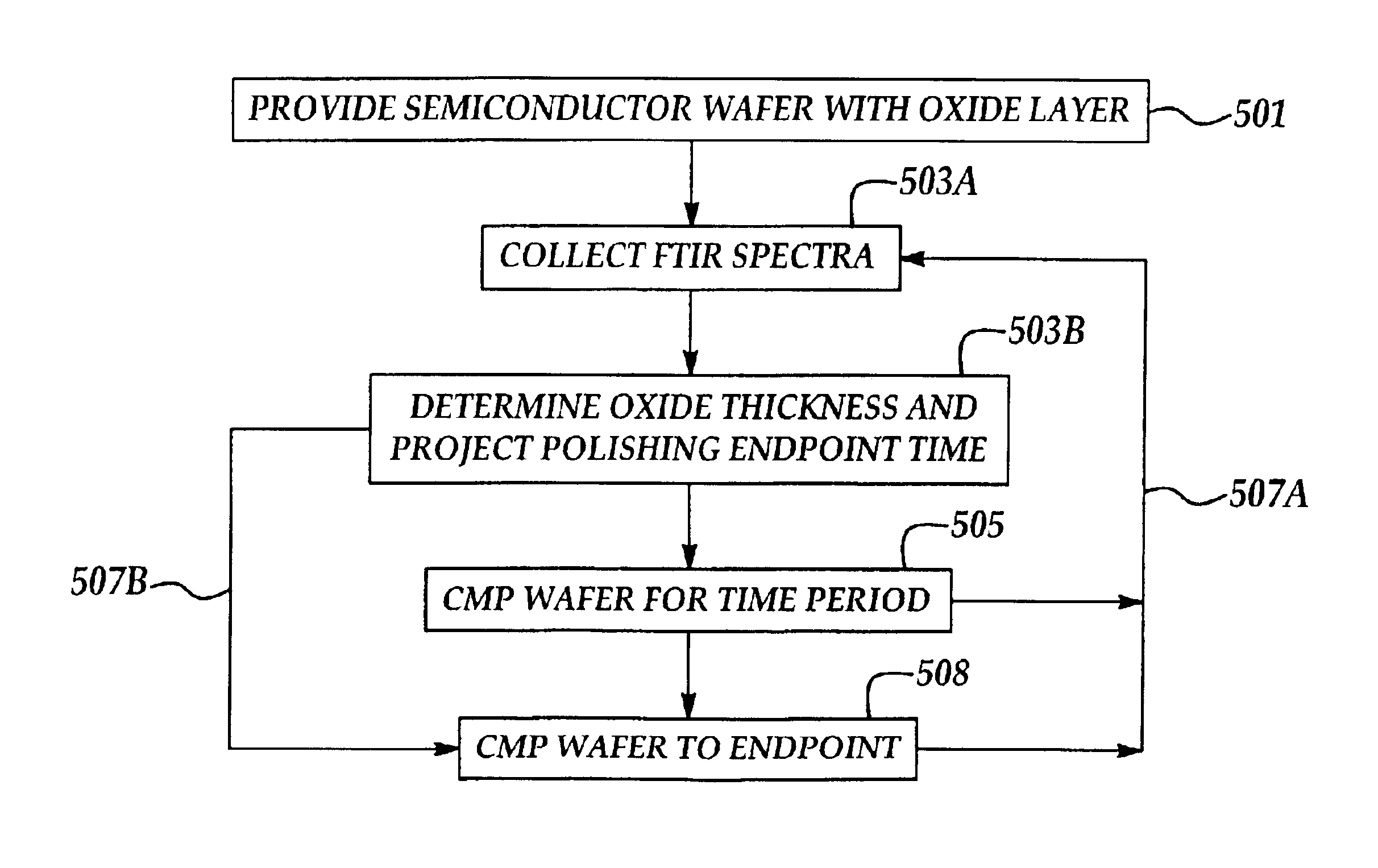

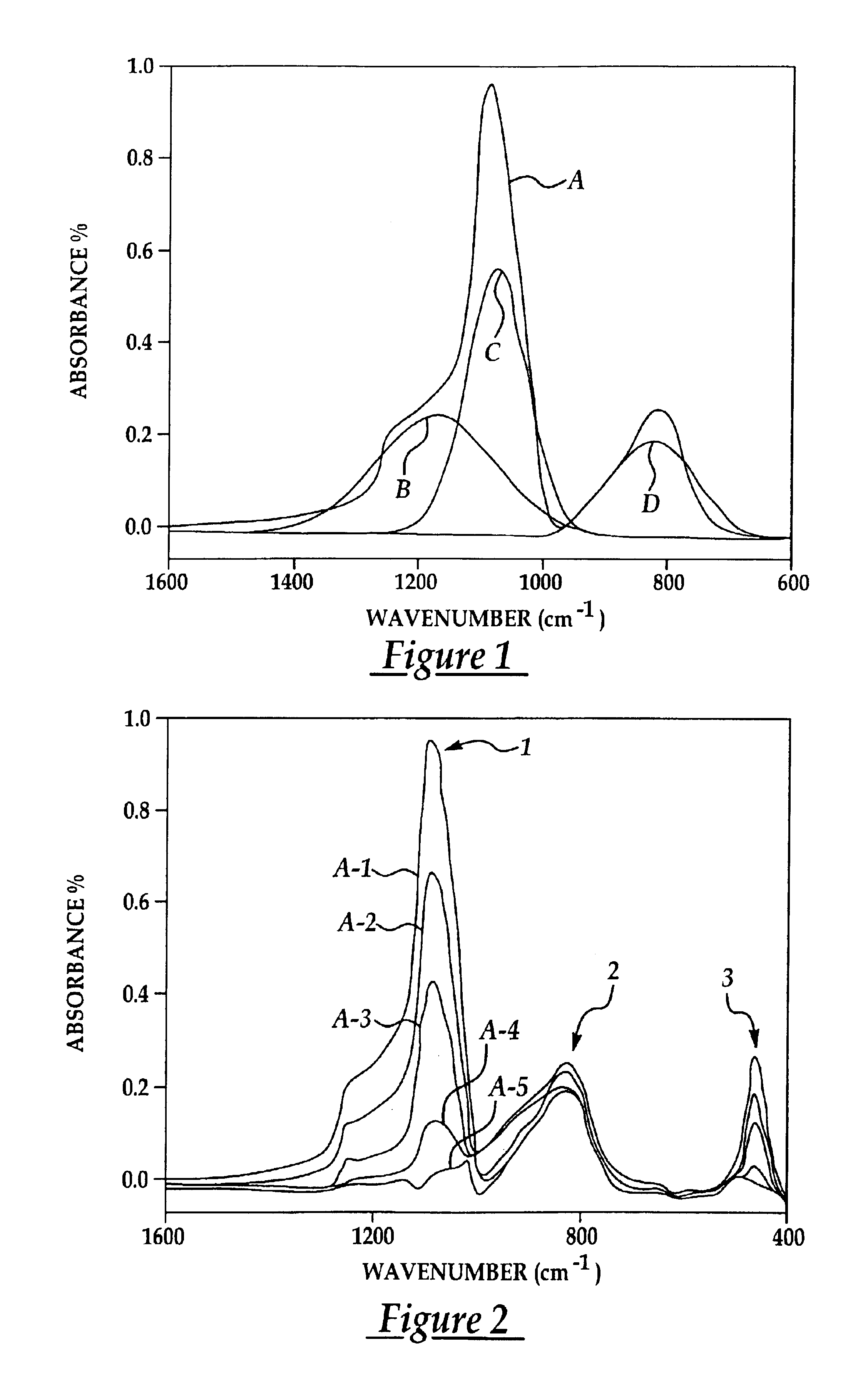

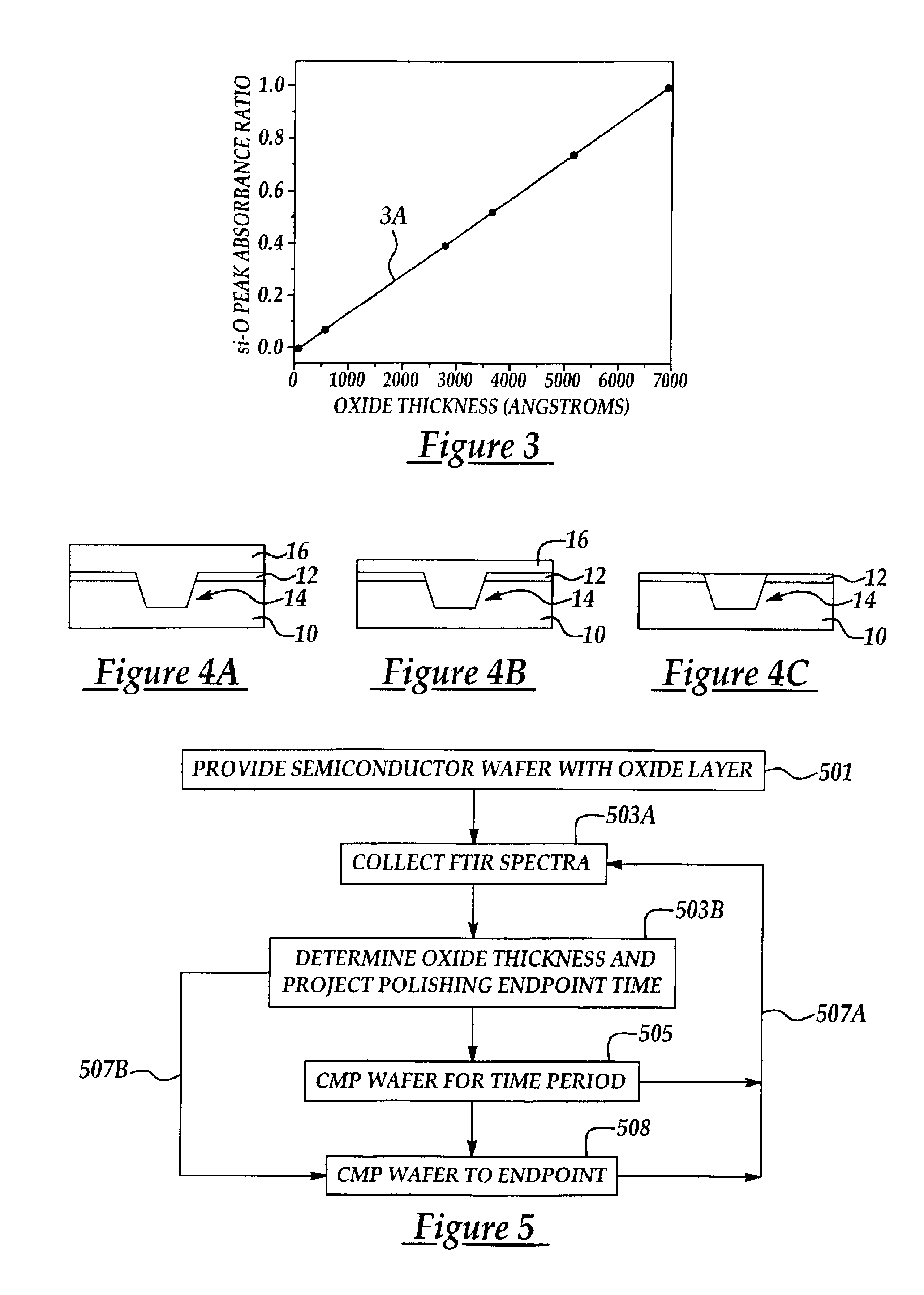

Method to measure oxide thickness by FTIR to improve an in-line CMP endpoint determination

A method for determining a material layer thickness transmissive to infrared (IR) energy in a semiconductor wafer manufacturing process including providing at least one semiconductor wafer comprising an IR transmissive layer; passing IR energy through the IR transmissive layer to produce at least one Fourier transform infrared (FTIR) spectrum; and, determining an amount of the IR transmissive layer present according to an amount of IR energy absorbed by a predetermined contributing characteristic vibrational mode portion of the FTIR spectrum.

Owner:TAIWAN SEMICON MFG CO LTD

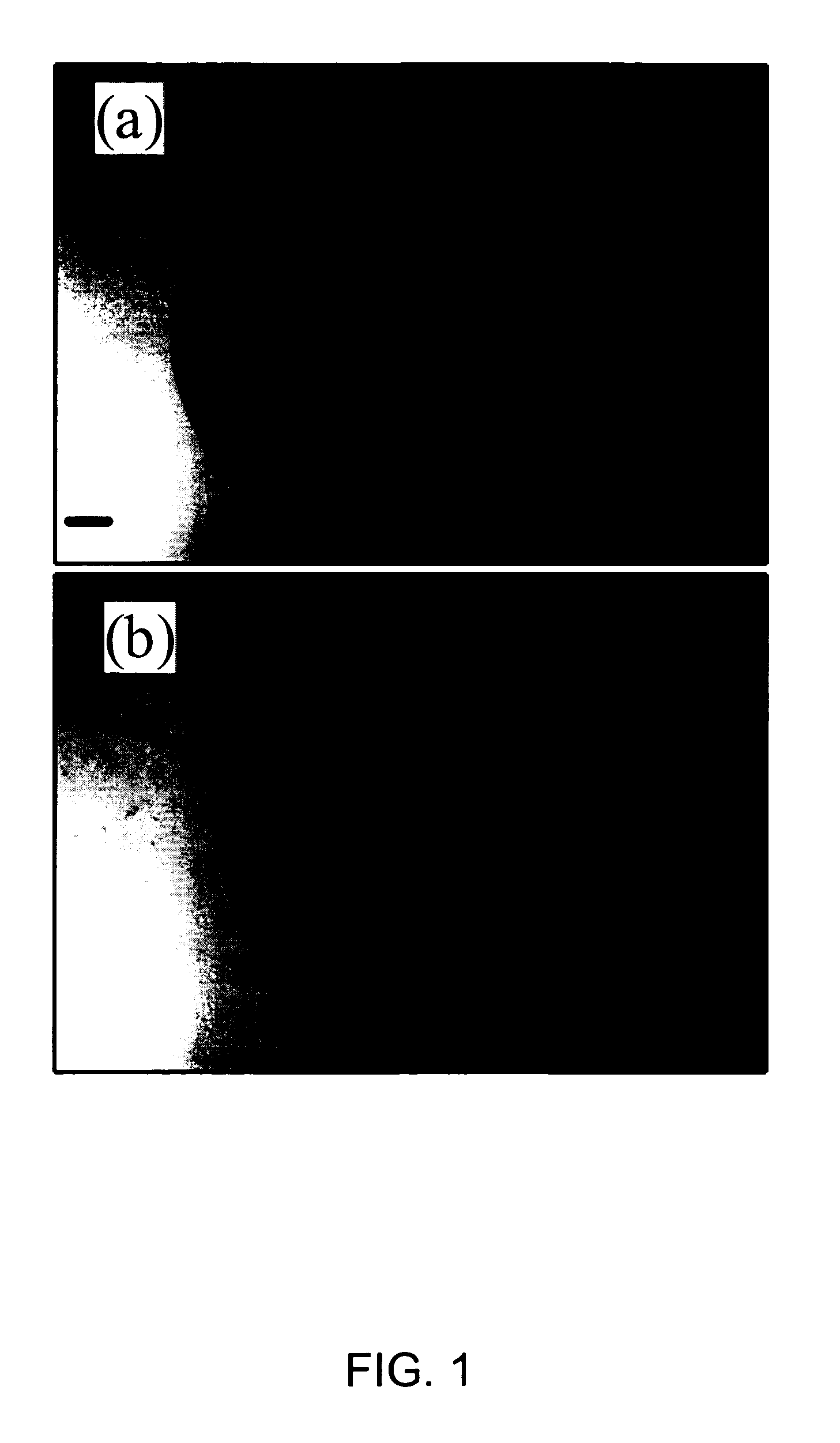

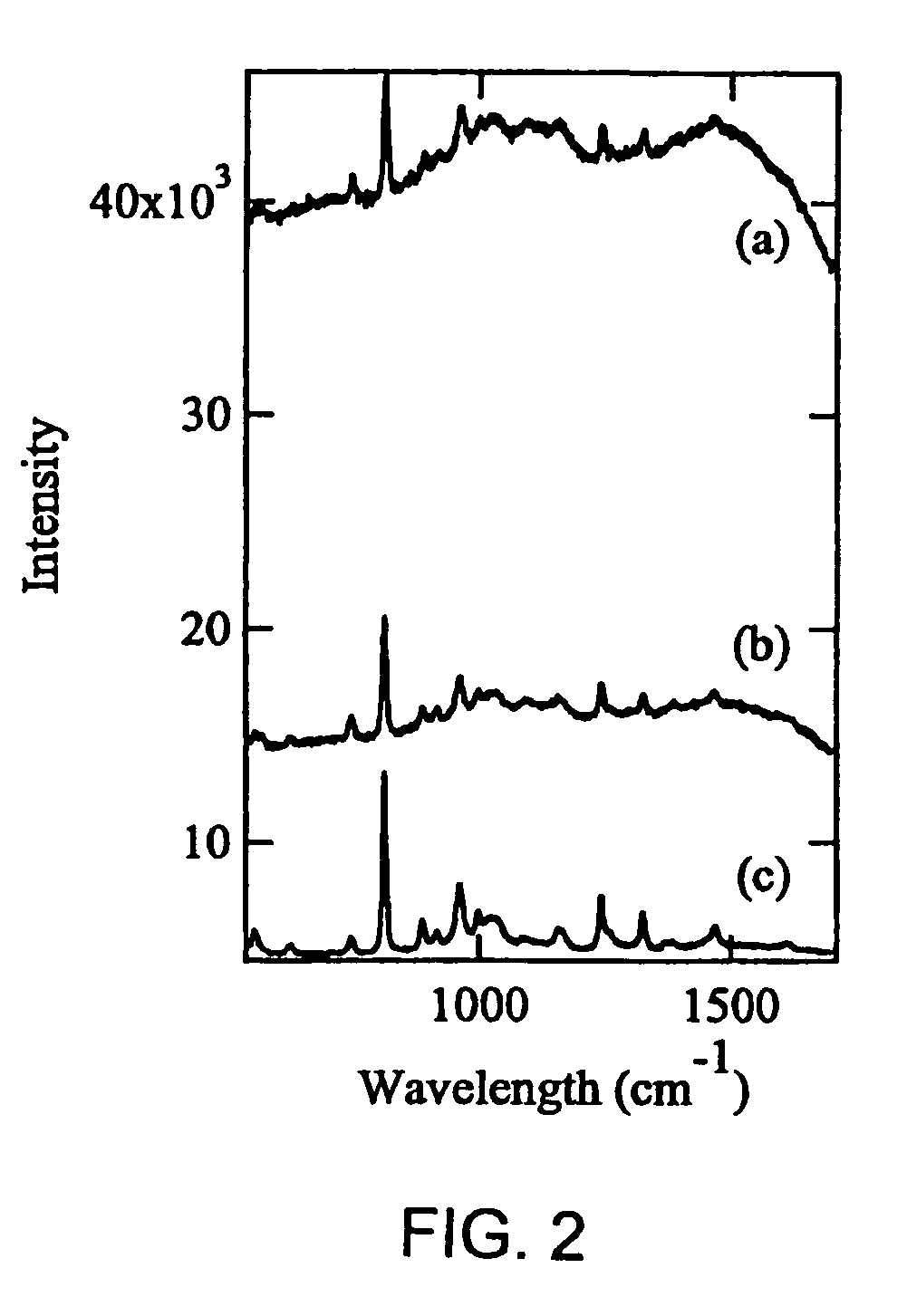

Process and apparatus for segregation and testing by spectral analysis of solid deposits derived from liquid mixtures

