Patents

Literature

32results about How to "Improve equipment quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

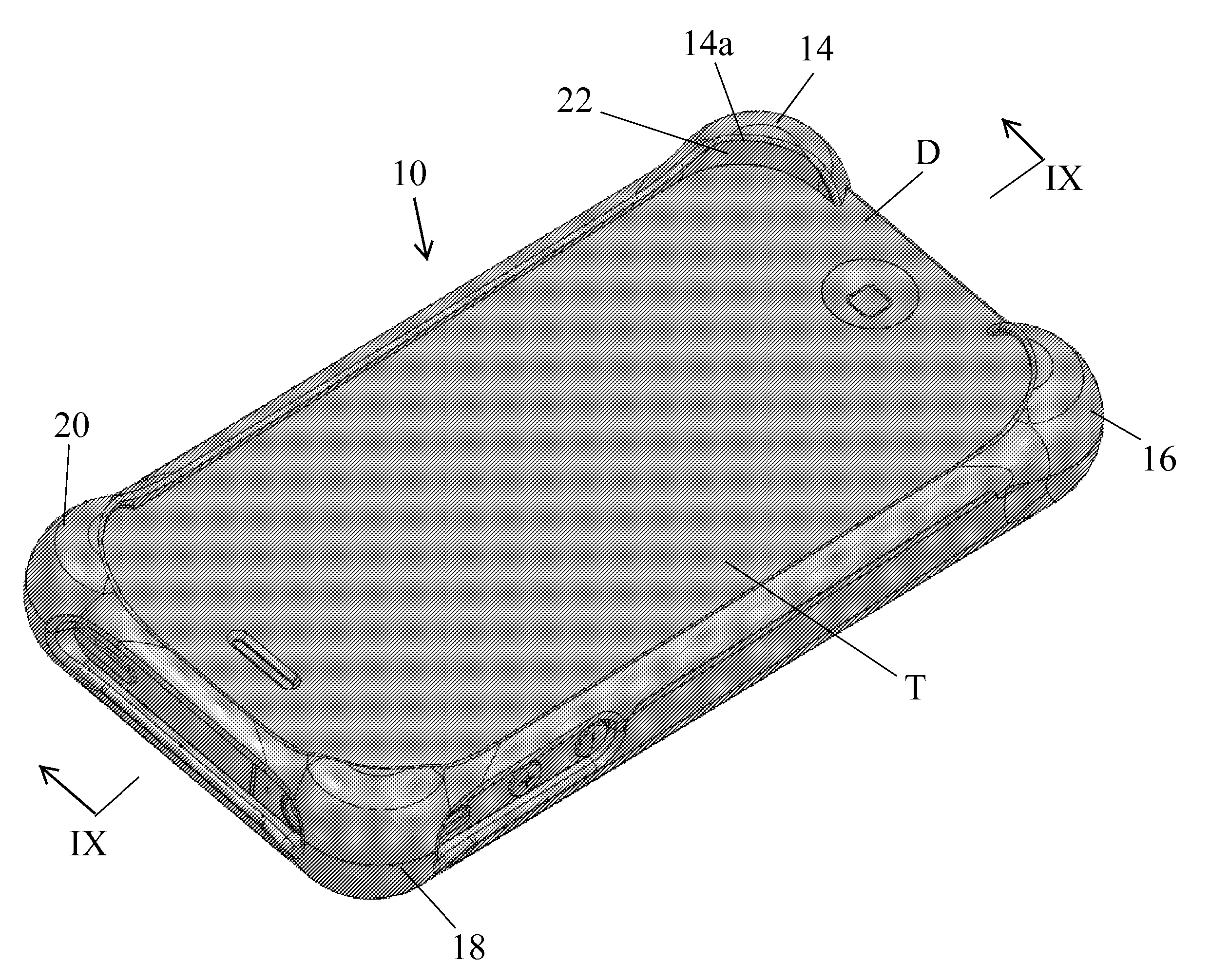

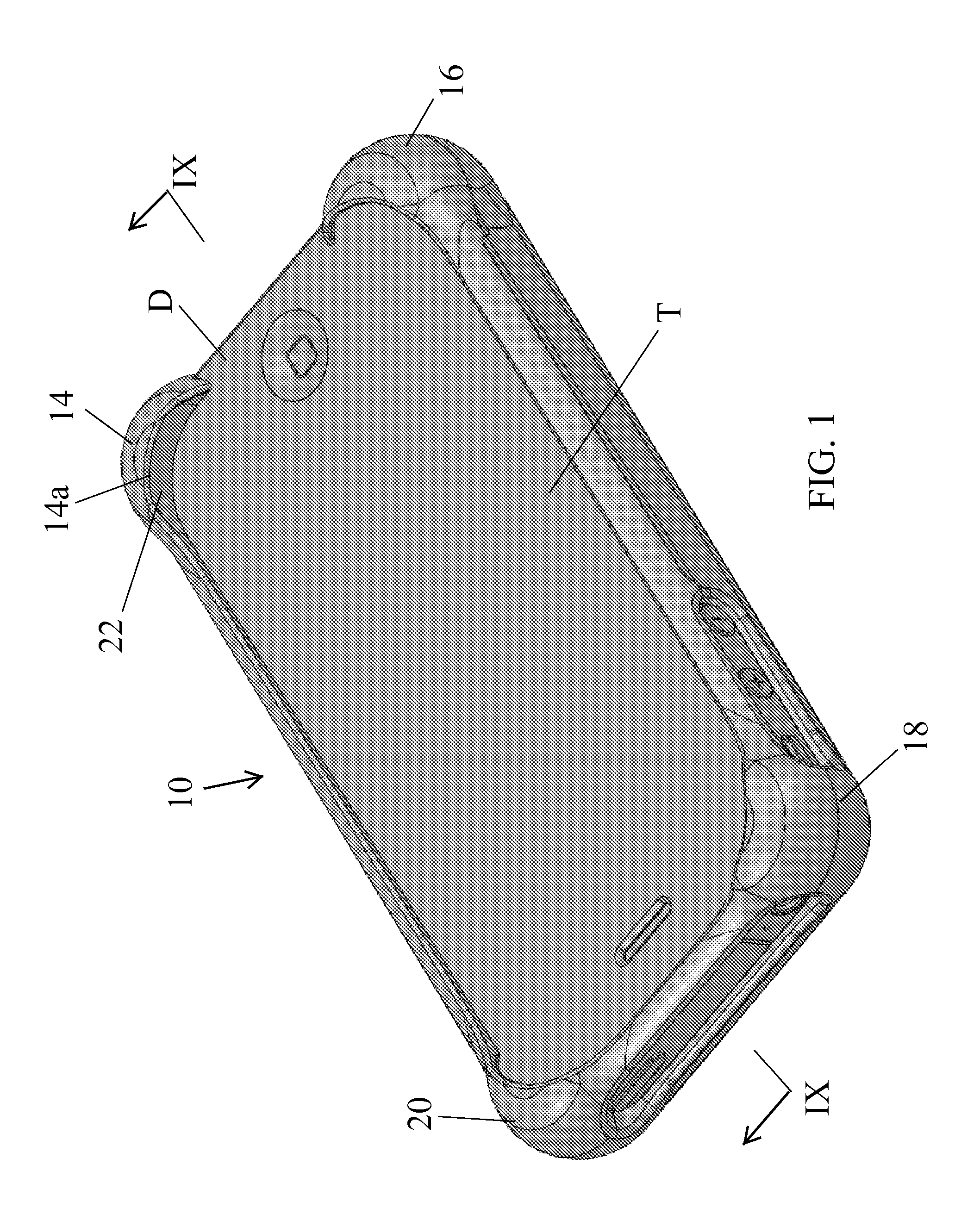

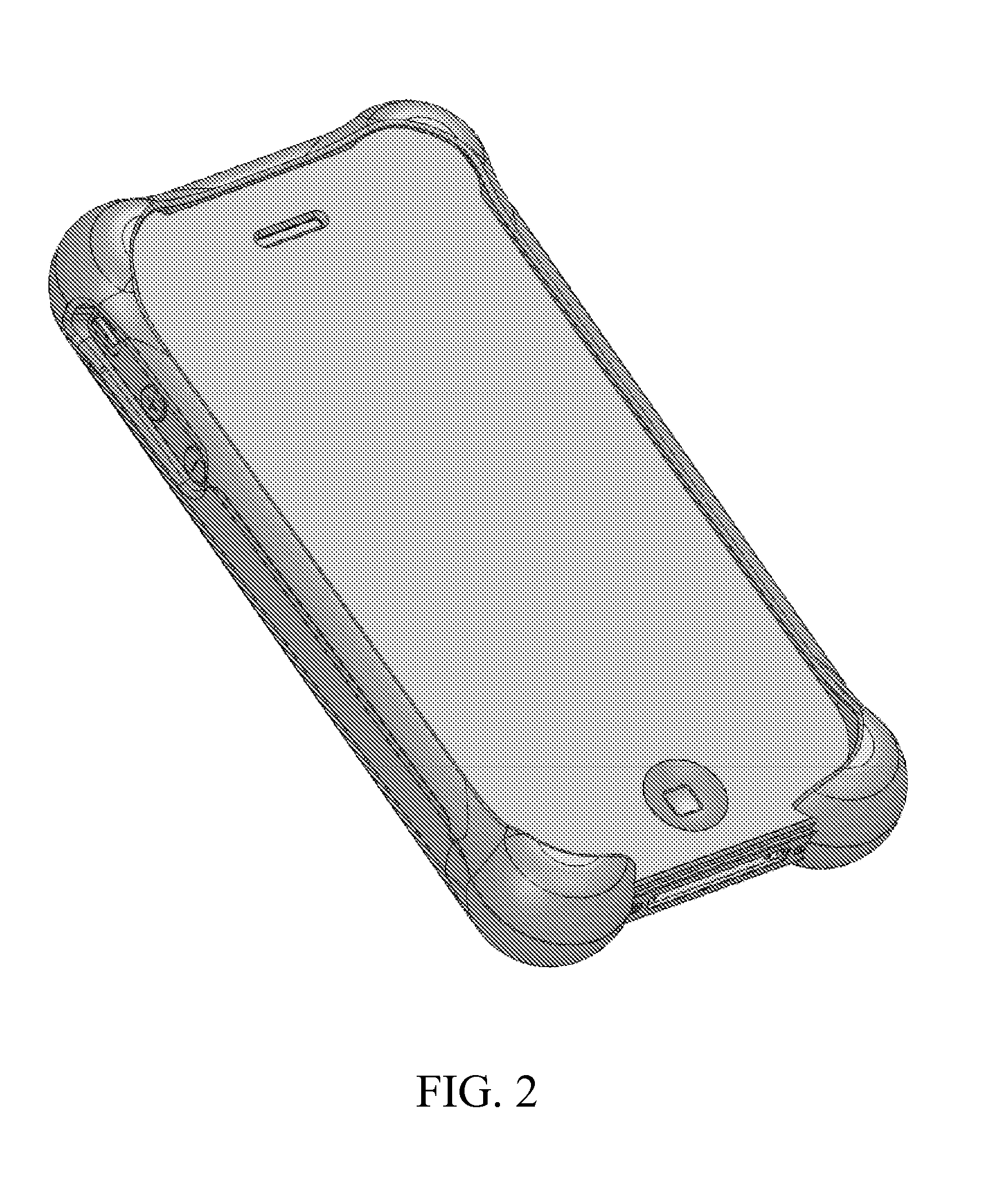

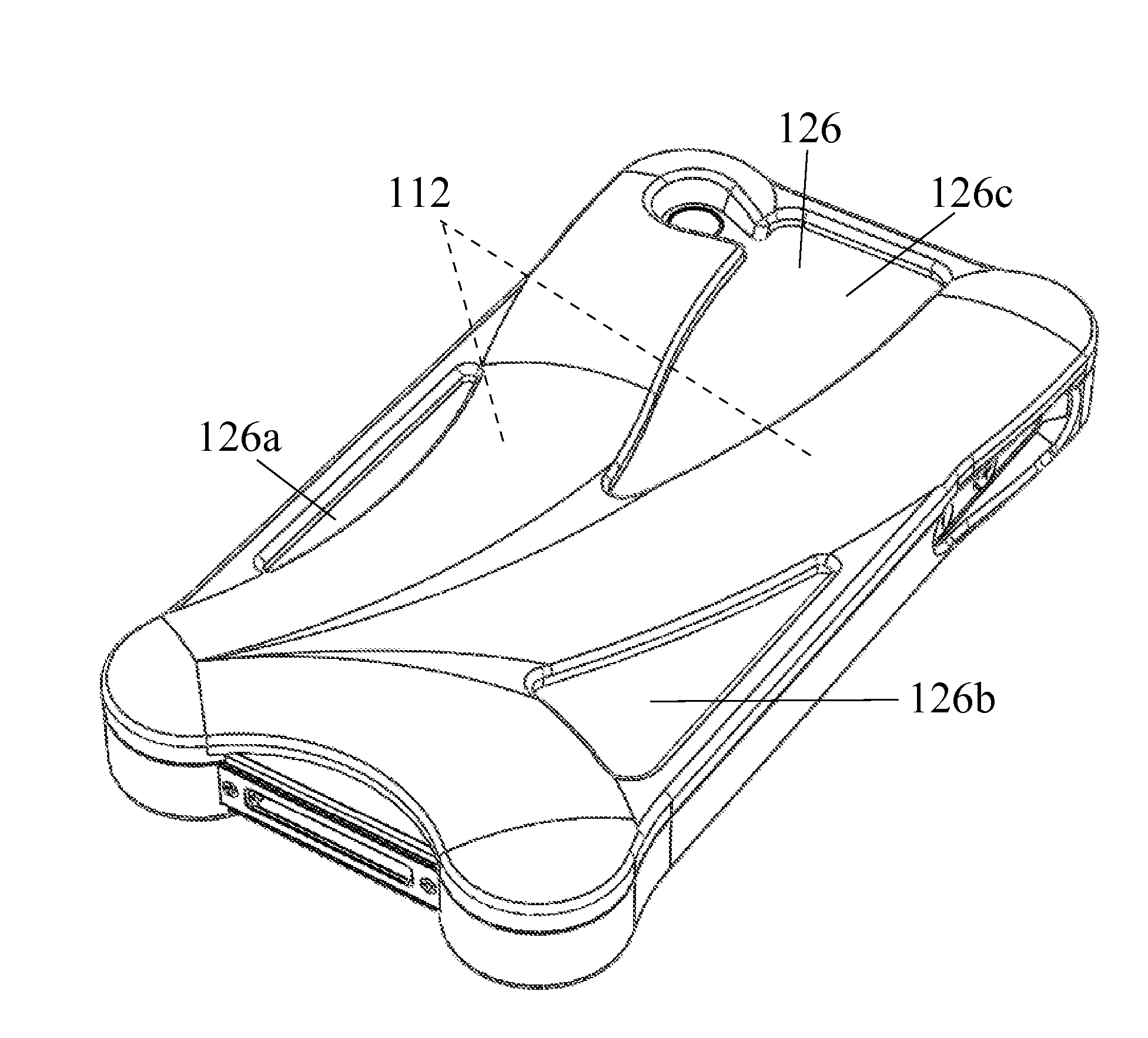

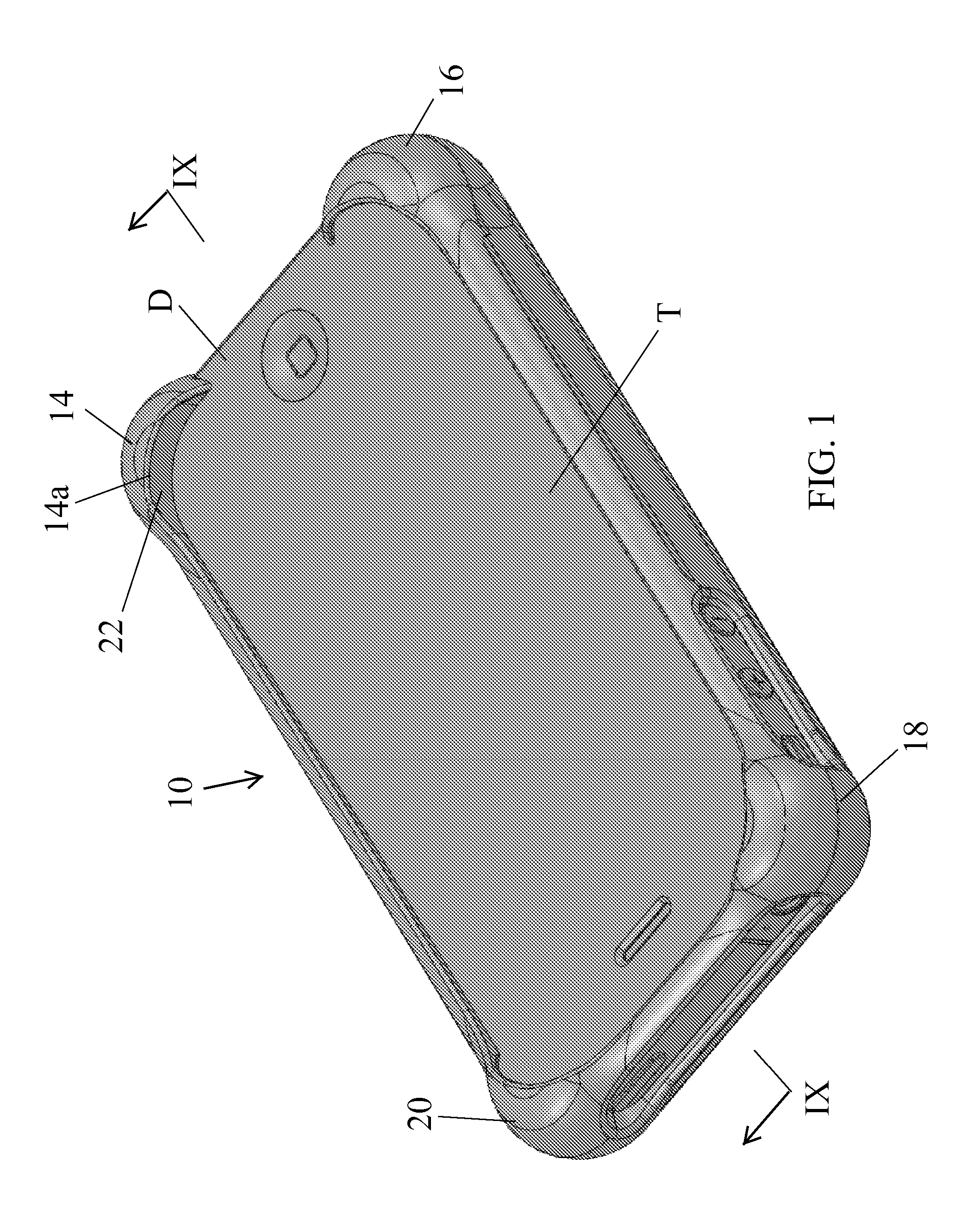

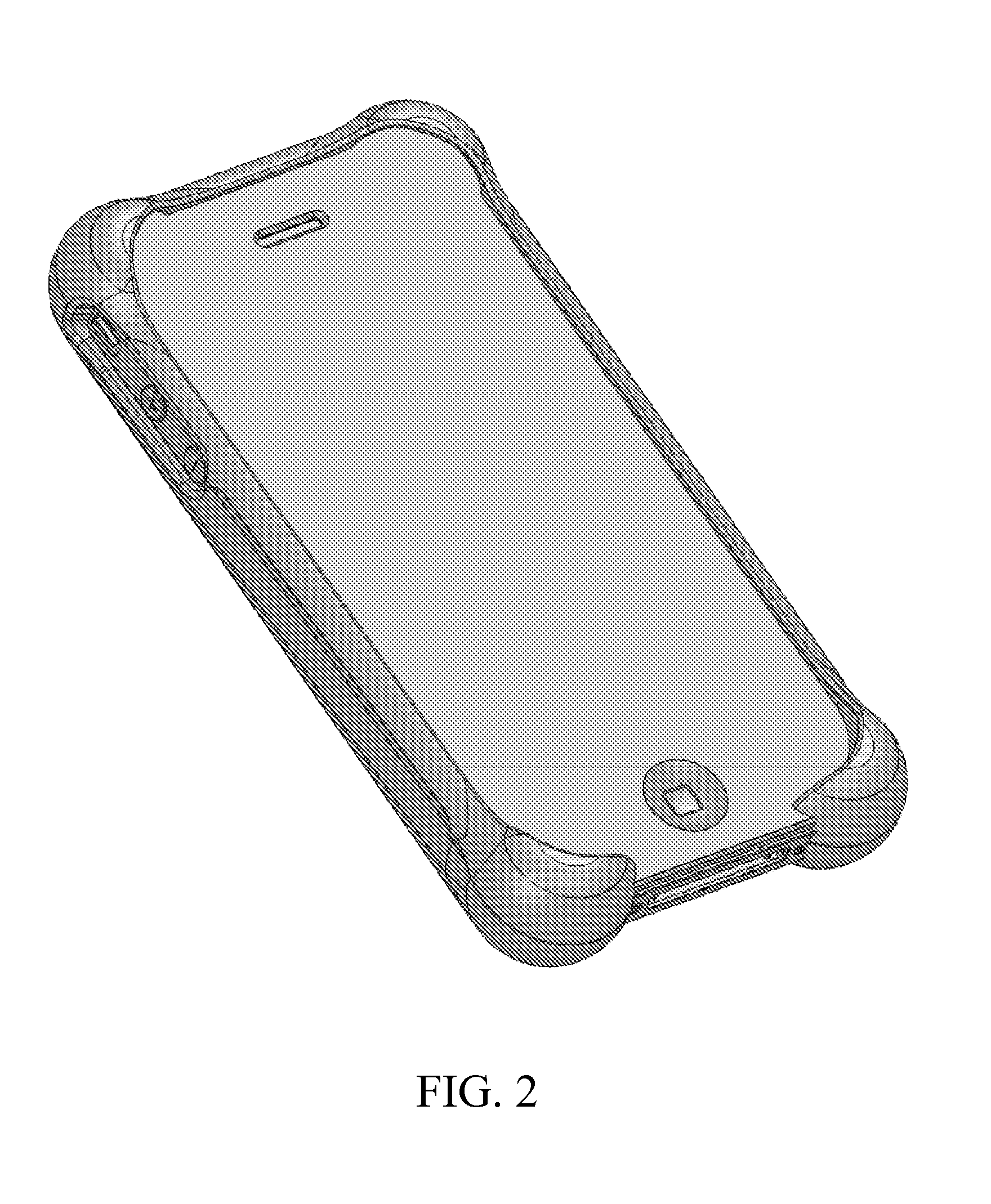

Cover for hand-held electronic device

InactiveUS20120294469A1Improve equipment qualityQuality of soundSubstation equipmentTransducer casings/cabinets/supportsLoudspeakerHand held devices

A cover for a hand-held device, which has a device body and a speaker, includes a cover body configured for covering a portion the device body and for covering the speaker and a channel for positioning adjacent the device body. The channel is configured to form a sound duct when mounted adjacent the back side of the device body and to be in communication with the speaker when the cover is mounted to the hand-held device for redirecting at least a portion of the sound waves emitted from the speaker to a location remote from the speaker.

Owner:NFLUKZ LLC

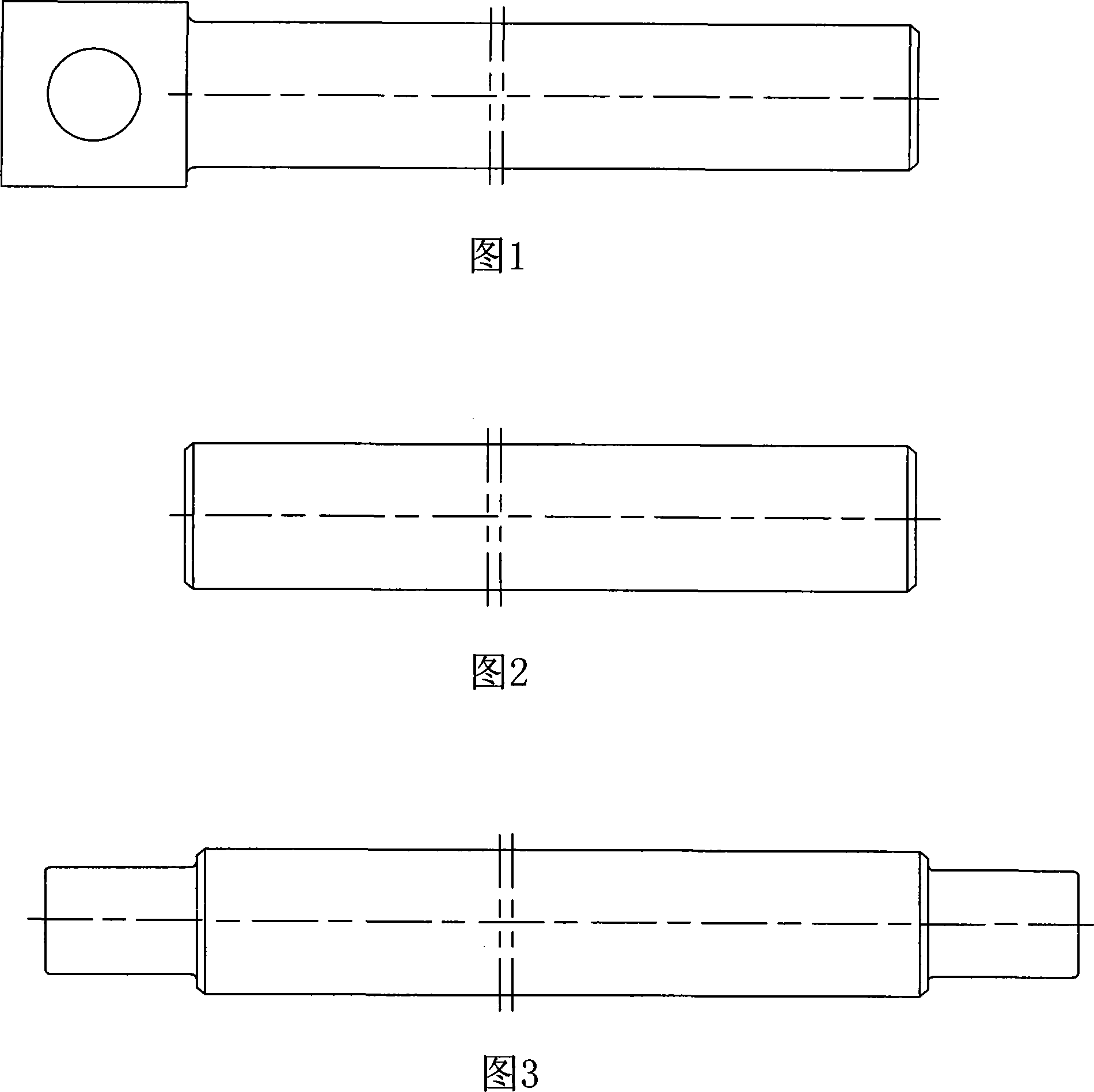

Roller and producing technique

The invention relates to the field of steel rolling machinery, in particular to a roller and a production process for the roller which is made of W6Mo5Cr4V2 high speed steel; the production process comprises the following steps: a. material preparation; b. the processing of two end faces of blanks; c. the processing of central holes of two ends; d. the processing of rough turn; e. the drilling of hoisting holes outside the length of finished products; f. carrying out quenching and tempering treatment to cause the roller hardness to reach 40 to 50 HSD; g. the modification of the central holes of the two ends; h. the processing of half finish turning; i. coarse grinding of the roller body; j. carrying out quenching and tempering treatment to lead the surface of the roller body to reach the quenching hardness of 88 to 93 HSD; k. the processing of the lengths of the two ends to required sizes; l. the processing of finish turning; m. the coarse grinding of the roller body and a roller neck; n. stress relief treatment; o. the repairing of the central holes of the two ends; p. fine grinding of the roller body and the roller neck; q. super grinding of the roller body and the roller neck to finished products. The roller and the production process thereof solves the problem of big size, high production cost, tedious process and great production difficulty of rollers which are produced with conventional materials.

