Dry etching technology of monocrystalline silicon solar cells

A solar cell, dry etching technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the performance of the cell, non-conductivity, and large leakage current of the cell, so as to prevent over engraving or incomplete engraving effect of translucency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

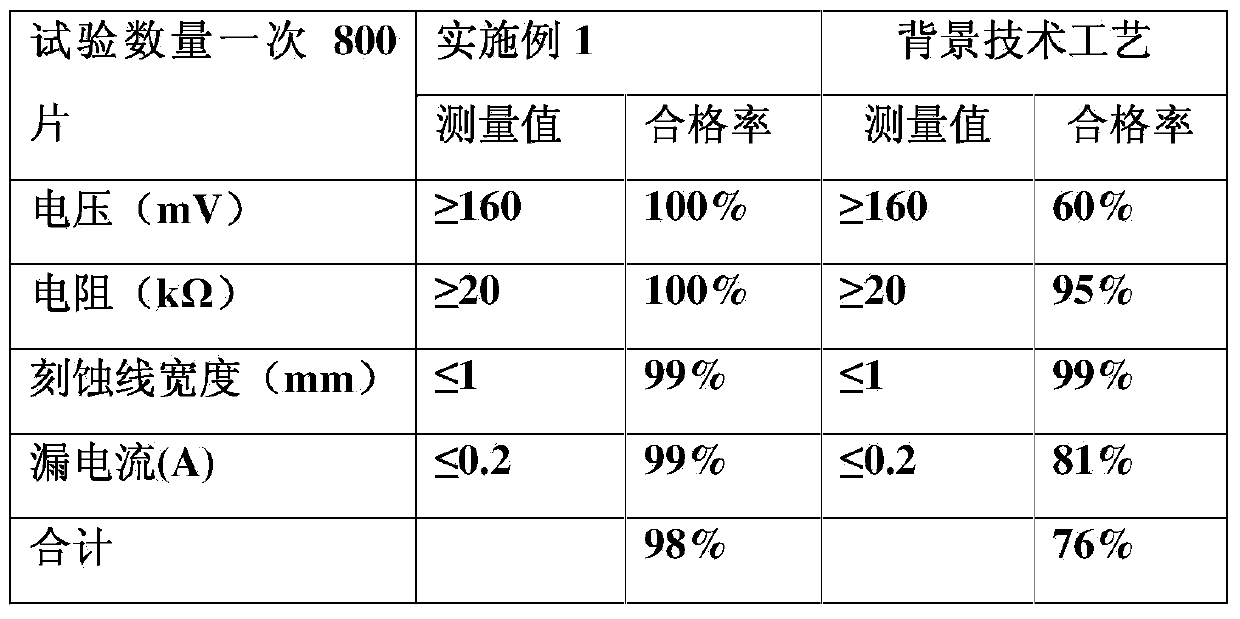

Embodiment 1

[0017] (1) Put the jig with the silicon wafer (125*125mm physical metallurgical method single crystal silicon wafer) into the cavity of the plasma etching machine. The equipment used is the plasma etching machine PRS of Taiwan Zhisheng Industrial Co., Ltd., Quantity 800 pieces. Of course, according to the actual situation, if there are less than 800 pieces, you can use fake pieces or PTFE gaskets instead;

[0018] (2) Vacuum until the pressure in the cavity is less than 60 psig;

[0019] (3) send gas, working gas CF 4 Flow 200sccm, O 2 The flow rate is 30sccm until the working pressure of 210psig is reached;

[0020] (4) Glow discharge, the control glow power is 800W, the reflected power is 20W, the speed is 12rpm, and the discharge time is 855s;

[0021] During glow discharge, the parent molecule CF 4 Under the impact of high-energy electrons, it is decomposed into a variety of neutral groups or ions, CF 4 、CF 3 、CF 2 , CF, F, C and their ions. Secondly, these active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com