InactiveUS7283228B2Limiting and controlling spreadAvoid spreadingMaterial nanotechnologyRadiation pyrometryAnalyteSpectroscopy

Micro-droplets of liquid confining organic molecules of interest are dried on selected planar solvo-phobic substrates under conditions facilitating segregated precipitation of the larger, less soluable analytes toward edge portions of the deposit. Micro-spectrometer imaging using white light and FTIR false color can identify points of interest, and the same optics generally directed perpendicularly to the substrates selectively captures normal Raman spectra from selected points in the deposit. The spectra are manipulated using various data techniques to extract reliable information concerning analytes present at pico-Molar levels. The selected spots can also be subjected to FTIR spectroscopy followed by MALDI mass spectroscopy to obtain a variety of information from the identical specimen.

Owner:PURDUE RES FOUND INC

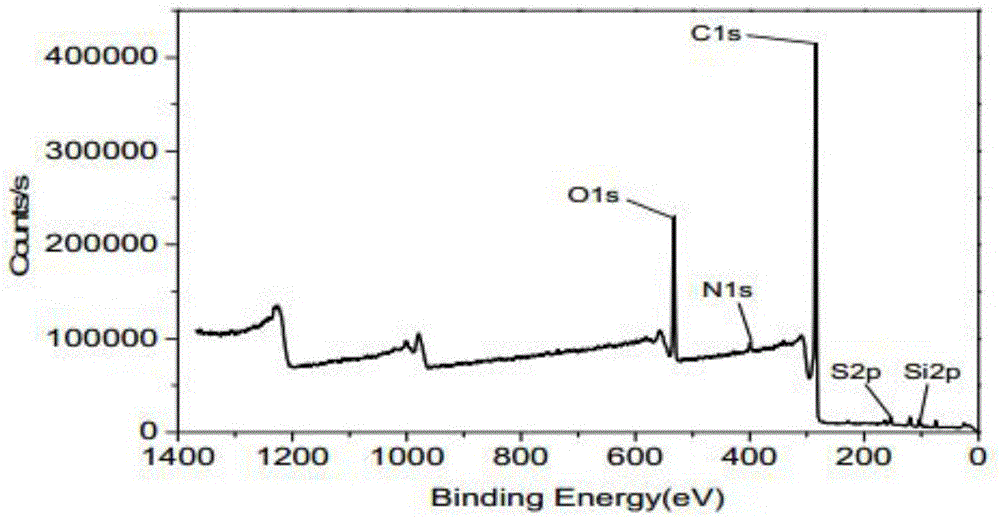

Building method for shale composite organic molecular model

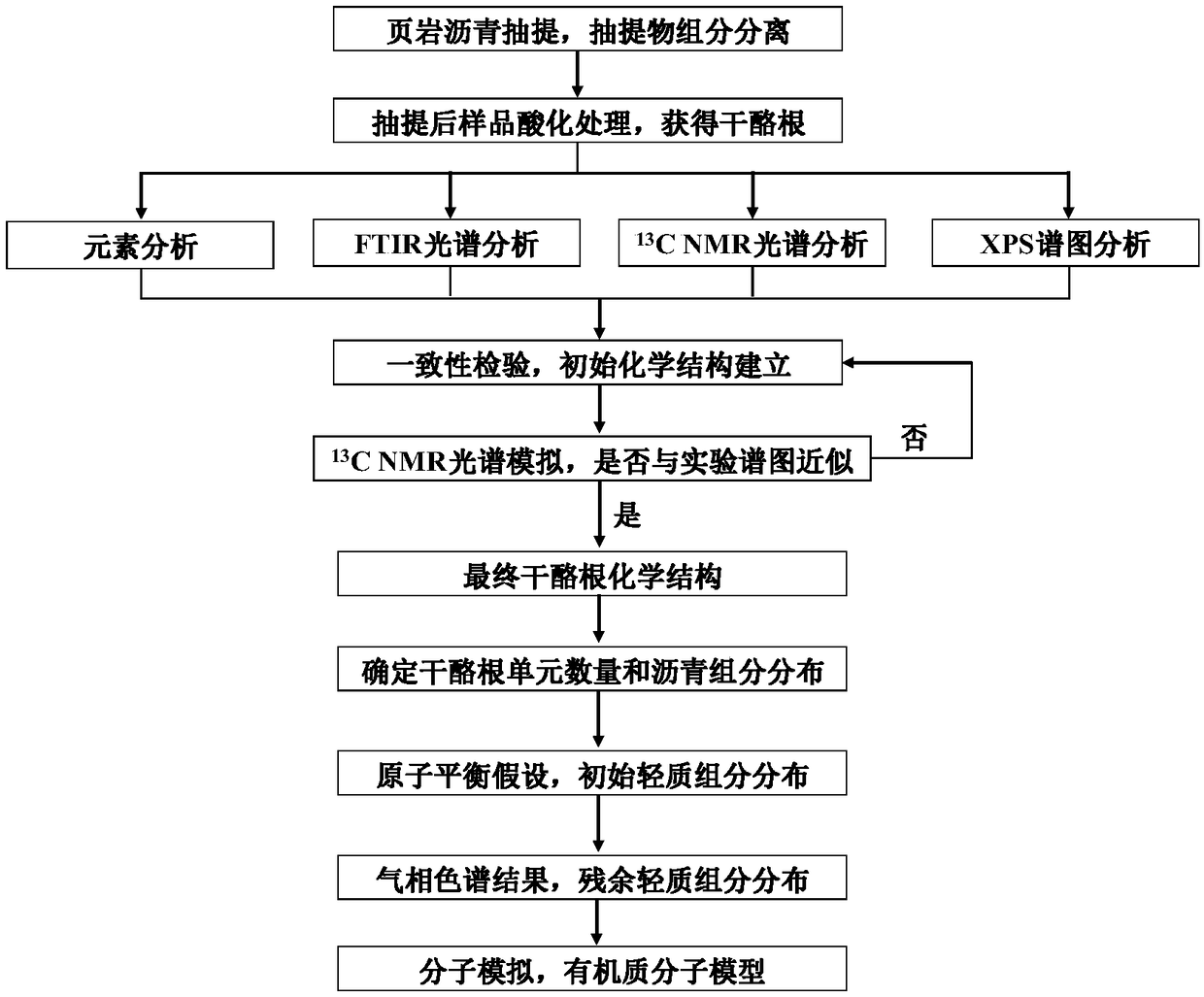

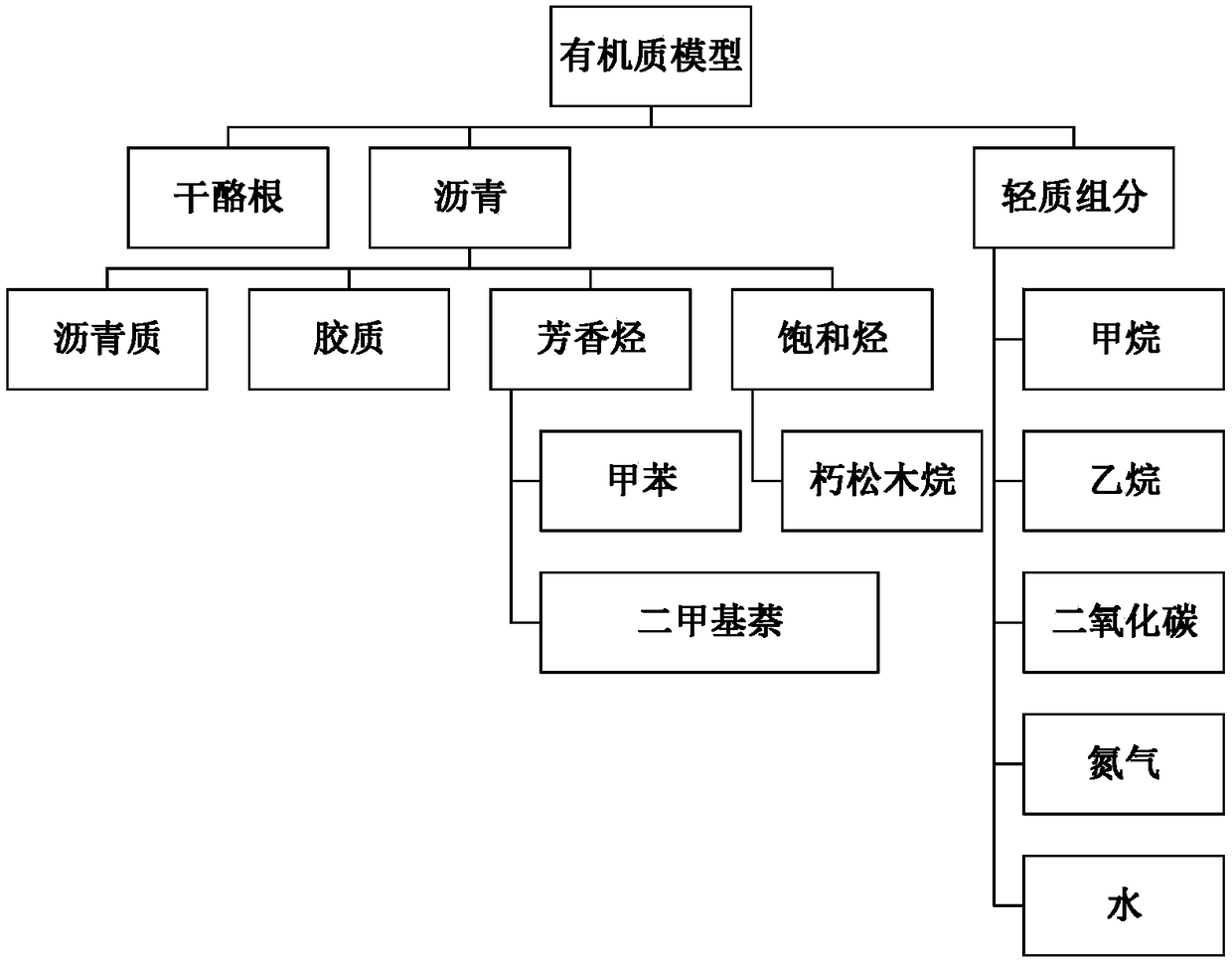

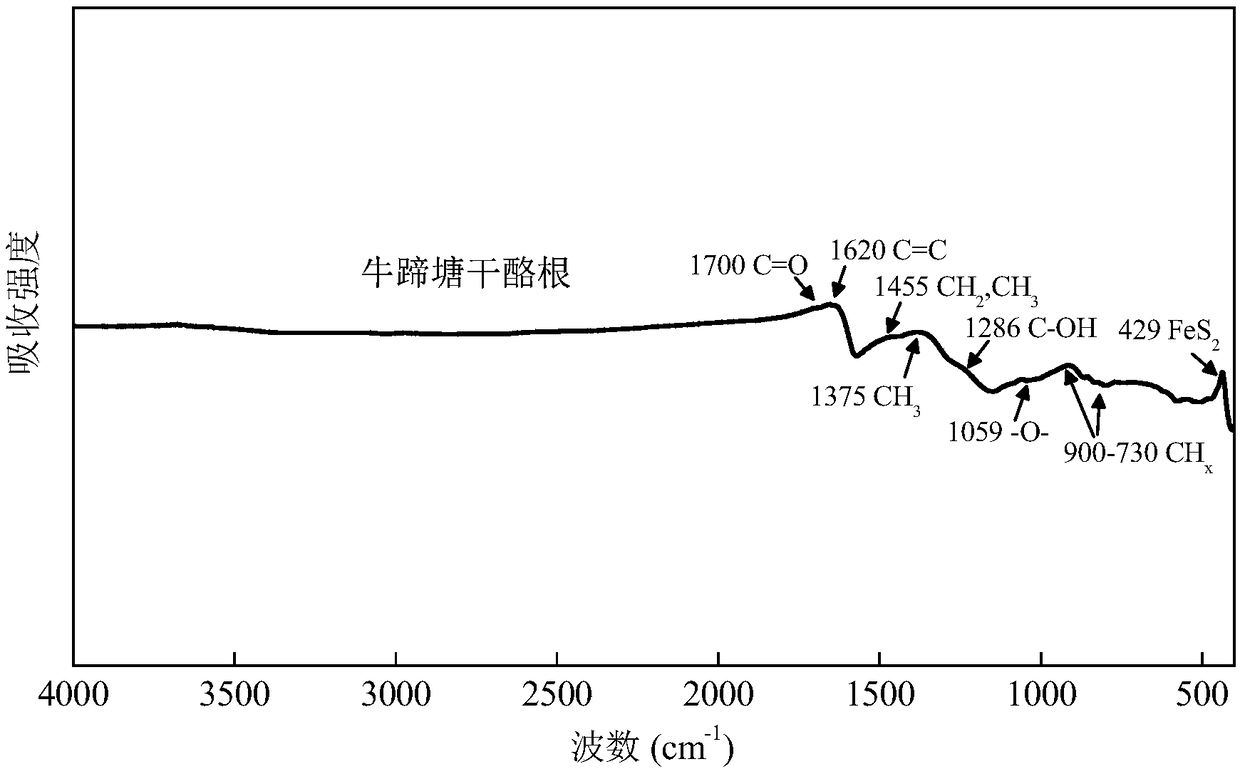

ActiveCN108595778APhysically inhomogeneousStrong transplantMaterial analysis using wave/particle radiationMaterial analysis by optical meansElement analysisMaterials science

The invention provides a building method for a shale composite organic molecular model. The method comprises the following steps of extracting asphalt sample components and a kerogen sample in a shalesample, and performing component analysis on an asphalt sample; performing element analysis, FTIR spectral analysis, 13C NMR spectrogram test and XPS energy spectrum analysis on the kerogen sample, and judging element composition, an atom ratio of carbon atoms to heteroatoms, functional group types, carbon skeleton structure parameters and existing forms of the heteroatoms in the kerogen sample;according to element analysis, FTIR spectral analysis, 13C NMR spectrogram test and XPS energy spectrum analysis results, constructing initial molecular structures of the kerogen sample; and determining the quantity of the initial molecular structures of kerogen, sample component distribution and organic light component distribution under a reservoir condition in the organic molecular model, and building the three-dimensional shale composite organic molecular model by adopting a molecular simulation technology, wherein the heteroatoms are atoms except carbon and hydrogen.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

