Patents

Literature

64 results about "O2 plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CVD oxide surface pre-conditioning by inductively coupled O2 plasma

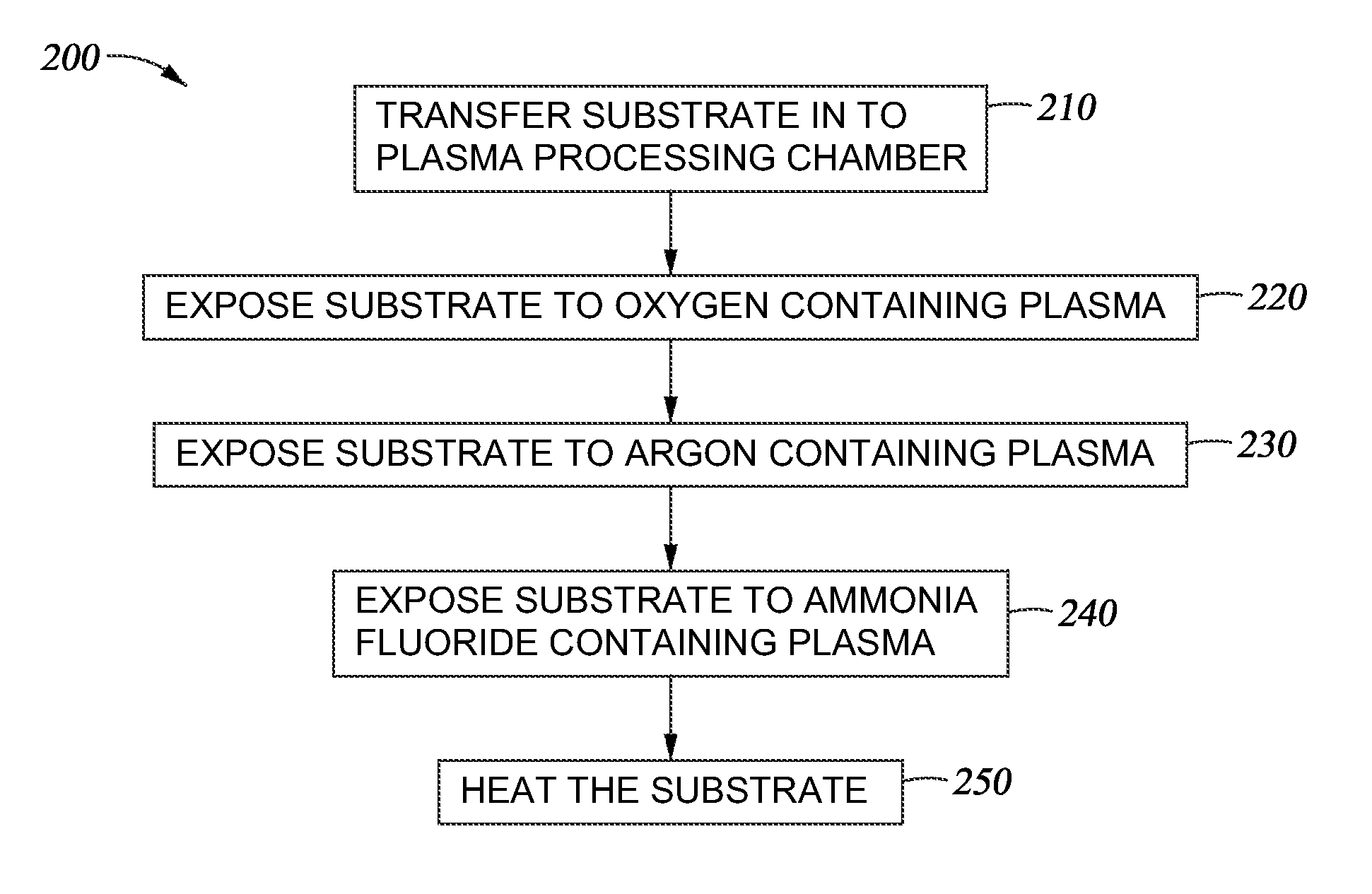

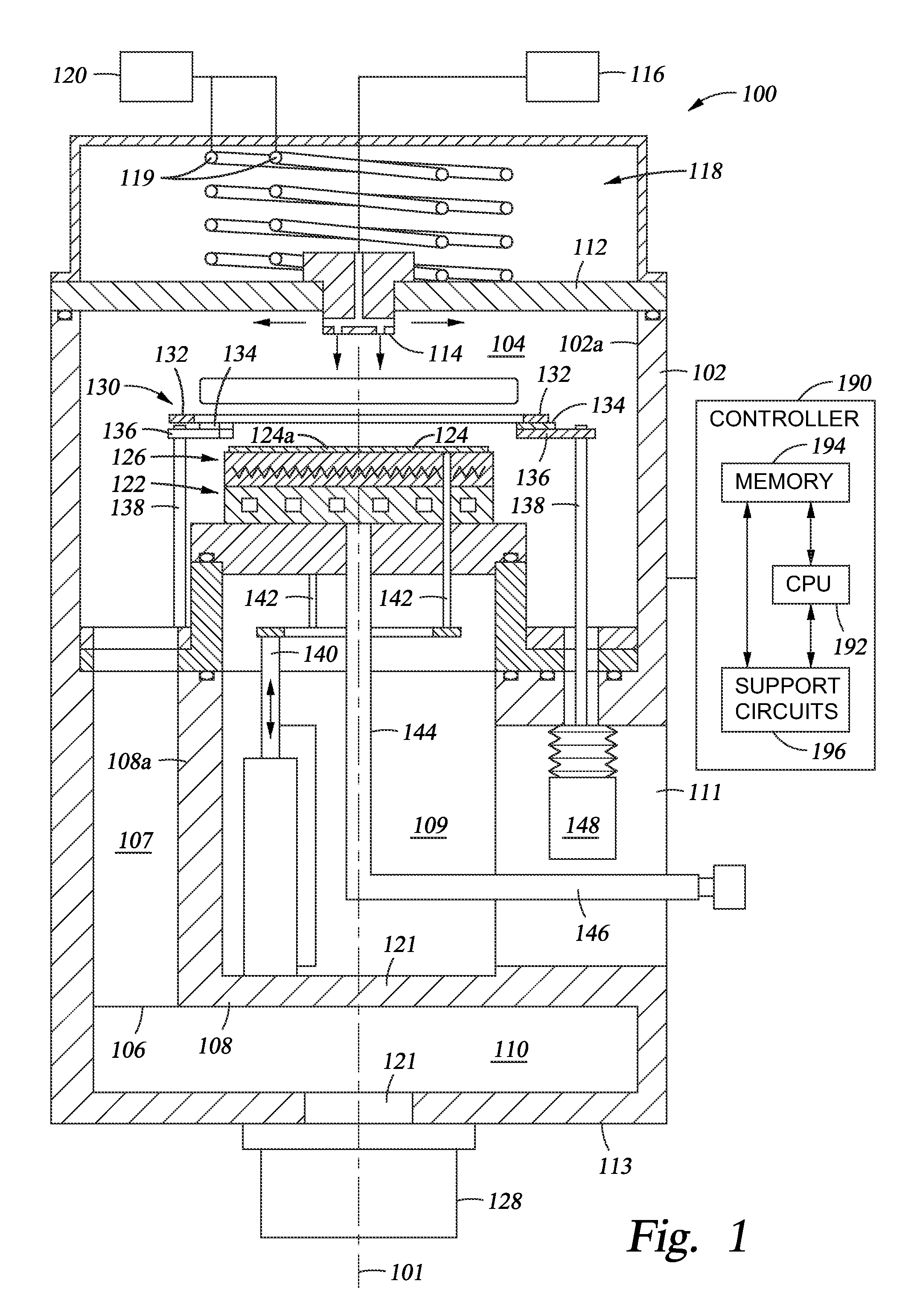

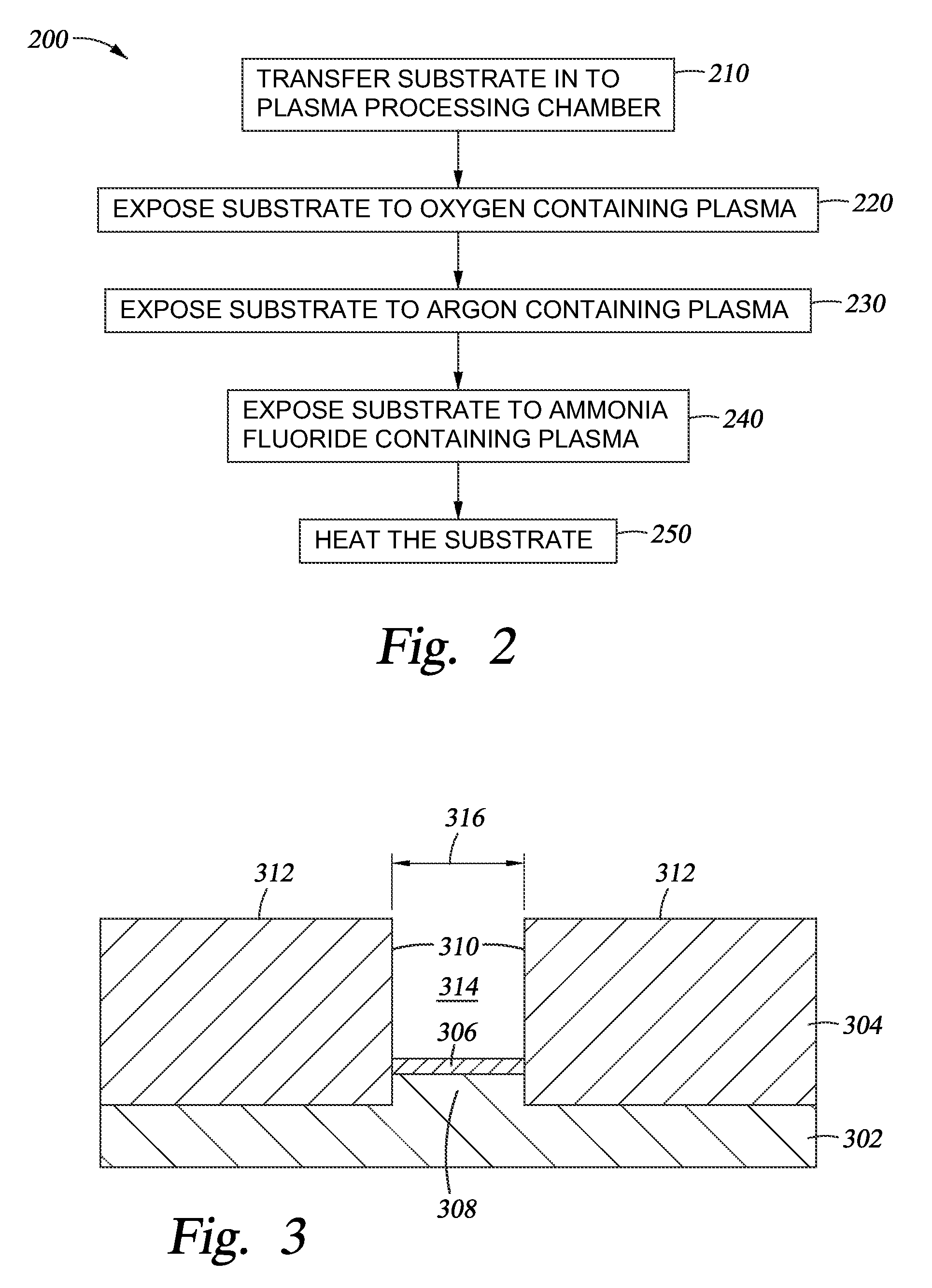

A method and apparatus for conditioning an oxide surface during a semiconductor device formation process is provided herein. One or more plasma processing operations are performed on a substrate having a fin structure and shallow trench isolation structure (STI) formed thereon. An oxygen containing plasma process may modify surfaces of the STI structure in preparation