Rotary drum device capable of automatically winding and unwinding cable

A technology of automatic retraction and cable length, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of low work efficiency, high cost and time, and achieve high work efficiency, simple equipment, flexible and convenient installation and removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

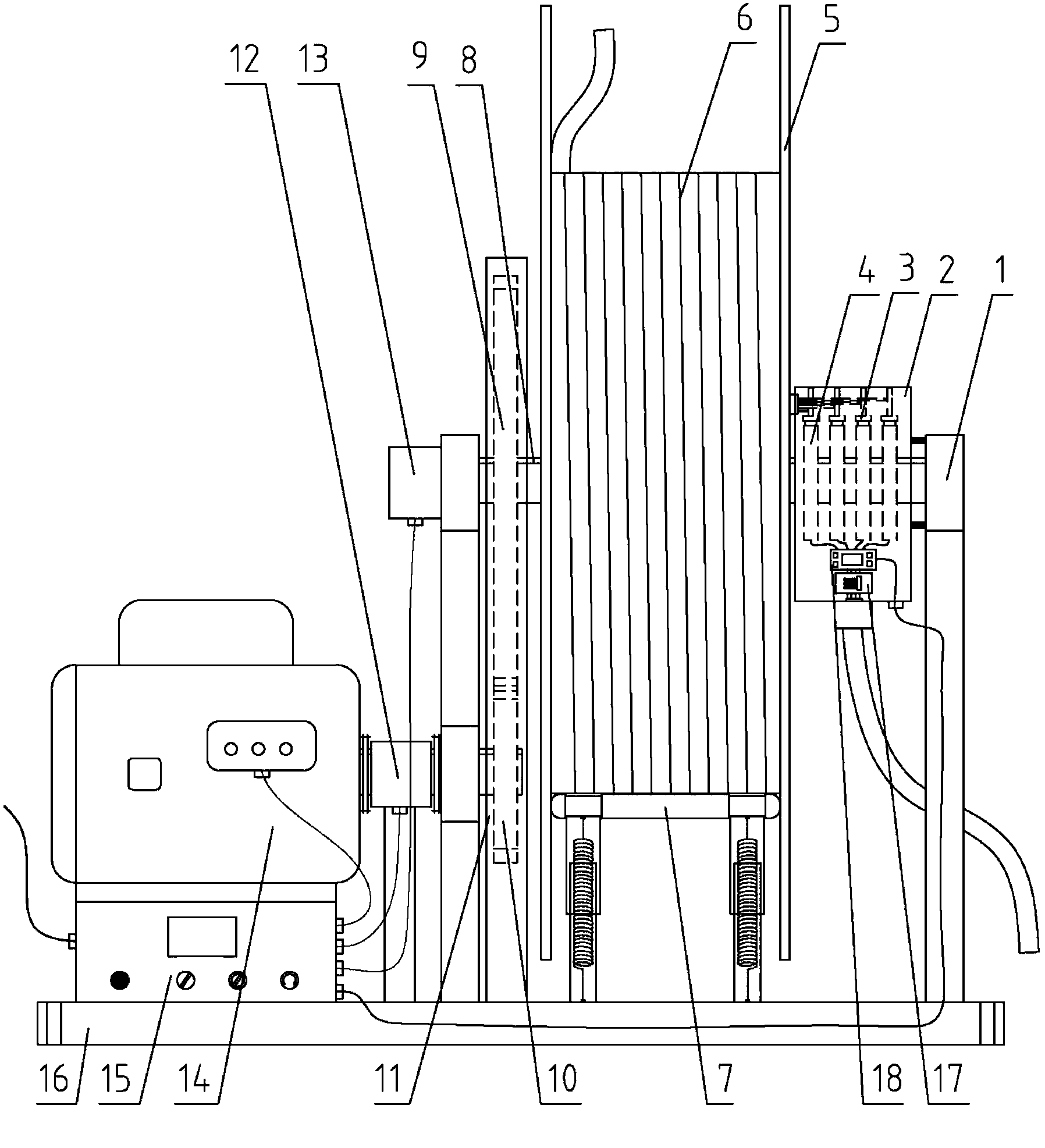

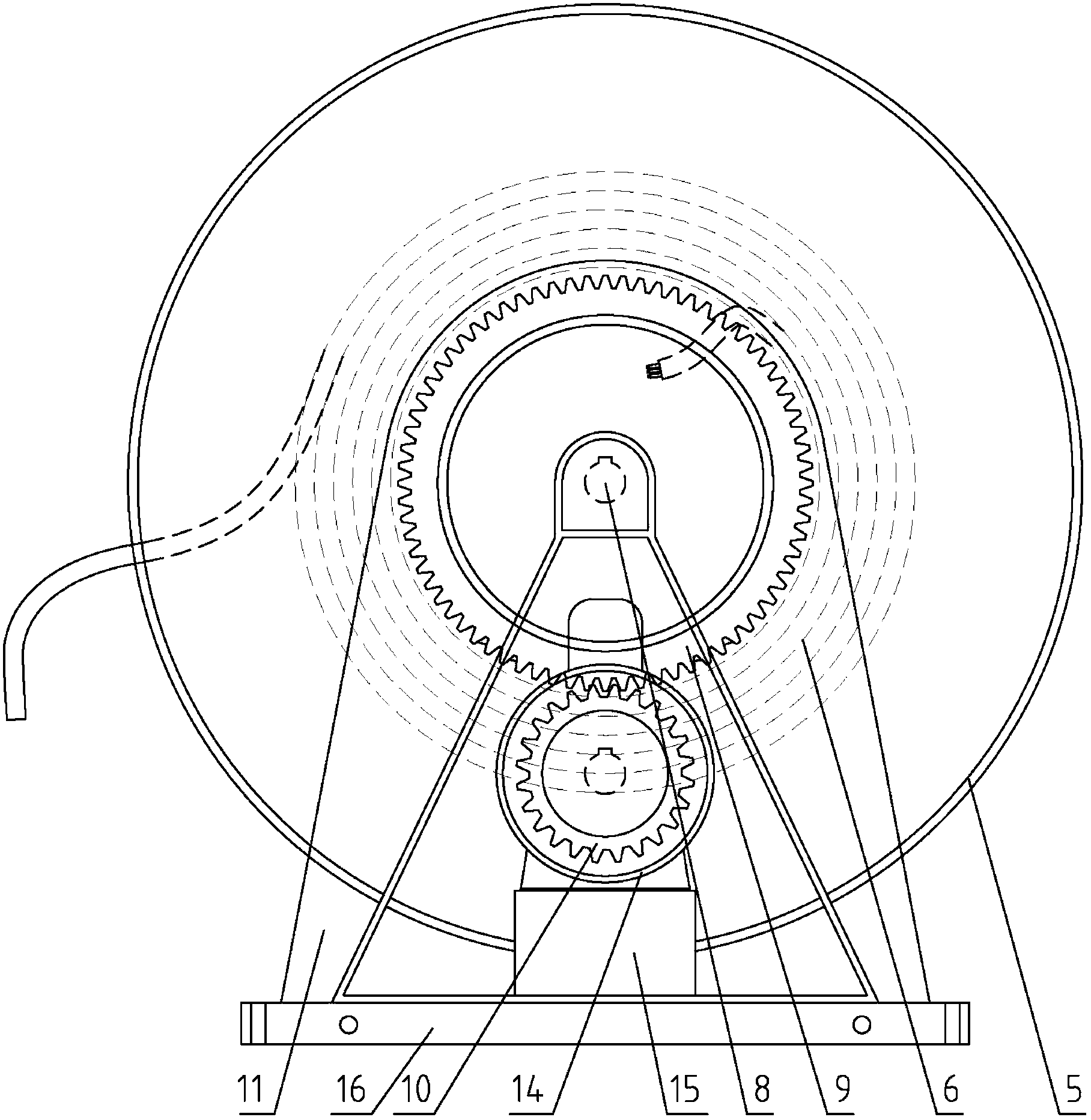

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] refer to figure 1 with figure 2 The structure of the drum device with automatic retractable cable length of the present invention is that a pair of bearing housings 1 are installed on the drum bracket seat 16, a bearing is installed in each bearing housing 1, and a drum shaft 8 is installed in a pair of bearings together. The drum shaft 8 is set with a drum end gear 9, a drum 5 and an explosion-proof junction box 2, the explosion-proof junction box 2 is fixedly connected to the bearing seat 1 on one side, and the explosion-proof junction box 2 is provided with a slip ring 4, an AC contactor 17 and Circuit breaker 18; the moving end of the cable 6 wound on the drum 5 is connected to the equipment load, and the fixed end of the cable 6 in the drum 5 is in contact with the slip ring 4 through the carbon brush 3; the drum 5 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com