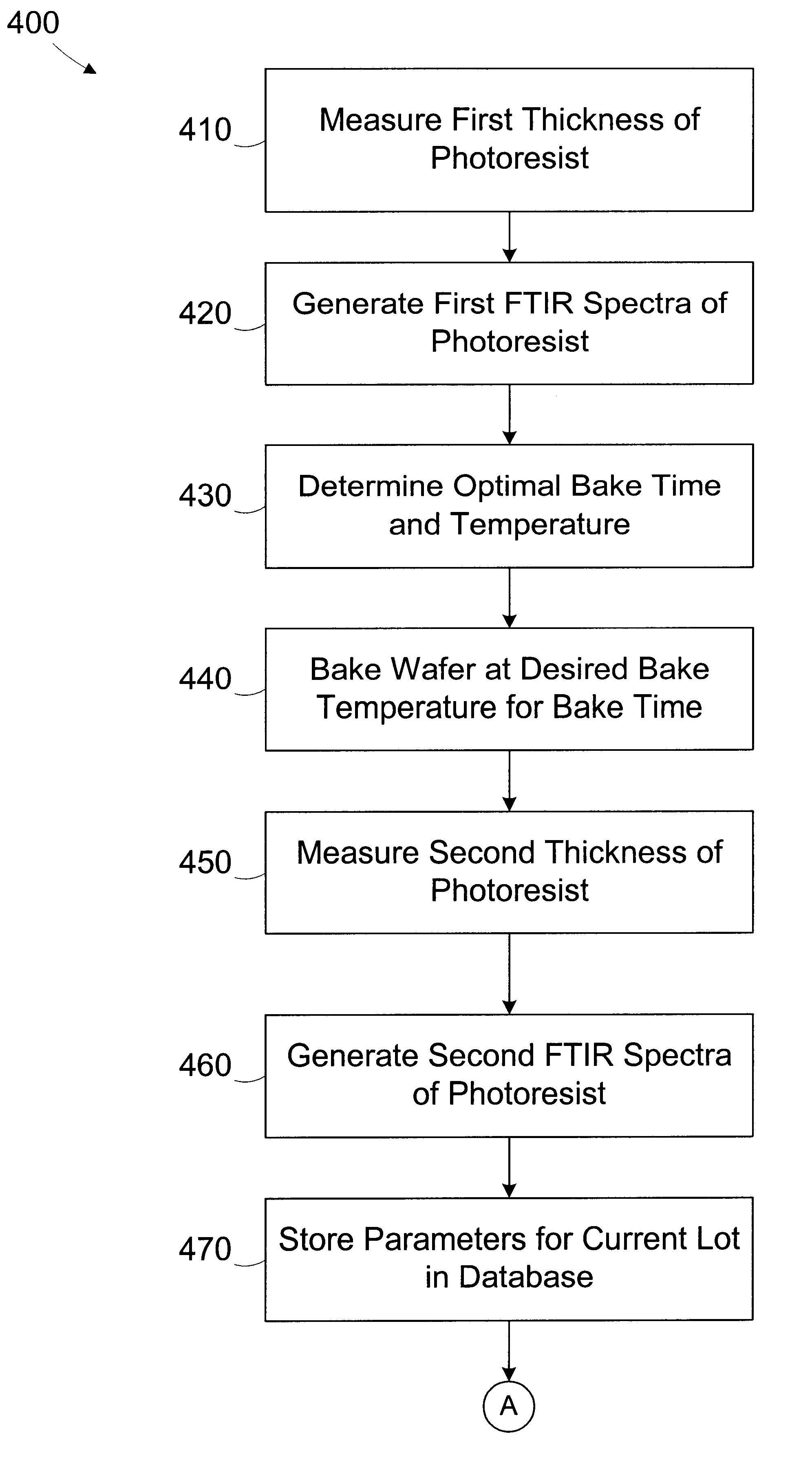

Method for controlling photoresist baking processes

InactiveUS6362116B1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusFtir spectraPhotoresist

A method and apparatus for controlling photoresist baking processes. A wafer is provided with the wafer having a layer of photoresist thereon. A first thickness of the photoresist layer is measured, and a first fourier transform infrared (FTIR) spectra of the photoresist layer is generated. Based on the first thickness and first FTIR spectra, a bake time and bake temperature is determined. The wafer is then baked at the bake temperature for the bake time.

