Device and method for purifying and recycling furnace gas of hermetic ore smelting furnace

A furnace gas purification and mine-sealing technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of loss of reuse value of dust, secondary pollution of water, water consumption, etc., to achieve efficient use of energy and prevent secondary pollution. , the effect of life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

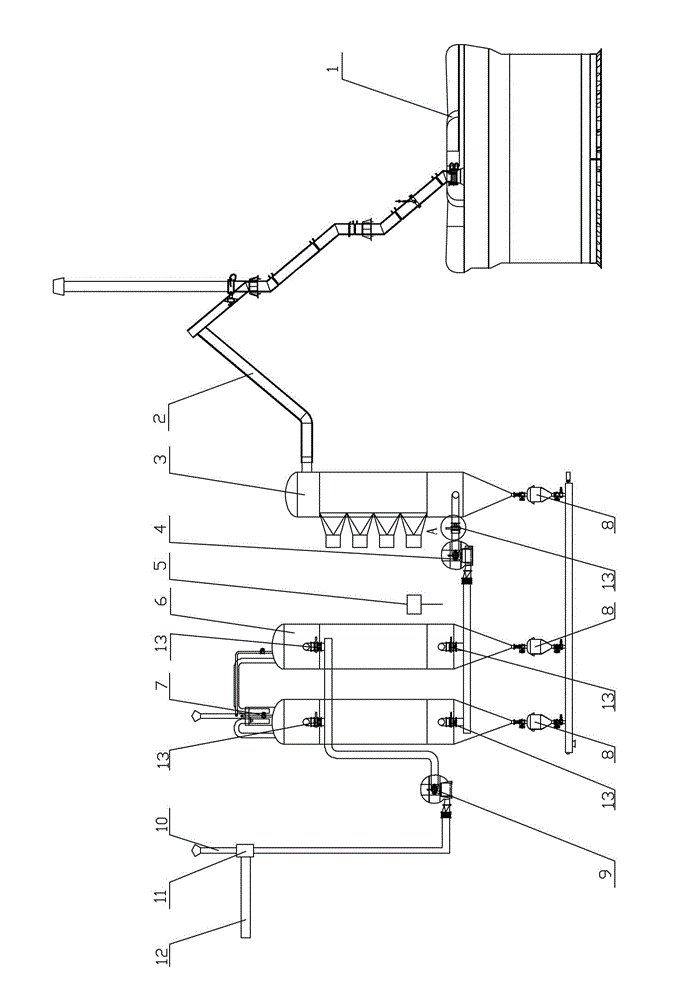

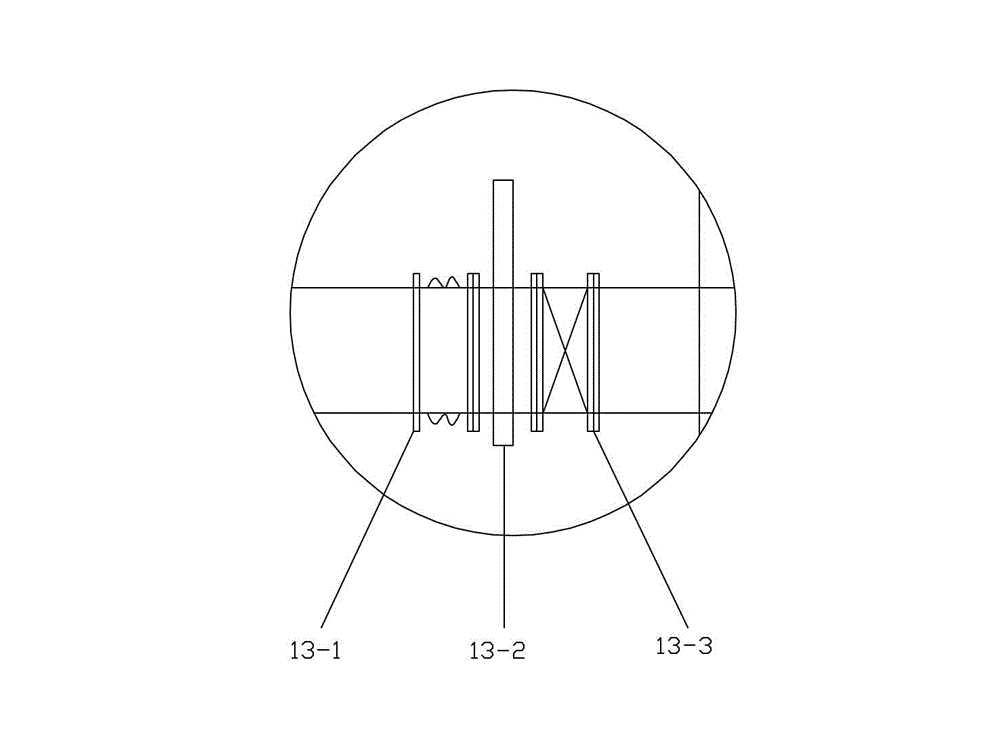

[0020] Such as figure 1 As shown, a closed submerged arc furnace gas purification recovery device, including a closed submerged arc furnace (1), the closed submerged arc furnace (1) is connected to a cooler (3) through a water-cooled flue (2), and the cooler ( 3) Connect with the barren furnace gas induced draft fan (4), CO 2 , CO, H 2 , O 2 The concentration online gas detection analyzer (5) is installed at the outlet of the barren furnace gas induced draft fan (4). ) is equipped with an explosion relief safety device (7), the outlet of the bag filter (6) is connected to the inlet of the clean furnace gas pressurization fan (9), and the clean furnace gas pressurization fan (9) is switched through the pipe and the tee The valve (11) is connected, the online gas detection analyzer (5) is interlocked with the three-way switching valve (11), and the three-way switching valve (11) is respectively connected to the user pipeline (12) and the release tower (10), and the cooler (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com