Adjusting tool for molded tobacco bale drying wheel in packaging machine

A technology for adjusting tools and packaging machines, used in packaging, transportation and packaging, labeling machines, etc., can solve the problems of scratches on the surface of cigarette packs and poor sticking of trademark paper, so as to reduce maintenance costs, improve equipment efficiency and product quality. Quality, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

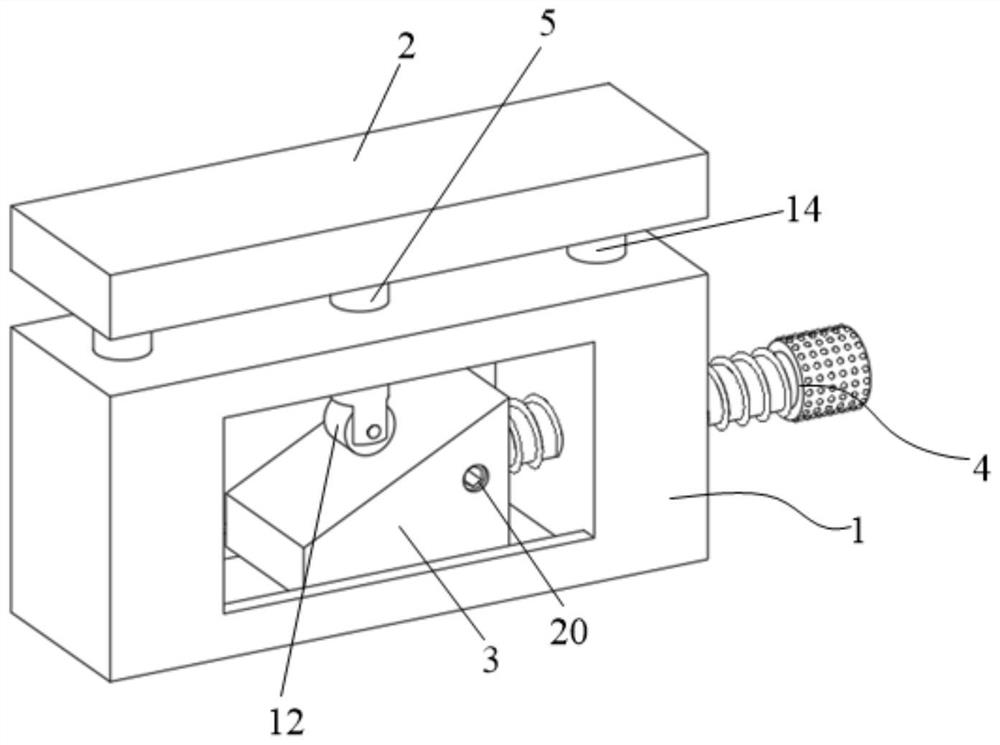

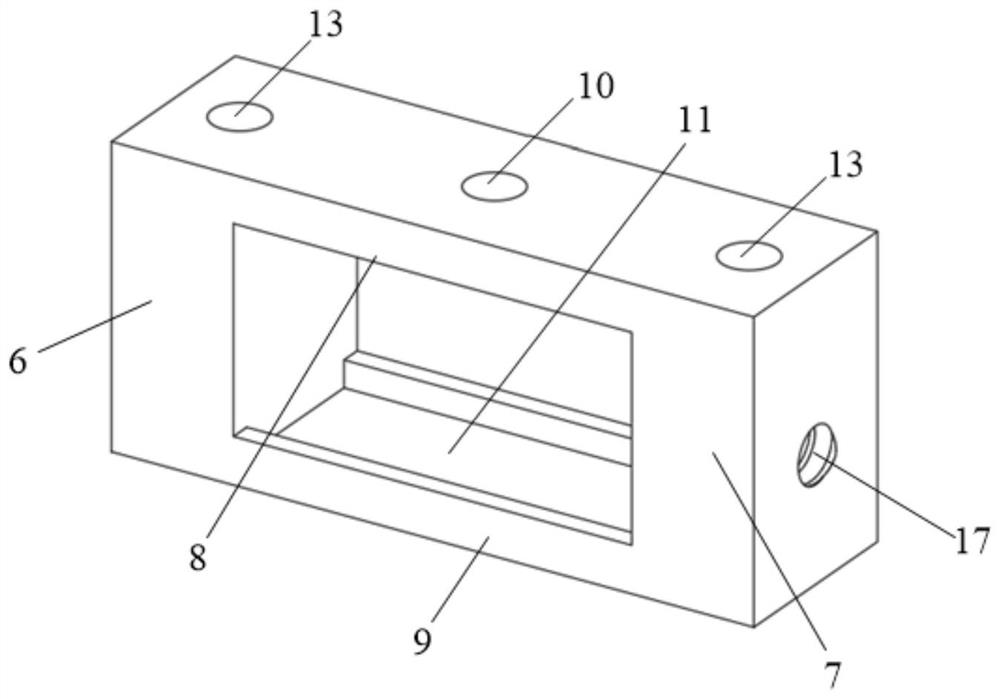

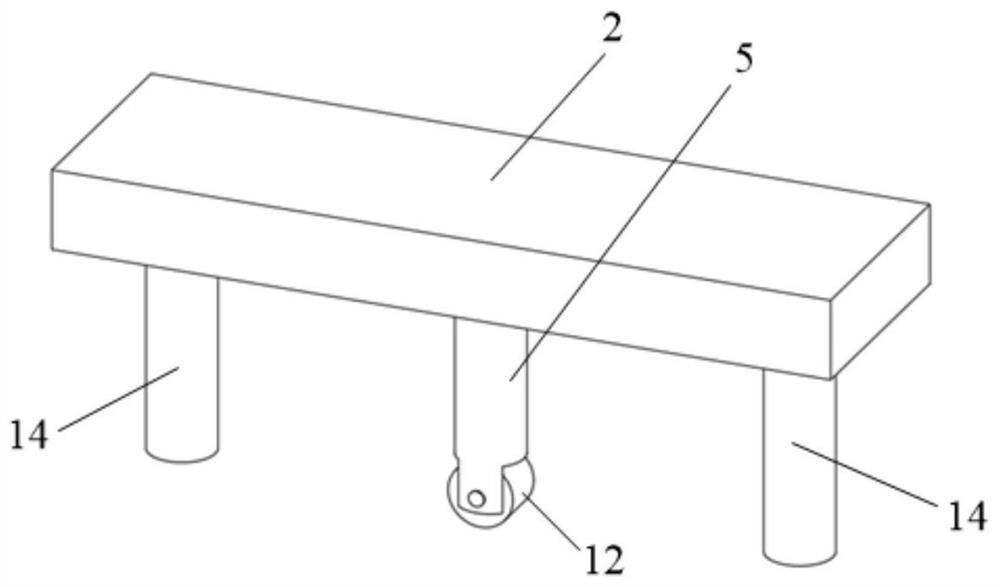

[0021] Embodiments of the present invention: as Figure 1-Figure 4 As shown, a tool for adjusting the drying wheel of formed cigarette packs in a packaging machine, including a main body 1, a support plate 2, a wedge block 3 and a driving part 4, the main body 1 is a cuboid structure, and a push rod is arranged in the middle of the bottom surface of the support plate 2 5. The ejector rod 5 is vertically arranged with the support plate 2, the wedge block 3 is set in the main body 1, and there is a space for the wedge block 3 to move in the main body 1, and the driving part 4 is set on the main body 1, and the driving part 4 is used to drive the wedge block 3 moves along the length direction of the main body 1, the push rod 5 penetrates the top of the main body 1, and the lower end of the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com