Single-pass double-core-head pipe drawing device

A pipe drawing and core head technology, which is applied in the direction of wire drawing dies, can solve the problems of small deformation of pipes in a single pass, low utilization rate of equipment, and uneconomical production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

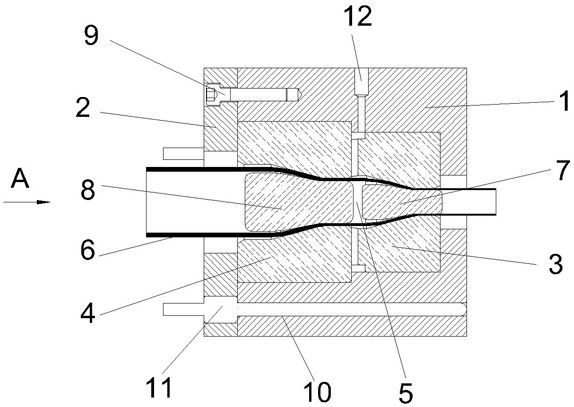

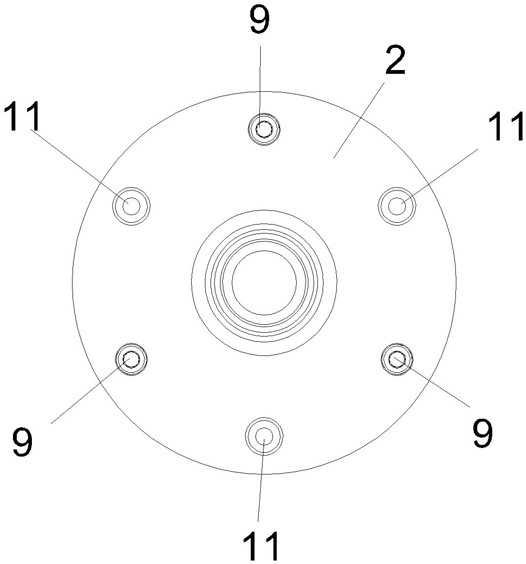

[0017] As shown in the accompanying drawings, this embodiment includes a mold cover 1 and a pressure plate 2. A through hole is provided in the center of the mold cover 1. A stepped groove is arranged inside the mold cover 1. The through hole communicates with the stepped groove. The mold 3 and the large-diameter external mold 4, the large-diameter external mold 4 realizes the first diameter-reducing and wall-reducing deformation of the pipe 6, and the small-diameter external mold 3 realizes the second diameter-reducing and wall-reducing deformation of the pipe 6. Under the action of friction force and deformation force when the pipe material 6 is drawn, the small-diameter outer mold realizes bonding with the inner wall of the mold sleeve end. The large-diameter outer mold 4 realizes bonding with the middle step surface of the stepped groove of the mold casing under the action of friction force and deformation force when the pipe material 6 is drawn.

[0018] There is a gap 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com