Owner:CHANGZHOU ECCO ROLLER

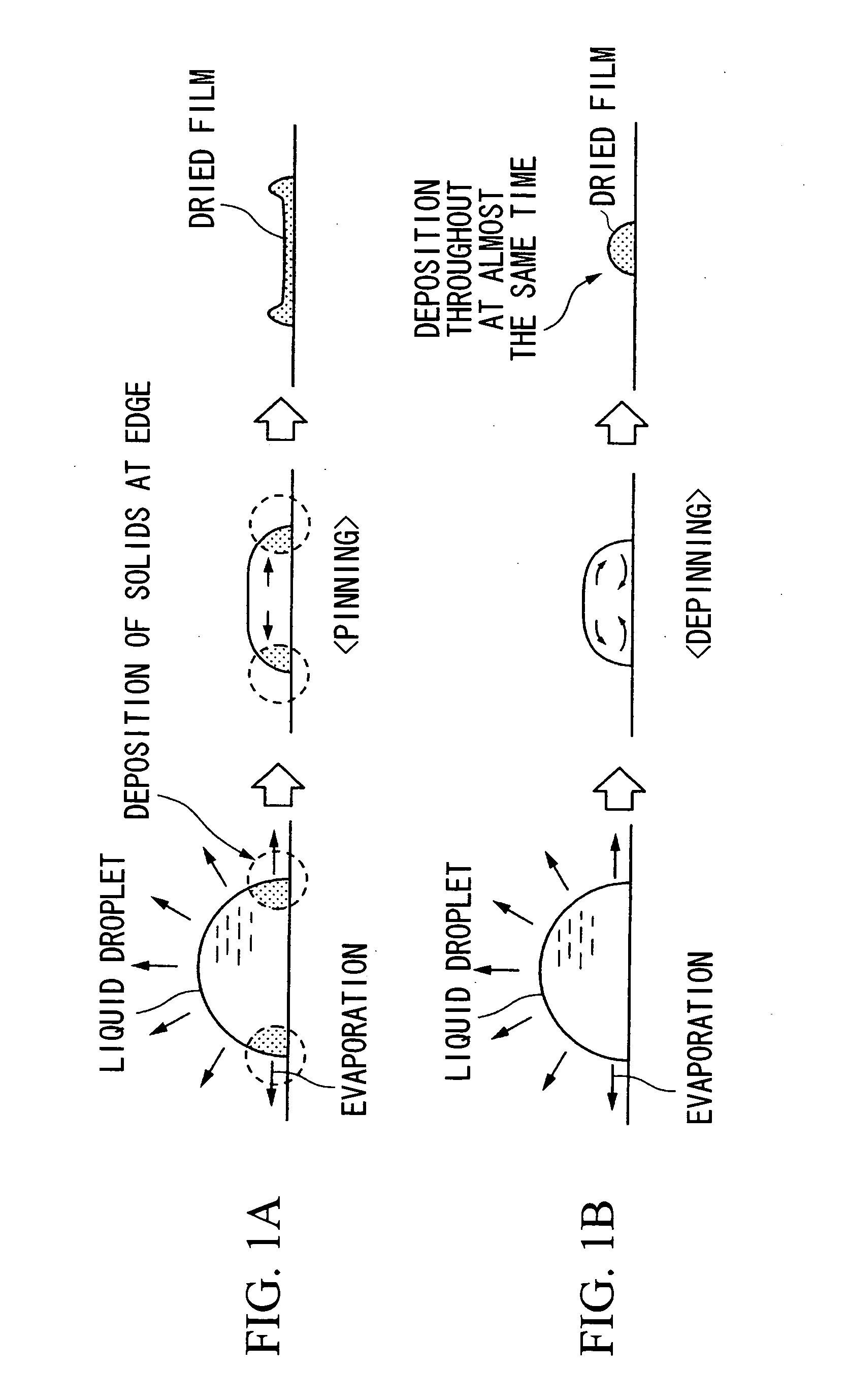

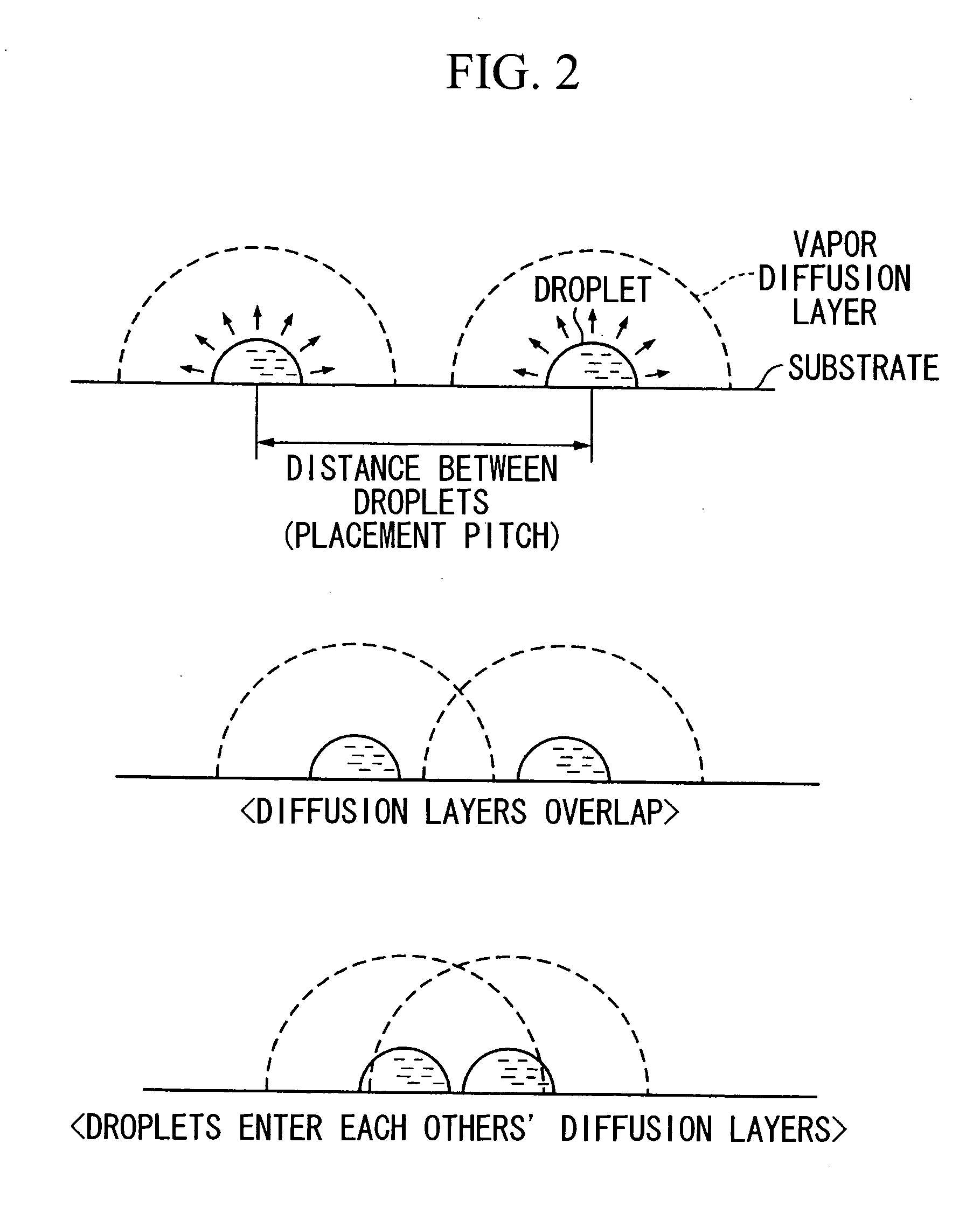

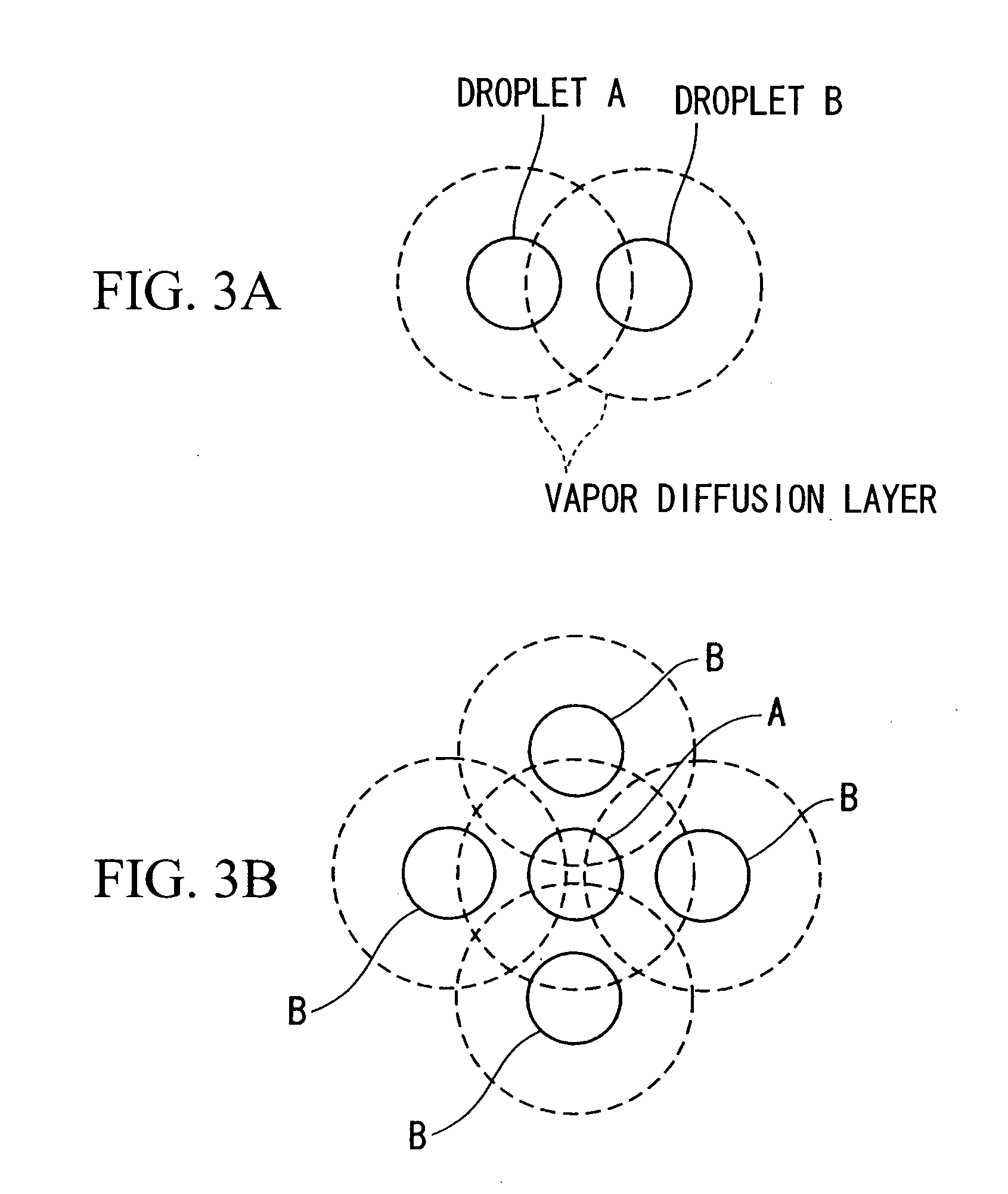

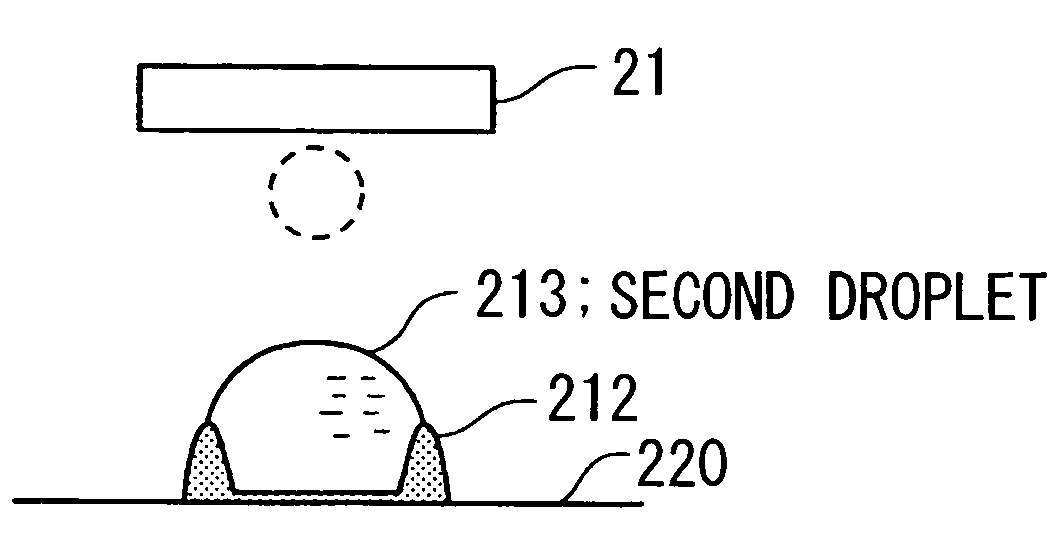

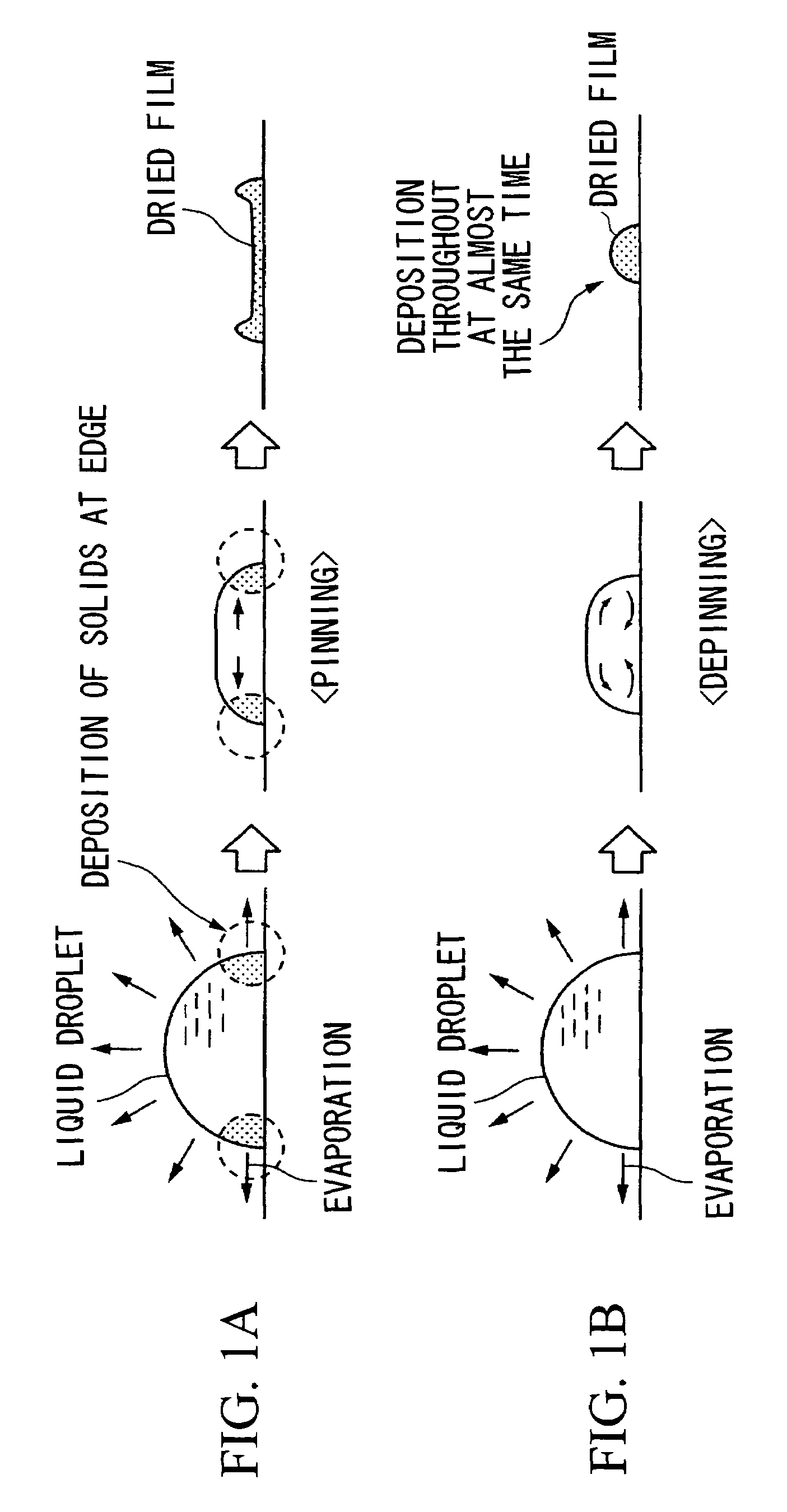

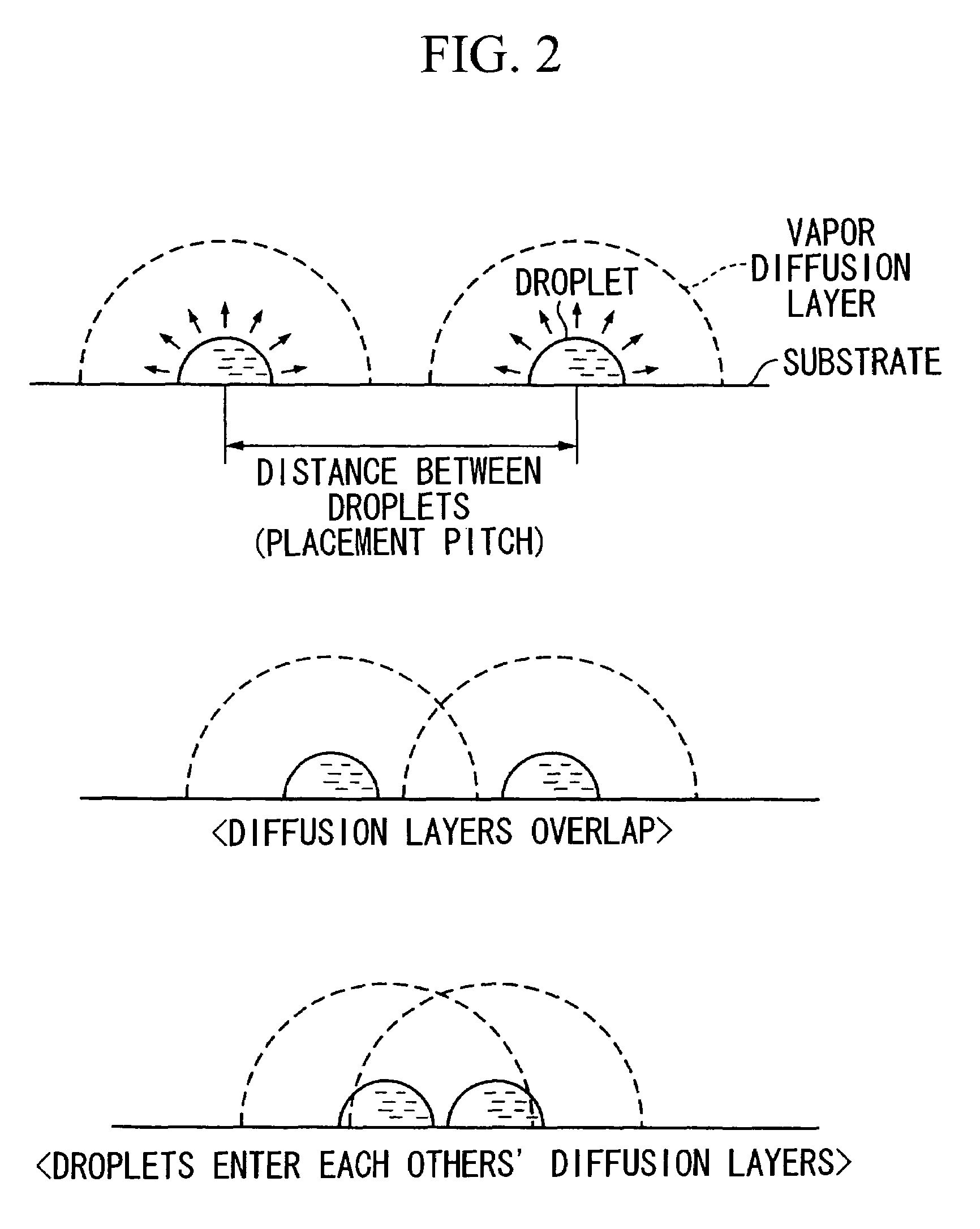

Process for forming a film, process for manufacturing a device, electro-optical device and electronic equipment

InactiveUS20050025880A1Stable and accurateAccurately and stably formedMaterial nanotechnologyNanoinformaticsEngineeringElectron

A liquid material is placed on a substrate as a droplet to form a film on the substrate. At least either one of a concentration of solids in the liquid material and a drying rate of the droplets is used as a parameter to control a form of a dried film of the droplets. Moreover, a first droplet is placed on a substrate, the first droplet is dried to form a dried film of a form in which a thickness of an edge is larger than that of a central part, and a second droplet is placed in a region surrounded by the edge section of a dried film of the first droplet to form a dried film of the second droplet. Furthermore, the liquid material is placed on the substrate as a droplet to form a film on the substrate, and a dried film of the droplet is formed by contracting the droplet.