Owner:GLOBALFOUNDRIES INC

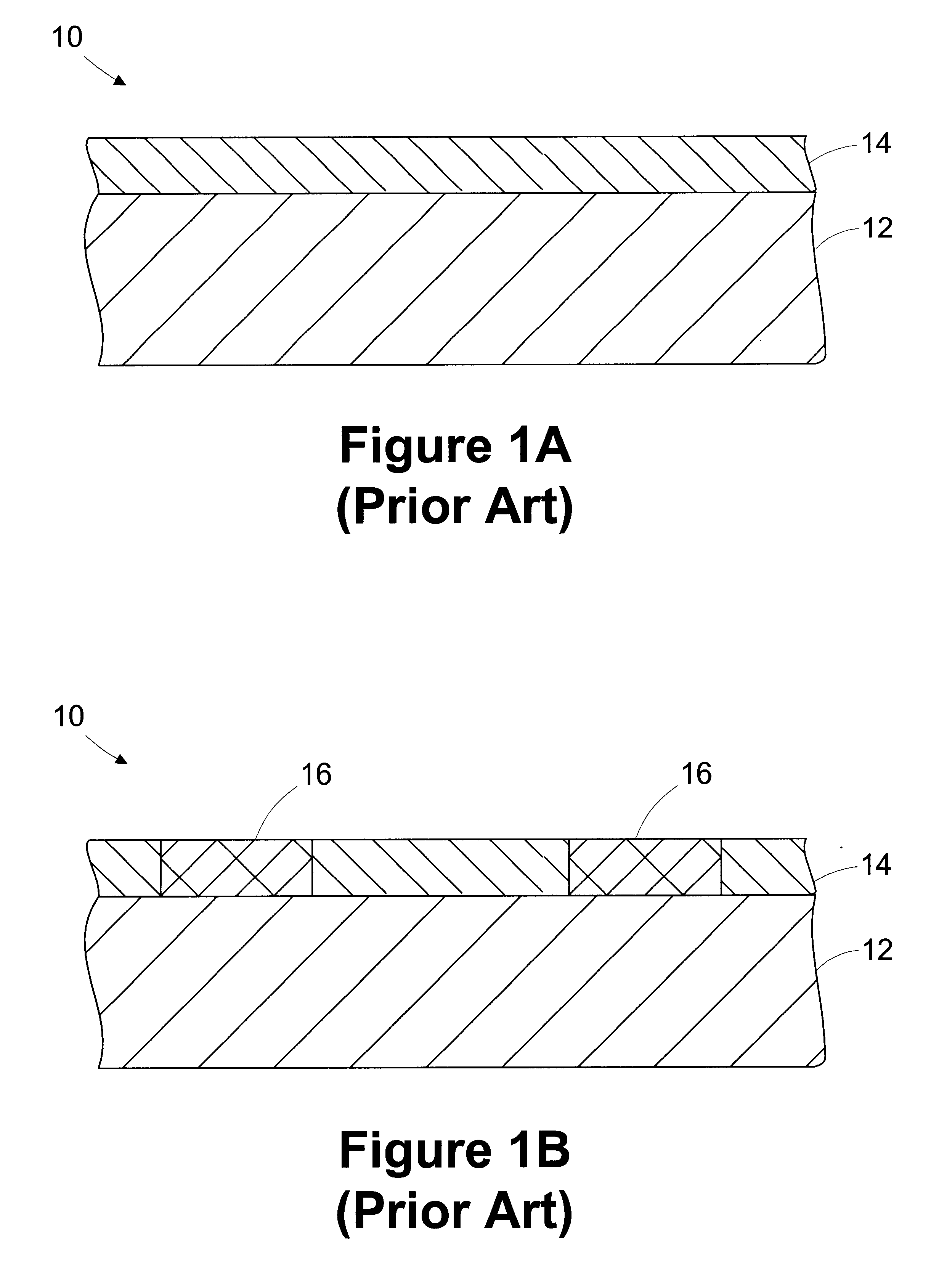

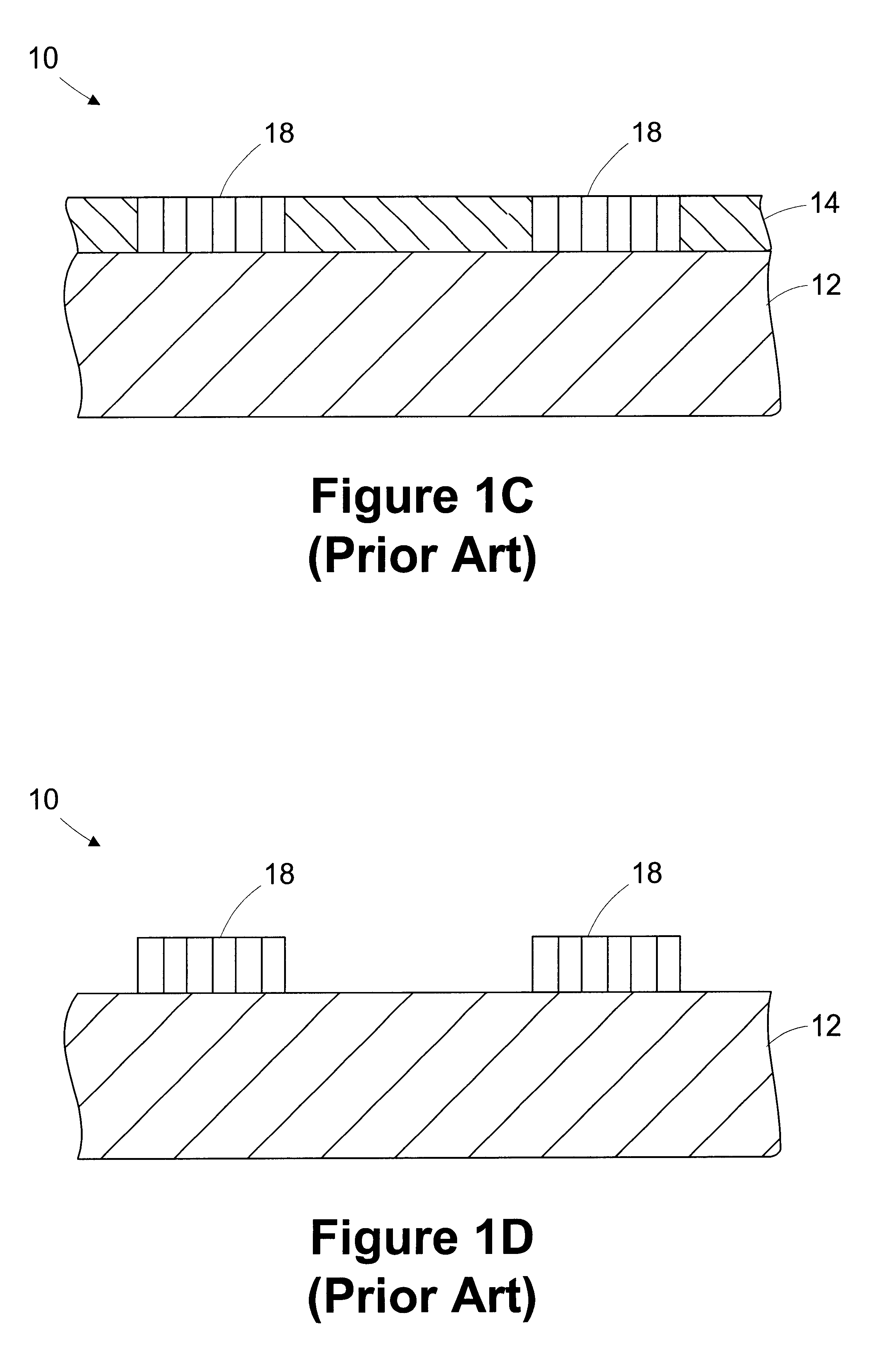

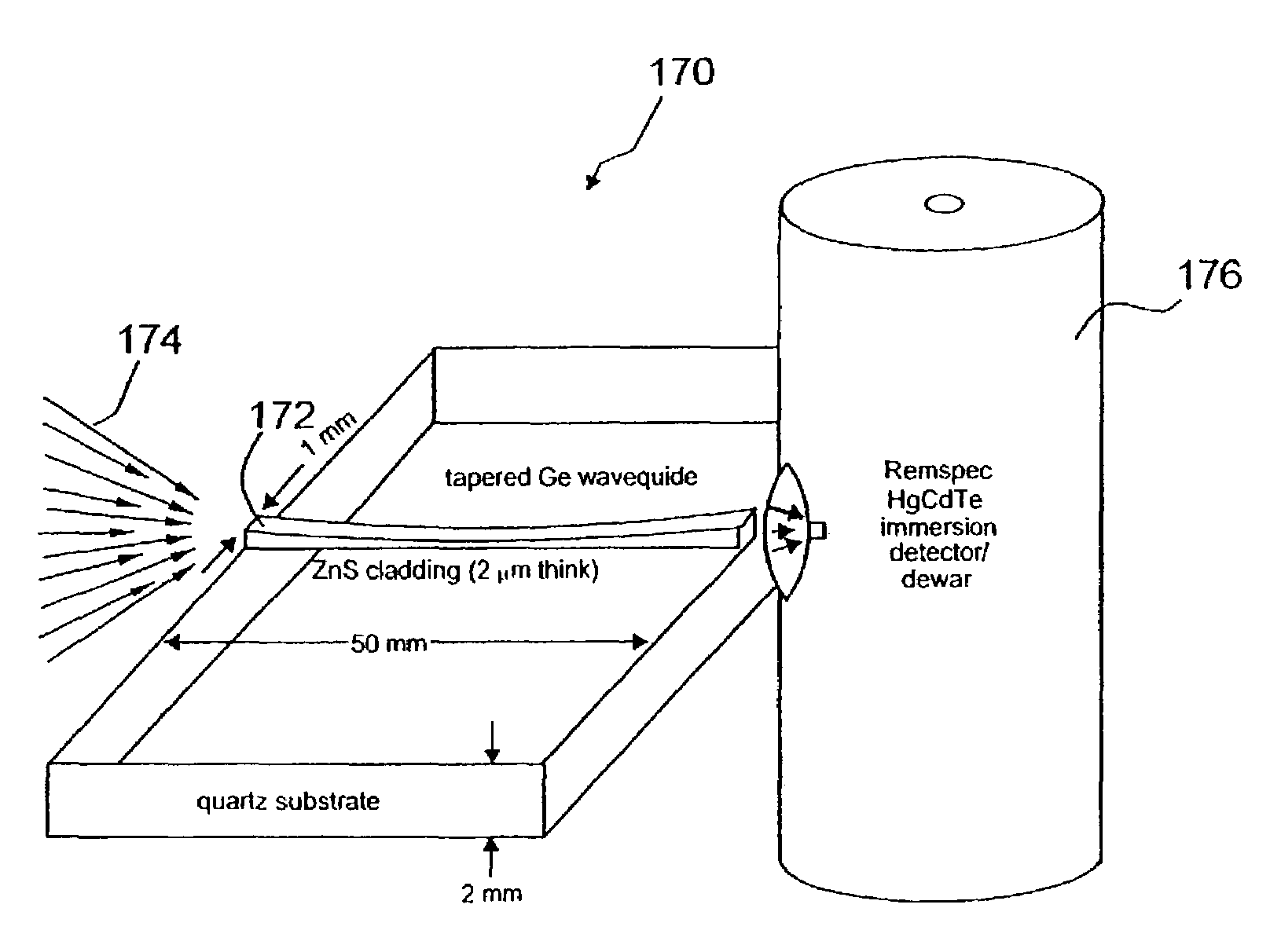

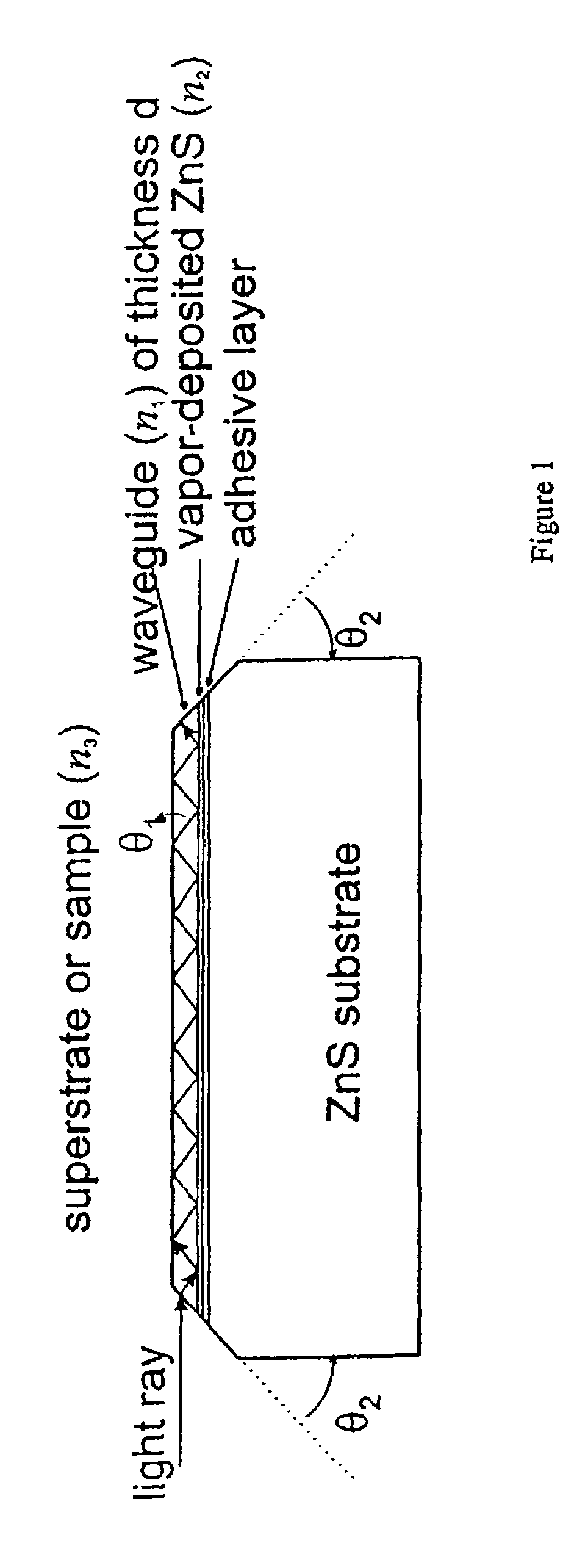

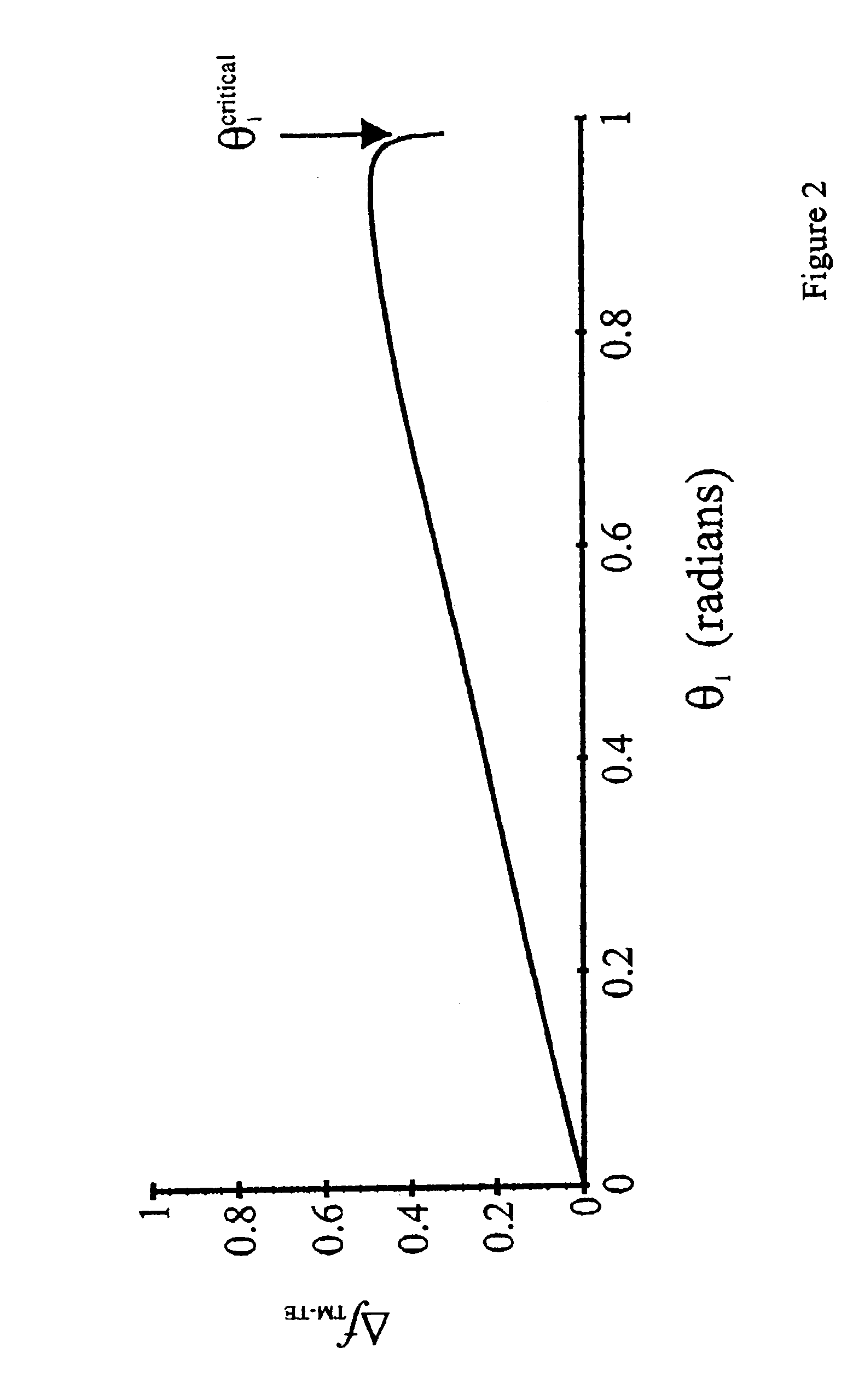

Support planar and tapered quasi-planar germanium waveguides for infrared evanescent-wave sensing

InactiveUS7282105B1Increase heightHigh sensitivityCladded optical fibreLamination ancillary operationsImage resolutionOptical coupling

Miniature planar IR waveguides of thickness 30–50 μm, consisting of 12-mm long, 2-mm wide strips of Ge supported on ZnS substrates and tapered quasi-tapered waveguides, tapered from a thickness of 1 mm at the ends to a minimum of 1–100 μm at the center, are disclosed. The surface sensitivity is increased as a function of incidence or bevel angle. The tapered waveguide improves the efficiency of the optical coupling both into the waveguide from an FTIR spectrometer, and out of the waveguide onto a small-area IR detector. The tapering makes it possible to dispense with using an IR microscope couple light through the waveguide, enabling efficient coupling with a detector directly coupled to an immersion lens. This optical arrangement makes such thin supported waveguides more useful as sensors, because they can be made quite long (e.g. 50 mm) and mounted horizontally. Furthermore, even with a 20-μm×1-mm cross section, sufficient throughput is obtained to give signal / noise ratios in excess of 1000 over most of the 1000–5000 cm-1 range, with just 2 min of scanning at 8 cm-1 resolution.

Owner:PLUNKETT SUSAN E +2

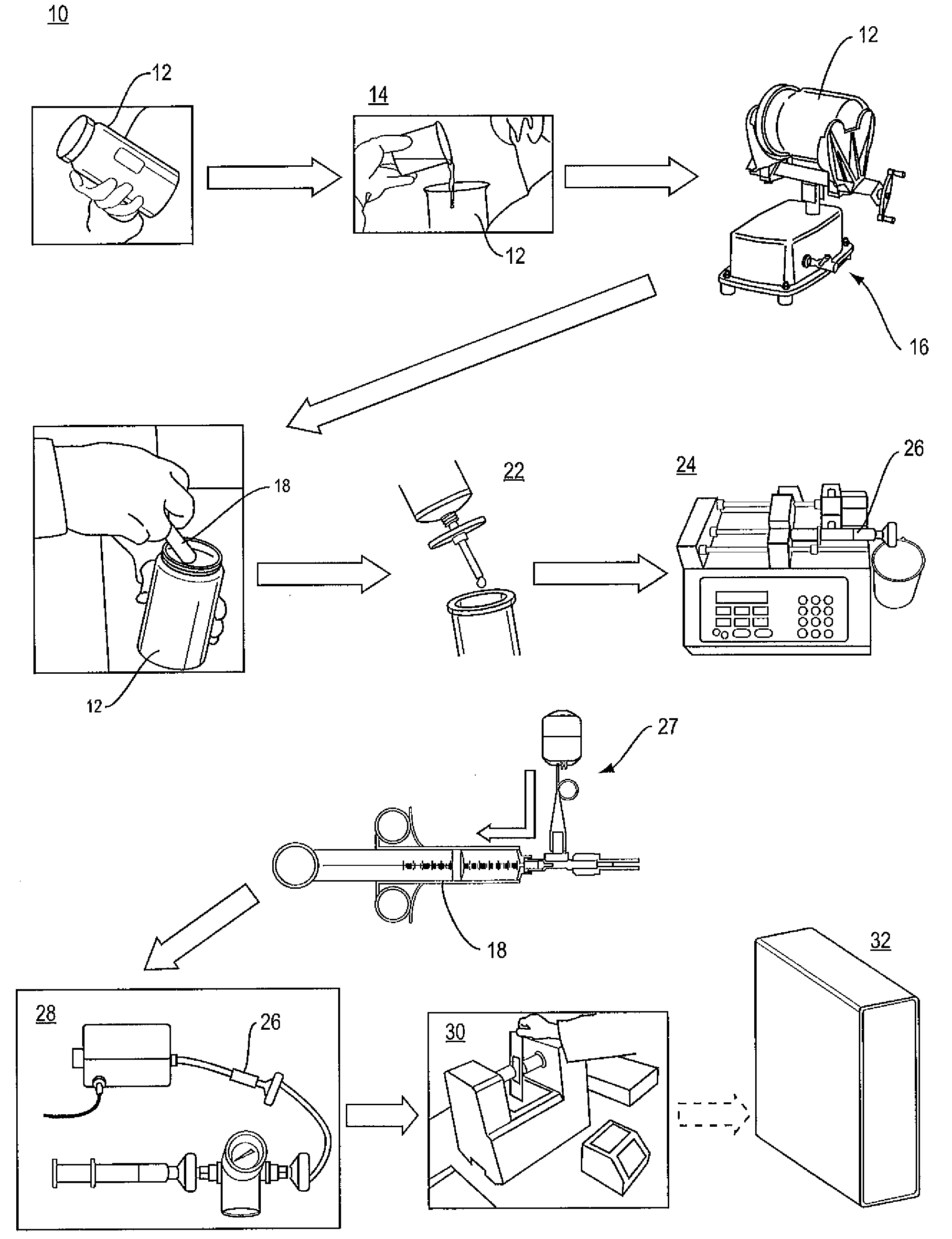

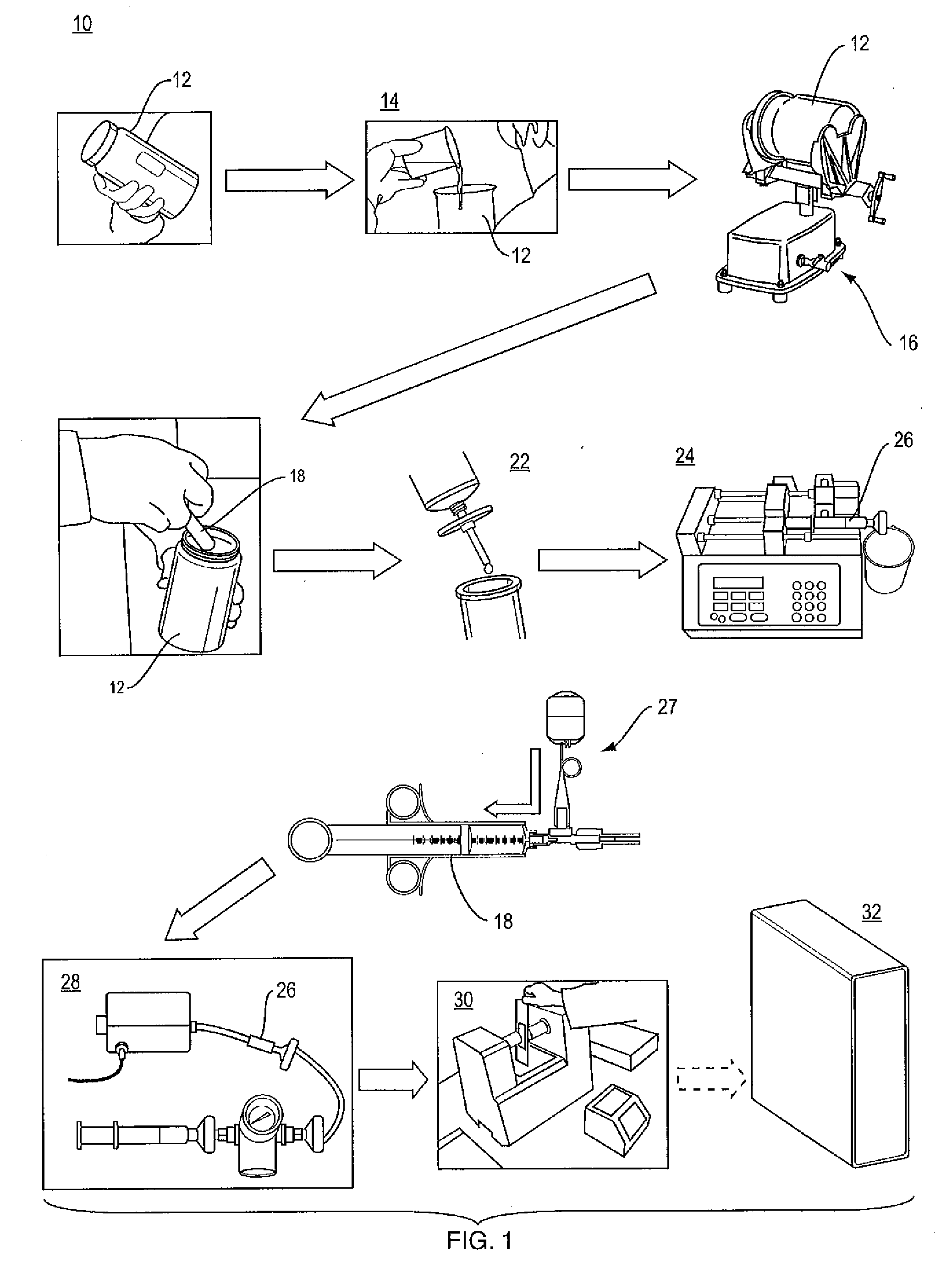

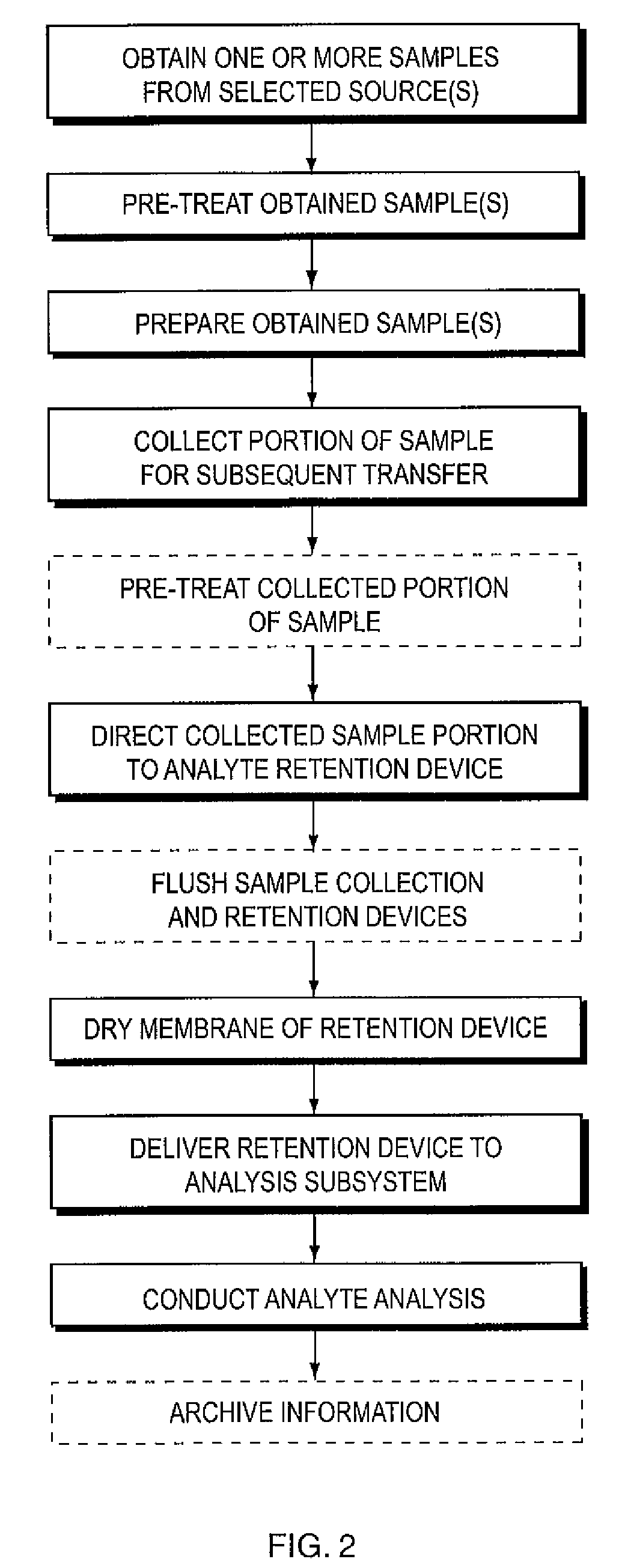

Apparatus and method for determining analyte content in a fluid

ActiveUS20090173145A1Accurate and reliable processAccurately passedRadiation pyrometryDirection finders using radio wavesWater useOil and grease

An apparatus and method to determine analytes in a fluid. One aspect of the present invention is for the determination of the oil content of water using UV, near-IR, IR or Raman spectroscopy or radiometry. In certain embodiments, a solid membrane material absorbs analytes from fluid brought into contact with it. The membrane is subsequently placed in a FTIR spectrometer, which spectrometer is enabled to determine the concentration of analytes in fluid by calibration. Certain embodiments can determine the type of hydrocarbon present, and thus can differentiate Total Petroleum Hydrocarbons (TPH) from Total Oil and Grease (TOG), without any separate sample preparation.

