Patents

Literature

300results about How to "Simple packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

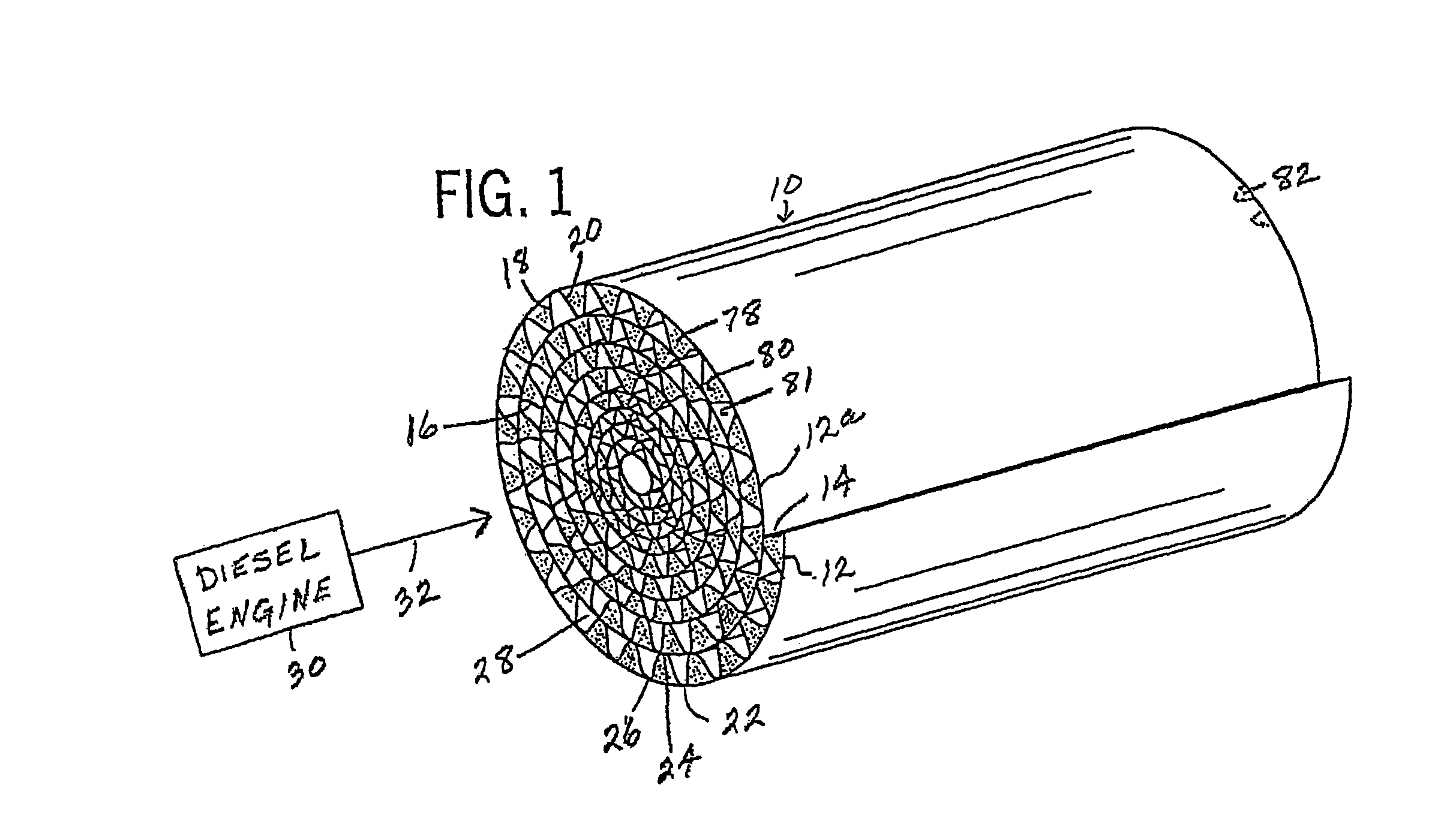

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

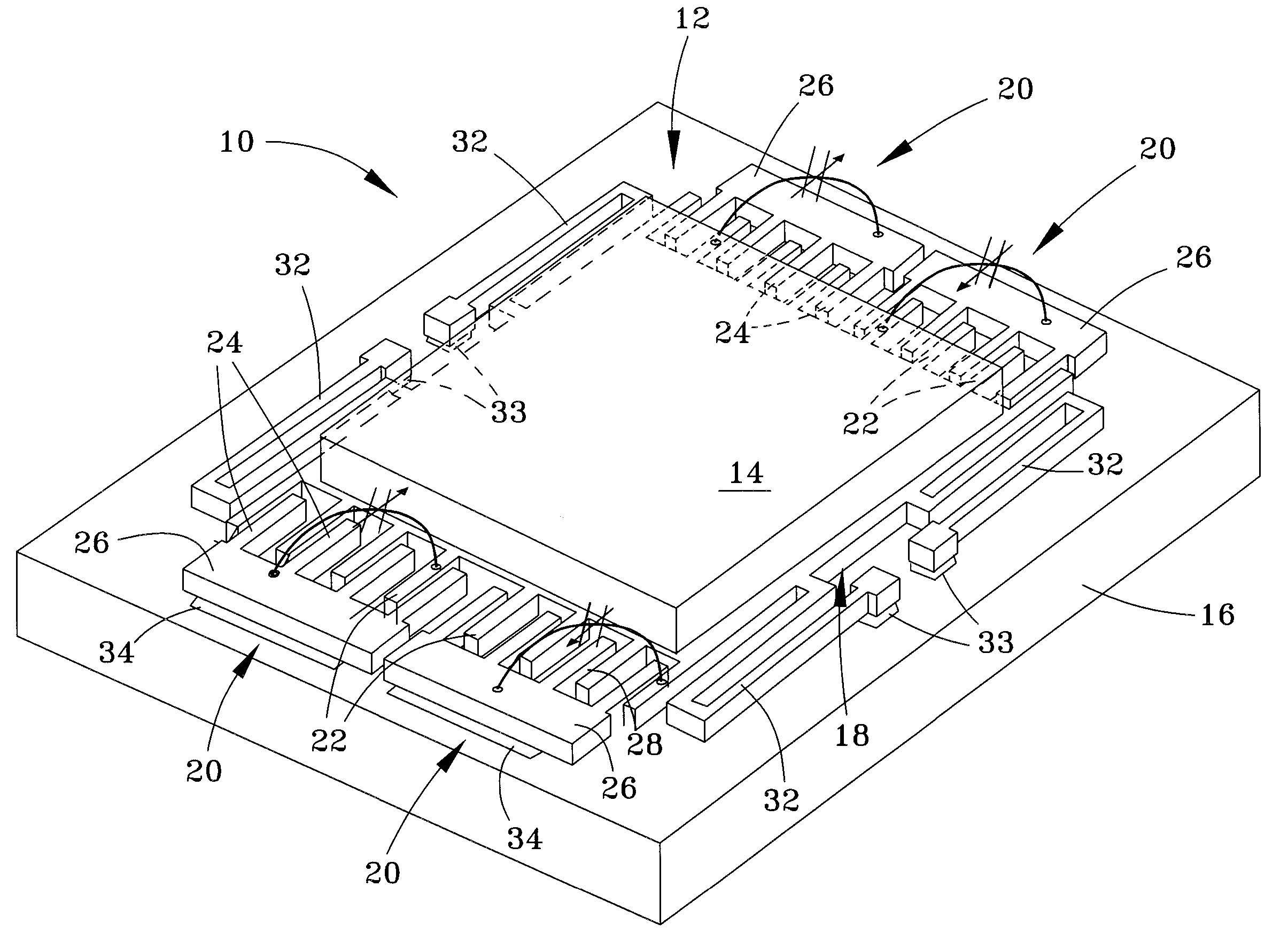

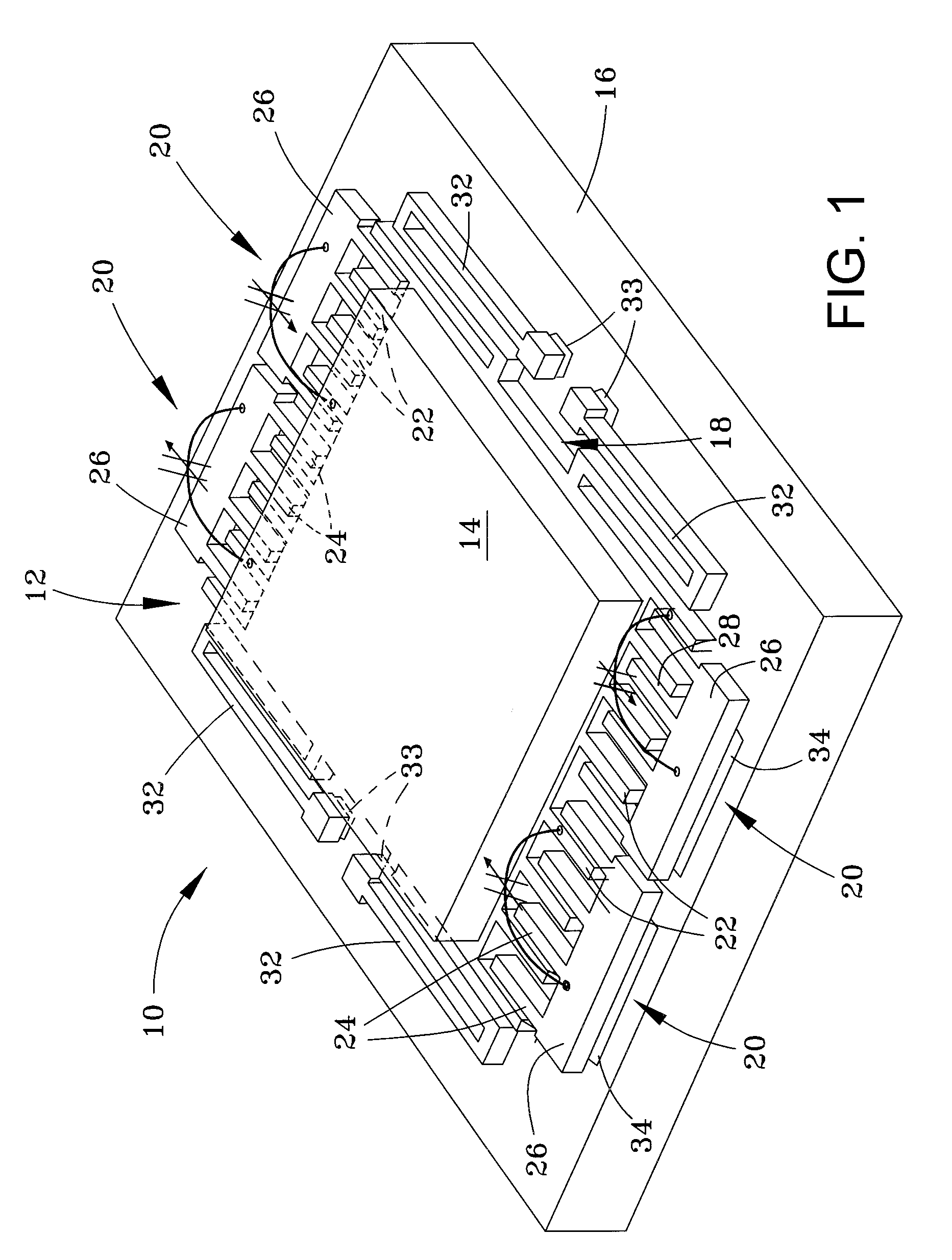

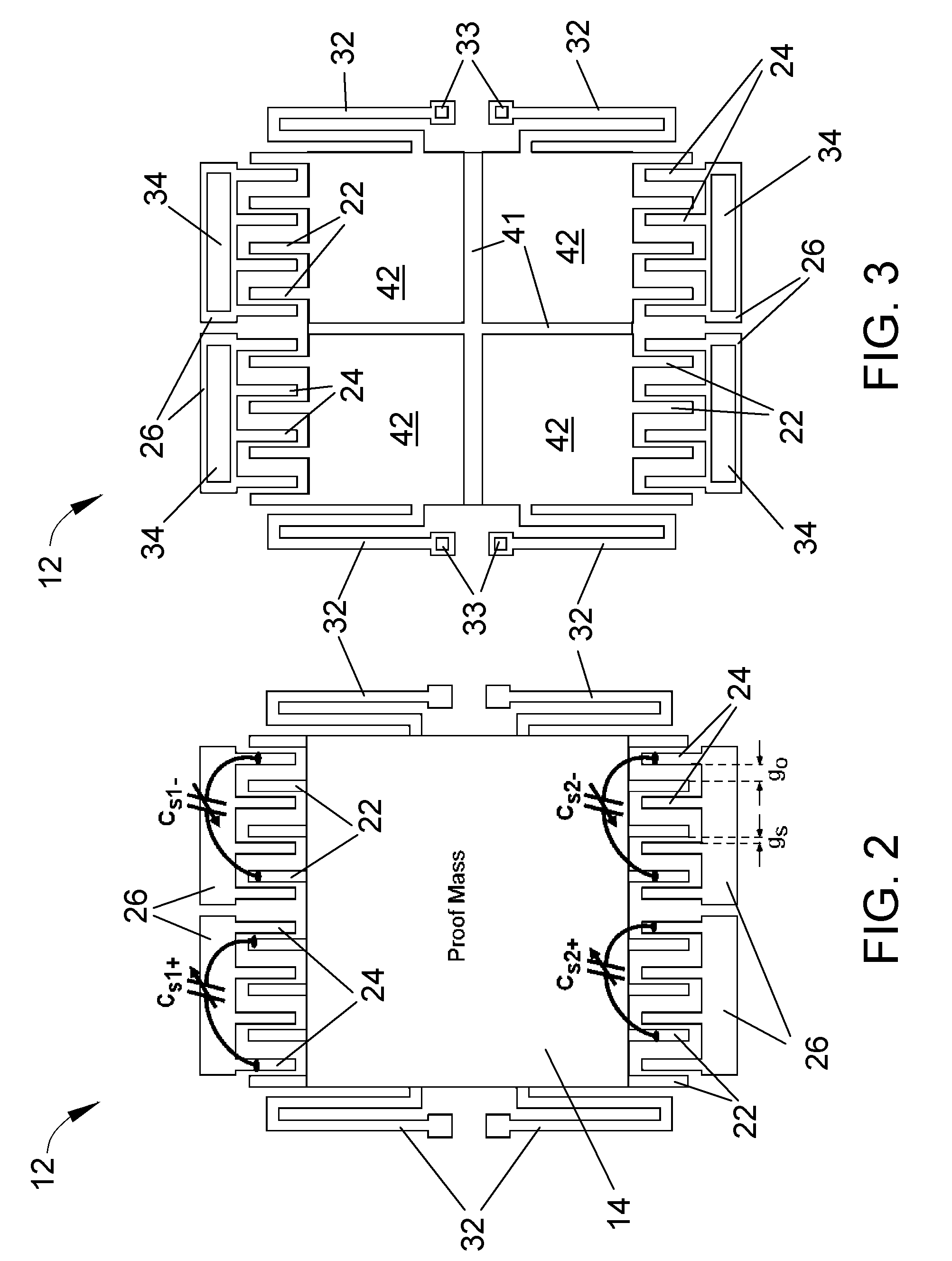

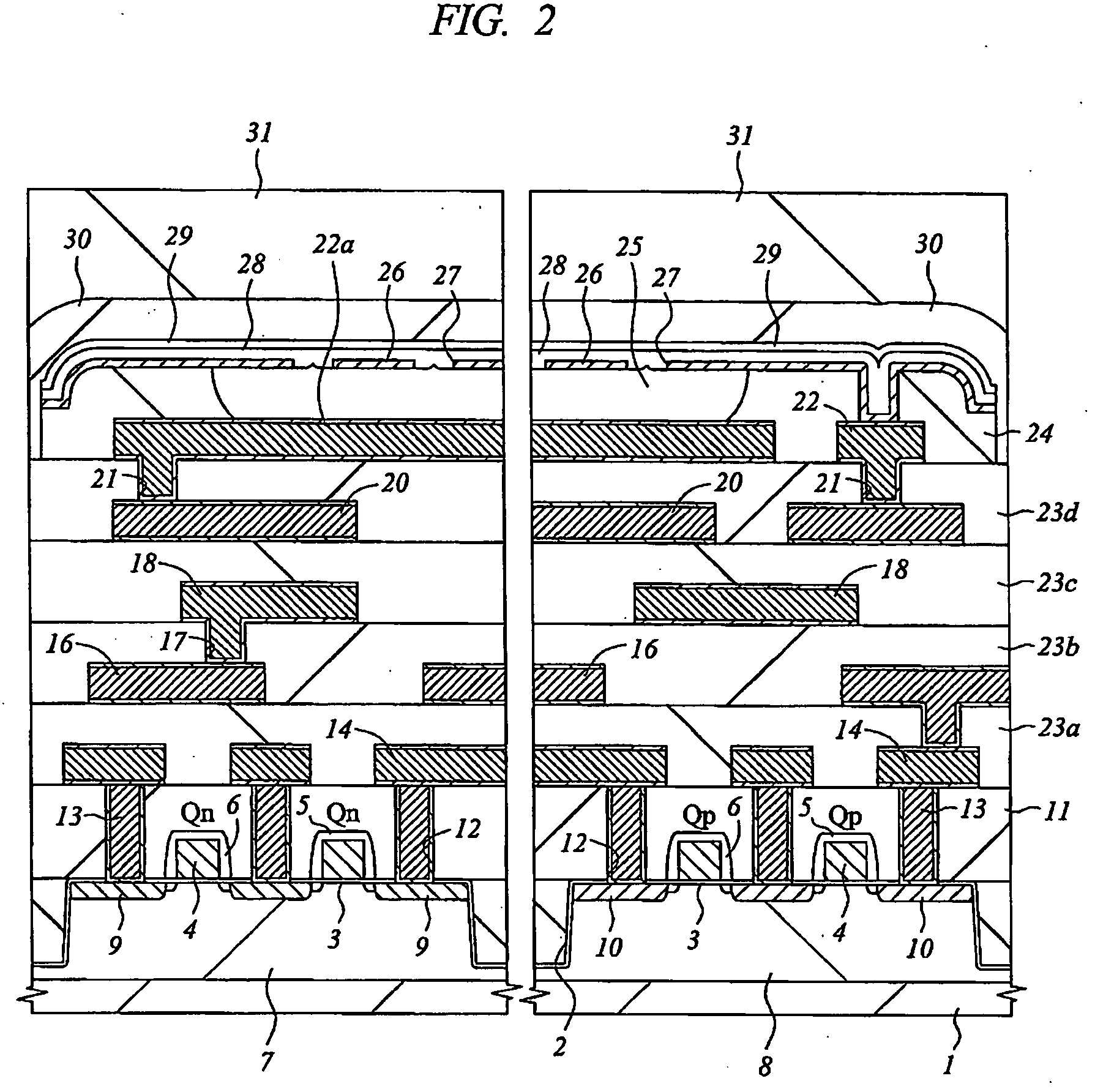

Integrated sensor and circuitry and process therefor

ActiveUS20070029629A1Large mechanical sensitivityReduce input parasiticsSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceFull bridge

A micromachined sensor and a process for fabrication and vertical integration of a sensor and circuitry at wafer-level. The process entails processing a first wafer to incompletely define a sensing structure in a first surface thereof, processing a second wafer to define circuitry on a surface thereof, bonding the first and second wafers together, and then etching the first wafer to complete the sensing structure, including the release of a member relative to the second wafer. The first wafer is preferably a silicon-on-insulator (SOI) wafer, and the sensing structure preferably includes a member containing conductive and insulator layers of the SOI wafer. Sets of capacitively coupled elements are preferably formed from a first of the conductive layers to define a symmetric capacitive full-bridge structure.

Owner:MICRO INERTIAL LLC

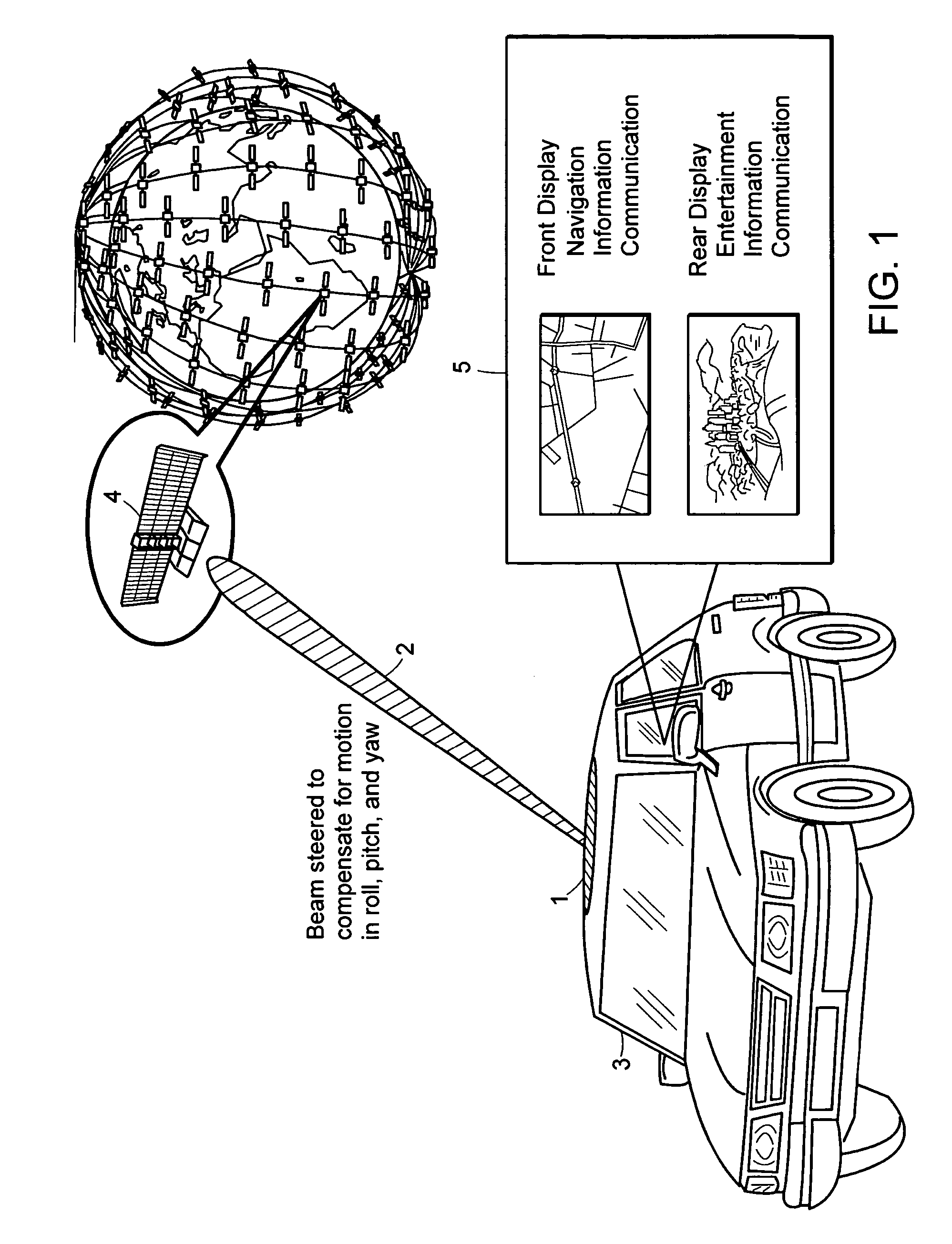

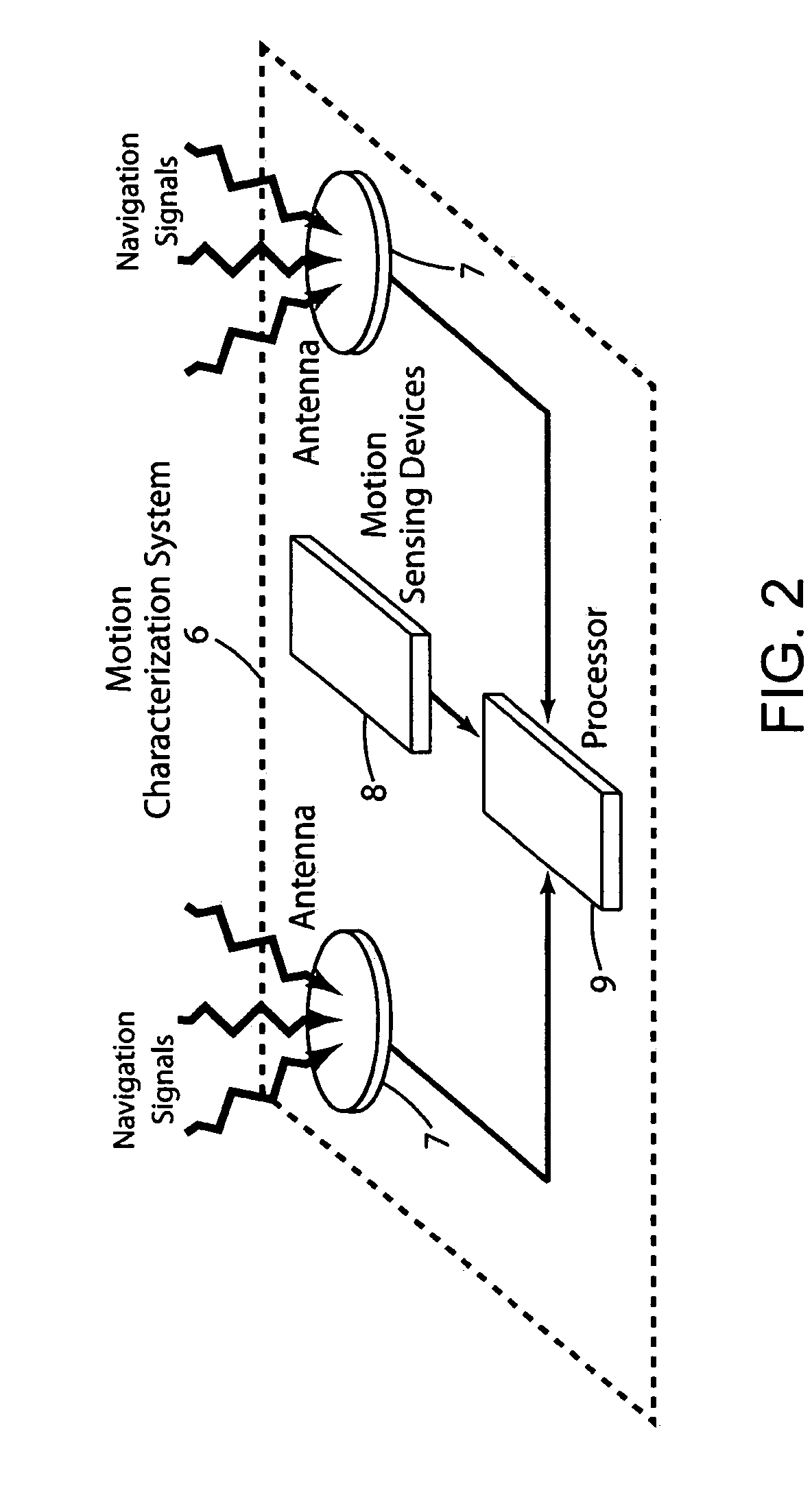

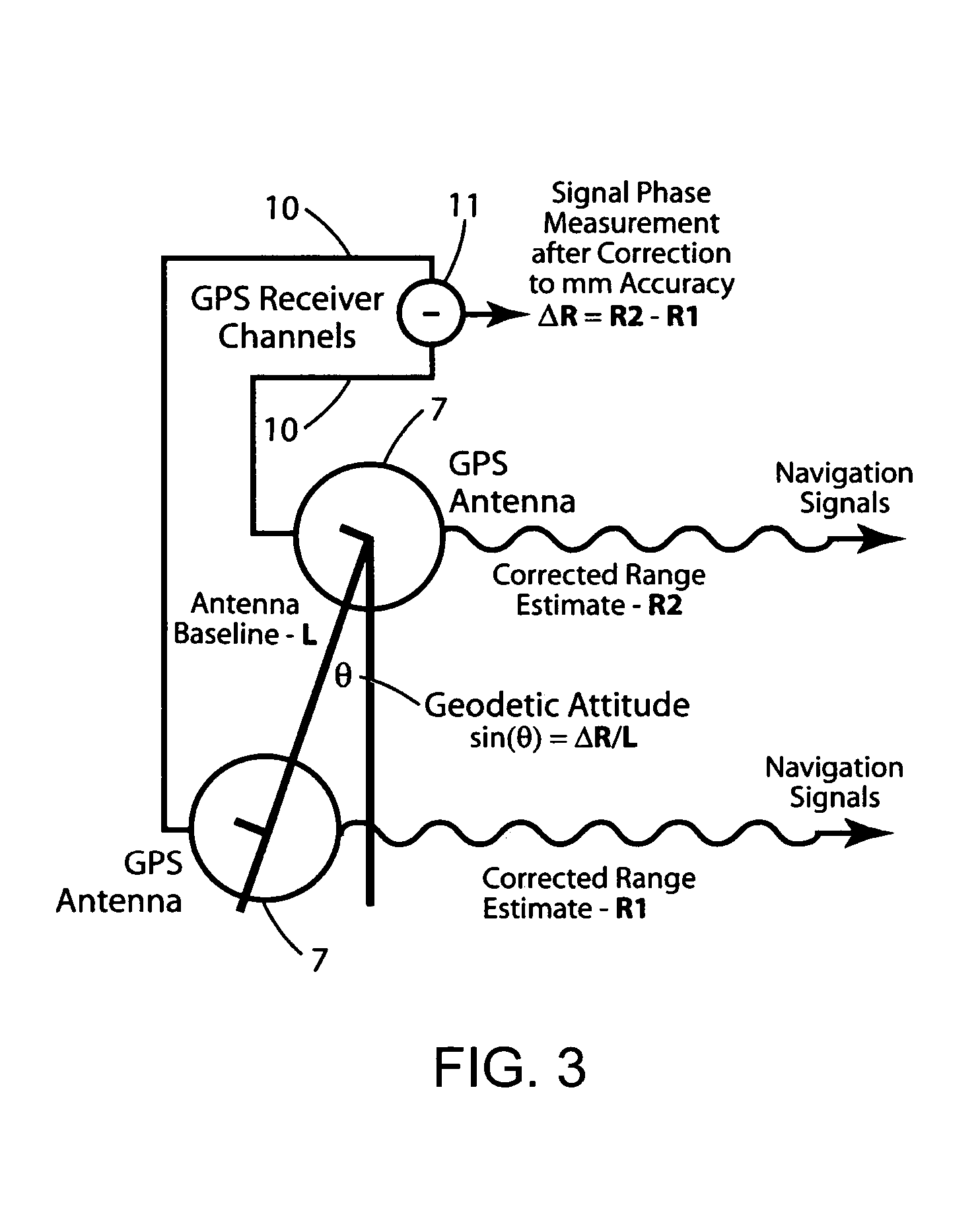

Attitude measurement using a GPS receiver with two closely-spaced antennas

InactiveUS7136751B2Low costCost advantageDigital data processing detailsAnimal undercarriagesAccelerometerAmbiguity

A system determines three-dimensional attitude of a moving platform using signals from two closely spaced Global Positioning System (GPS) antennas. The system includes three rate gyroscopes and three accelerometers rigidly mounted in a fixed relationship to the platform to aid in determining the attitude. The system applies signals from one of the two GPS antennas to sufficient channels of a GPS receiver to support navigation. The system applies signals from a second of the two GPS antennas to the additional receive channels to support interferometry. The system resolves the ambiguity normally associated with the interferometric heading solution by having closely spaced GPS antennas, and uses interferometry to refine a coarse heading estimate from a GPS plus Inertial Measurement Unit (IMU) transfer alignment solution. The system achieves sub-meter spacing of the two GPS antennas by merging many temporal interferometric measurements and the attitude memory provided by the IMU time-history solution.