Owner:SEIKO EPSON CORP

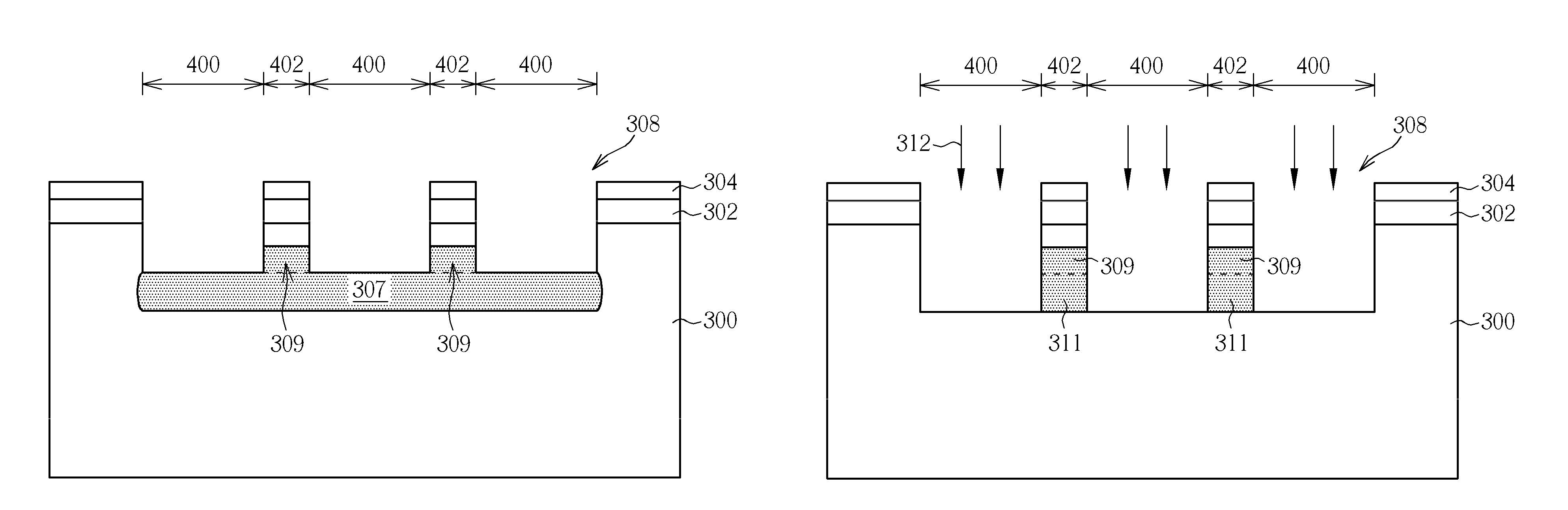

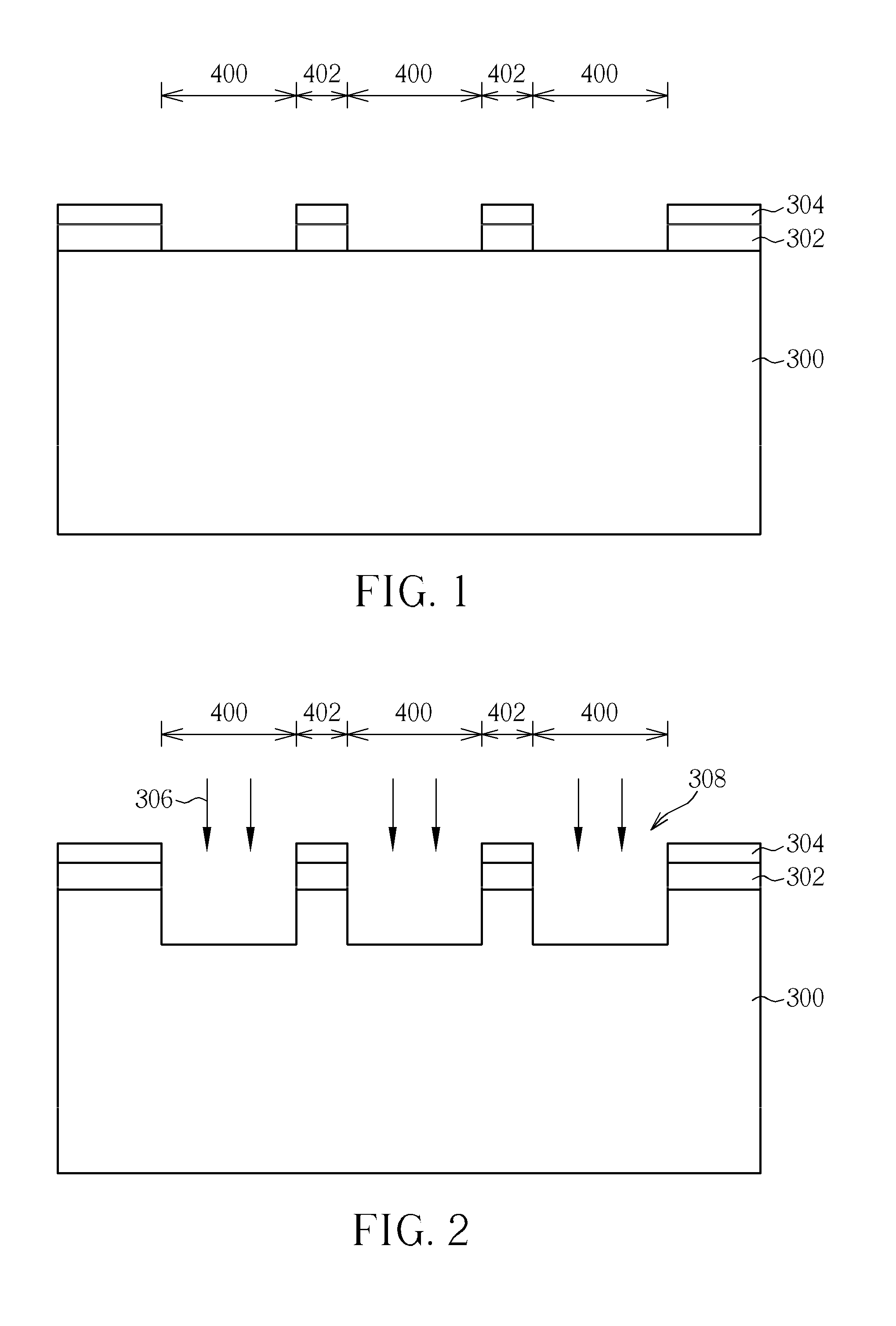

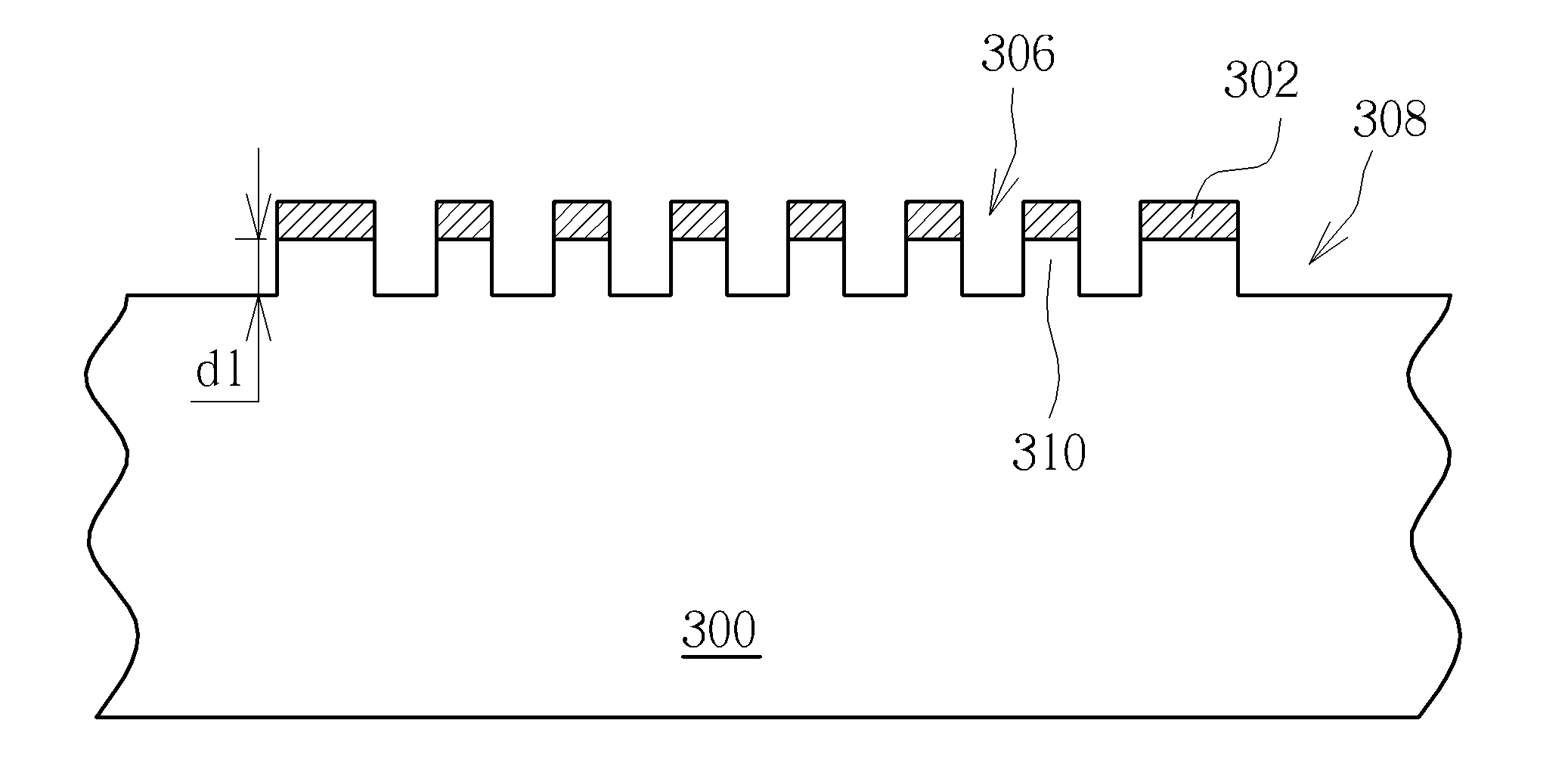

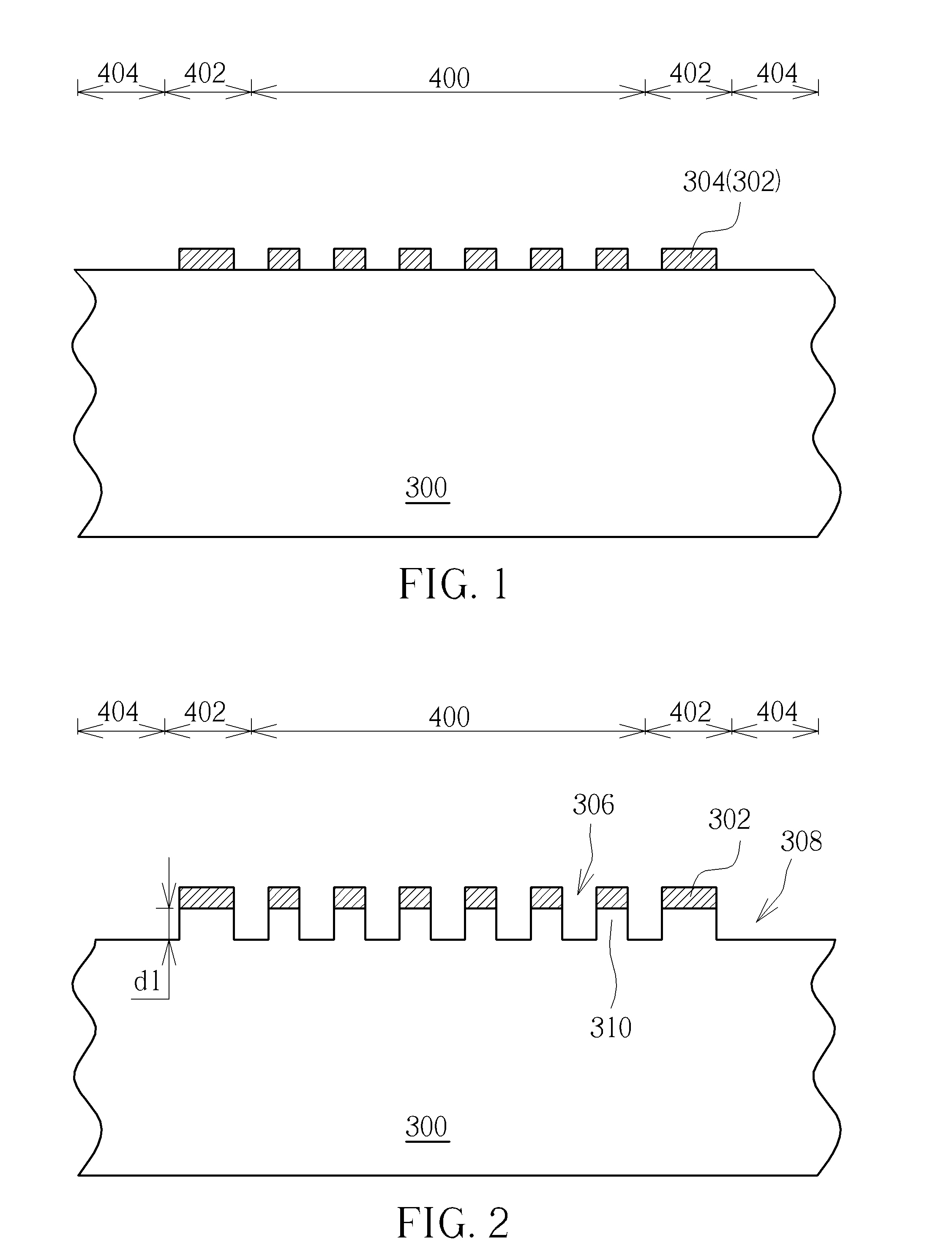

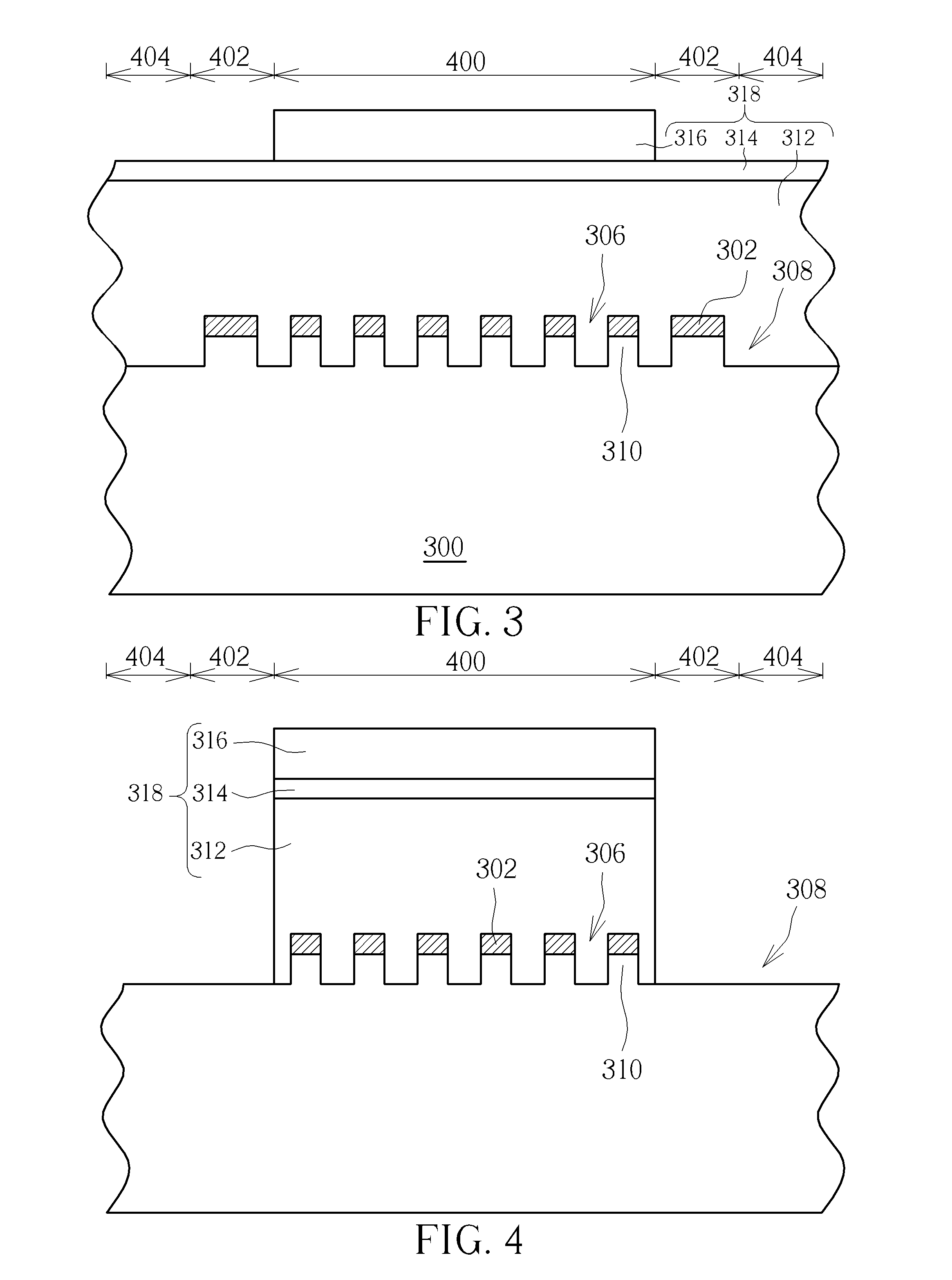

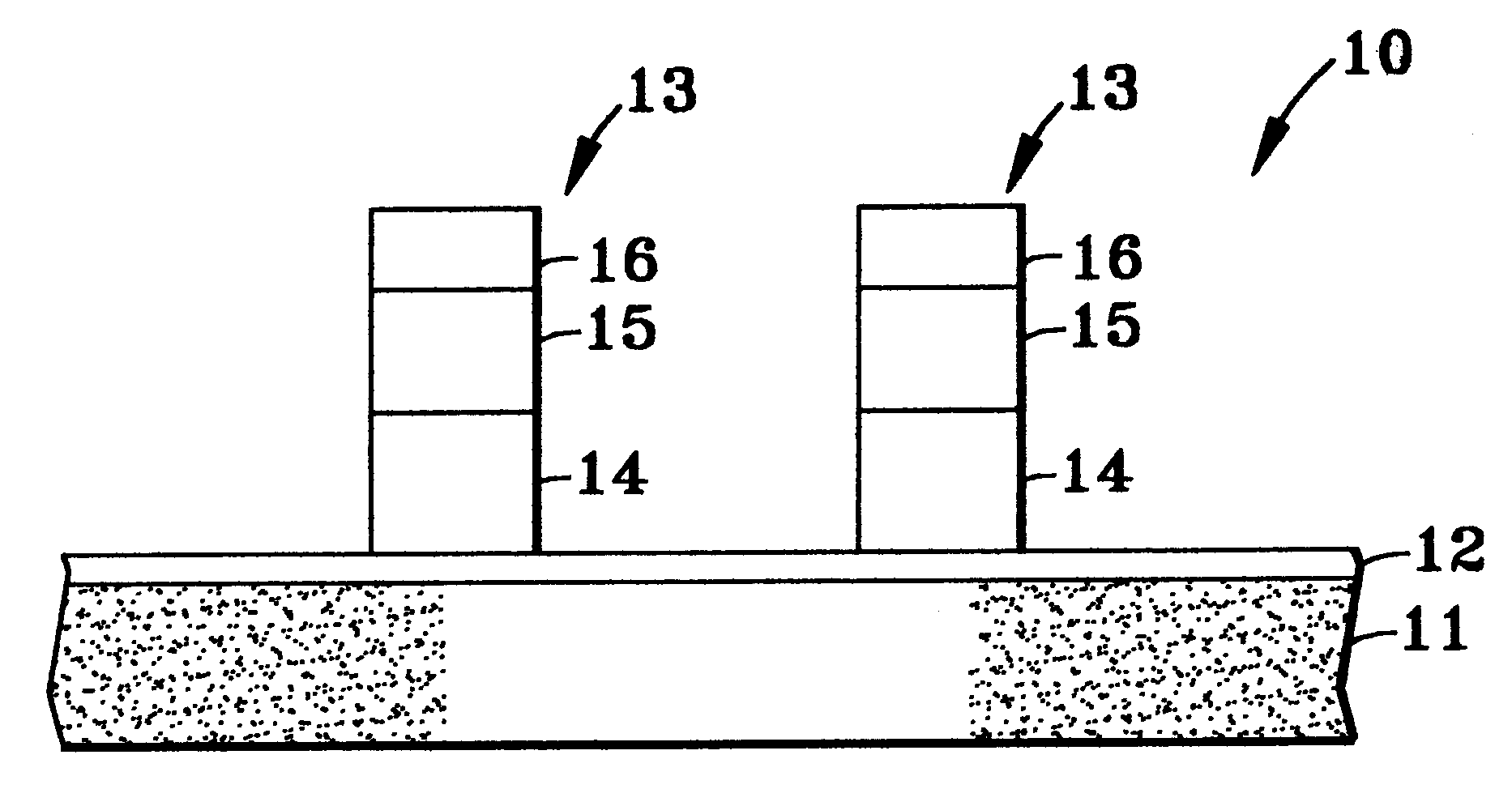

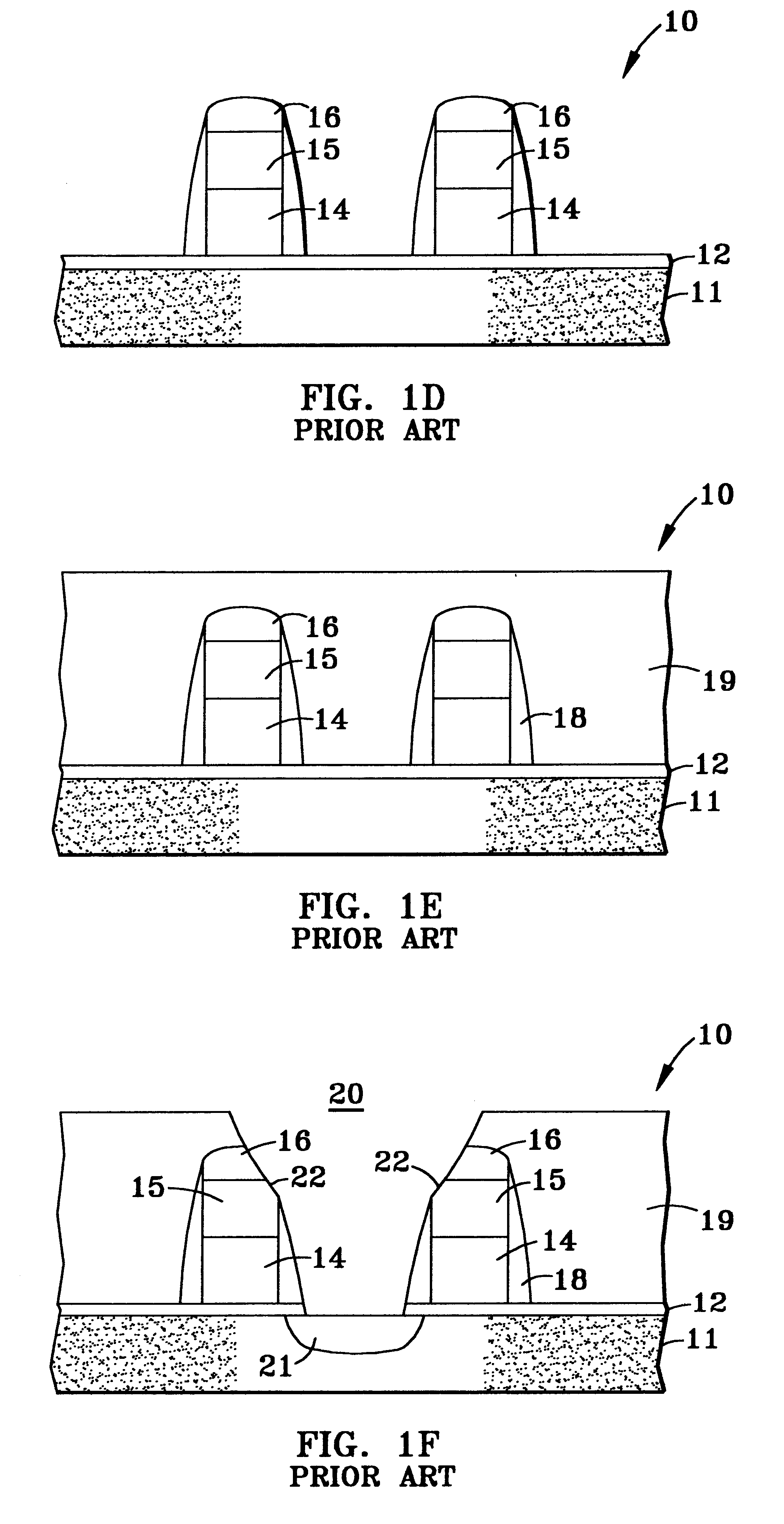

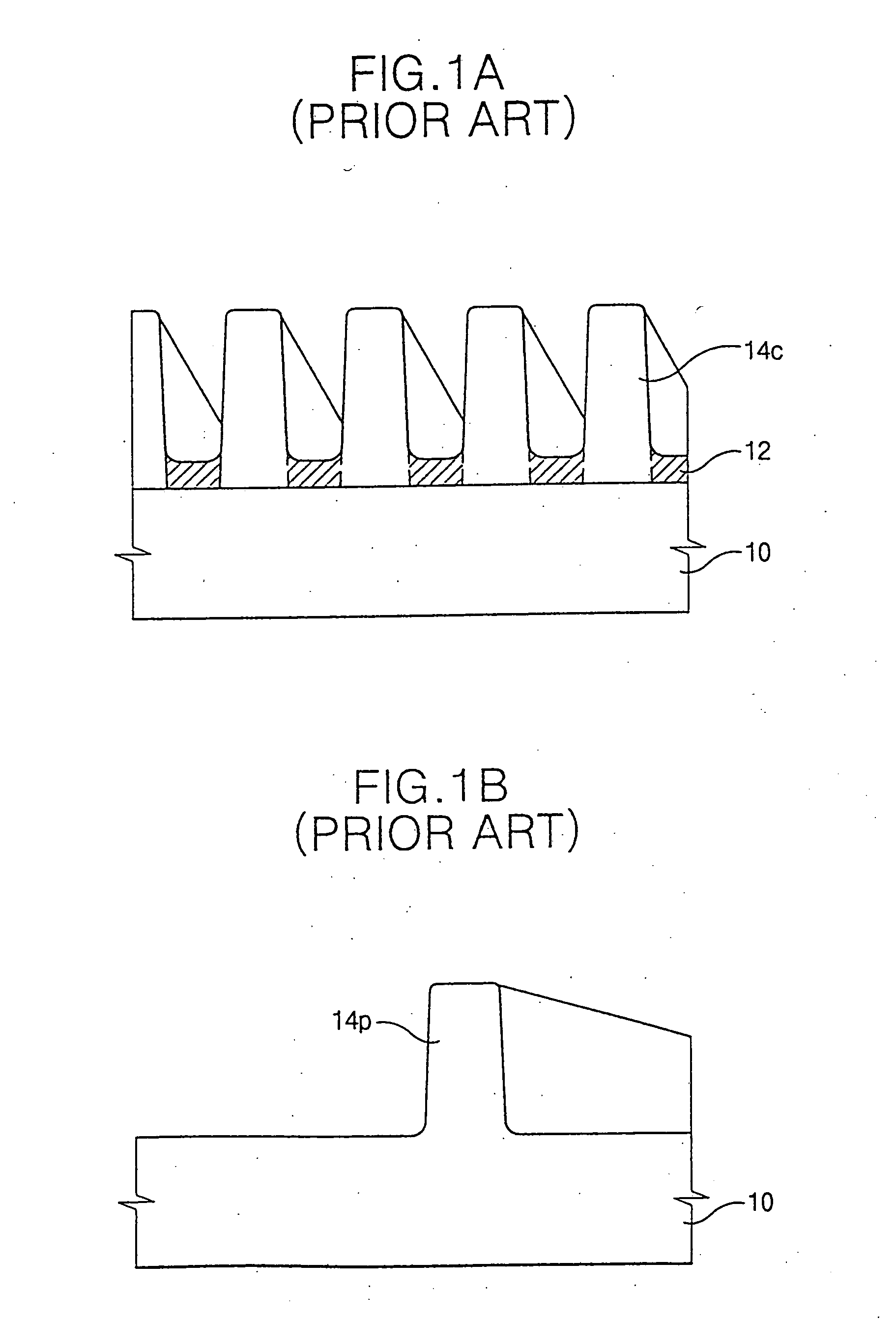

Fabrication method of a non-planar transistor

ActiveUS8278184B1Improve equipment qualityQuality improvementSemiconductor/solid-state device manufacturingTransistorElectrical and Electronics engineering

A method of forming a non-planar transistor is provided. A substrate is provided. The substrate has a plurality of isolation regions to be formed and a plurality of fin regions to be formed. A first etching process is performed to form a plurality of first trenches having a first depth in the substrate within the isolation regions. At least a doping region is formed in the substrate within the fin regions. A second etching process is performed to deepen the first depth to a second depth and a plurality of fin structures are formed in the substrate within the fin regions. Lastly, a gate is formed on the fin structures.

Owner:UNITED MICROELECTRONICS CORP

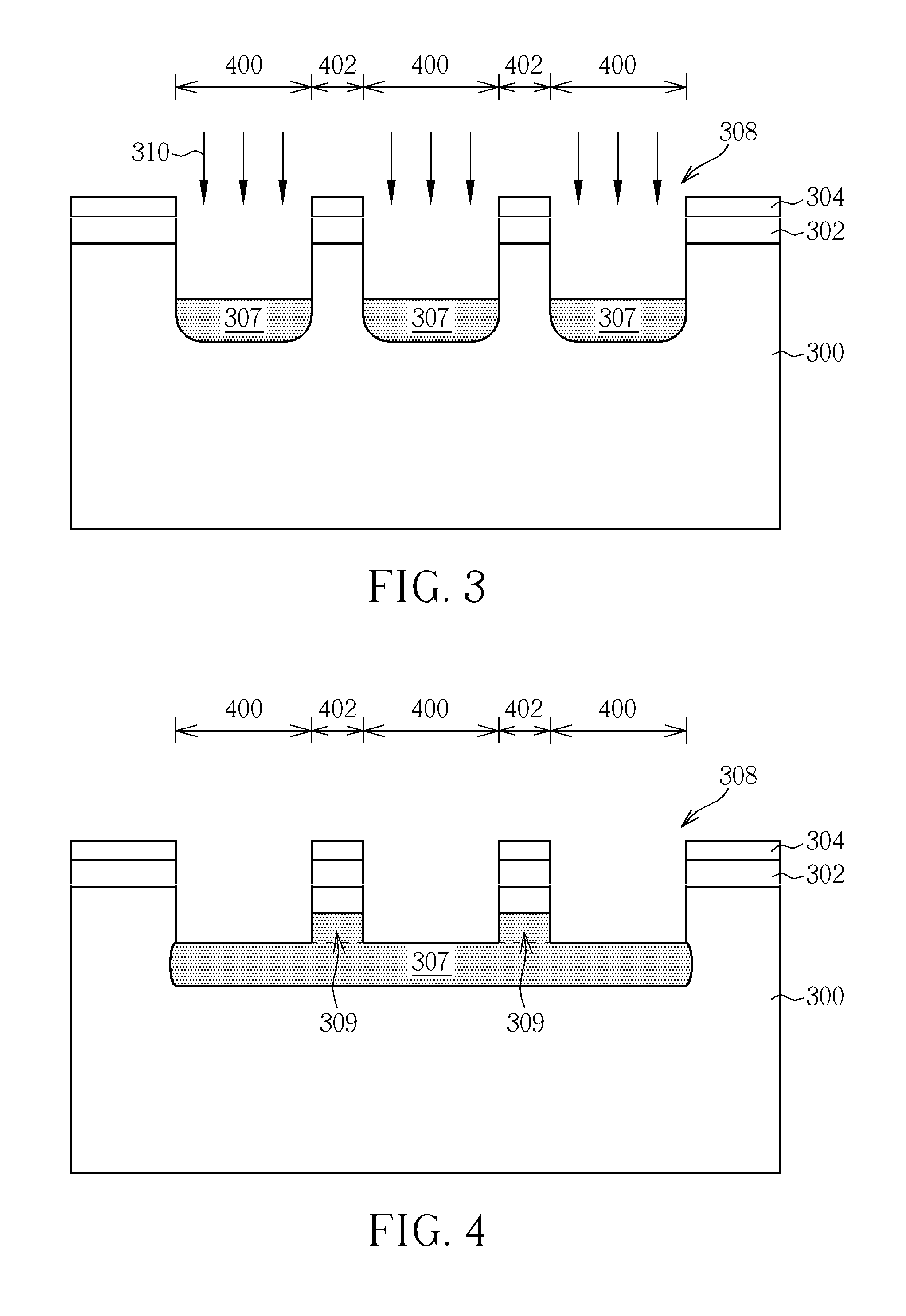

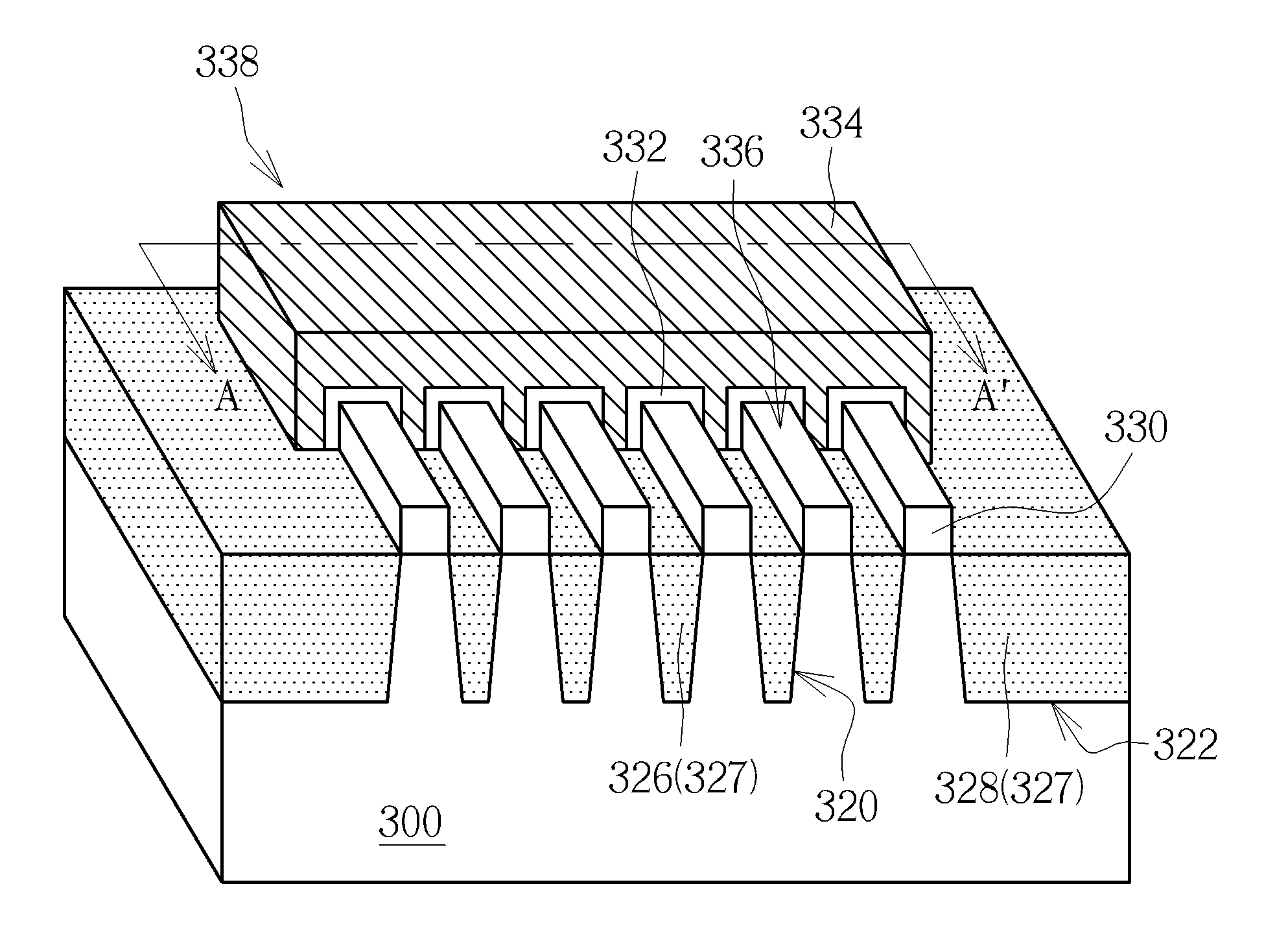

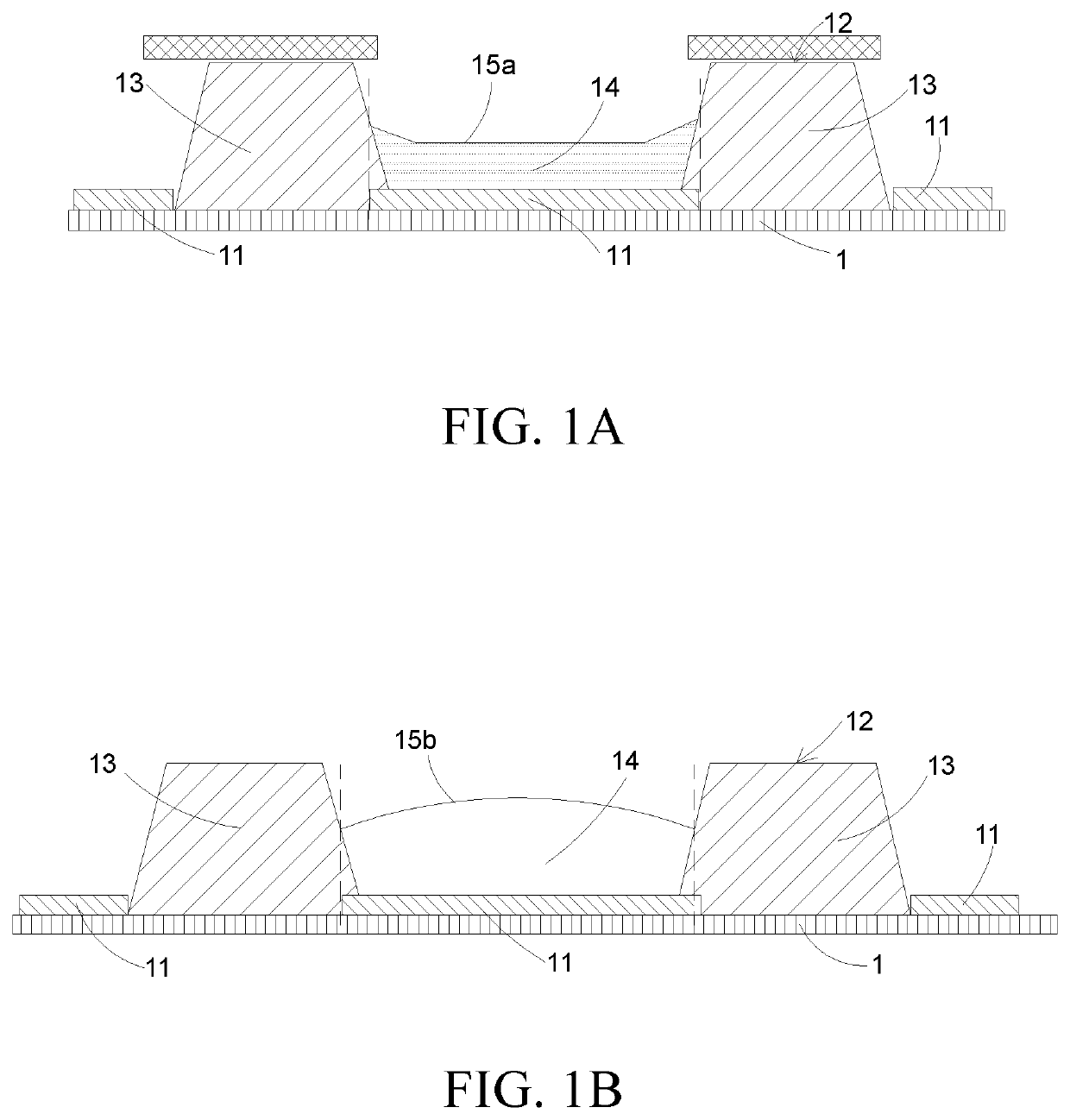

Method of forming a FinFET structure

ActiveUS8853015B1Improve equipment qualityQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A method of forming a fin structure is provided. First, a substrate is provided, wherein a first region, a second region encompassing the first region, and a third region encompassing the second region are defined on the substrate. Then, a plurality of first trenches having a first depth are formed in the first region and the second region, wherein each two first trenches defines a first fin structure. The first fin structure in the second region is removed. Lastly, the first trenches are deepened to form a plurality of second trenches having a second depth, wherein each two second trenches define a second fin structure. The present invention further provides a structure of a non-planar transistor.

Owner:MARLIN SEMICON LTD

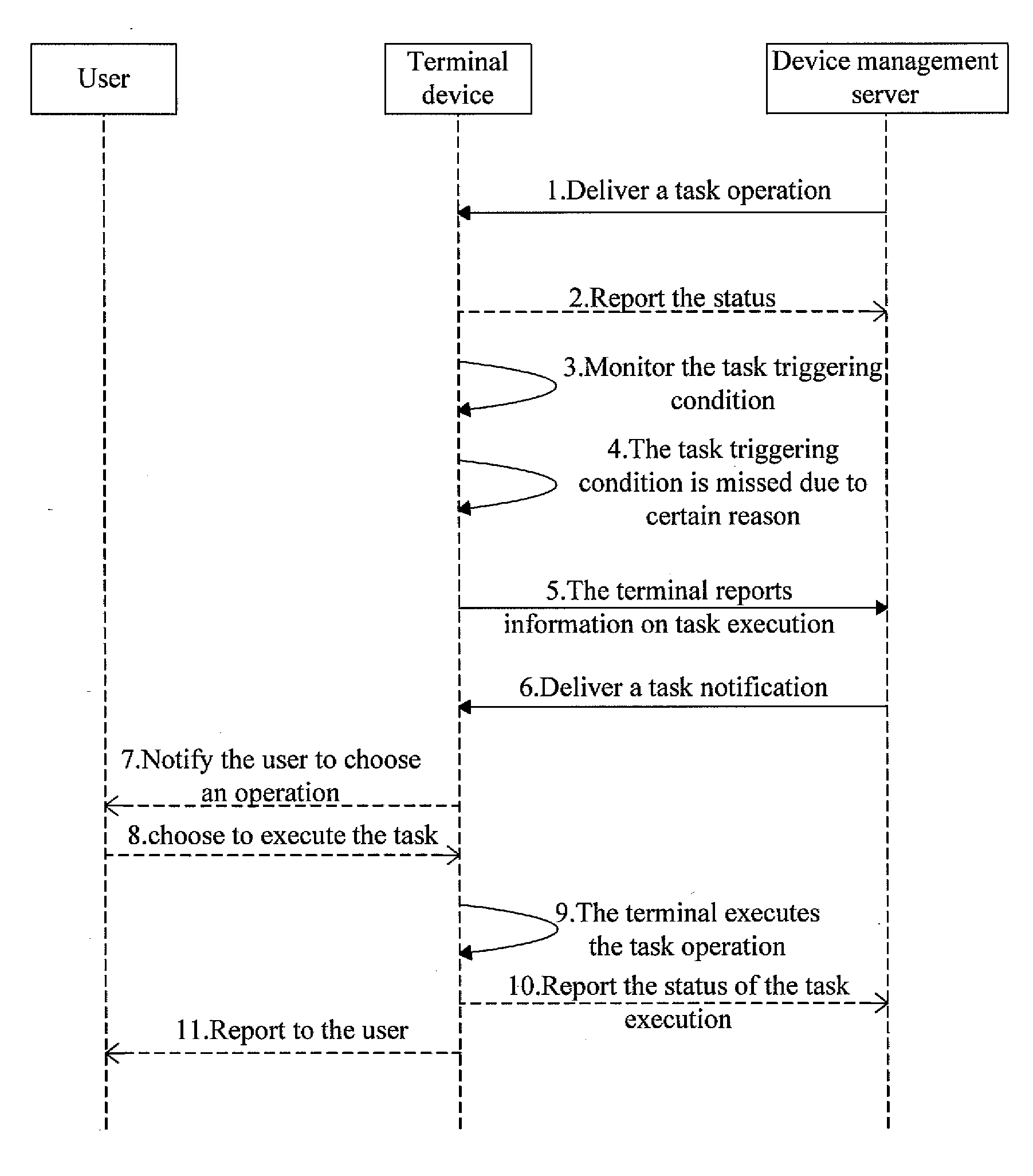

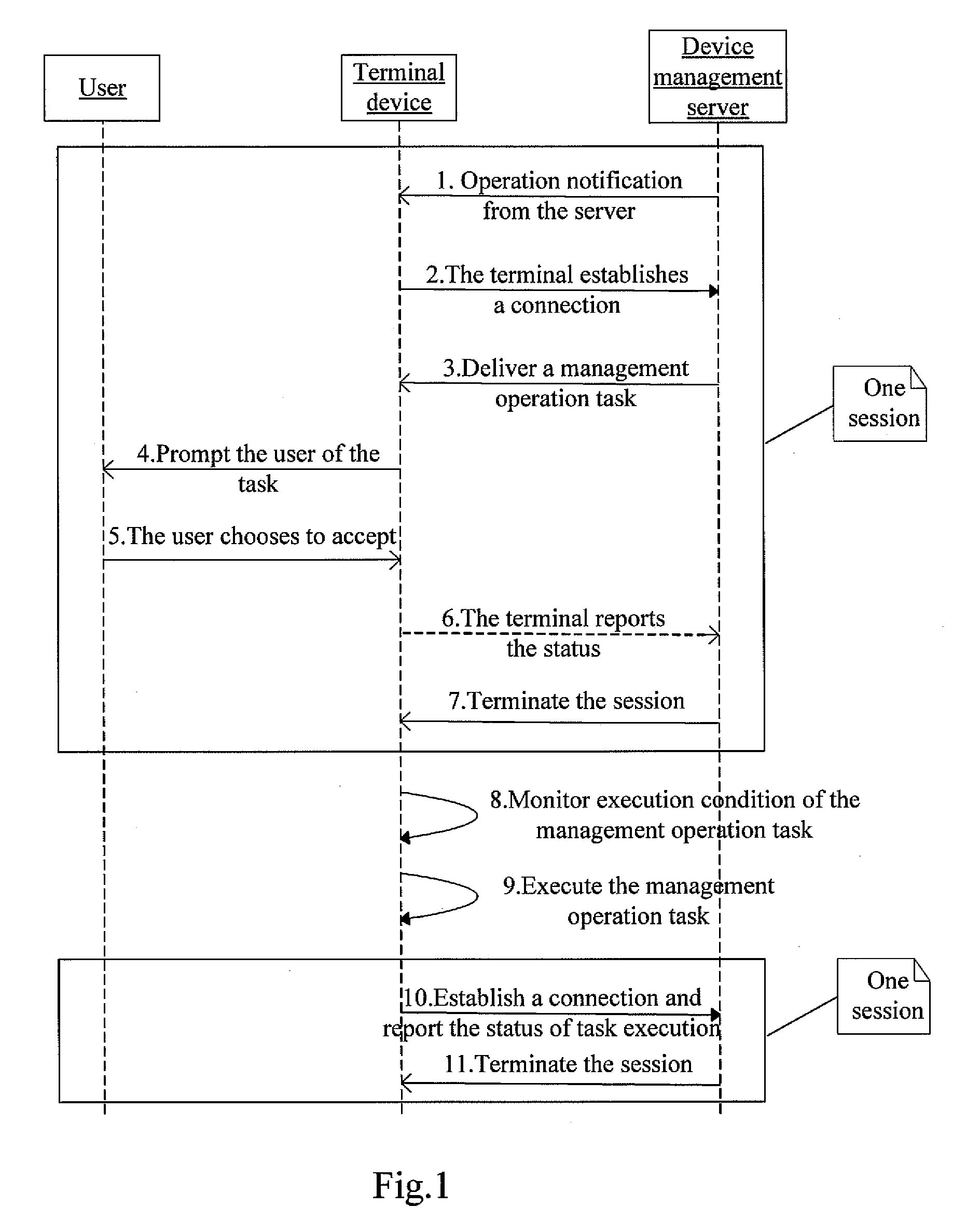

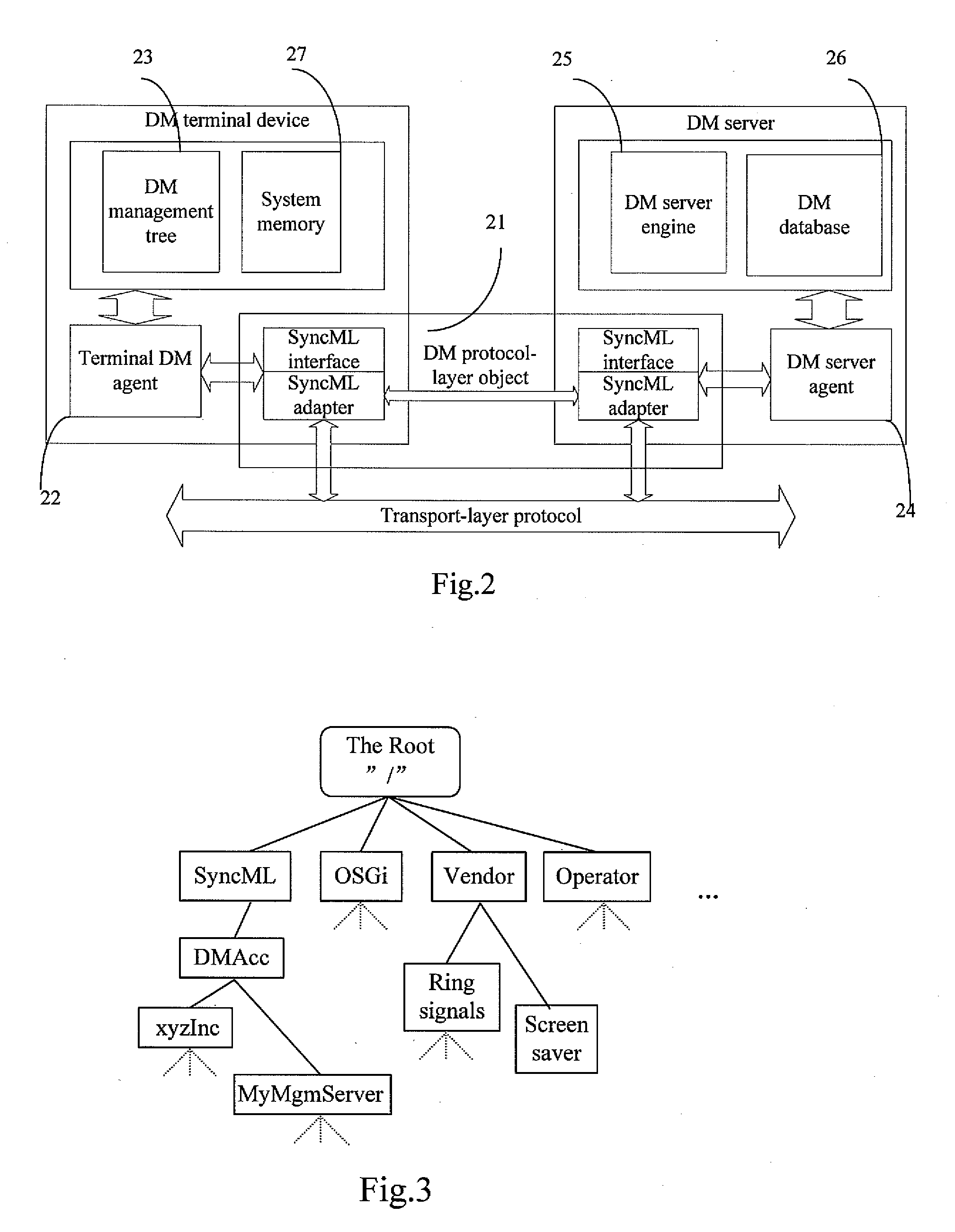

Method and system for processing a scheduling task in device management

InactiveUS20080127190A1Quality improvementReduce managementService provisioningMultiprogramming arrangementsDevice MonitorMobile telephony

A method, device, device management server and system for processing a scheduling task in device management are provided. The method includes: a device management server delivering a scheduling task; a device monitoring an execution condition of the scheduling task; the device reporting information on execution of the task; if the device does not execute the task normally according to the execution condition, the device management server delivering a task, and the device executing an operation according to the instruction; and the device reporting a task execution status. Thus, an effective mechanism for ensuring execution of the scheduling task is provided, so that the uncertainty in device management may be reduced, the flexibility of device management on the mobile phone may be increased, a scheduling demand from the user may be satisfied, and the quality of device management services may be improved.

Owner:HUAWEI TECH CO LTD

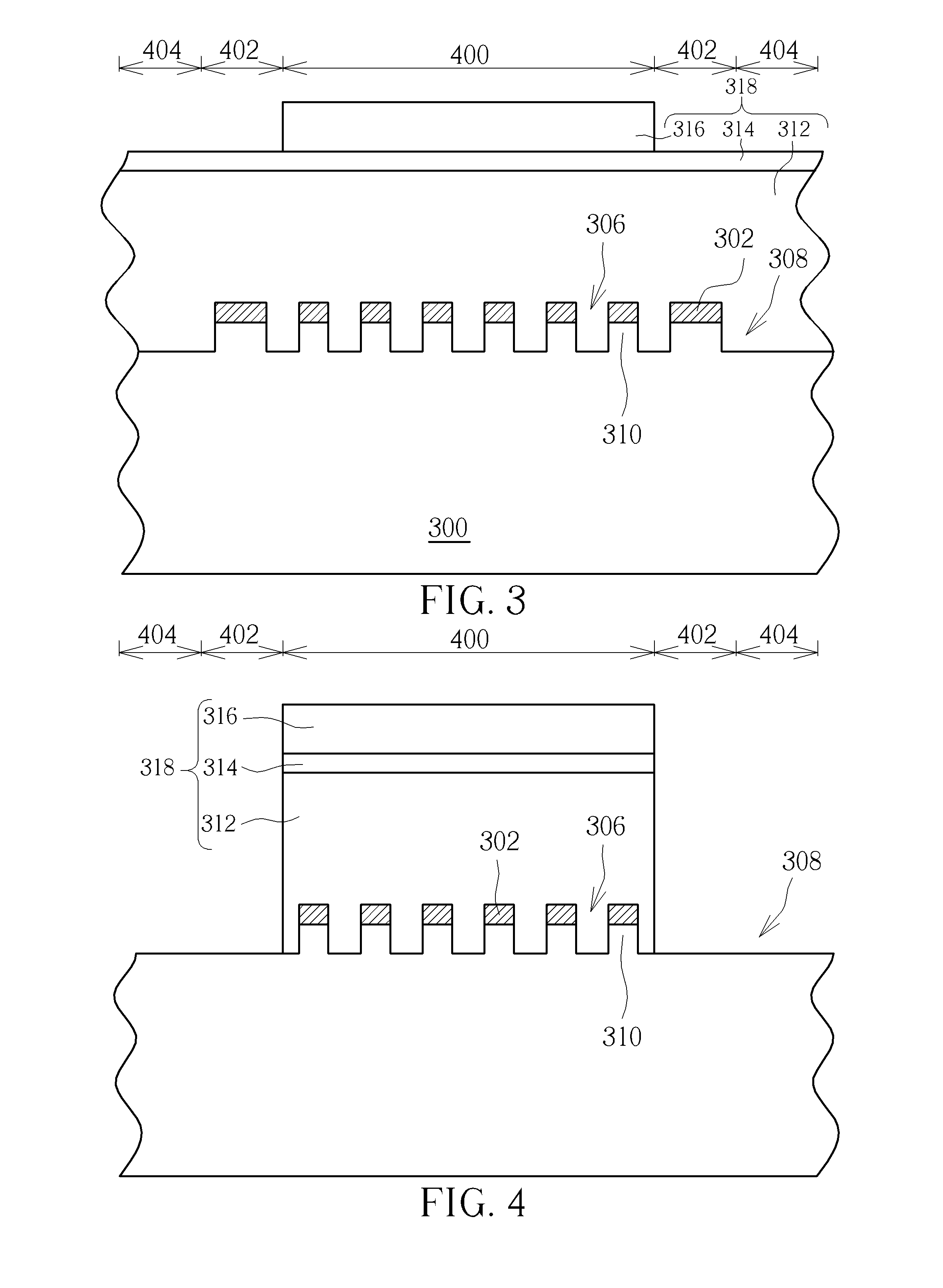

Method of forming a finfet structure

ActiveUS20140306272A1Improve equipment qualityQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A method of forming a fin structure is provided. First, a substrate is provided, wherein a first region, a second region encompassing the first region, and a third region encompassing the second region are defined on the substrate. Then, a plurality of first trenches having a first depth are formed in the first region and the second region, wherein each two first trenches defines a first fin structure. The first fin structure in the second region is removed. Lastly, the first trenches are deepened to form a plurality of second trenches having a second depth, wherein each two second trenches define a second fin structure. The present invention further provides a structure of a non-planar transistor.

