A kind of biological leaching method of purified terephthalic acid sludge

A technology of purified terephthalic acid and biological leaching, which is applied in the field of environmental engineering, can solve the problems of prolonged time and poor dehydration effect, and achieves the effects of cost saving, simplification of complexity, and reduction of inhibition and toxic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

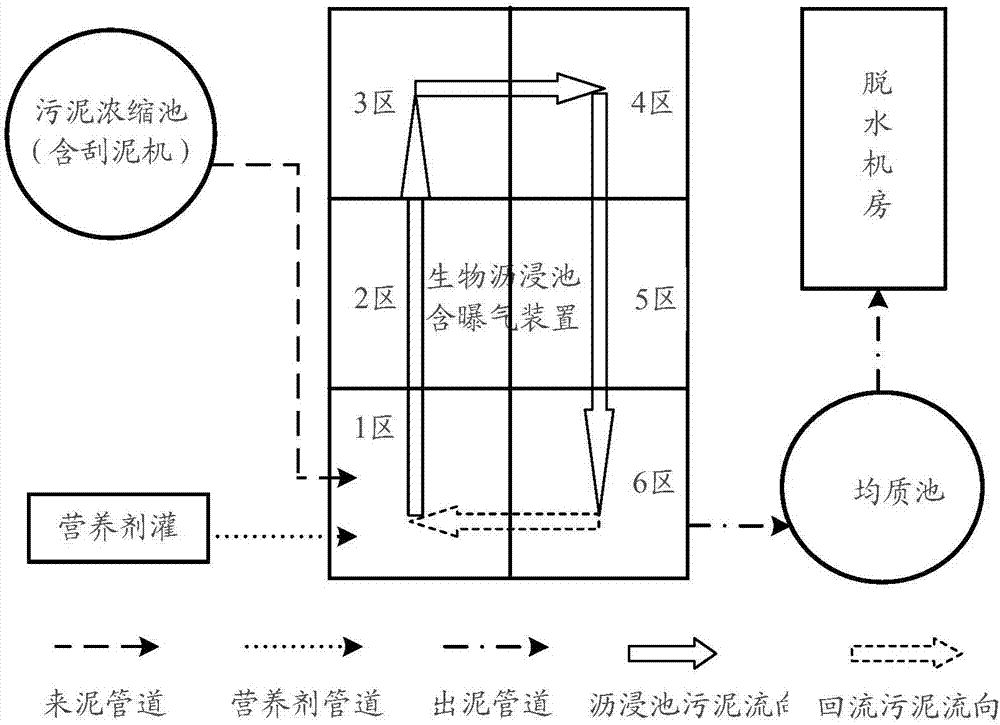

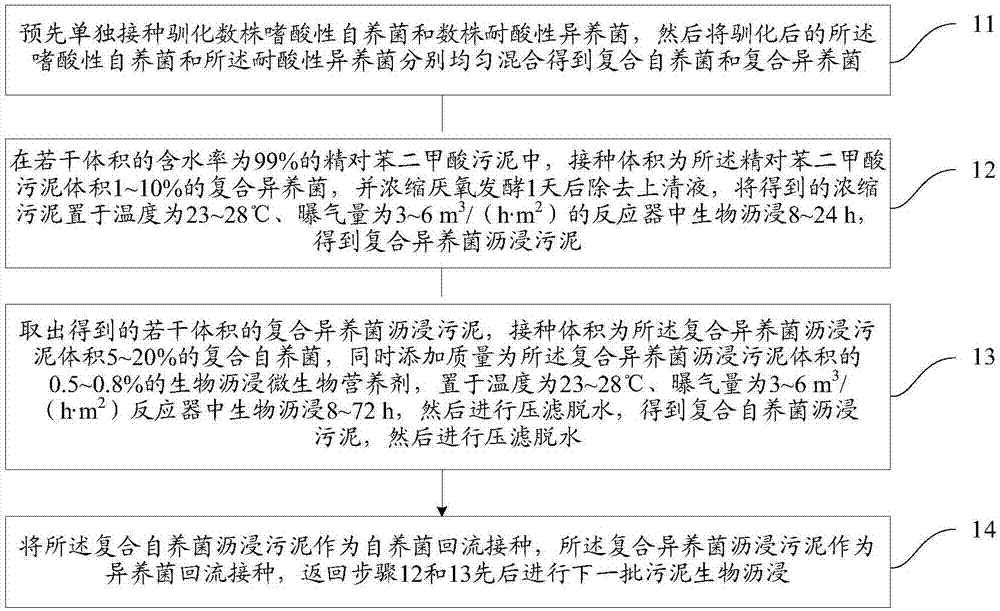

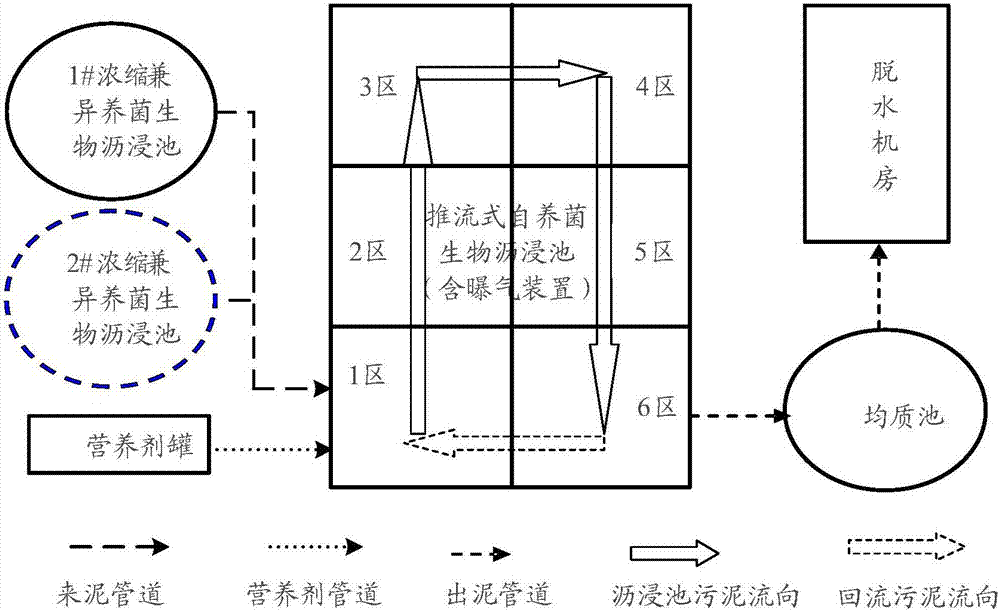

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] PTA (Pure Terephthalic Acid, PTA) is the most important raw material for the production of polyester, and polyester fiber (polyester) is the most important type of synthetic fiber, accounting for nearly 80% of the world's total synthetic fiber production. The deep dehydration of the sludge of this type of PTA wastewater is very important for the subsequent disposal of the sludge.

[0039] Bioleaching is a new sludge treatment technology that can remove heavy metals in the solid phase of sludge and significantly improve the settleability and dehydration of sludge (Zhou et al, 2005; Tyagi et al, 1998), It is generally used to treat municipal sludge. The specific resistance of municipal sludge is reduced by more than 80% after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com