Owner:ENPOINT

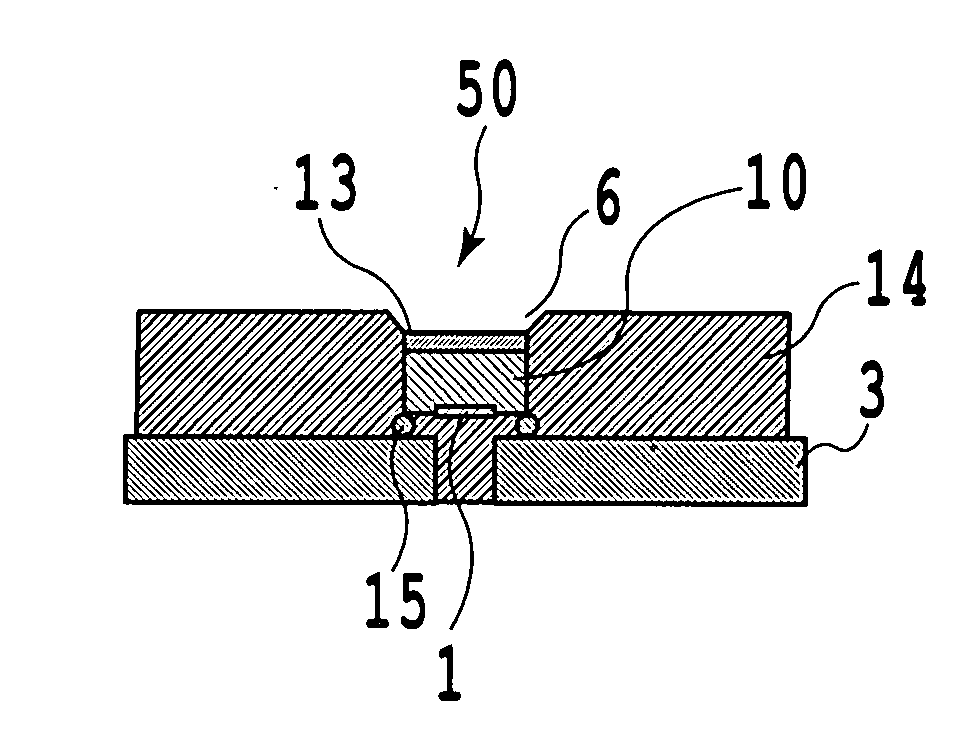

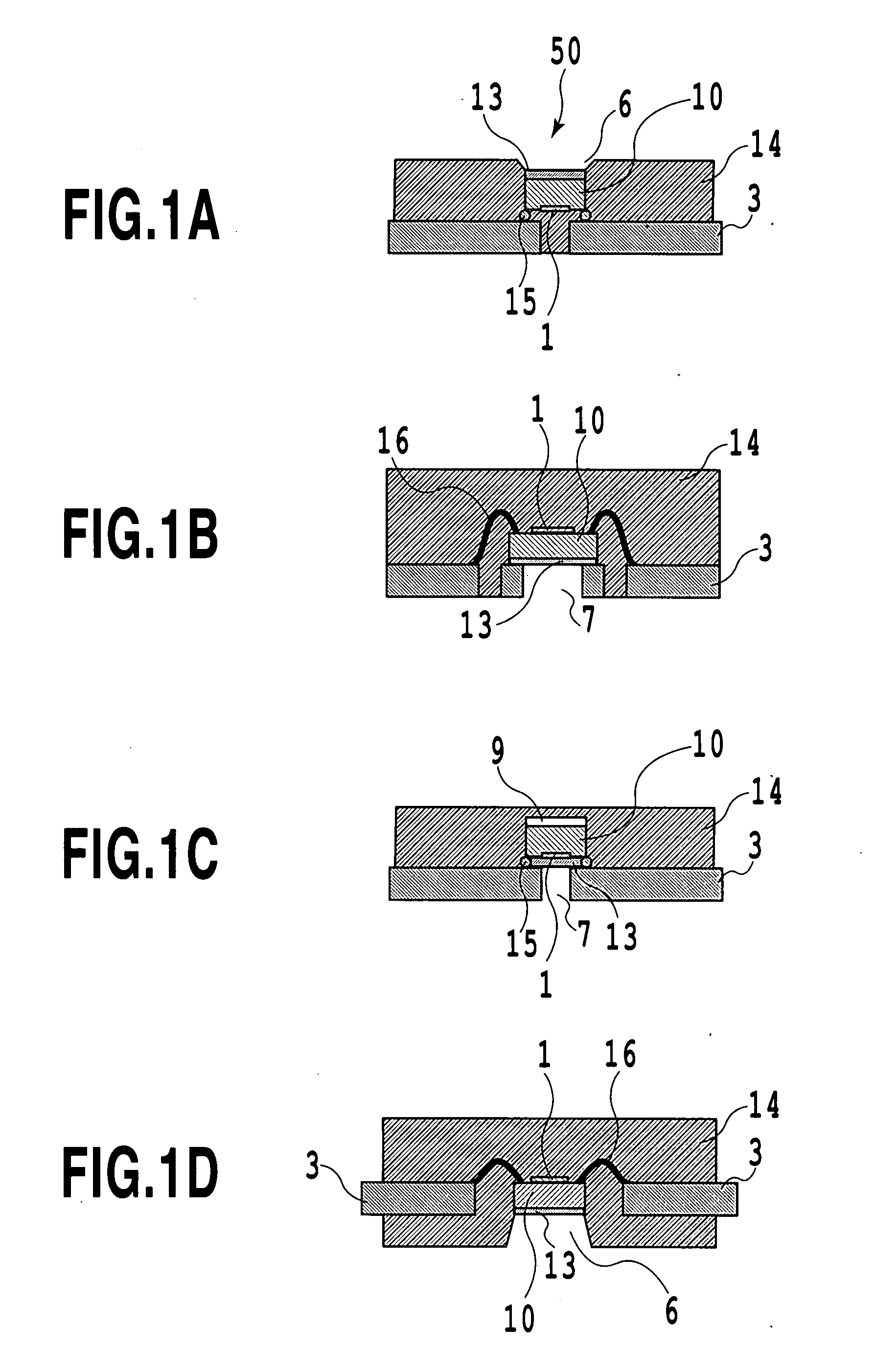

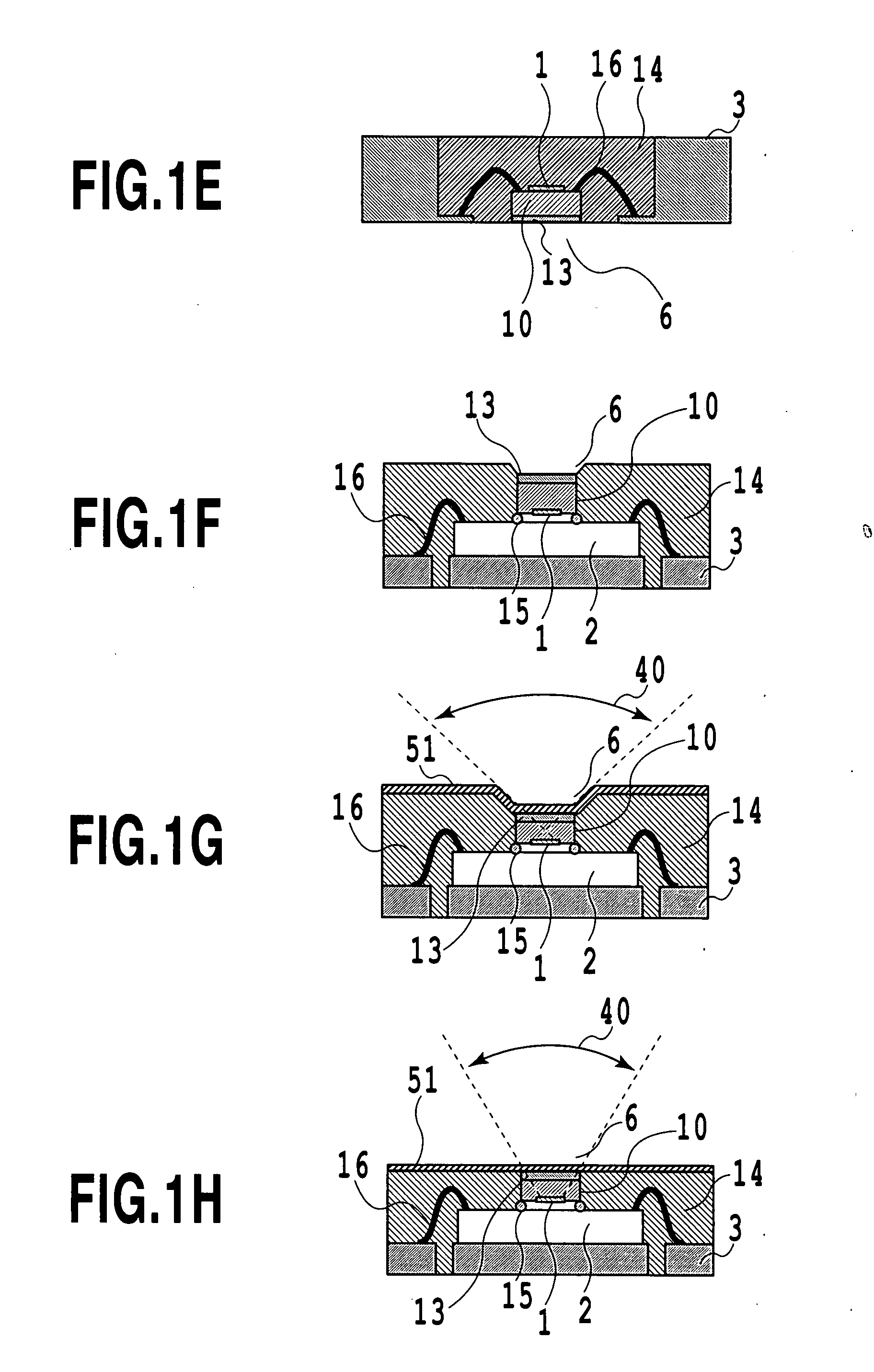

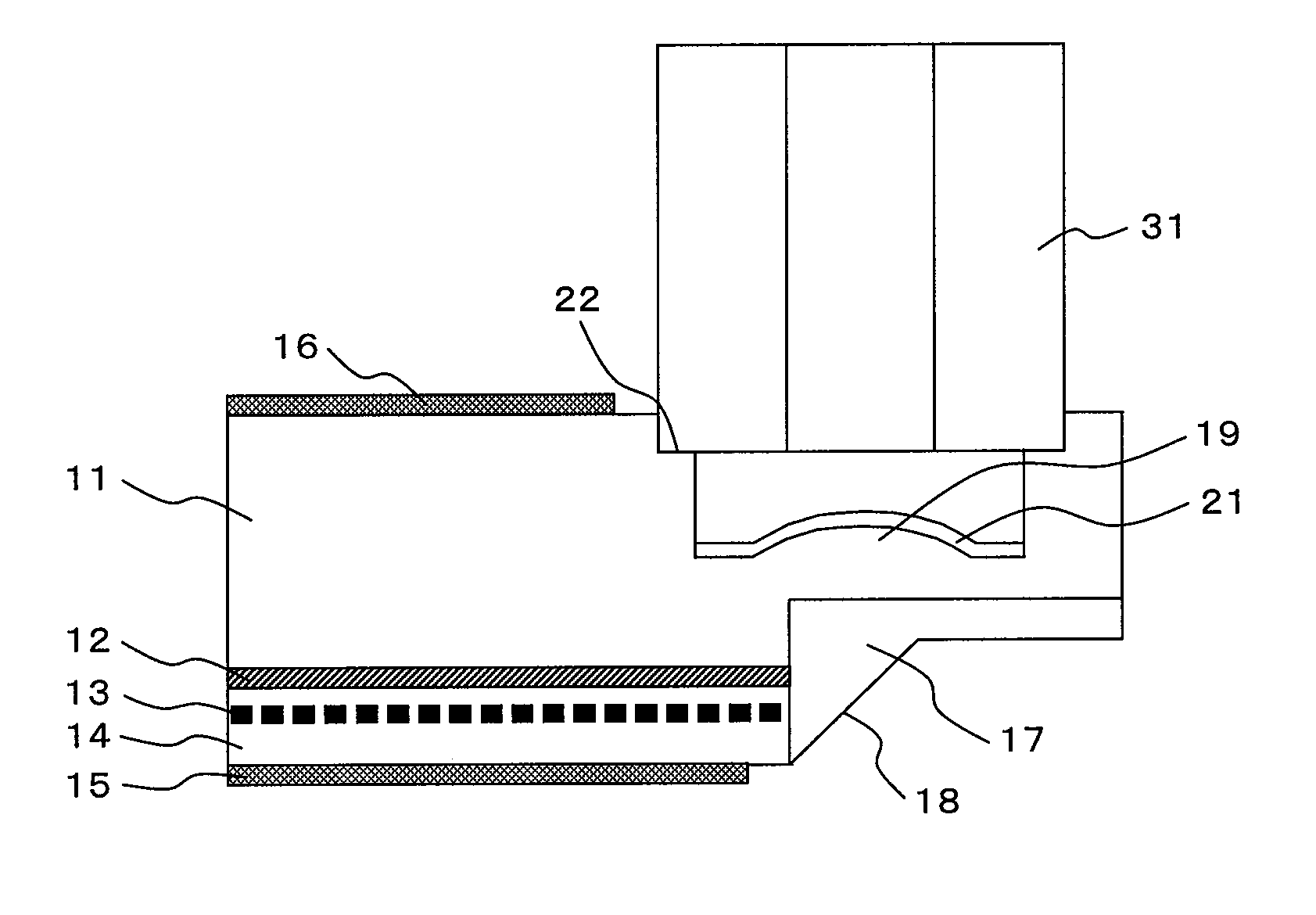

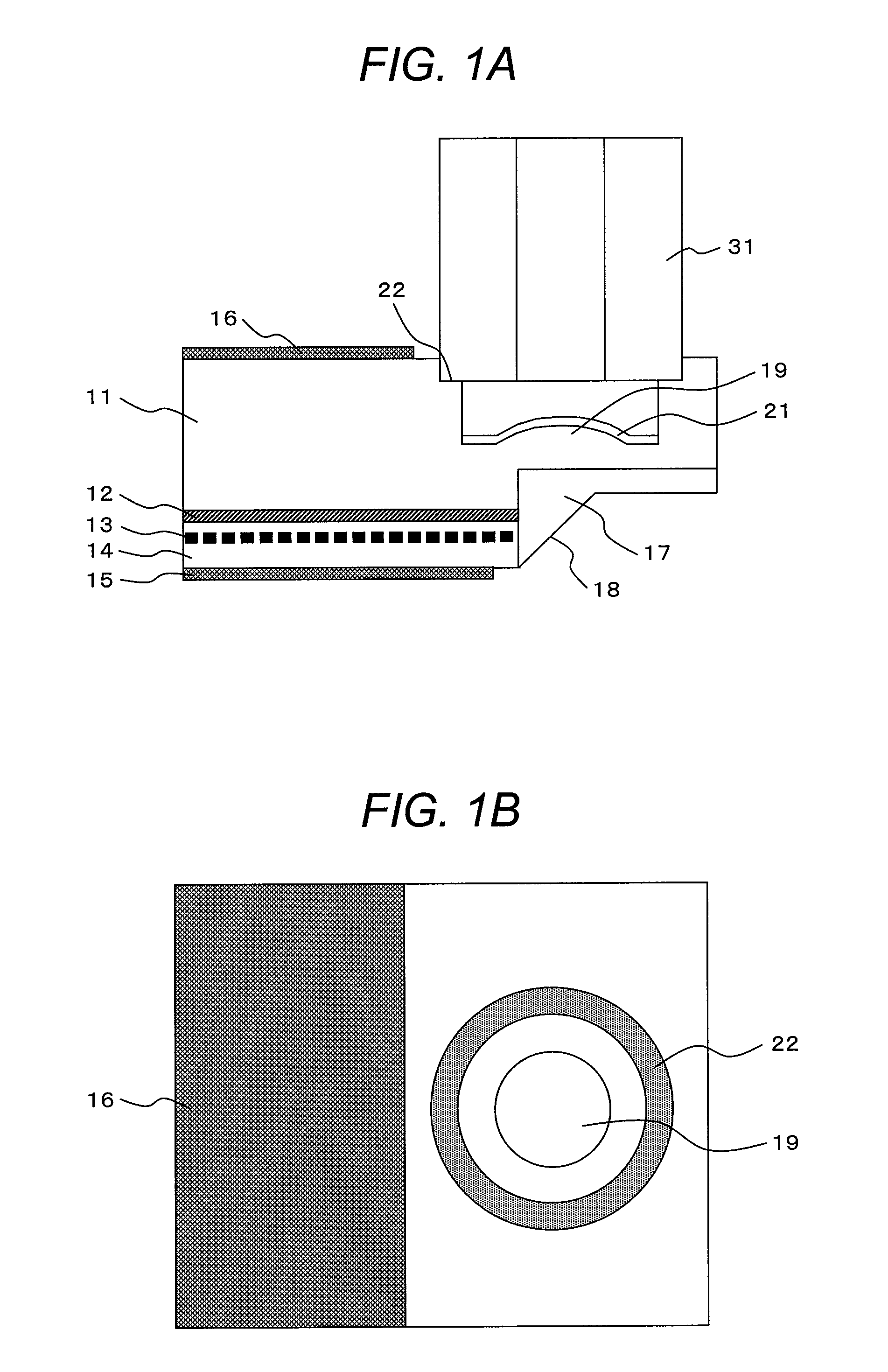

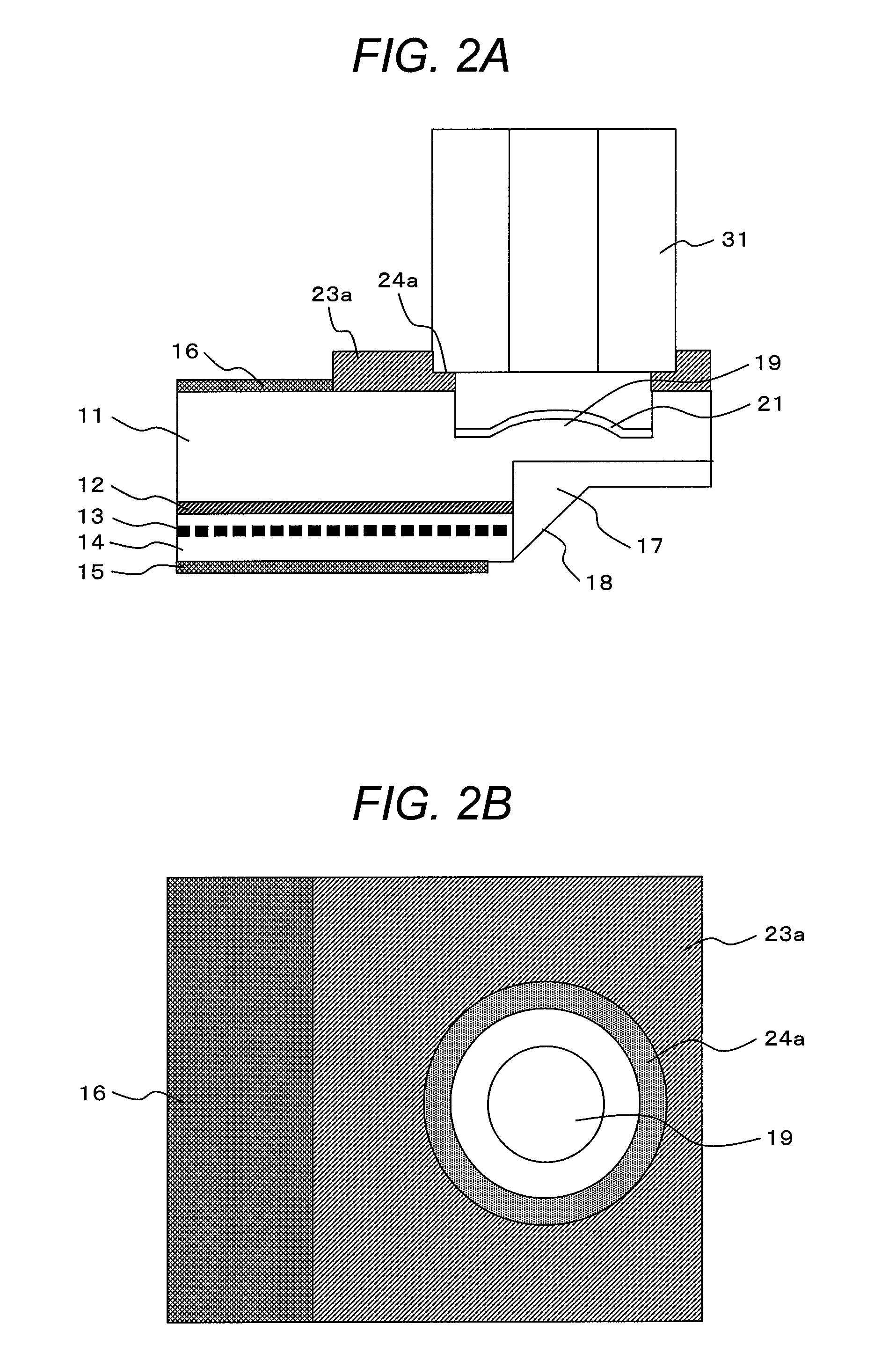

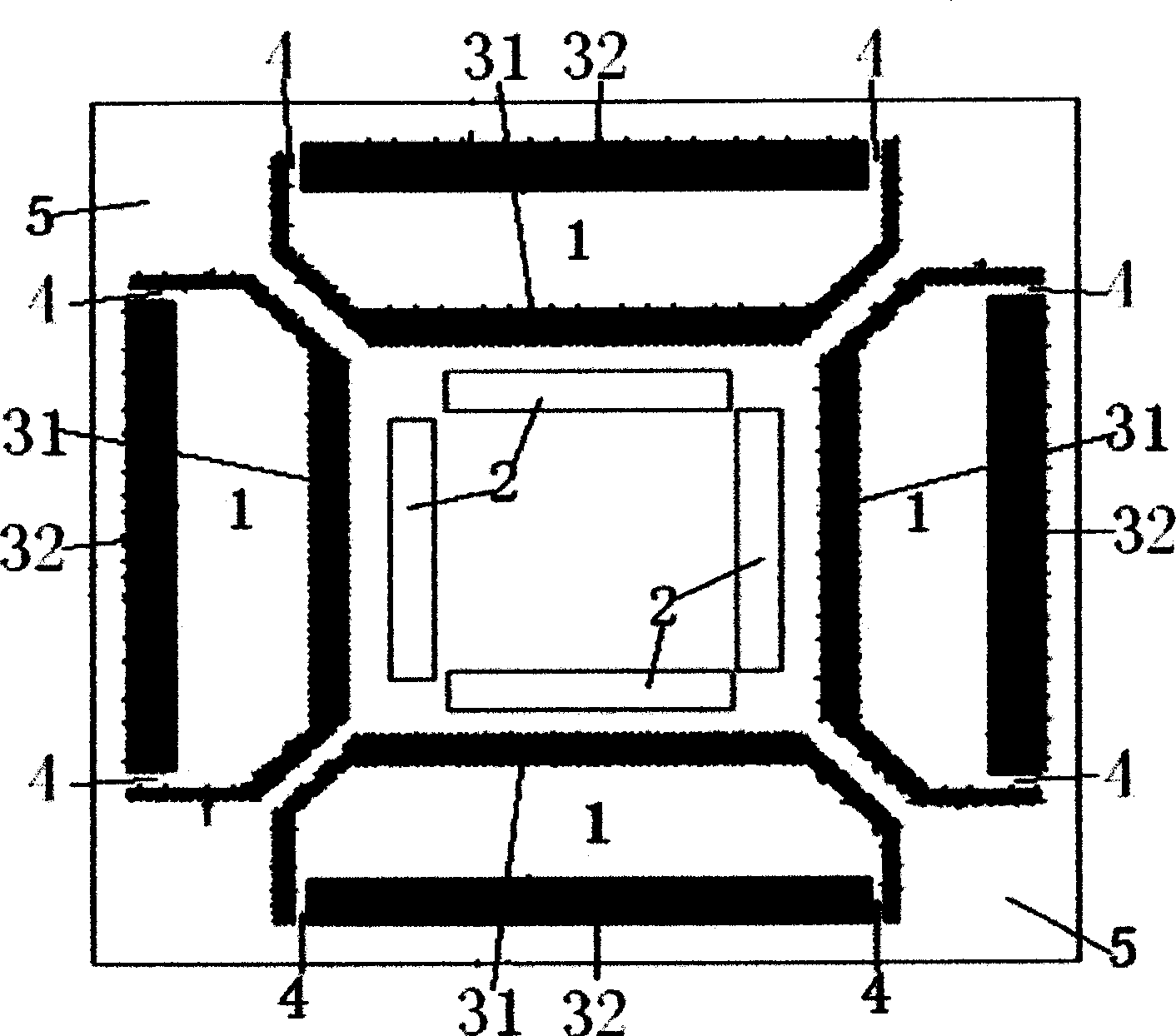

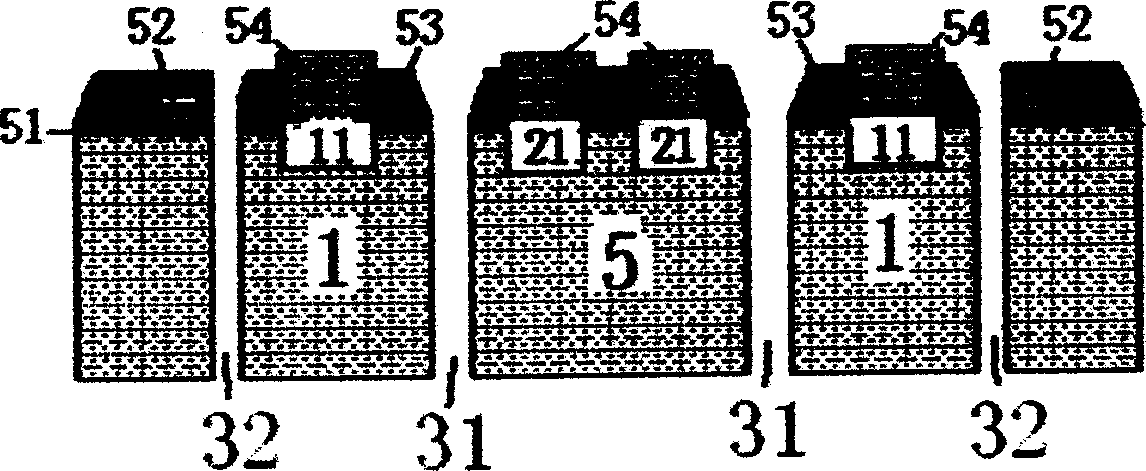

Optical Device and Manufacturing Method of Optical Device

ActiveUS20080179503A1Excellent in light inputImprove output characteristicsBeam/ray focussing/reflecting arrangementsSolid-state devicesEngineeringPhotoelectric conversion

The present invention provides an optical device that is miniature, is highly sensitive and has a simplified package, and a manufacturing method thereof with high production efficiency and high reliability. The present invention is an optical device comprising: a photoelectric conversion element (50) having at least one photoelectric conversion portion (1) which is formed on a substrate (10); a sealing material (14); and a connection terminal (3). The optical device comprises an optical window which is an interface between the photoelectric conversion element (50) and an outside of the optical device; and an aperture (6) formed in the sealing material 14, and whose bottom face is the optical window. An entire face of the optical window is exposed to the outside. An optical adjustment element (13) may be formed on the interface. In this case, the interface between the optical adjustment element (13) and the outside is the optical window.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Drive configuration for a skid steered vehicle

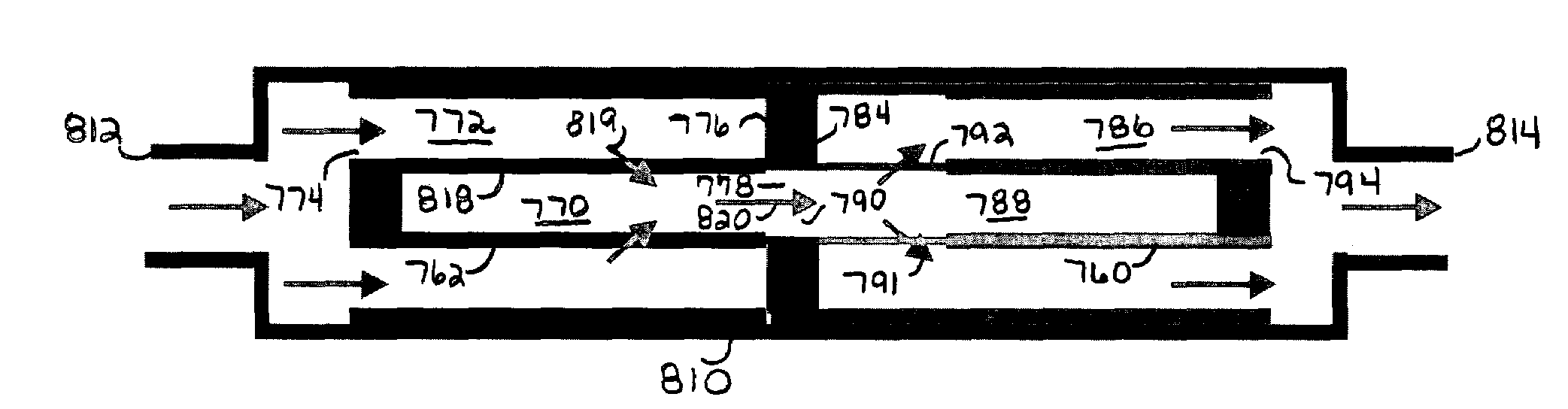

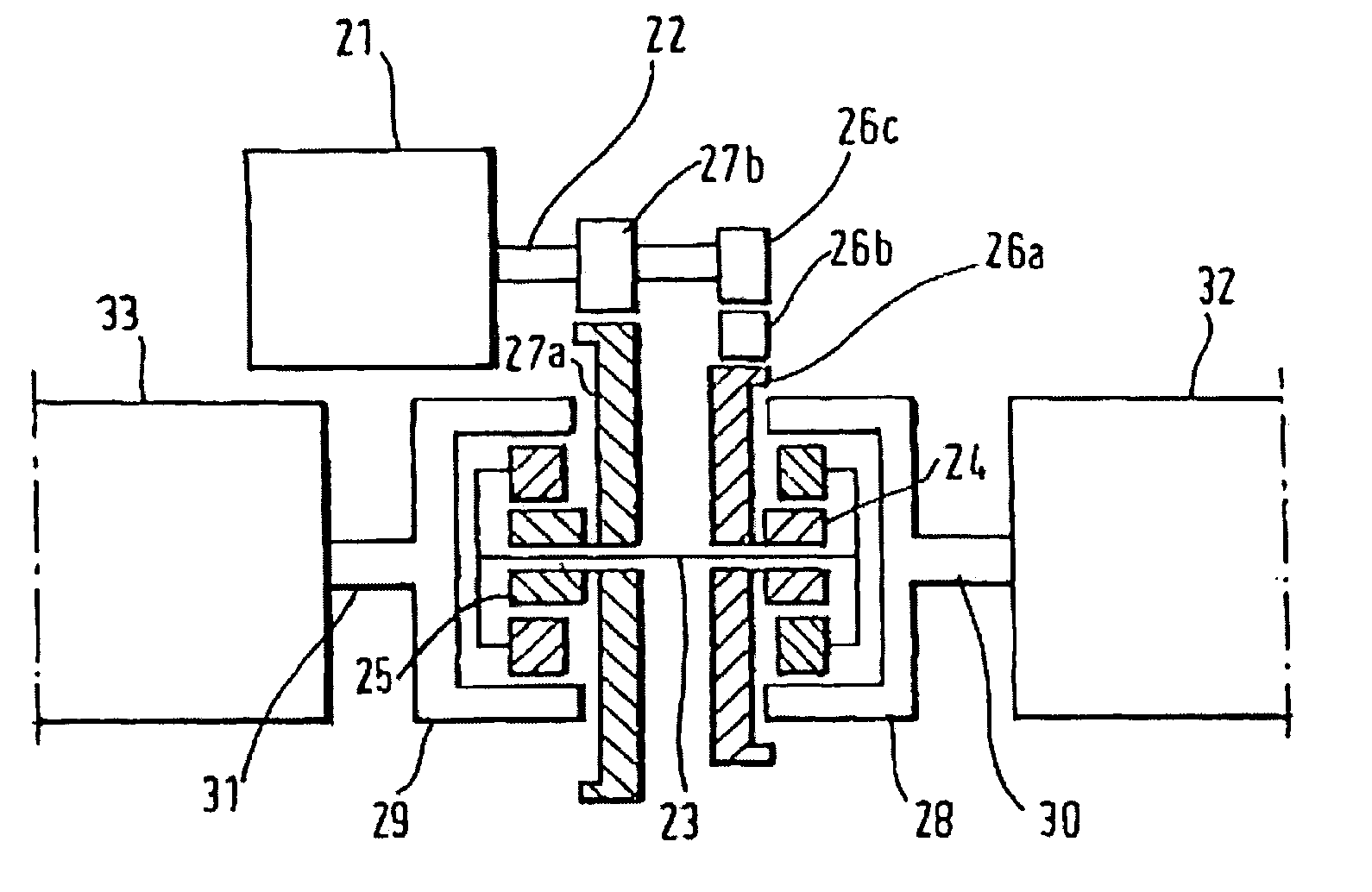

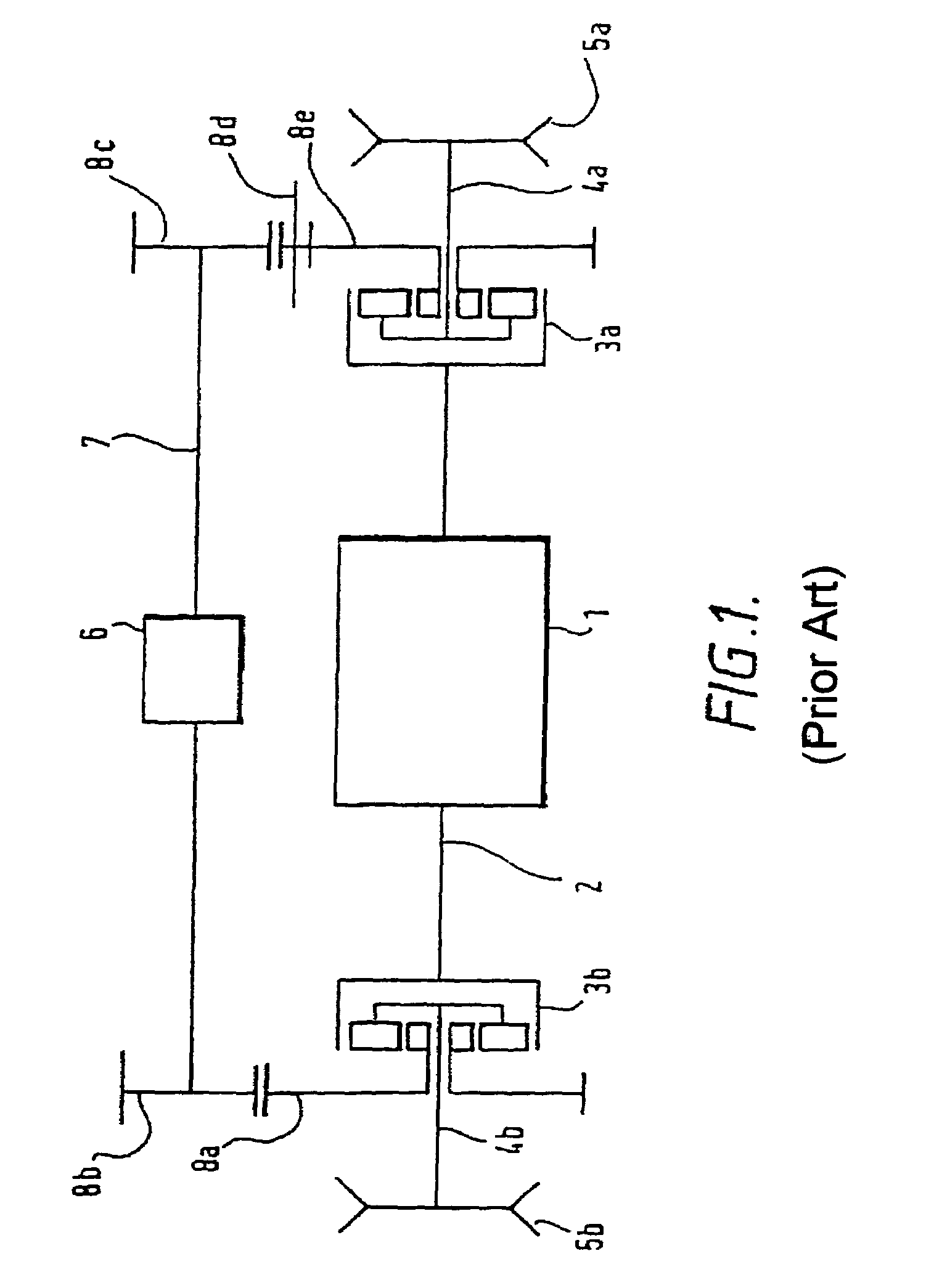

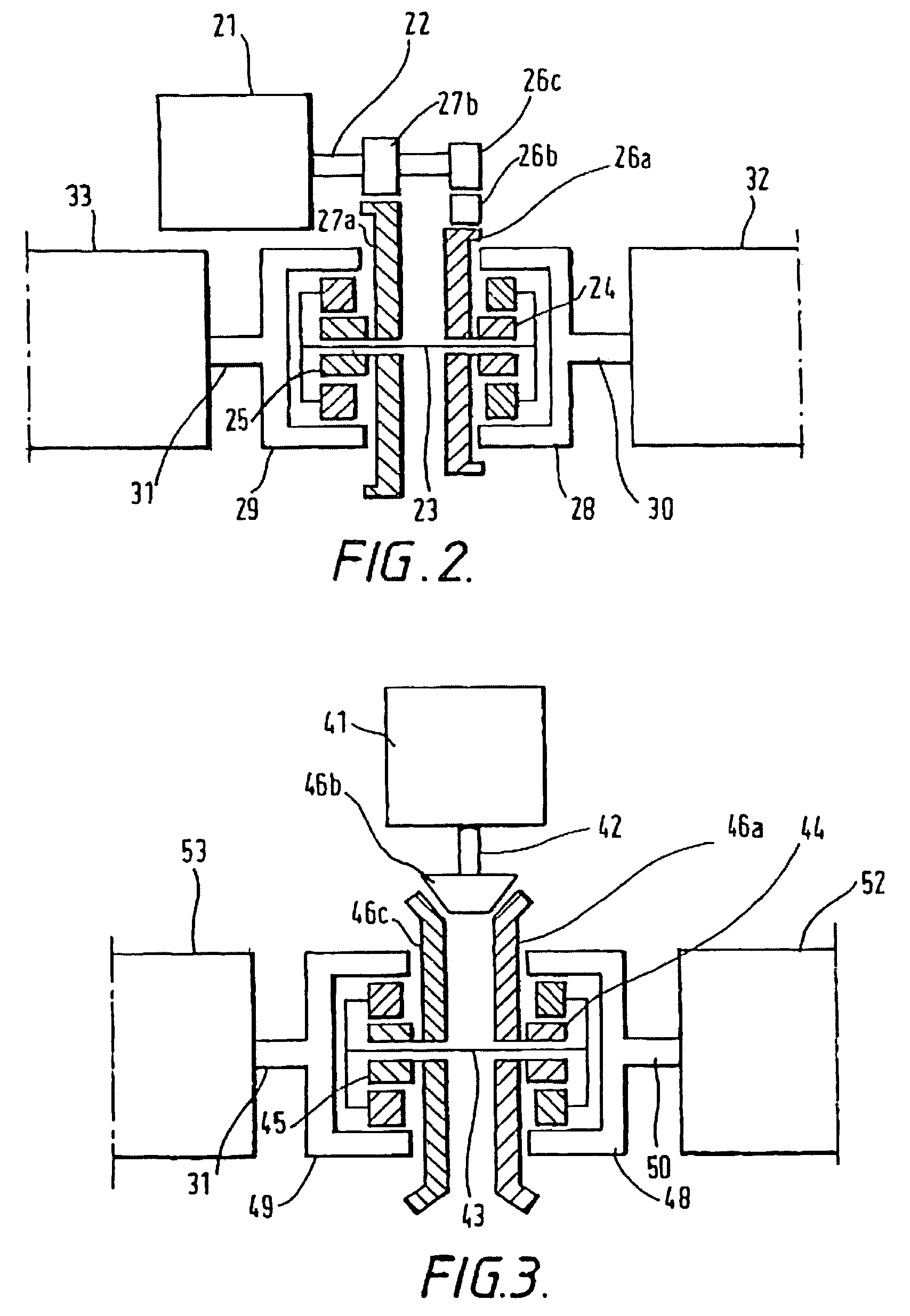

InactiveUS7074151B2Simple packagingSimple designDifferential gearingsMotor depositionControl theoryMotor shaft