Owner:ORONO SPECTRAL SOLUTIONS

Ultra-hard low friction coating based on A1MgB14 for reduced wear of MEMS and other tribological components and system

InactiveUS7238429B2Convenient coatingHigh hardnessSolid-state devicesVacuum evaporation coatingMicroelectromechanical systemsAlloy

Performance and reliability of microelectromechanical system (MEMS) components enhanced dramatically through the incorporation of protective thin film coatings. Current-generation MEMS devices prepared by the LIGA technique employ transition metals such as Ni, Cu, Fe, or alloys thereof, and hence lack stability in oxidizing, corrosive, and / or high temperature environments. Fabrication of a superhard, self-lubricating coating based on a ternary boride compound AlMgB14 is described in this letter as a potential breakthrough in protective coating technology for LIGA microdevices. Nanoindentation tests show that hardness of AlMgB14 films prepared by pulsed laser deposition ranges from 45 GPa to 51 GPa, when deposited at room temperature and 573 K, respectively. Extremely low friction coefficients of 0.04-0.05, which are thought to result from a self-lubricating effect, have also been confirmed by nanoscratch tests on the AlMgB14 films. Transmission electron microscopy studies show that the as-deposited films are amorphous, regardless of substrate temperature; however, analysis of FTIR spectra suggests that the higher substrate temperature facilitates formation of the B12 icosahedral framework, therefore leading to the higher hardness.

Owner:IOWA STATE UNIV RES FOUND

Coating Material and method for providing asset protection

InactiveUS6060169ANot easy to copyPrinted electric component incorporationSemiconductor/solid-state device detailsUltravioletSpectroscopy

A material and a method for forming a tamper-indicating identification coating are provided. The components of the coating are selected such that the coating exhibits a characteristic absorption spectrum with distinct features in individual regions during Fourier-transform infra-red (FTIR) spectroscopy. The coating components are selected to provide a distinct spectrum while, at the same time, providing a sufficiently complex spectrum such that the coating is difficult to duplicate. Also, a blowing agent in the coating decomposes to change the FTIR spectrum due to the heat associated with resoldering of an out-of-warranty electronic part marked with the identification coating to an in-warranty circuit card. In addition, the coating may contain a fluorophore to reveal the presence of a tamper-indicating identification coating, allowing a manufacturer to check the card by exposure with ultra-violet (UV) light. Further, the coating composition may be changed periodically and tracked to provide a date marker.

Owner:IBM CORP

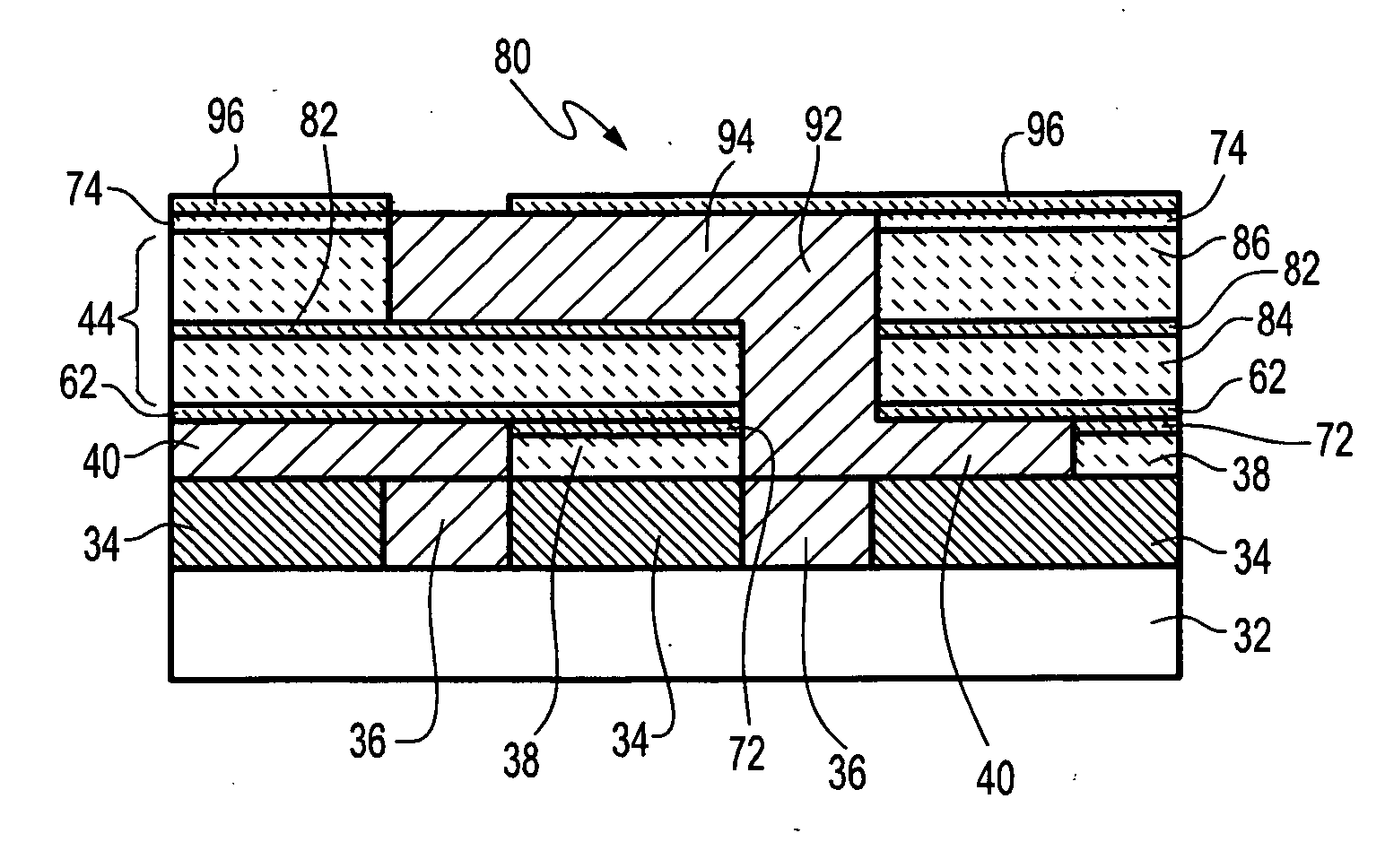

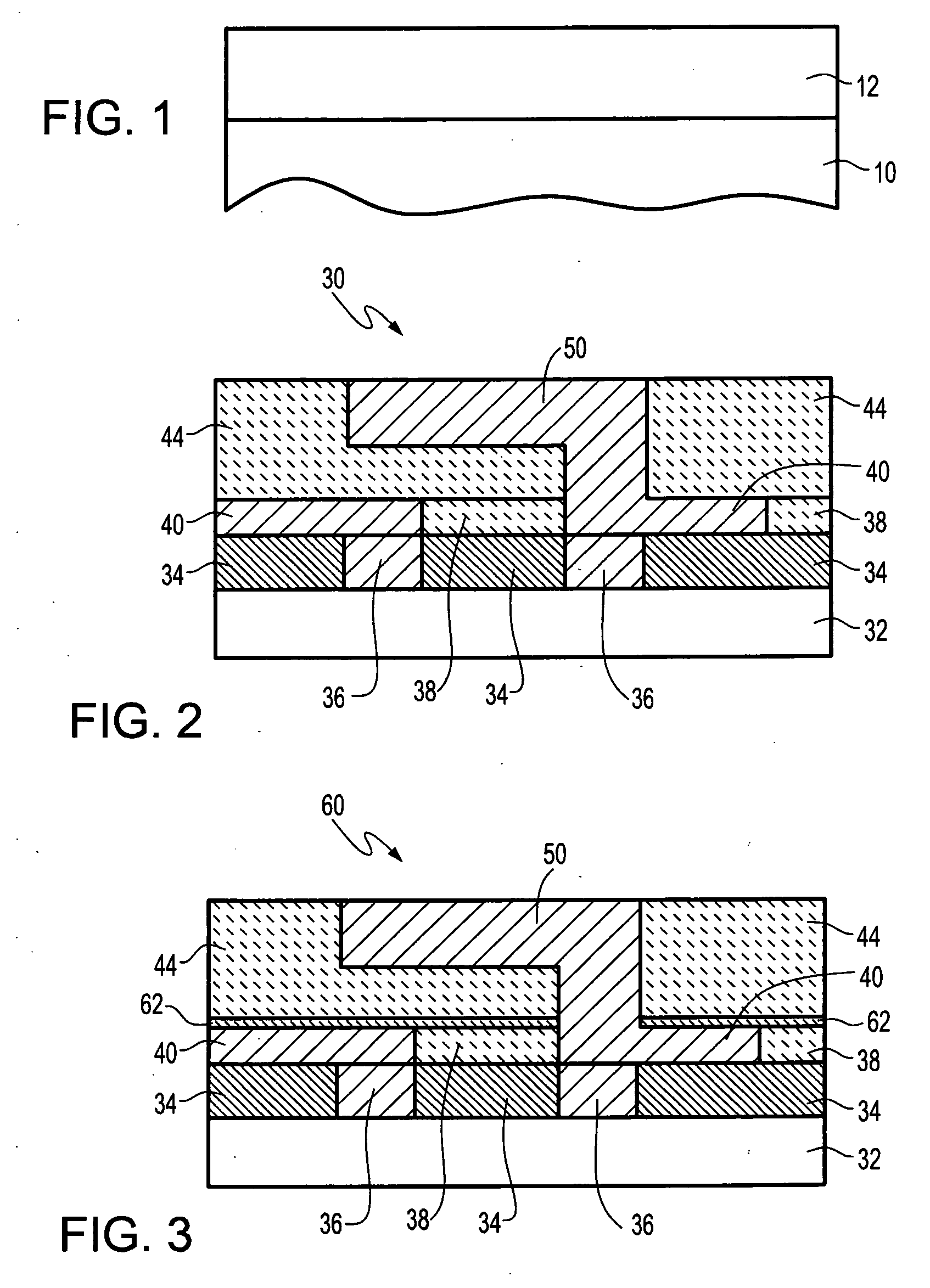

Advanced low dielectric constant organosilicon plasma chemical vapor deposition films

ActiveUS7202564B2High mechanical strengthDecreased amount of crosslinkingSemiconductor/solid-state device detailsSolid-state devicesPorosityNetwork structure

A porous low k or ultra low k dielectric film comprising atoms of Si, C, O and H (hereinafter “SiCOH”) in a covalently bonded tri-dimensional network structure having a dielectric constant of less than about 3.0, a higher degree of crystalline bonding interactions, more carbon as methyl termination groups and fewer methylene, —CH2— crosslinking groups than prior art SiCOH dielectrics is provided. The SiCOH dielectric is characterized as having a FTIR spectrum comprising a peak area for CH3+CH2 stretching of less than about 1.40, a peak area for SiH stretching of less than about 0.20, a peak area for SiCH3 bonding of greater than about 2.0, and a peak area for Si—O—Si bonding of greater than about 60%, and a porosity of greater than about 20%.

Owner:SONY CORP +2

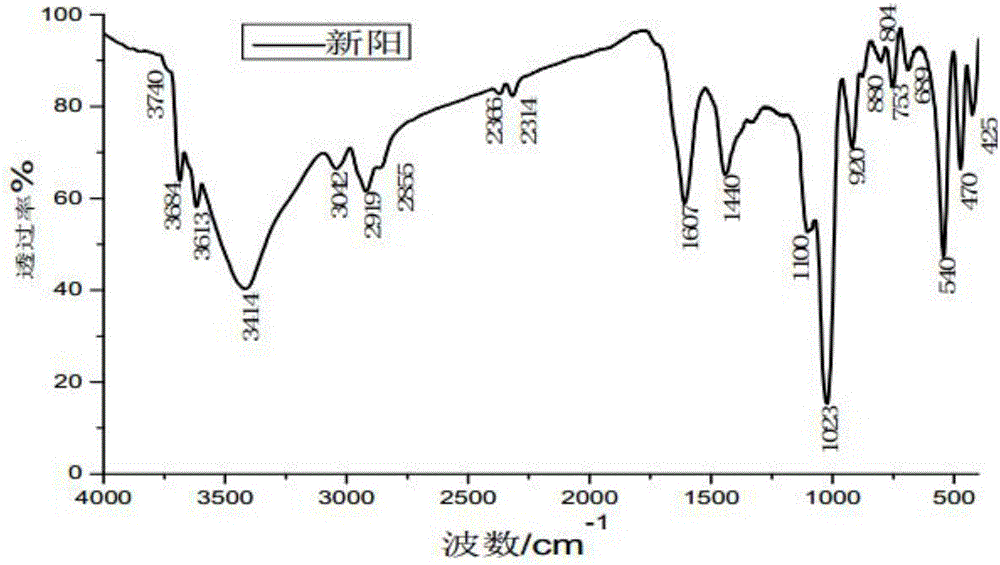

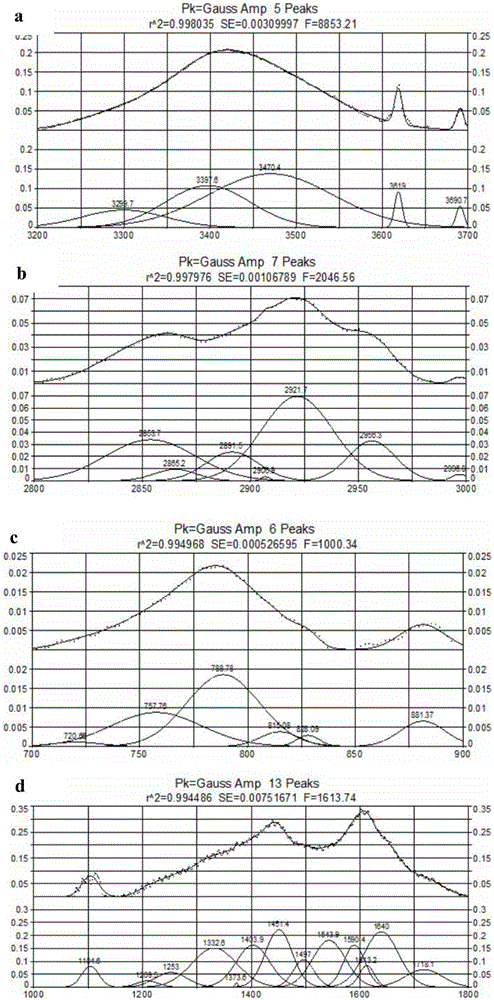

Construction method of coking coal sulfur-containing macromolecular structure model

InactiveCN106169016AImprove pollutionHarm reductionComputational theoretical chemistrySpecial data processing applicationsMicrowaveElemental analysis

The invention provides a construction method of a coking coal sulfur-containing macromolecular structure model. The method comprises the following steps that 1, elemental analysis is conducted on coking coal; 2, FTIR spectral analysis is conducted on the coking coal, functional groups in the coking coal structure are represented, and FTIR structural parameters are calculated; 3, XPS analysis characterization is conducted on the coking coal, and existing forms of major elements in the coking coal are analyzed; 4, fitting analysis is conducted on a coking coal <13>C-NMR spectrum, and structure parameters of the coking coal are obtained; 5, the coking coal sulfur-containing macromolecular structure model is constructed; 6, a model compound matched with sulfur structure morphology in the coking coal is screened on the basis of the coking coal sulfur-containing macromolecular structure model. According to the construction method of the coking coal sulfur-containing macromolecular structure model, the coking coal sulfur-containing macromolecular structure model can be accurately constructed, therefore, a theoretical basis is provided for screening the sulfur-containing model compound, and a theoretical basis is provided for carrying out microwave devulcanization research by replacing coal with the model compound.

