Internal combustion engine with liquid cooling

An internal combustion engine, liquid cooling technology, used in liquid cooling, engine components, machines/engines, etc., can solve problems such as unused, dissipation, etc., to achieve the effect of improving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

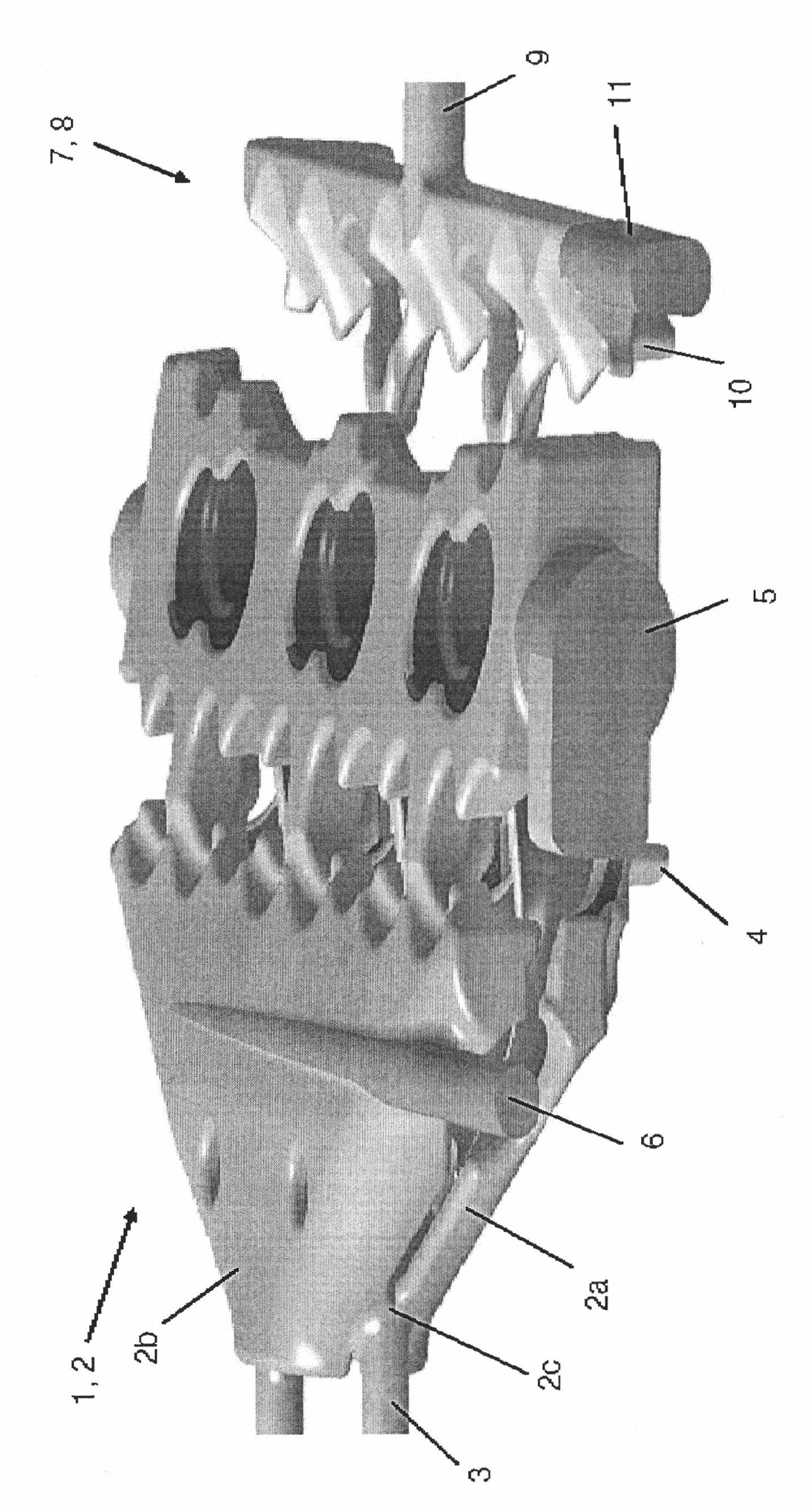

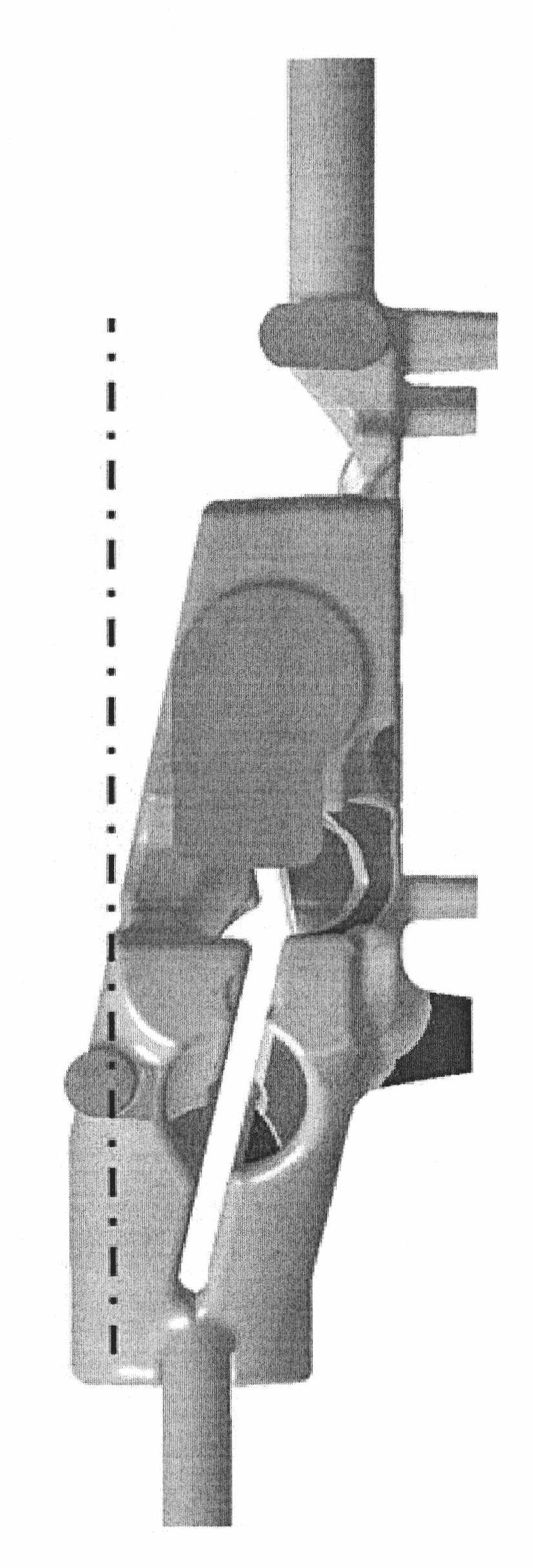

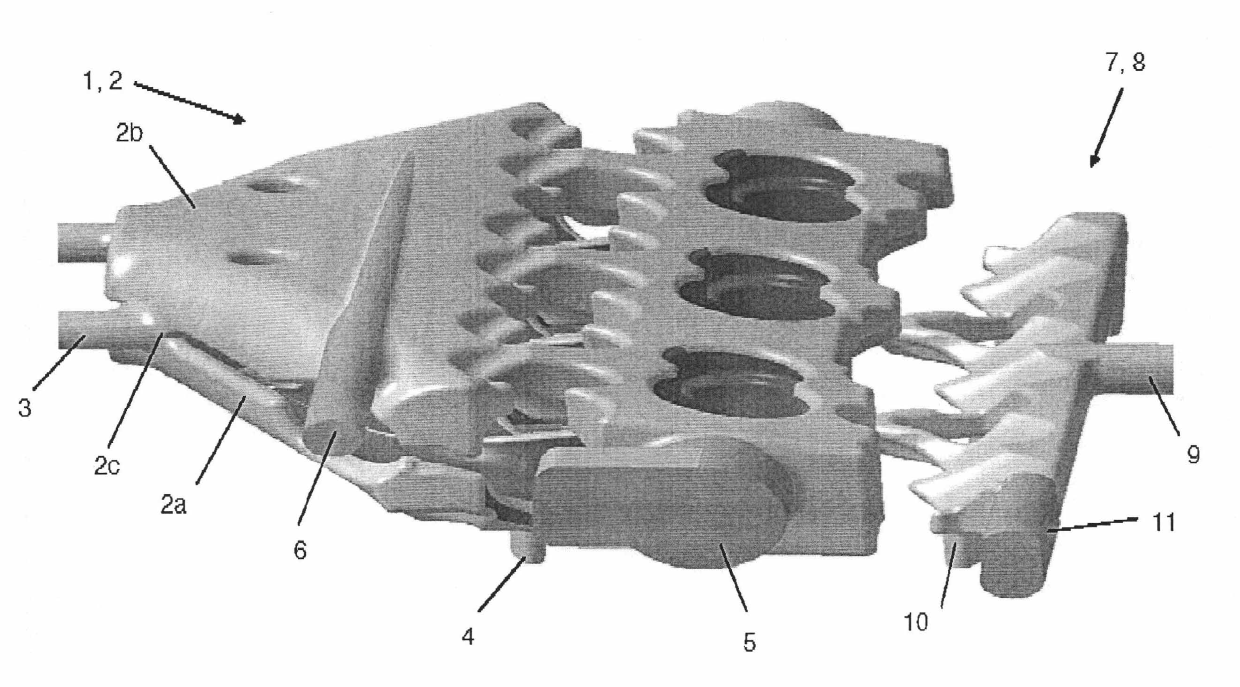

[0123] figure 1 A slightly inclined plan view showing the sand cores 1 , 7 of the cooling jackets 2 , 8 of the two coolant circuits separated from one another according to the first embodiment, which are integrated in the cylinder head of the internal combustion engine.

[0124] With the aid of sand cores 1, 7, figure 1 The components of the two cooling circuits, which are integrated in the finished cylinder head and in particular in the respective cooling jacket 2 , 8 , are also schematically shown. For this purpose, the sand cores 1 , 7 are also provided with identification numbers associated with the cooling jackets 2 , 8 .

[0125] In order to form a liquid cooling structure, two cooling jackets 2a, 2b are arranged on the outlet side of the cylinder head, and one cooling jacket 8 is arranged on the inlet side of the cylinder head, the two outlet side cooling jackets 2a, 2b belong to the cooling water circuit, On the other hand, the cooling jacket 8 on the inlet side is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com