An electric drive configuration for a skid steered vehicle comprises: a pair of propulsion motors (74a, 74b), each with a motor shaft protruding from both ends of the motor and mounted on the same axis across the vehicle, each being coupled at the outer end to drive one of a pair of tracks or set of wheels of the skid steered vehicle; a control differential steep gear unit (72) positioned between the two propulsion motors and in driveable communication with the inner ends of the two motor shafts: and a steer motor (71) in driveable communication with the controlled differential (72), the steer motor (71) being controllable from zero speed giving straight line running in which both motor shafts are coupled to run at the same speed, to a range of speeds in both directions of rotation giving steering capability in both directions.

Owner:QINETIQ LTD

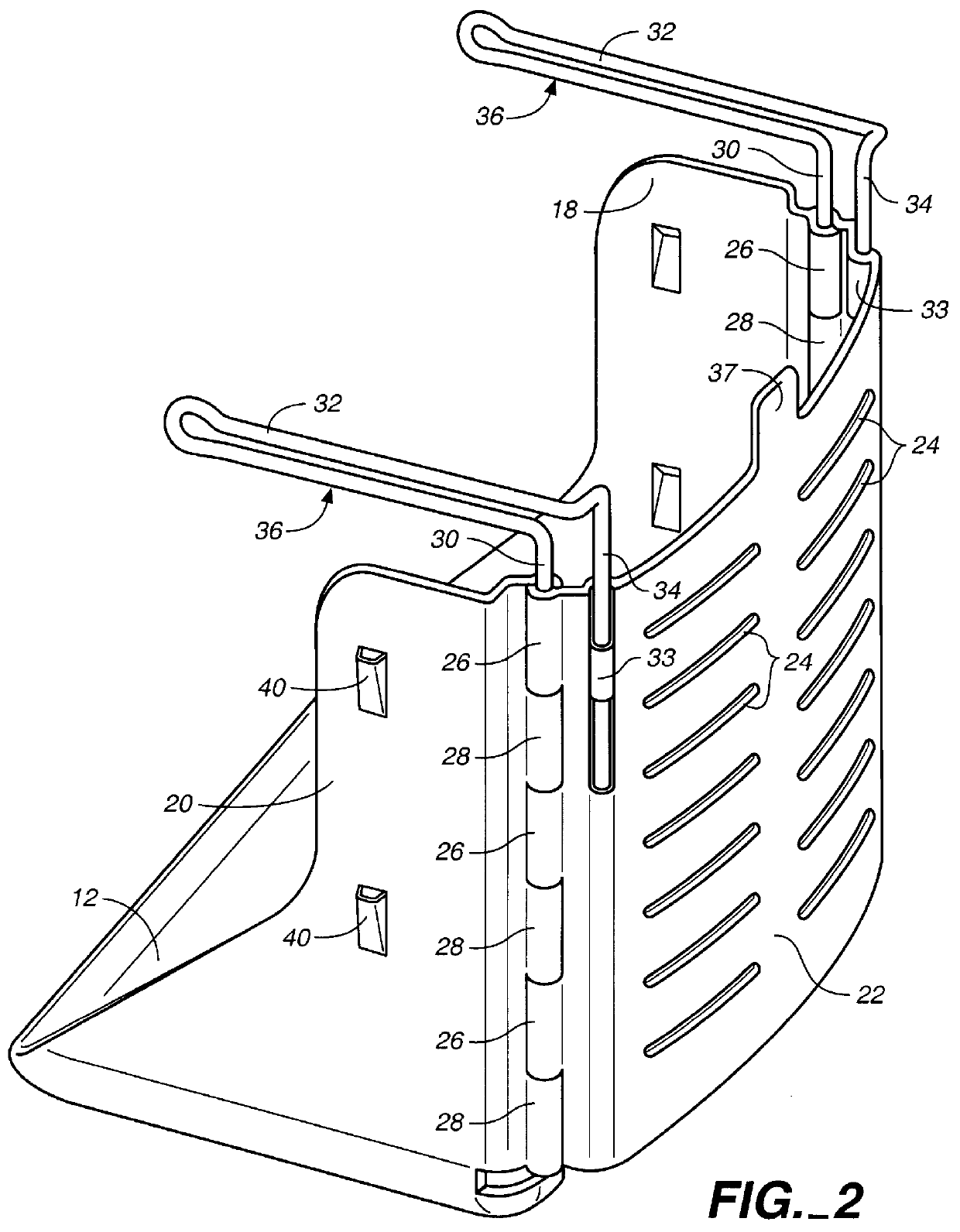

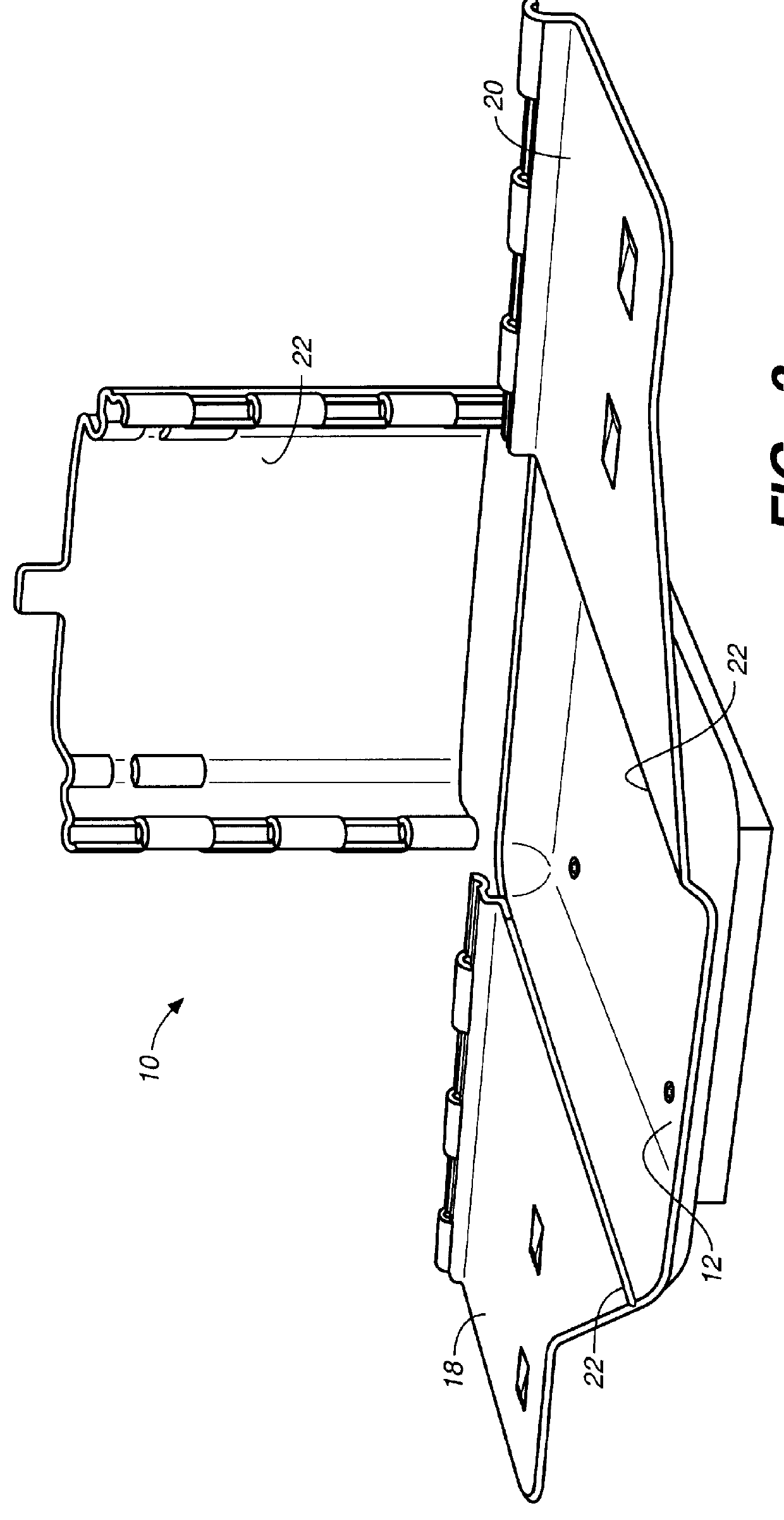

Plastic bag rack

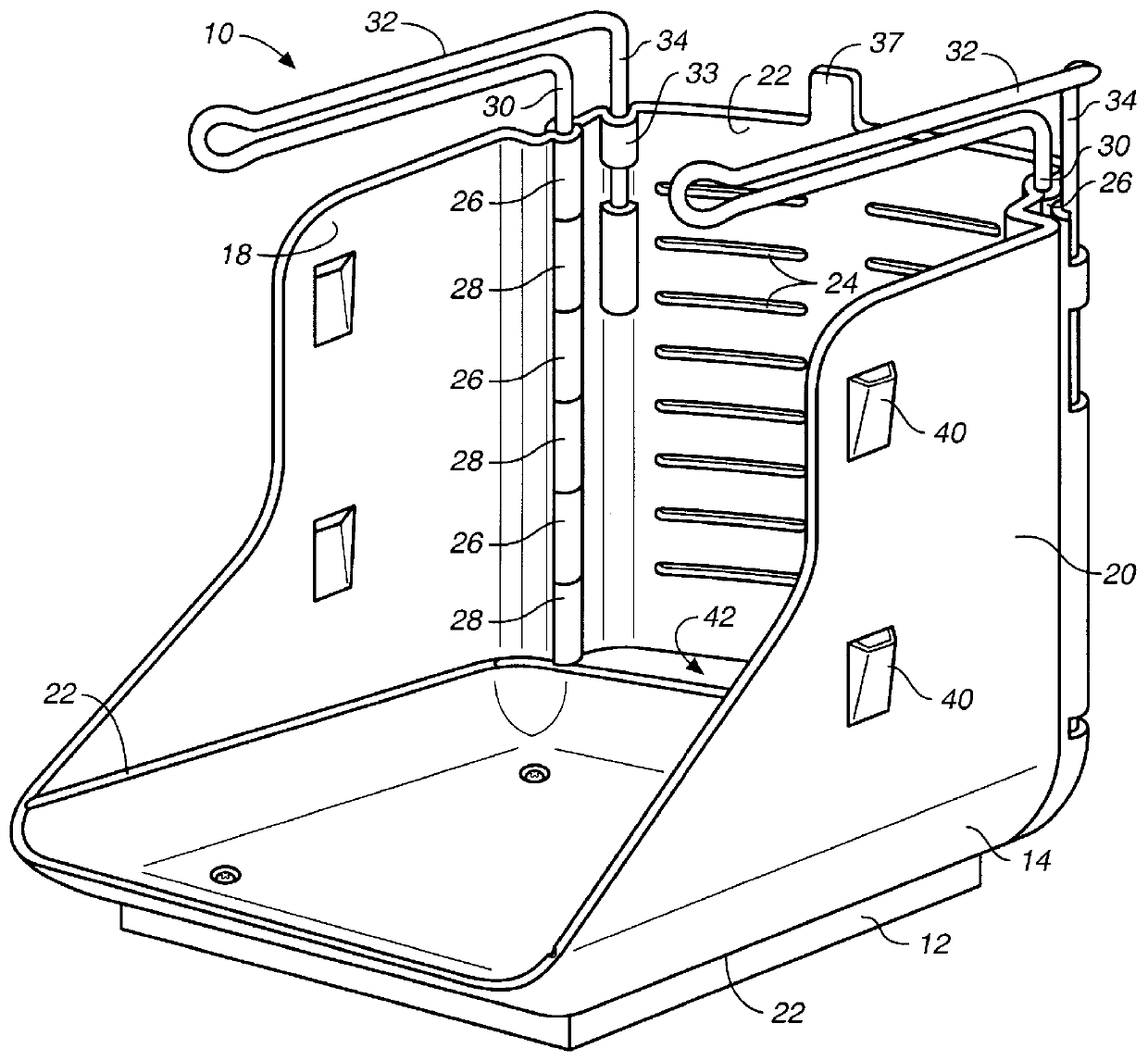

InactiveUS6086023AEfficiently stackedSimple packagingWing accessoriesStands/trestlesEngineeringPlastic bag

A bag rack (10) including a base (12), side walls (18, 20), a back wall (22) and a pair of L-shaped bag support arms (32). Side walls (18, 20) are releasably joined and secured to back wall (22) by the upright legs (30) of bag support arms (32) by means of a series of interlocking, aligned slots (26, 28). A rear slot (42) is provided between back wall (22) and base (12) to allow the bottom edges of a multiplicity of bags carried by a hook (37) to extend back of base (12).

Owner:HANDLE HELPER

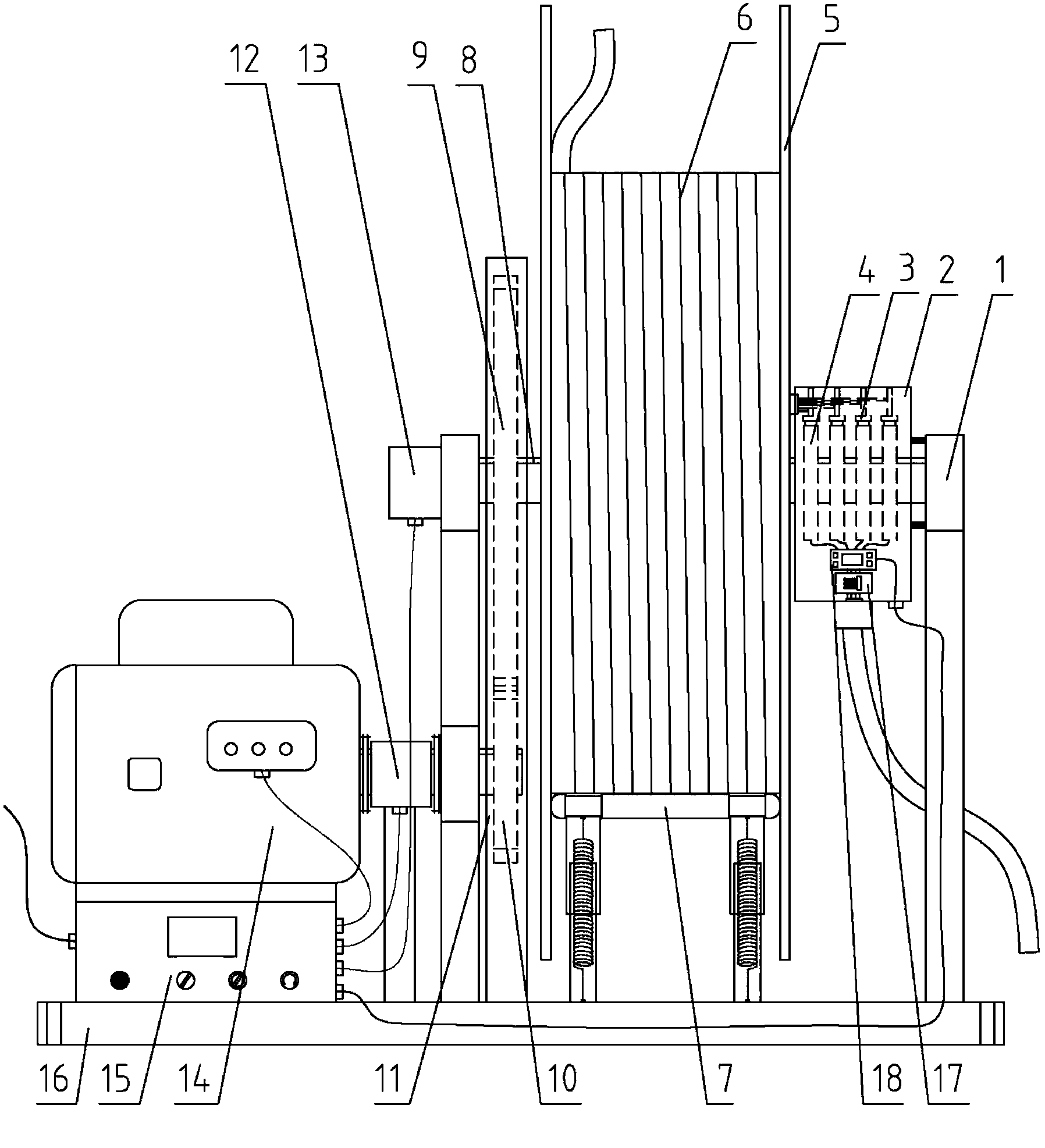

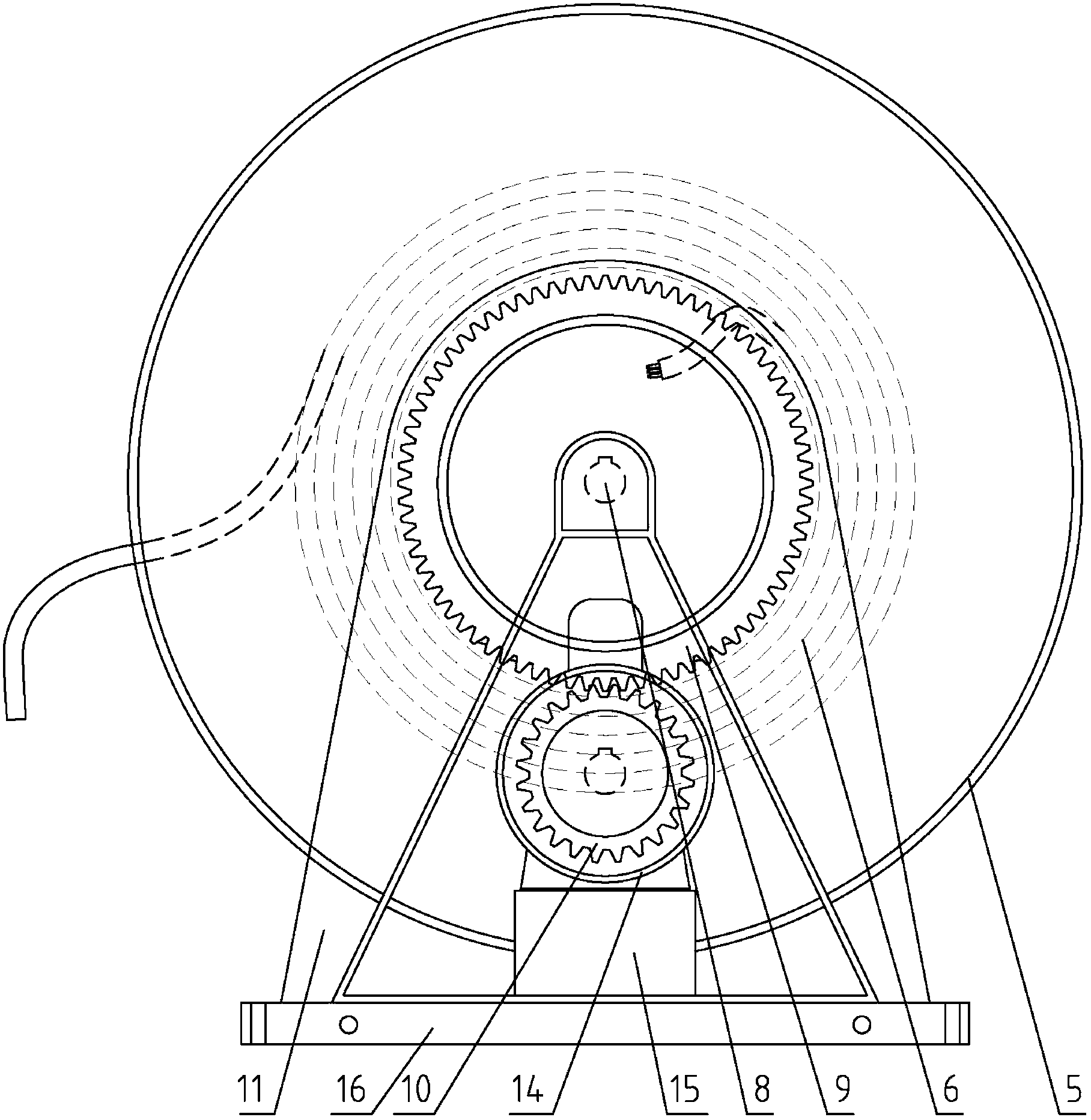

Rotary drum device capable of automatically winding and unwinding cable

InactiveCN103224202ASafe and reliable connectionFully automatedWinding mechanismsTransducerElectric machinery

The invention discloses a rotary drum device capable of automatically winding and unwinding a cable. A rotary drum shaft is sleeved with a rotary drum end gearwheel, a rotary drum and an anti-explosion junction box; the anti-explosion junction box is fixedly connected with a bearing support on one side; a slip ring, an AC contactor and a breaker are arranged in the anti-explosion junction box; an encoder is arranged at one end of the rotary drum shaft; the rotary drum and the rotary drum end gearwheel are coaxially and fixedly connected; the rotary drum end gearwheel is in meshing transmission connection with a motor end pinion; a gear protection cover is arranged on the outer surfaces of both the rotary drum end gearwheel and the motor end pinion; the motor end pinion is coaxially connected with an AC asynchronous motor through a torque transducer; and the AC asynchronous motor, the encoder, the torque transducer, the AC contactor and the breaker are all connected with an anti-explosion motor control cabinet. The rotary drum device provided by the invention effectively avoids excessive cable being damaged caused by friction or abrasion by other equipment.

