Balanced pressure drilling pressure control device and method

A technology for balancing pressure and wellhead devices, applied in the field of drilling, which can solve the problems of adding back pressure pumps, complex matching, and difficult control, etc., and achieve the effect of simple measurement and operation, and simple matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

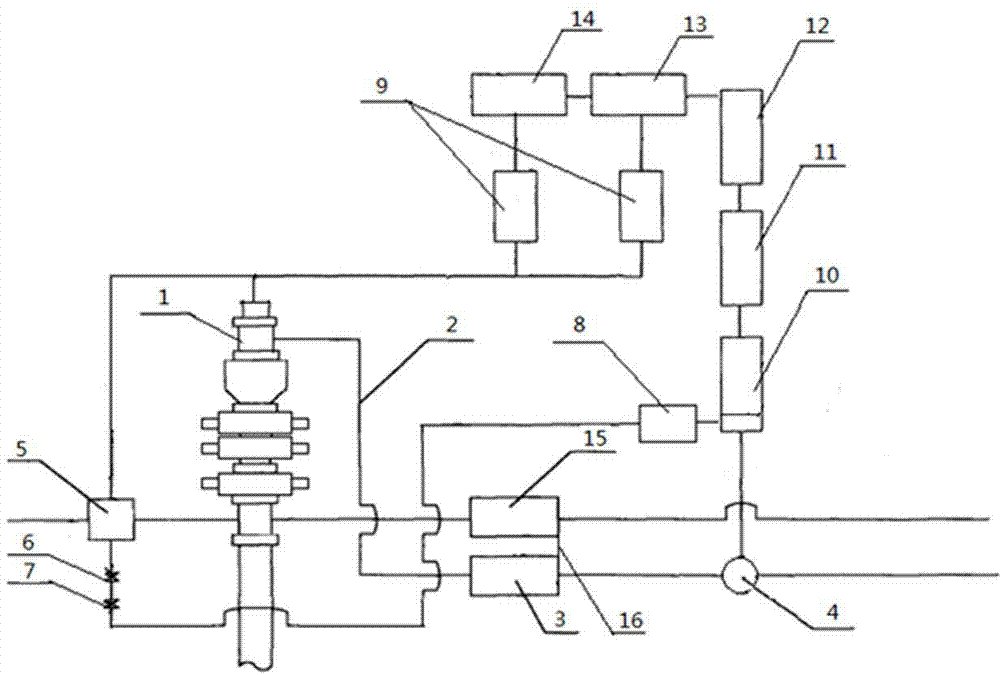

[0028] Describe in detail below in conjunction with accompanying drawing.

[0029] The balanced pressure drilling pressure control device of the present invention is mainly composed of a wellhead spool, a wellhead blowout preventer group, a wellhead standpipe, a wellhead rotary blowout preventer 1, a pressure control choke manifold 3, a conventional choke manifold 15 and a drilling fluid injection system , liquid-gas separator 4, liquid level gauge and drilling fluid circulation system and other components. The wellhead rotary blowout preventer 1 is installed on the upper end of the wellhead blowout preventer group, and is connected to the pressure control throttle manifold 3 through the high pressure pipeline 2, and the pressure control throttle manifold 3 is connected to the liquid-gas separator 4 through the pipeline and connected to the circulation tank 10. The kill manifold 5 connected from the cross of the wellhead device is connected to the drilling fluid injection syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com