Owner:MARLIN SEMICON LTD

Cover for hand-held electronic device

InactiveUS8971974B2Improve equipment qualityQuality of soundInterconnection arrangementsTransmissionHand heldAcoustic wave

A cover for a hand-held device, which has a device body and a speaker, includes a cover body configured for covering a portion the device body and for covering the speaker and a channel for positioning adjacent the device body. The channel is configured to form a sound duct when mounted adjacent the back side of the device body and to be in communication with the speaker when the cover is mounted to the hand-held device for redirecting at least a portion of the sound waves emitted from the speaker to a location remote from the speaker.

Owner:NFLUKZ LLC

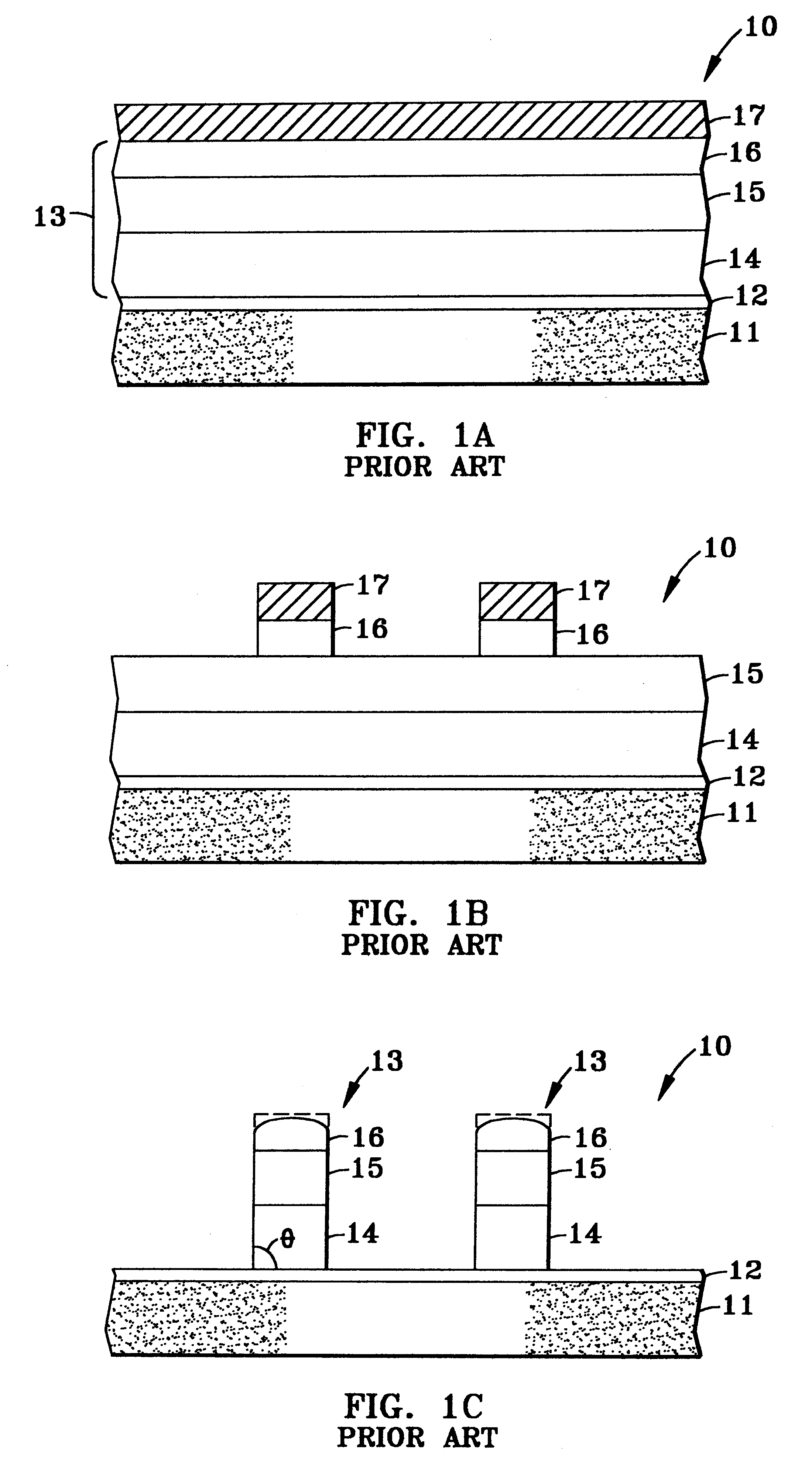

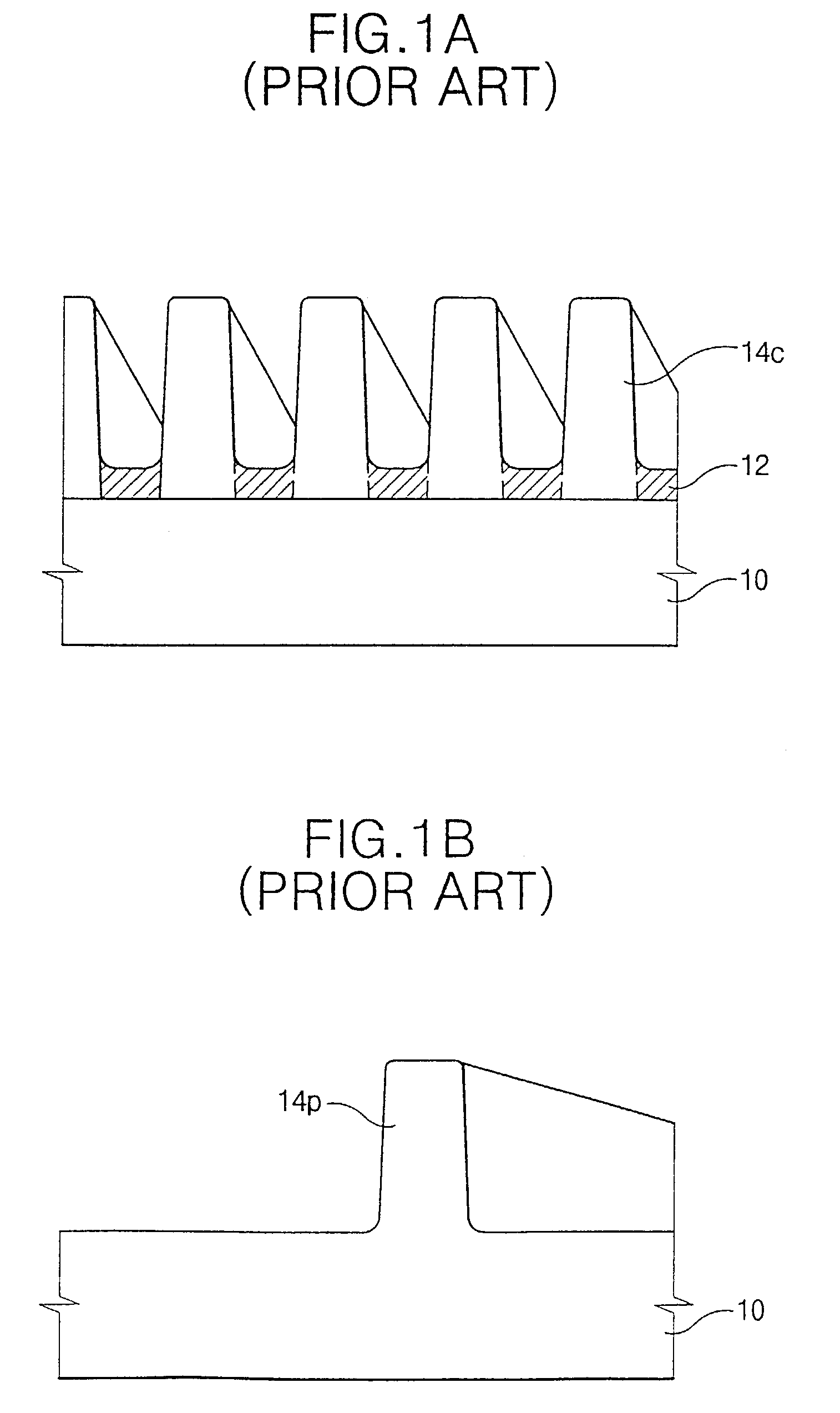

Method of plasma etching the tungsten silicide layer in the gate conductor stack formation

InactiveUS6207580B1Improves device quality factorImprove equipment qualitySemiconductor/solid-state device manufacturingSuccessful completionElectrical conductor

A method of plasma etching a Si3N4 masked tungsten silicide layer down to an underlying doped polysilicon layer in the gate conductor stack formation process is disclosed. The method is performed in a plasma etcher and the etching mixture contains C12, HCl and O2 wherein the C12 / HCl ratio is approximately equal to 4.7 and the oxygen flow varies between 20 and 30 sccm, 25 sccm being the optimal value. A slight overetching of the underlying doped polysilicon layer with this mixture is recommended. The etching method of the present invention preserves the thickness and integrity of the top Si3N4 masking layer that are essential elements for the successful completion of the remaining steps of the gate conductor stack formation process.

Owner:IBM CORP

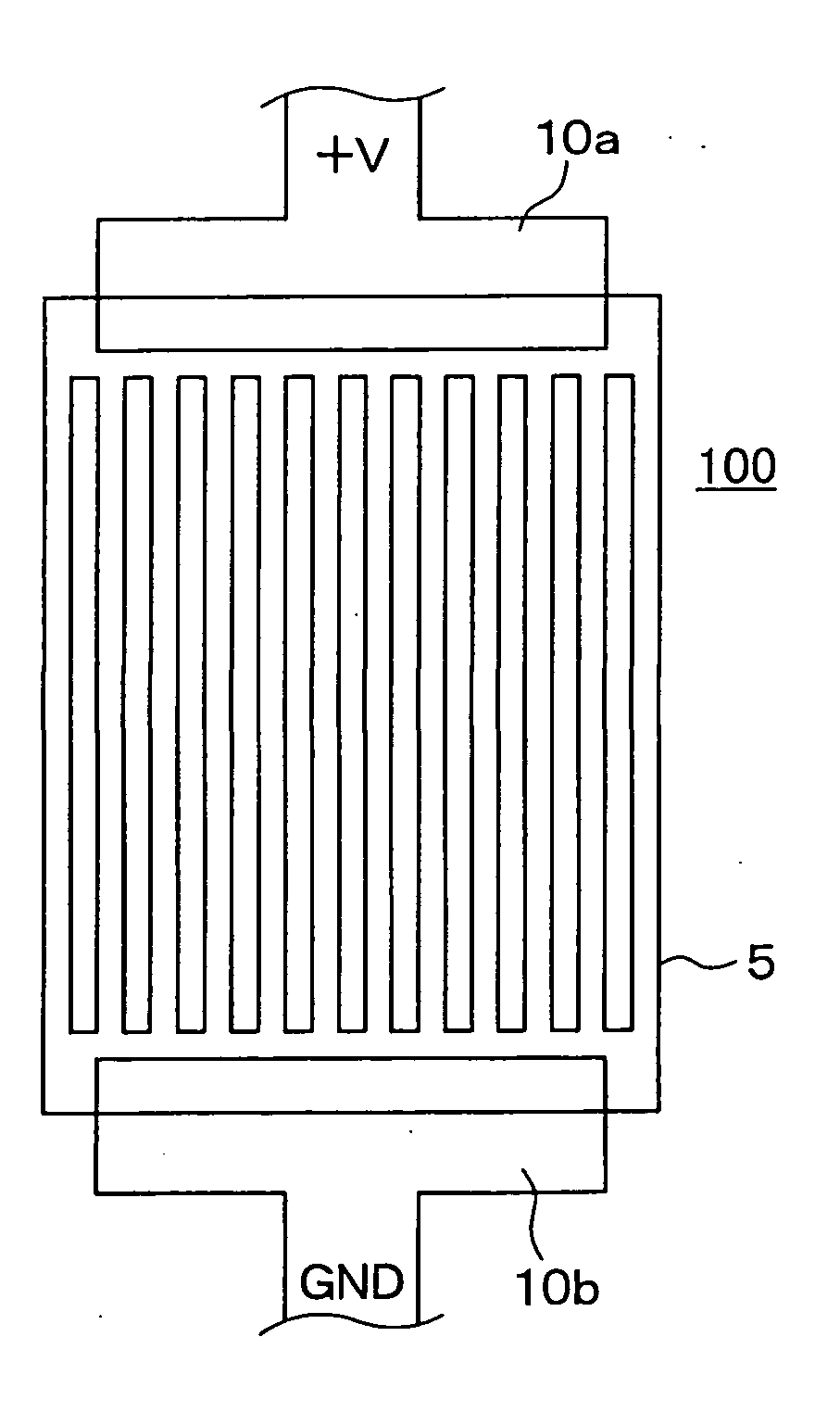

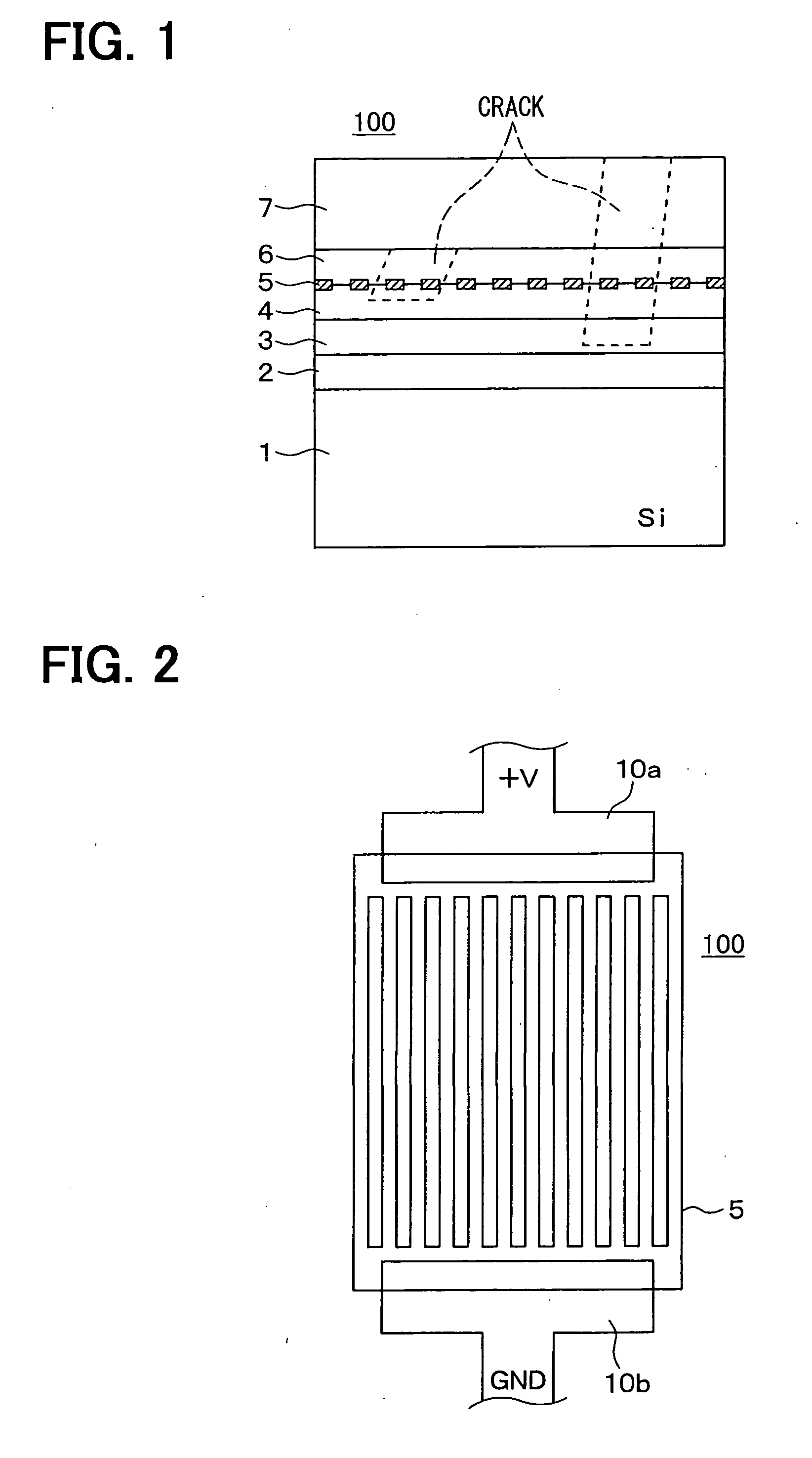

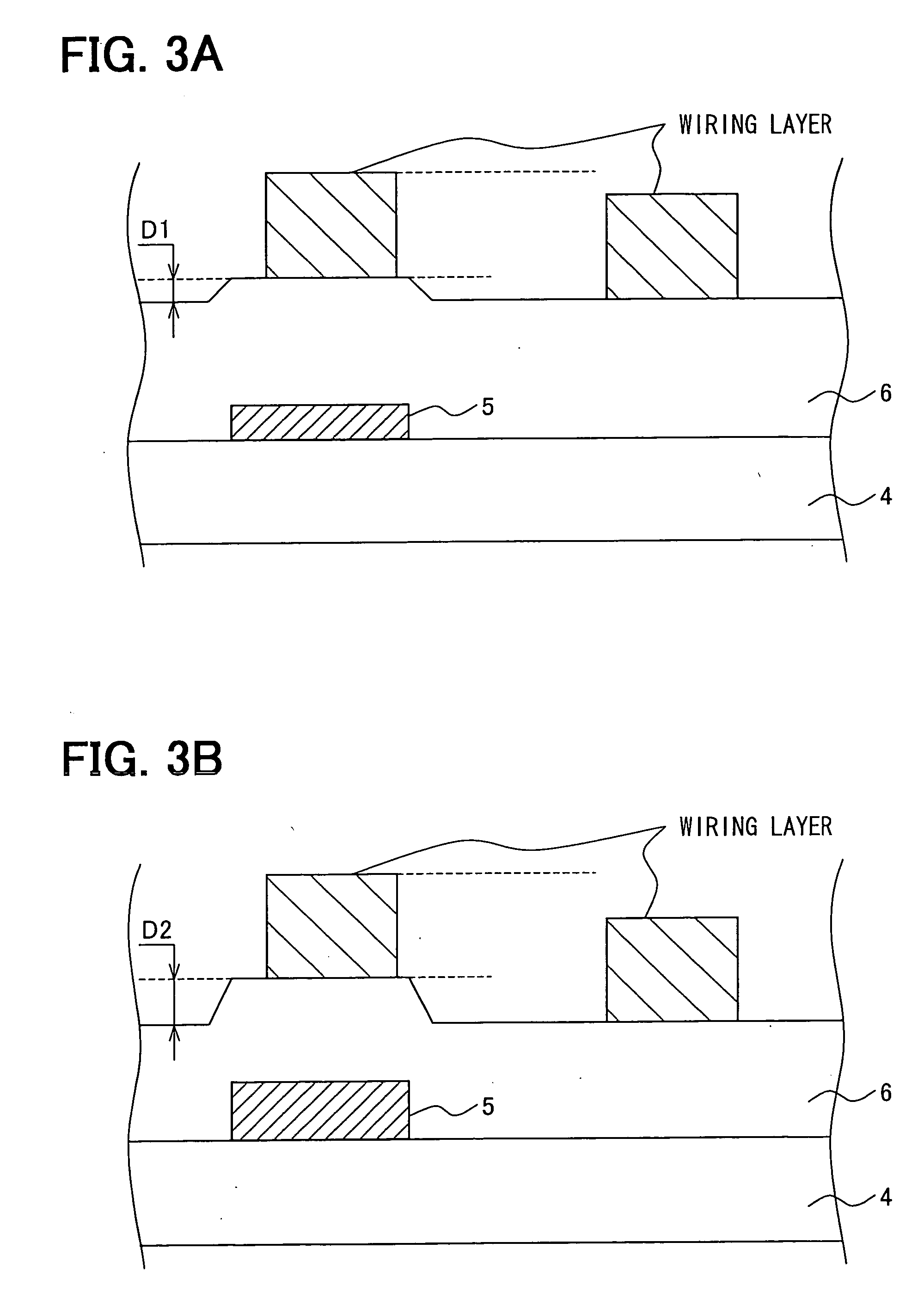

Easily crack checkable semiconductor device

InactiveUS20060071284A1Improve equipment qualityQuality improvementSemiconductor/solid-state device testing/measurementSolid-state devicesSheet resistanceEngineering

A semiconductor device includes a first insulation film, a second insulation film, a thin film resistor interposed between the insulation films. A predetermined voltage is applied to the thin film resistor so that a current flows through the thin film resistor. When a crack occurs in the insulation films, the thin film resistor is partially destroyed and the resistance of the thin film resistor changes. The crack is detected by measuring the change in resistance of the thin film resistor based on the predetermined voltage and the current flowing through the thin film resistor. Therefore, a crack inspection can be conducted without destruction of the device.

Owner:DENSO CORP

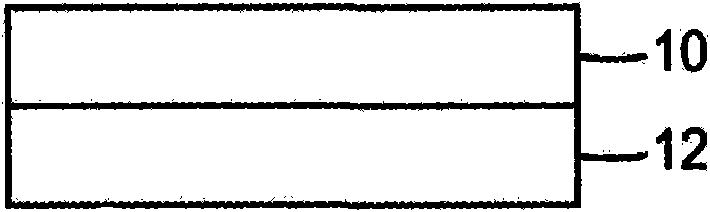

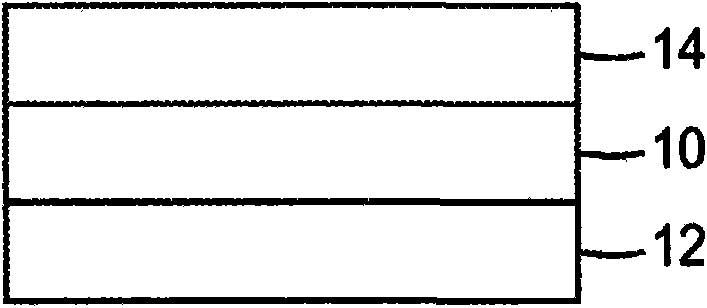

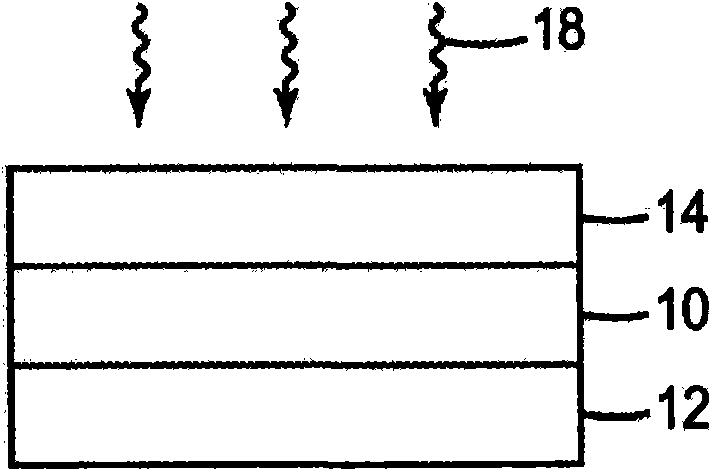

Method for making optical waveguides

InactiveCN101910899AReduce stressEffective for annealingNanoopticsOptical light guidesAlloyWaveguide

A method for making a waveguide comprises (a) providing a waveguide structure comprising a substrate (22), a lower cladding (20) layer on the substrate, and a core layer (24) comprising silicon nitride, amorphous silicon, or amorphous silicon-germanium alloy on the lower cladding layer; (b) patterning the core layer; and (c) annealing (28) the waveguide structure.