Owner:ANHUI UNIV OF SCI & TECH

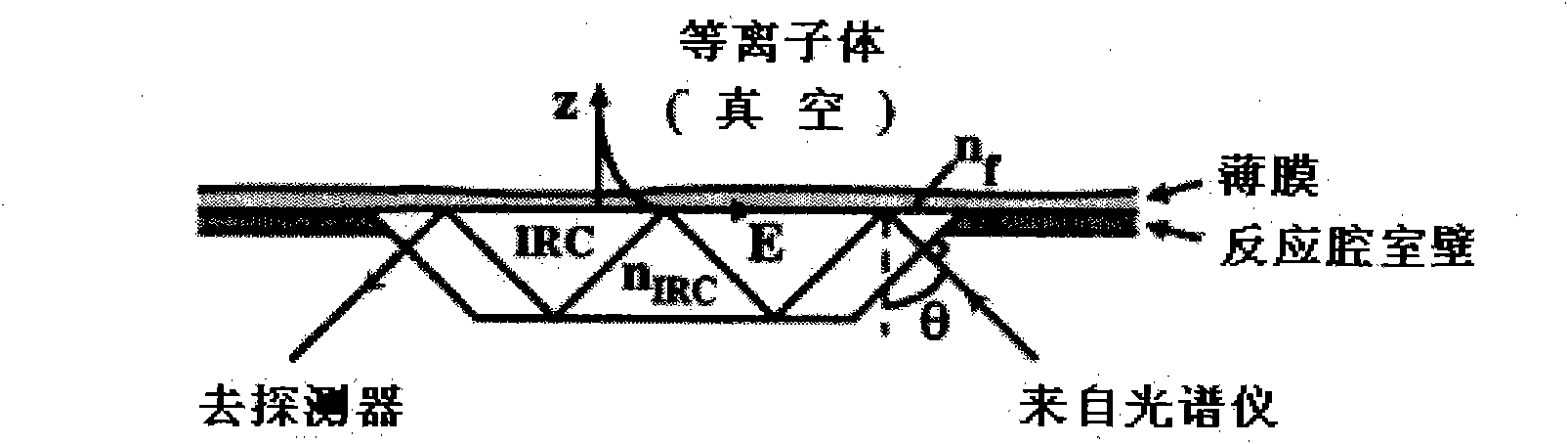

FTIR spectrum monitoring based internal state maintenance method of plasma etcher

ActiveCN101958232ATimely maintenancePrecise maintenanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingFast Fourier transformPlasma etcher

The invention provides an FTIR spectrum monitoring based internal state maintenance method of a plasma etcher. The outer wall of a reaction chamber of a plasma etcher is provided with a window for installing an internal reflection crystal. An ATR-FTIR spectrum probe is installed at one end of the window, and an infrared detector is installed at the other end of the window. After light rays emitted by the Fourier transform infrared spectrum probe are reflected many times in the internal reflection crystal, the light rays are emitted from the other end of the internal reflection crystal, and are focused on the infrared detector. An HgCdTe detector is connected with a spectrum processing system so as to obtain the Fourier transform infrared spectrum graph of the inner wall of the reaction chamber of the plasma etcher regularly or at real time. The Fourier transform infrared spectrum graph is used for measuring the components of attached polymers, and is compared with a standard Fourier transform infrared spectrum graph to determine whether the reaction chamber needs cleaning. If so, the reaction chamber of the plasma etcher is cleaned.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

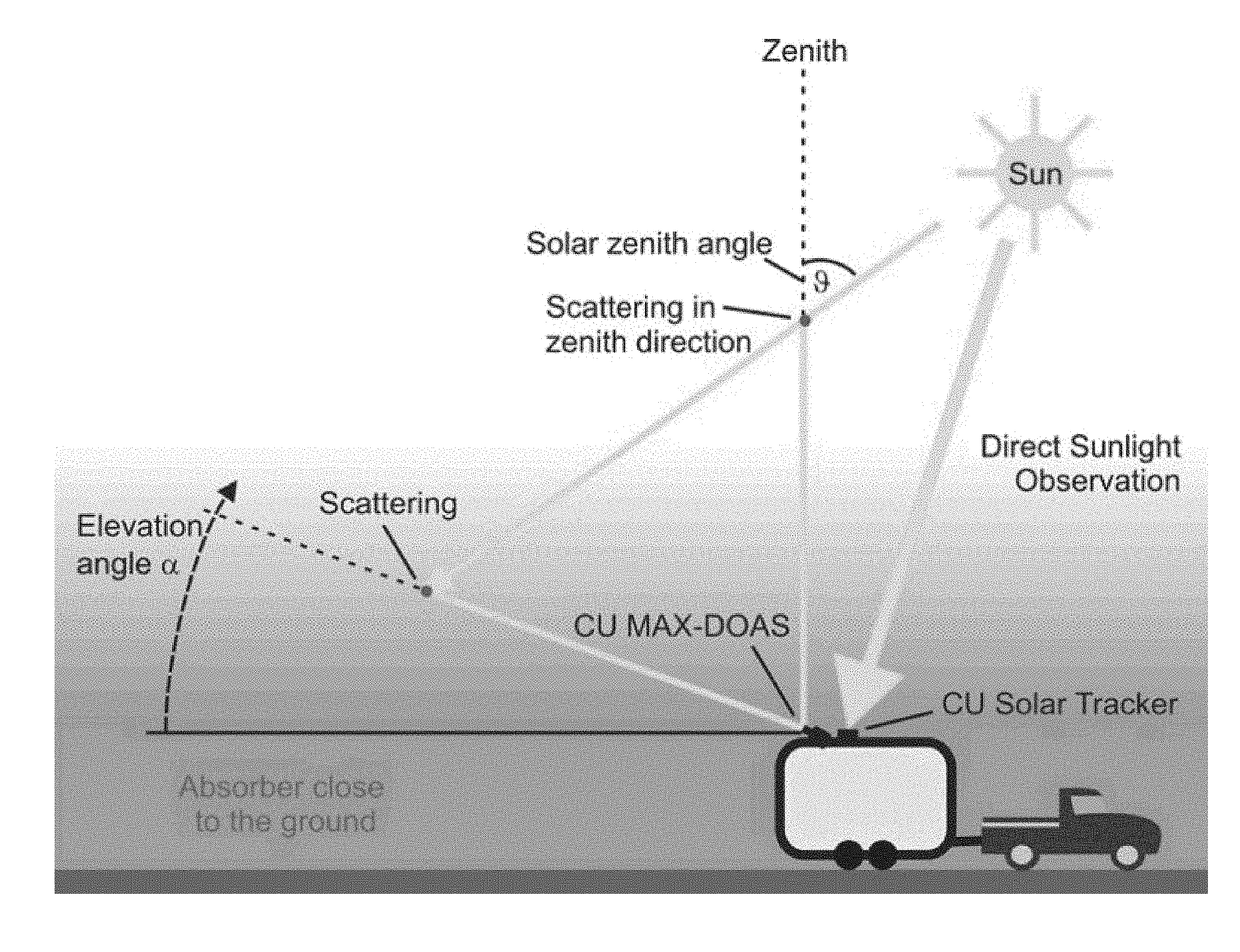

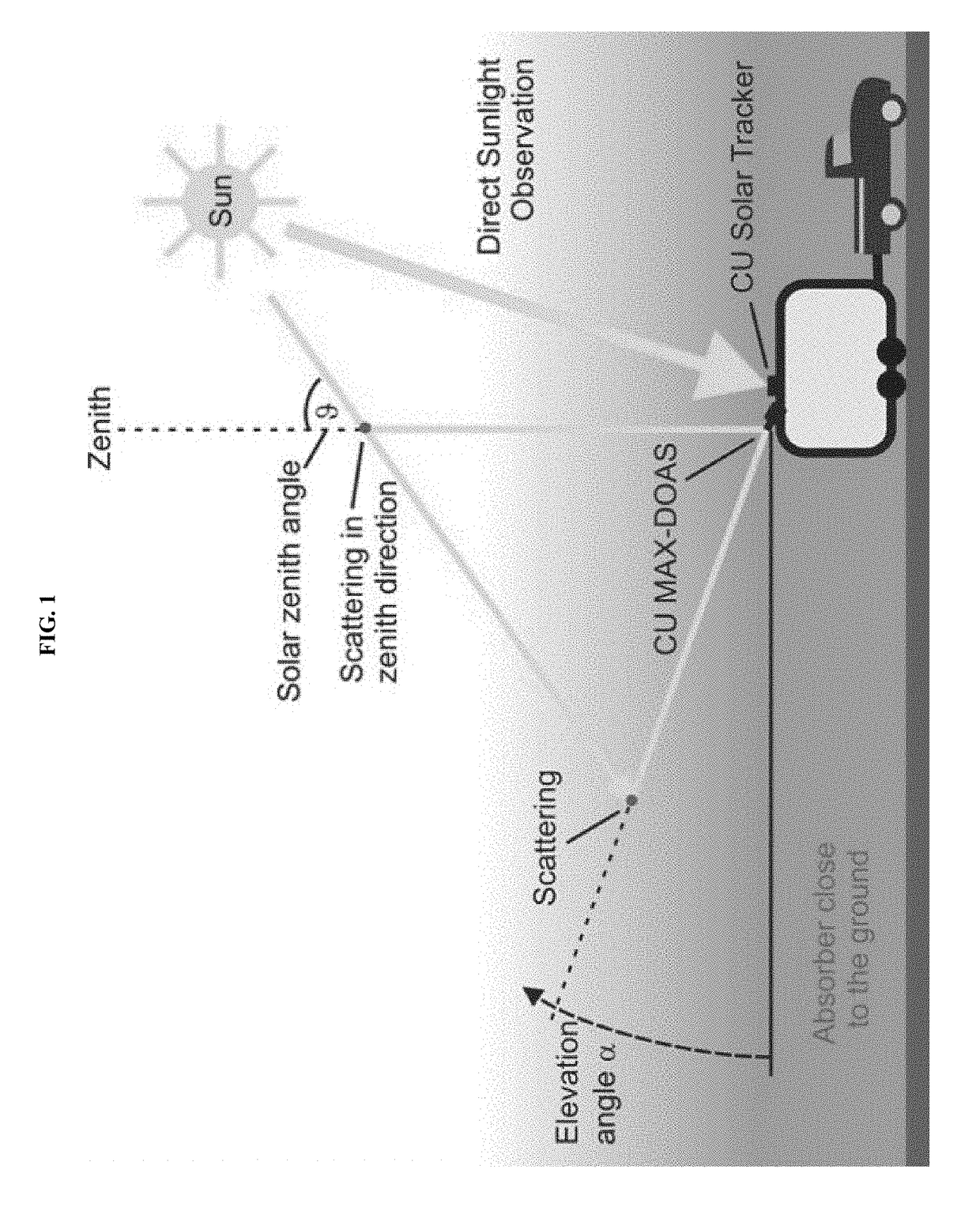

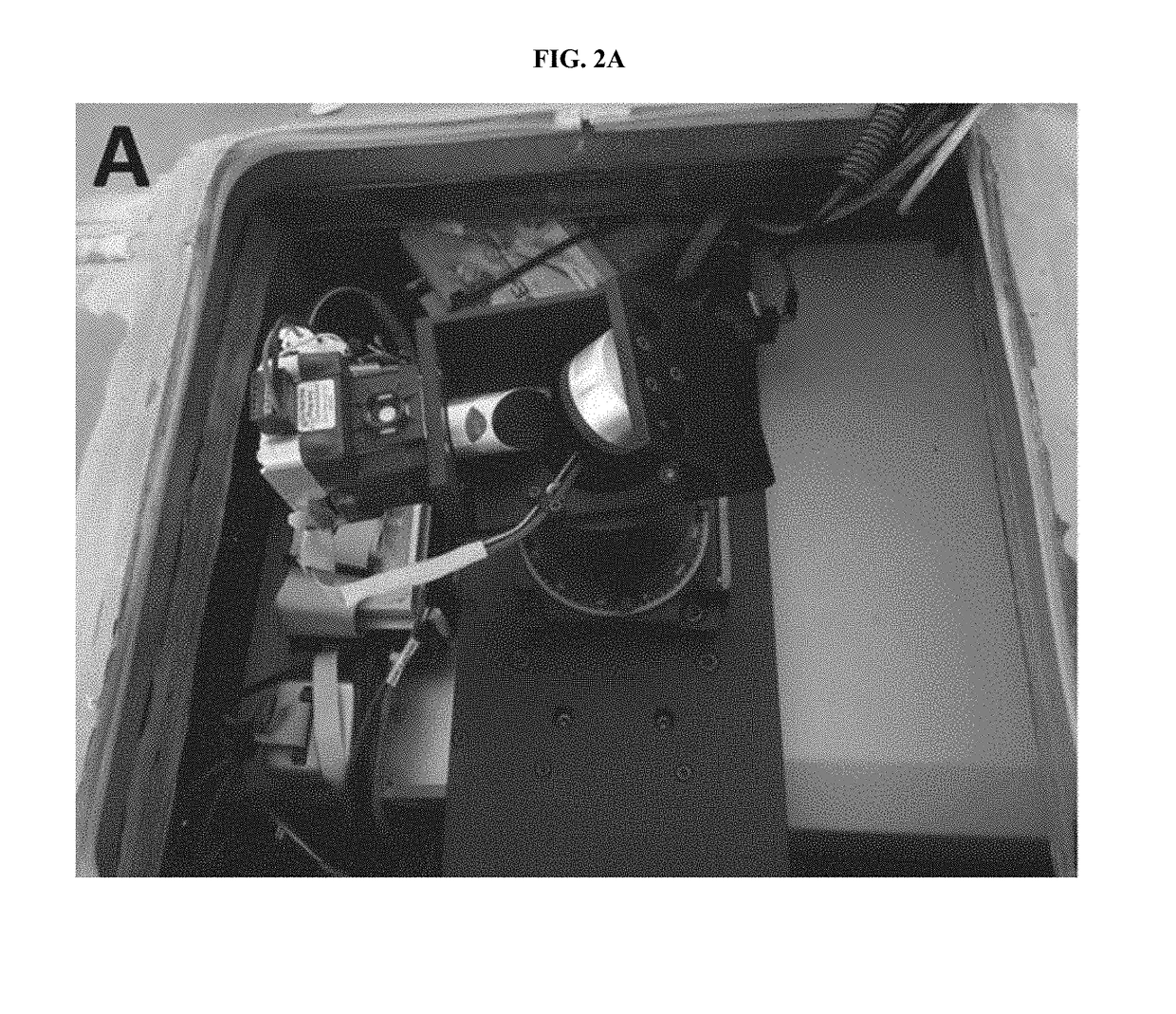

Mobile devices for tracking a radiation disk light source and methods using same

ActiveUS20180088204A1Optimize light source tracking precisionDirection/deviation determining electromagnetic systemsColor/spectral properties measurementsCamera lensOptoelectronics

The invention provides in one aspect a fast digital light source tracker aboard a moving ground-based or airborne platform. The tracker consists of two rotating mirrors, a lens, an imaging camera, and a motion compensation system that provides the Euler angles of the mobile platform in real time. The tracker can be simultaneously coupled to UV-Vis and FTIR spectrometers, making it a versatile tool to measure the absorption of trace gases using the light source's incoming radiation.

