Drive configuration for a skid steered vehicle

a technology of drive configuration and skid steer, which is applied in the direction of mechanical equipment, transportation and packaging, gearing, etc., can solve the problems of not revealing a practical embodiment of such a device, requiring oversized motors, and requiring large and heavy arrangements, etc., to simplify the packaging and design of the other components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

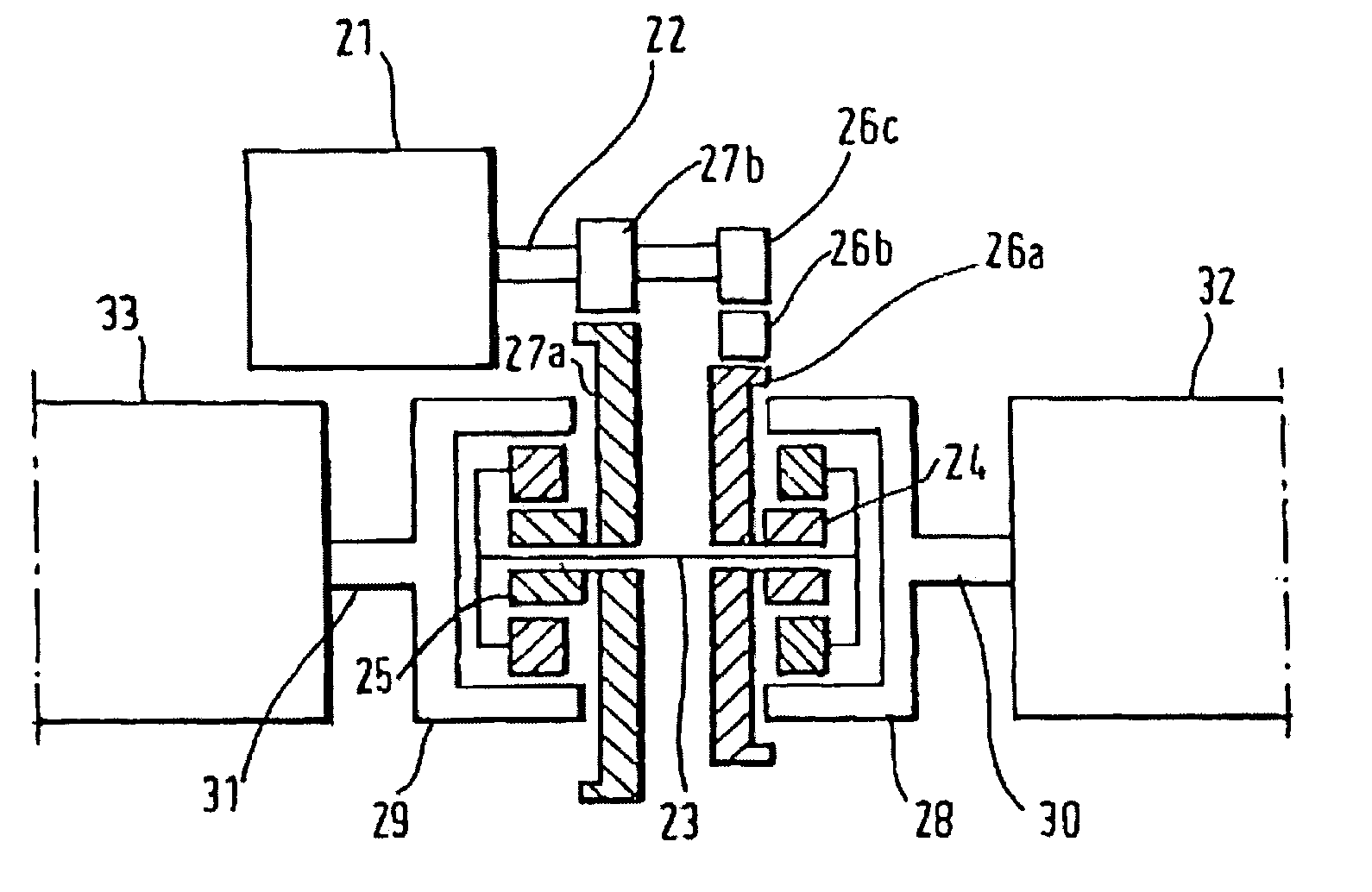

[0039]As can be seen from FIG. 1, the prior art drive configuration comprises a propulsion motor (1) mounted on a cross-shaft (2) which is coupled to the annuli of the two epicyclical steer differential (3a, 3b). The planet carriers of the two epicyclical steer differentials are connected to the output shafts (4a and 4b) and the track drive sprockets (5a and 5b). The steer motor (6) is mounted on a steer cross shaft (7). The steer cross shaft is coupled to the sun gears of the steer epicyclical differentials by a number of spur gears (8a, 8b, 8c, 8d, and 8e). An extra spur gear (8d) is used on one side to reverse the rotation of the sun gear. This layout is identical to that used in a conventional mechanical drive tank transmission, the propulsion motor is fitted in place of the gear range change pack and the hydraulic steer motor has been substituted for a electric motor. This is the basis of the electric drive shown in U.S. Pat. No. 4,998,591.