Owner:3M INNOVATIVE PROPERTIES CO

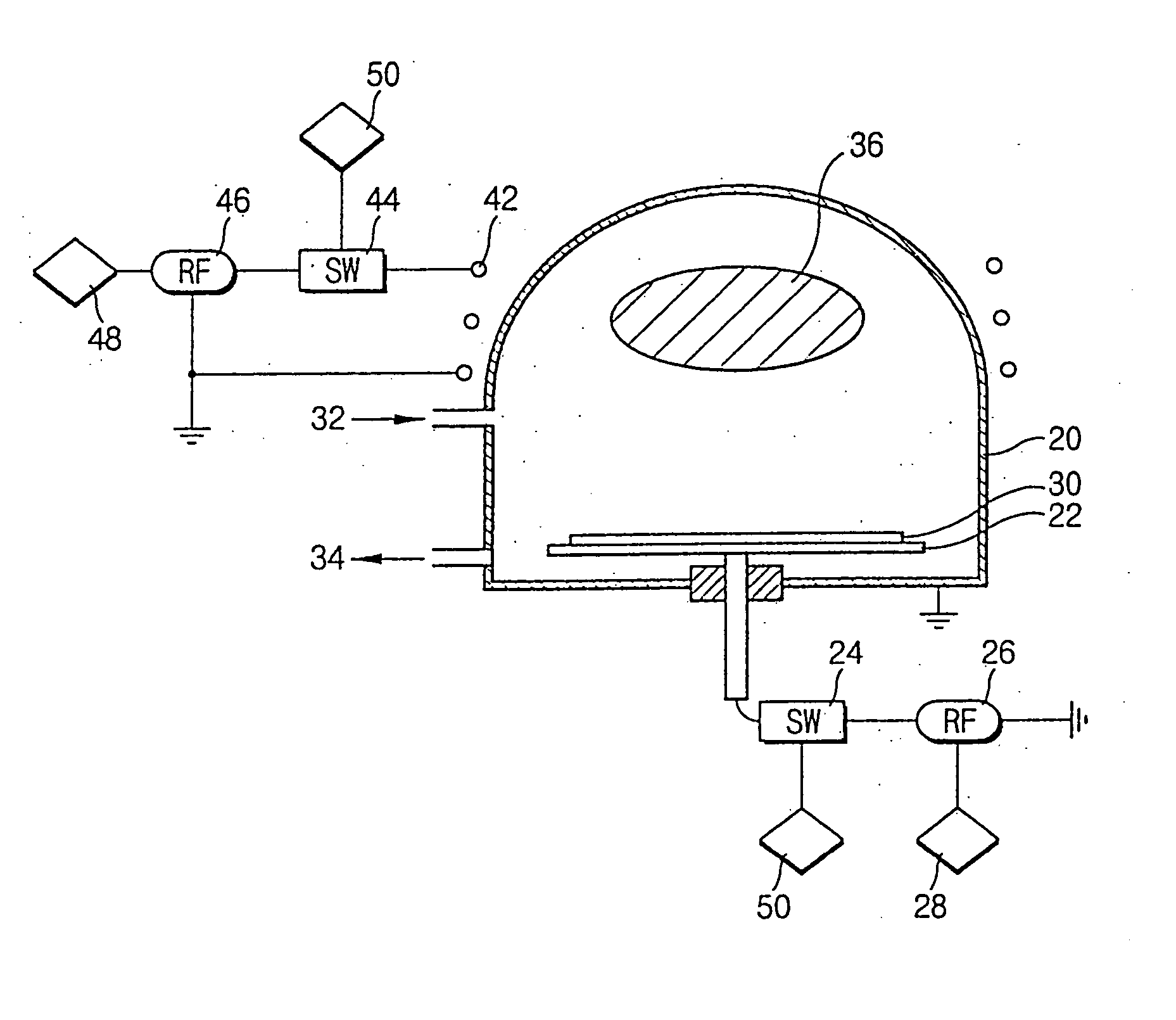

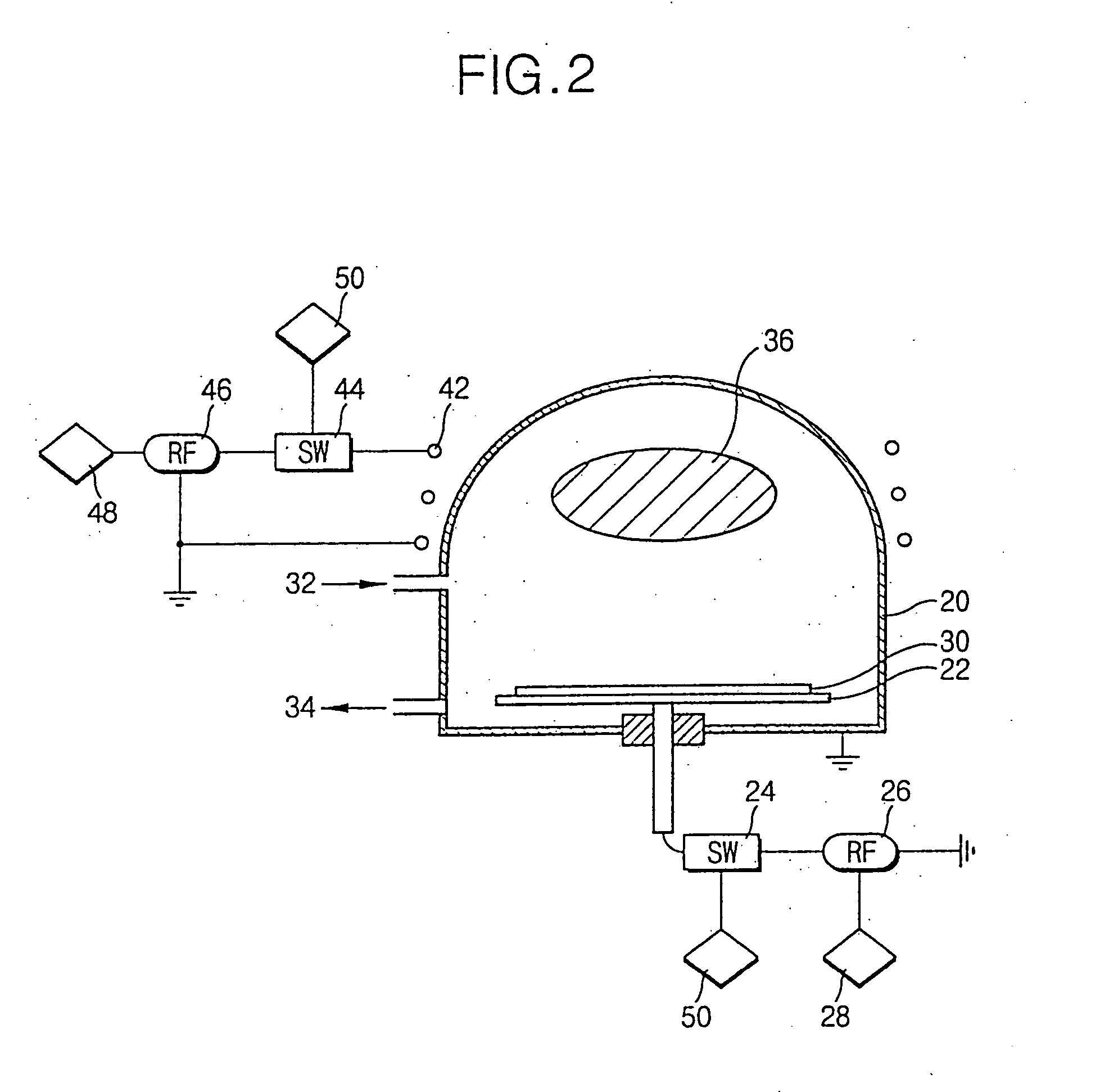

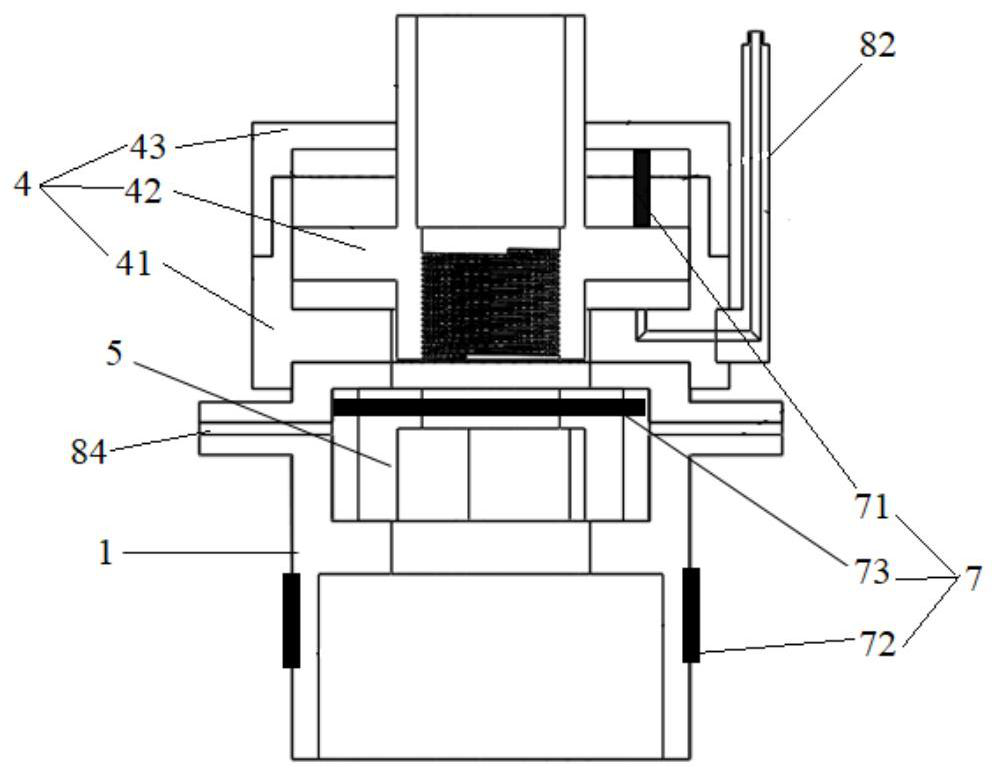

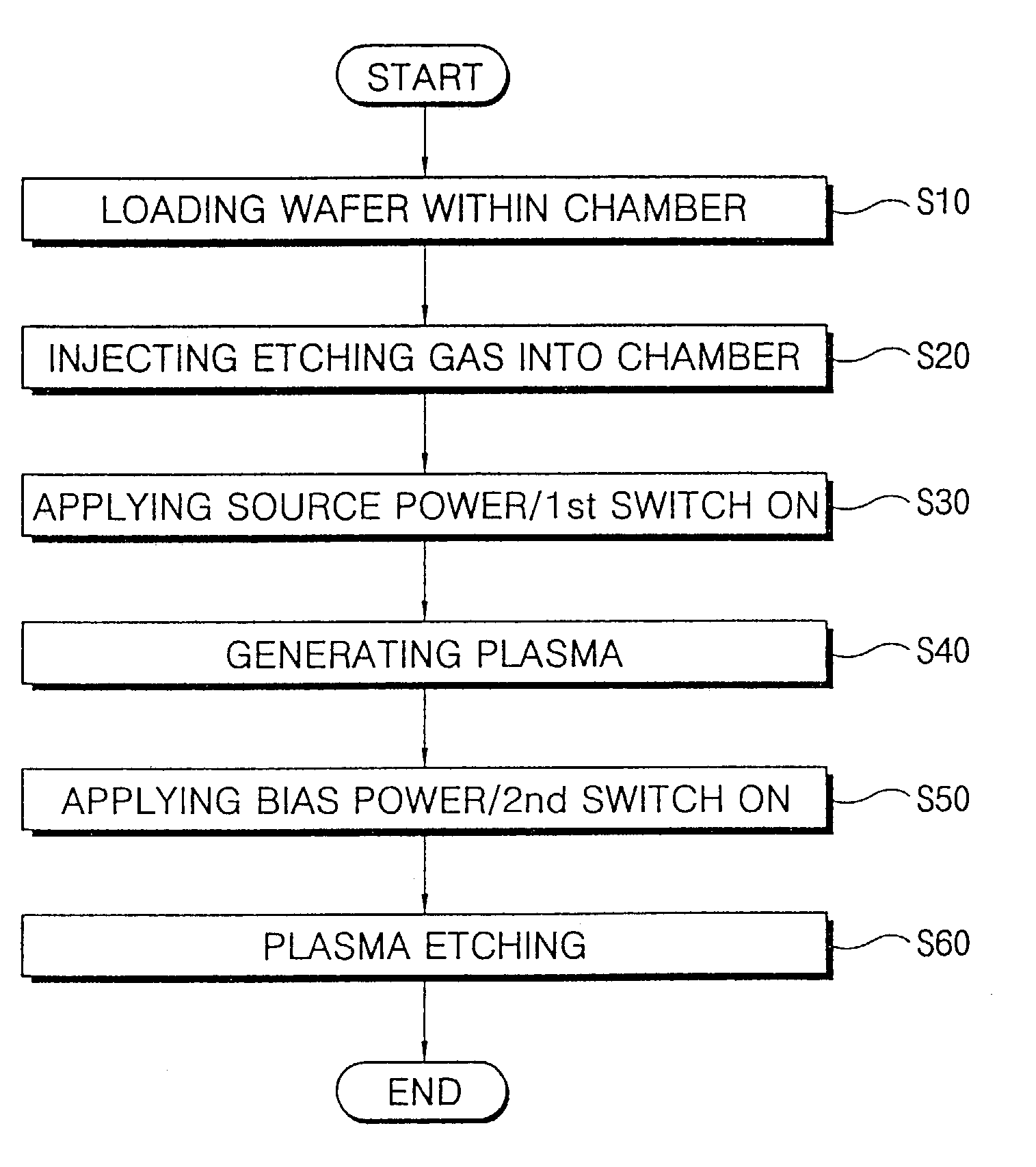

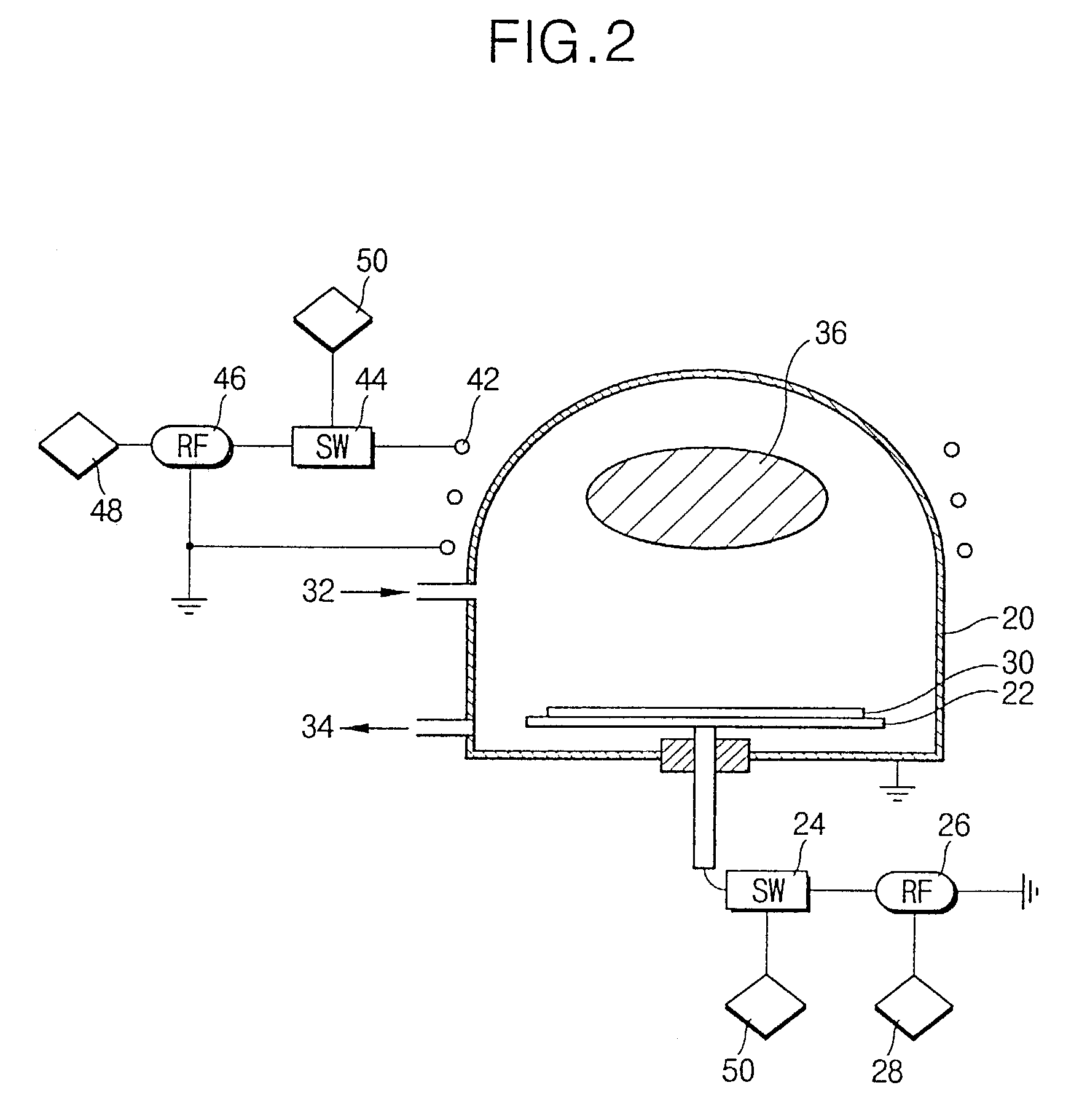

Etching method in a semiconductor processing and etching system for performing the same

InactiveUS20070000610A1Inhibit progressEasy to disassembleElectric discharge tubesSemiconductor/solid-state device manufacturingVolumetric Mass DensitySemiconductor

Disclosed is an etching method for semiconductor processing by which a pattern loading phenomenon is reduced. First, plasma is generated while setting a bias power applied to a wafer to zero and applying a source power. After a predetermined time period, an etching process is implemented onto a predetermined layer formed on the wafer by setting the bias power to a predetermined value. Since by-products generated during preceding etching processes can be readily removed during an etching using plasma, an etching process change due to a difference of pattern densities can be reduced. In addition, a progressive pattern loading generated as the number of processed wafers increase, can be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

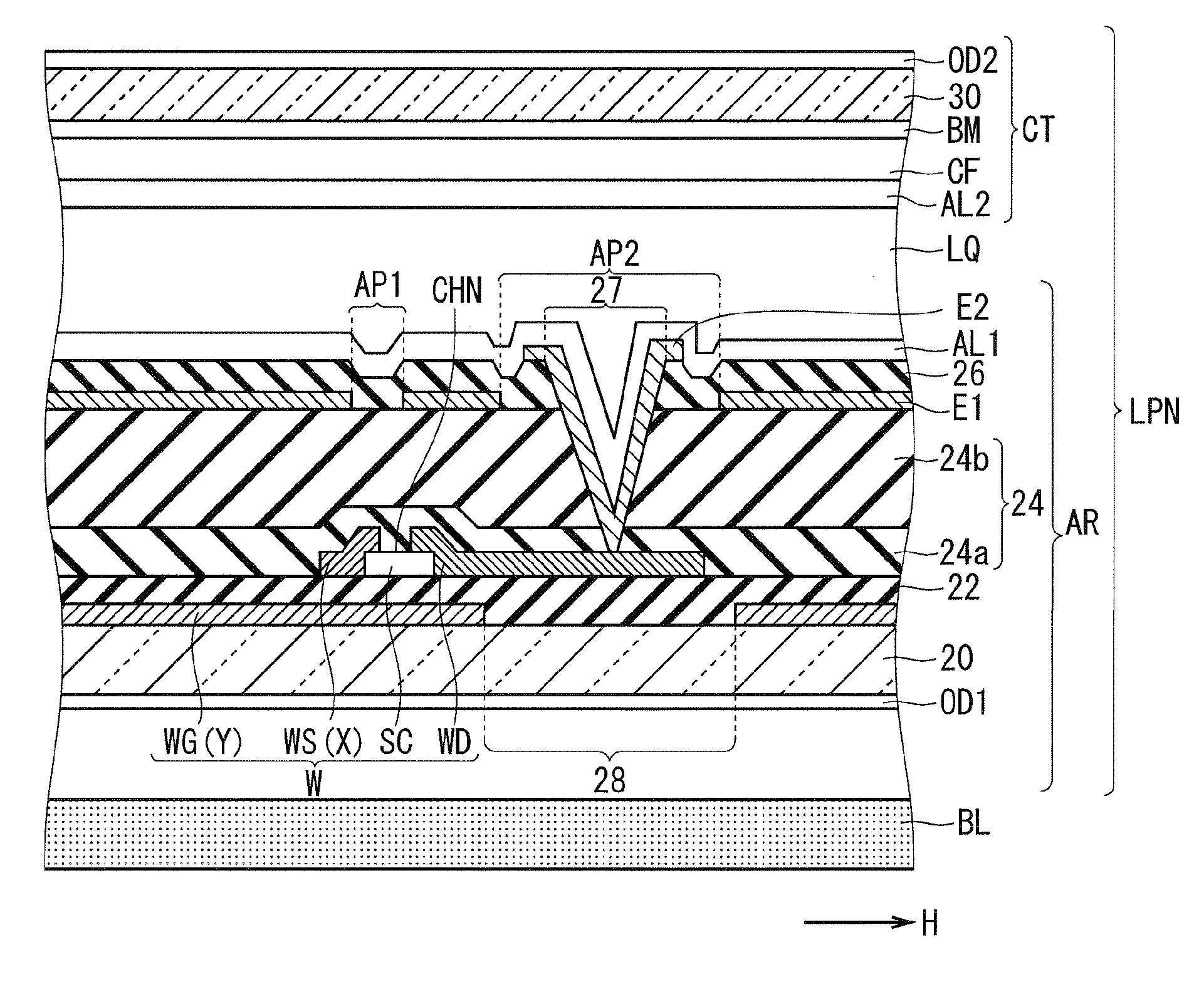

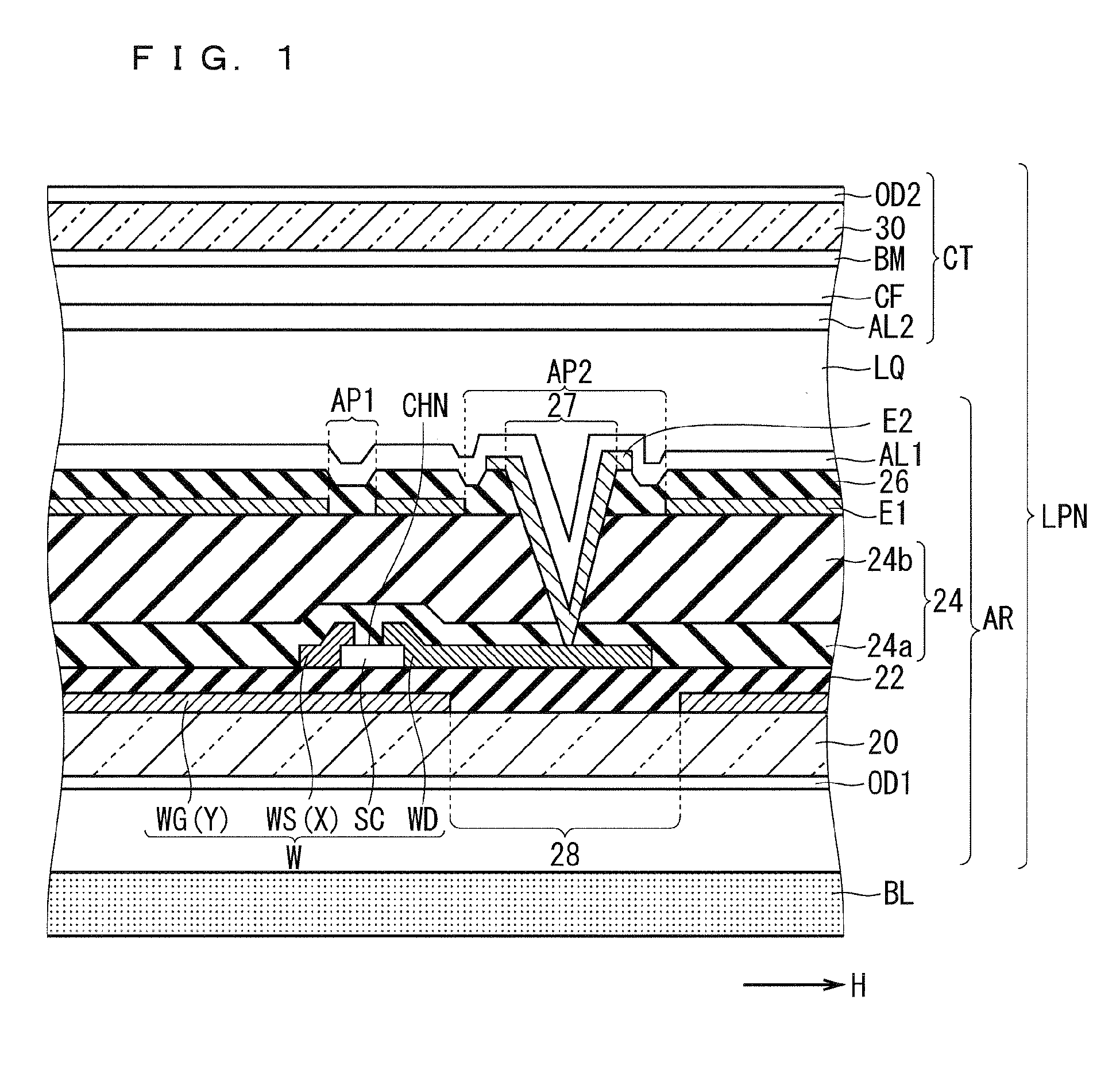

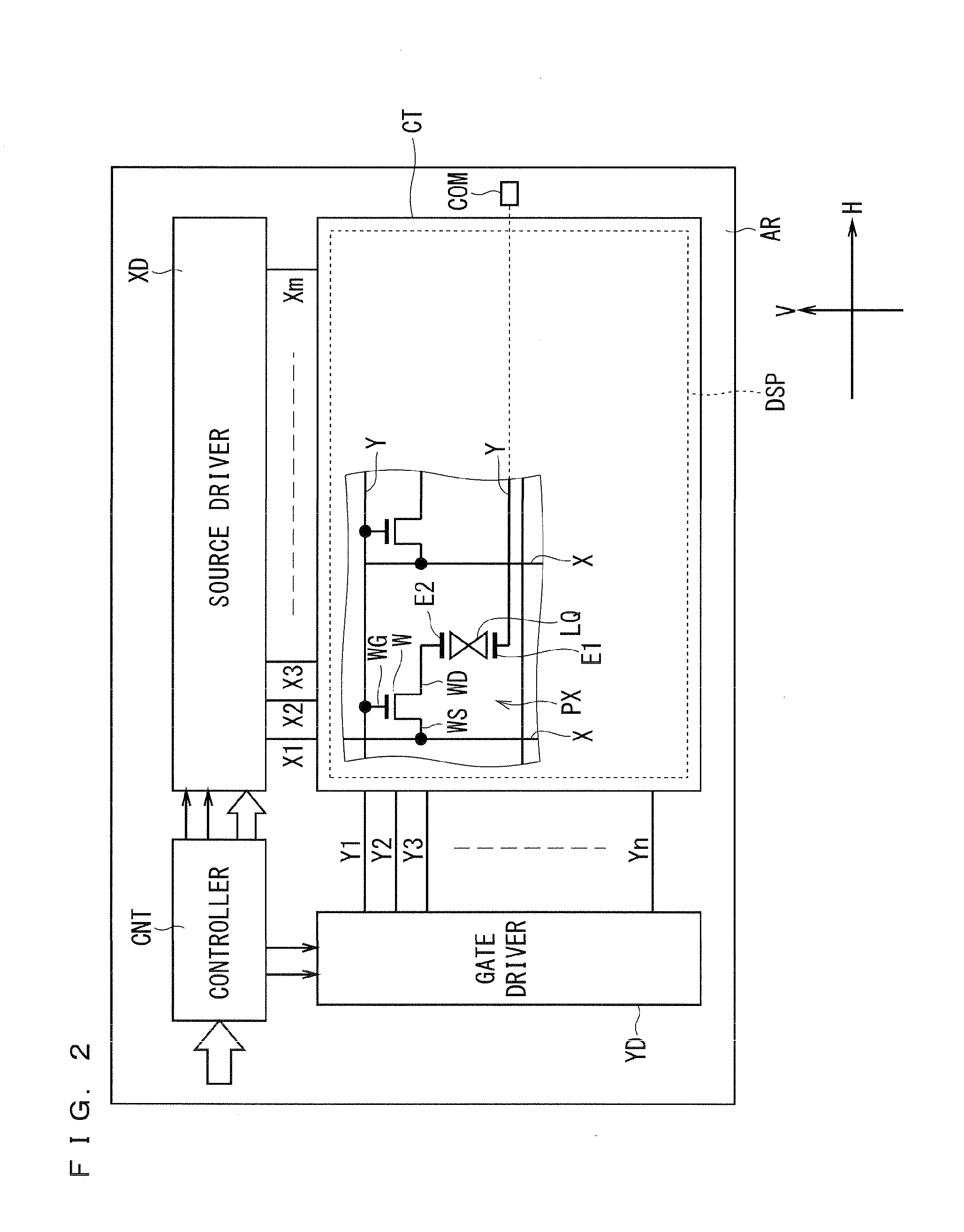

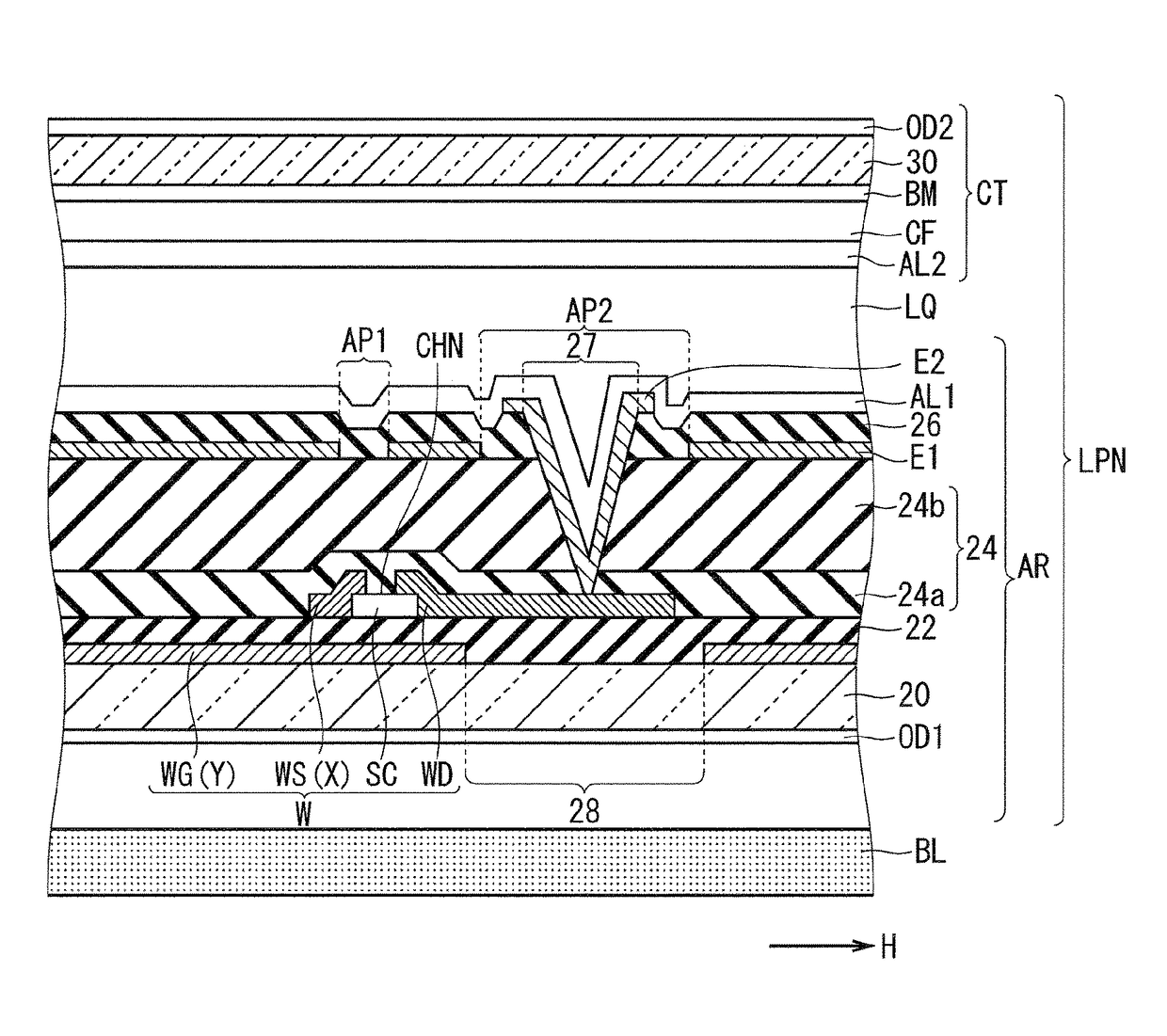

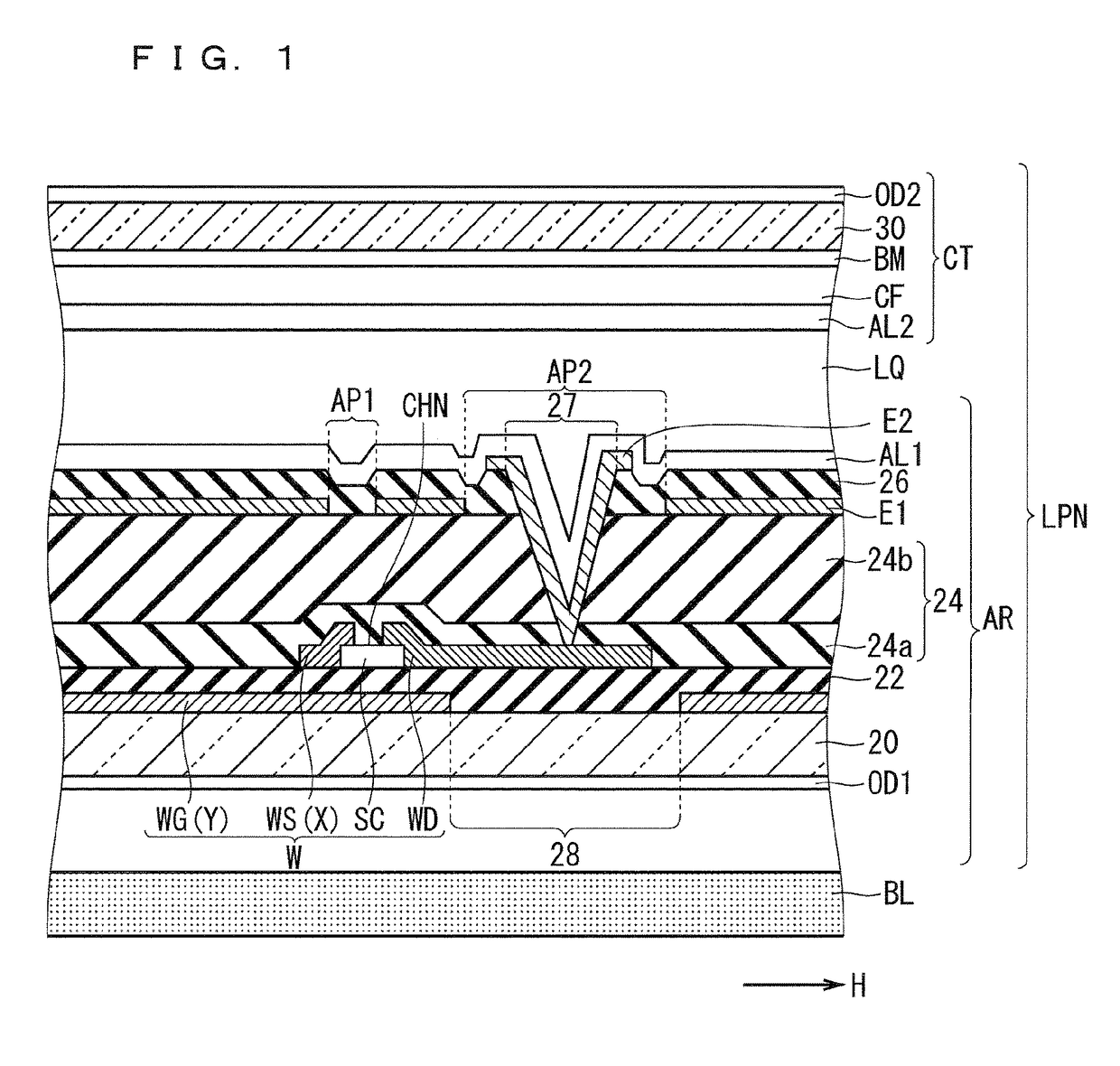

Array substrate and display device

ActiveUS20140159070A1Improve device qualityImprove pixel aperture ratioSolid-state devicesNon-linear opticsDisplay deviceEngineering

An array substrate includes a first electrode located above a switching element through a first insulating film, a second electrode located above the first electrode through a second insulating film, and a connection portion that is located to pass through the first insulating film, first electrode, and second insulating film and electrically connects a drain electrode of the switching element and the second electrode. The connection portion is disposed in an avoidance region provided by carving out a gate line connected to the switching element.

Owner:TRIVALE TECH

Process for forming a film, process for manufacturing a device, electro-optical device and electronic equipment

InactiveUS7601386B2Stable and accurateAccurately and stably formedMaterial nanotechnologyNanoinformaticsEngineeringElectron

Owner:SEIKO EPSON CORP

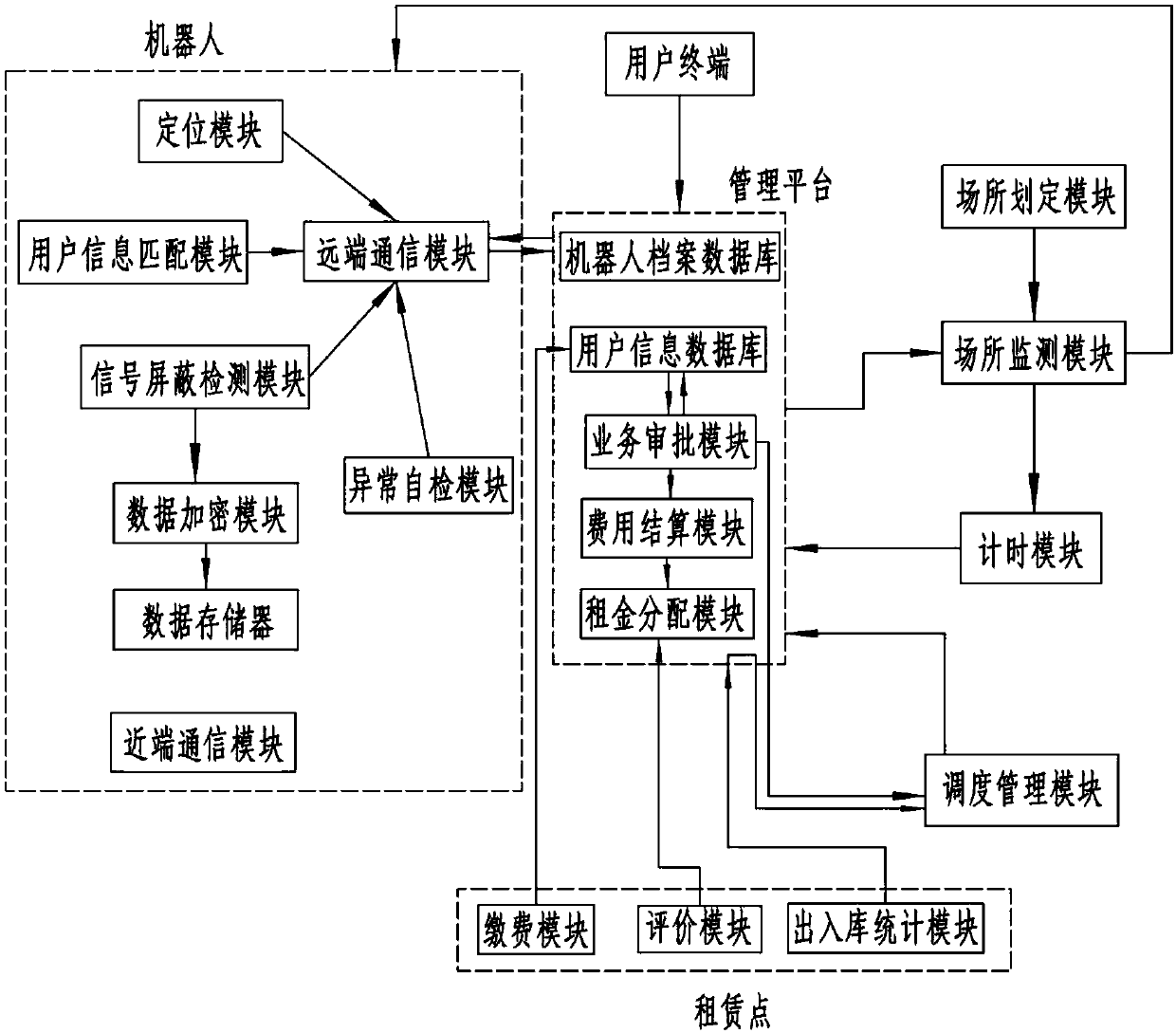

Robot rental support system

InactiveCN108022148ACost-effectiveReduce the scope of managementPayment architectureApparatus for meter-controlled dispensingCost performanceField monitoring

The invention discloses a robot rental support system comprising a robot, a rental point, and a management platform capable of communicating with the robot and the rental point. The robot is able to enter in or exit from a sleep mode and is provided with a positioning module for acquiring position information. The management platform consists of a field division module and a field monitoring module; the field division module is used for dividing a usage range of the robot and providing corresponding field information for the field monitoring module; the field monitoring module connected wit the robot obtains the position information of the robot by the management platform and monitors whether the field information covers the position information. According to the support system, a burgeoning robot terminal can be helped enter the home or institution in a public intelligent device manner, so that people try to introduce the intelligent device like the robot with the good cost performance. Therefore, the development of the robot field is promoted.