Owner:BAOJI PETROLEUM MASCH CO LTD

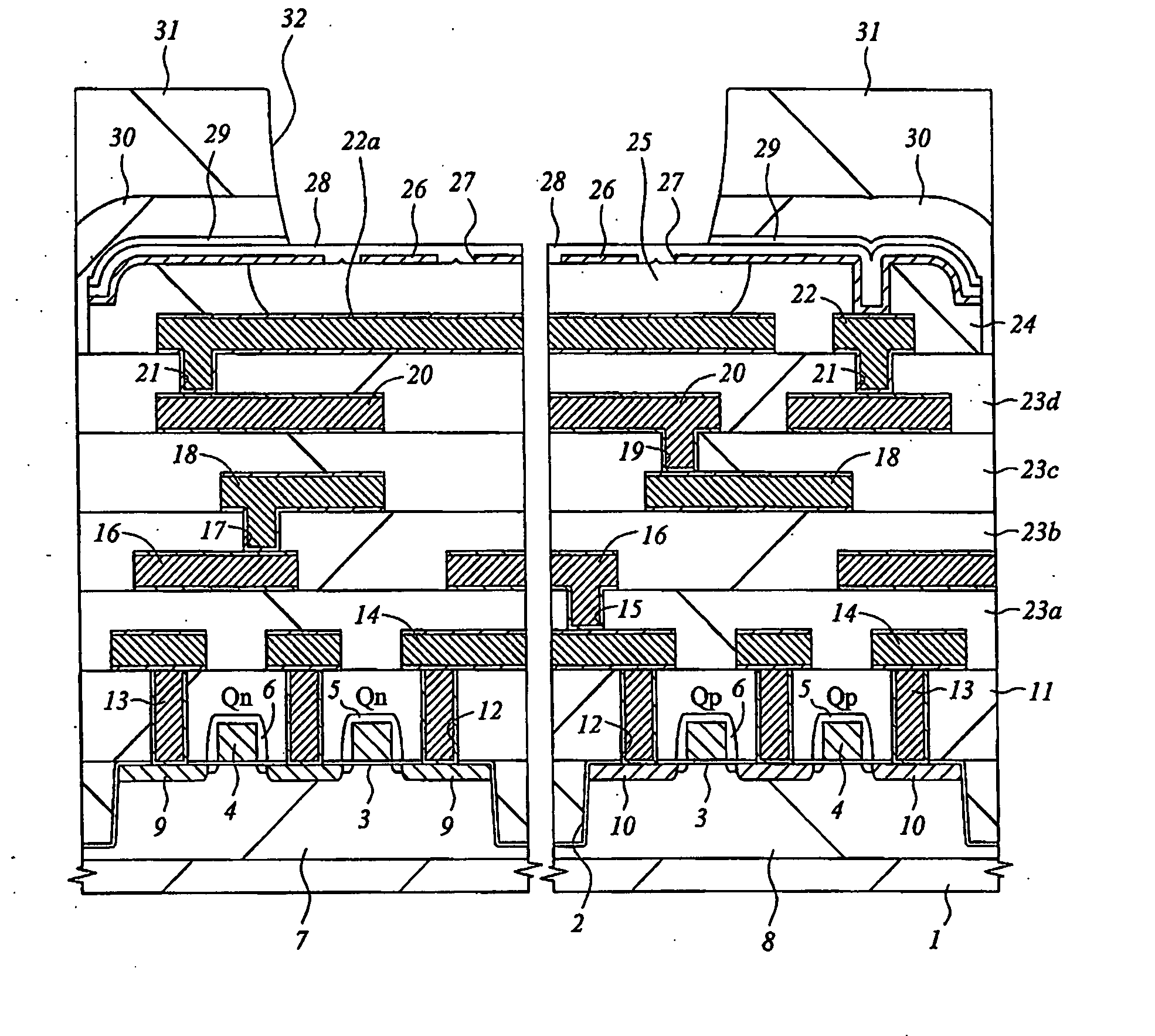

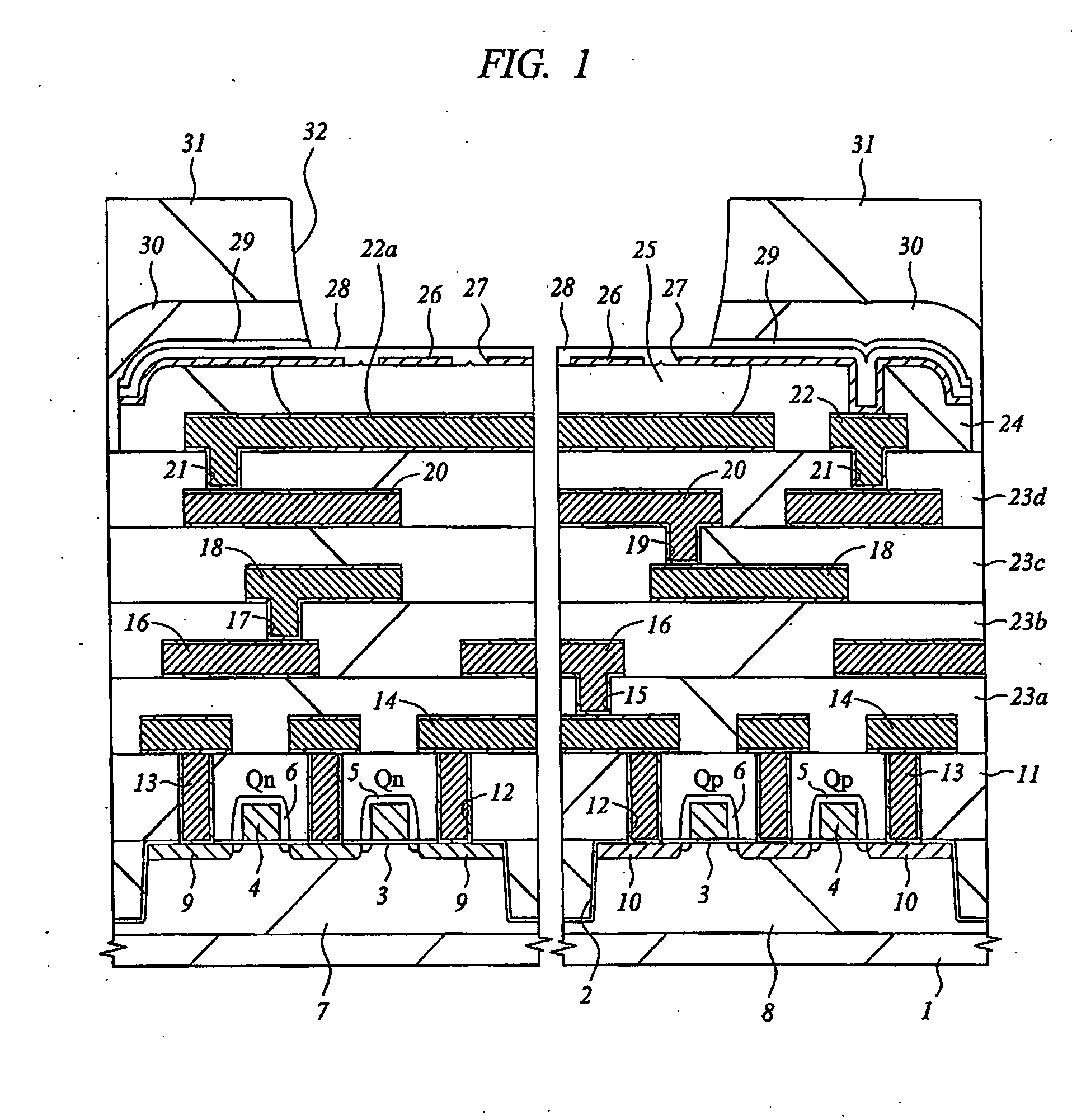

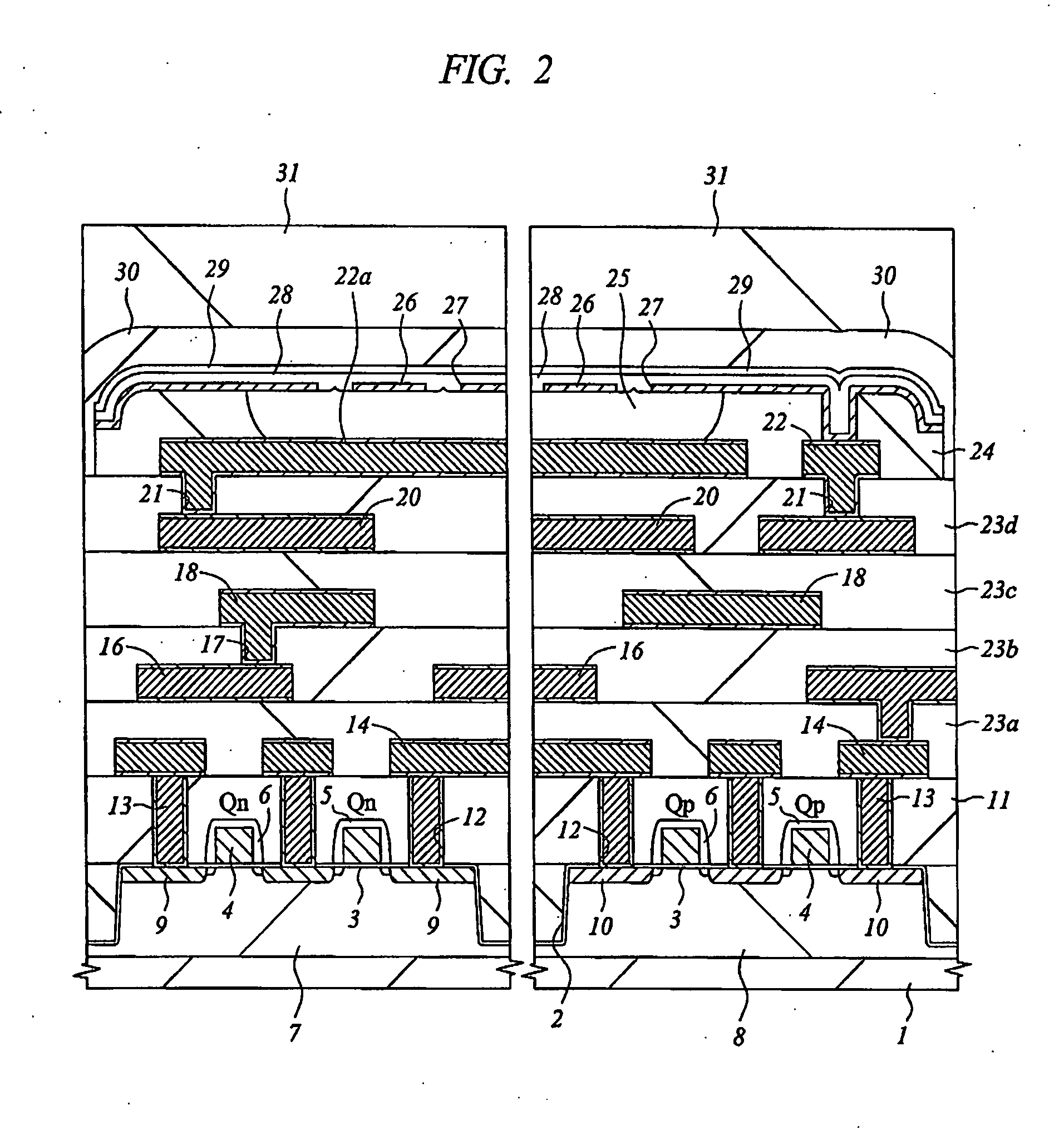

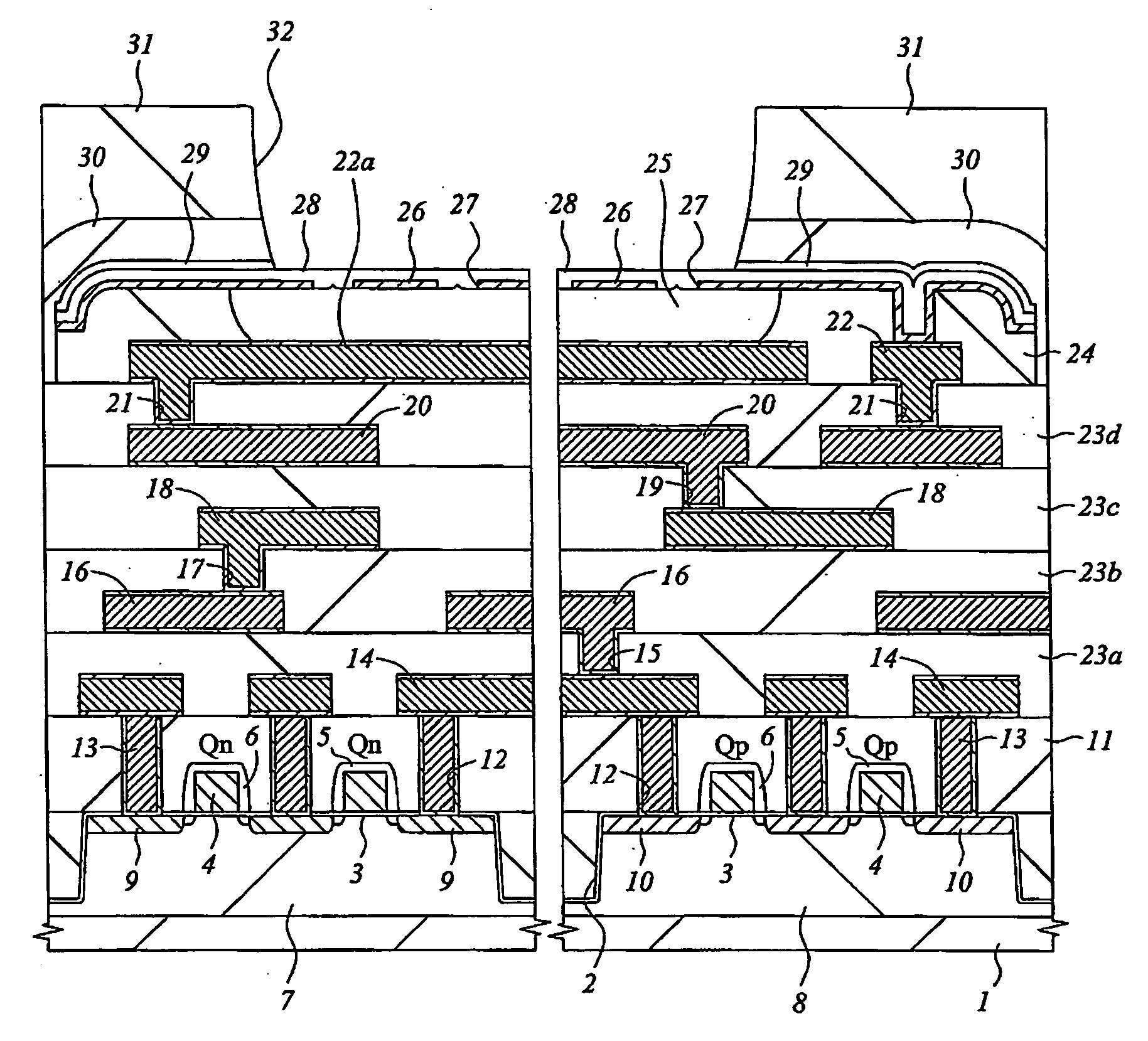

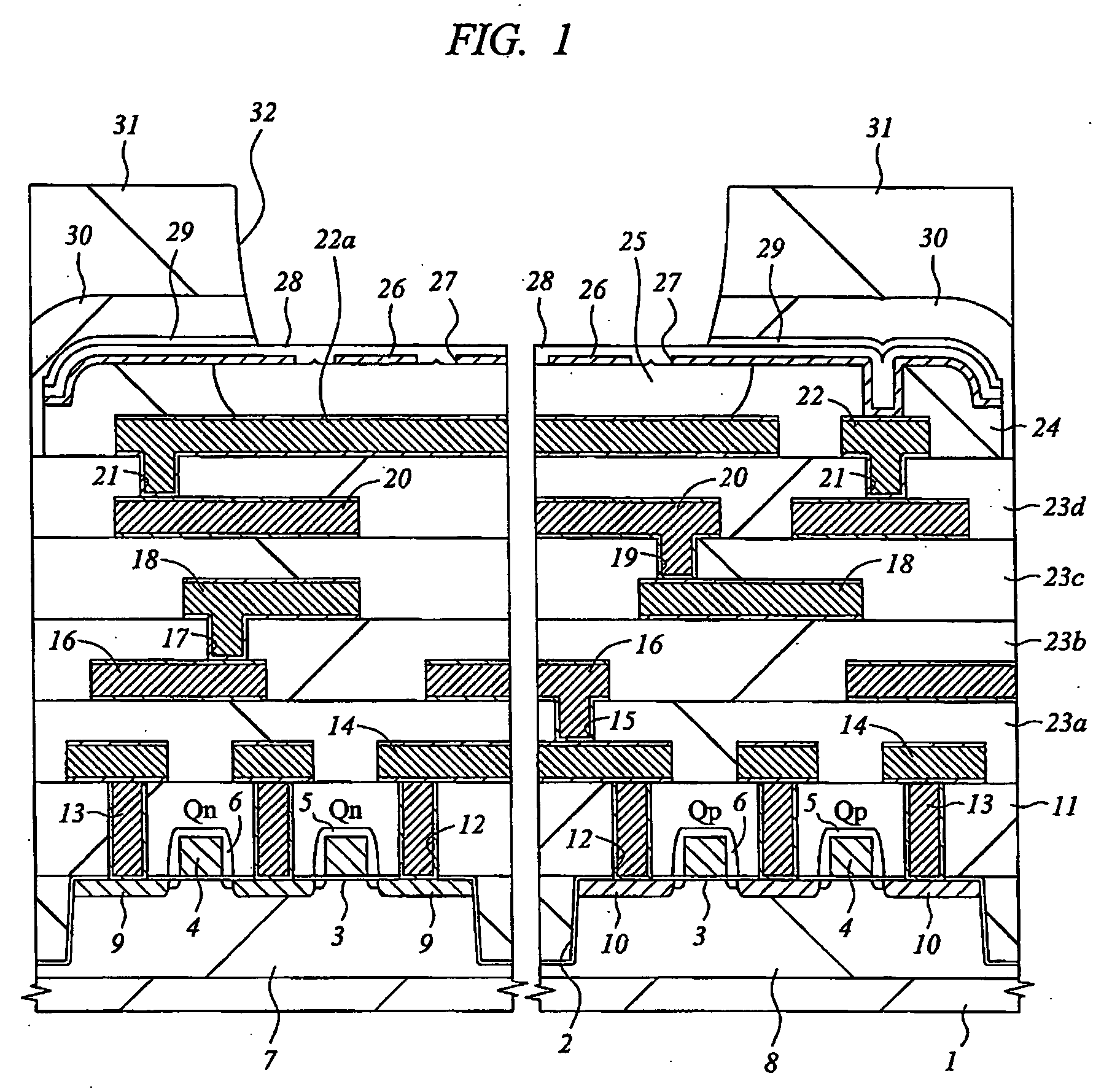

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS20070262401A1High precision measurementReduced footprintFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsDevice materialSilicon oxide

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

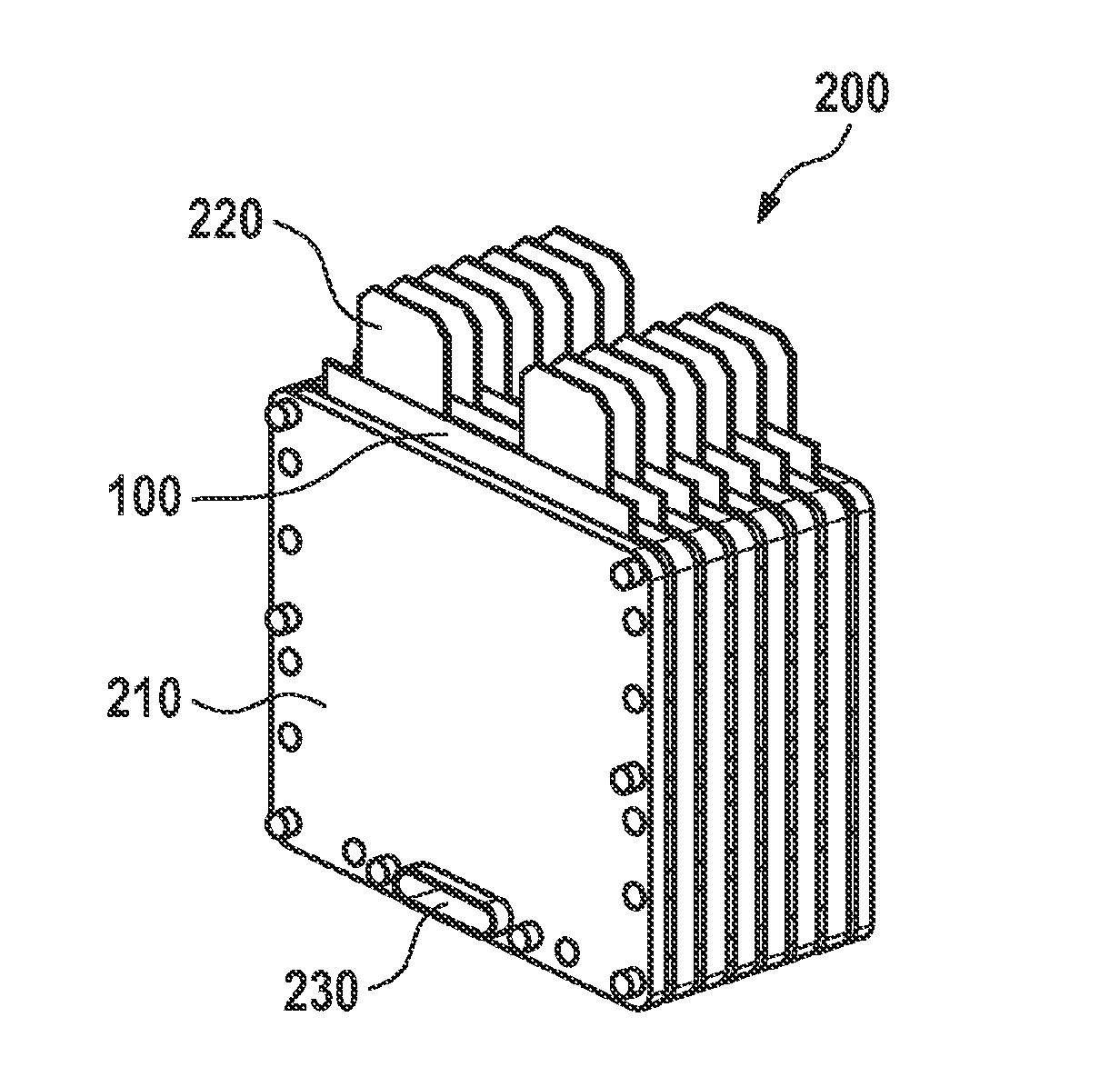

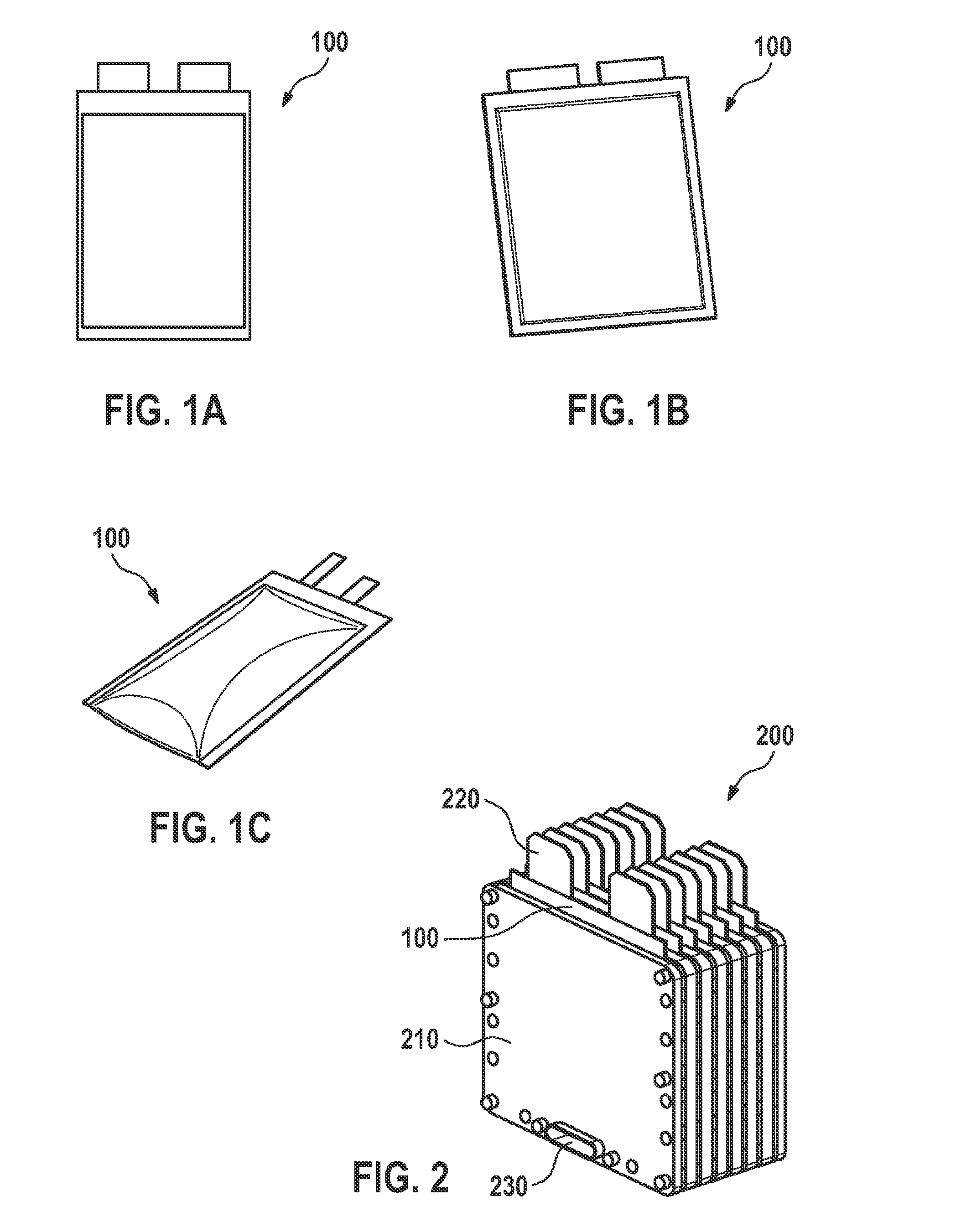

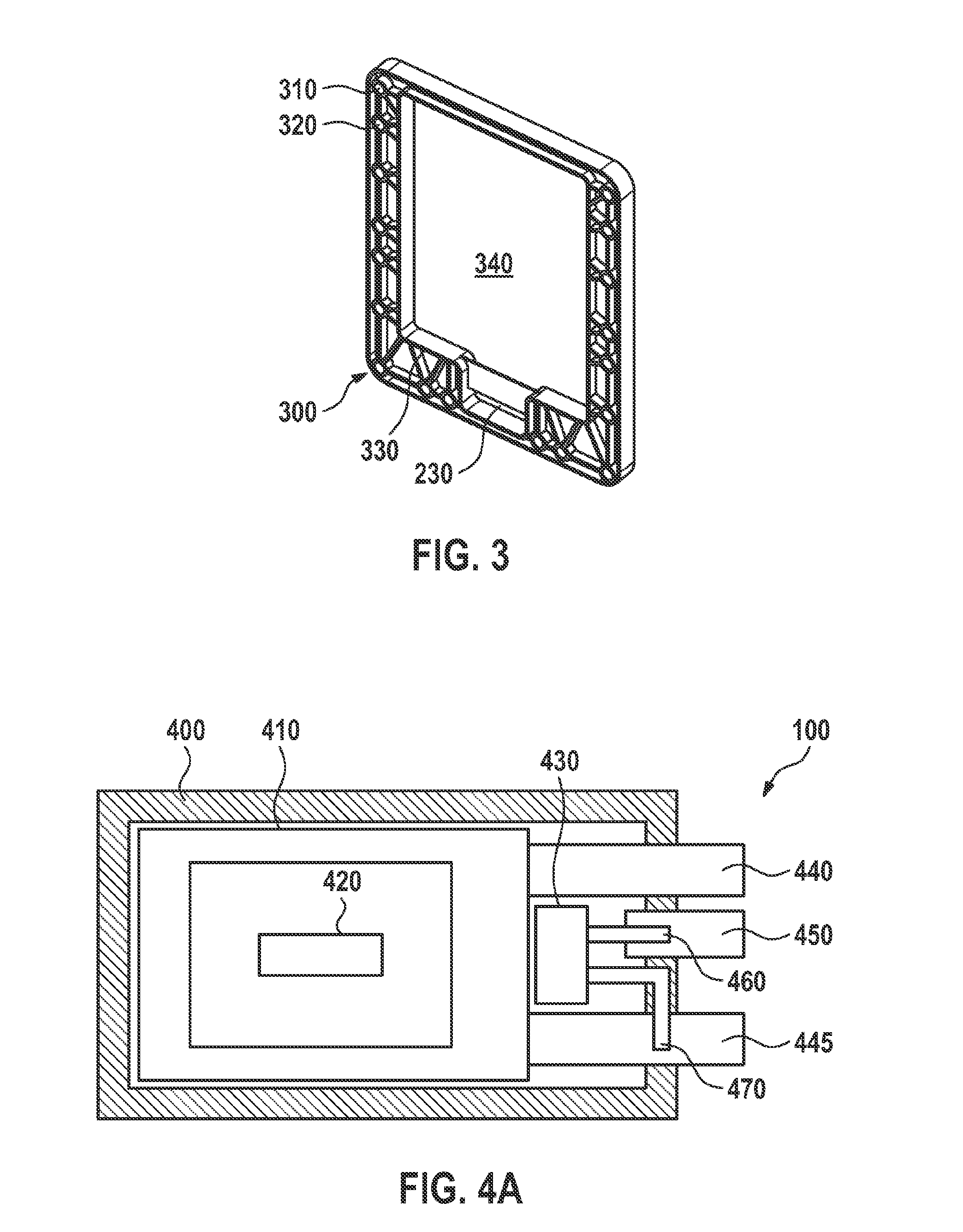

Encasing film for a galvanic element, electrochemical store, electrochemical storage system, flexible film for an encasing of a galvanic element, and method for determining a state variable of an electrochemical store

ActiveUS20150132621A1Easy to clickFirmly connectedForce measurement by measuring frquency variationsBatteries circuit arrangementsElectricityState variable

An encasing film for a galvanic element has at least one force sensor for detecting an expansion state of the encasing film. The encasing film is produced from an elastic and electrically insulating material, e.g., plastic. The force sensor, which has a strain gauge, is situated on a surface of the encasing film.

Owner:ROBERT BOSCH GMBH

Surface emitting laser module and vertical illuminated photodiode module

InactiveUS20100265983A1Readily self-alignedHighly efficient optical couplingOptical wave guidanceLaser detailsOptical ModuleOptical coupling

In order to provide a compact optical module permitting highly efficient optical coupling and having components thereof highly densely packaged, a light emitting diode that is included in the optical module and emits light in a vertical direction with respect to a principal surface of a semiconductor substrate is provided with a lens integrated into a light emitting region, and a retaining section integrated to surround the light emitting region. Accordingly, readiness in alignment of the light emitting diode and an optical fiber, which guides light emitted from the light emitting diode, with each other is upgraded. Eventually, the compact optical module permitting highly efficient optical coupling and having components thereof highly densely packaged can be provided.

Owner:HITACHI LTD

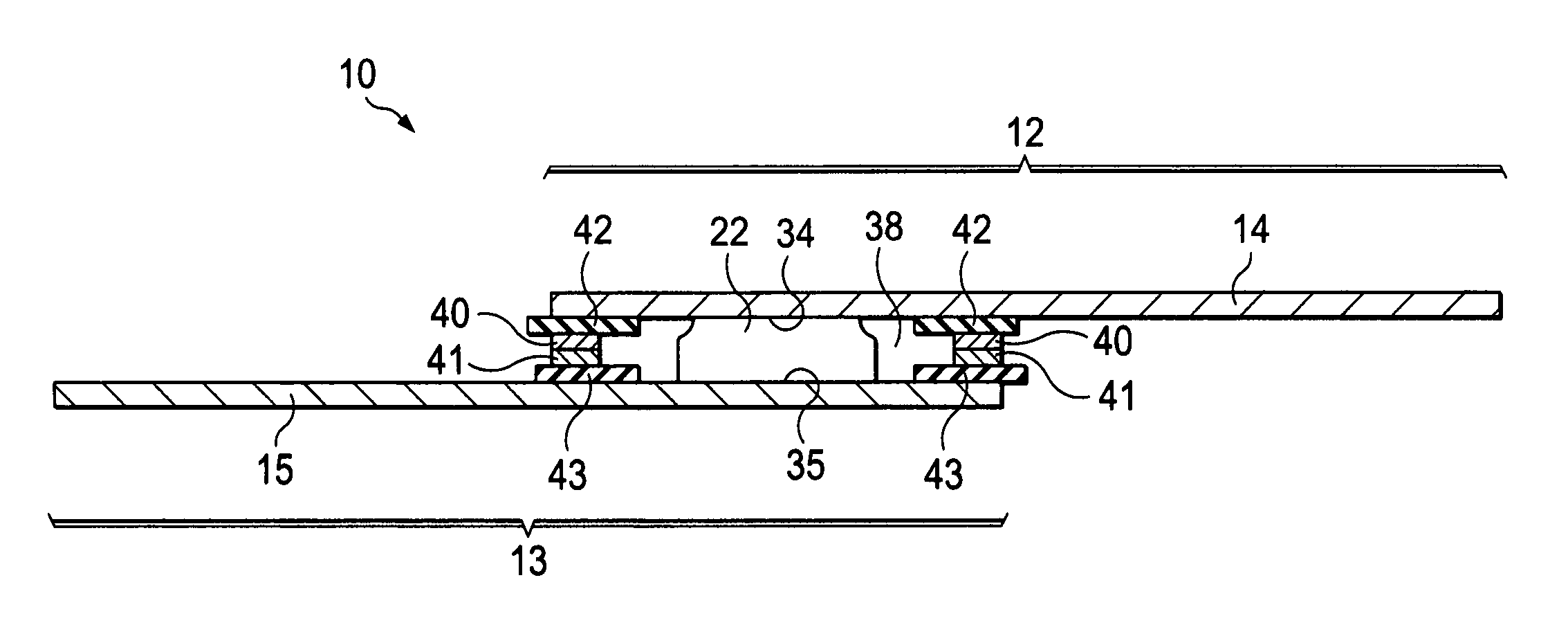

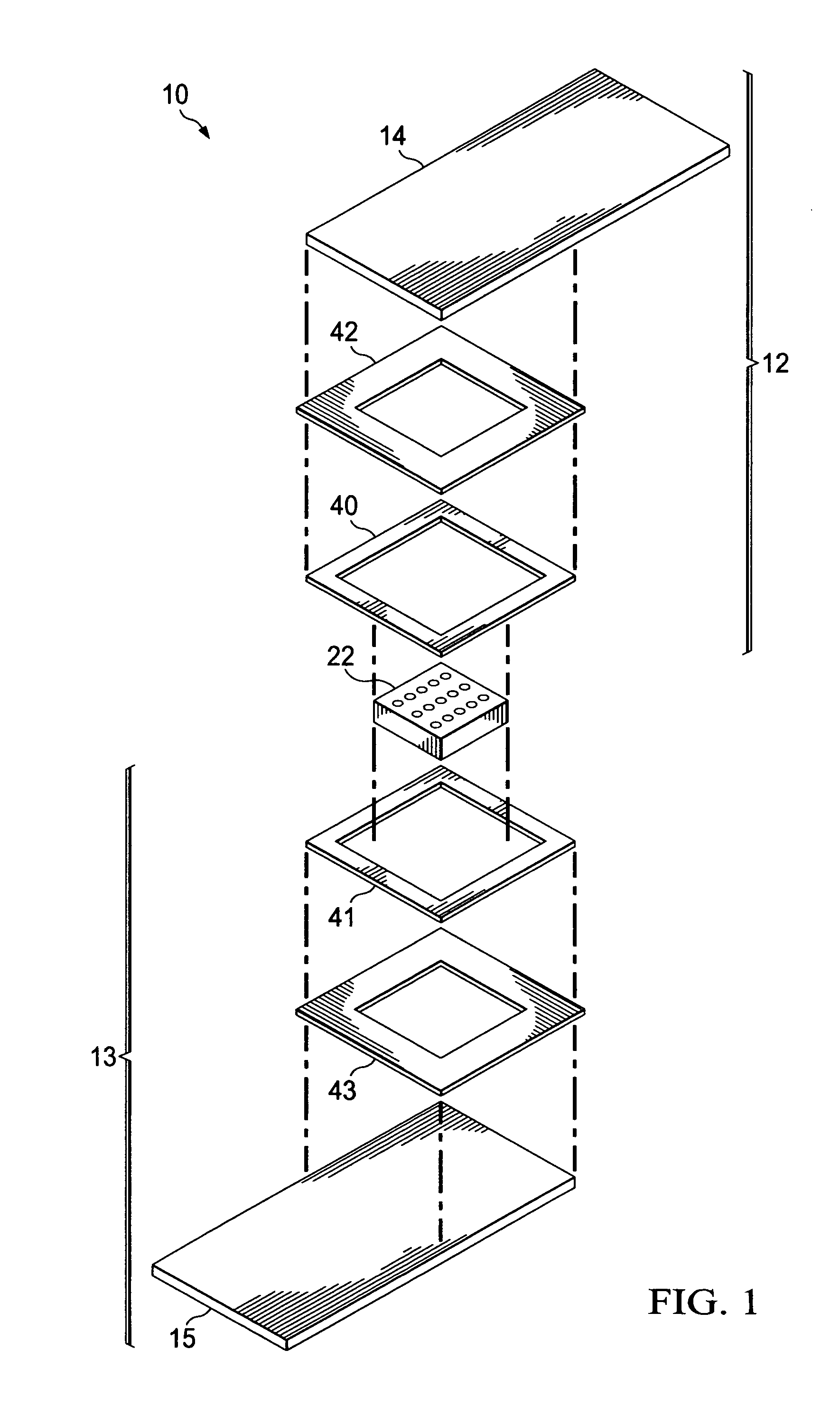

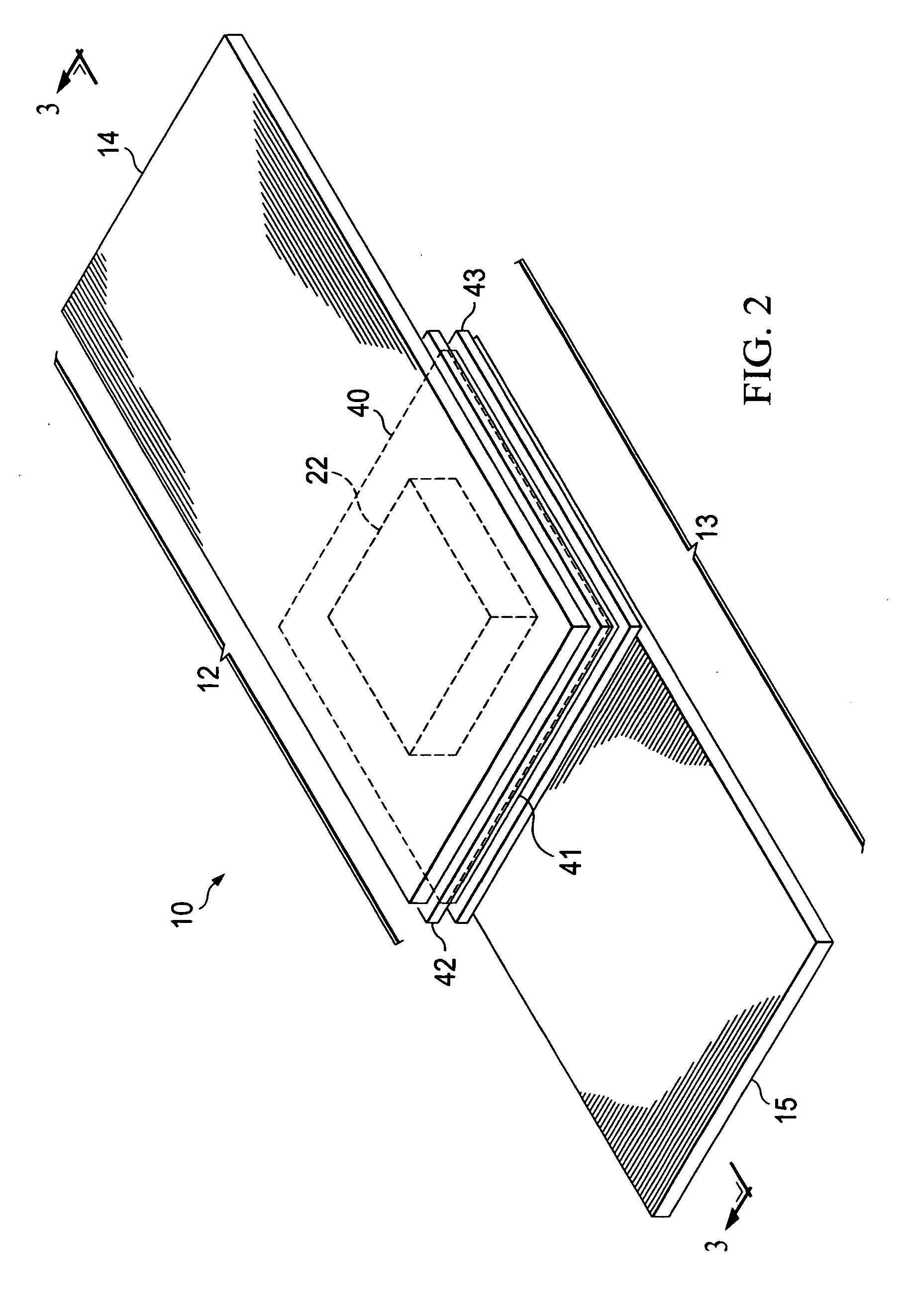

Flexible diode package and method of manufacturing

InactiveUS20100136748A1Simple packagingLow production costSemiconductor/solid-state device detailsSolid-state devicesAdhesiveExtreme temperature

A single step packaging process that both melts a solder and also cures an adhesive about a microelectronic circuit. The process finds technical advantages by simplifying packaging of a die that may be coupled to a planar flexible lead, which leads to a lower production cost and quicker manufacturing time. The planar flexible lead may be adapted to bend and flex during mechanical stress and during extreme temperature cycling, and allow direct mounting of the device to a member by easily welding or soldering. The invention may comprise a flexible solar cell diode that can be closely positioned on solar panels at an extremely low cost.