Owner:UNIV OF COLORADO THE REGENTS OF

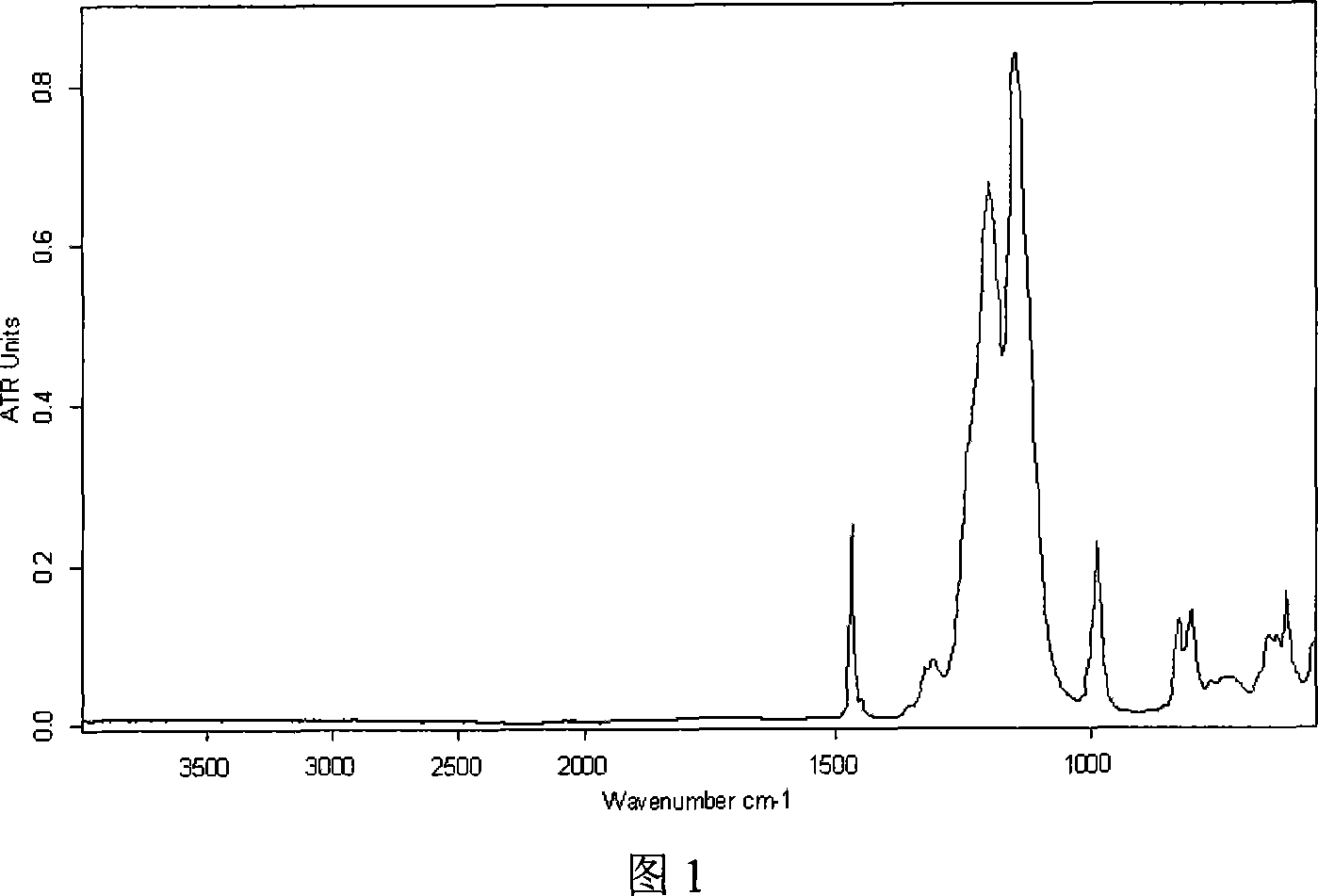

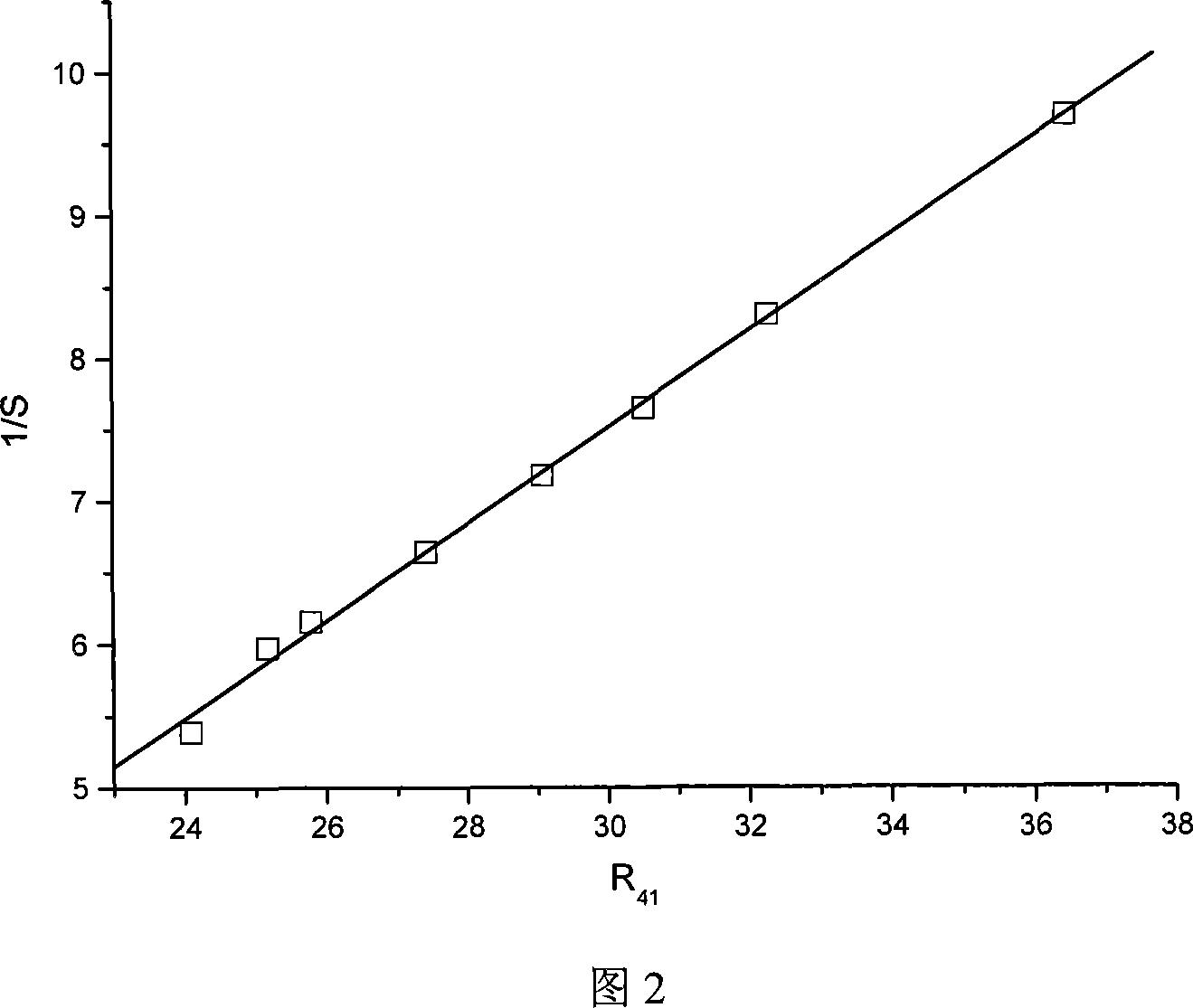

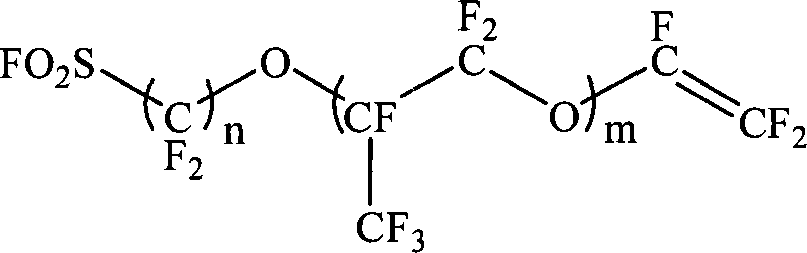

Method for measuring full fluorine sulphonyl resin and sulphonyl monomer content

InactiveCN101051024ATest accurateAccurate measurementAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsCarbon–fluorine bondUltimate tensile strength

A method for measuring sulphonyl monomer content of total fluosulphoylresin resin includes selecting total fluosulphonyl resin samples with different sulphonyl monomer contents, determining ATR-FTIR spectrum corresponding to each sample, selecting absorption spectrum band caused by sulphonyl monomer and carbon-fluorine bond from infrared spectrum as character absorption spectrum hand, setting up operation curve of absorption light intensity of said spectrum hand to sulphonyl monomer content, testing infrared spectrum of unknown sample to know sulphonyl monomer content based on obtained operation curve.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

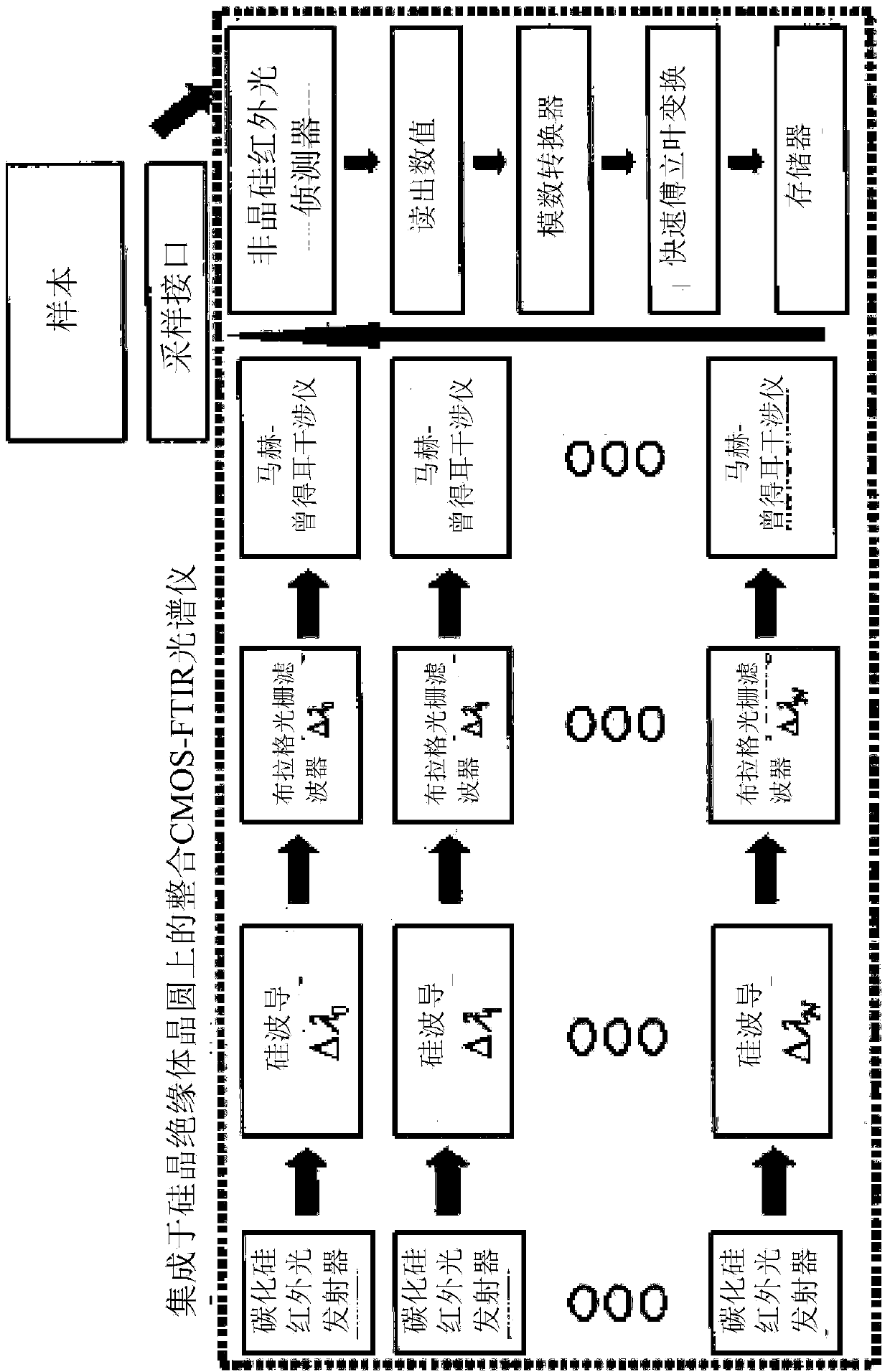

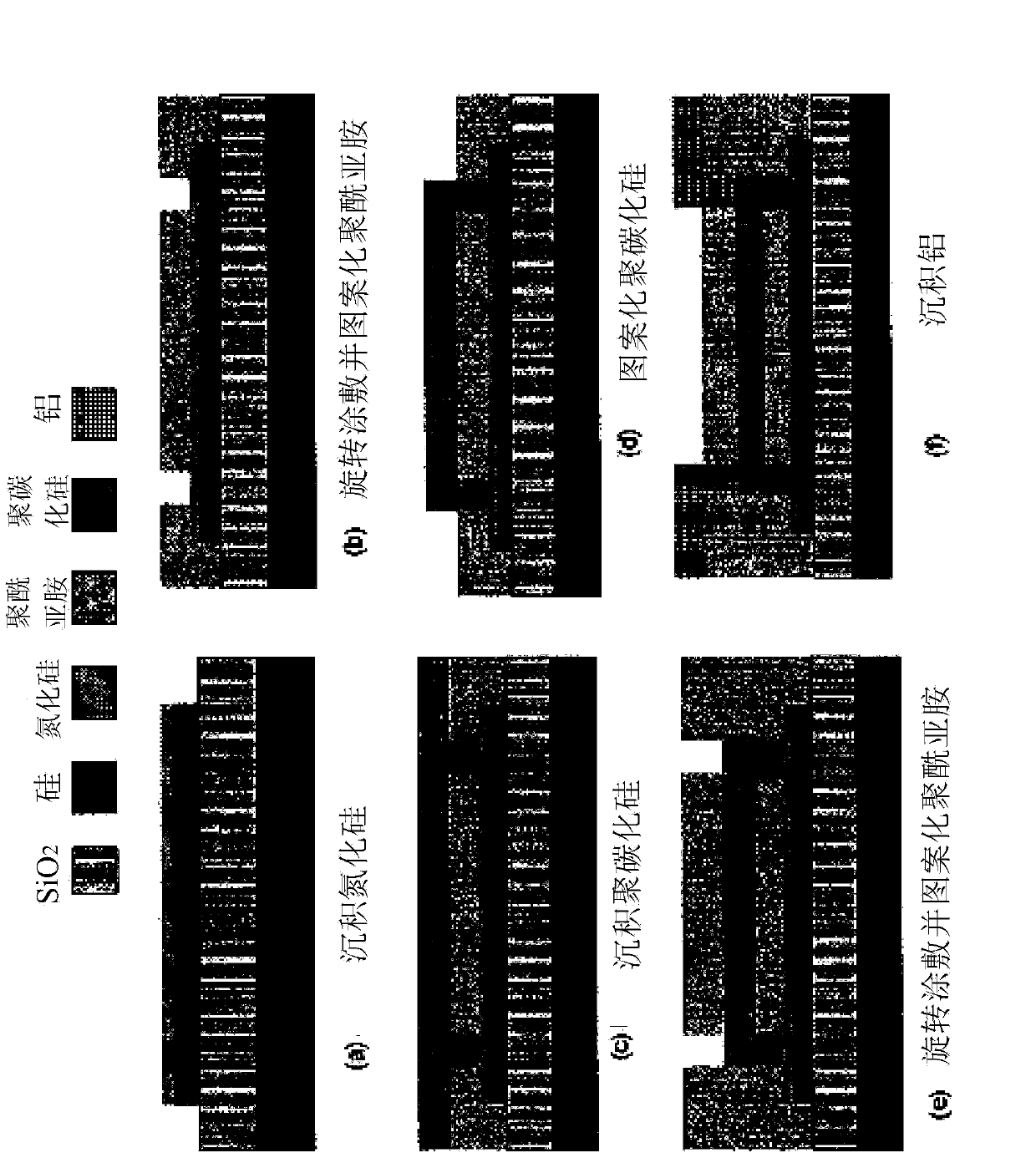

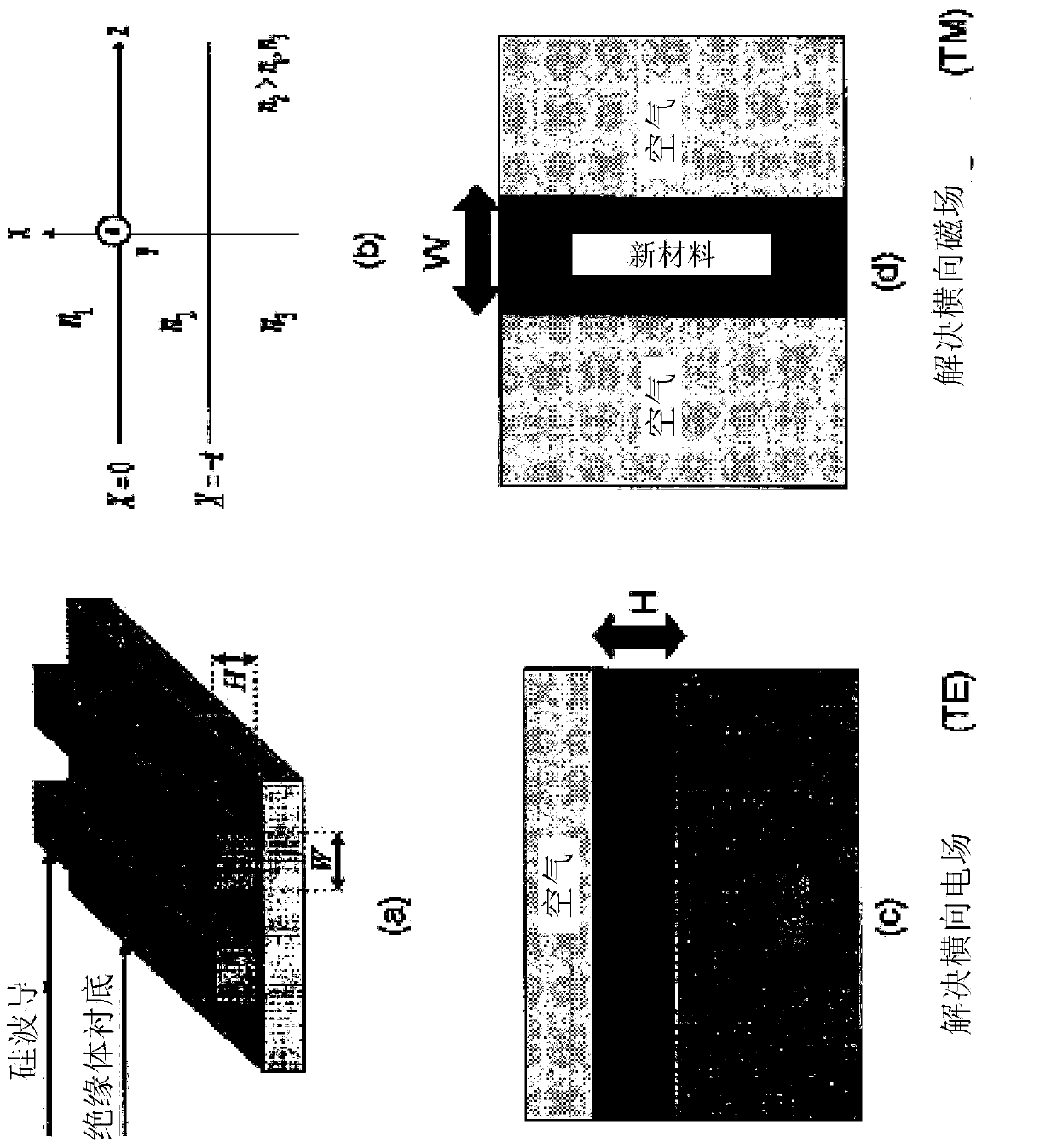

A fully integrated complementary metal oxide semiconductor (CMOS) fourier transform infrared (FTIR) spectrometer and raman spectrometer and method thereof