for an argon containing plasma process. The argon containing plasma process may form a first layer on the fin structure and STI structure and an ammonia fluoride containing plasma process may form a second layer on the first layer. The first and second layers may be removed from the substrate during a subsequent heating process to provide a cleaned fin structure suitable for subsequent processing operations.

Owner:APPLIED MATERIALS INC

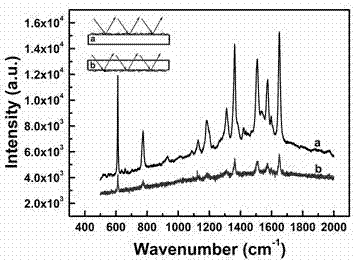

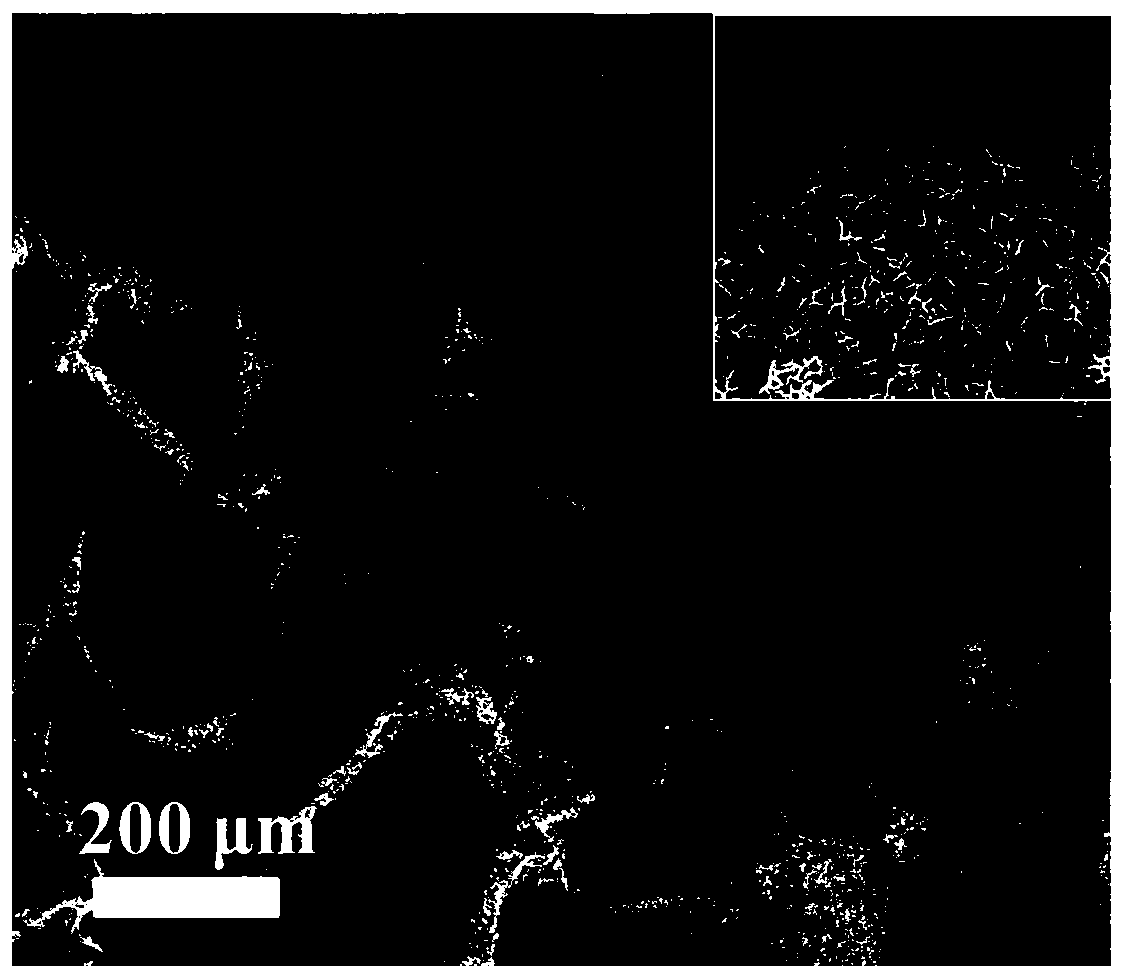

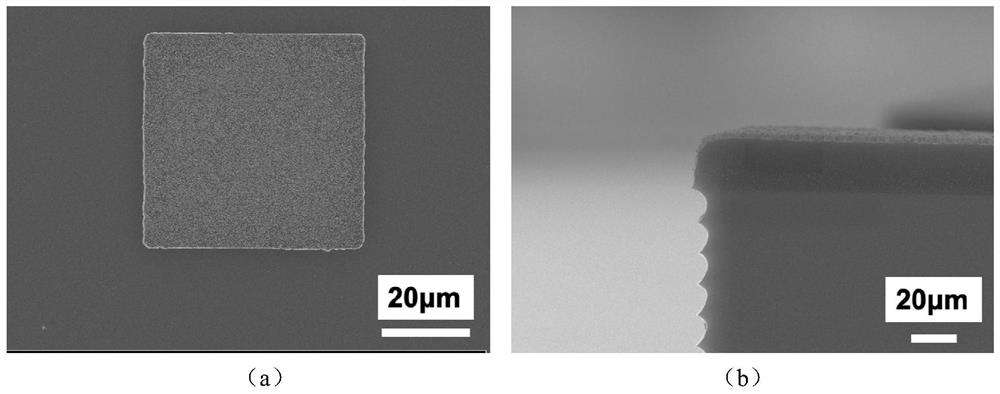

Transparent flexible surface enhanced Raman active substrate and preparation method thereof