Owner:MICROSEMI

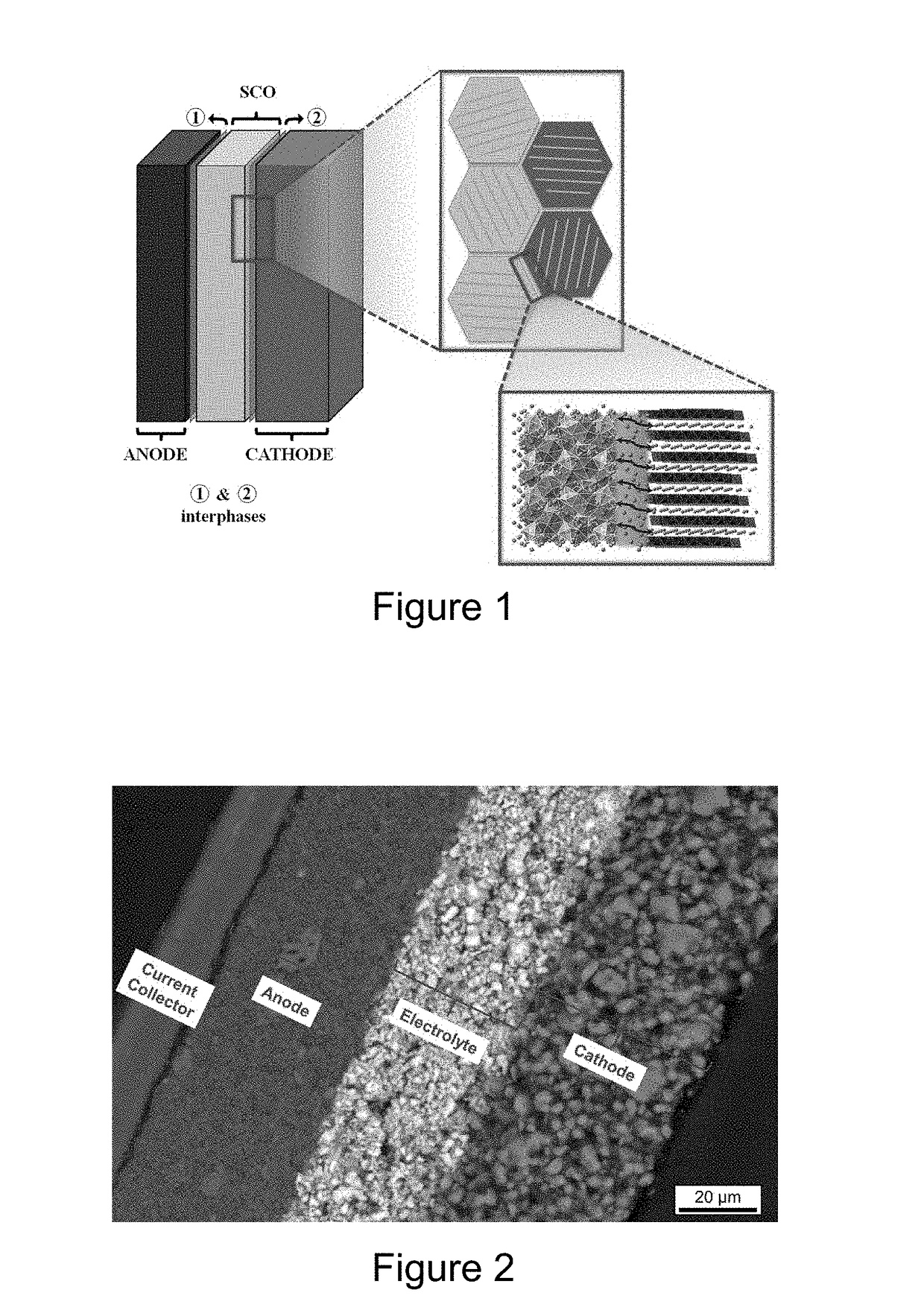

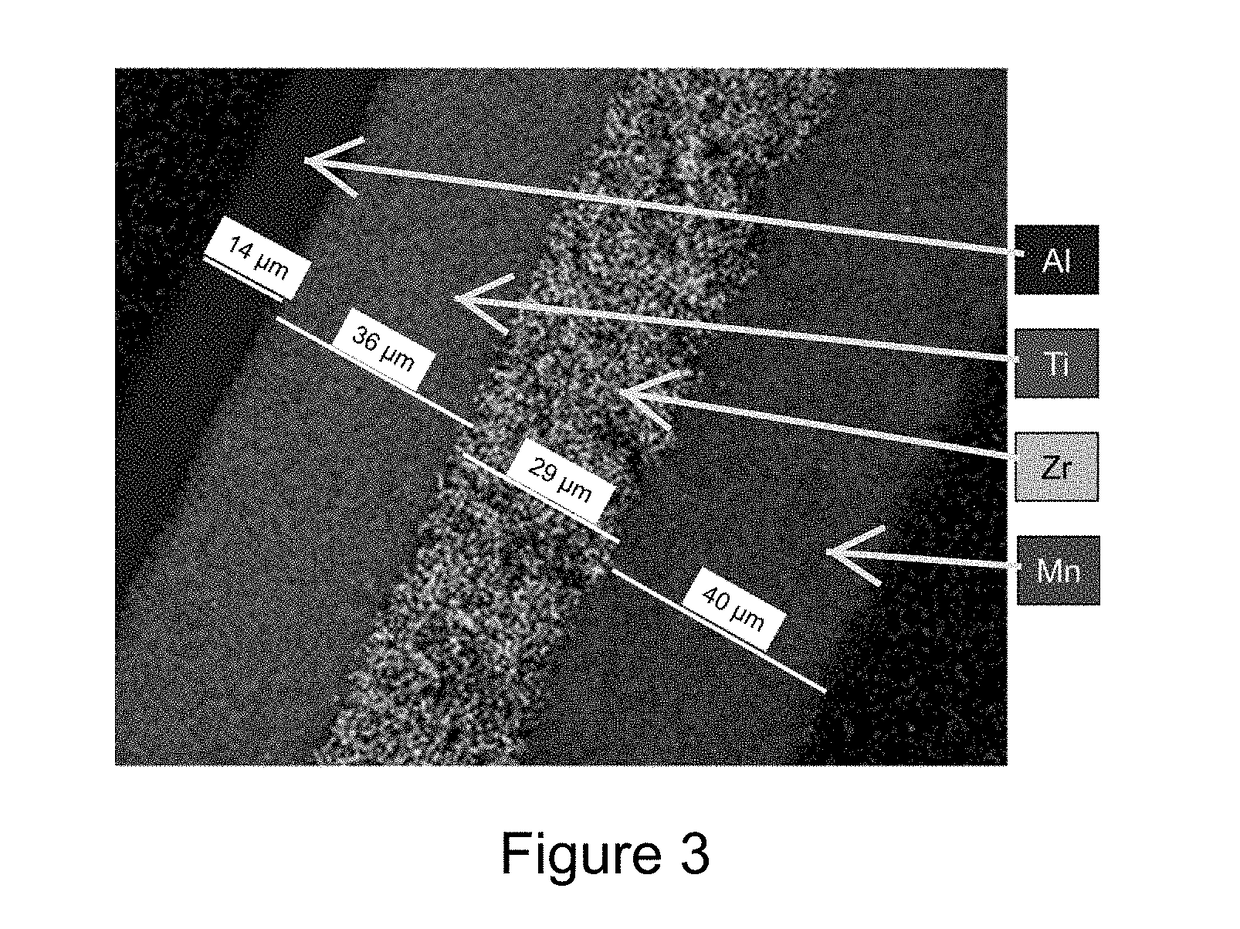

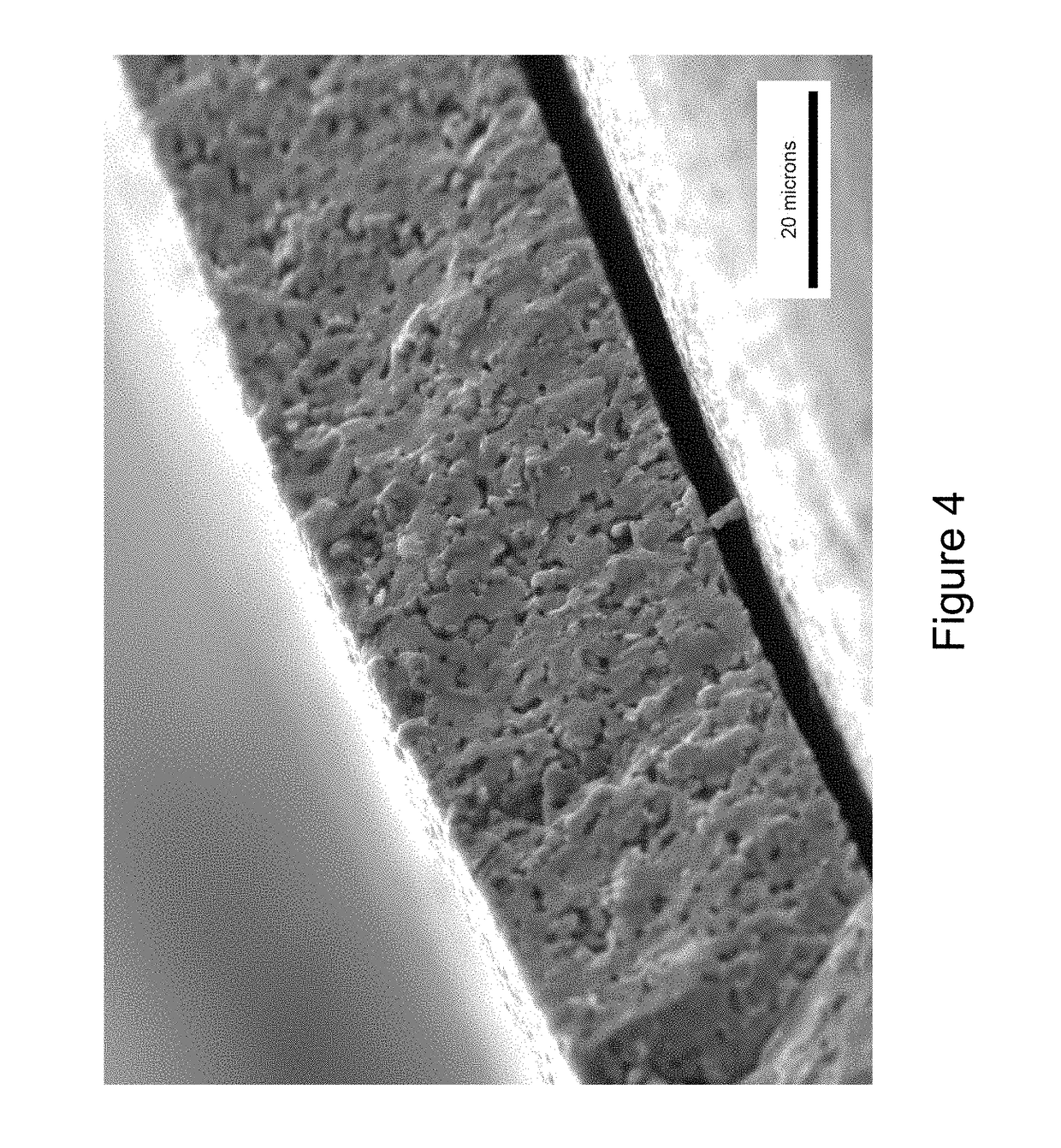

Slurry Formulation for the Formation of Layers for Solid State Batteries

ActiveUS20170179521A1Increase energy densityLower battery costsSolid electrolytesLiquid surface applicatorsSolid state electrolyteSlurry

Owner:RGT UNIV OF MICHIGAN +1

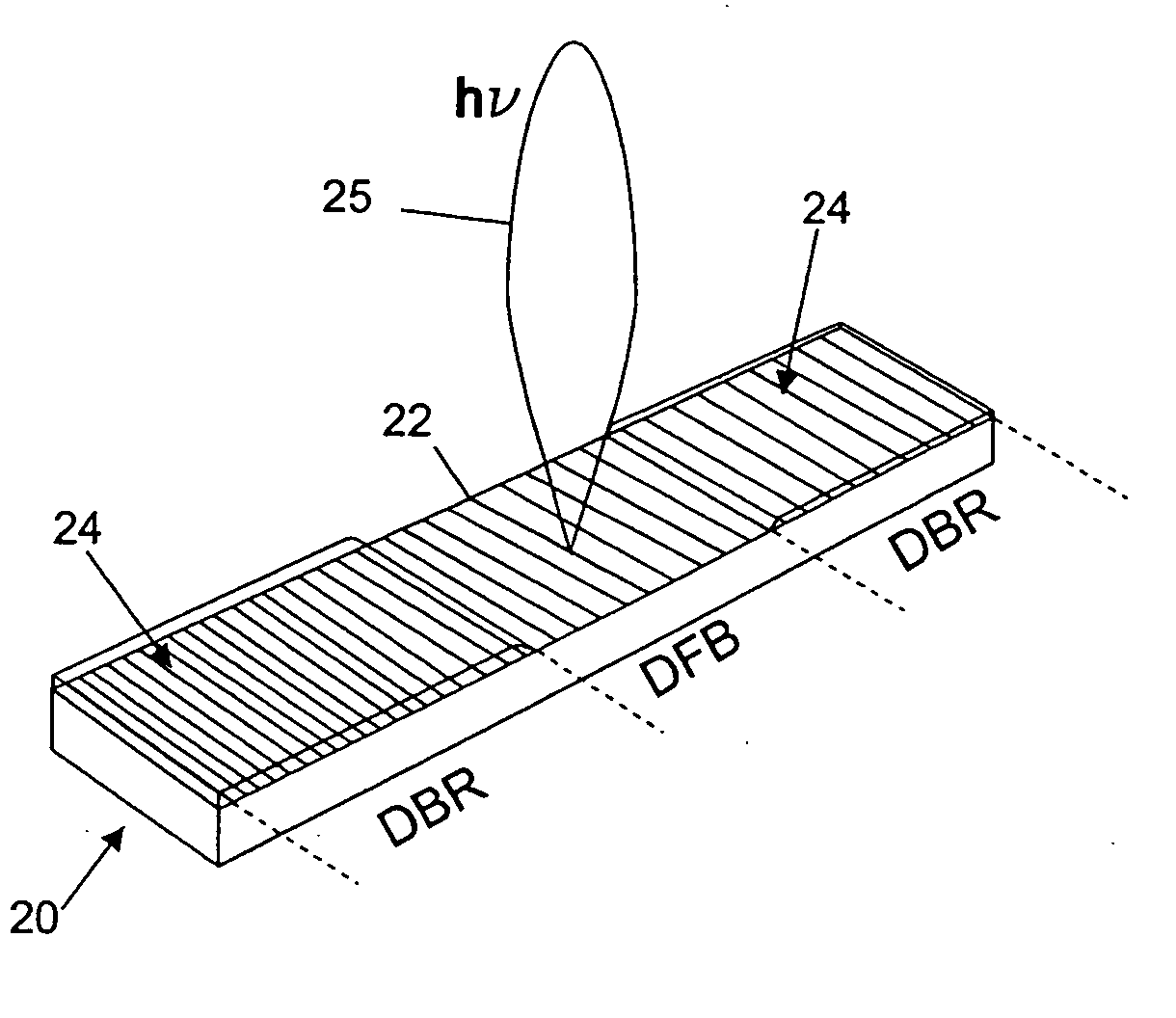

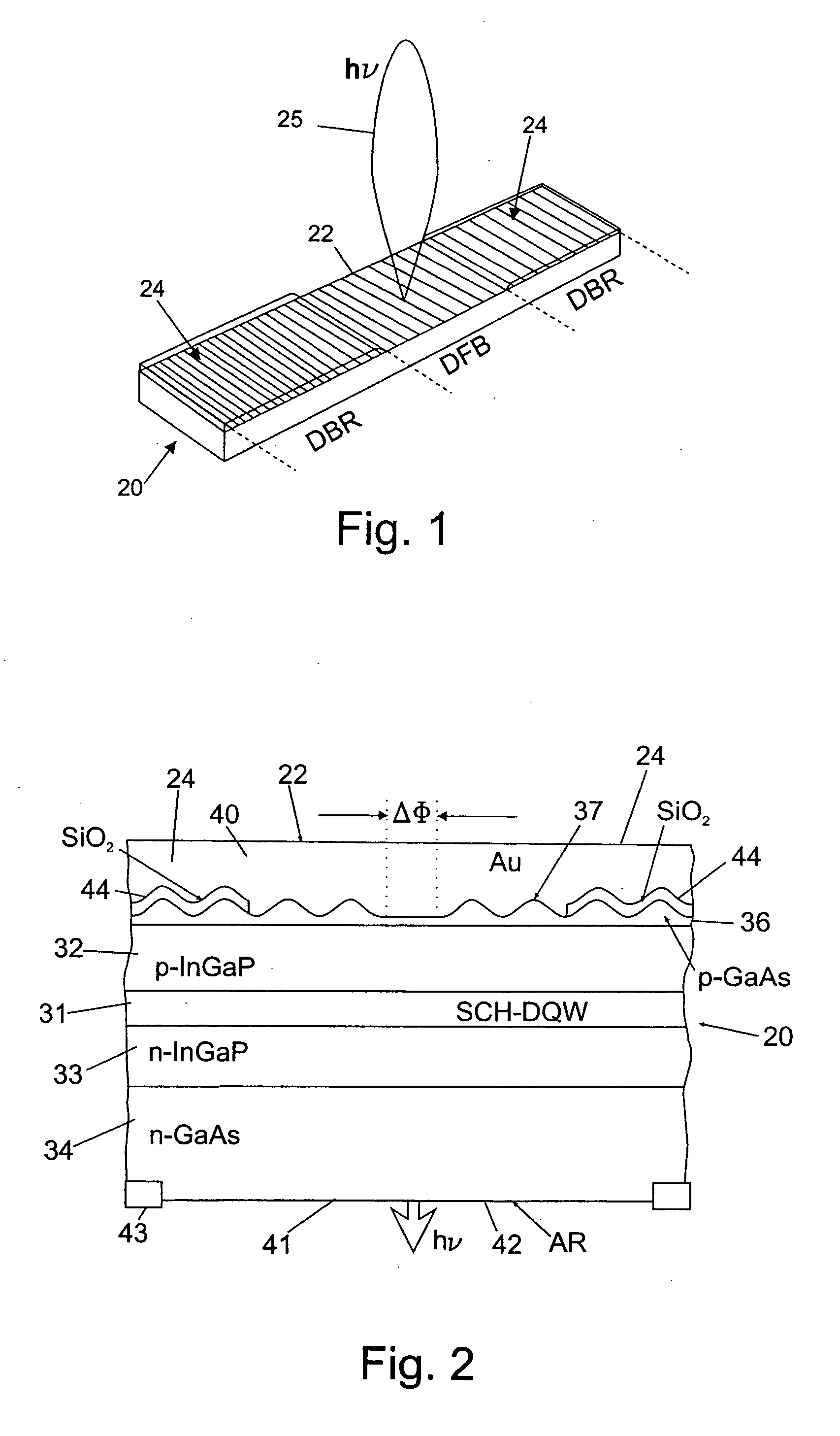

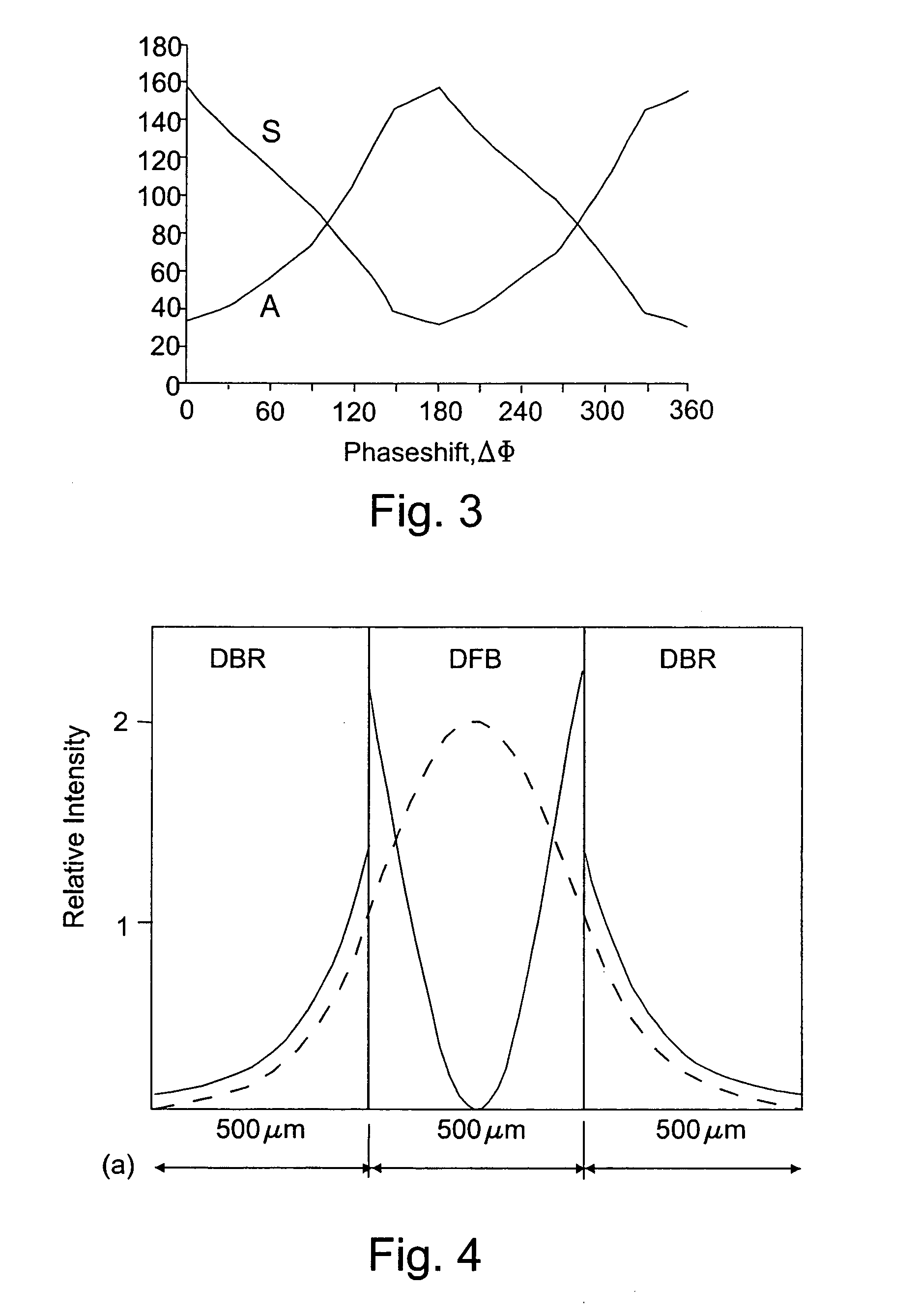

High coherent power, two-dimensional surface-emitting semiconductor diode array laser

ActiveUS20050238079A1No penalty in device efficiencyImprove efficiencyLaser optical resonator constructionSemiconductor laser arrangementsGratingDistributed Bragg reflector

A semiconductor laser is formed on a semiconductor substrate with an array of laterally spaced laser device elements each including a second order distributed feedback grating bounded by distributed Bragg reflector gratings. The device elements in which the distributed feedback grating and the distributed Bragg reflector gratings are formed have a lower effective index than the index of the interelement regions and are spaced so as to form an antiguided array.

Owner:WISCONSIN ALUMNI RES FOUND

Wind speed sensor based on micro mechanic working and its producing method

ActiveCN1588091ASimple packagingSmall lateral heat transferFluid speed measurement using thermal variablesEtchingPhotolithography

The invention is a wind speed sensor based on micro mechanical process and its manufacturing method, which uses silicon resistance as temperature measuring unit, the invention is a wind speed sensor and its manufacturing method with silicon substrate conduction. The whole structure of the sensor is integrated on the substrate, the manufacturing method is: a) plants a layer of oxidization layer on the silicon substrate, photoetching and corroding the internal ICP slots and external ICP slots, and injects the edge area of the heating bar; b) deposits a layer of multi-crystal silicon on the silicon, and forms a multi-crystal resistance through photoetching; c) photoetchs the injecting area; injects phosphor with high density, which is used as the contacting area of the substrate and the silicon induce; d) carries on low temperature silicon dioxide deposition, and corrodes out the inducing line contact window; e) deposits the aluminum, photoetchs the aluminum inducer, and corrodes aluminum; f) deposits passivation layer; g) photoetchs IPC slots, and carries on ICP etching; h) thins the back surface, and releases out the structure of the silicon resistance.

