Vacuum light well point dewatering method

A light well point and vacuum technology, applied in drainage, earthwork drilling, safety devices, etc., to achieve strong operability, simple installation, and good precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

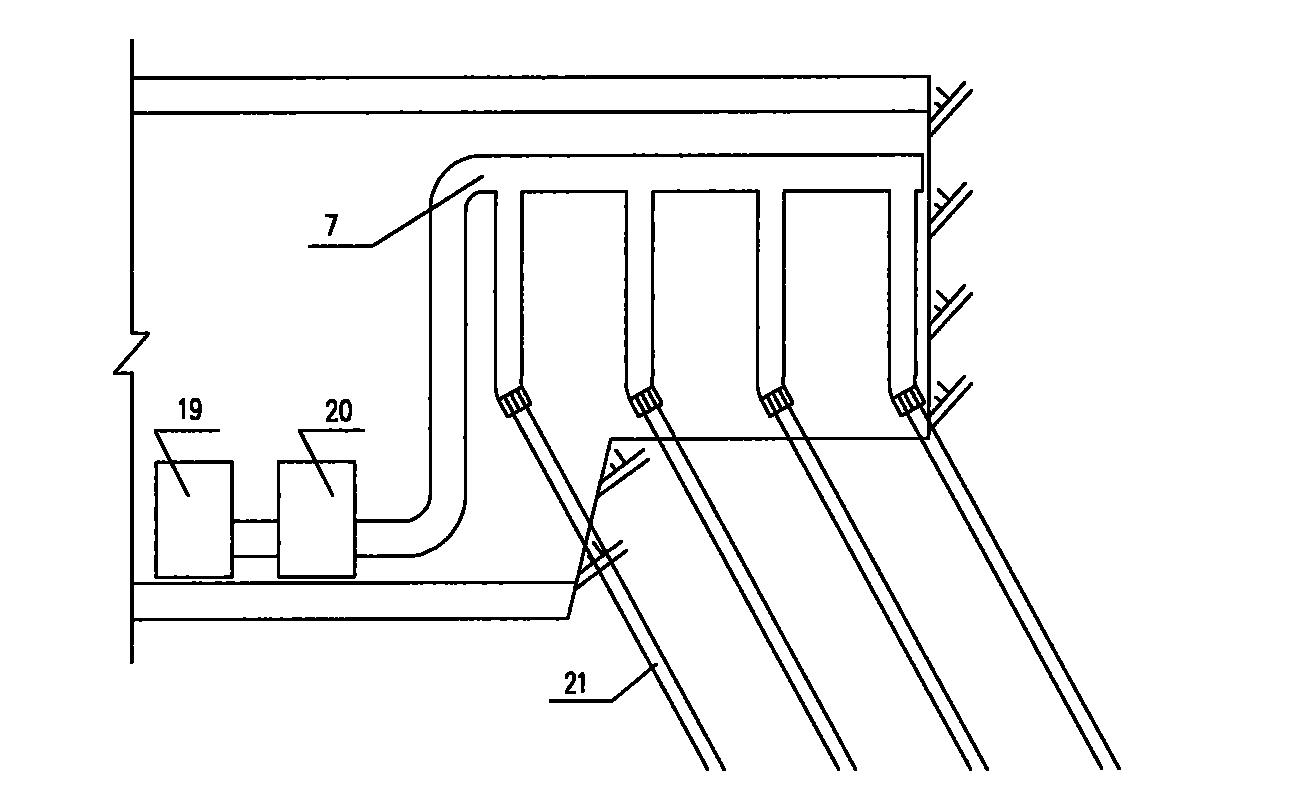

[0034] Next, take the 50.7m inclined shaft and the 505m main tunnel construction project left over from the previous construction in the 4# inclined shaft of the Lanzhou-Chongqing Railway Taoshuping Tunnel undertaken by the applicant as an example to introduce the vacuum light well point dewatering method of the present application. The angles, distances, lengths, number of downcomers and material selection involved are all determined according to the actual situation of the specific project and combined with common sense in the field. Those skilled in the art should know that these angles, distances, lengths, number of downwater pipes and material selection are not limited to those described here, and appropriate selections can be made according to actual engineering needs to achieve a good precipitation effect.

