Method for recovering zinc and manganese by waste dry batteries and directly preparing desulfurizer for industry

A dry battery and desulfurizer technology, applied in battery recycling, recycling technology, separation methods, etc., can solve the problems of difficult process processing, economic infeasibility, complicated procedures, etc., to simplify the processing process, eliminate secondary pollution and energy. The effect of consumption and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

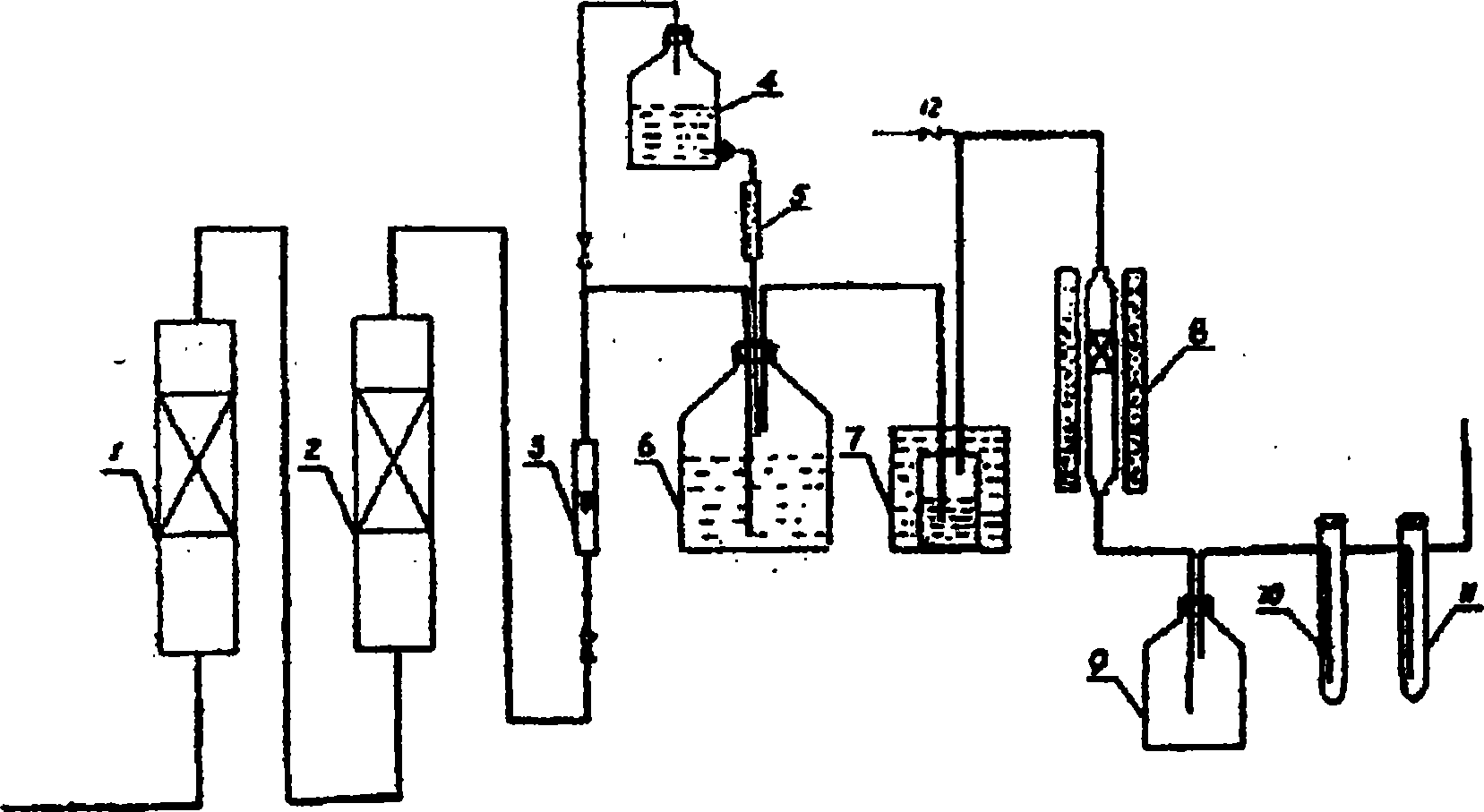

Image

Examples

Embodiment 1

[0030] Embodiment 1. Preparation of a mixture of metal oxides

[0031] Clean the zinc-manganese waste batteries of different specifications and models collected from the sanitation department with water, dry them, cut them manually, and soak them in dilute sulfuric acid with a concentration of 3.4M. The volume ratio of waste batteries to dilute sulfuric acid is 1: 6. After soaking for 6 hours, start heating, control the temperature at 70-75°C for 6 hours to make the acid leaching reaction complete, stop stirring and heating. After filtering to remove the dregs, the liquid is neutralized and precipitated with a sodium carbonate solution with a concentration of 10% (Wt). In order to ensure that the neutralization reaction is complete, the temperature is controlled at 70 ° C for 1 hour. After the neutralization solution is left to stand for a period of time, it is filtered Solid-liquid separation was carried out, and the solid was dried and calcined at 450°C to obtain 502 grams o...

Embodiment 2

[0032] Example 2. Preparation of a mixture of metal oxides

[0033] Wash the zinc-manganese waste batteries of different specifications and models collected from the environmental sanitation department with water, dry them, cut them manually, and soak them in dilute sulfuric acid with a concentration of 3.86M. The volume ratio of waste batteries to dilute sulfuric acid is 1: 6. After soaking for 4 hours, start heating, control the temperature at 80-85°C for 4.5 hours to make the acid leaching reaction complete, stop stirring and heating. After filtering to remove the dregs, the liquid is neutralized and precipitated with a sodium carbonate solution with a concentration of 20% (Wt). In order to ensure that the neutralization reaction is complete, the temperature is controlled at 75 ° C for 1 hour. After the neutralization solution is allowed to stand for a period of time, it is filtered Solid-liquid separation was performed, and the solid was dried and calcined at 450°C to obta...

Embodiment 3

[0034] Example 3. Preparation of a mixture of metal oxides

[0035] Wash the zinc-manganese waste batteries of different specifications and models collected from the environmental sanitation department with water, dry them, cut them manually, and soak them in dilute sulfuric acid with a concentration of 5.15M. The volume ratio of waste batteries to dilute sulfuric acid is 1: 6. After soaking for 2 hours, start heating, control the temperature at 85-90°C for 3 hours to make the acid leaching reaction complete, stop stirring and heating. After filtering to remove the dregs, the liquid is neutralized and precipitated with a sodium carbonate solution with a concentration of 30% (Wt). In order to ensure that the neutralization reaction is complete, the temperature is controlled at 80°C for 1 hour. After the neutralization solution is left to stand for a period of time, it is filtered Solid-liquid separation was carried out, and the solid was dried and calcined at 450°C to obtain 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com