The invention discloses a transparent flexible surface enhanced Raman active substrate and a preparation method thereof. The preparation method of the substrate comprises the following steps: taking a transparent flexible material such as polybutylene terephthalate (PET) plastics as a substrate, performing O2 plasma etching to form a nano wire array, loading gold, silver and other precious metal nanoparticles on the nano wire surface by virtue of a coating technology, and forming a three-dimensional nanometer structure array. The transparent flexible surface enhanced Raman active substrate provided by the invention is uniform in morphology and controllable in structure and has high-density electromagnetic hot spots in three-dimensional distribution. Therefore, the substrate has high sensitivity and reproducibility. The PET plastic film is high in flexibility and high in transparency, and incident laser and Raman scattered light easily penetrate through the substrate at low loss, so that the substrate can be used for in-situ detection of to-be-detected objects. The preparation method provided by the invention is simple in process, large-area preparation is easily realized, even roll-to-roll production process is permitted, and the cost is low.

Owner:ANHUI NORMAL UNIV

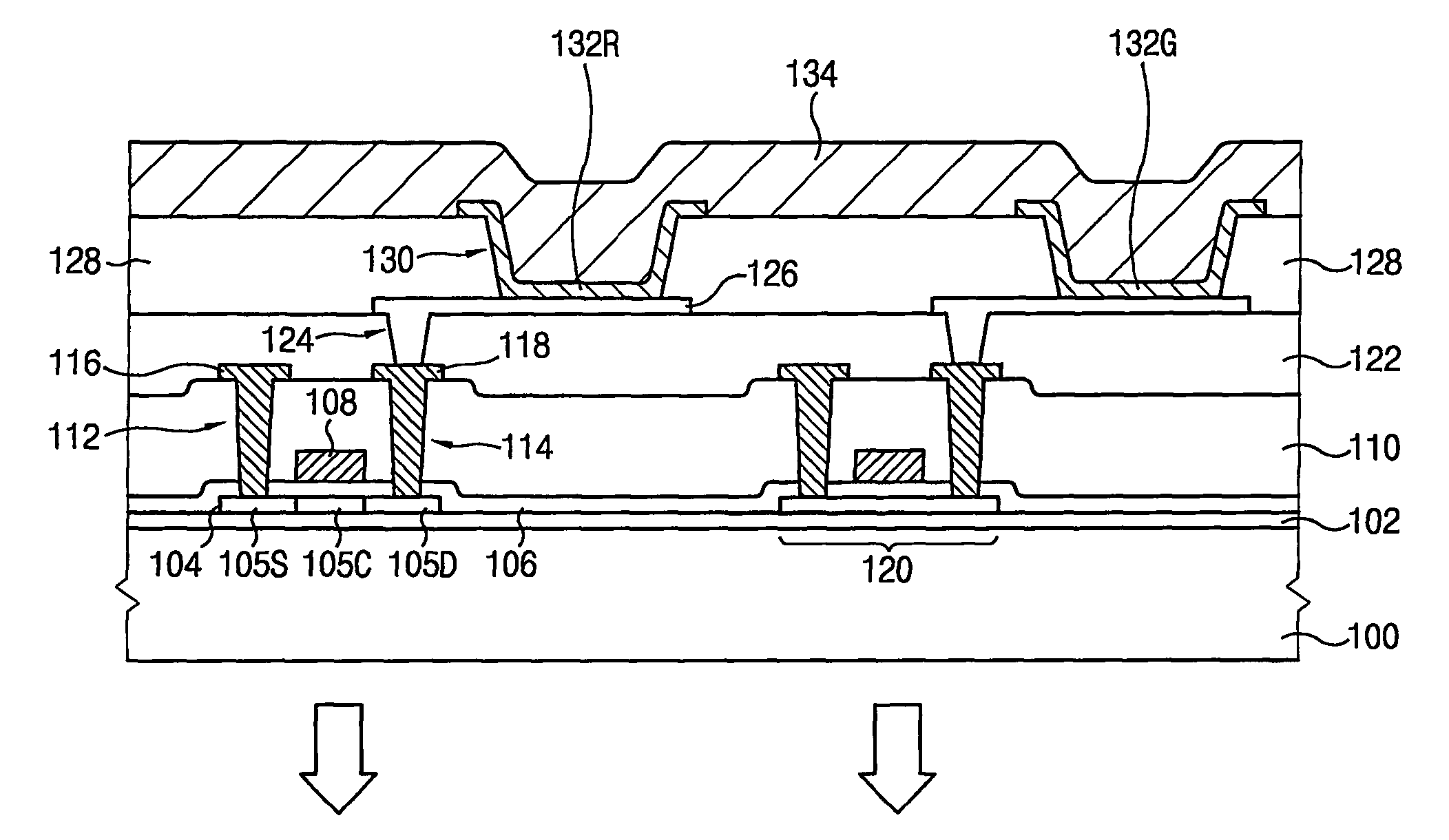

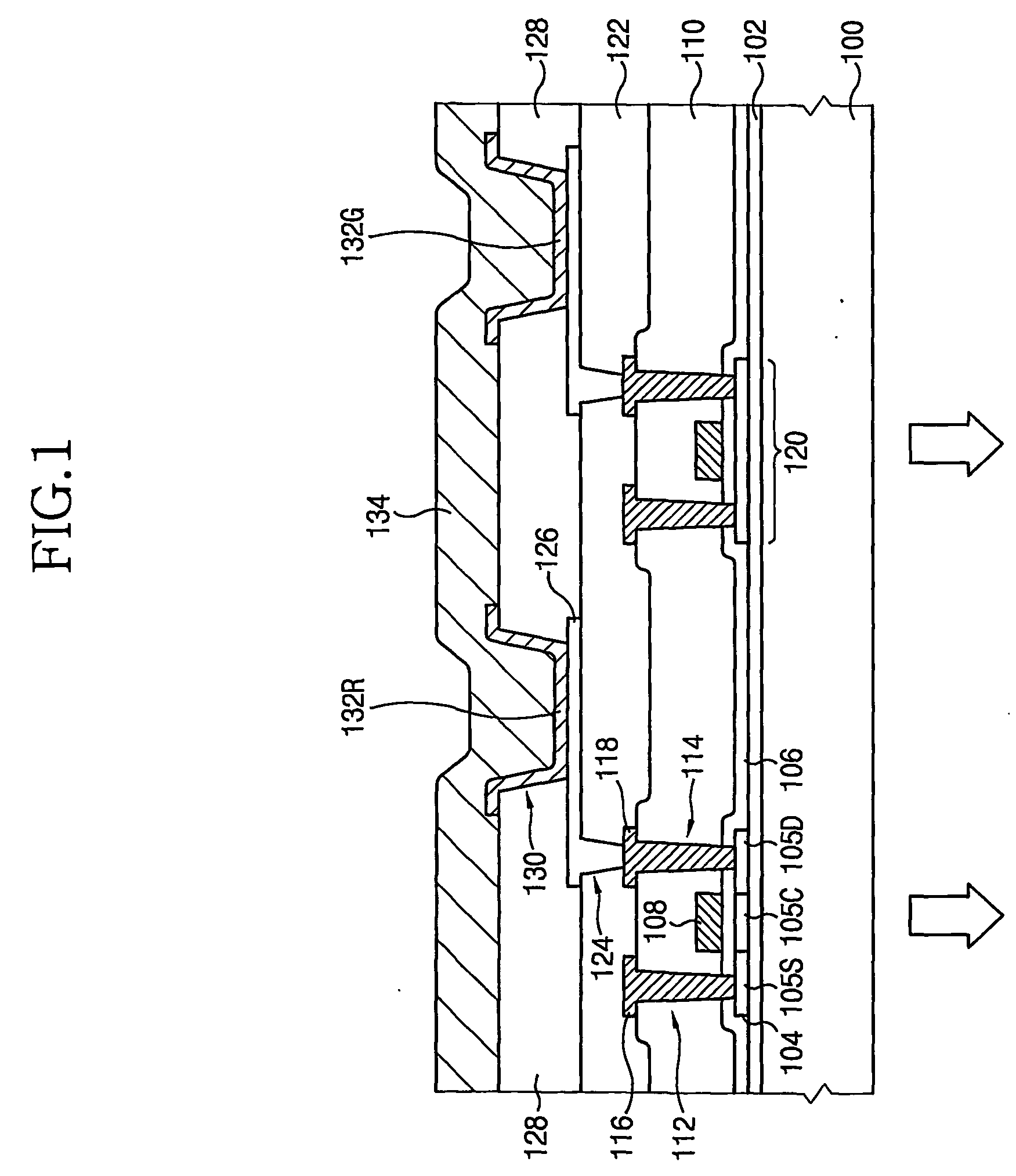

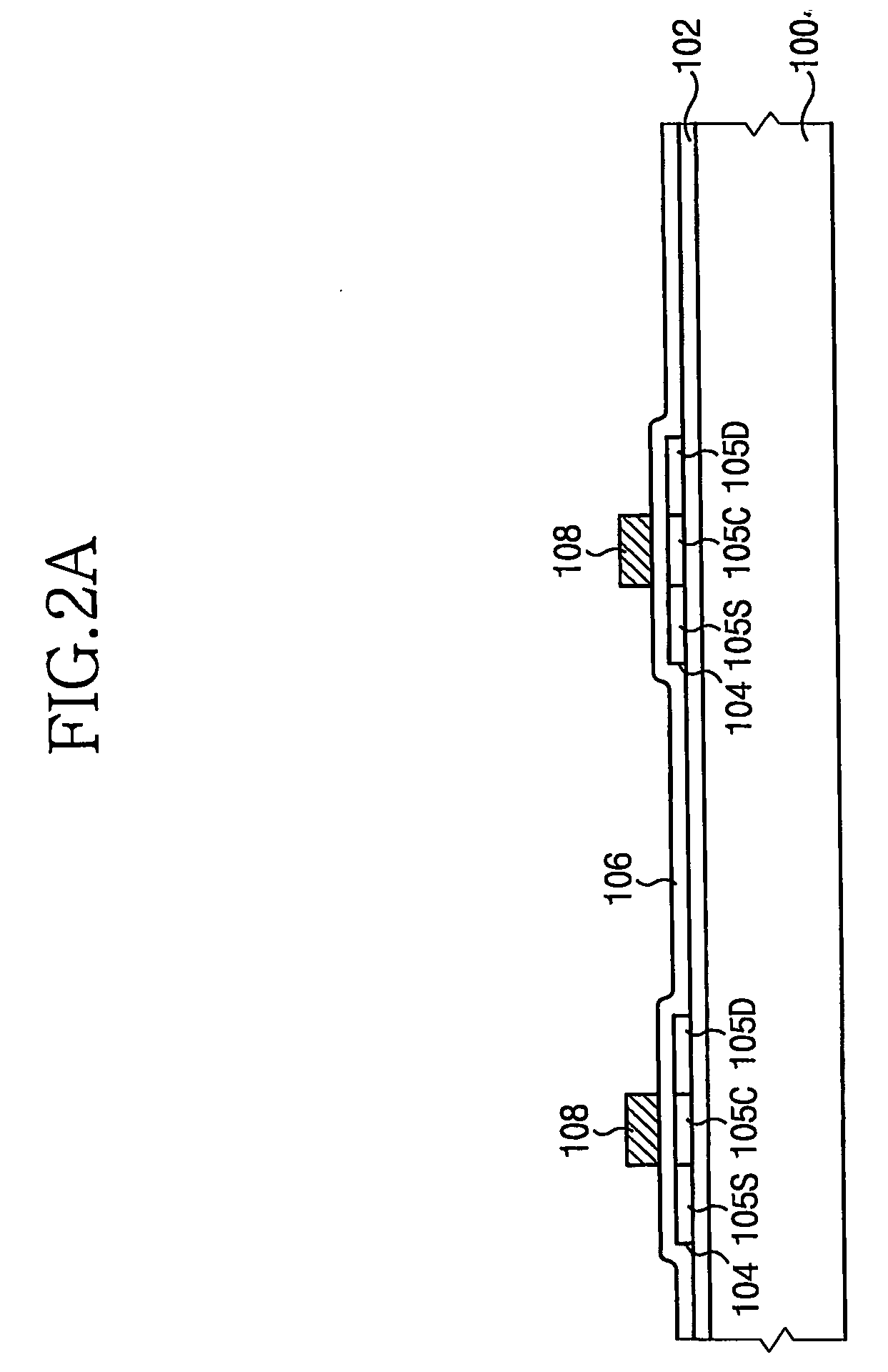

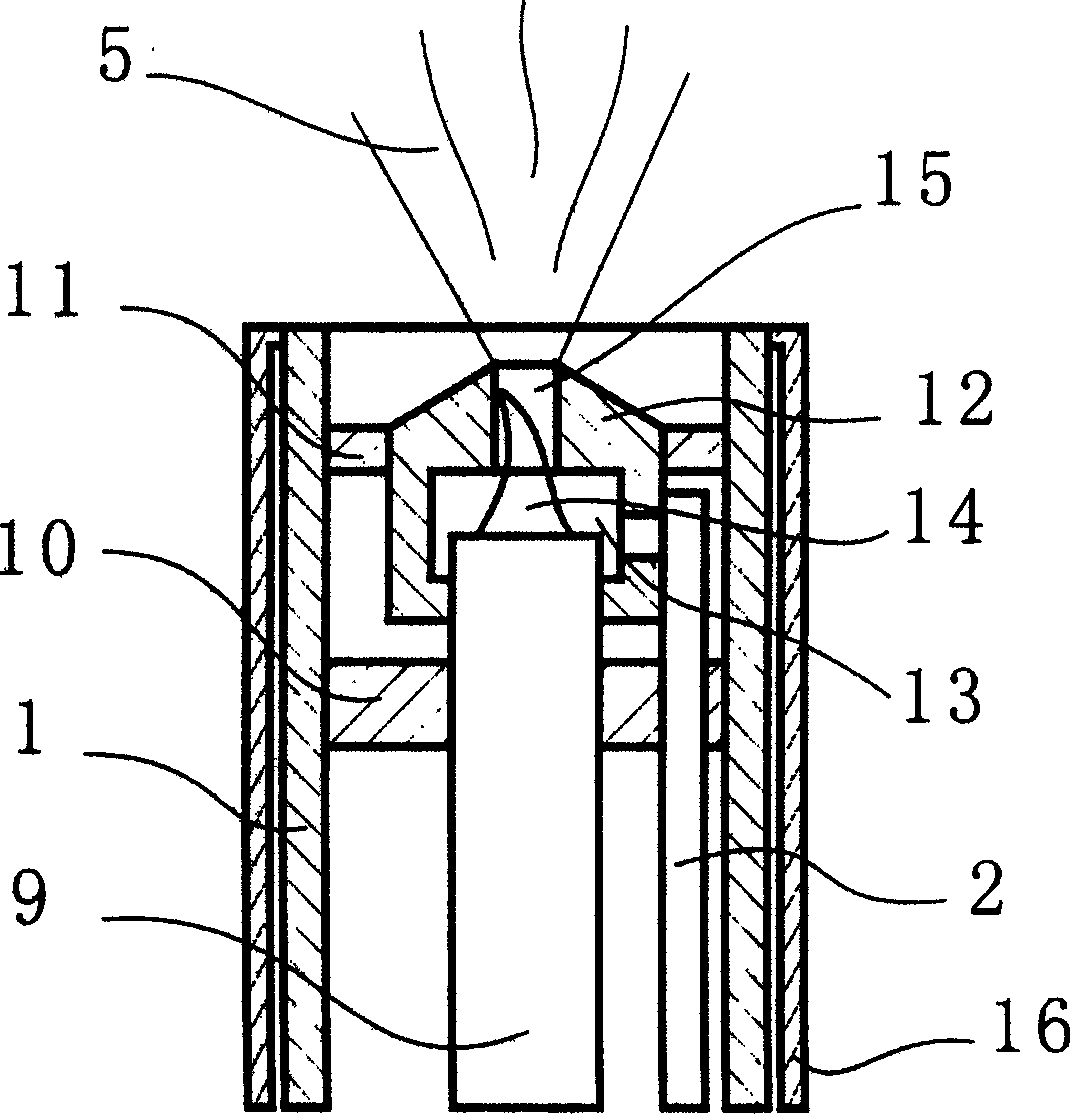

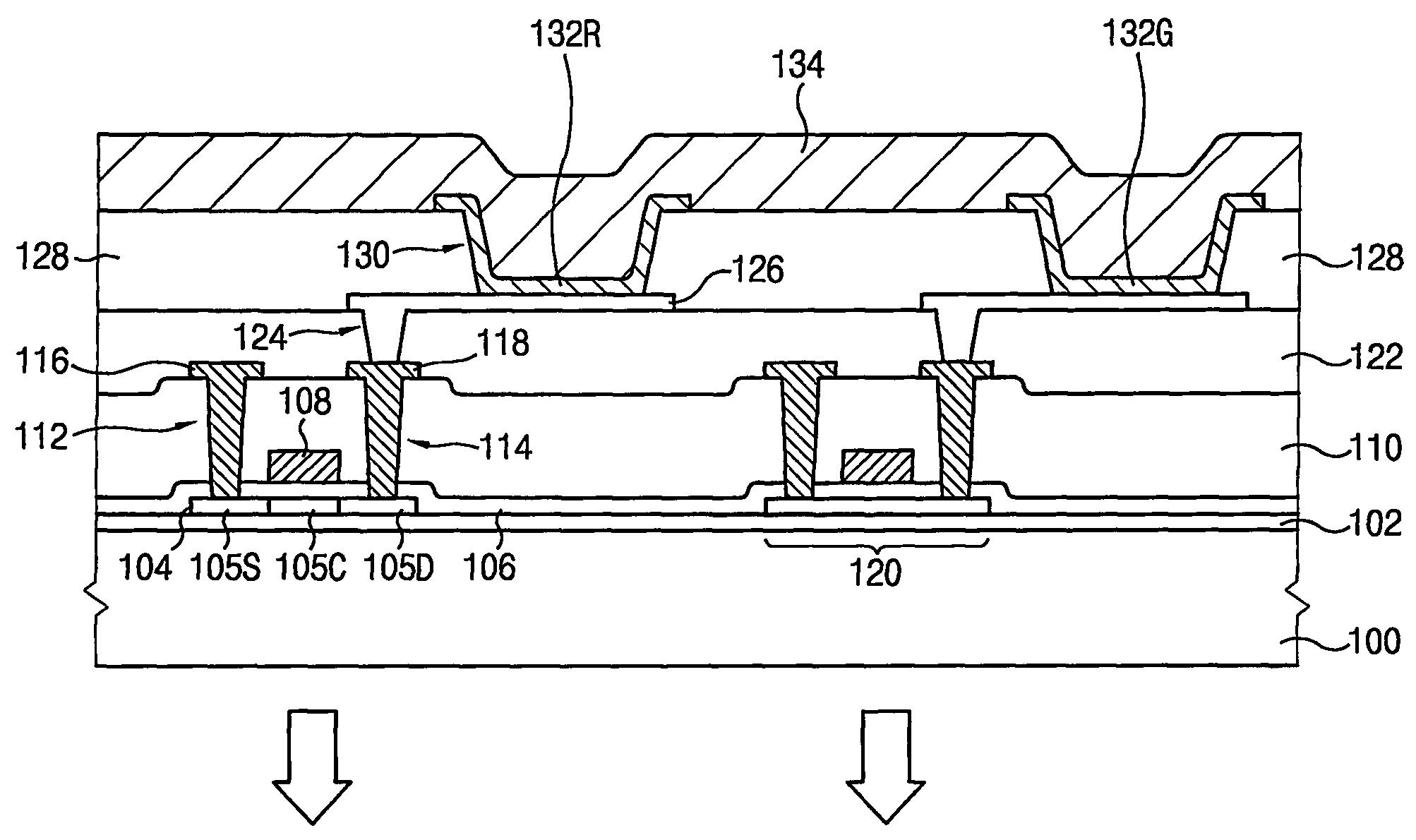

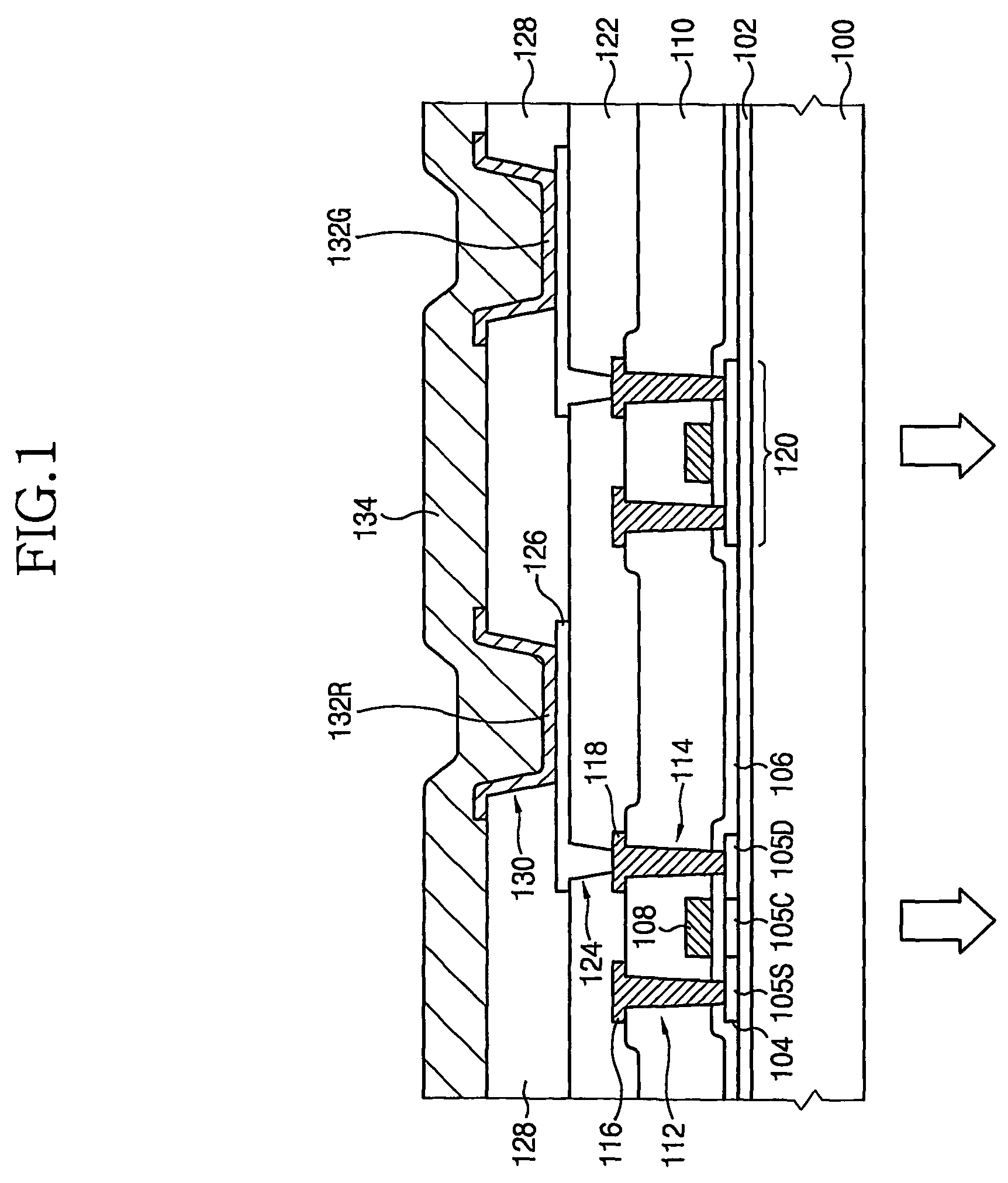

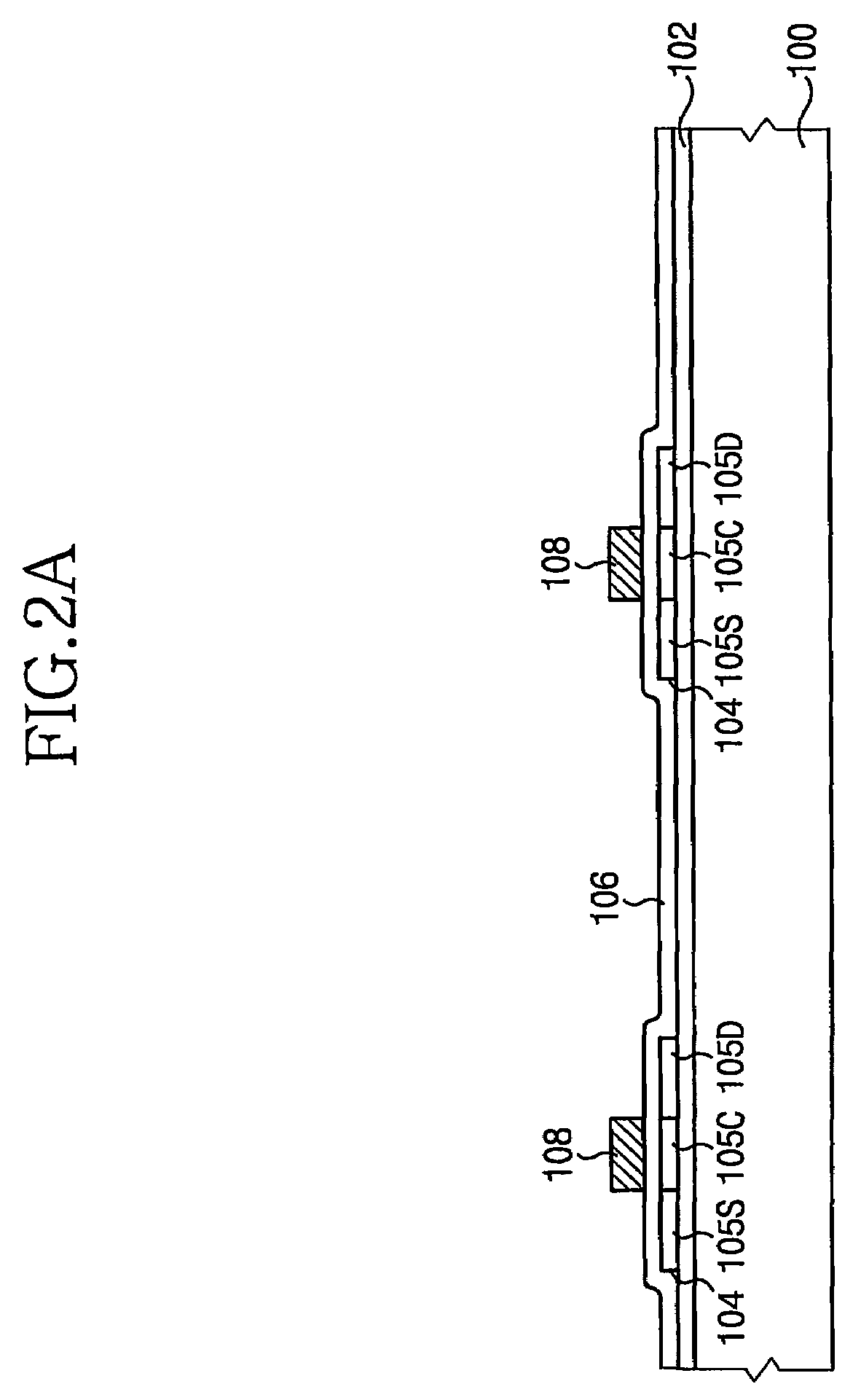

Organic electroluminescent device

InactiveUS20050242714A1Solve low luminous efficiencyExcellent luminous propertiesDischarge tube luminescnet screensElectroluminescent light sourcesO2 plasmaOrganic electroluminescence

Disclosed is an organic electroluminescent (EL) device for enhancing the luminous efficiency. A first electrode is formed on a substrate. A CVD insulating film of low dielectric constant having an opening exposing the first electrode