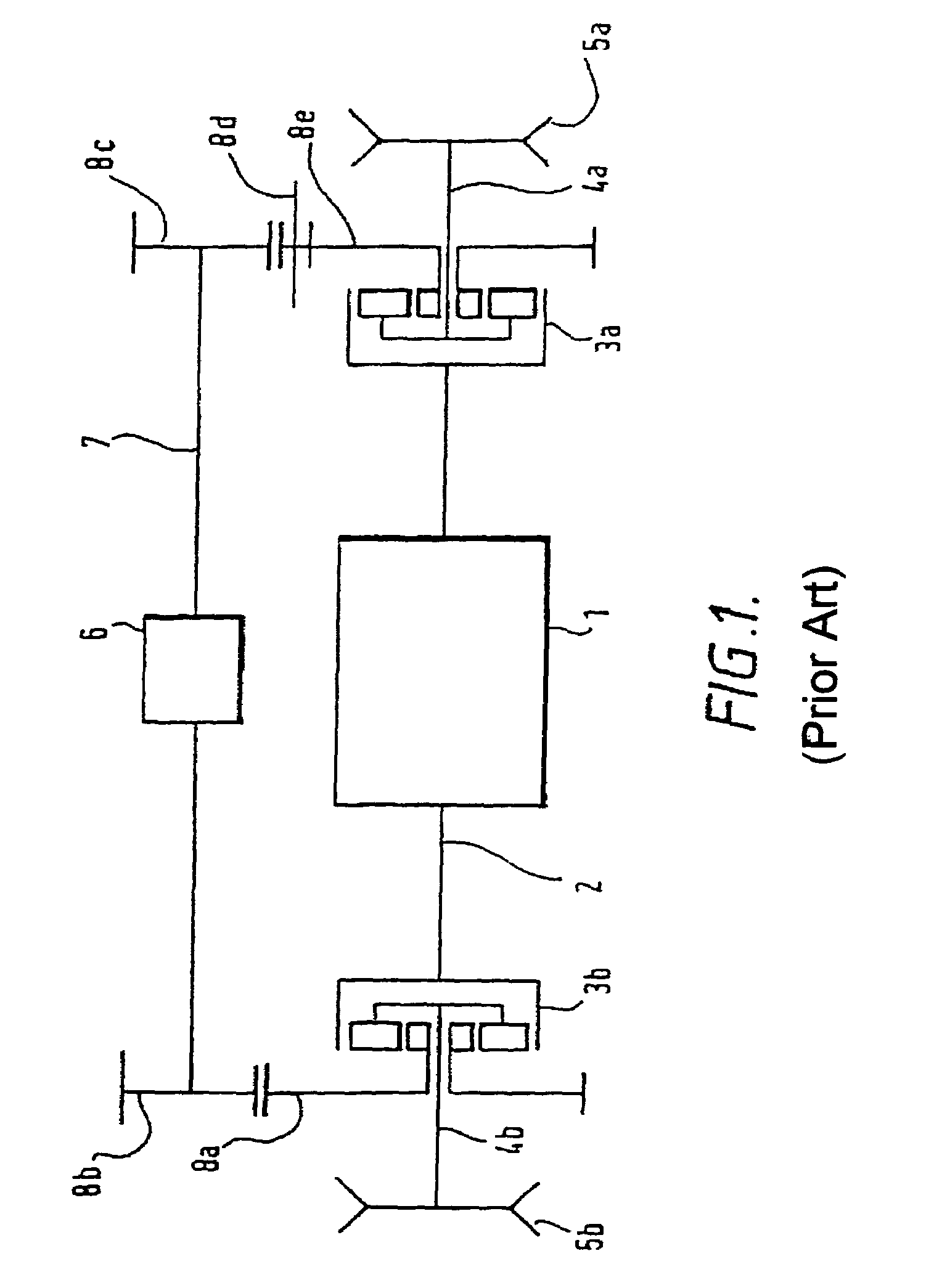

[0040]As can be seen from FIG. 2, a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com