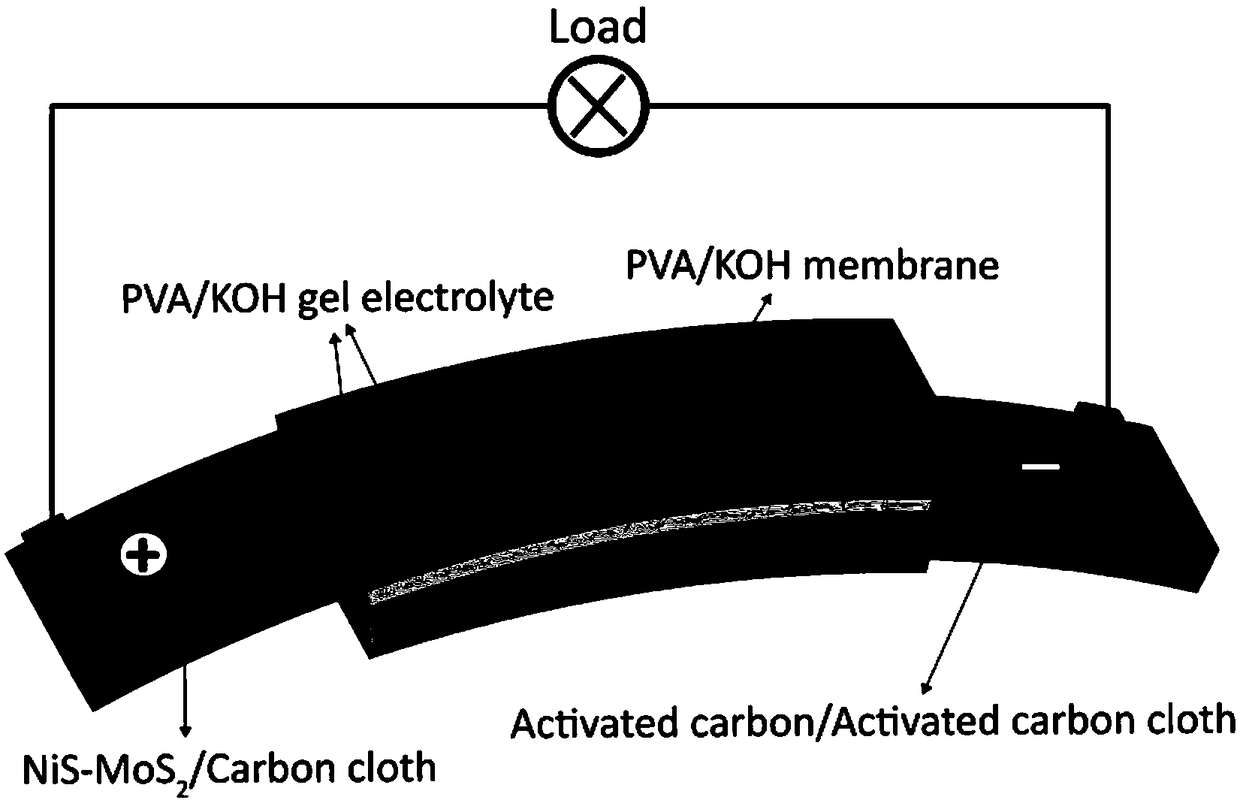

Flexible supercapacitor with nickel sulfide-molybdenum sulfide heterogeneous nano-sheet array structure based on carbon cloth loading and preparation method thereof

A nanosheet array and supercapacitor technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor compatibility and difficulty in growing active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] NiS-MoS based on carbon cloth supported by the present invention 2 A method for preparing a flexible supercapacitor with a heterogeneous nanosheet array structure, comprising the following steps and contents:

[0051] (1) Cleaning of the carbon cloth: The carbon cloth was ultrasonically cleaned in advance with acetone, 1-2 mol / L hydrochloric acid aqueous solution, and deionized water for 0.5-1 hour in sequence, dried at 60°C, and stored for later use.

[0052] (2) Preparation of anode material: Put commercially available analytically pure nickel acetate, ammonium molybdate, thiourea and sodium lauryl sulfate powder into a beaker, then add deionized water and stir to make it evenly mixed, and control the mixing solution The concentration of nickel acetate is 0.03-0.05mol / L, the concentration of ammonium molybdate is 0.001-0.005mol / L, the concentration of thiourea is 0.05-0.08mol / L, and the concentration of sodium lauryl sulfate is 0.15-0.25mol / L ; Utilize the sodium hyd...

Embodiment 1

[0061] Embodiment 1: The preparation steps of the supercapacitor of this embodiment are as follows in sequence:

[0062] (1) Two 2×4cm carbon cloths were ultrasonically cleaned with acetone, 1mol / L hydrochloric acid aqueous solution and deionized water for 1 hour in advance, dried at 60°C, and stored for later use.

[0063] (2) In a 100mL beaker, add 0.224g nickel acetate, 0.074g ammonium molybdate, 0.137g thiourea and 1.73g sodium lauryl sulfate in sequence, then add 30mL deionized water and stir until the solution is clear; then slowly Add an appropriate amount of 0.5mol / L sodium hydroxide aqueous solution dropwise to adjust the pH value of the reactant mixed solution to 6.2; Immerse it vertically in the solution, seal the reaction vessel; then put it into an electric furnace and heat it to 180°C at a speed of 5°C / min and react for 9 hours. After naturally cooling to room temperature, open the reactor, take out the carbon cloth, rinse it with deionized water and alcohol alt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Overall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com