Owner:SOUTHEAST UNIV

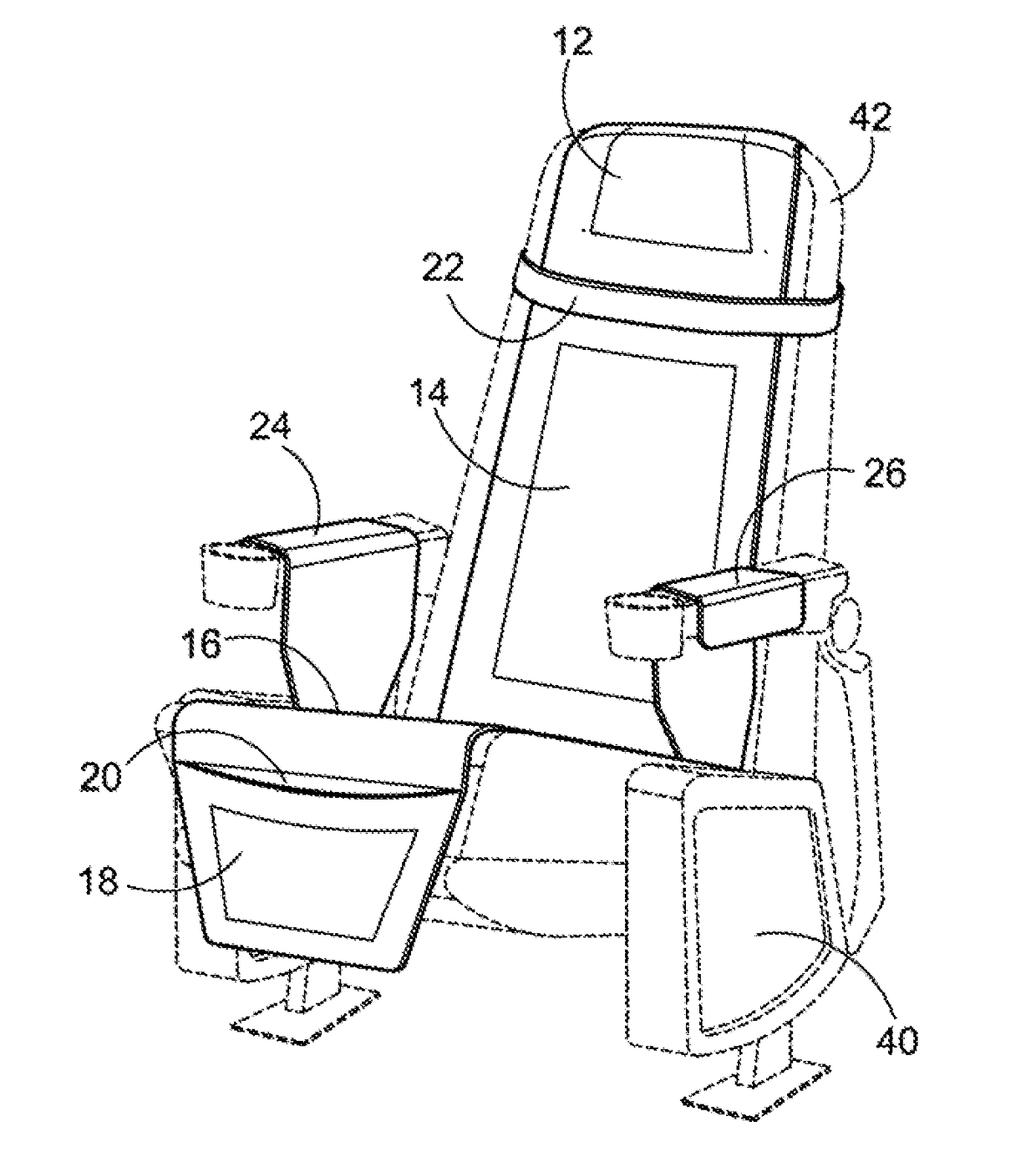

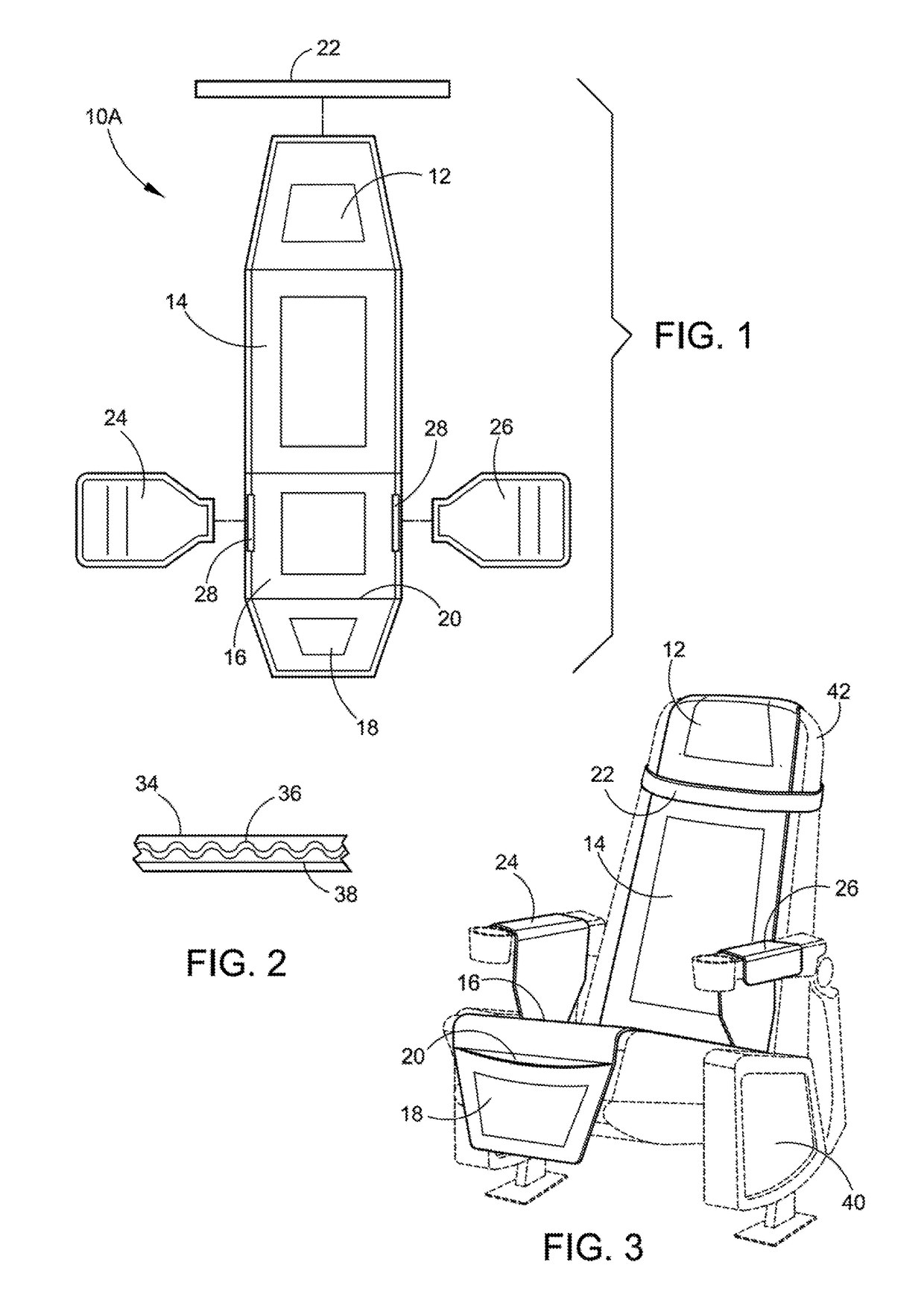

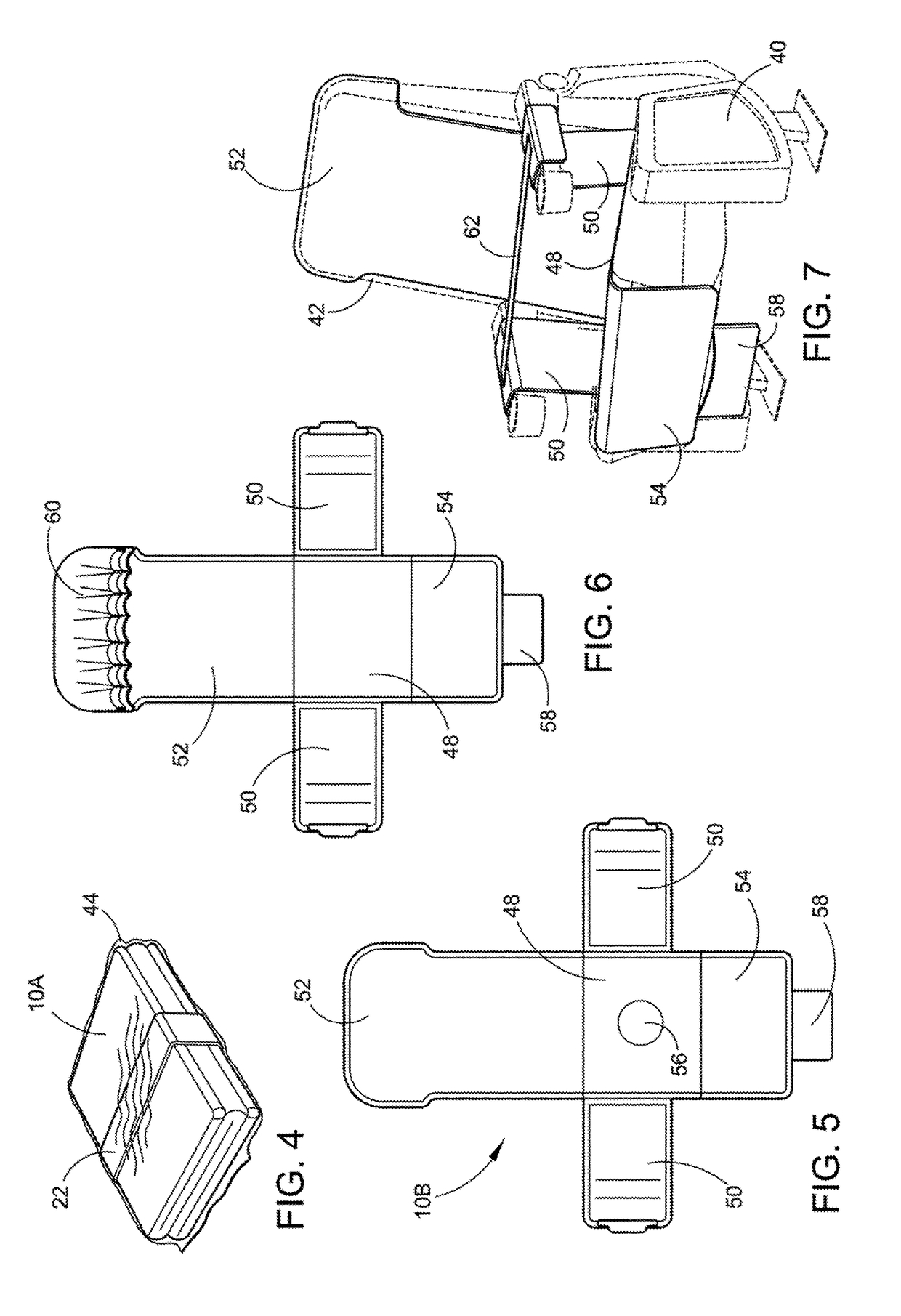

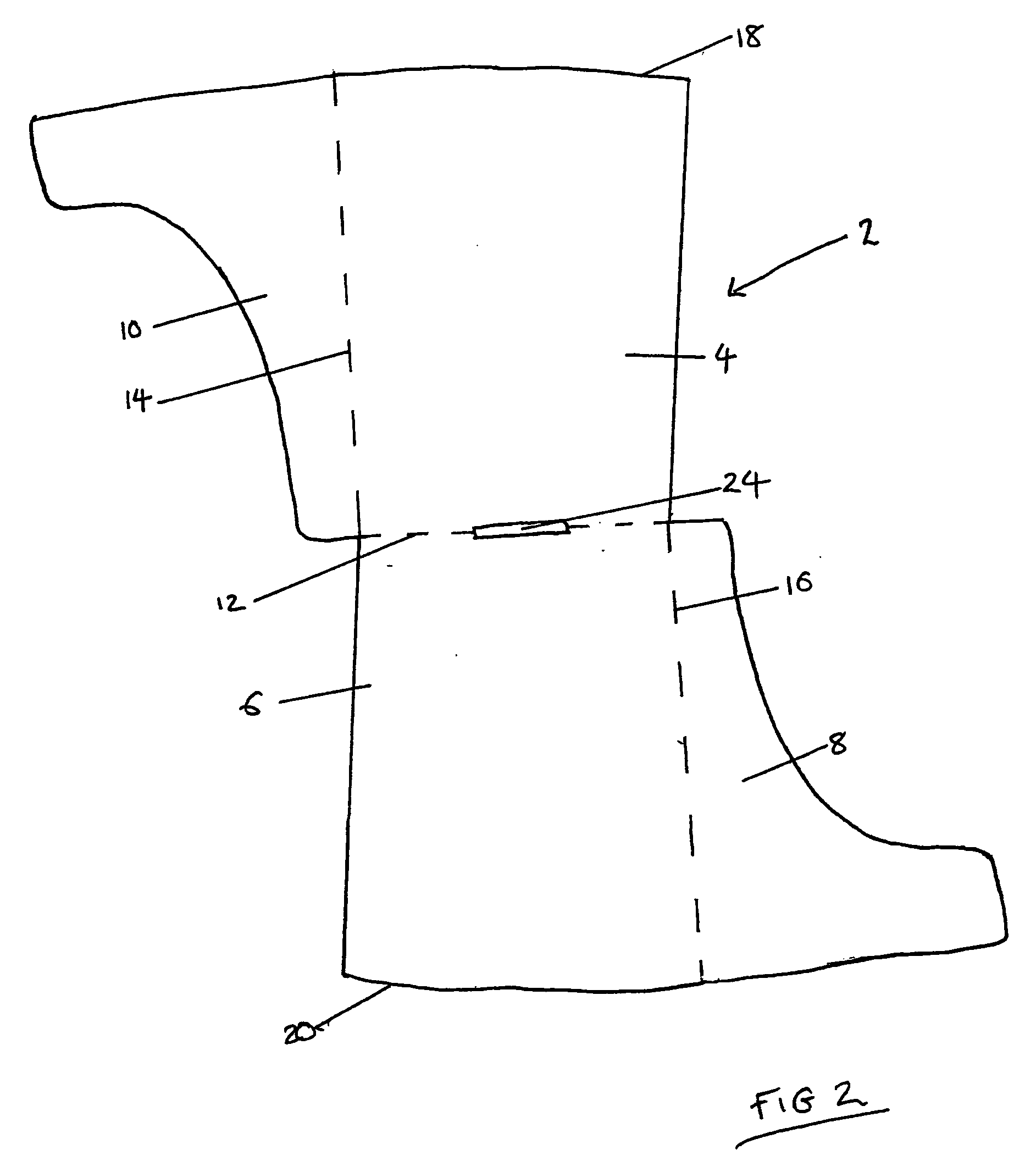

Antimicrobial disposable seat cover

The present invention is directed to an Antimicrobial Disposable Seat cover that is made of a material that is light, disposable and biodegradable, but resistant to dust mites, bed bugs, lice, mold, fungi, feces, viruses and bacteria, and a whole host of various microorganisms. Moreover, the provided Antimicrobial Disposable Seat Cover product is waterproof, breathable and as easy to use as a conventional disposable toilet seat cover. It will be AstM f1670 tested, and include an indicator of heat or moisture to indicate prior use. Any available pre-manufactured antimicrobial fabric or textile may be used in construction of the provided Antimicrobial Disposable Seat Cover product. Additionally, any to or textile that has been finished to exhibit antimicrobial characteristics may be used to configure and construct the present Antimicrobial Disposable Seat Covers provided herein.

Owner:LARKING INC

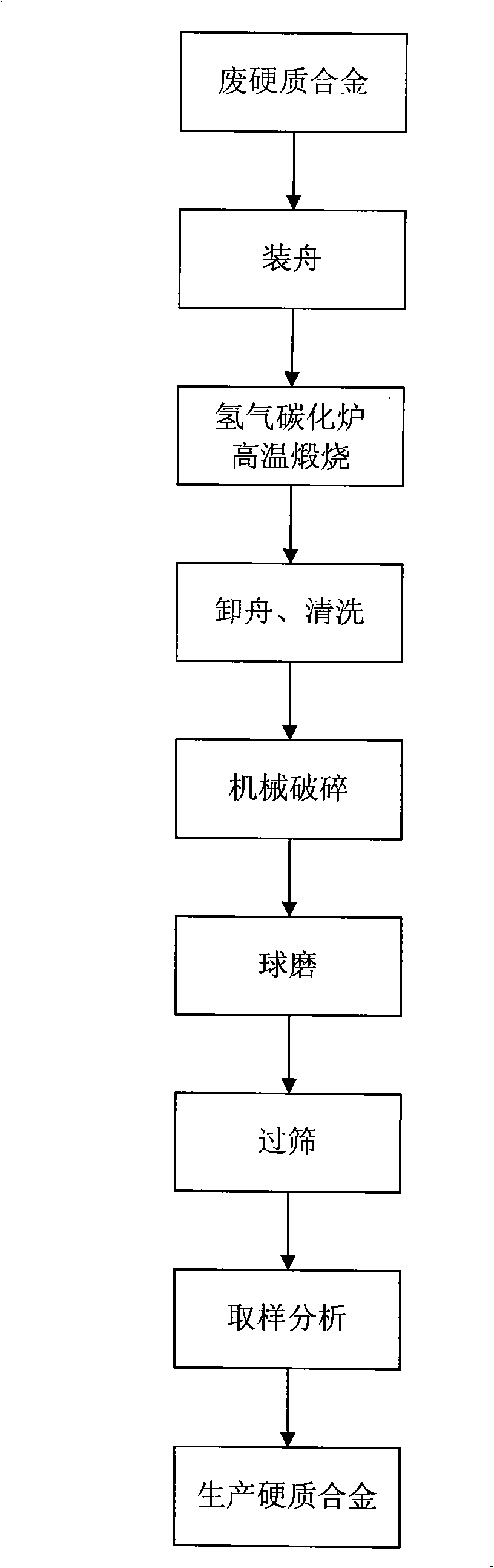

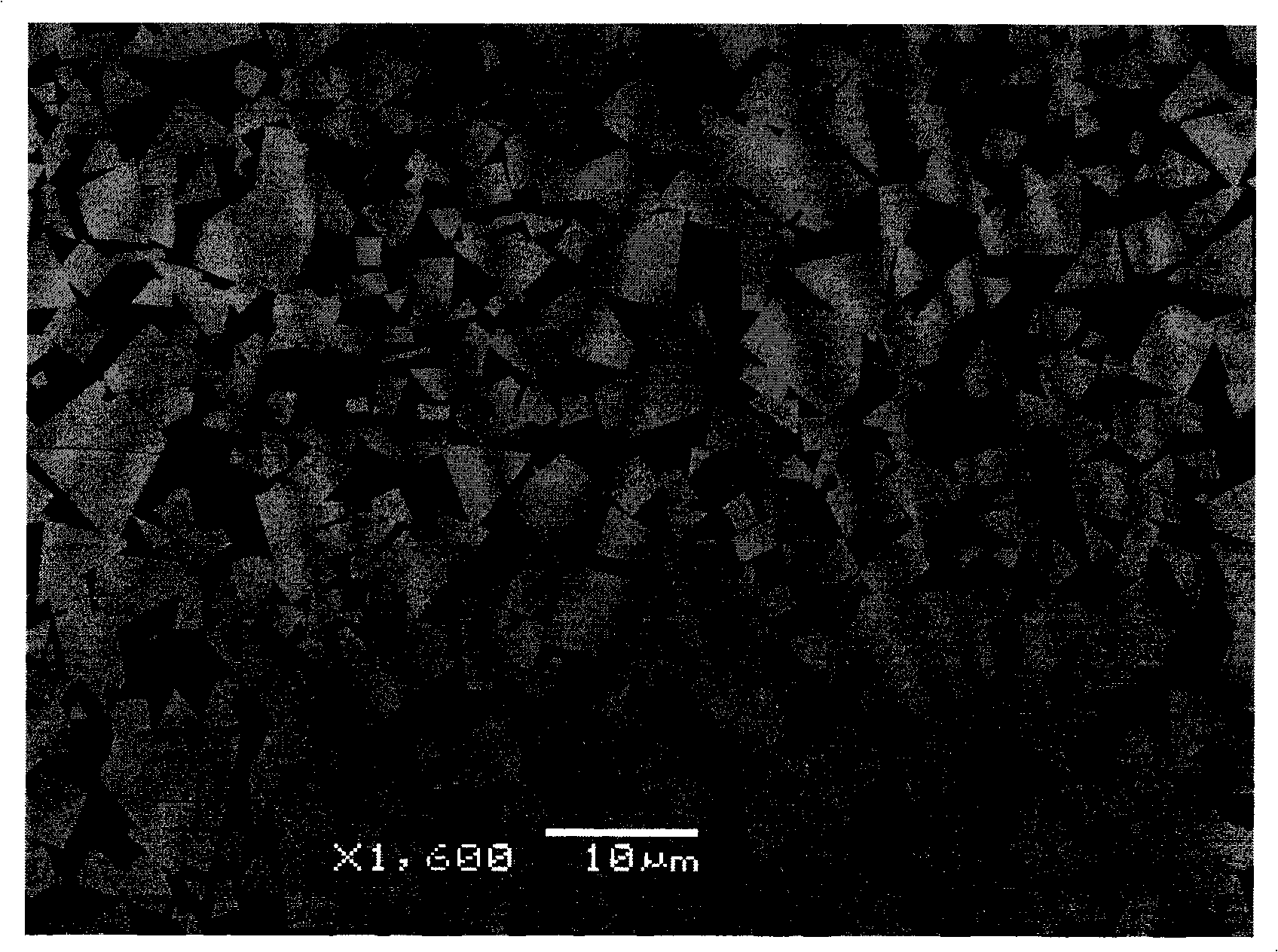

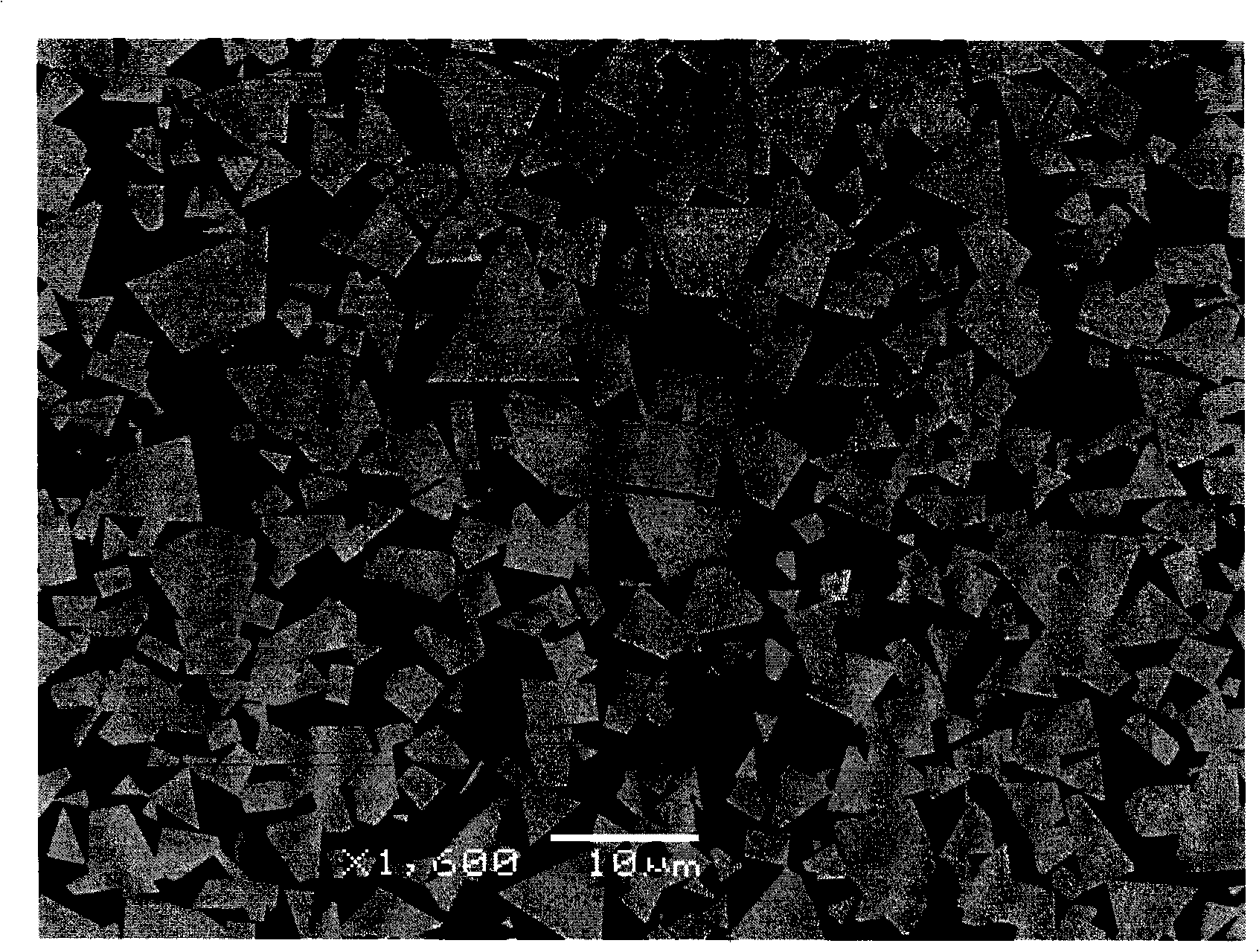

Recovery processing method of hard alloy scraps

The invention discloses a recovery processing method of hard alloy scraps. The method comprises the following steps: a. the hard alloy scraps and a filling agent of charcoal black are put into a graphite boat and put into a carbon tube furnace to be calcined under hydrogen at a high temperature, the calcining temperature is from 1600 DEG C to 2400 DEG C, the calcining time is from 30 min to 80 min, and the hydrogen amount is 1.2 to 2.6m<3> / h; b. the hard alloy scraps after being calcined at the high temperature are unloaded from the boat, cleaned on the surfaces, crushed at two stages by a jaw crusher and a roller crusher into alloy granules with the granularity of 2 mm to 8 mm; c. ball milling is carried out to the alloy granules after being crushed, the ratio of grinding media to material is (4 to 5):1, and the ball milling time is from 8 hours to 16 hours; d. alloy powder which is obtained after ball milling is screened, and the screened alloy powder which is detected to be qualified is used for mixing by a traditional production technology and manufacturing a hard alloy. The method adopts high-temperature calcination so that the hard alloy scraps are extremely easy to crush and process, and the recovered alloy powder has the same ingredients as the tungsten carbide of the processed hard alloy scraps and a binding metal.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

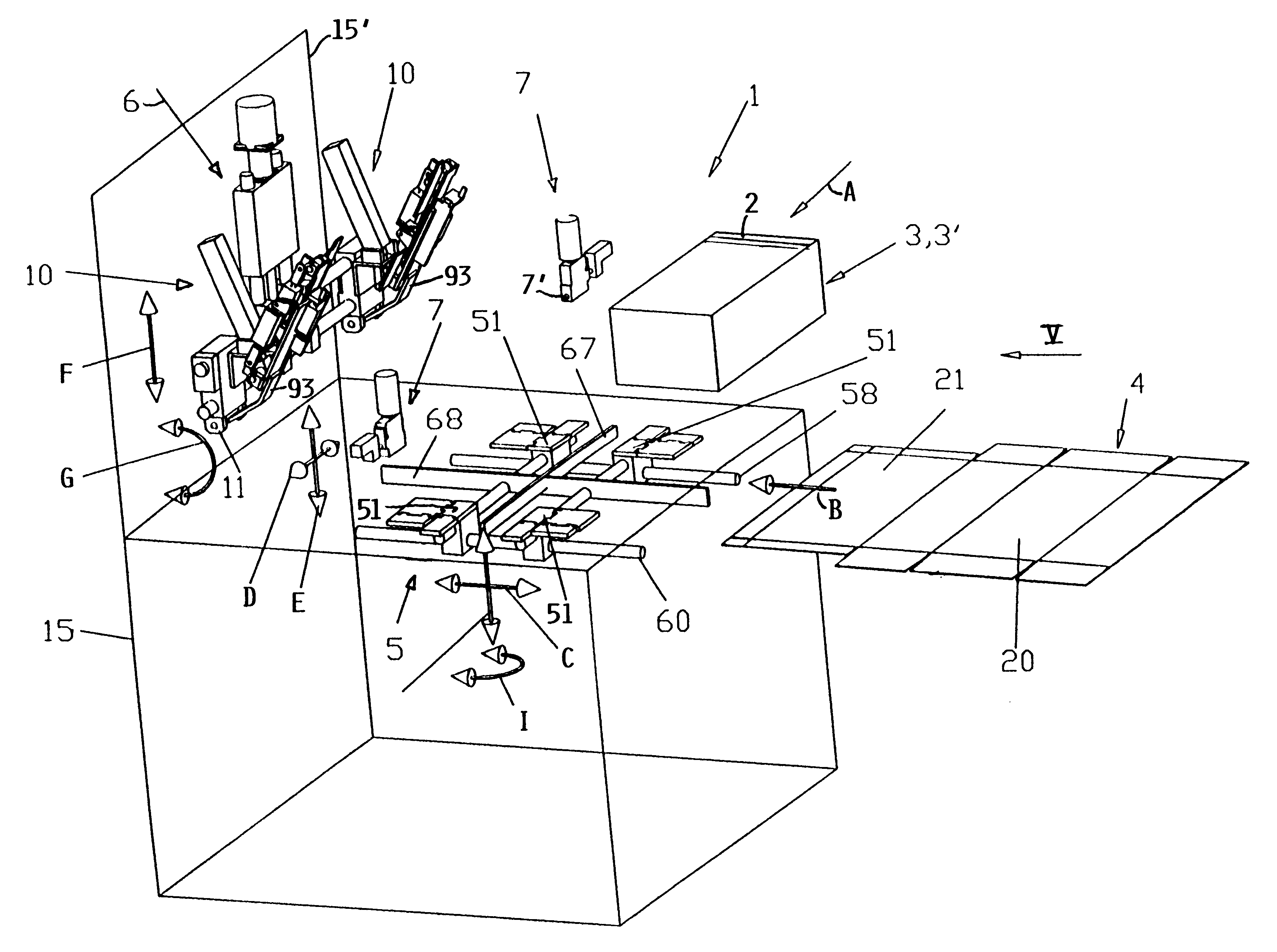

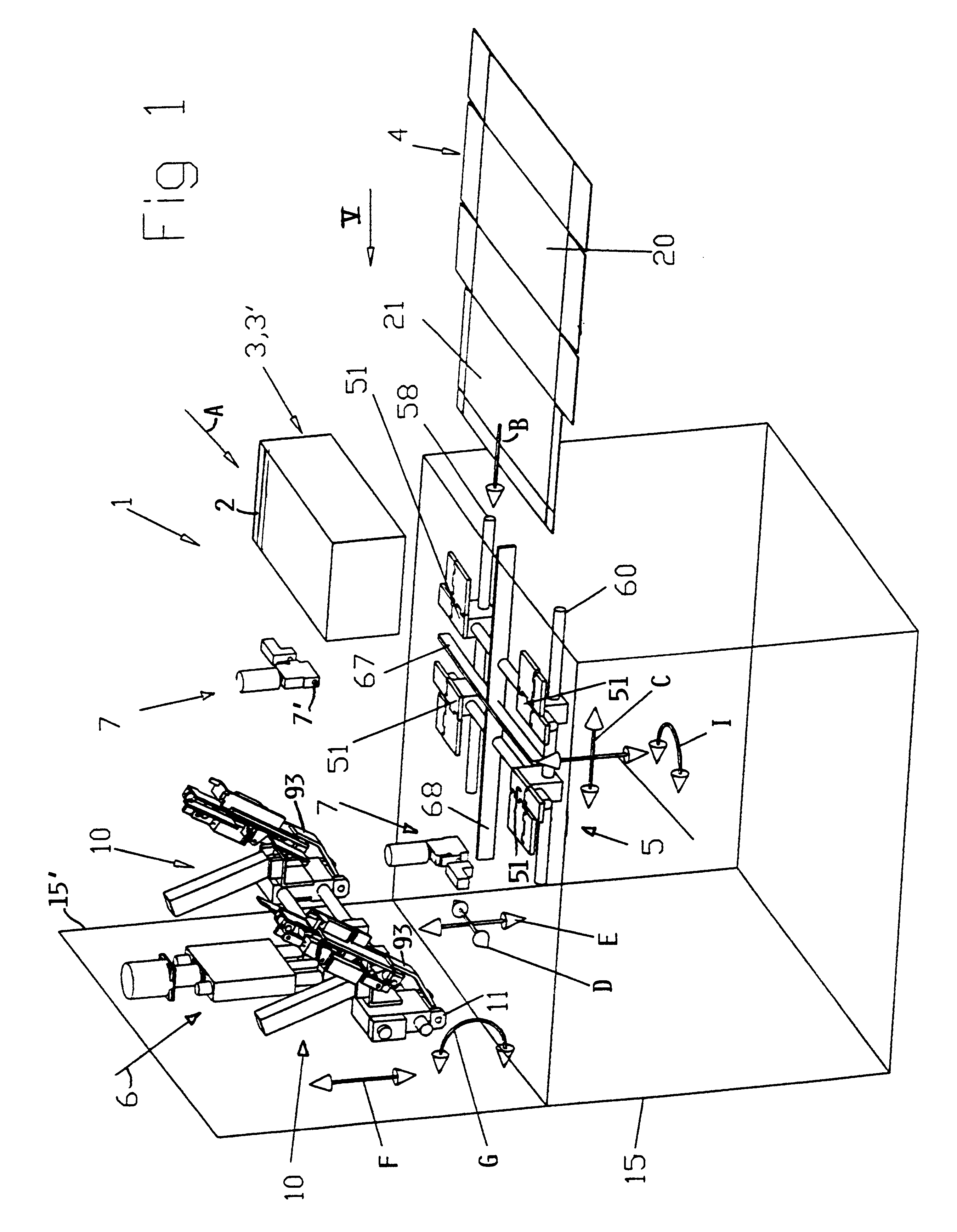

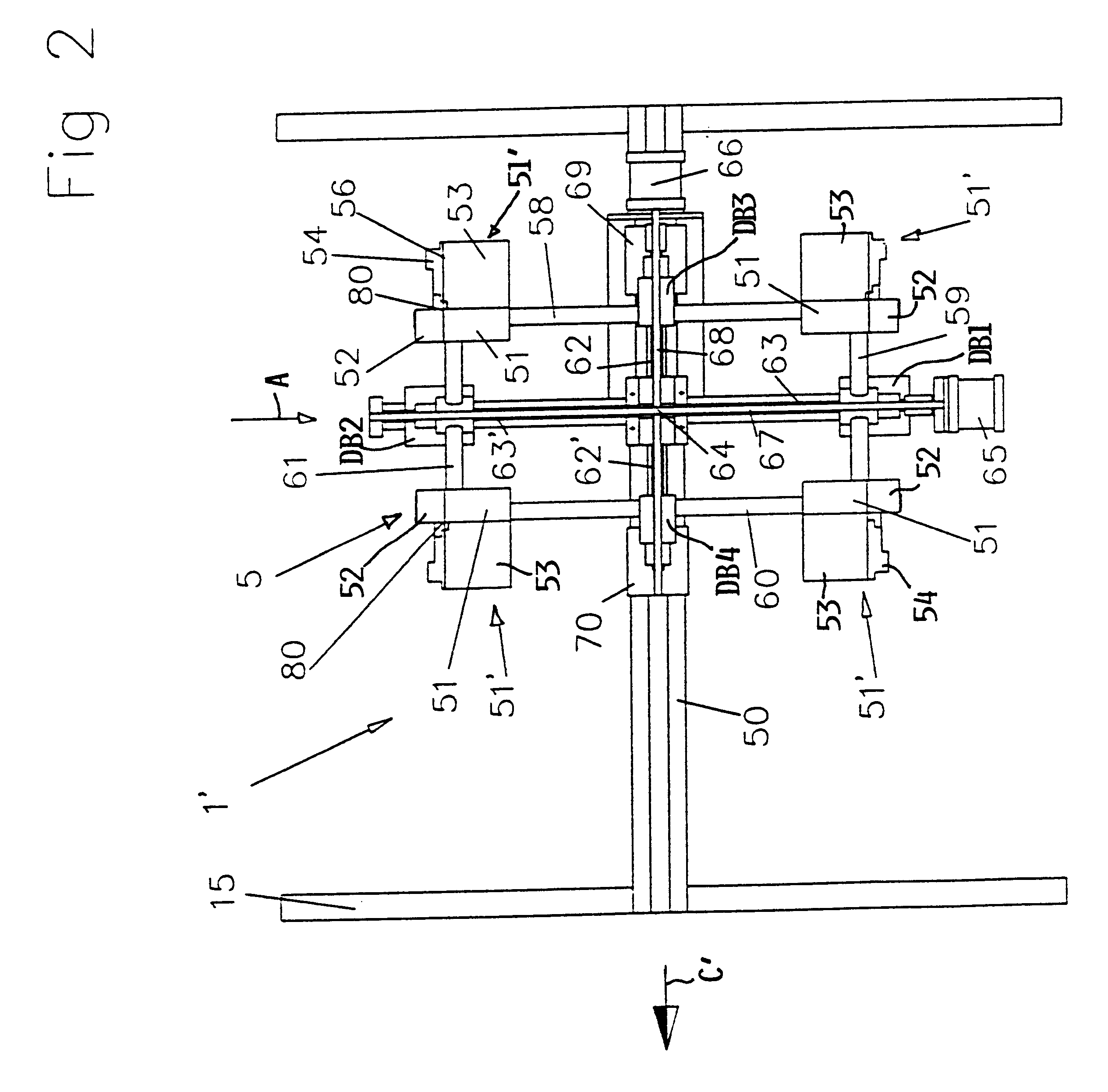

Apparatus for forming cartons from blanks and for simultaneously filling the cartons

InactiveUS6357212B1Easy to adjustPrecise positioningPaper article packagingBox making operationsCartonEngineering

A box folding and article packaging apparatus has a lower tool section positioned below a work support surface and several upper tool sections positioned above the work support surface. The lower tool section includes four modular corner units each with folding flaps and a fixed support element. The four support elements together define the work support surface. The four corner units are displaceable relative to each other for adapting the apparatus for handling blanks of different sizes. A precut and precreased blank is first placed on the work support surface. The article to be packaged is then placed on the blank whereupon folding begins. One upper tool section also includes folding elements for folding a cover portion of a box and closing the box. Another upper tool section includes either adhesive applicators or staplers or the like for fastening folded blank sections to one another to complete the carton around the article or articles.

Owner:WINKLER DUNNEBIER GMBH

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS20060070449A1High precision measurementReduced footprintFluid pressure measurement by electric/magnetic elementsSolid-state devicesDevice materialSilicon oxide

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

Method for preparing bactericidal agent using antagonizing bacteria M18 strain

InactiveCN1802927AControl sheath blightGood broad spectrumBiocideBacteriaHigh concentrationMetabolite

The invention relates to a method for preparing bactericide by using derivative bacterial of growth promoting antagonist bacterial M18, preparing fermentation liquor with high concentration of under phenazine-1-carboxyl acid and pyoluteorin under optimized culture medium and condition by using derivative bacterial M18G and M18R of growth promoting antagonist bacterial M18, preparing the fermentation liquor M18G and M18R into dry powder, double crossing physically the phenazine-1-carboxyl acid in M18G powder and pyoluteorin in M18R according to the weight ratio of 90%-10% and 10%-90%, and finally getting bactericide of high efficiency for preventing plant disease. Compared with current technology, the bactericide provided in this invention is wet powder taking metabolite of microorgsanism as active element but not live bacterial agent, as a result of which the product is characterized by high stability, not easy to be influenced by environment and better prevention and curing effect for multiple plant disease under low consumption.