Owner:ZHITONG TIME XIAMEN TECH CO LTD

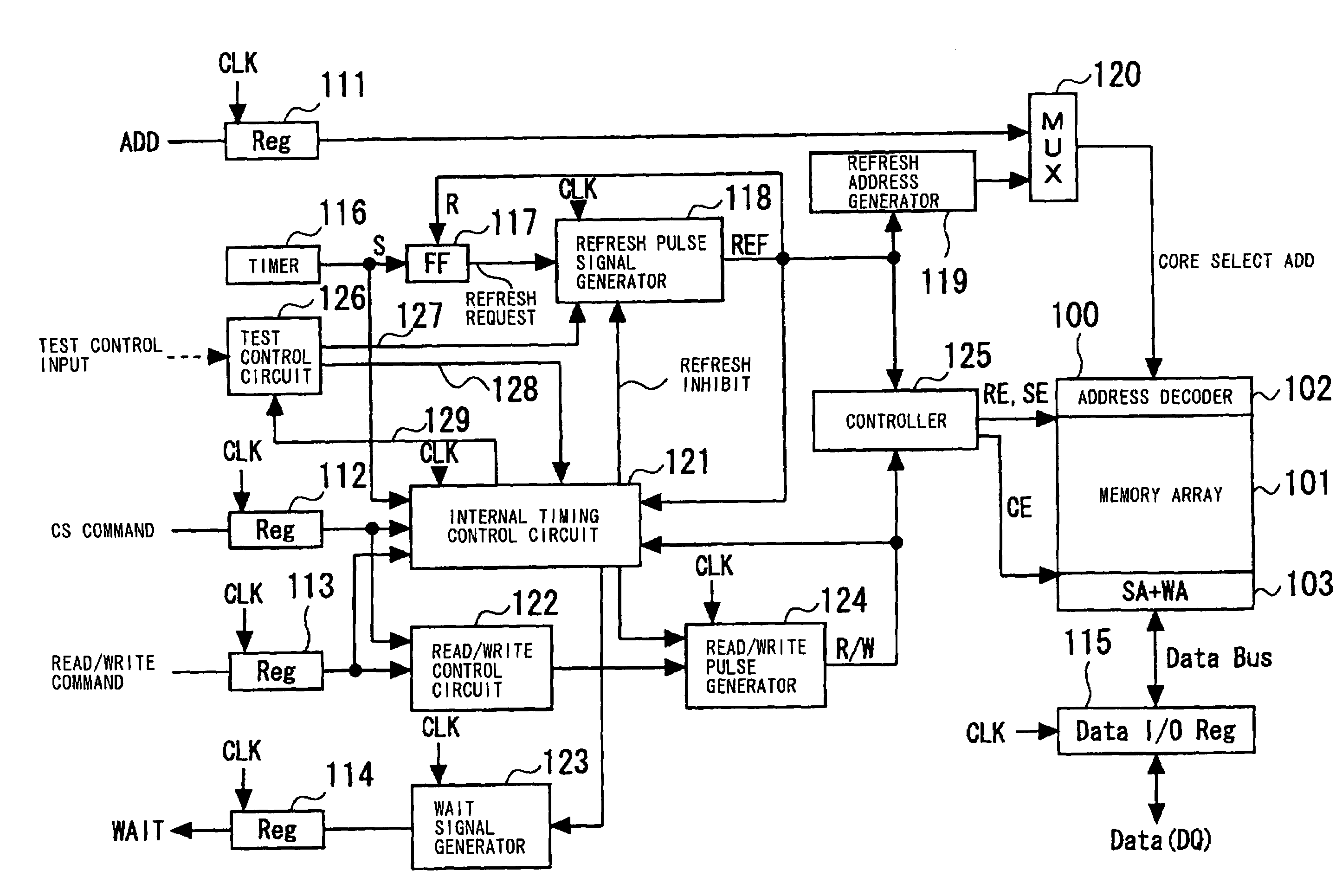

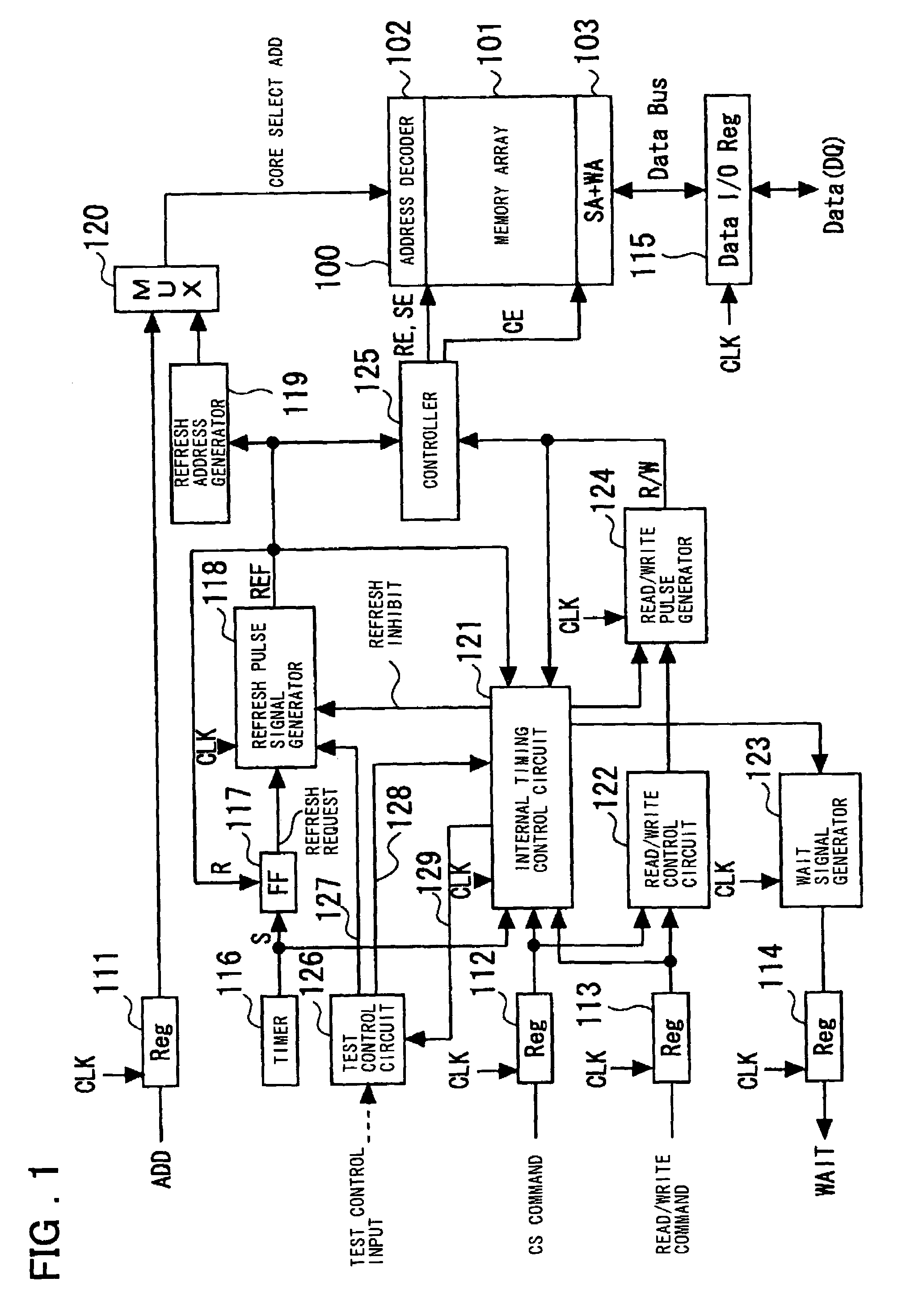

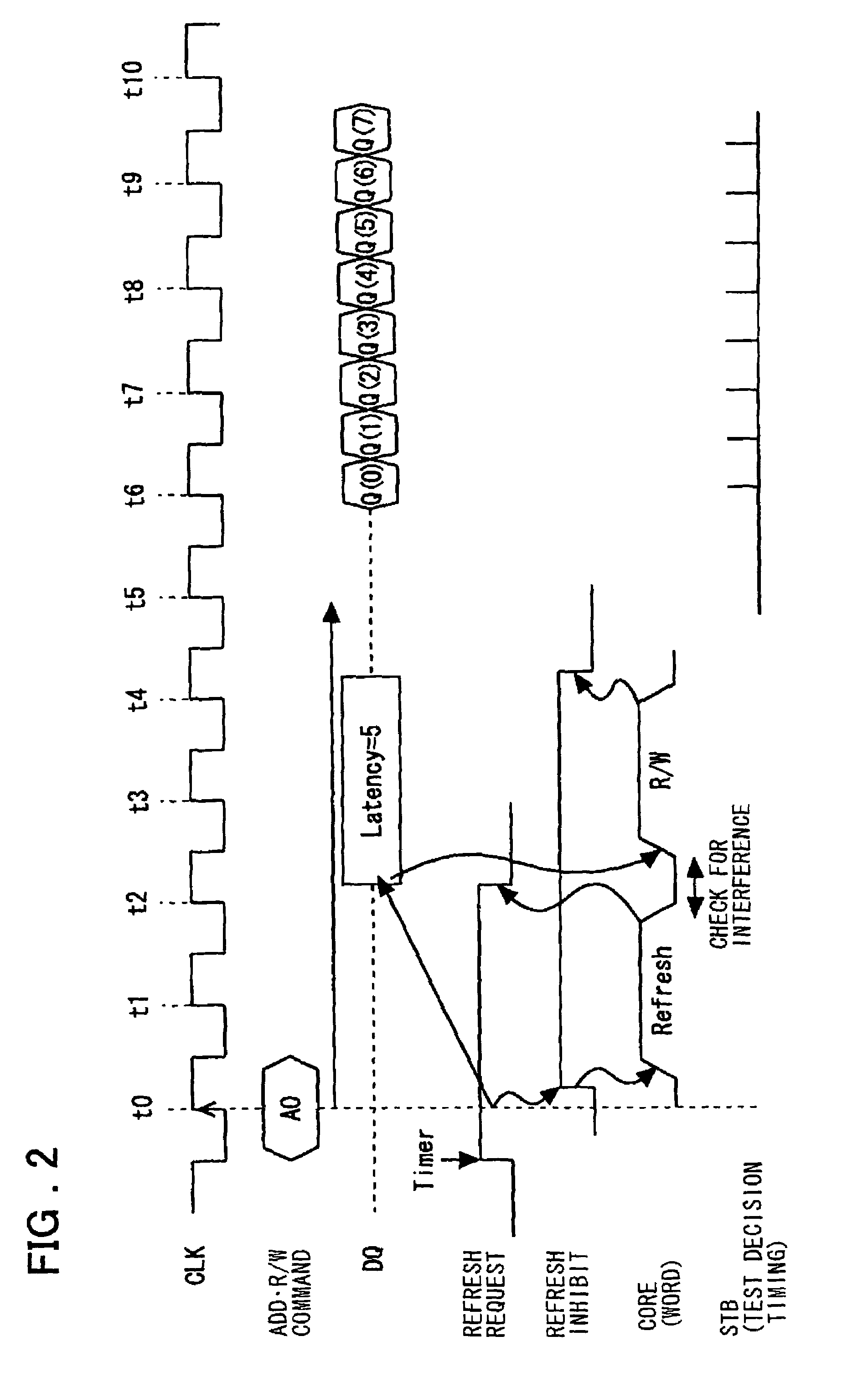

Semiconductor memory device, test circuit and test method

ActiveUS7652943B2Increased cost of testingImprove equipment qualityDigital storageControl circuitComputer science

Disclosed is a semiconductor memory device having memory cells that are in need of refresh for data retention, includes control circuits for necessarily generating the refresh immediately before the read / write operation, and for setting the latency to a first fixed value at all times, for the first mode during the testing, and for necessarily generating the refresh immediately after the read / write operation, and for setting the latency to a second fixed value at all times, for the second mode during the testing.

Owner:RENESAS ELECTRONICS CORP

Production technique of roller

InactiveCN103451542AImprove toughnessImprove wear resistanceRollsMetal rolling arrangementsHardnessPulp and paper industry

The invention relates to a production technique of a roller, which is characterized by comprising the following steps: 1) preparing materials; 2) processing two end surfaces of a blank; 3) processing central holes on the two ends; 4) abutting against the two ends, and carrying out rough turning; 5) drilling a suspension hole beyond the length of the finished product; 6) carrying out quenching and tempering until the hardness of the roller body reaches 40-50 HSD; 7) correcting the central holes on the two ends; 8) abutting against the two ends, and carrying out semi-finish turning; 9) carrying out rough grinding on the roller body; 10) carrying out quenching and tempering until the as-quenched hardness of the roller body surface reaches 88-93 HSD; 11) processing the length between the two ends to the required size; 12) carrying out finish turning; 13) carrying out rough grinding on the roller body and journal; 14) carrying out stress relief treatment; 15) correcting the central holes on the two ends; 16) abutting against the two ends, and carrying out fine grinding on the roller body and journal; 17) abutting against the two ends, and carrying out supergrinding on the roller body and journal to obtain the finished product. The roller prepared from a steel tube material has better toughness, wear resistance, thermoplasticity and the like than the roller prepared from a common material.

Owner:湖州市银鑫轧辊有限公司

Array substrate and display device

ActiveUS9666608B2Quality improvementRaise the ratioSolid-state devicesNon-linear opticsDisplay deviceElectrode

An array substrate includes a first electrode located above a switching element through a first insulating film, a second electrode located above the first electrode through a second insulating film, and a connection portion that is located to pass through the first insulating film, first electrode, and second insulating film and electrically connects a drain electrode of the switching element and the second electrode. The connection portion is disposed in an avoidance region provided by carving out a gate line connected to the switching element.

Owner:TRIVALE TECH

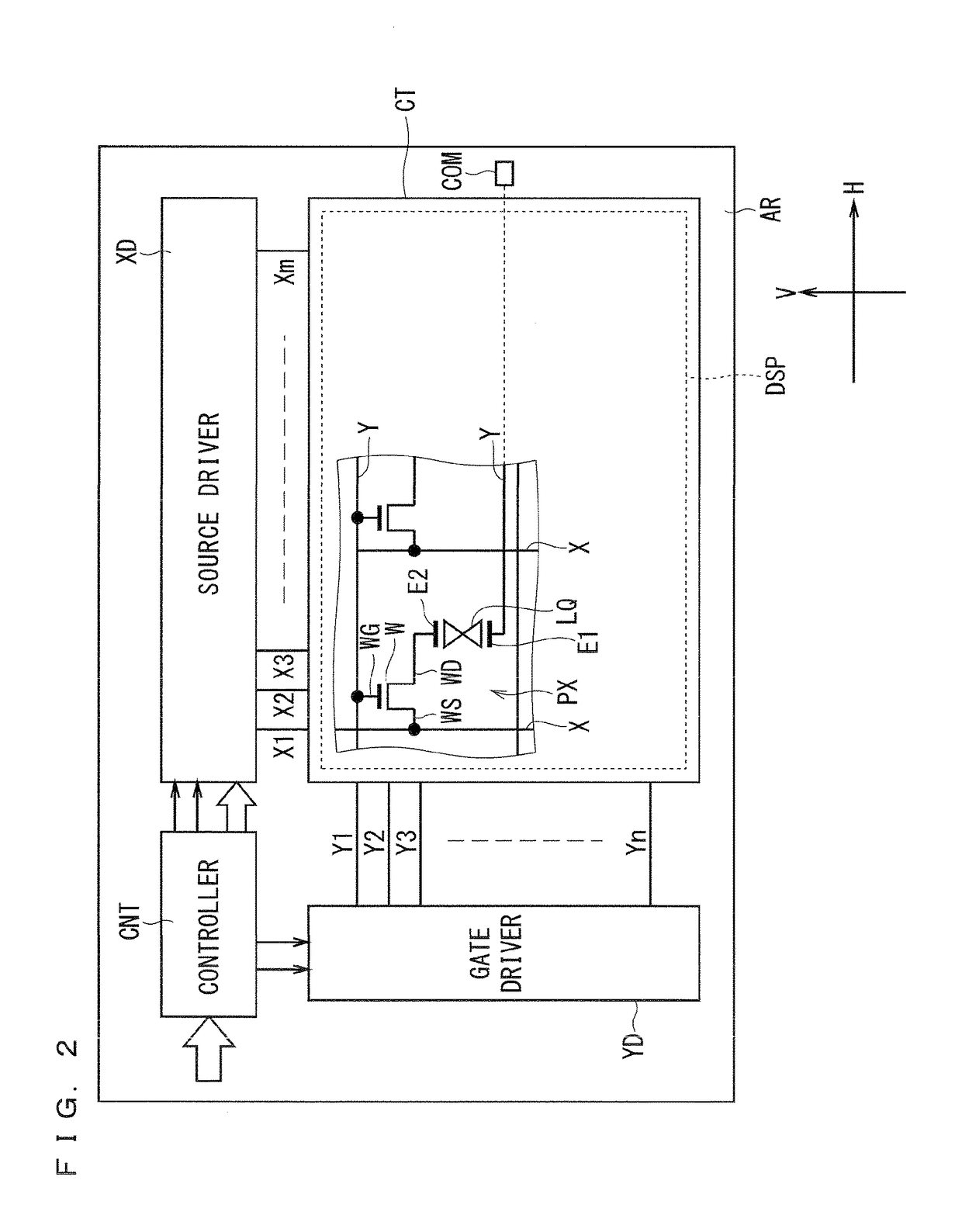

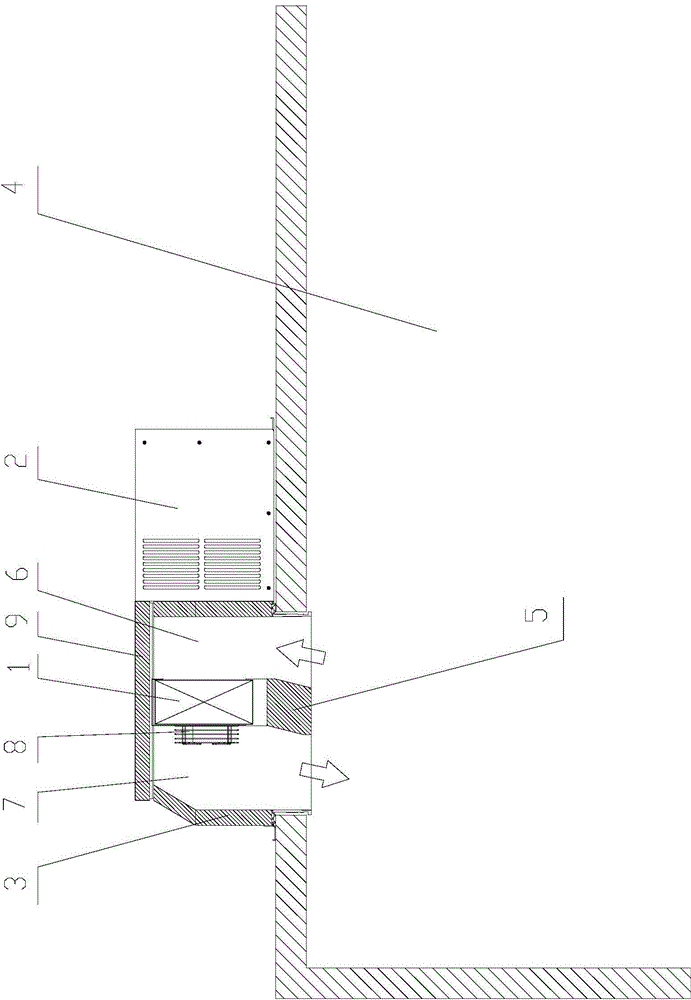

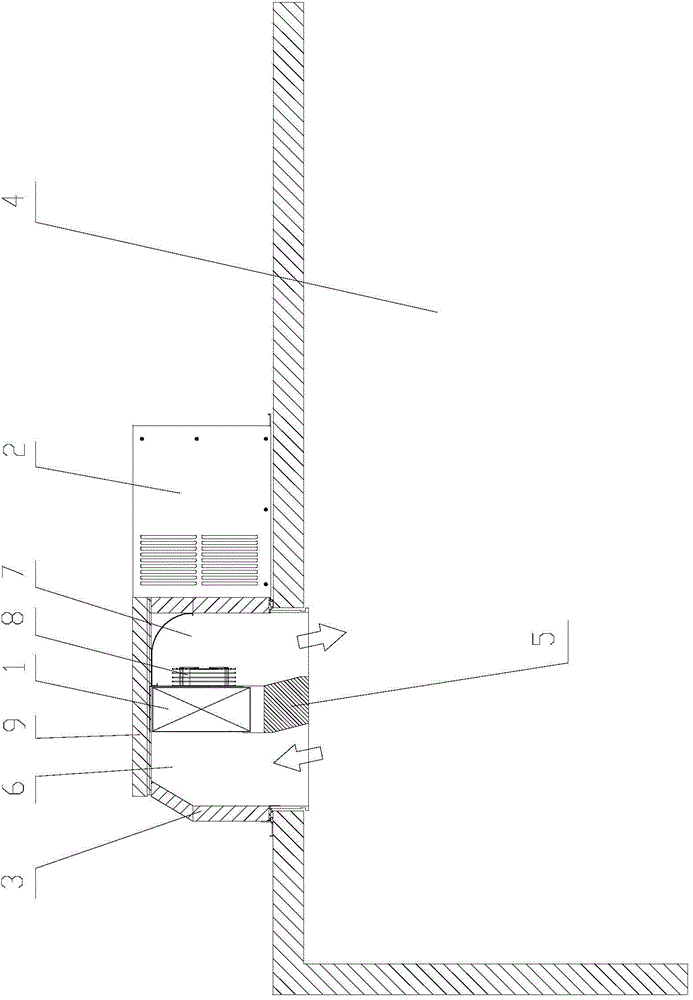

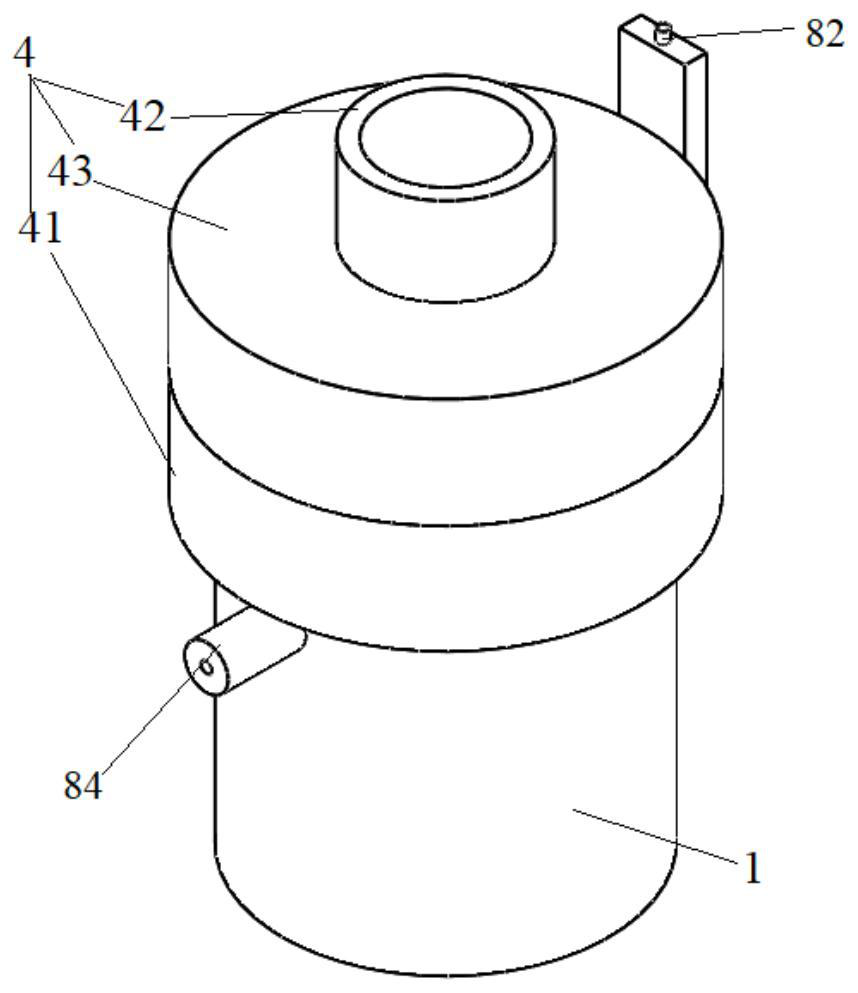

Overhead integral refrigerator

InactiveCN104482705AReduce construction and maintenance costsImprove equipment qualityLighting and heating apparatusRefrigeration devicesEvaporatorEngineering

The invention discloses an overhead integral refrigerator, which comprises a cold air unit and a refrigerating unit, wherein the refrigerating unit is used for providing refrigerant for the cold air unit, the cold air unit comprises an evaporator, a fan and a heat isolation box body, the evaporator is arranged in the heat isolation box body, the heat isolation box body is arranged at the top part of a cold storage, the bottom part of the heat isolation box body is communicated with the top part of the cold storage, a flow separating plate is arranged at the communicating part, the heat isolation box body is separated into an air return area and an air outlet area by the flow separating plate and the cold air unit, the fan is arranged in the air outlet area and is used for exhausting the air from the air return area to the air outlet area, and the refrigerating unit and the heat isolation box body are arranged at the top part of the cold storage. The overhead integral refrigerator has the advantages that the overhead integral refrigerator is independent refrigerating equipment, the site construction and installation of the cold storage are convenient, the construction and maintenance cost of the refrigerating equipment is reduced, the quality of the equipment is improved, and the overhead integral refrigerator is suitable for one to fifteen refrigerating equipment.

Owner:广西钦州市奇福保温冷冻设备有限公司

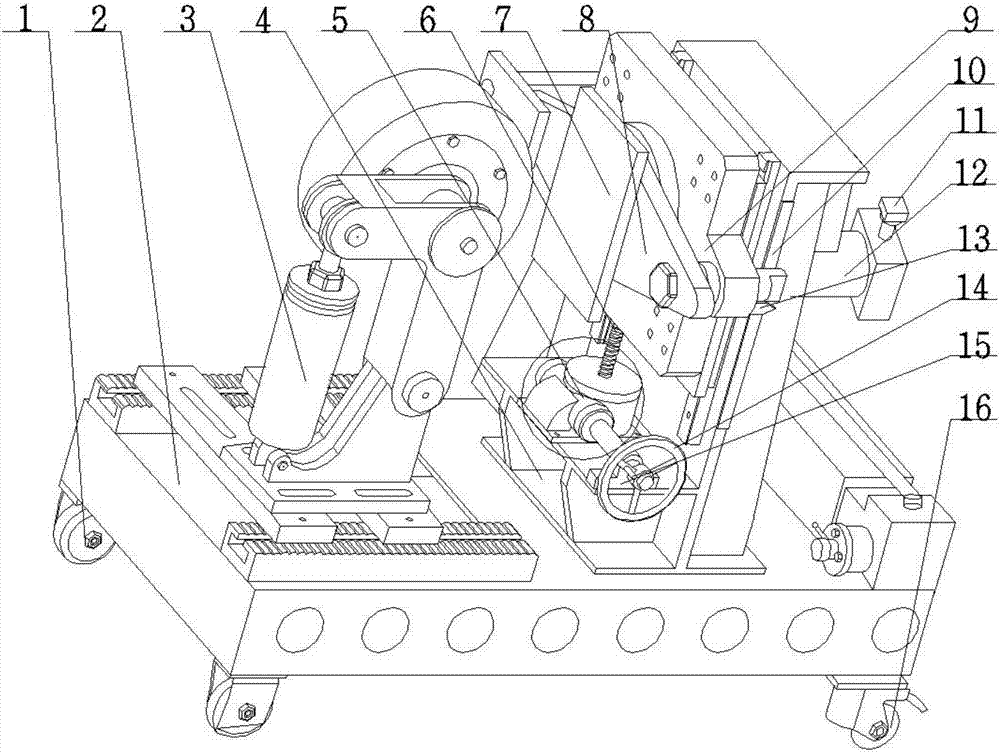

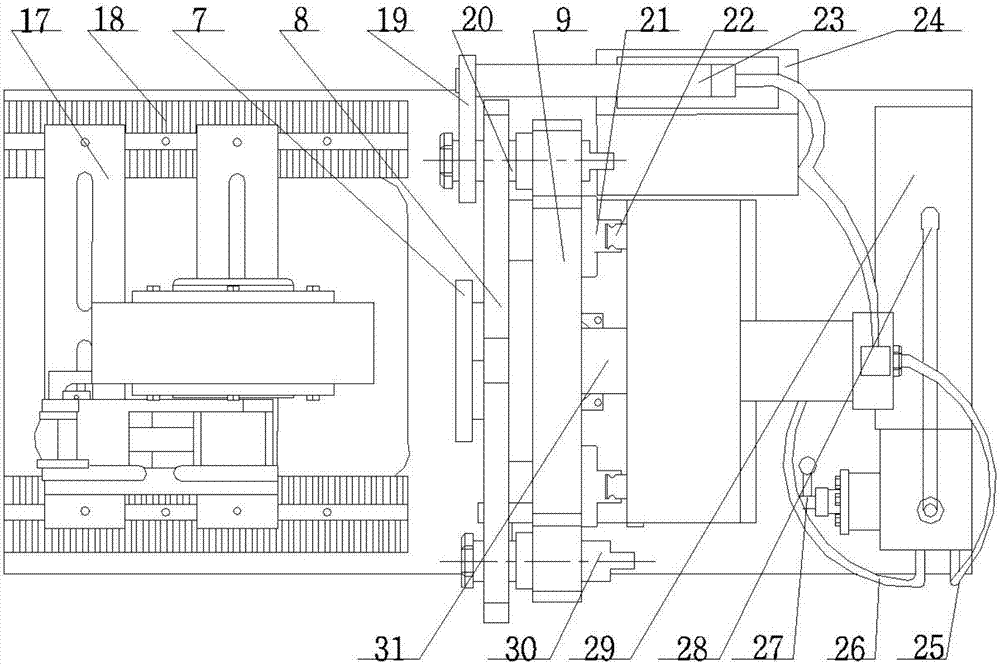

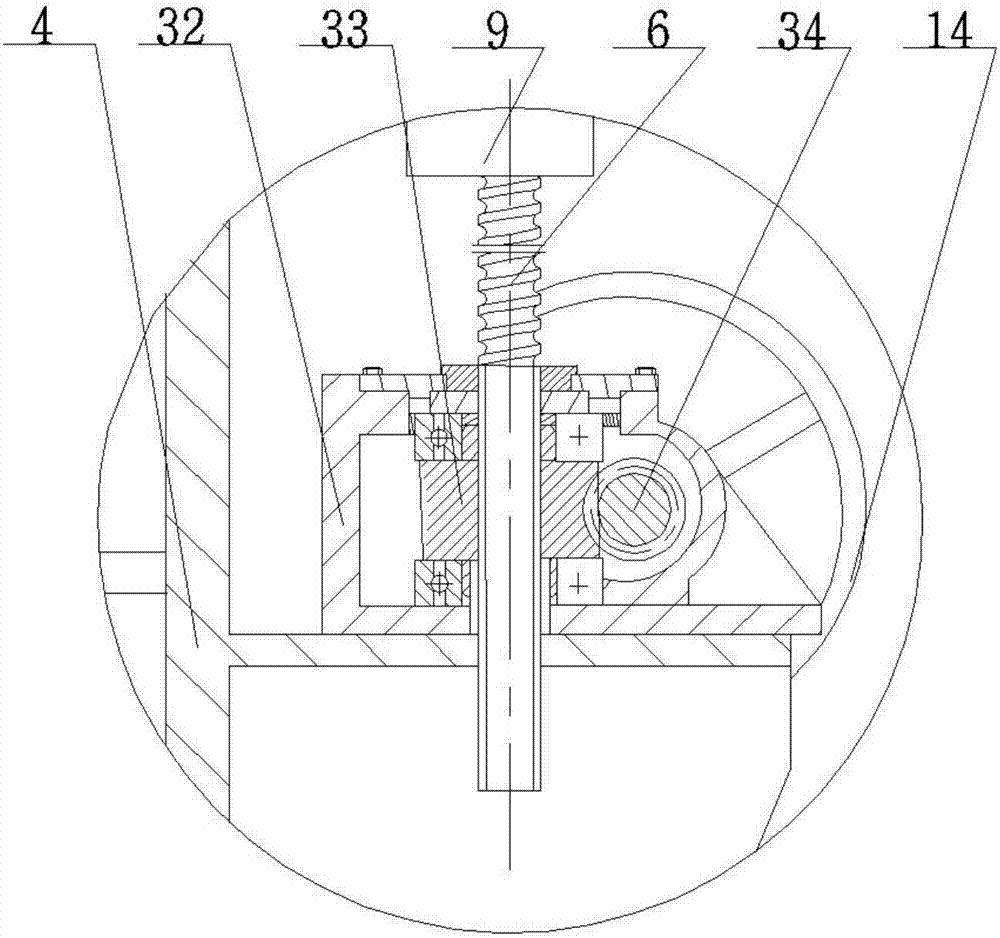

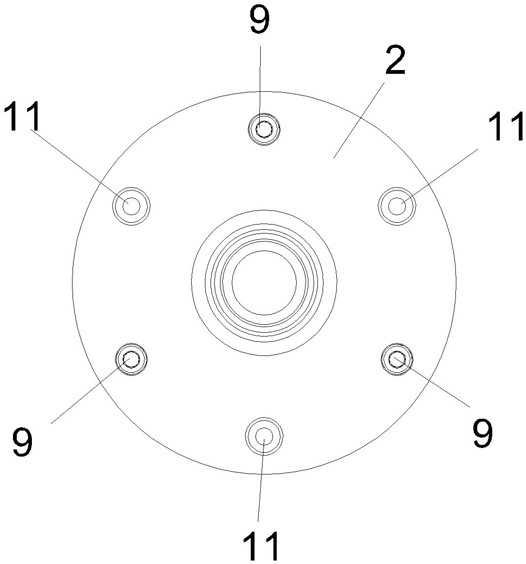

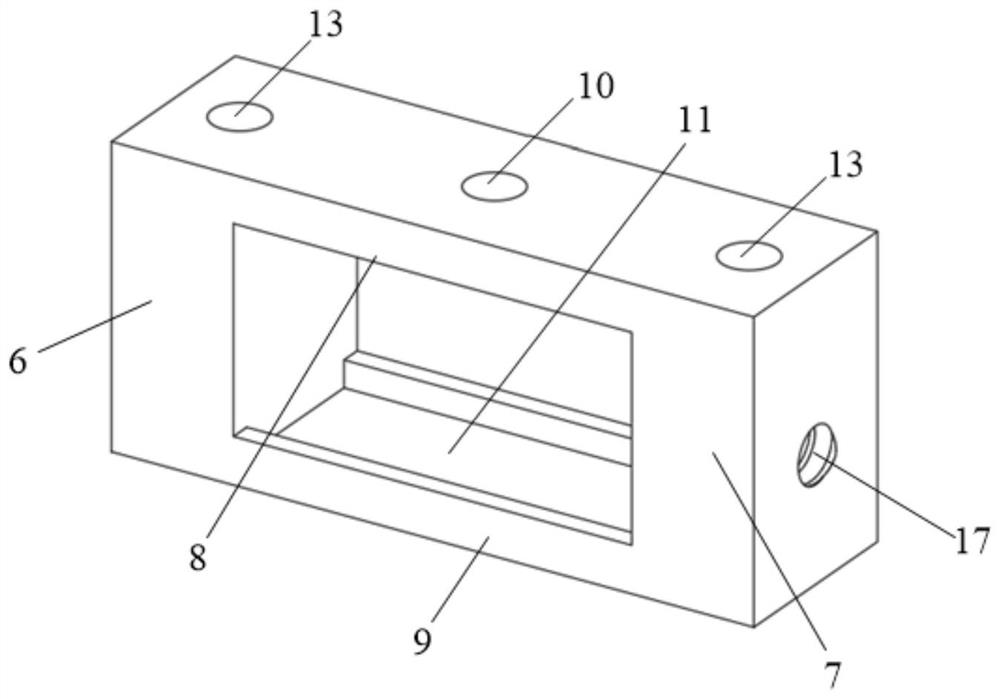

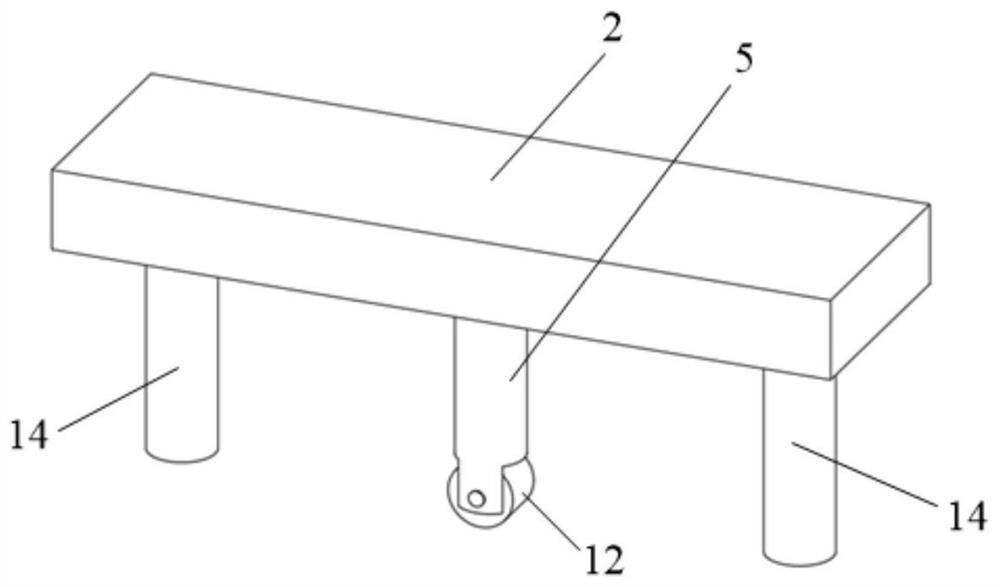

Roller cage shoe rigidity test device with adjustable center height

PendingCN107121246AImprove product qualityImprove equipment qualityElasticity measurementStress sensorsHydraulic control

The invention discloses a roller cage shoe rigidity test device with the adjustable center height. The rigidity test device comprises a moving device, a rack, a vertical lifting device, and a horizontal control device. The moving device consists of brake-included heavy fixed truckles and brake-included heavy universal truckles and is installed at the bottom of the rack. The vertical lifting device includes a worm and gear lifting device, a height measuring device, and a vertical support frame and is fixed at the rack by the vertical support frame; and the worm and gear lifting device includes a lead screw connected with the height measuring device. The horizontal control device consists of a hydraulic control device, a displacement sensor, a pressure sensor, and a digital display instrument. The vertical lifting device and the horizontal control device control a push head guiding unit jointly; the push head guiding unit is connected with a pressing plate; and the pressing plate applies forces to a to-be-tested roller cage shoe horizontally. According to the test device, the center height of the test stand of the roller cage shoe can be adjusted; the test and measurement become conveniently; and the tedious operations of mounting and dismounting of roller cage shoes with different center heights can be avoided.