is formed on the first electrode and the substrate. An organic EL layer and a second electrode are sequentially stacked on the opening. A wall surrounding a region of the organic EL layer is formed of the CVD insulating film of low dielectric constant, the surface treatment of the pixel electrode can be performed using O2 plasma to thereby enhance luminance properties.

Owner:SAMSUNG DISPLAY CO LTD

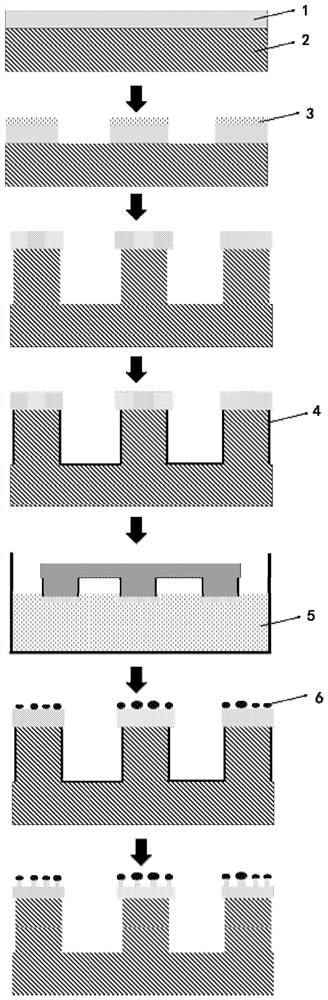

Manufacturing method of infrared detector based on temporary release protective layer

ActiveCN102683475APerformance impactDoes not directly affect the structureFinal product manufactureSemiconductor devicesCMOSO2 plasma

The invention discloses a surface micromachining method for a microelectromechanical system based on a temporary release protective layer and particularly relates to a manufacturing method of an uncooled infrared detector. The manufacturing method comprises the following steps of: sequentially depositing a metal layer, an amorphous silicon sacrificial layer, a first temporary release protective layer of polyimide on a CMOS (complentary metal-oxide-semiconductor transistor) silicon substrate; manufacturing a sensitive layer and a metal electrode layer in a cascading way, and imaging the sensitive layer, the electrode layer and a microbridge structure; and finally manufacturing a second temporary release protective layer. When the sacrificial layer is released, firstly XeF2 is adopted for releasing the amorphous silicon sacrificial layer, and then O2 plasma is utilized for removing the temporary release protective layers after the release is completed. According to the manufacturing method of the infrared detector provided by the invention, compared with the prior art, the adopted temporary release protective layers are completely removed in the later period of manufacturing, thus not causing any influence on the microbridge performance, and being beneficial to the reduction of process difficulty and improvement of the performance of the detector.

