Whole process construction method of driven cast-in-place piles and special device for same

A technology of immersed tube grouting piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, foundation structure tests, etc., and can solve the problems of easy deviation of the reinforcement cage, inconvenient operation of the rear insertion reinforcement cage, low noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

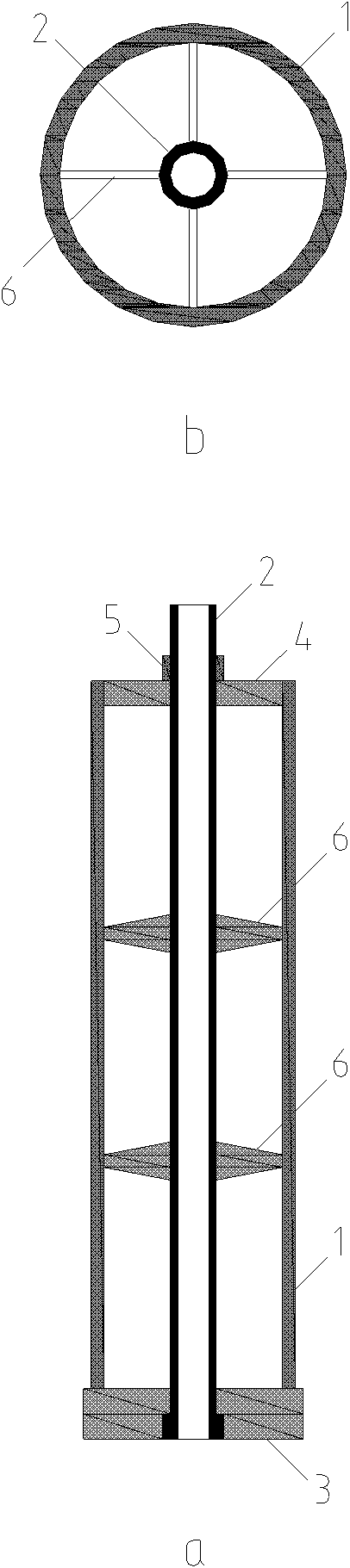

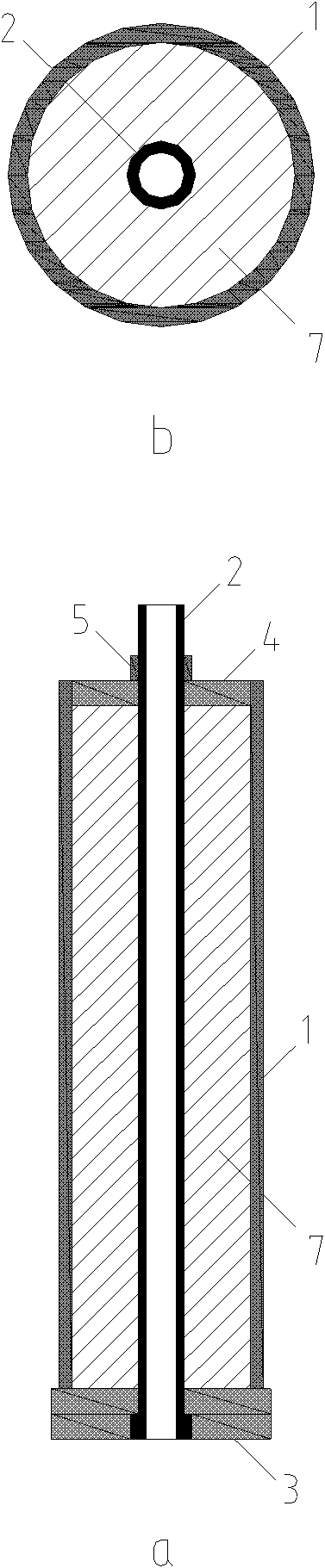

[0258] Embodiment 1 The implementation method of the whole process construction method of the immersed pipe grouting pile using the A2 type pile pipe is as follows:

[0259] A construction project site, soil layer from top to bottom: 2m thick miscellaneous fill, 8m thick plastic state silty clay, 2m thick fully weathered mudstone, 2m thick strongly weathered mudstone, the following is moderately weathered mudstone.

[0260] The designed pile diameter is 800mm, the pile length is 15m, the bearing layer at the pile end is moderately weathered mudstone, and the ultimate bearing capacity of a single pile is 1700t, of which: the ultimate resistance of the pile end is 1300t, and the ultimate resistance of the pile side is 400t.