Owner:ANHUI UNIV OF SCI & TECH

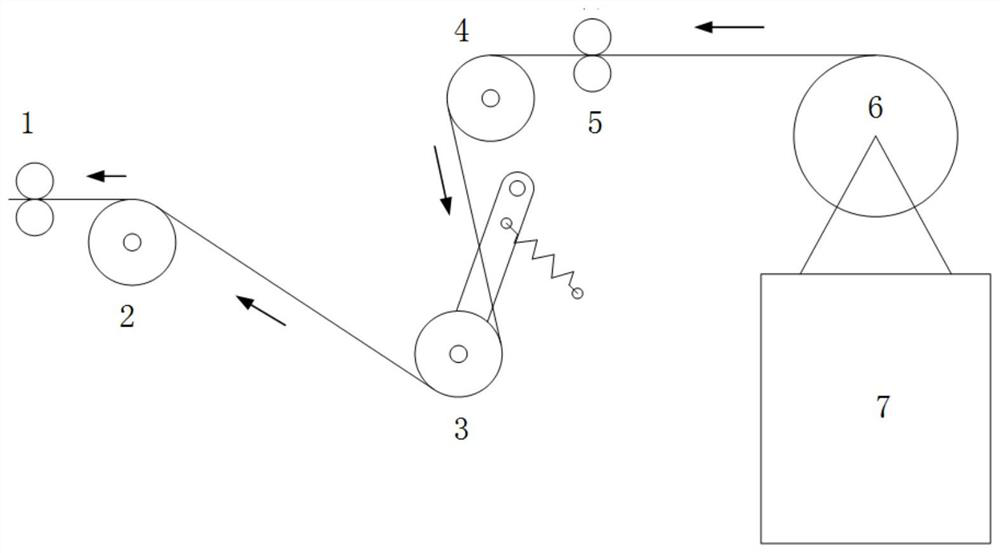

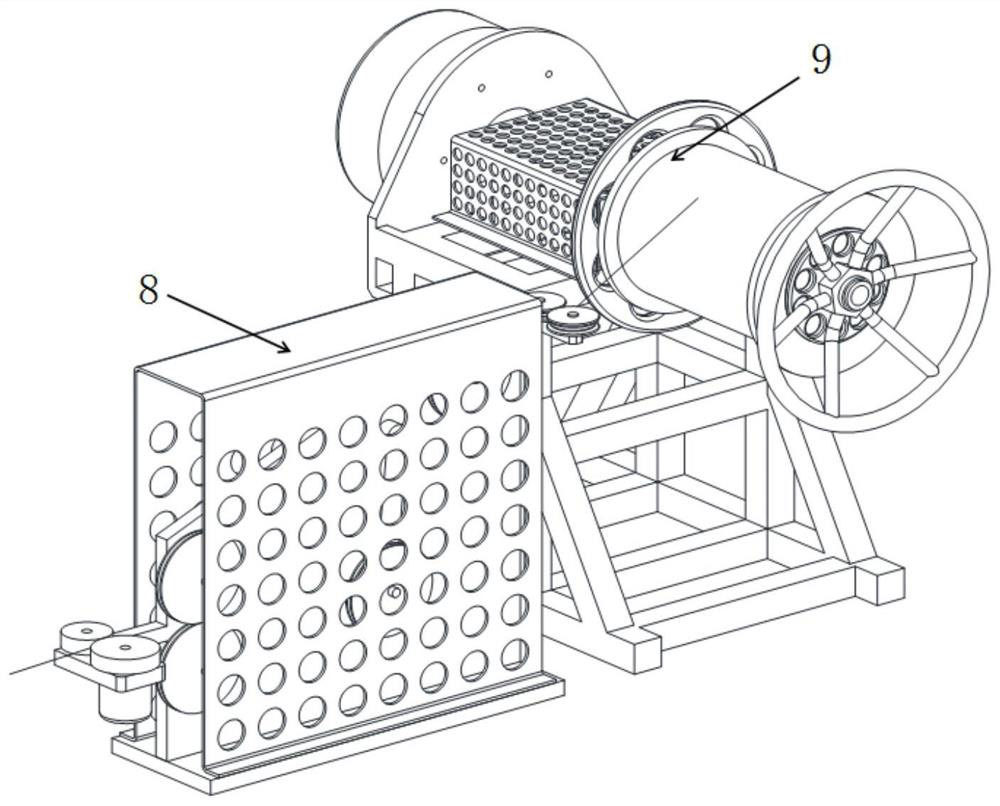

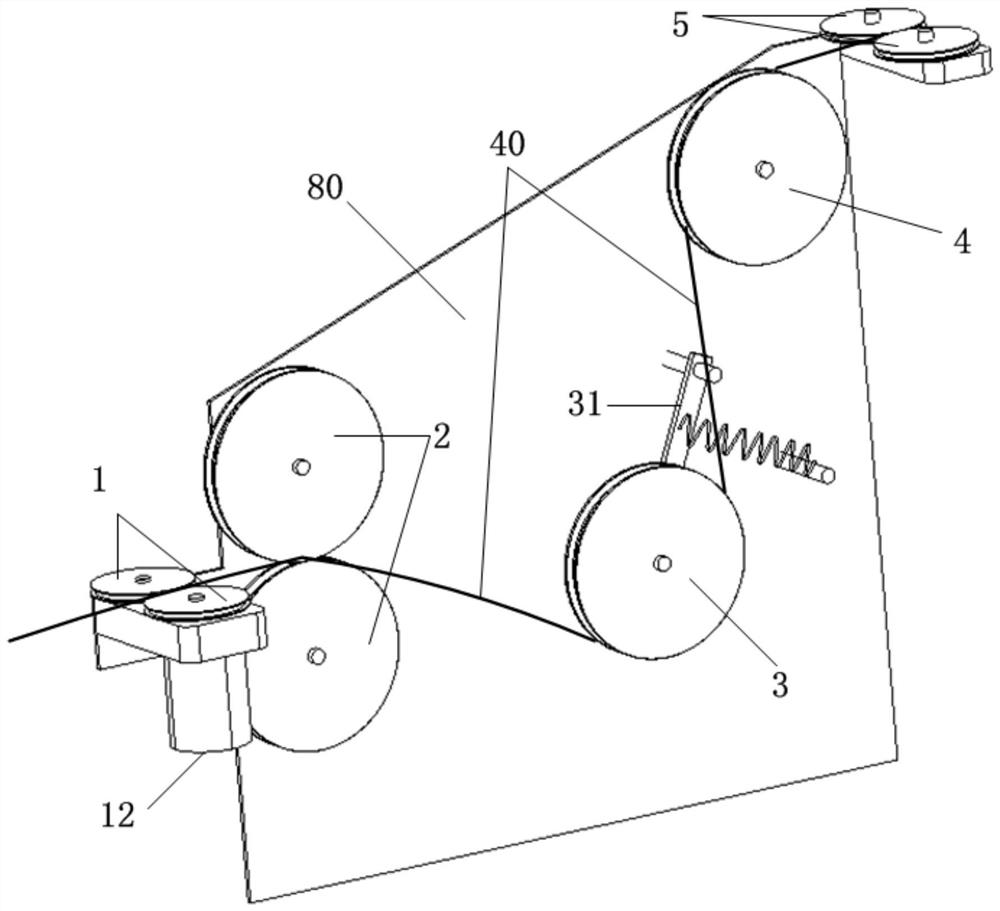

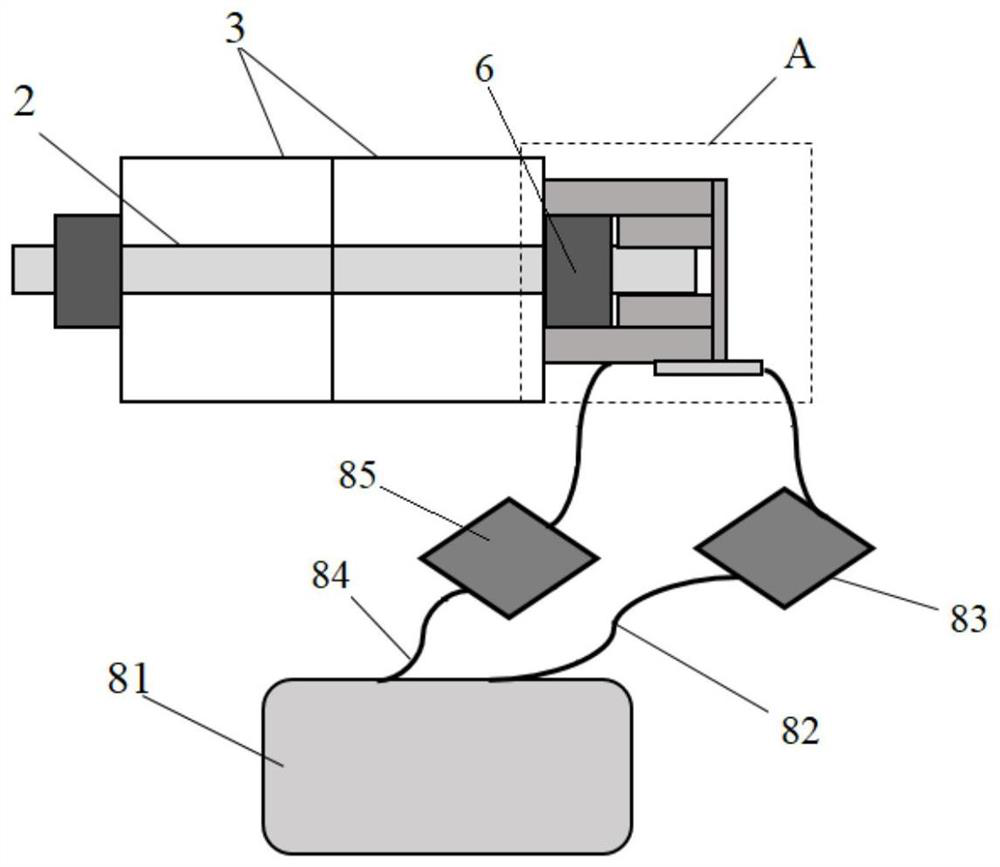

A vehicle-mounted optical cable laying device for coal mine roadway with automatic deployment

ActiveCN108802948BDoes not affect normal retractionQuick installationOptical fibre/cable installationIn vehicleControl system

The invention discloses an automatic-arranging coal mine roadway vehicle-mounted optical cable laying device which comprises an optical cable roller winding and unwinding mechanism (9), an optical cable tensioning and conveying mechanism (8) and a movement control system. The optical cable roller winding and unwinding mechanism (9) mainly realizes mounting, demounting and replacing of an optical cable roller and releasing and recycling of an optical cable. The optical cable tensioning and conveying mechanism (8) mainly completes functions of tensioning degree adjusting and active conveying ofthe optical cable. The movement control system completes autonomous contraction and release of the optical cable and other mechanism actions through feedback control of the winding and unwinding mechanism (9) and the tensioning and conveying mechanism (8). The device is simple in structure, convenient to operate, capable of realizing automatic contraction and release functions of the optical cableand convenient for moving and carrying, and working efficiency and safety are improved.

Owner:北京航天万鸿高科技有限公司 +1

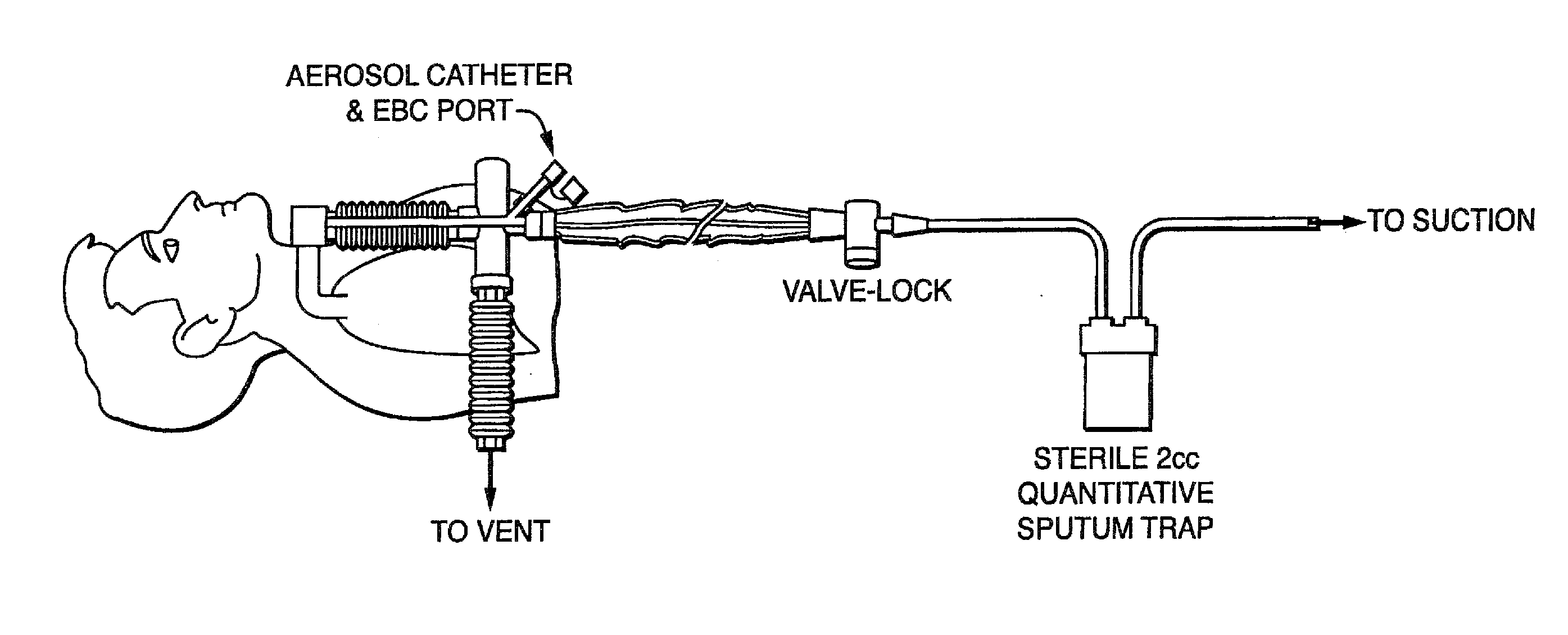

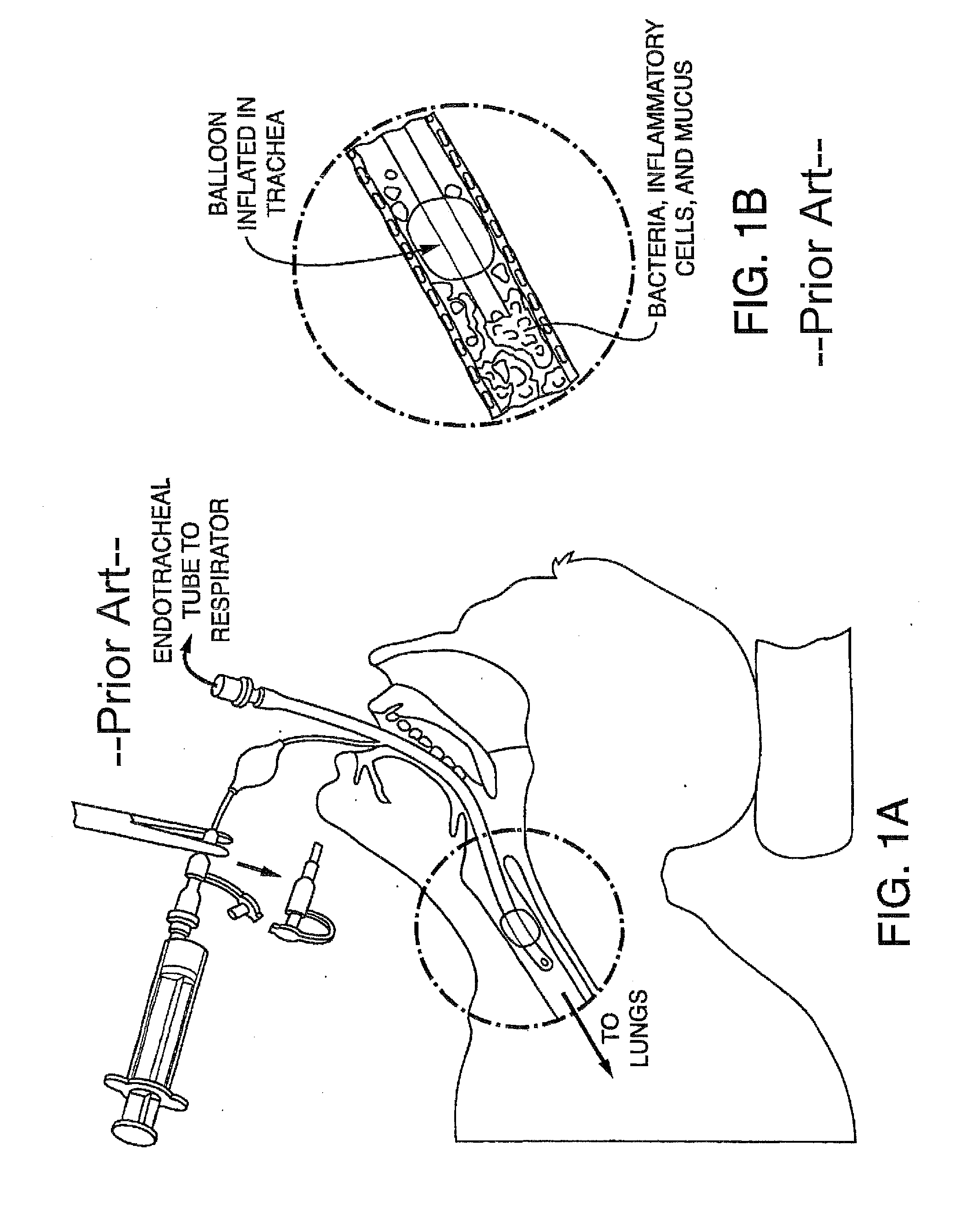

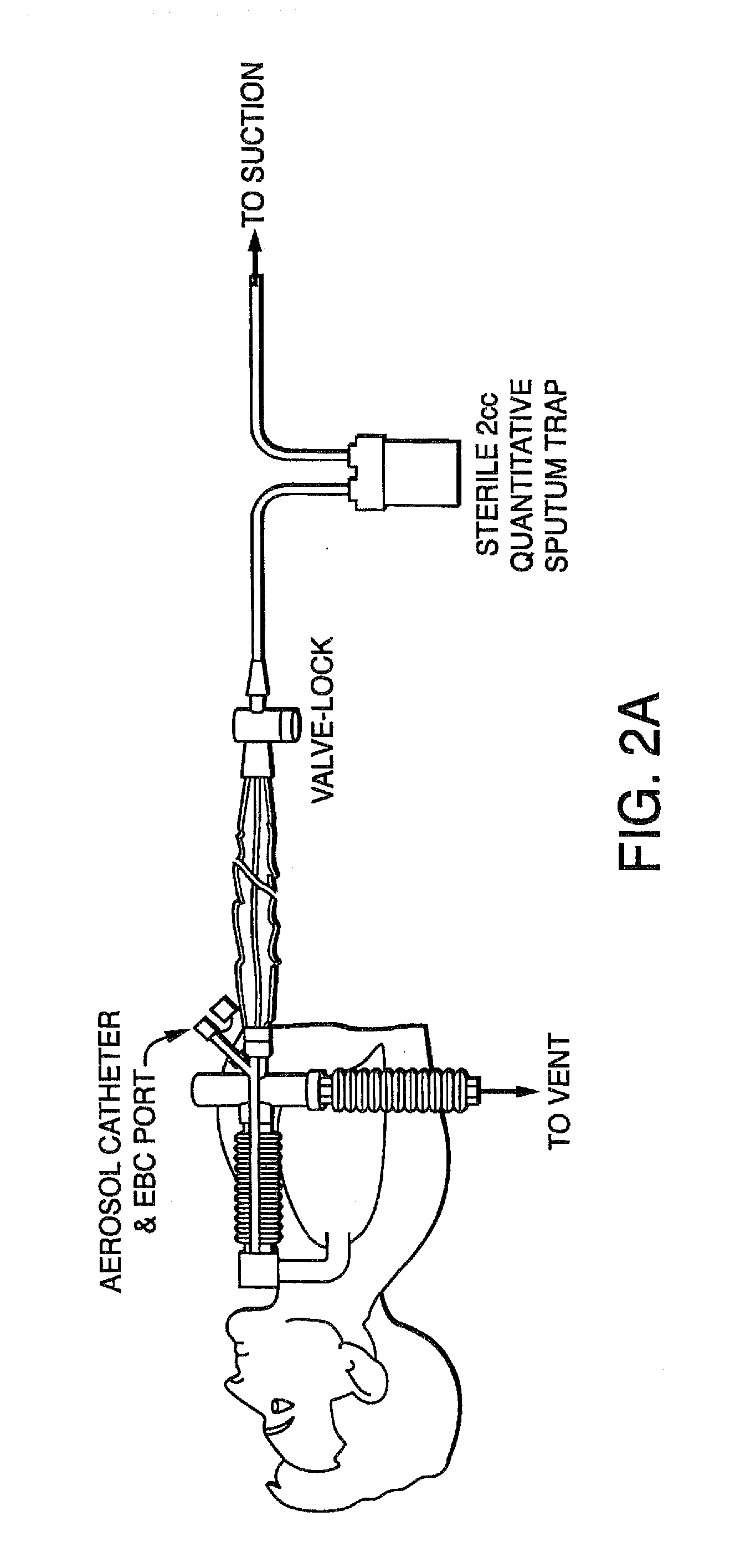

Methods, devices and Formulations For Targeted Endobronchial Therapy

InactiveUS20160375212A1Mortality rate is decreasedReduce morbidityTracheal tubesMedical devicesTracheobronchitisRegimen

The present invention provides an improved means of treating tracheobronchitis, bronchiectasis and pneumonia in the nosocomial patient, preferably with aerosolized anti gram-positive and anti-gram negative antibiotics administered in combination or in seriatim in reliably sufficient amounts for therapeutic effect. In one aspect, the invention assures this result when aerosol is delivered into the ventilator circuit. In one embodiment the result is achieved mechanically. In another embodiment, the result is achieved by aerosol formulation. In another aspect, the invention assures the result when aerosol is delivered directly to the airways distal of the ventilator circuit. The treatment means eliminates the dosage variability that ventilator systems engender when aerosols are introduced via the ventilator circuit. The treatment means also concentrates the therapeutic agent specifically at affected sites in the lung such that therapeutic levels of administrated drug are achieved without significant systemic exposure of the patient to the drug. The invention further provides a dose control device to govern this specialized regimen.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

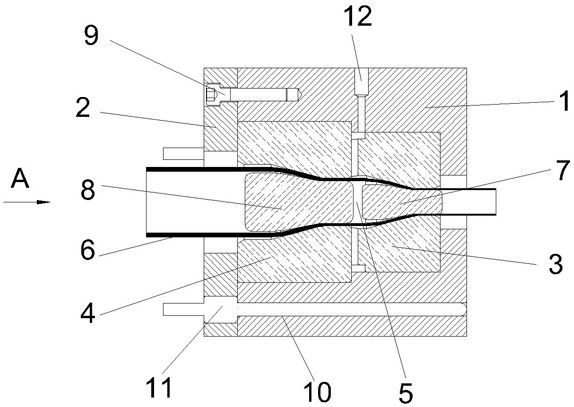

Single-pass double-core-head pipe drawing device

PendingCN113385546AImprove plastic deformation abilityRealize single-pass continuous deformationDrawing diesOne passMechanical engineering

The invention discloses a single-pass double-core-head pipe drawing device, belongs to the technical field of pipe drawing forming, and aims to realize continuous deformation of a pipe in one pass, improve the production efficiency and the equipment utilization rate, reduce the labor intensity, and is wide in application range and high in practicability. The single-pass double-core-head pipe drawing device comprises a die sleeve and a pressing plate. The single-pass double-core-head pipe drawing device is characterized in that a through hole is formed in the center of the die sleeve; a stepped groove is formed in the die sleeve; the through hole is communicated with the stepped groove; a small-diameter outer die and a large-diameter outer die are correspondingly arranged in the stepped groove; a gap is reserved between the corresponding faces of the small-diameter outer die and the large-diameter outer die; the small-diameter outer die and the large-diameter outer die are provided with coaxial pipe holes at the same time; a pipe is arranged in the pipe hole; a small-diameter moving core head and a large-diameter moving core head are arranged in the pipe; the small-diameter moving core head corresponds to the small-diameter outer die; the large-diameter moving core head corresponds to the large-diameter outer die; and the pressing plate is detachably connected to one end of the die sleeve through a screw.

