Roller and producing technique

A production process and roll technology, applied in the field of rolls and their production processes, can solve the problems of high production cost, high production difficulty, complicated process and the like, and achieve the effects of convenient operation, improved yield and reduced process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

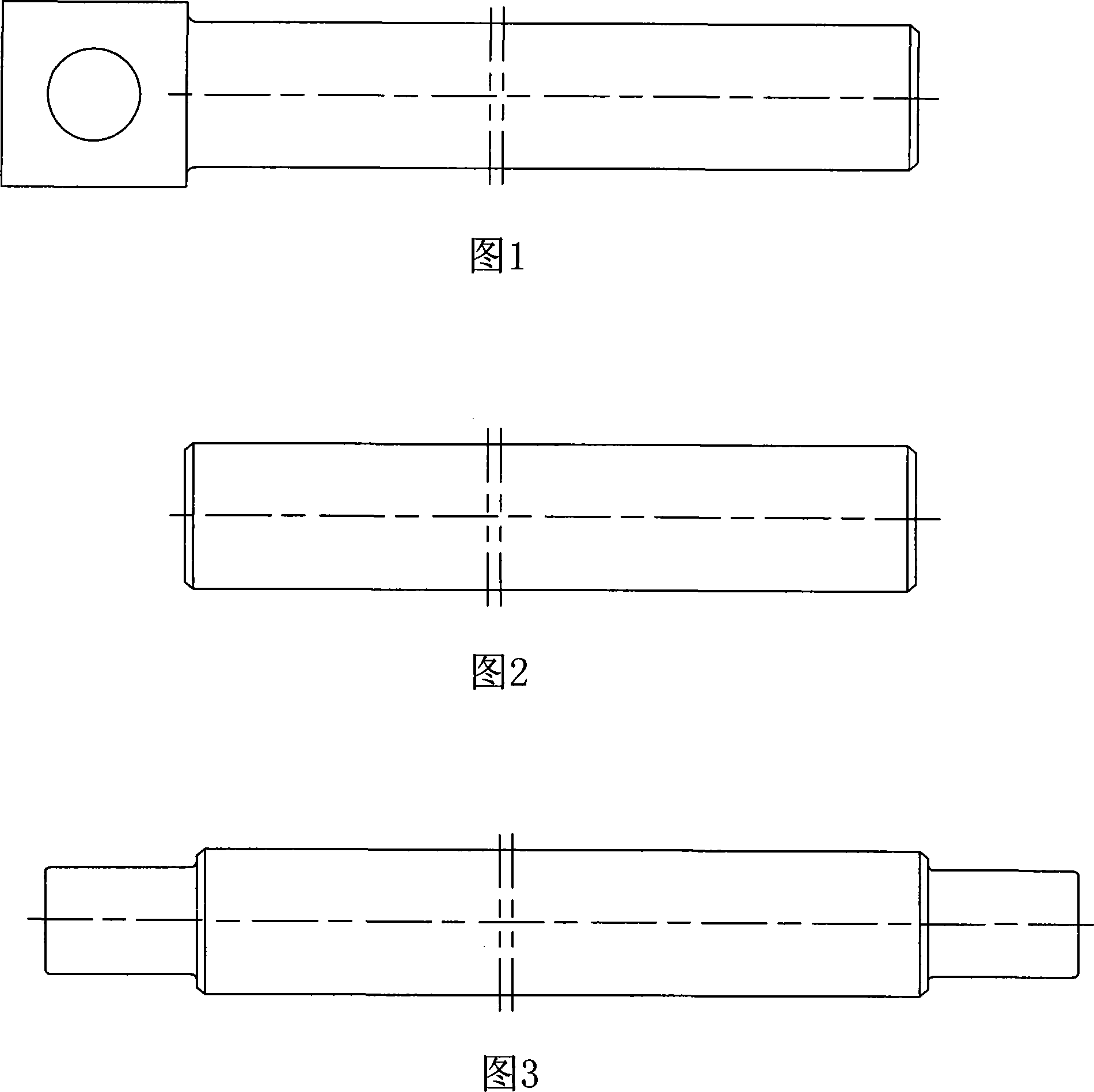

[0015] The following takes the production of rolls of Φ25mm×430mm×490mm as an example to illustrate the process of producing rolls in detail.

[0016] The roll material is W6Mo5Cr4V2 high-speed steel, and the specific production process steps are as follows: a. Select W6Mo5Cr4V2 round steel Φ40mm×540mm, so that the bending rate of the round steel is less than 0.006. For round steel pipes with a bending rate exceeding 0.006, they should be straightened and left for hoisting holes for processing b. Processing the two ends of the blank; c. Processing the center holes at both ends; d. Rough turning at both ends of the top (see Figure 1); e. Drilling the hoisting hole Φ20mm outside the length of the finished product; f. Quality treatment to make the hardness of the roller body reach 40-50HSD; g, modify the center holes at both ends; h, the two ends of the top, semi-finishing processing (see Figure 2); i, rough grinding the roller body to Φ27.5mm~Φ27. 6mm, and then carry out ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com