Owner:SHANGHAI JIAO TONG UNIV

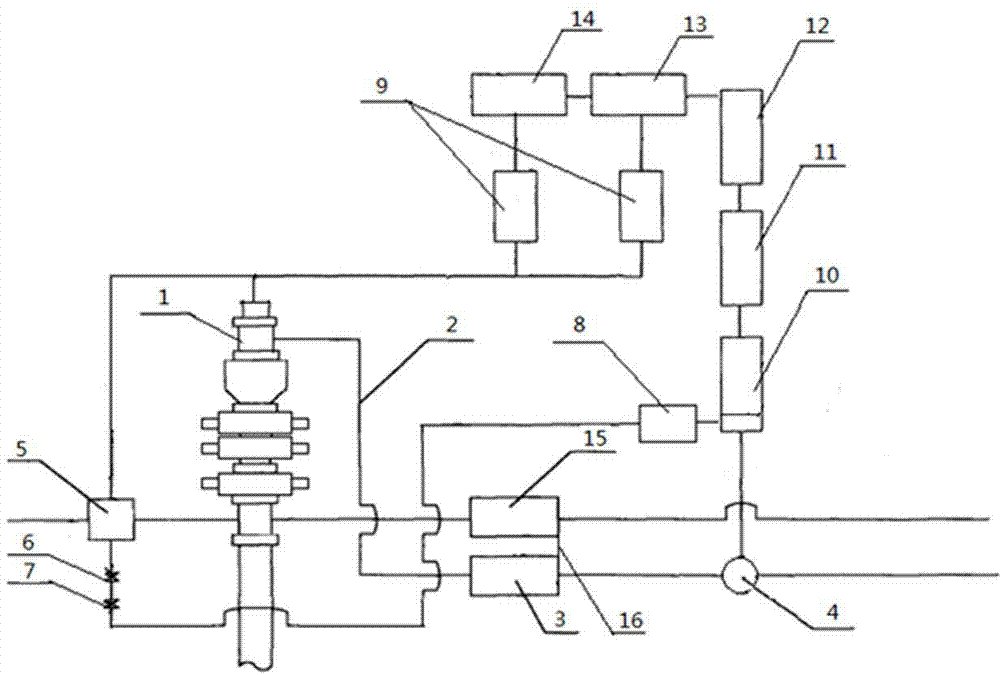

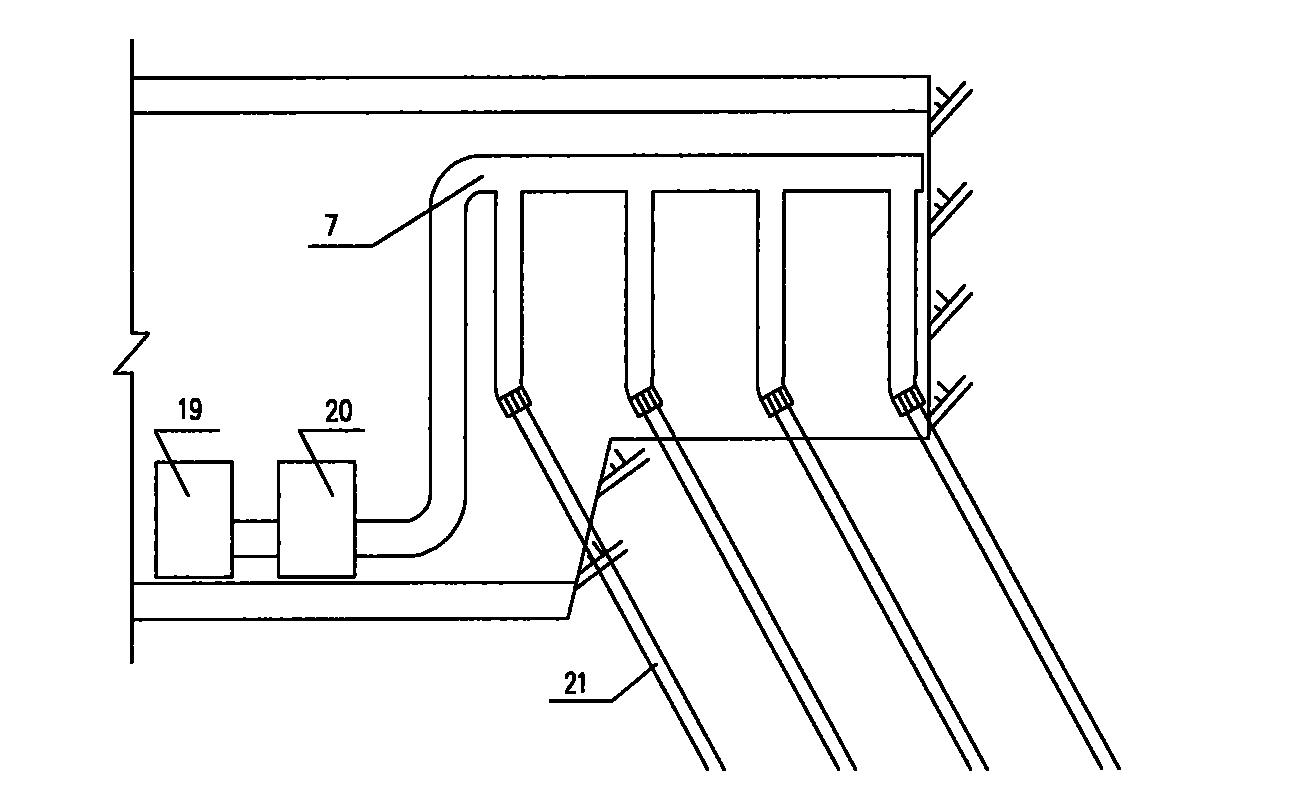

Balanced pressure drilling pressure control device and method

The invention provides a balanced pressure drilling pressure control device and a method for conducting well drilling pressure control through the balanced pressure drilling pressure control device. In the balanced pressure drilling pressure control device, a wellhead rotary blowout preventer is installed at the upper end of a wellhead blowout preventer set, and the wellhead rotary blowout preventer and a pressure control throttling pipe manifold are connected through a high-pressure pipeline, and a kill manifold is connected with a well drilling fluid filling system through a wellhead four-way part. A filling pump, a gate valve and a check valve are installed on the well drilling fluid filling system in sequence at the outlet end of the kill manifold, and the filling pump is connected with a well drilling fluid circulating tank through a pipeline. The pressure control throttling pipe manifold is connected with a liquid-gas separator through a pipeline, and then is connected to the well drilling fluid circulating tank, so that the well drilling fluid cycle is formed. Compared with an existing pressure control well drilling method, the method has the advantages that facilities and devices such as a return pressure pump and a flowmeter are not arranged on the ground, no pressure measuring transmission devices exist in a well, and matching is easy; and due to the fact that control is conducted according to the stability of the amount of fluid in the well drilling fluid circulating tank in drilling operation, and the size of a drilling stem in tripping operation, and measurement, metering and operation are quite easy and convenient.

Owner:CHINA PETROCHEMICAL CORP +1

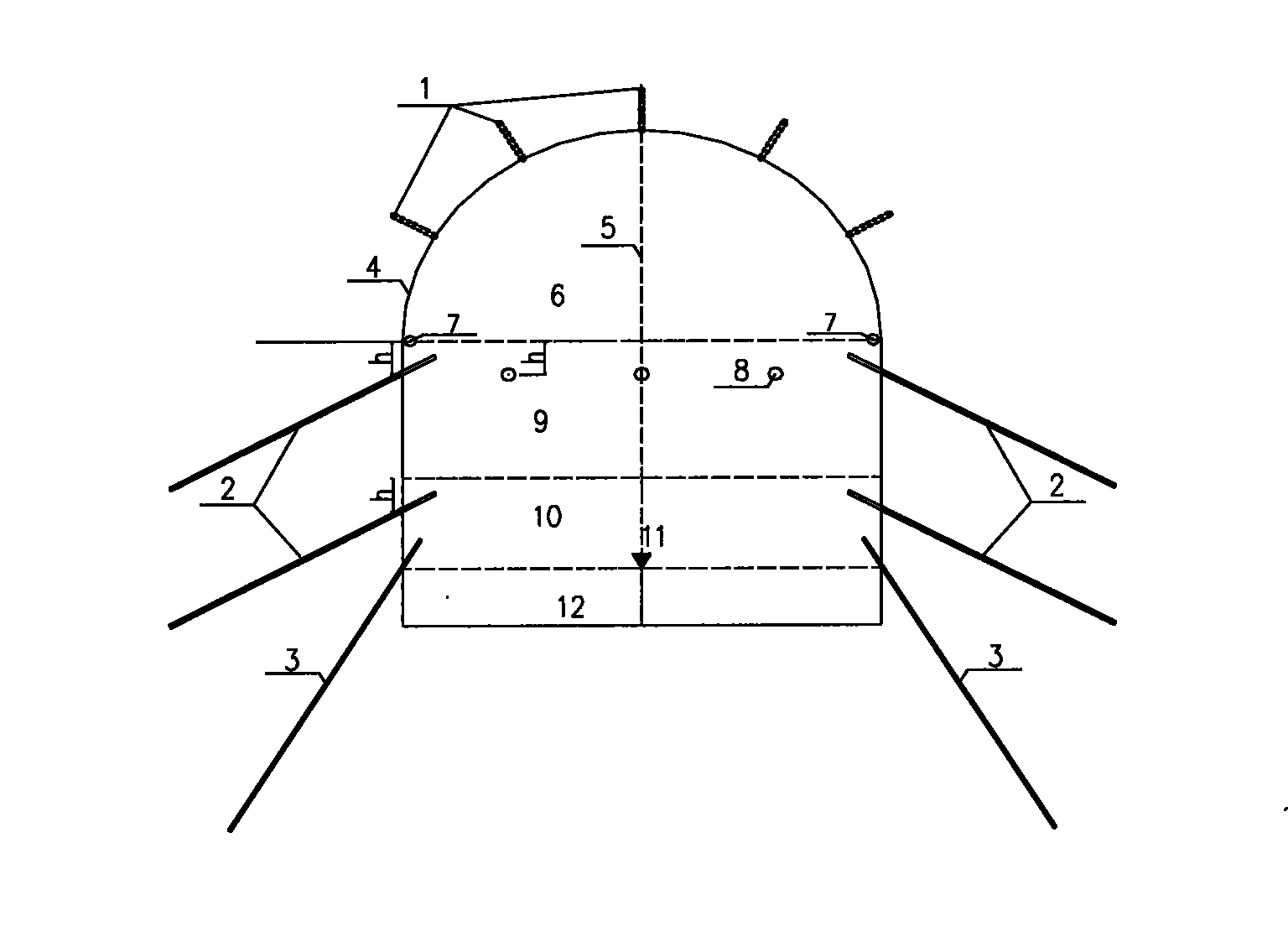

Vacuum light well point dewatering method

InactiveCN102278142AExcavation is normalSimple packagingDrainageArchitectural engineeringOperability

The invention provides a vacuum lightweight well-point dewatering method, which comprises the following steps of: arranging at least one row of working face advanced vacuum dewatering pipes according to a certain annular interval within a certain angle range of working face vault; excavating an upper step, and arranging at least one row of first vacuum dewatering pipes at a certain distance under the arch foot of the upper step; and excavating an intermediate step, and arranging at least one row of first vacuum dewatering pipes at a certain distance under the arch foot of the intermediate step. The dewatering pipes are arranged according to an excavating working method adopted in tunneling, therefore the method disclosed by the invention has the advantages of simple process, convenience for construction and operation, low energy consumption, low construction cost and good dewatering effect; and the construction equipment is simple to assort, the arrangement of large-scale equipment when other dewatering methods are adopted is reduced, and the construction equipment has the advantages of simpleness in installation, strong operability and convenience for maintenance.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

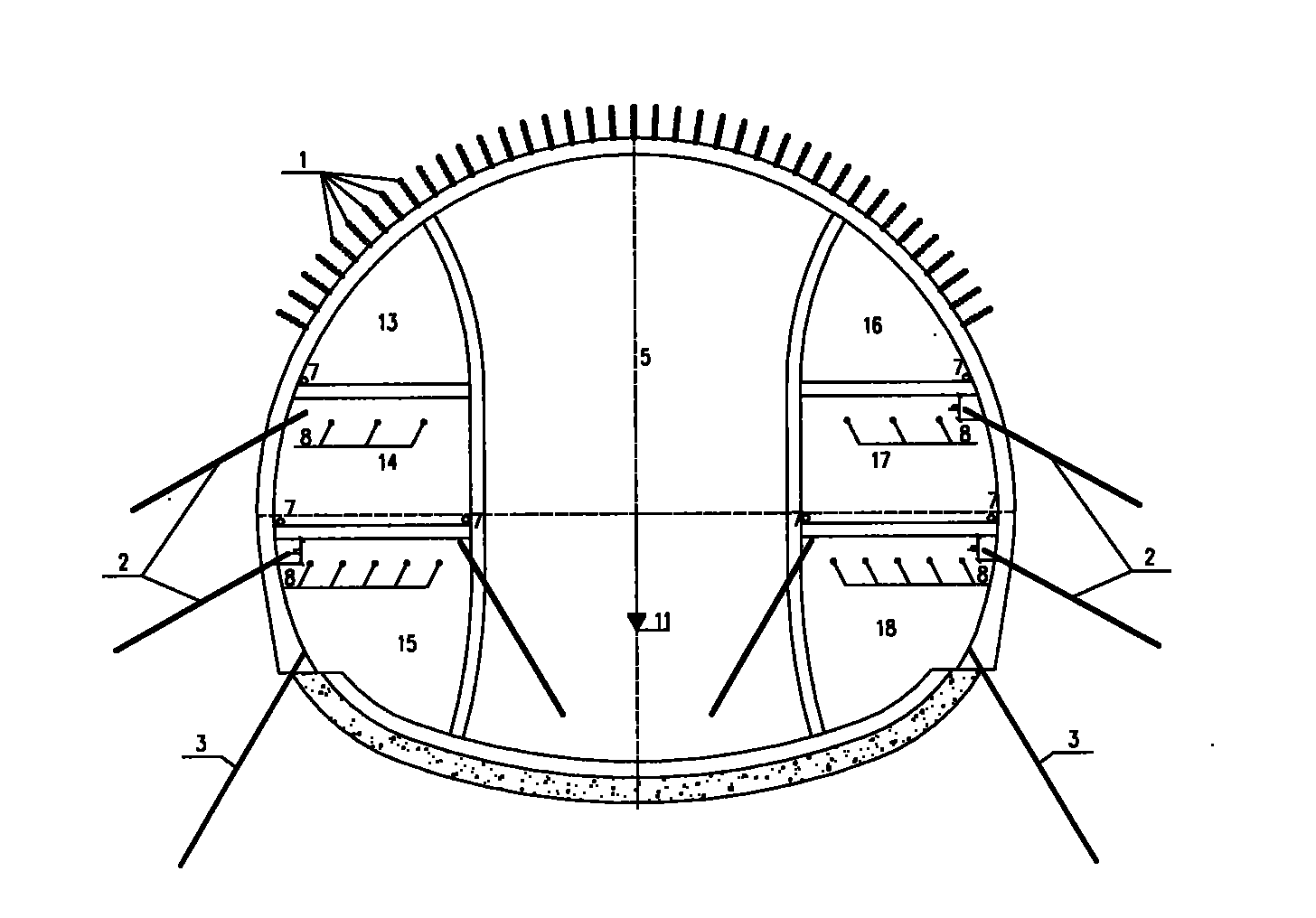

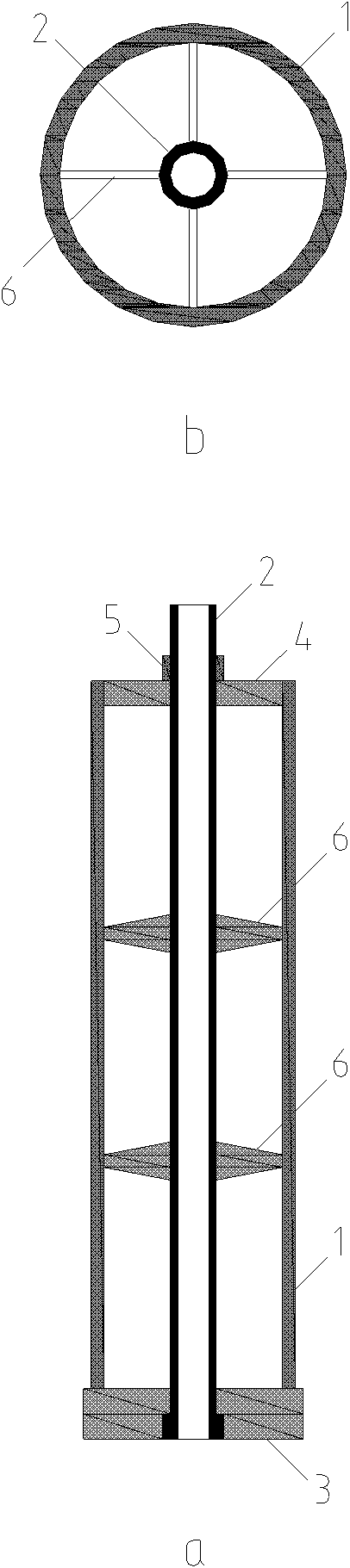

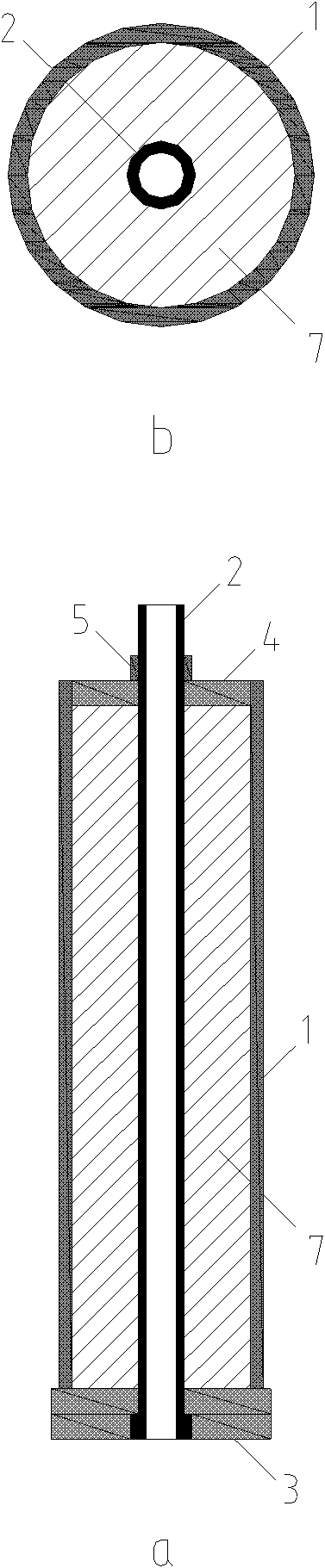

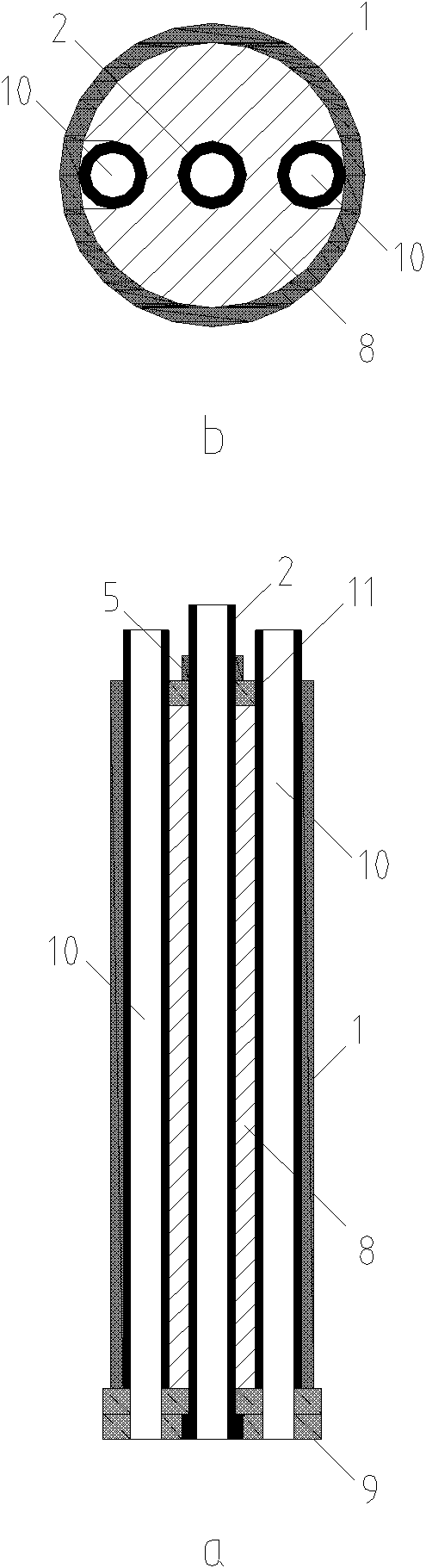

Whole process construction method of driven cast-in-place piles and special device for same

ActiveCN102286970ASimple packagingEasy to controlFoundation testingBulkheads/pilesEconomic benefitsSoil horizon

The invention provides a whole process construction method of driven cast-in-place piles and a special device for the same. The special device comprises pile pipes and base plates, wherein the pile pipes comprise class-A pile pipes, class-B pile pipes and class-C pile pipes. The whole process construction method comprises a pile testing method, a pile manufacturing method, a pile measuring method and a bottom vibration method for inserting reinforcement cages later. The construction method and the device have the following beneficial effects: the problem of higher control difficulty and pile tip cost of the traditional internally driven piles is solved; compared with the long augered press-grouting piles, the driven cast-in-place piles manufactured with the construction method have the pile tip bearing capacity improved by several times; with respect to the aspects of pile testing and pile measuring, the pile tip resistance is obtained not by pressing the whole piles but by pressing the cast-in-place pipes or inner tips with sections being much smaller than the sections of the whole piles, the pressed pile tonnage is greatly reduced and the pile testing and measuring costs and construction periods can be substantially reduced; the ultimate resistance of the tips of the long augered press-grouting piles with diameter being 800mm under the given soil horizon condition is within 400t, but the ultimate resistance of the tips of the piles manufactured by using the construction method exceeds 1300t, which is more than three times that of the tips of the long augered press-grouting piles; and the construction method and the device have good technical and economic benefits.

Owner:毕建东

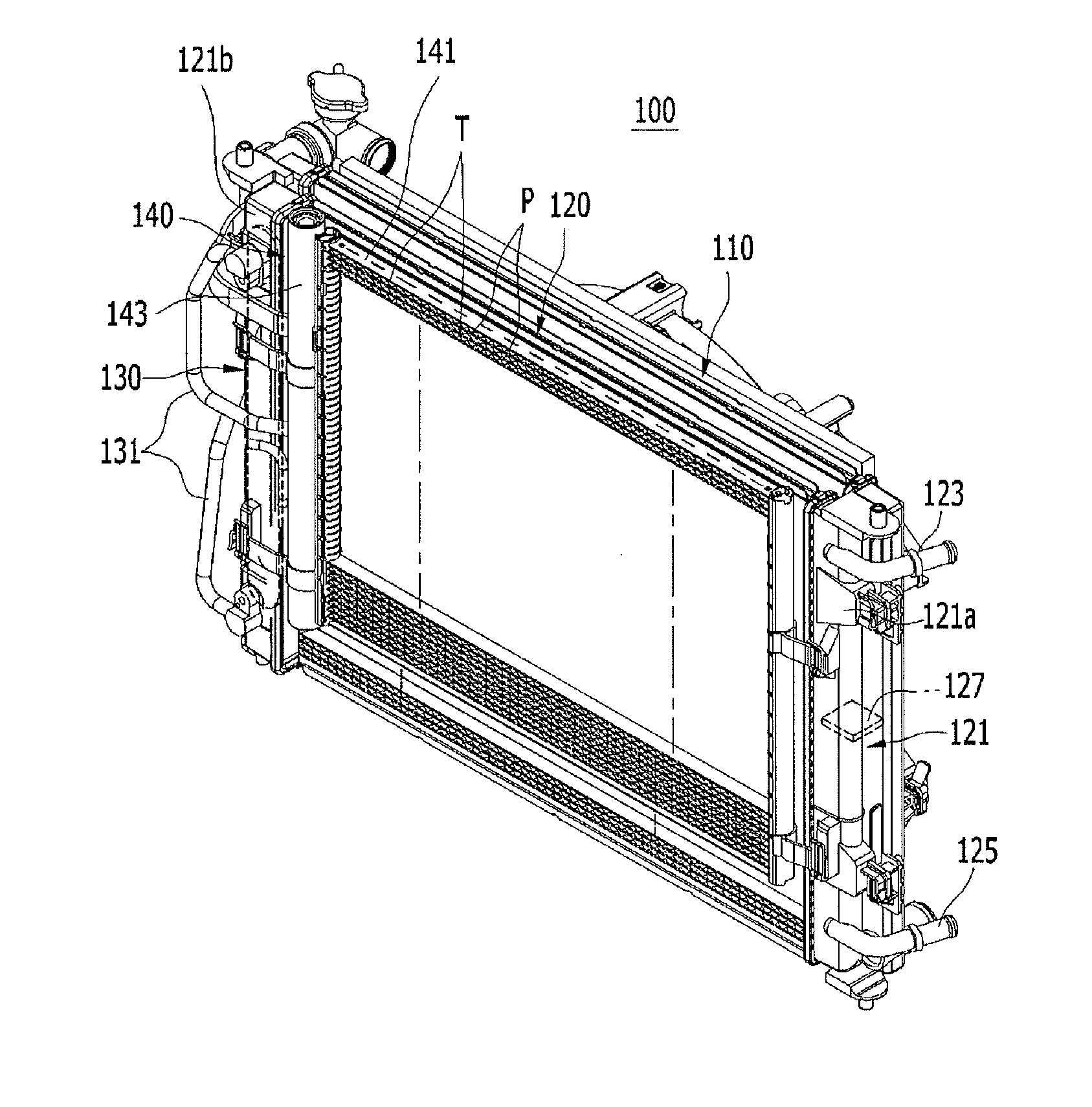

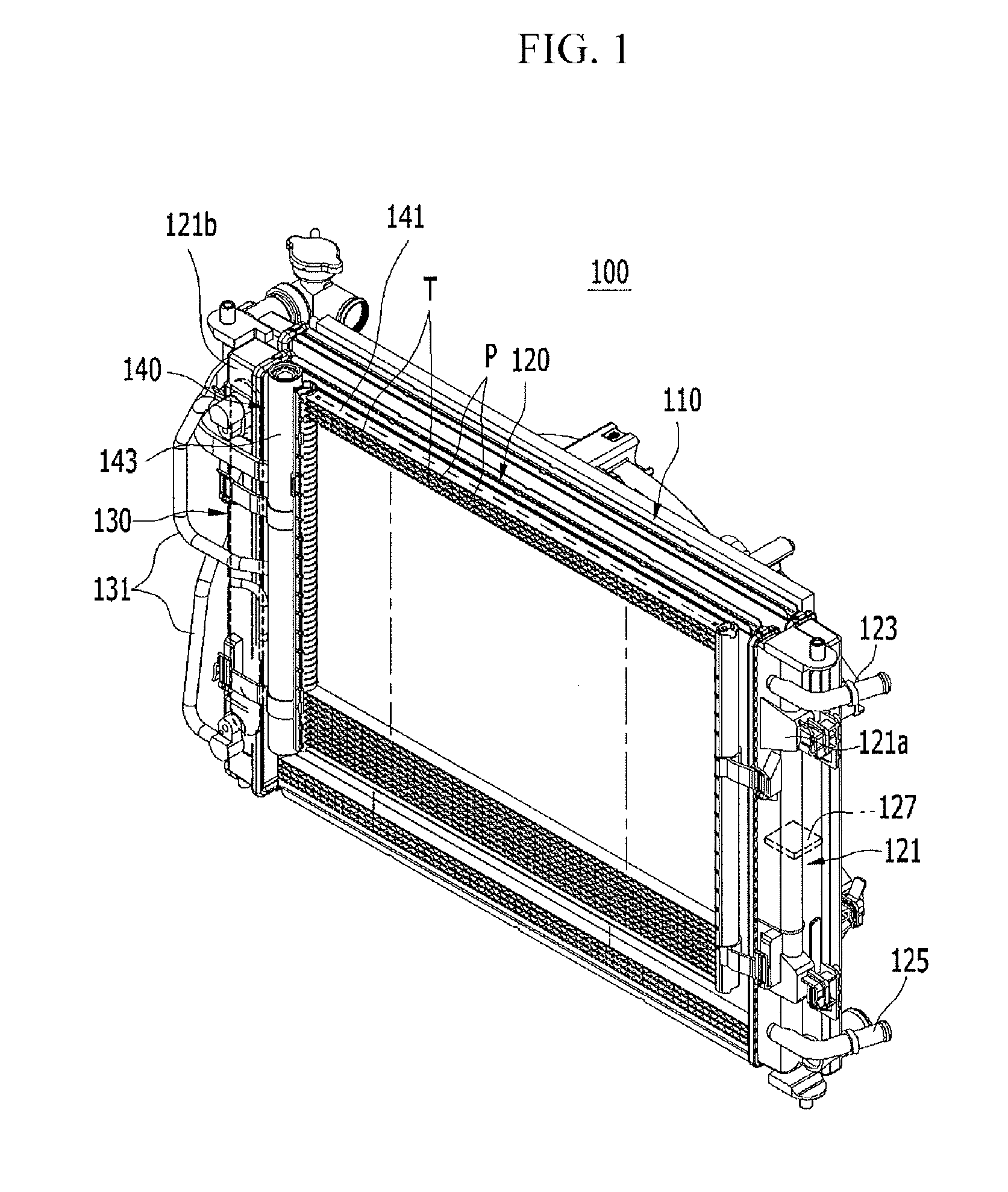

Cooling module for vehicle

InactiveUS20150167532A1Increase heat radiate amountImprove cool performanceLiquid coolingAir-treating devicesIntercoolerRefrigerant

A cooling module for a vehicle may include a main radiator, a sub-radiator, a water-cooled condenser and an air-cooled condenser. The main radiator may be disposed at a front region of an engine room and supplies cooled cooling water to an engine. The sub-radiator may be disposed substantially in parallel with the main radiator and in front of the main radiator, have header tanks at both sides and supply the cooled cooling water to an intercooler or electric components. The water-cooled condenser may be disposed in one of the header tanks and primarily condenses a refrigerant by using the cooling water as a heat exchange medium. The air-cooled condenser may be in fluidic communication with the water-cooled condenser to be introduced with the refrigerant condensed in the water-cooled condenser and may be disposed in front of the sub-radiator to secondarily condense the refrigerant.