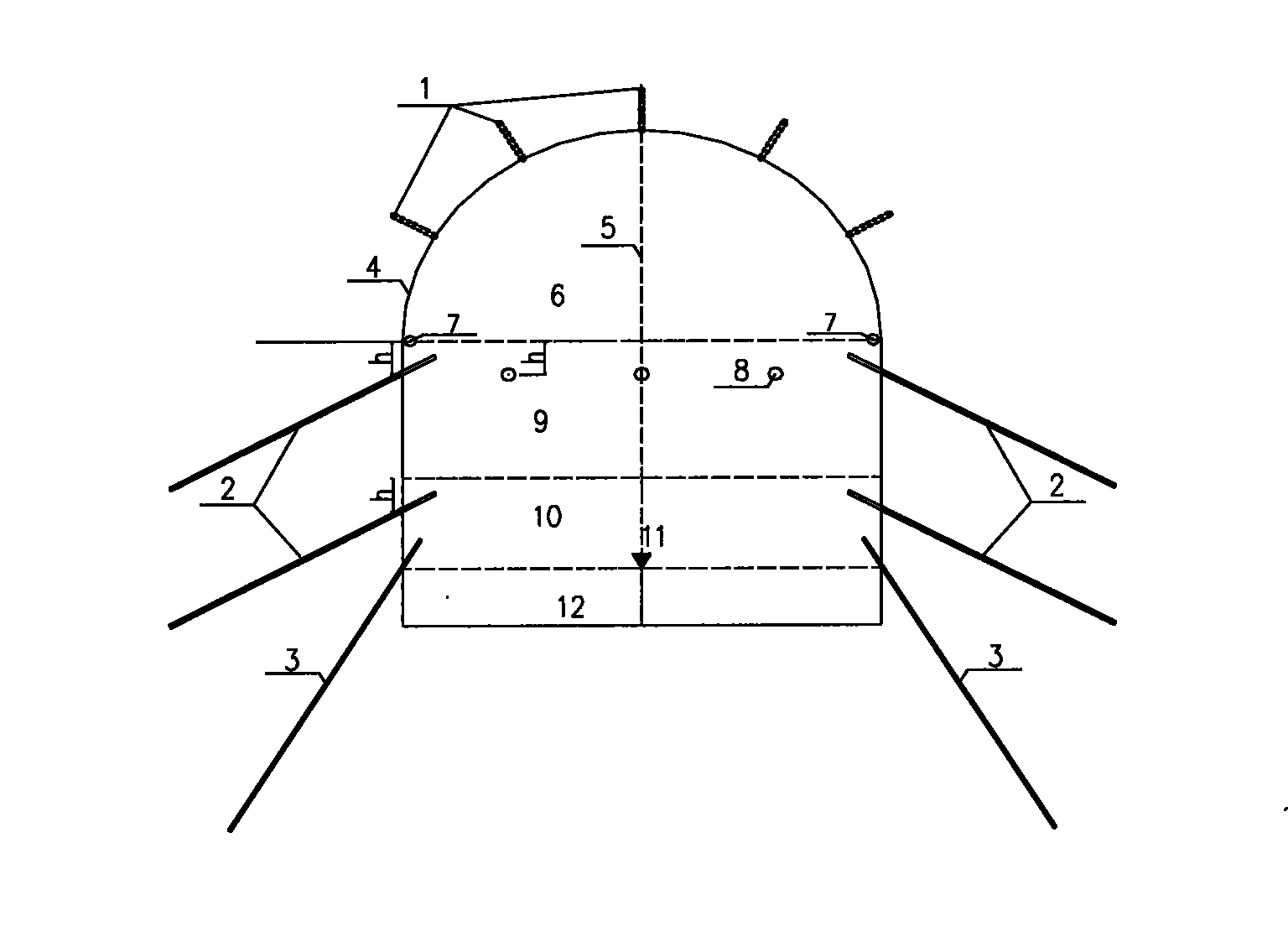

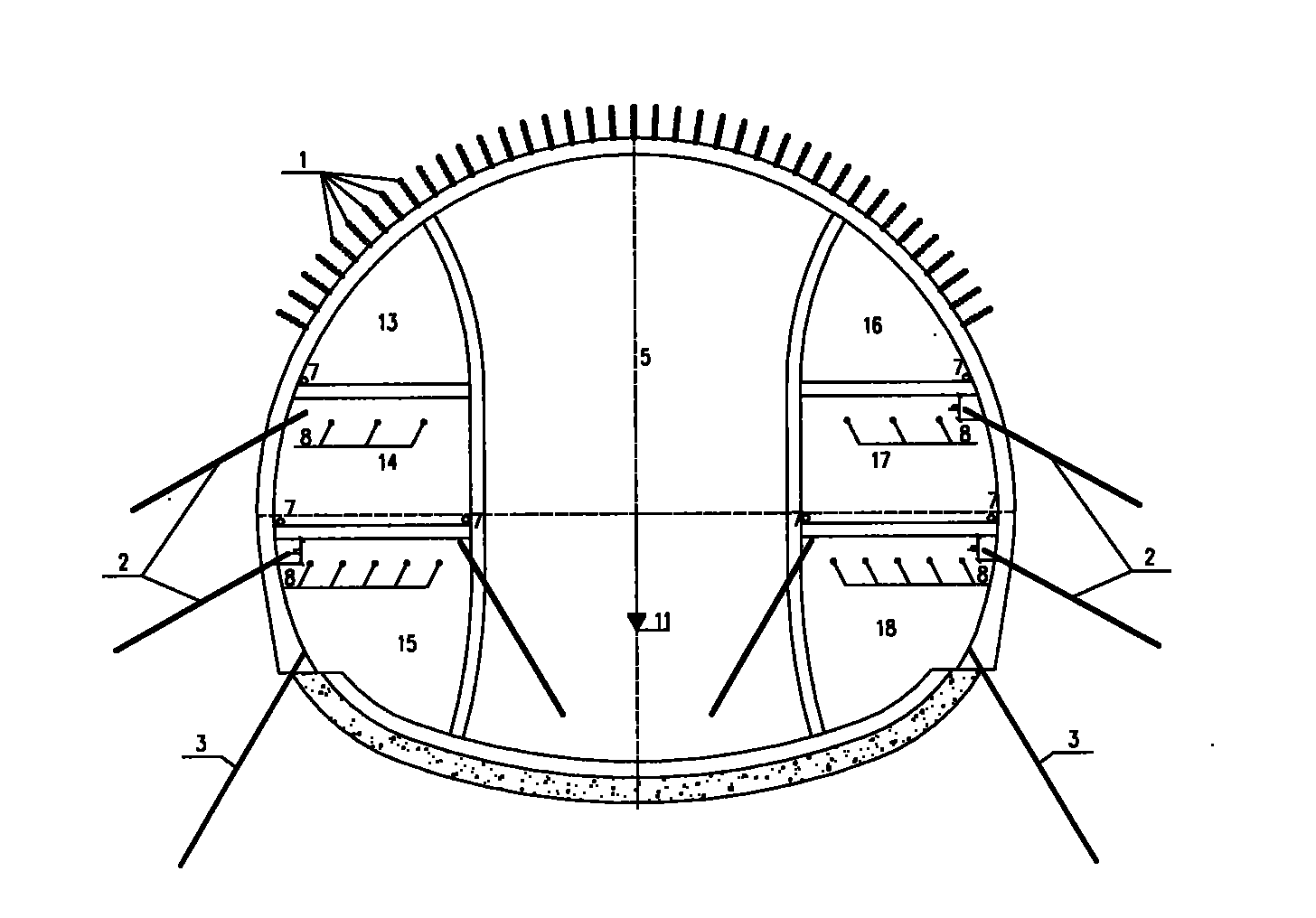

[0035] For details on the layout of downpipes in inclined shafts, see figure 1 , see the layout of the downwater pipes in the construction of the double side walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com