Owner:SHENYANG LIGONG UNIV

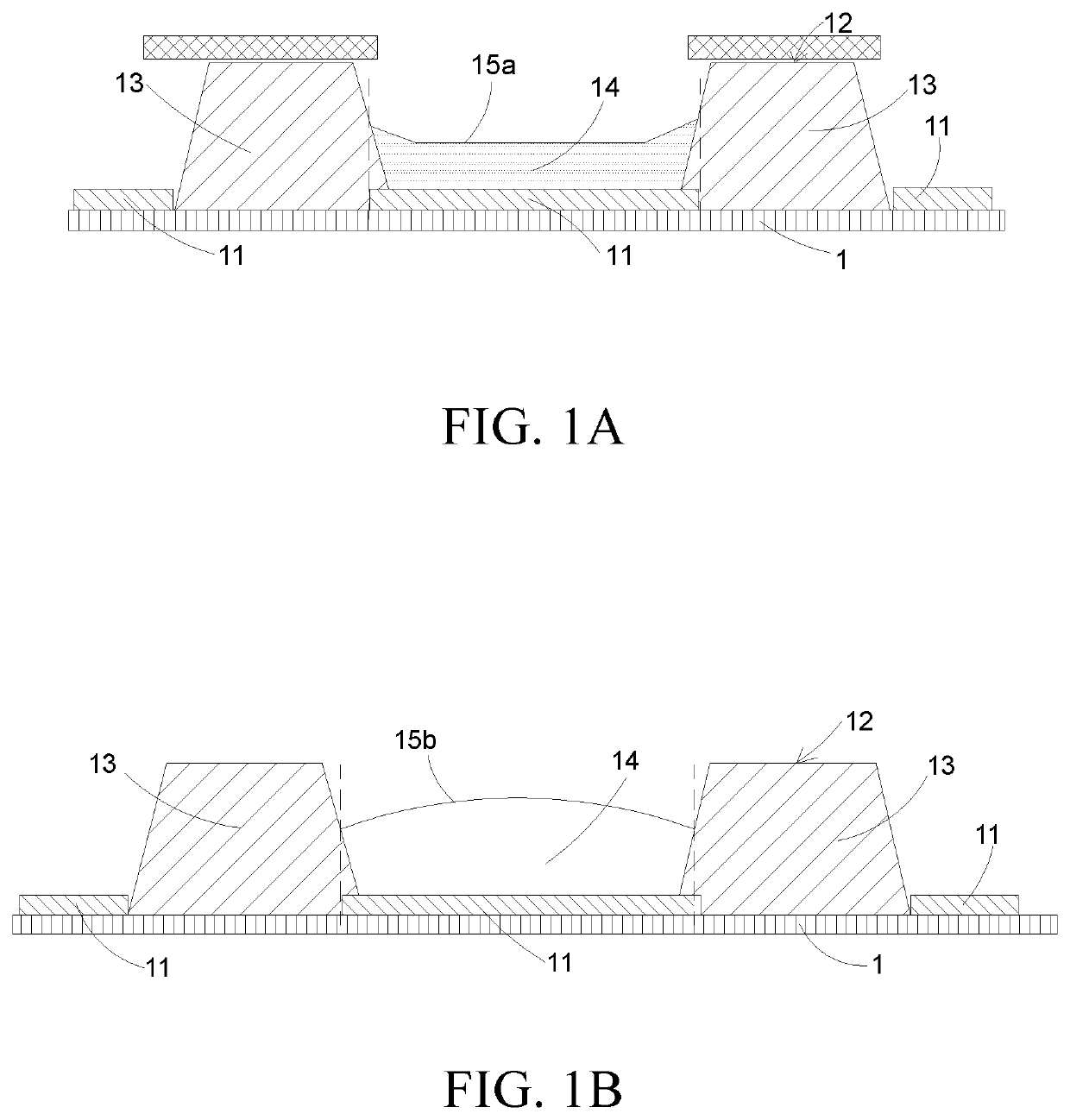

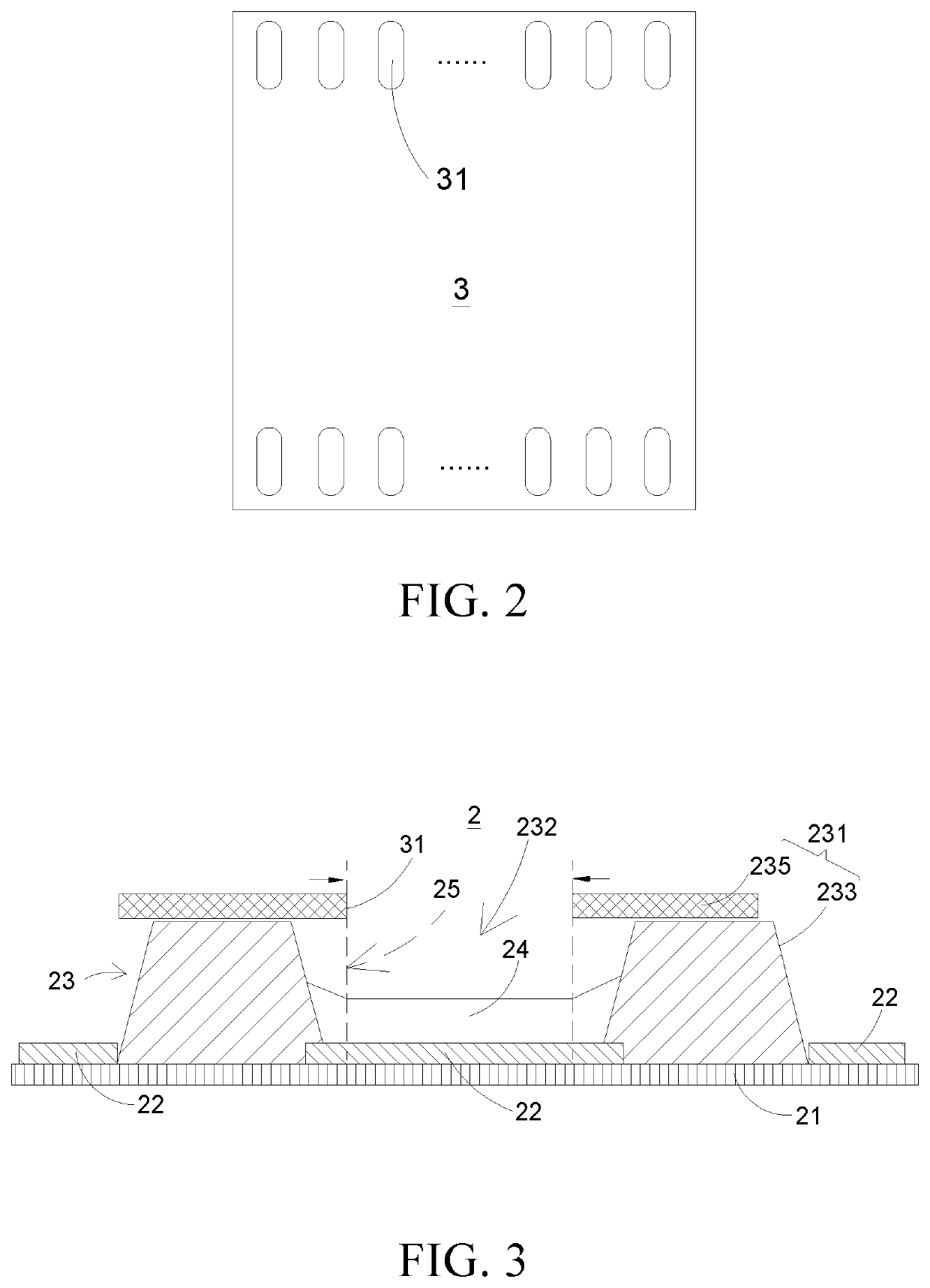

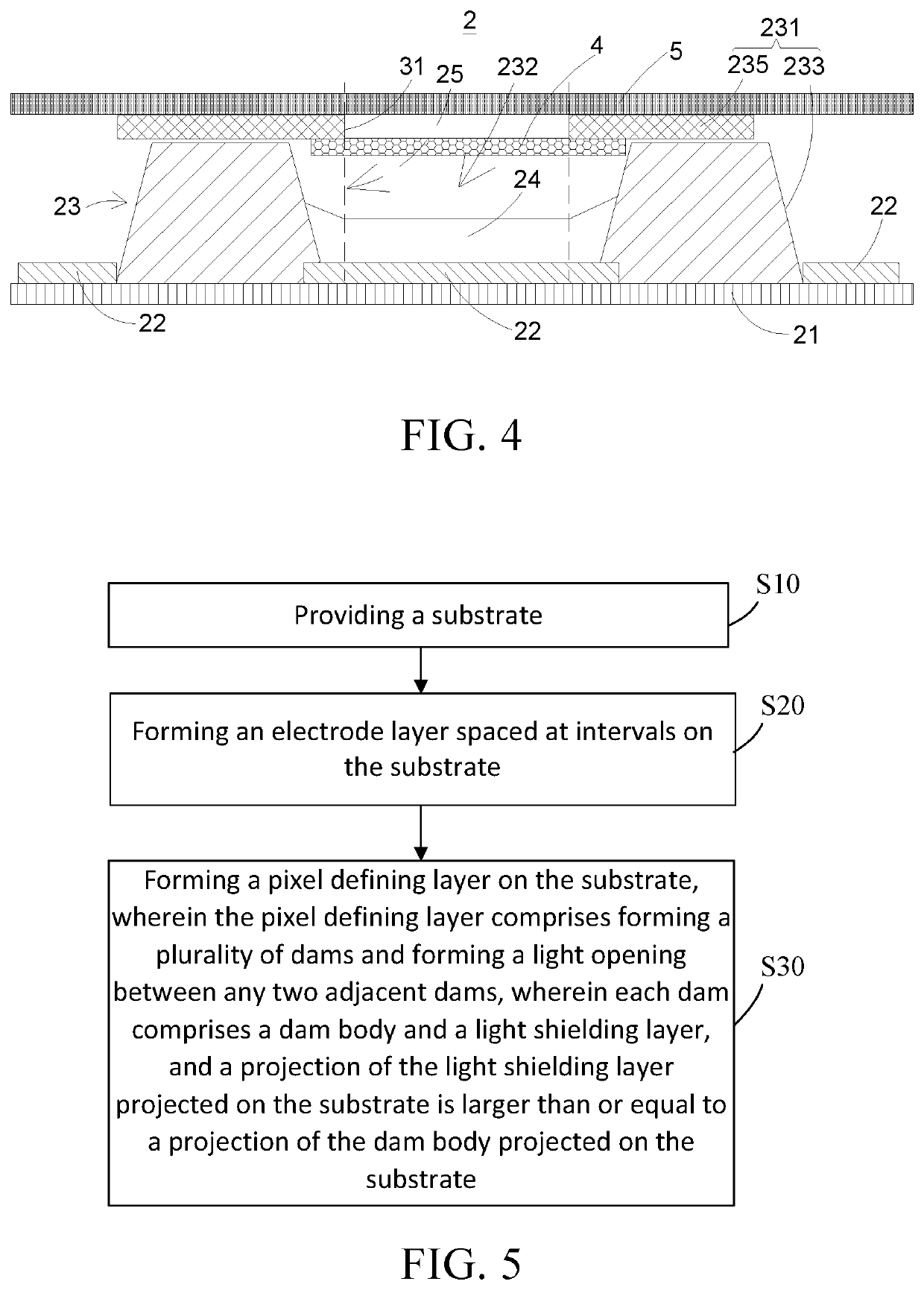

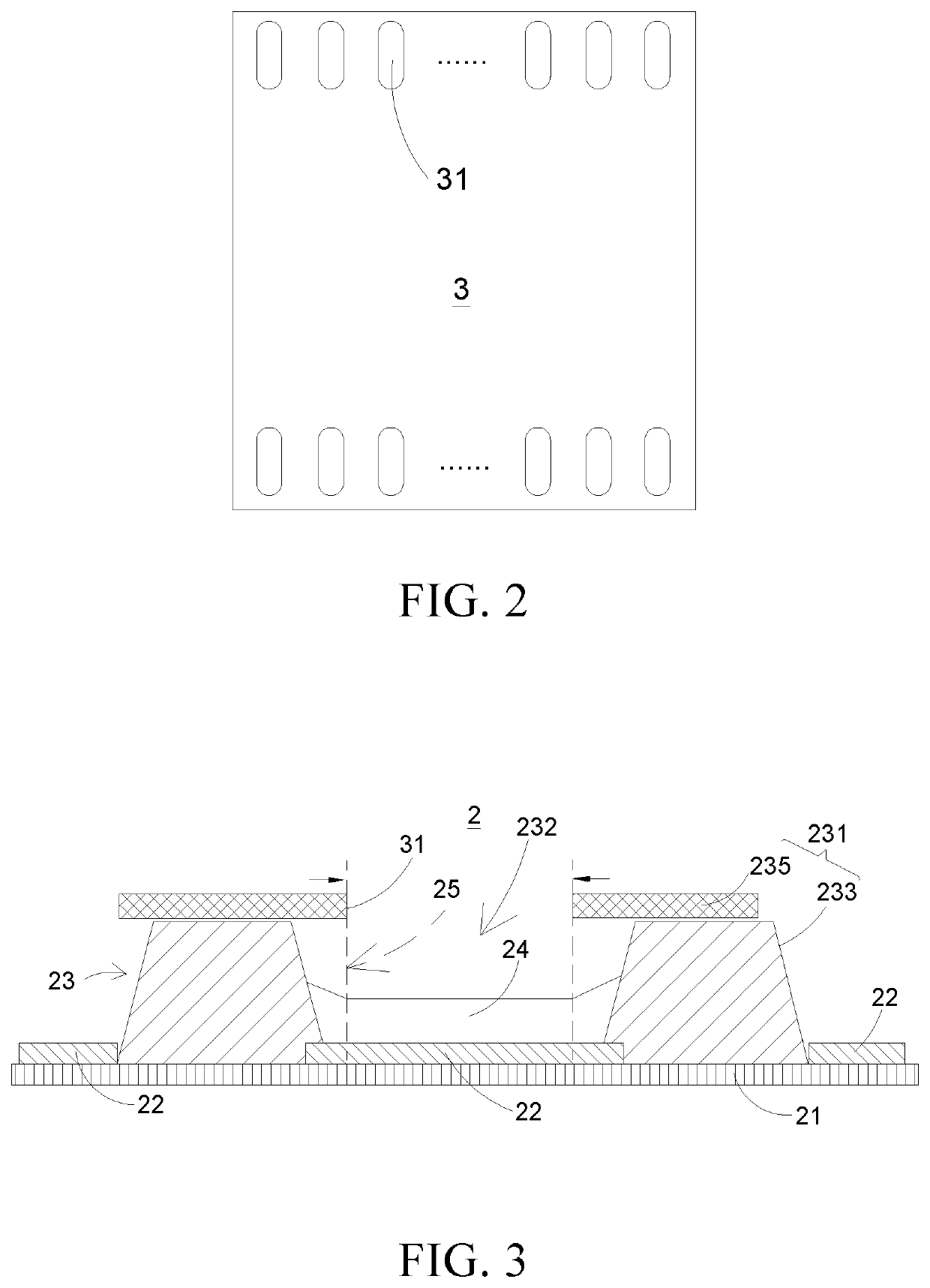

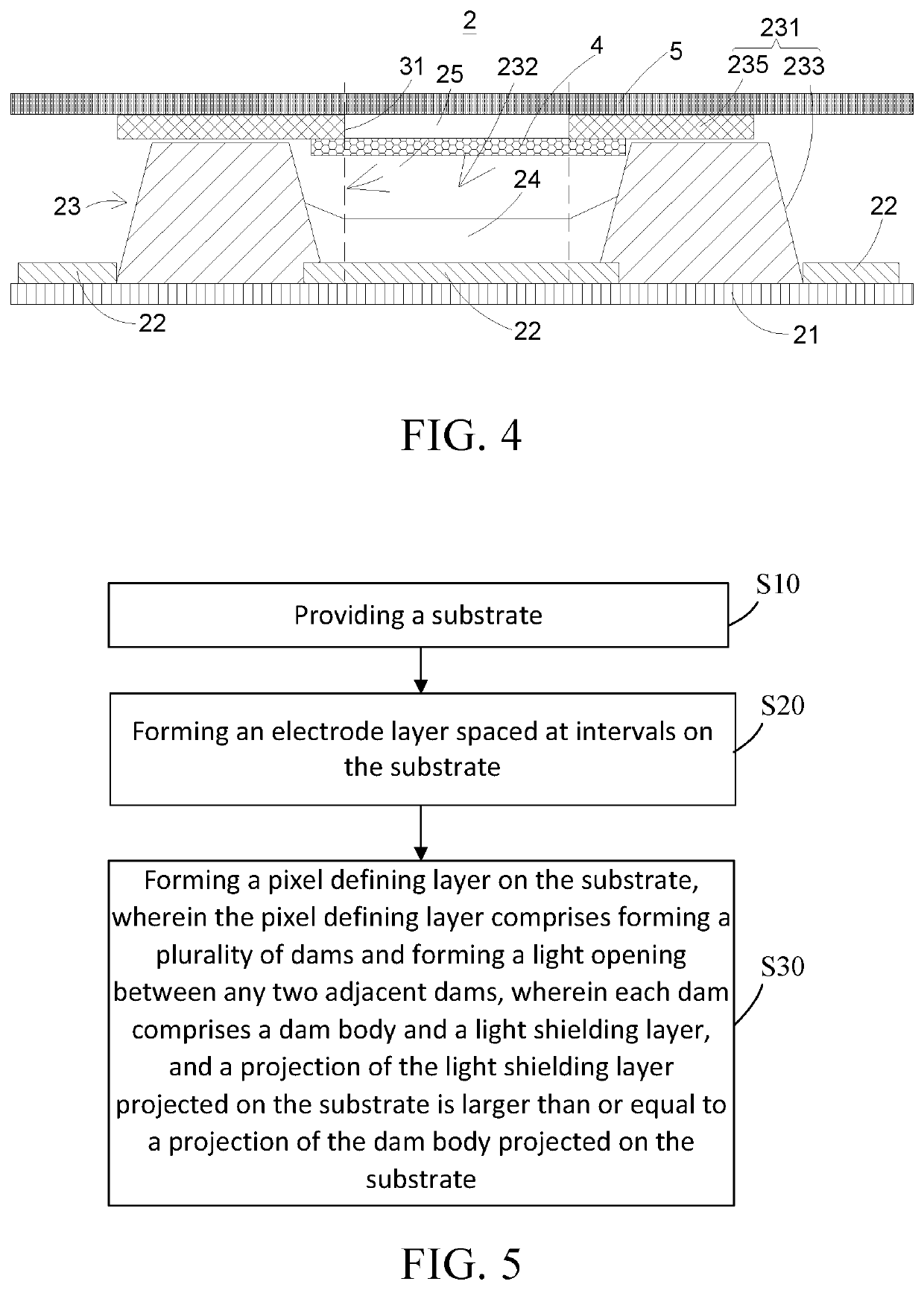

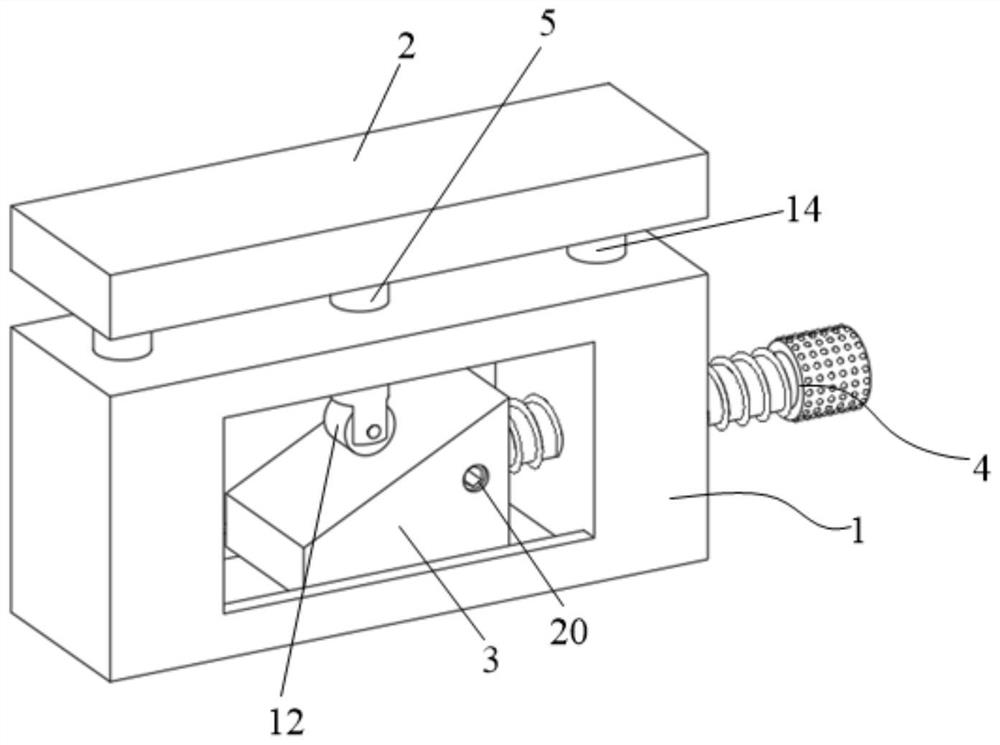

OLED display panel, manufacturing method thereof, and OLED display device

ActiveUS20210335966A1Uniform lightReduce areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

The present invention provides an organic light-emitting diode (OLED) display panel, a manufacturing method thereof, and a display device. The OLED display panel includes a substrate, an electrode layer, a pixel defining layer, and a light shielding layer. The electrode layer is spaced at intervals on the substrate. The pixel defining layer is placed on the substrate. The pixel defining layer includes dams and a light opening between any two adjacent dams. Each dam includes a dam body and a light shielding layer. A projection of the light shielding layer projected on the substrate is larger than or equal to a projection of the dam body projected on the substrate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

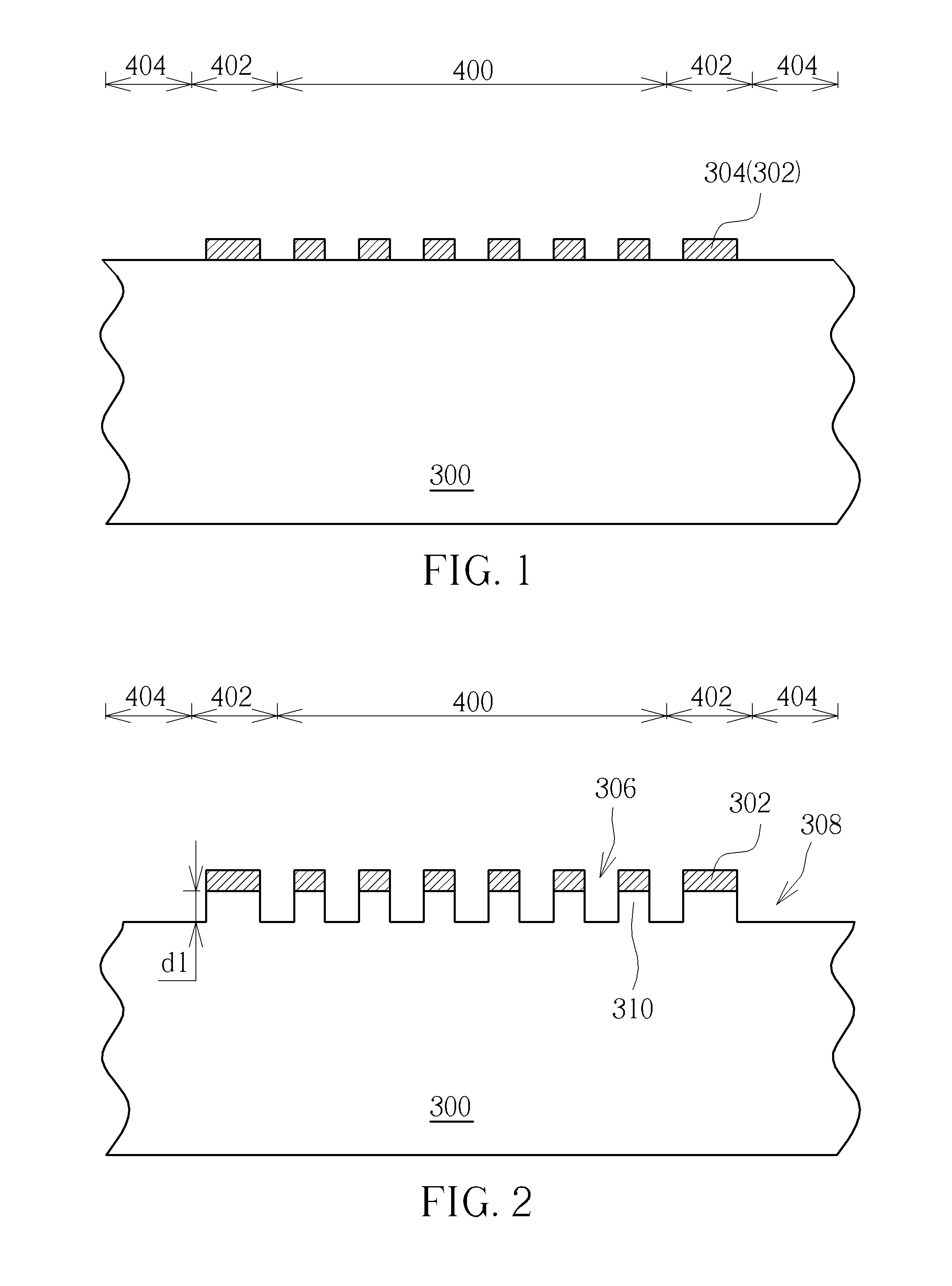

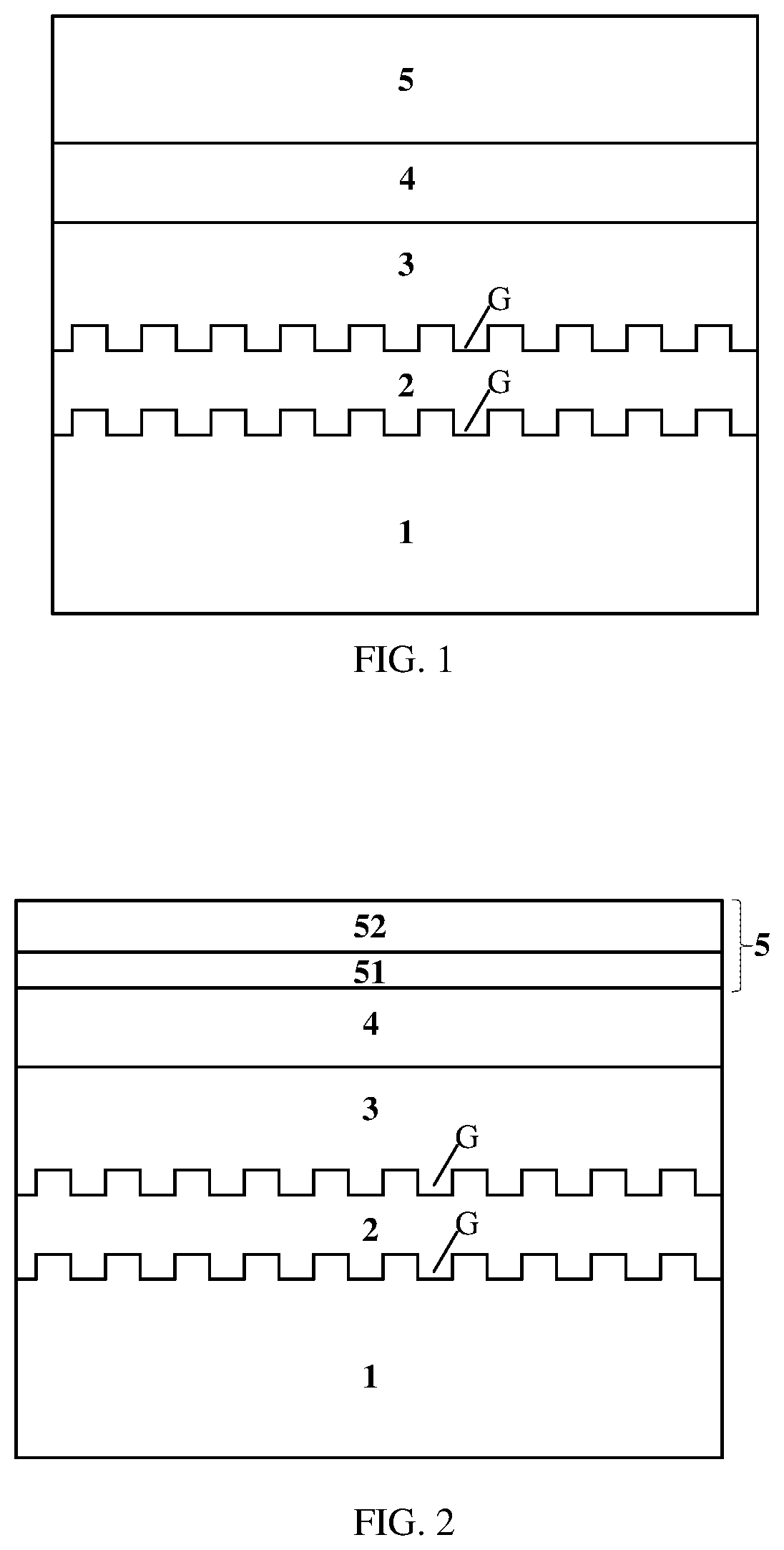

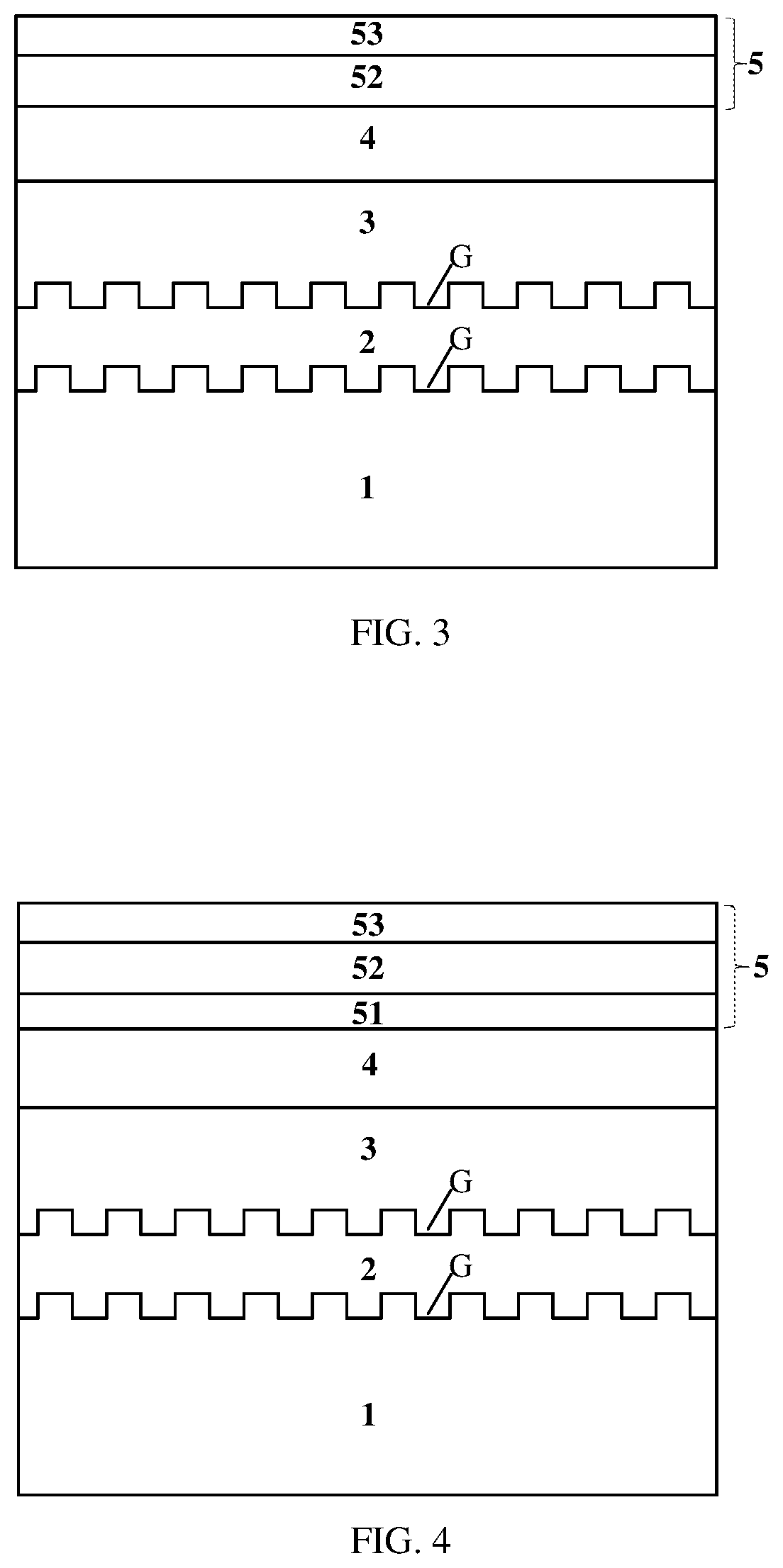

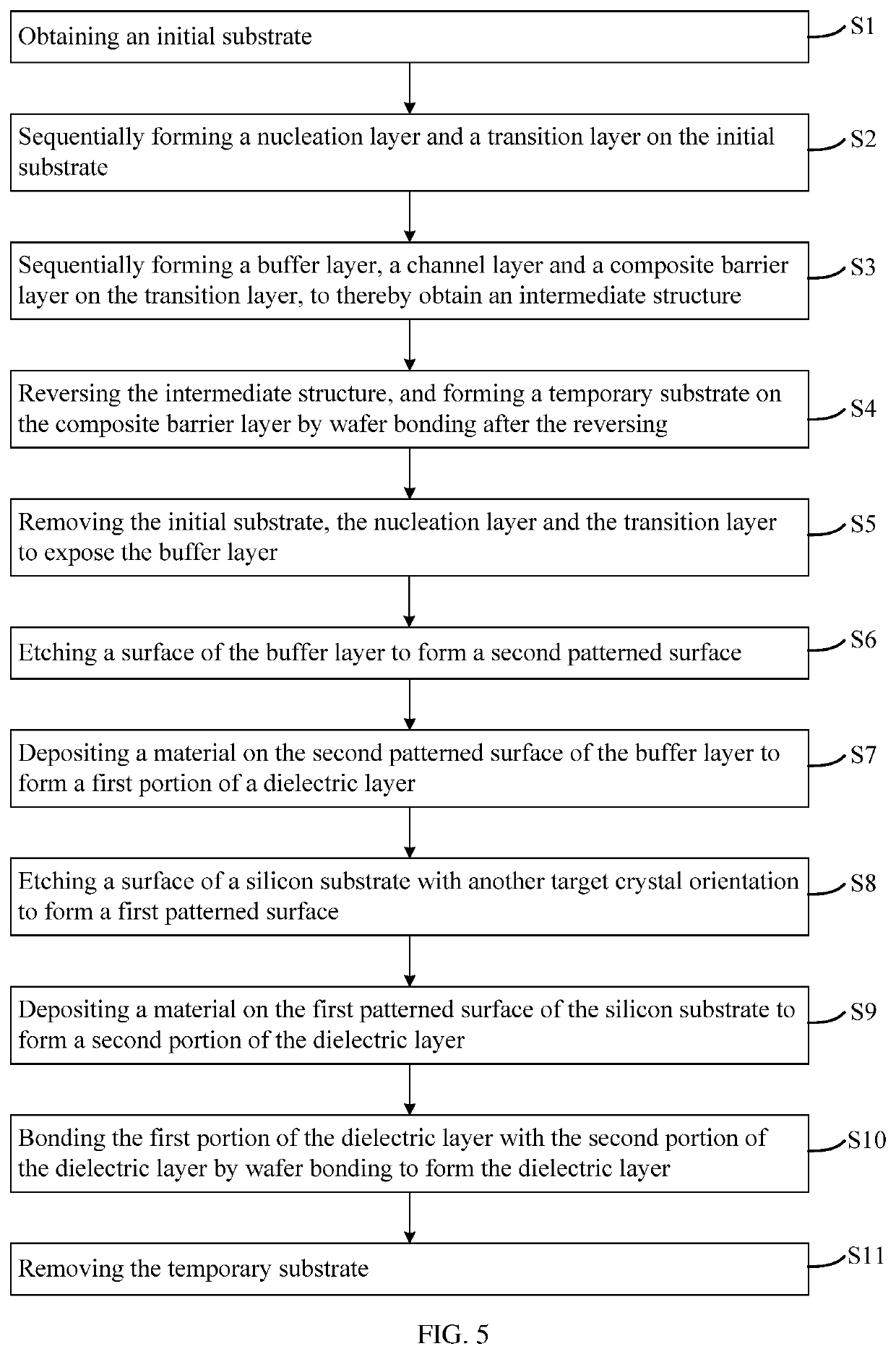

Material structure for low thermal resistance silicon-based gallium nitride microwave and millimeter-wave devices and manufacturing method thereof

PendingUS20220310796A1Reduce thermal resistanceImprove performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringGallium nitride

A material structure for silicon-based gallium nitride microwave and millimeter-wave devices and a manufacturing method thereof are provided. The material structure includes: a silicon substrate; a dielectric layer of high thermal conductivity, disposed on an upper surface of the silicon substrate, and an uneven first patterned interface being formed between the dielectric layer and the silicon substrate; a buffer layer, disposed on an upper surface of the dielectric layer, and an uneven second patterned interface being formed between the buffer layer and the dielectric layer; a channel layer, disposed on an upper surface of the buffer layer; and a composite barrier layer, disposed on an upper surface of the channel layer. In the material structure, the uneven patterned interfaces increase contact areas of the interfaces, a thermal boundary resistance and a thermal resistance of device are reduced, and a heat dissipation performance of device is improved.

Owner:XIDIAN UNIV

OLED display panel having light shielding layer for shielding light emitted at edges of pixel-emitting region, manufacturing method thereof, and OLED display device

ActiveUS11257889B2Uniform lightReduce areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The present invention provides an organic light-emitting diode (OLED) display panel, a manufacturing method thereof, and a display device. The OLED display panel includes a substrate, an electrode layer, a pixel defining layer, and a light shielding layer. The electrode layer is spaced at intervals on the substrate. The pixel defining layer is placed on the substrate. The pixel defining layer includes dams and a light opening between any two adjacent dams. Each dam includes a dam body and a light shielding layer. A projection of the light shielding layer projected on the substrate is larger than or equal to a projection of the dam body projected on the substrate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Adjusting tool for molded tobacco bale drying wheel in packaging machine

PendingCN113602624AEliminate various problems caused by improper adjustmentEliminate consumptionLabelling machinesStructural engineeringSoldering iron

The invention discloses an adjusting tool for a molded tobacco bale drying wheel in a packaging machine. The tool comprises a main body, a support plate, a wedge block and a driving piece, the main body is of a cuboid structure, an ejector rod is arranged in the middle of the bottom surface of the support plate, the wedge block is arranged in the main body, the driving piece is arranged on the main body, and the driving piece is used for driving the wedge block to move along the length direction of the main body; and the ejector rod penetrates through the top of the main body, and the lower end of the ejector rod abuts against the inclined face of the wedge block. The distance between an upper soldering iron and a lower soldering iron can be accurately adjusted, and the problems that the surfaces of cigarette packets are scratched and label paper is not firmly pasted are solved.

Owner:CHINA TOBACCO HENAN IND

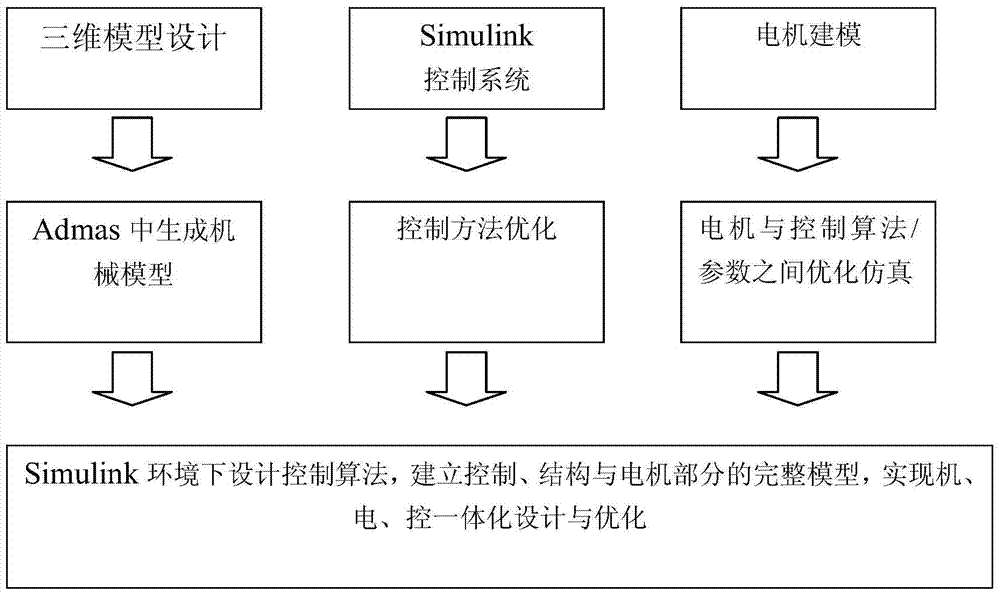

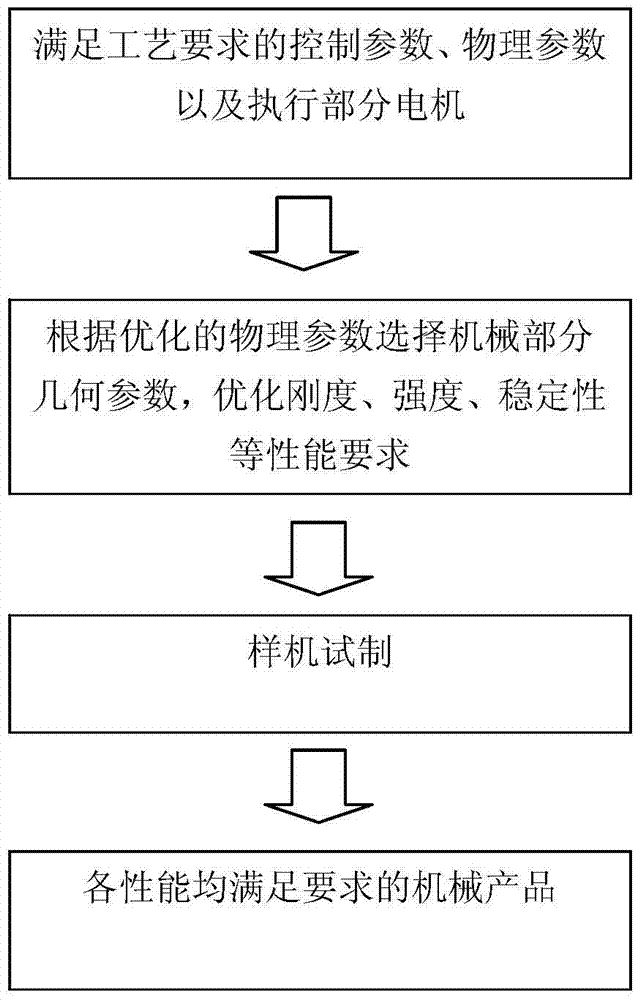

An Optimal Design Method for Mechatronic Control Integration

ActiveCN103744296BImprove efficacyEfficient use ofSimulator controlManufacturing enterprisesCost savings

An optimization design method for mechatronic control integration, which first establishes an electromechanical control model including a mechanical structure model, a motor model, and a control system model; then optimizes each physical parameter of the mechanical structure model and the control algorithm or control parameters of the control system model to adapt to the working conditions, and then simulate; at the same time, establish the motor model according to the motor response characteristic curve obtained in the optimization process; finally determine the geometric parameters of the mechanical structure model, and then according to the optimized mechanical structure model and its geometric parameters, motor model Carry out prototype trial production with the control system model, and repeat step 2) to obtain a mechanical product that is consistent with the trial prototype and the electromechanical control model. The invention directly optimizes the machine, electricity, and control to obtain the performance of future products before the product is put into production, and truly realizes the integration and deep integration of mechatronics and control. Efficiency plays an important role.

Owner:XI AN JIAOTONG UNIV

High-strength screw fastening detection device and fastening detection method thereof

ActiveCN113340510AHigh precisionImprove efficiencyMeasurement of torque/twisting force while tighteningWind energy generationPull forceClassical mechanics

The invention relates to the technical field of structural engineering, in particular to a high-strength screw fastening detection device and a fastening detection method thereof. The high-strength screw fastening detection device comprises a supporting cylinder, a jacking device and a tensioning force detection and analysis device. The supporting cylinder sleeves a screw, and one end of the supporting cylinder abuts against a to-be-fastened structure through which the screw penetrates. The jacking device is arranged at the other end of the supporting cylinder and used for being arranged on the screw in a sleeving mode and detachably connected with the screw so as to tension the screw. The tensioning force detection and analysis device is used for obtaining the jacking displacement of the jacking device and the tensioning force of the screw, and determining whether the tensioning force of the screw before tensioning meets the design requirement or not according to the jacking displacement of the jacking device and the tensioning force of the screw. The problem that in the prior art, the fastening force cannot meet the requirement due to the fact that the fastening force of the screw is inconvenient to detect can be solved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

Etching method in a semiconductor processing and etching system for performing the same

InactiveUS7176139B2Improve device yieldImproved profileElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Disclosed is an etching method for semiconductor processing by which a pattern loading phenomenon is reduced. First, plasma is generated while setting a bias power applied to a wafer to zero and applying a source power. After a predetermined time period, an etching process is implemented onto a predetermined layer formed on the wafer by setting the bias power to a predetermined value. Since by-products generated during preceding etching processes can be readily removed during an etching using plasma, an etching process change due to a difference of pattern densities can be reduced. In addition, a progressive pattern loading generated as the number of processed wafers increase, can be prevented.

Owner:CONVERSANT INTPROP MANAGEMENT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com