[0261] Basic data of pile pipe: circular outer pipe 1 has an outer diameter of 800mm and a wall thickness of 30mm; Form upper plate 4 external diameter 740mm, thick 50mm, central circular hole diameter 195mm; Nut 5 internal diameter 190mm, high 50mm; Intern...

Embodiment 2

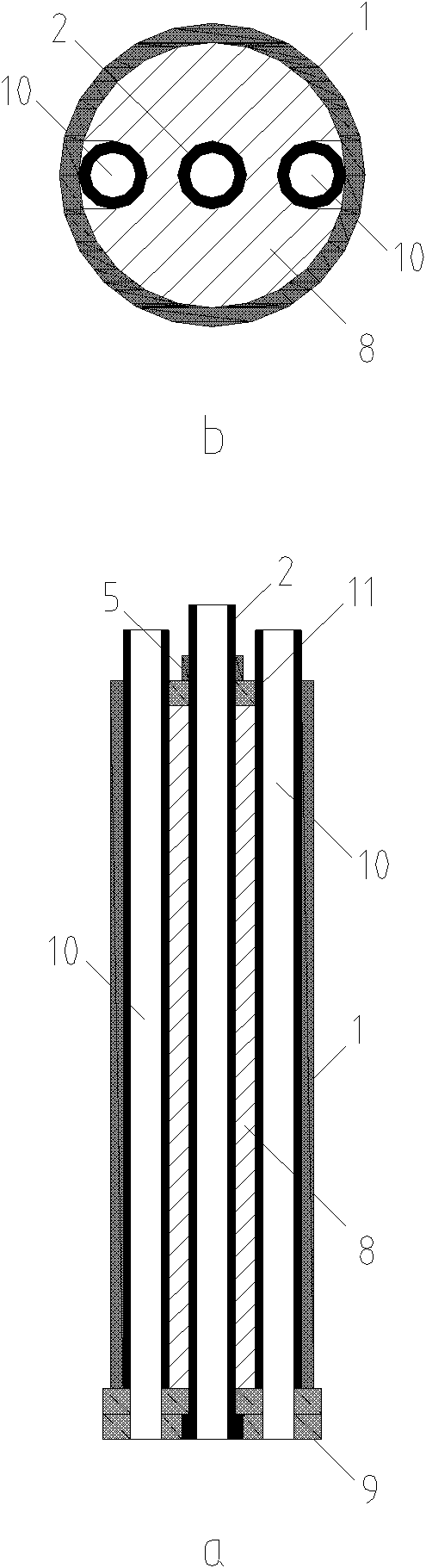

[0278] Embodiment 2 The implementation method of the whole process construction method of the immersed pipe grouting pile using the A5 type pile pipe is as follows:

[0279] Site conditions, pile diameter, and bearing capacity are the same as above.

[0280] Basic data of pile pipe: circular outer pipe 1 has an outer diameter of 800mm and a wall thickness of 30mm; circular pouring pipe 2 has an inner diameter of 150mm and a wall thickness of 20mm, and each side of the lower end is thickened by 20mm; circular slurry discharge pipe 10 has an inner diameter of 150mm and a wall thickness of 20mm; The snap ring 13 is 50mm high, and the diameter of the circular hole is 195mm; the outer diameter of the circular lower plate 14 is 820mm, and the height is 200mm.

[0281] Basic data of E-type backing plate: round thin steel plate 47 thick 3mm, diameter 850mm; round thick steel plate 42 thick 30mm, diameter 180mm, round hole 46 diameter 180mm.

[0282] 2.1 Test pile: After the mud retai...

Embodiment 3

[0292] Embodiment 3 The implementation method of the whole process construction method of the immersed pipe grouting pile using the B1 type pile pipe is as follows:

[0293] Site conditions, pile diameter, and bearing capacity are the same as above.

[0294] Basic data of pile pipe: circular outer pipe 21 with an outer diameter of 800mm and a wall thickness of 30mm; a ring 24 with an outer diameter of 820mm; an inner hammer 22 with a weight of 10t, of which: the hammer body 34 has an outer diameter of 700mm, an inner diameter of 600mm, and a wall thickness of 50mm; The plate 30 has a diameter of 720 mm and a height of 200 mm; the inner tip 33 has a diameter of 100 mm at the upper and lower segments, a diameter of the middle segment of 60 mm, a height of 50 mm at the upper segment, a height of 150 mm at the middle segment, and a height of 100 mm at the lower segment; the circular upper plate 31 has an inner diameter of 600 mm, an outer diameter of 1 m, and a thickness of 50 mm; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pile diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com