Treatment method for phosphorus trichloride production wastewater

A technology for phosphorus trichloride and waste water production, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing the operating load of the biochemical treatment process, major safety risks and environmental risks, etc. To achieve the effect of convenient source of raw materials and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

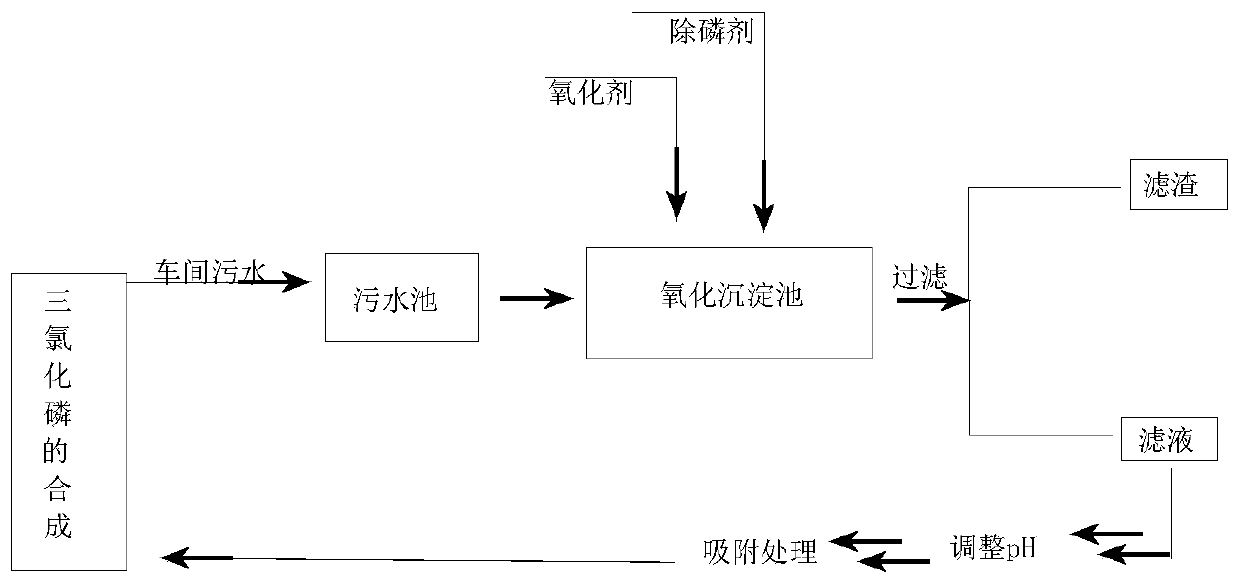

[0021] This embodiment discloses a treatment method for phosphorus trichloride production wastewater, combining figure 1 It can be seen that it includes getting 350g phosphorus-containing sewage and placing it in the oxidation sedimentation tank, wherein, the COD48mg / L and total phosphorus of this phosphorus-containing sewage are 2370mg / L; under normal temperature stirring state, add 15g calcium hypochlorite, after the reaction time 60min, Continue to add the phosphorus removal agent ferric chloride until no more precipitation occurs, filter, and the filter residue is used as a phosphate fertilizer, and the filtrate continues to be post-treated, specifically including adjusting the pH of the solution to about 7 with dilute sulfuric acid, and then adding polyaluminum chloride for further processing. The total phosphorus in the supernatant liquid obtained by adsorption and filtration of the water was measured by relevant chemical analysis methods, and the total phosphorus reached...

Embodiment 2

[0023] This embodiment discloses a method for treating wastewater from phosphorus trichloride production, which includes taking 250g of phosphorus-containing sewage and placing it in an oxidation sedimentation tank, wherein, the COD of the phosphorus-containing sewage is 45mg / L, and the total phosphorus is 2100mg / L; 18g of sodium hypochlorite is added under the condition of 60 minutes after the reaction time, continue to add the dephosphorization agent aluminum chloride until no more precipitation occurs, filter, the filter residue is precipitated and used as phosphate fertilizer, and the filtrate continues to be post-treated, specifically including the use of dilute sulfuric acid to adjust the pH of the solution To about 7, then add polyaluminum chloride and then further absorb and filter the clear liquid to measure its total phosphorus by relevant chemical analysis methods, reaching about 0.08mg / L. Analyzing the COD40mg / L in the supernatant, the total phosphorus removal rate ...

Embodiment 3

[0025] This embodiment discloses a method for treating waste water from phosphorus trichloride production, which includes taking 300g of phosphorus-containing sewage and placing it in an oxidation sedimentation tank, wherein, the COD of the phosphorus-containing sewage is 46 mg / L, and the total phosphorus is 2284 mg / L; stirring at room temperature Under the state, add 10g of chlorine gas, after 60 minutes of reaction time, continue to add phosphorus removal agent quicklime until no precipitation occurs, filter, the filter residue precipitates to be used as phosphate fertilizer, and the filtrate continues to be post-treated, specifically including using dilute sulfuric acid to adjust the pH of the solution to 7 After adding polyaluminum chloride, the clear liquid obtained by further adsorption and filtration was measured by relevant chemical analysis methods, and the total phosphorus reached about 0.06mg / L. The COD in the clear liquid was analyzed at 42mg / L, and the removal rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com