Oil sludge cleaning and recycling method based on kitchen waste oil

A recovery method and oil technology, applied in chemical instruments and methods, petroleum industry, sludge treatment, etc., can solve problems such as restricted application and high cost, and achieve simplified treatment process and cost, simple treatment process, and mild fermentation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

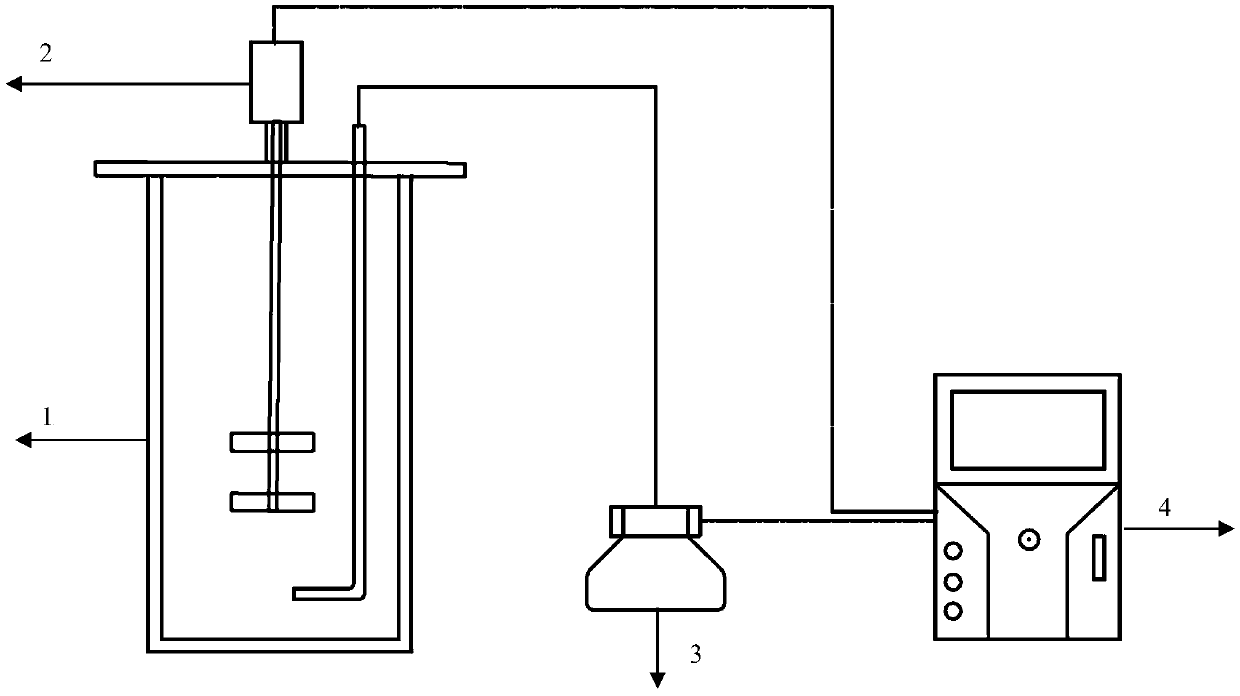

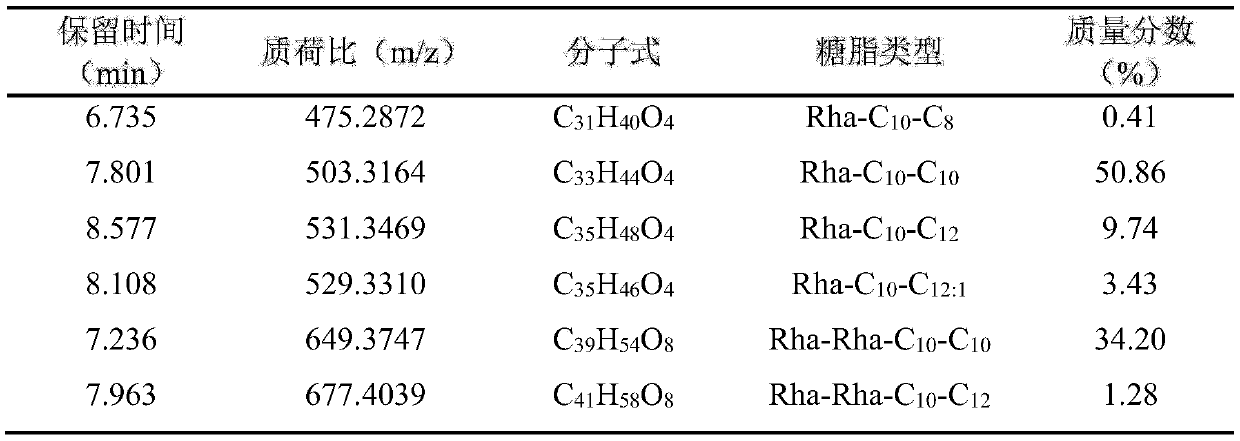

[0026] A proper amount of kitchen waste oil was taken from the recycled dining car in the school cafeteria as raw material, and sterilized in an autoclave at 121°C for 15 minutes. Prepare 5L nutrient solution, the formula per liter is: 5.00g sodium chloride, 1.00g ammonium sulfate, 0.25g magnesium sulfate, 2.00g sodium nitrate, 1.00g potassium dihydrogen phosphate, 1.00g dipotassium hydrogen phosphate, 5.00g yeast extract, Kitchen waste oil 20.00g, pH=8.0. The activated Pseudomonas aeruginosa seed liquid is inoculated into the fermenter 1 according to the inoculation ratio of 5%, and the stirring motor 2, the air compressor 4, the heating coil at the bottom of the tank, etc. are controlled through the control cabinet 3, and the fermenter is set. The temperature inside is 37°C, the ventilation rate is 0.2vvm, and the stirring rate is 300r / min.

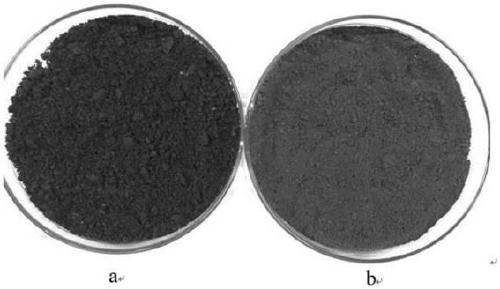

[0027] Taking the oil sludge in the drilling site of Weiyuan Oilfield in Neijiang City, Sichuan Province as the cleaning object, the ...

Embodiment 2

[0034] Carry out according to embodiment one, but oil sludge is the oil sludge of certain oilfield in Xinjiang, all the other are the same as embodiment one, and its crude oil recovery rate is 84%.

Embodiment 3

[0036] Carry out according to embodiment one, but the kitchen waste oil is family kitchen waste oil, all the other are the same as embodiment one, and its crude oil recovery rate is 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com