Owner:ZHEJIANG DALI TECH

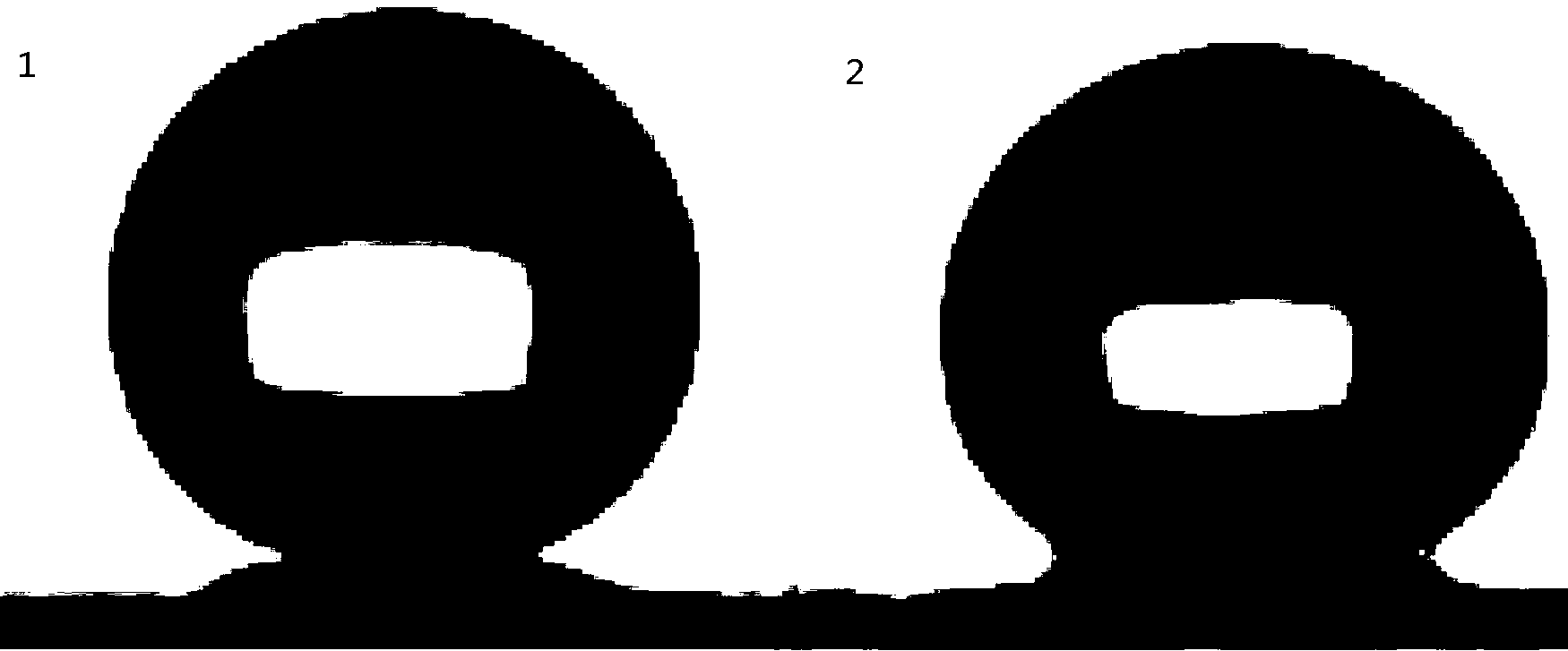

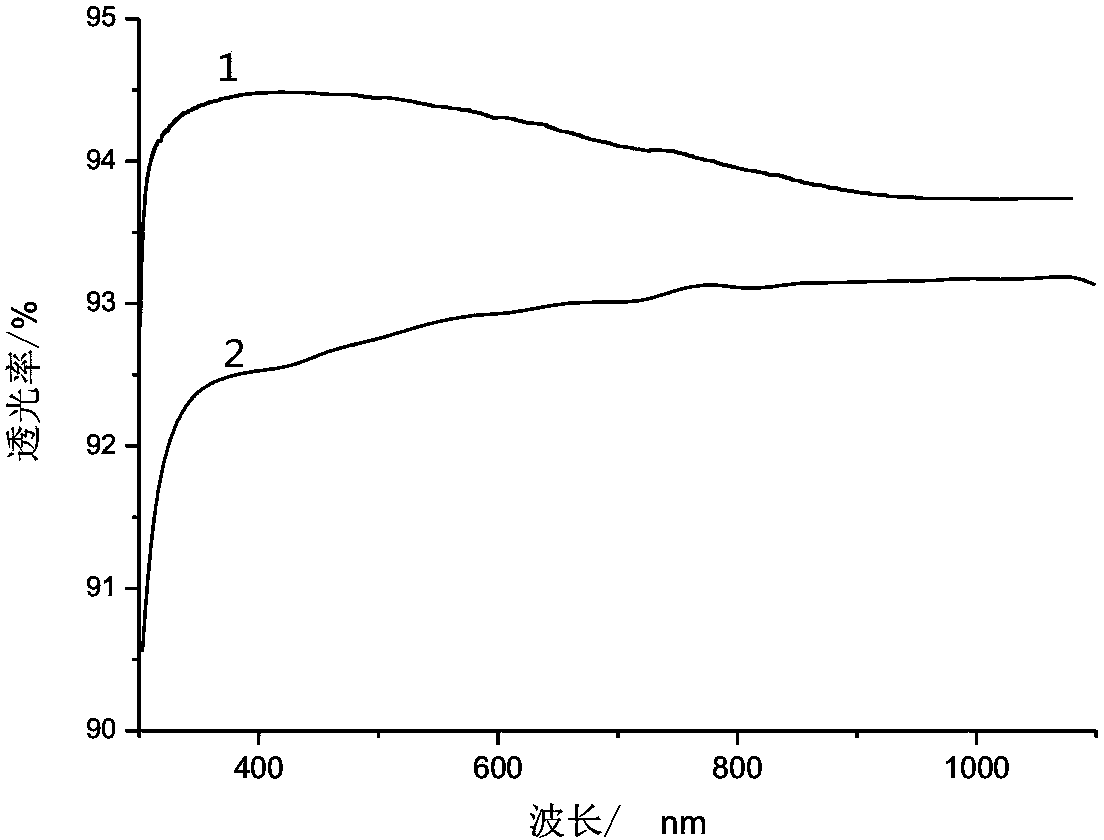

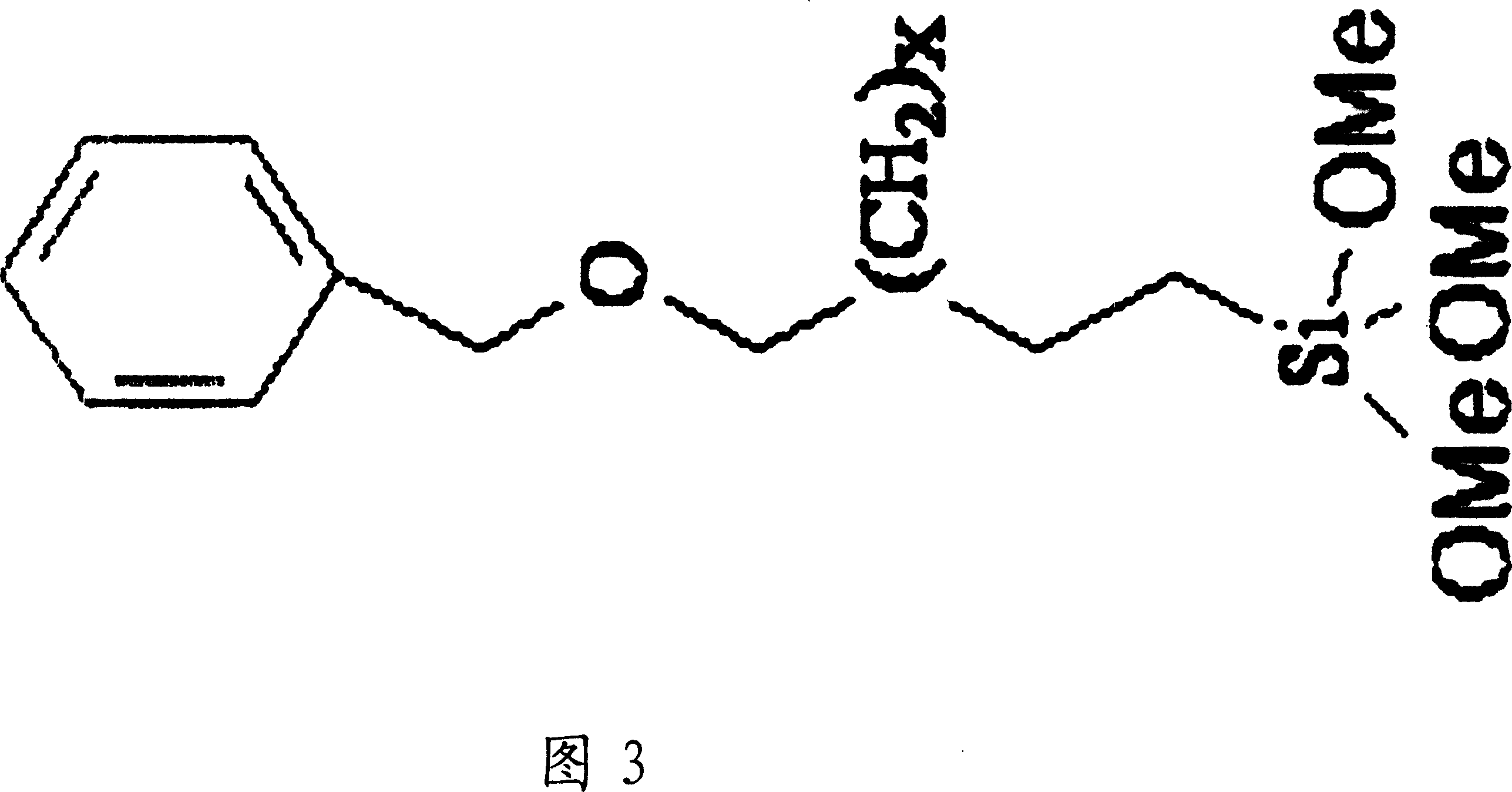

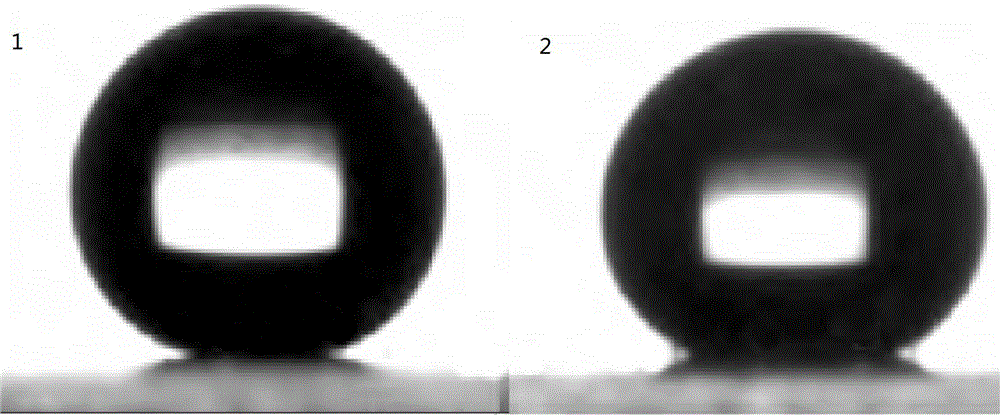

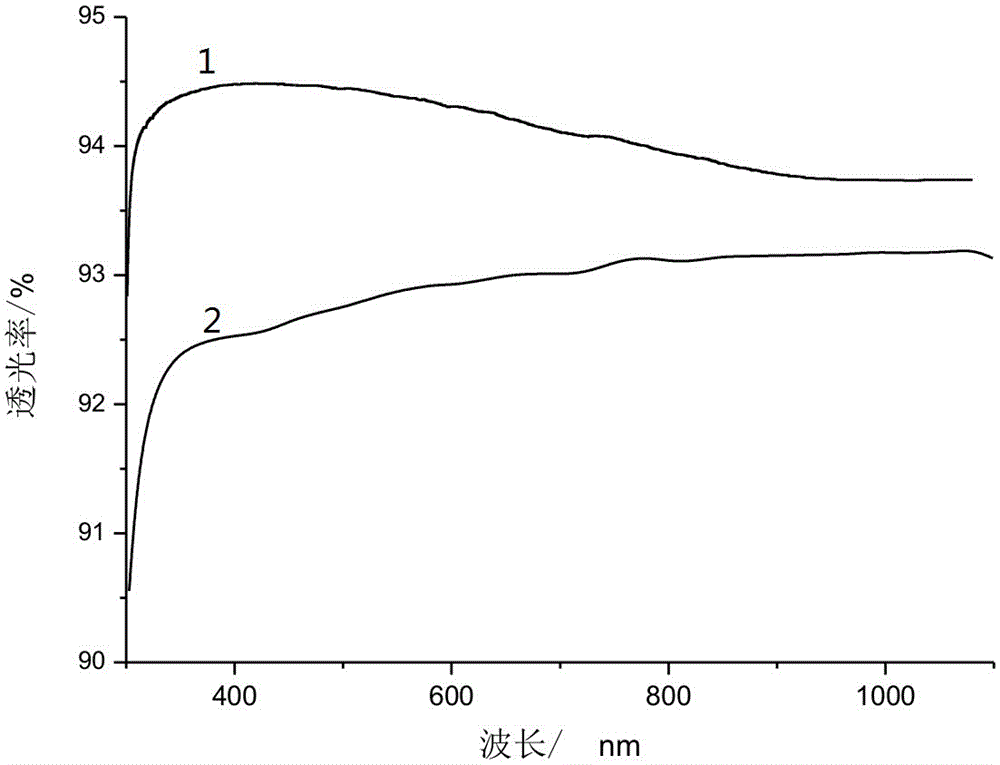

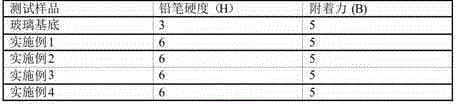

Super-hydrophobic super-oleophobic anti-reflection glass surface layer and preparation method thereof

The invention discloses a super-hydrophobic super-oleophobic anti-reflection glass surface layer and a preparation method thereof, which belong to the field of novel materials and particularly belong to the field of self-cleaning optical materials. The preparation method comprises the following steps: firstly, etching the surface of a glass body by CF3 / O2 plasma to construct a submicron coarse structure; secondly, chemically bonding a SiO2 nano porous layer; adjusting the space packing factor