Owner:HYUNDAI MOTOR CO LTD

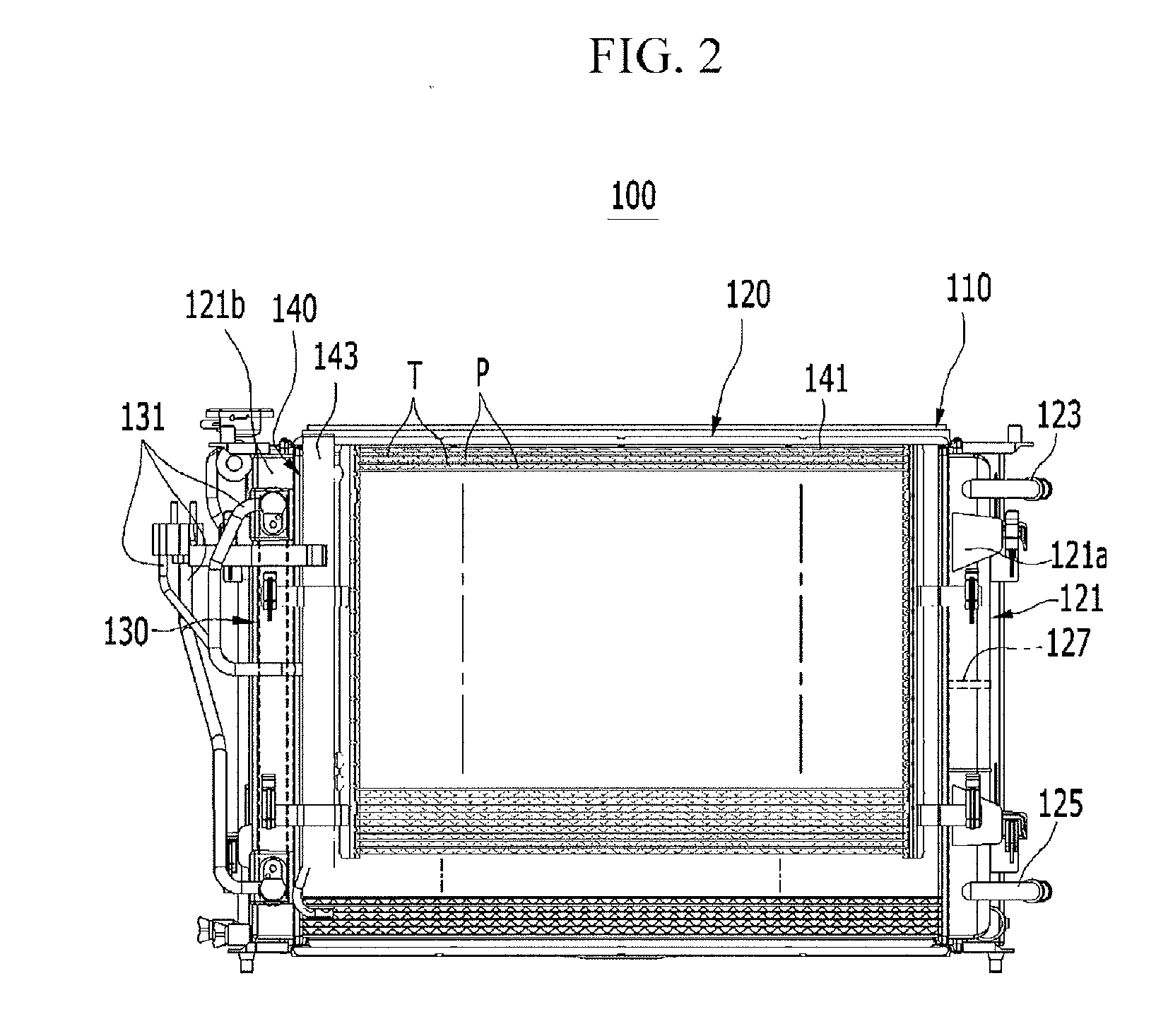

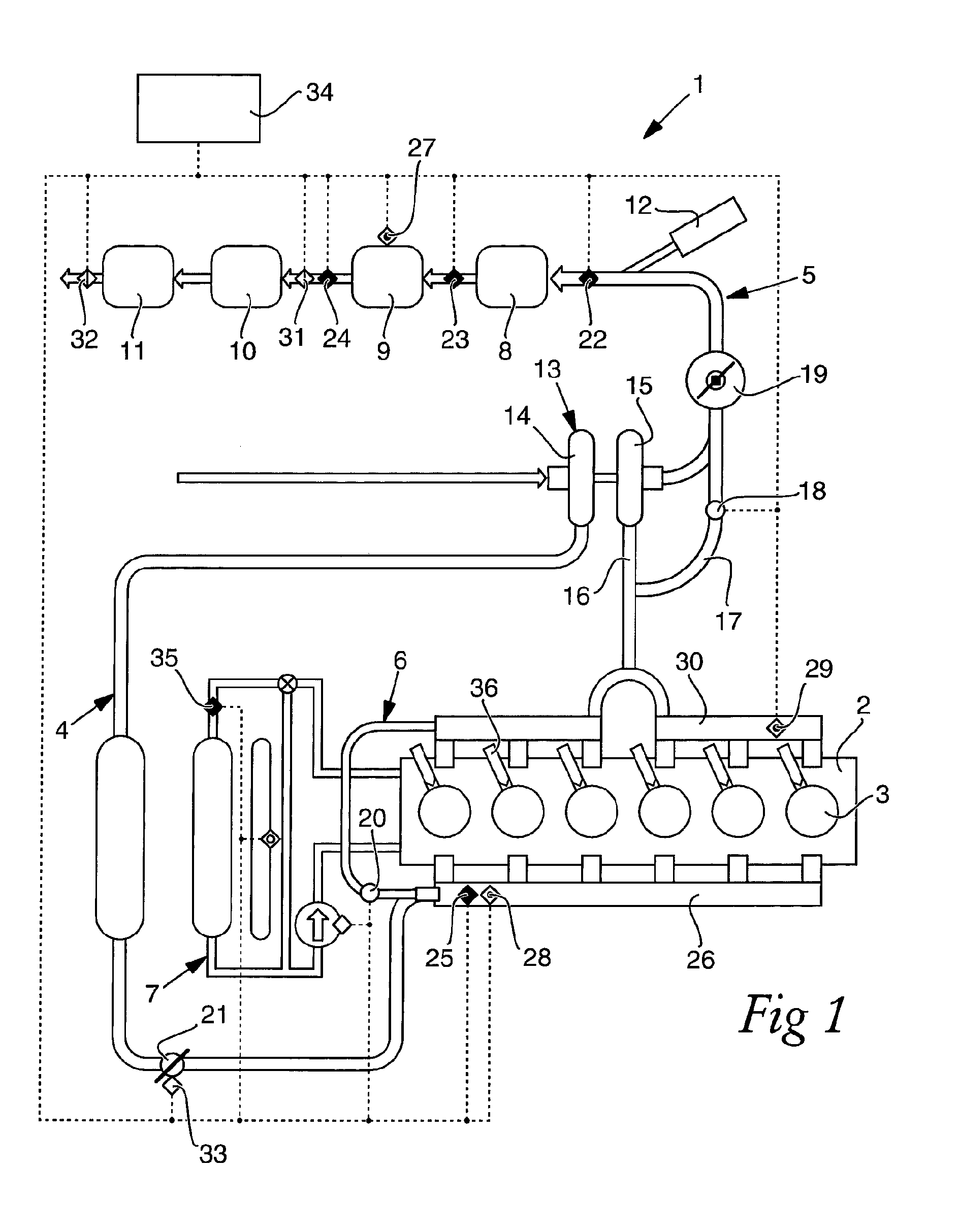

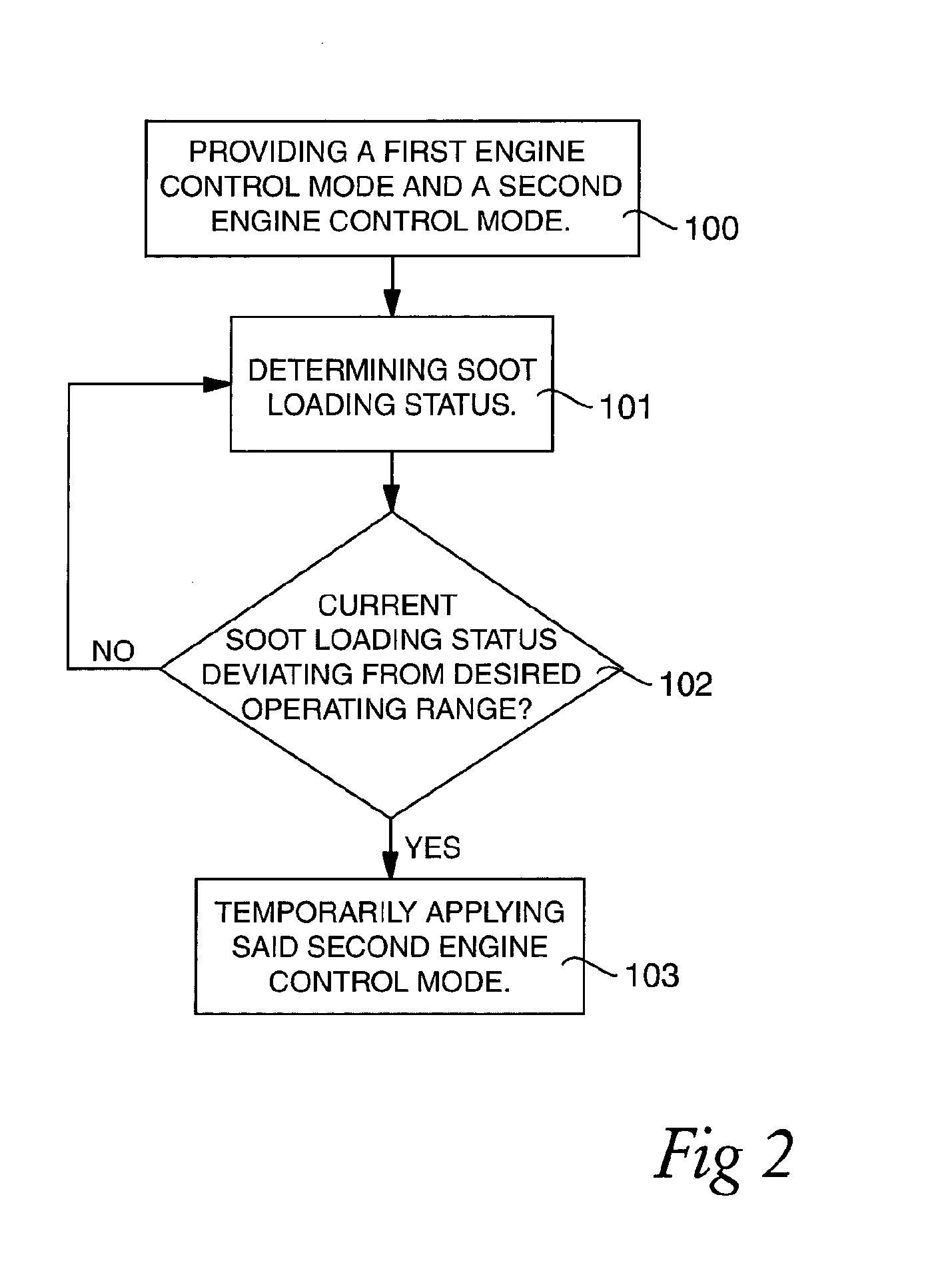

Method of conditioning a particle filter

ActiveUS20150285173A1Improve filtration efficiencyThermal propertyAnalogue computers for vehiclesElectrical controlFill rateInternal combustion engine

A method of conditioning a particle filter provided for receiving exhaust gases from internal combustion engine is provided and includes providing a first engine control mode and a second engine control mode, wherein in the second engine control mode at least one combustion control parameter that affects the characteristics of particles emitted together with and carried by the exhaust gases from the engine is different in relation to the first control mode such that the filling rate of the particle filter with particles is increased compared to the filling rate that would have been achieved with the first engine control mode, determining a soot loading status of the particle filter, and temporarily applying the second engine control mode to the engine based on the soot loading status.

Owner:VOLVO LASTVAGNAR AB

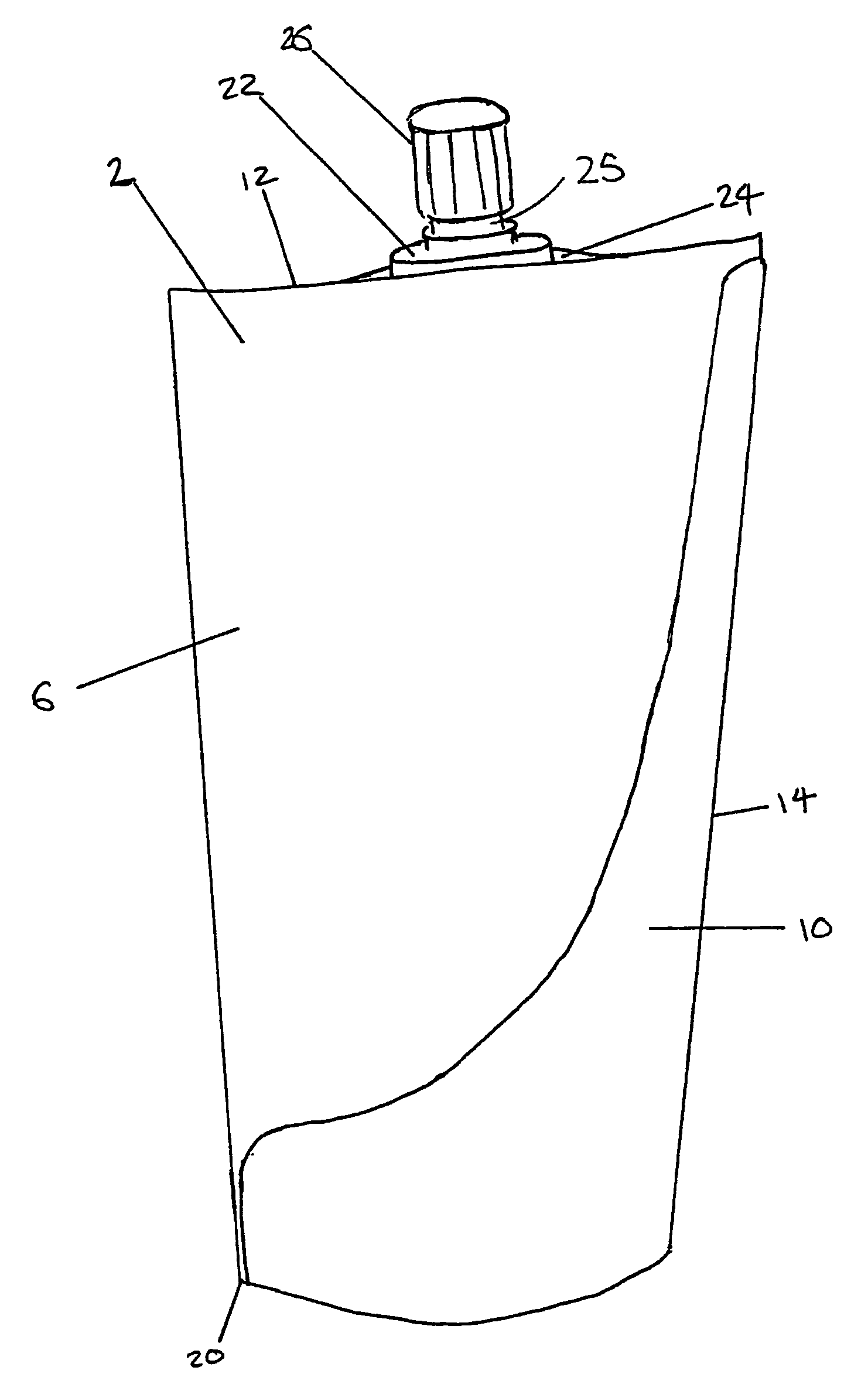

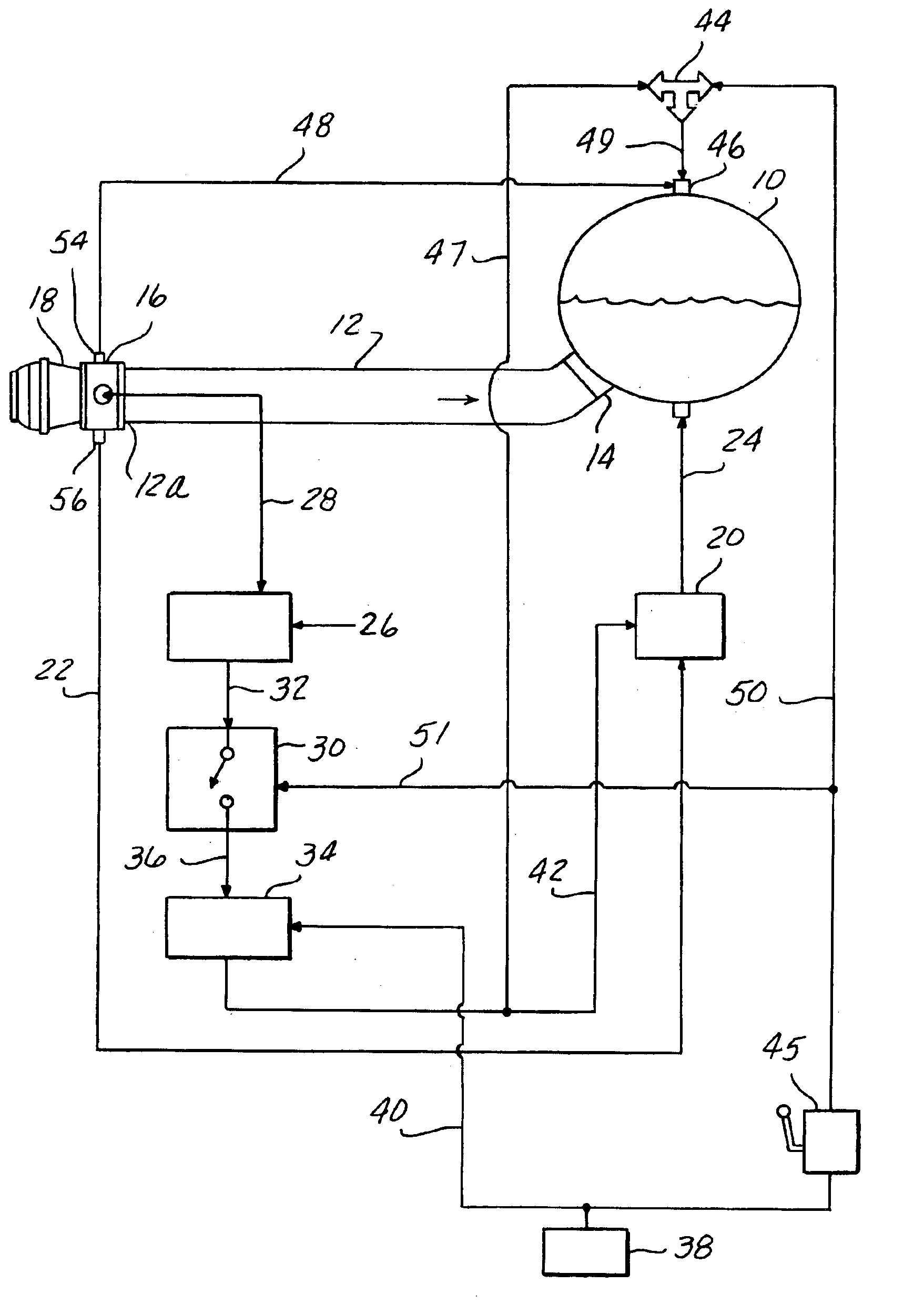

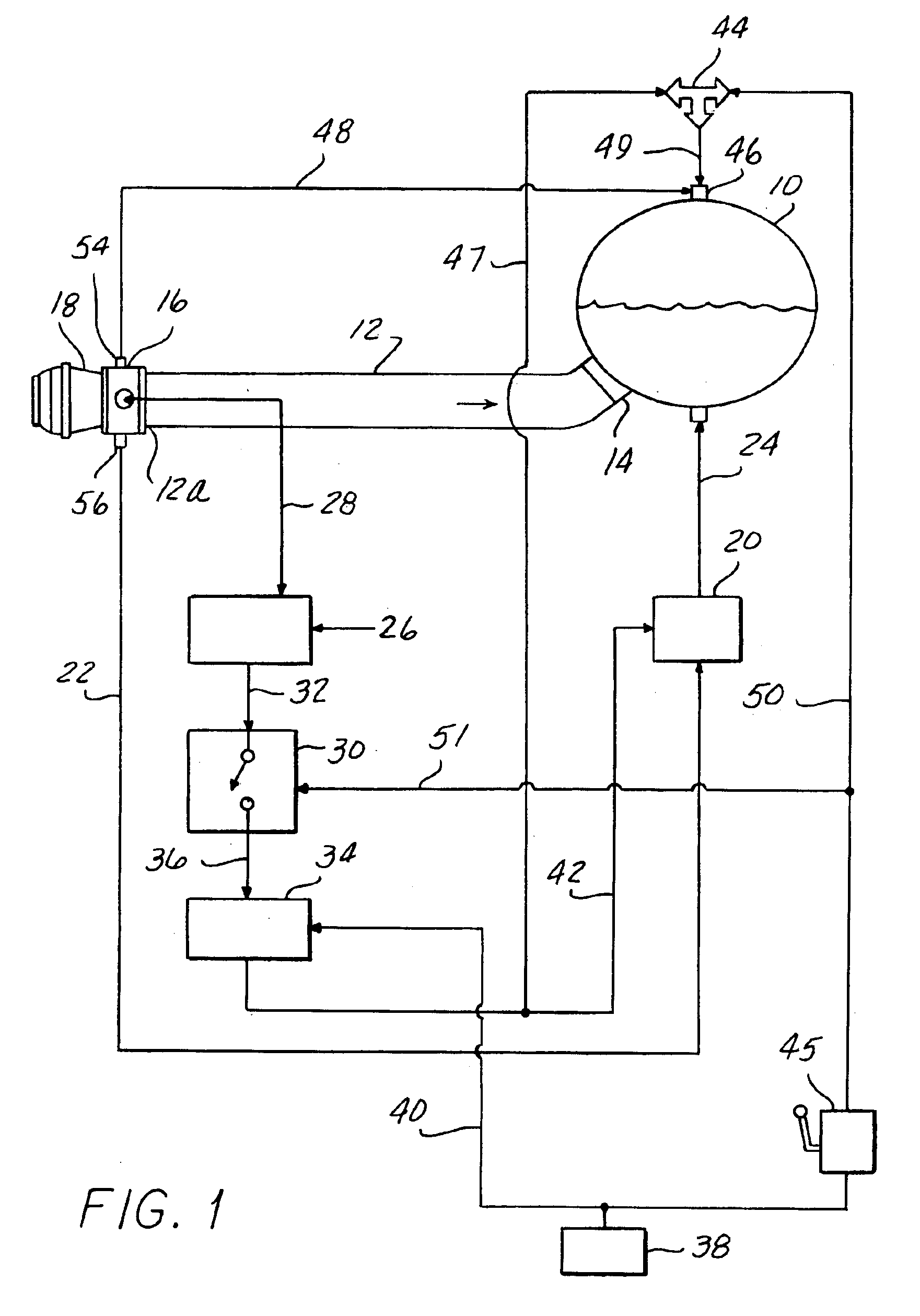

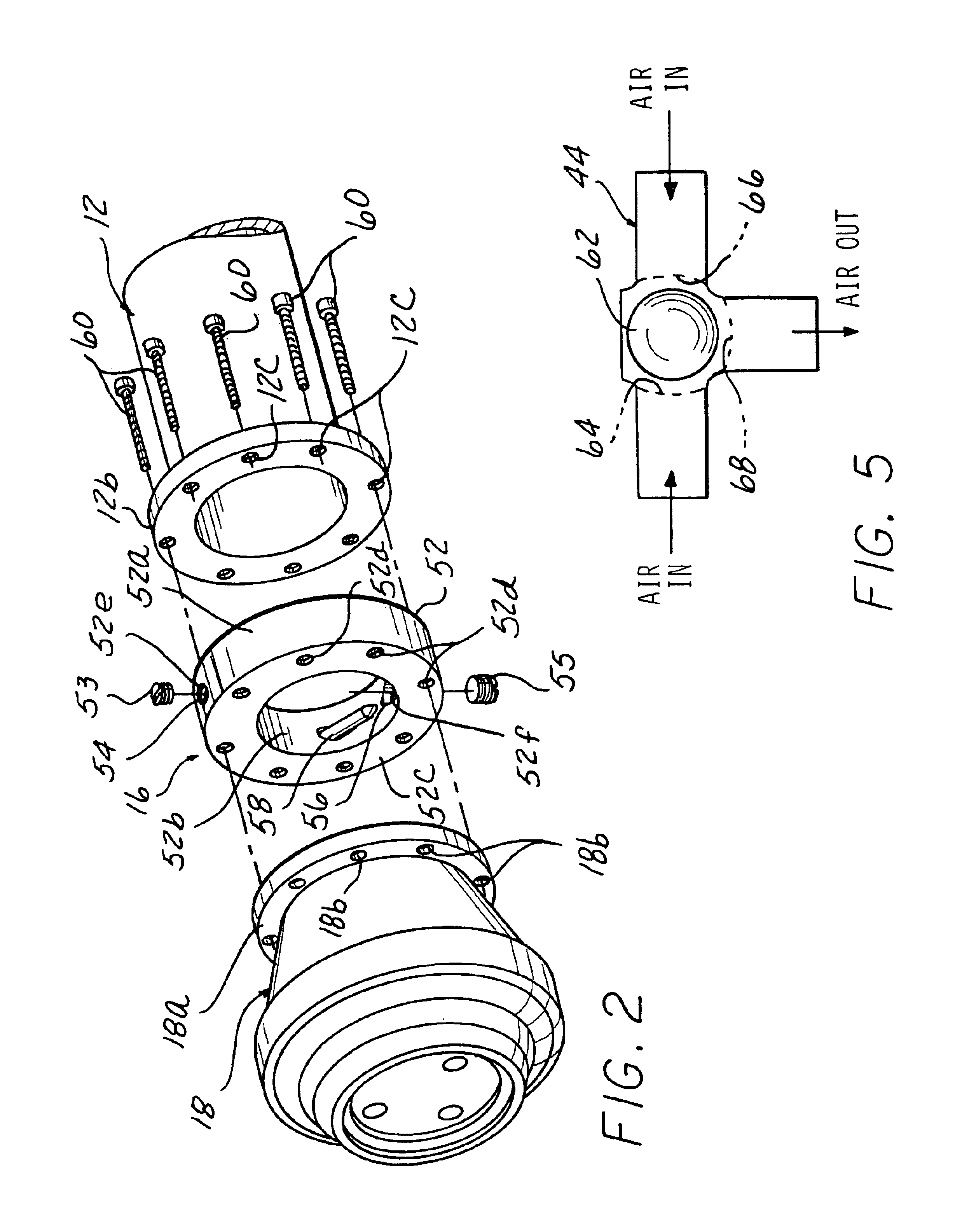

Packaging

Owner:IMI CORNELIUS UK

Method and apparatus for removing hazardous liquid from petroleum tanker trailer delivery/loading piping

Owner:FRANKLIN FUELING SYST

Method for extracting germanium from brown coal

The invention provides a process of germanium extraction from brown coal, which is germanium extraction by employing a cyclone furnace. The process includes that the brown coal is added in the cyclone furnace to mix with hot wind which is sent into the cyclone furnace, the brown coal is burned, the CO content inside the cyclone furnace is controlled within the range of 0.5-1%, germanium in the brown coal is reduced and volatilized into flue gas, and flue dust is collected as raw material of the germanium. The process can achieve the purposes that the flour shaped brown coal is fully used to enlarge the productivity of the germanium, the recovery ratio of the germanium is increased, and the excess energy is effectively recovered.

Owner:锡林郭勒通力锗业有限责任公司

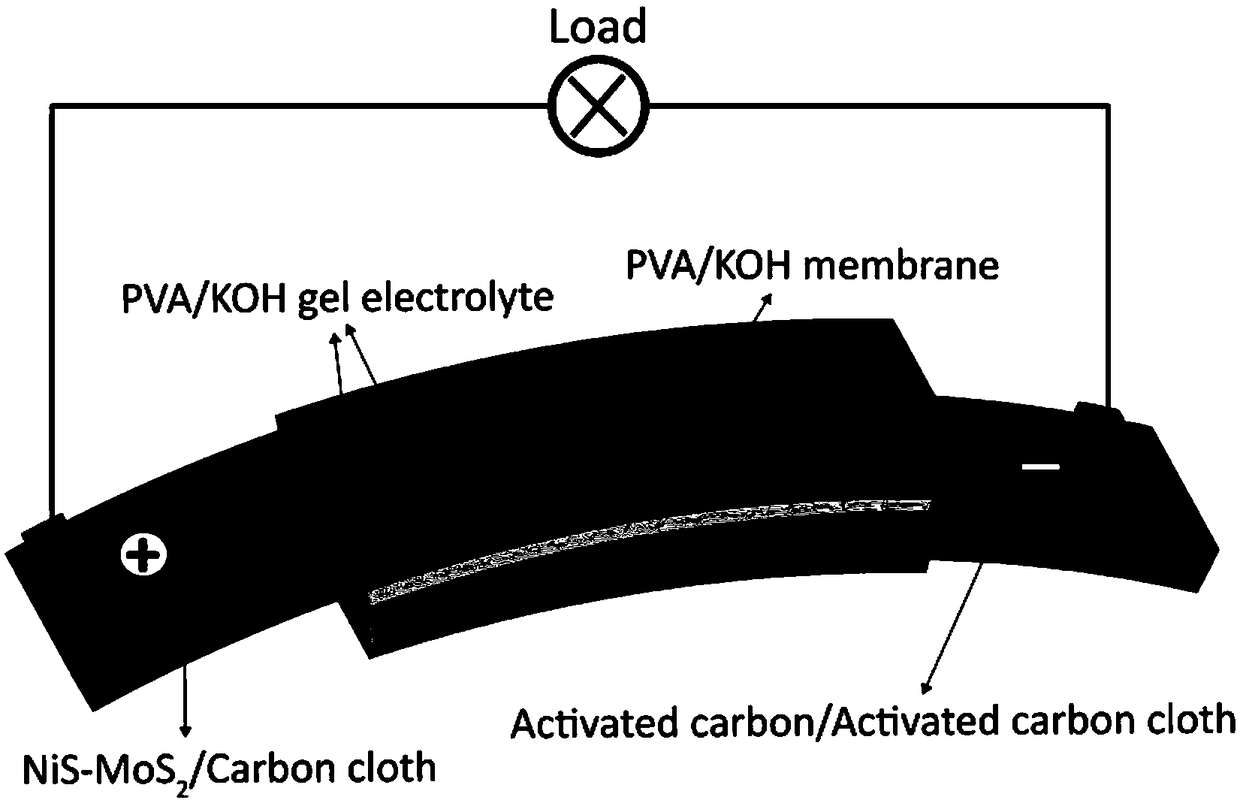

Flexible supercapacitor with nickel sulfide-molybdenum sulfide heterogeneous nano-sheet array structure based on carbon cloth loading and preparation method thereof

ActiveCN109065368ALarge capacityImprove charge and discharge stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNew energy

The present invention relates to a flexible supercapacitor with with NiS-MoS2 heterogeneous nano-sheet array structure based on carbon cloth loading and a preparation method thereof, belonging to thetechnical field of new energy material and device preparation. The flexible supercapacitor grows high-purity, high-density and high-orientation carbon cloth-loaded NiS-MoS2 heterogeneous nanosheet array by using anode material, carbon cloth coated with activated carbon as cathode material, PVA / KOH gel as diaphragm and electrolyte respectively. The anode has the advantages of high purity, high density, tidy appearance, strict controllable growth condition, simple equipment and process, low cost, high capacitance and good charge-discharge stability. The cathode material has excellent conductivity and large double-layer capacitance. The preparation process of the capacitor is simple, economical and environmentally friendly, and no post-treatment is needed. The supercapacitor provided by the invention has the advantages of light weight, large capacity, good cycle charging and discharging stability, and good flexibility, and can be used for power supply equipment of wearable electronic devices.

Owner:BEIJING UNIV OF POSTS & TELECOMM

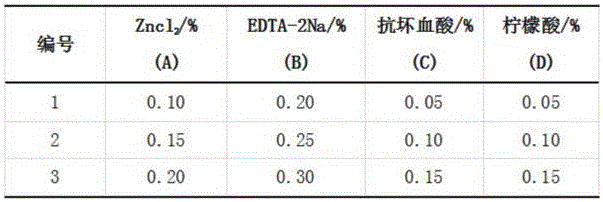

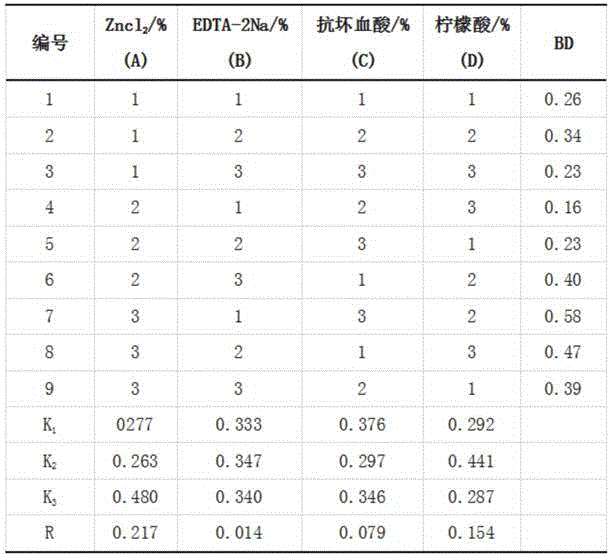

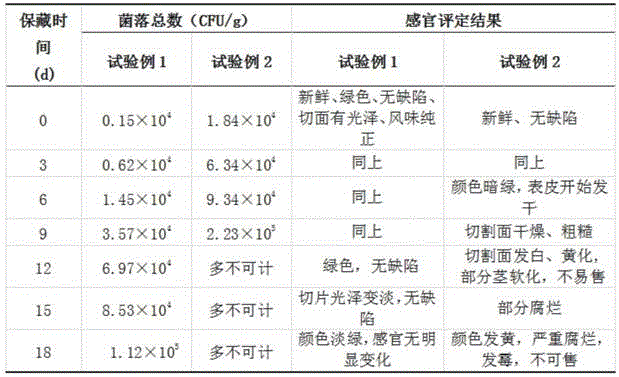

Fresh kiwi fruit slices and preparation method thereof

InactiveCN105962190ADelayed ripeningGuaranteed fresh qualityFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by coatingActinidiaKiwi fruit

The invention discloses a preparation method of fresh kiwi fruit slices. The preparation method comprises the following steps: taking fresh high-quality kiwi fruits of which the hardness is between 9.0 kg / cm<2> and 11.0 kg / cm<2> as standard raw materials, putting slices into distilled water after washing, peeling and cutting the kiwi fruits, pumping ozone until the concentration is 0.8 to 1.0 mg / L, and carrying out ultrasonic assisted sterilization for 5 to 8 minutes; then, adding the slices into a kiwi fruit mixed color protecting solution which is prepared from 0.2 percent of ZnCl2, 0.25 percent of EDTA (Ethylene Diamine Tetraacetic Acid)-2Na, 0.10 percent of ascorbic acid and 0.1 percent of citric acid for carrying out color protection, and infiltrating by using 0.5 to 2.0 percent of PEG (Polyethylene Glycol)-chitosan edible coating film after dewatering; finally, packaging by using a PP (Propene Polymer) pallet and a PE (Poly Ethylene) film, and storing at low temperature. The fresh kiwi fruit slices prepared through the preparation method have the characteristics that the appearance color is well kept, browning is not easy to cause, the bacteria inhibiting and fresh keeping effects are good, the storage period is long, and the quality is stable.

Owner:SICHUAN UNIV

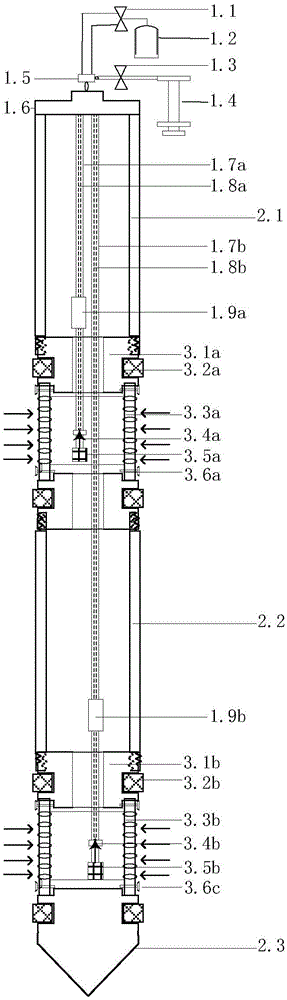

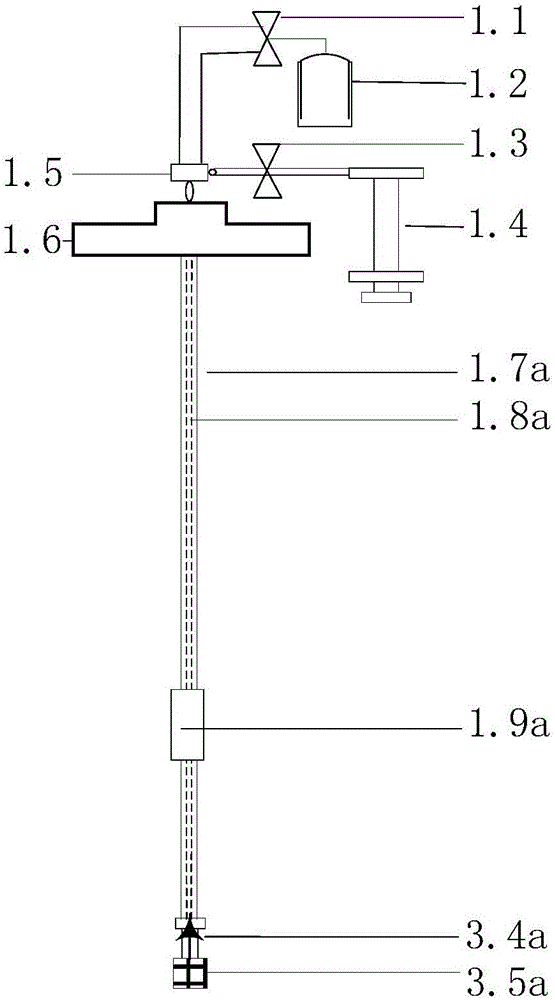

Underground water depth-setting stratified sampling device and underground water depth-setting stratified sampling method applicable to regions without wells

PendingCN106353141ARealize fluctuation monitoringIncrease authenticityWithdrawing sample devicesProportional Stratified SamplingWater level

The invention belongs to the technical field of underground water sampling and particularly relates to an underground water depth-setting stratified sampling device and an underground water depth-setting stratified sampling method applicable to regions without wells. The underground water depth-setting stratified sampling device at least comprises a sampling mechanism, a connecting mechanism and an underground sample injection mechanism, wherein the sampling mechanism comprises a first sampling mechanism body, a second sampling mechanism body, a sampling bottle, a gas-phase check valve, a nested flow splitting mechanism, a ball valve and a wellhead fixing support seat, the underground sample injection mechanism comprises a first underground sample injection mechanism body and a second underground sample injection mechanism body, and the connecting mechanism comprises a first connecting rod and a second connecting rod. Compared with similar technical products, the underground water depth-setting stratified sampling device applicable to the regions without the wells has the advantages that the device is novel in structural design and improved in working performance, functions, precision, stability and durability substantially, integrates a high-precision stratified sampling function and an underground water level line fluctuation monitoring function and can be rapidly mounted in the regions without the wells.

Owner:WUHAN CENT CHINA GEOLOGICAL SURVEY CENT SOUTH CHINA INNOVATION CENT FOR GEOSCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com