An Optimal Design Method for Mechatronic Control Integration

An optimized design, electromechanical technology, applied in the field of mechanical processing, can solve the problems of time-consuming and laborious, and achieve the effect of improving efficiency, good energy and good utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

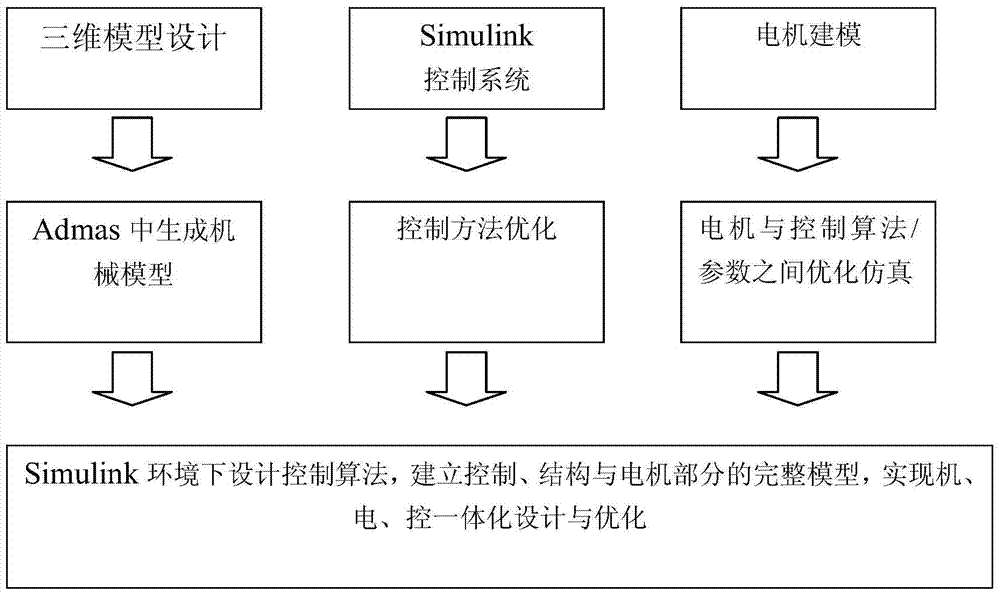

[0016] refer to figure 1 , the present invention comprises the following steps:

[0017] 1) First establish the electromechanical control model including mechanical structure model, motor model and control system model; establish the joint optimization method of mechanical structure physical parameters and control algorithm: firstly design the 3D model through Pro / E, Solidworks or other three-dimensional modeling software Then import the 3D model into the dynamics simulation software Adams, add constraints and drives to become a visualized multi-body dynamics model, and then import the model into Simulink to establish a mechanical mechanism model and a control system model; Simultaneously use Simulink Design the control algorithm and build the motor model.

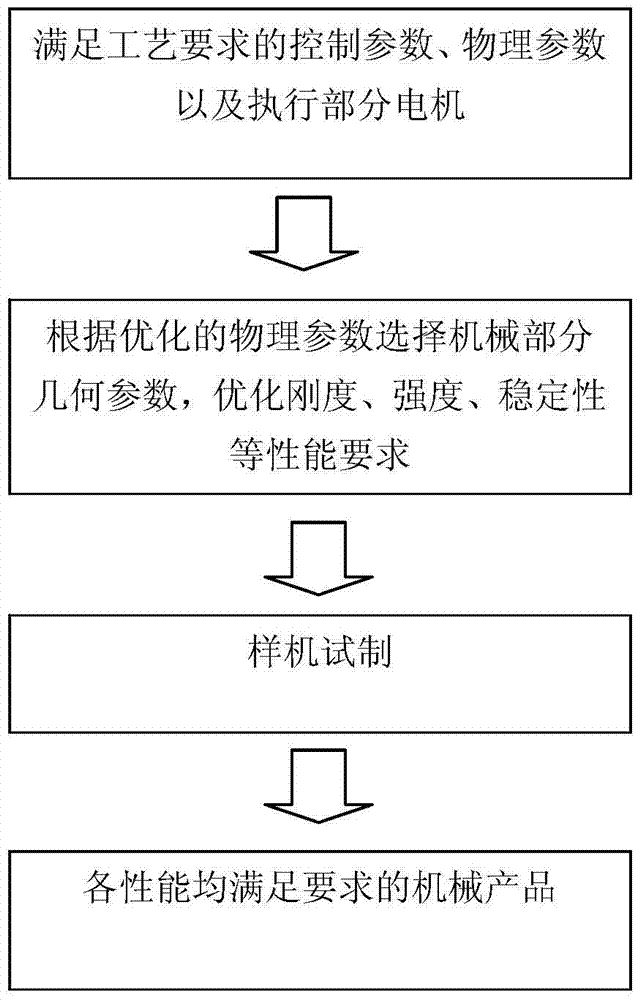

[0018] 2) Then optimize each physical parameter of the mechanical structure model and the control algorithm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com