Owner:LUXMUX TECH CORP

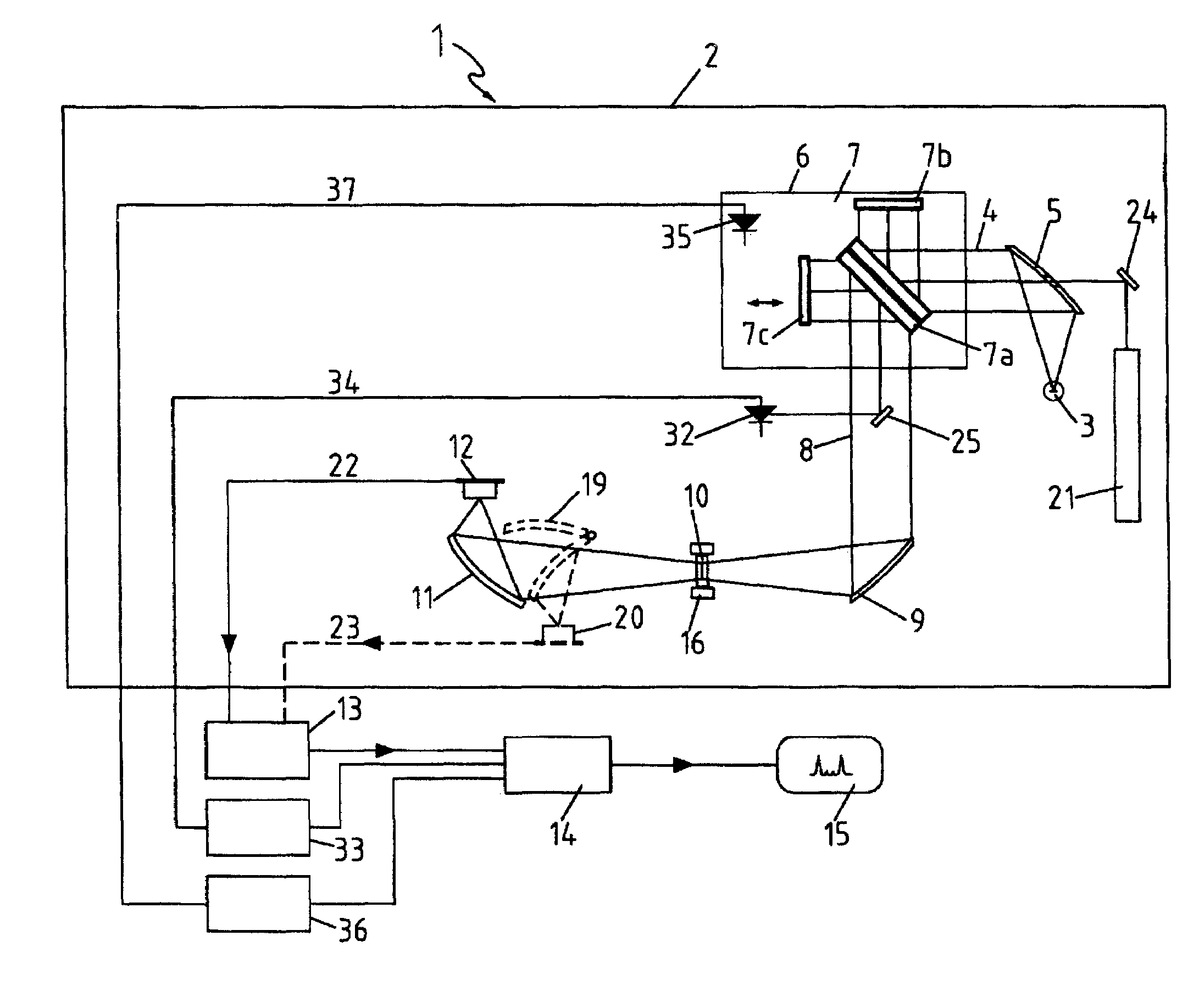

Method for operating an FTIR spectrometer, and FTIR spectrometer

InactiveCN101918814AAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsCalibration gasGas composition

Owner:ABB (SCHWEIZ) AG

Digital FTIR spectrometer

InactiveUS7034944B2Analogue distanceReduce sensitivityRadiation pyrometryInterferometric spectrometrySingle elementLight beam

The present invention relates to an FTIR spectrometer comprising a single-element detector to analyze a detector light beam emitted by a sample, with a unit to digitize the voltage available at the detector output and with a unit to process the digitized voltage. The single-element detector and the dedicated unit to digitize the detector voltage are located immediately adjacent to each other.

Owner:BRUKER OPTICS GMBH & CO KG

Method for cleaning wind turbine blades

ActiveUS20130133199A1Efficient and effectiveEasy to detectHollow article cleaningMachines/enginesTurbine bladeSpectroscopy

A fast and effective method for cleaning and repairing the shell-spar glue voids of a wind turbine blade, comprising the steps of detecting voids, raising the turbine blade at an incline, drilling holes into top and bottom ends of the void, injecting cleaning solution into the holes, and allowing the cleaning solution to drain out of the bottom holes and drain holes at the tip. The void is then inspected for oil by FTIR spectroscopy. If oil is detected, additional cleaning steps are performed comprising injection of a second cleaning solution into at least two holes of the void followed by a rest period, washing the holes with water via a pressure washer, and drying with compressed air. The blade is then inspected for oil and moisture, and when clean, adhesive is applied to the void through the holes.

Owner:GAMESA INNOVATION & TECH SA

Fuel additives for treating internal deposits of fuel injectors

InactiveUS8852297B2Reduce the amount requiredEasy to cleanInternal combustion piston enginesEngine operationsHydrogenDicarboxylic acid

A method cleaning up internal components of a fuel injector for a diesel engine. The method includes operating a fuel injected diesel engine on a fuel composition that includes a major amount of diesel fuel and from about 5 to about 500 ppm by weight of a reaction product derived from (a) a hydrocarbyl substituted dicarboxylic acid, anhydride, or ester and (b) an amine compound or salt thereof of the formulawherein R is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product is characterized by a particular FTIR spectrum.

Owner:AFTON CHEMICAL

Isocyanate trimerization catalyst system, precursor formulation, method for trimerizing isocyanate, rigid polyisocyanurate/polyurethane foam prepared therefrom, and method for preparing such foam

Owner:DOW GLOBAL TECH LLC

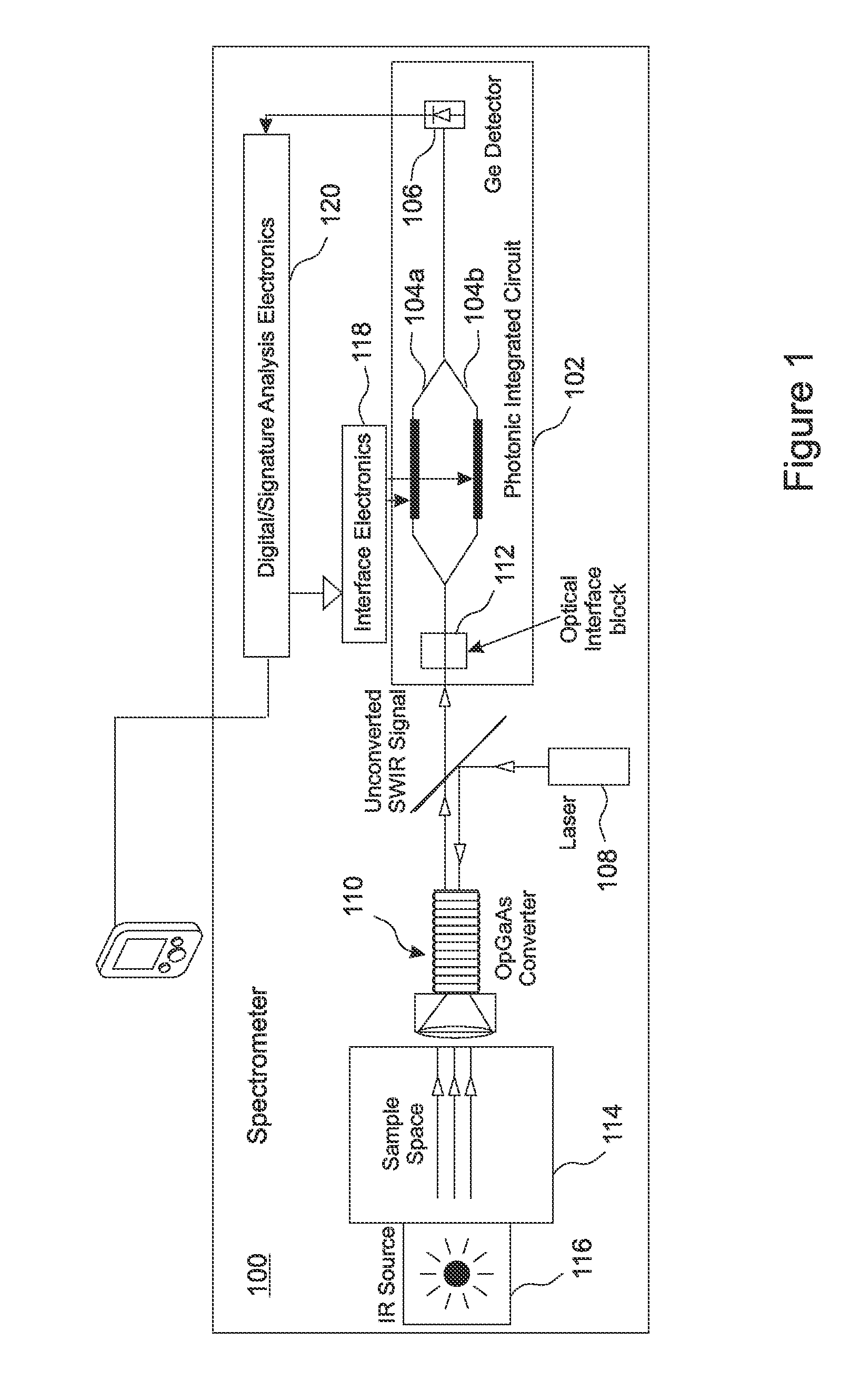

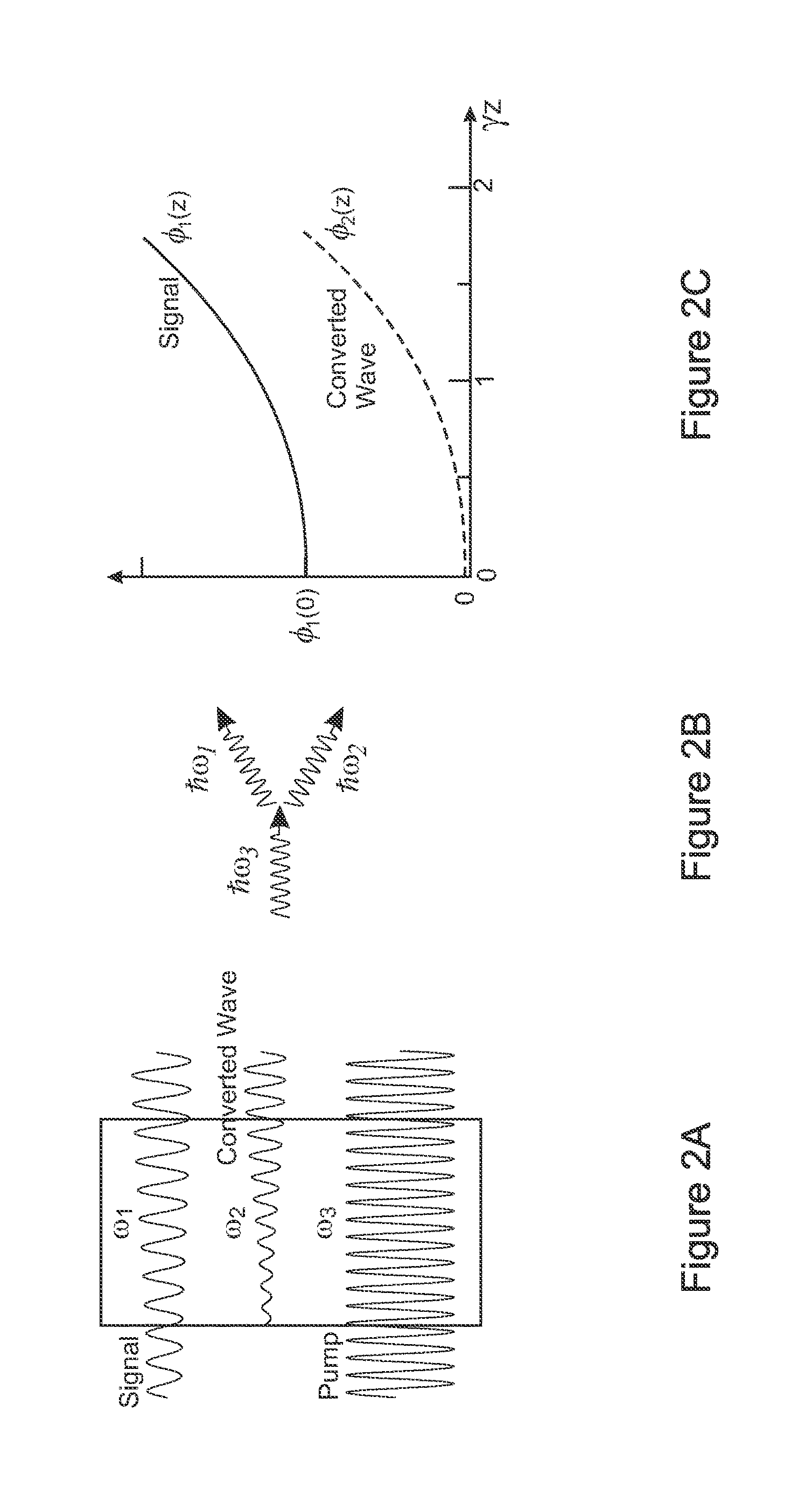

Solid state wideband fourier transform infrared spectrometer

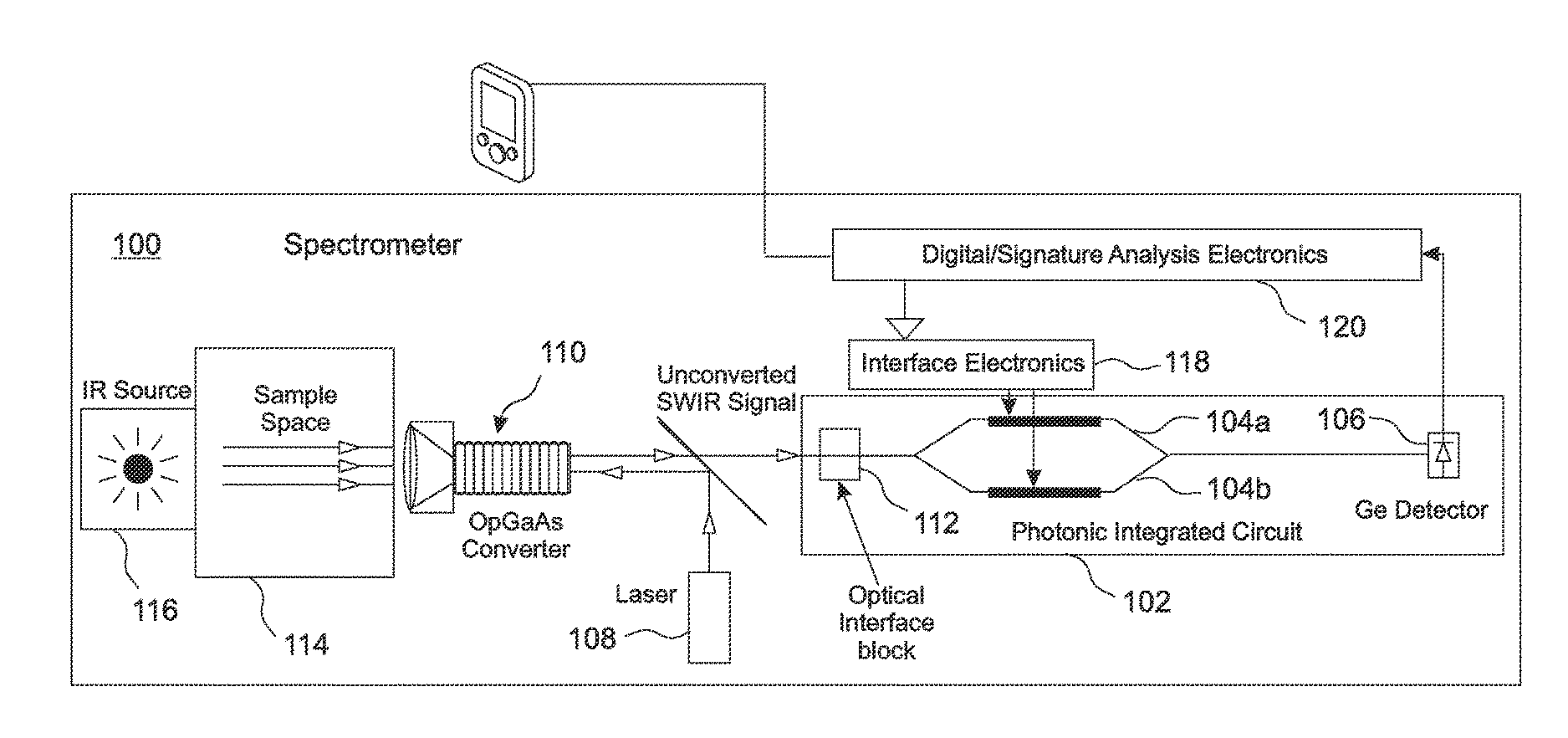

ActiveUS20160377482A1Low costSimple packagingRadiation pyrometryMaterial analysis by optical meansMach–Zehnder interferometerWaveguide

A compact, low cost FTIR spectrometer with no moving parts includes an interferometer having optical paths through silicon waveguides. The optical path lengths are varied by changing the temperature and / or carrier density of at least one of the waveguides. In embodiments, the interferometer is a Mach-Zehnder interferometer. Embodiments vary both optical path lengths in opposite directions. In embodiments, a germanium or InGaAs IR detector is grown on the same wafer as the waveguides. Embodiments include a laser pump, such as a COT CW diode laser, and wavelength mixer, such as an OPGaAs or OPGaP converter, for up and / or down converting measured IR wavelengths into a range compatible with the waveguide and detector materials. The wavelength mixer can be a waveguide. Embodiments include a sample compartment and an IR source such as a glowbar. In embodiments, the sample compartment can be exposed to ambient atmosphere for analysis of gases contained therein.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com