by means of adding a pore-foaming agent so as to construct a double-stage coarse glass surface with a suspended structure; and finally fluoridizing for modification so as to reduce surface free energy. The obtained glass surface layer achieves super-hydrophobic and super-oleophobic self-cleaning standards and has excellent light transmission. As the lower layer submicron structure in a micro-nano composite structure required by super-amphiphobic performance is directly constructed from the glass body and then a nano porous layer is chemically bonded, so that the double-layer loose structure in the prior art is avoided and the mechanical strength of the surface layer is enhanced greatly; the glass surface is high in stability and excellent in durability, thereby having significant practical application value.

Owner:JIANGNAN UNIV

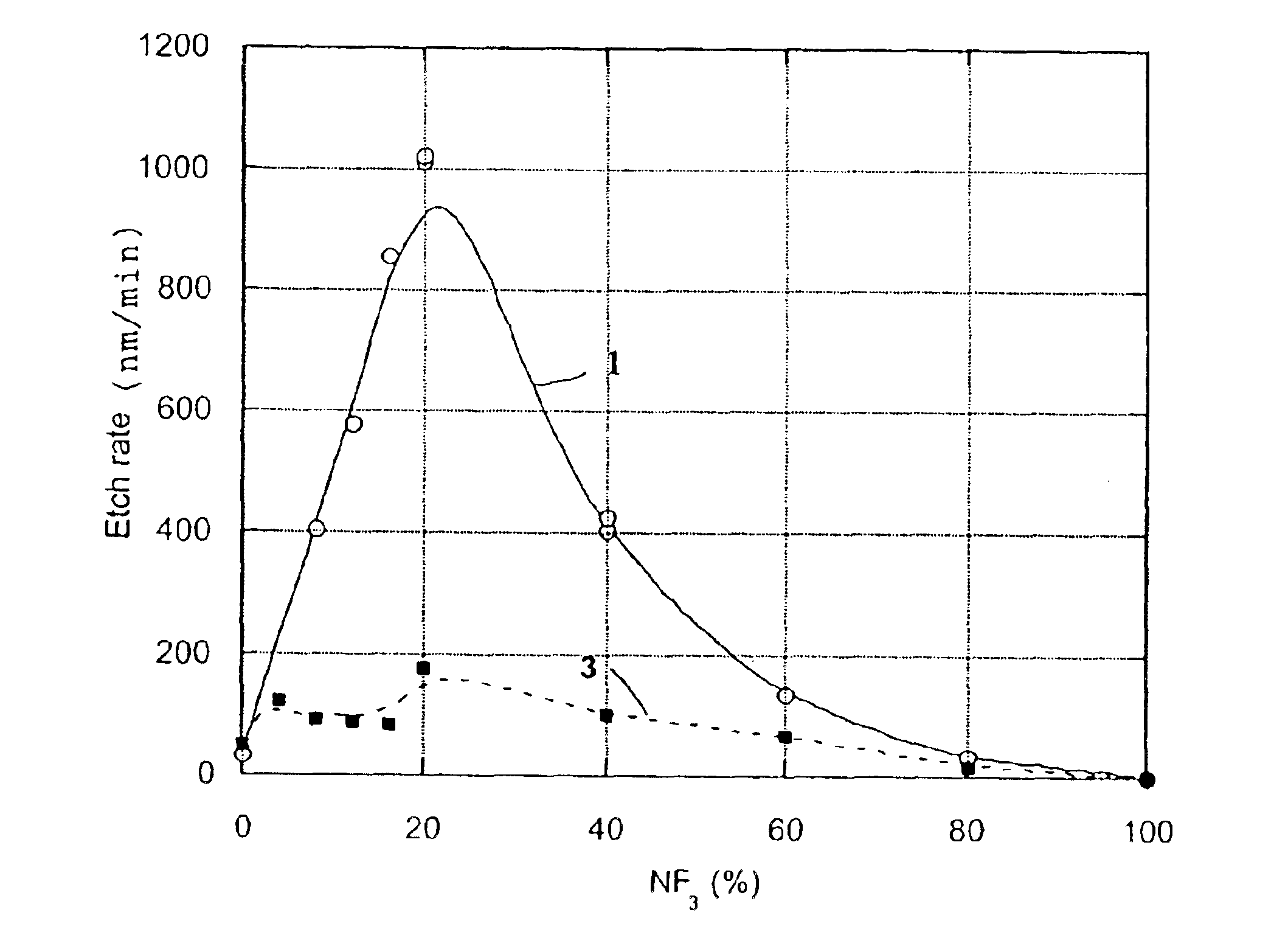

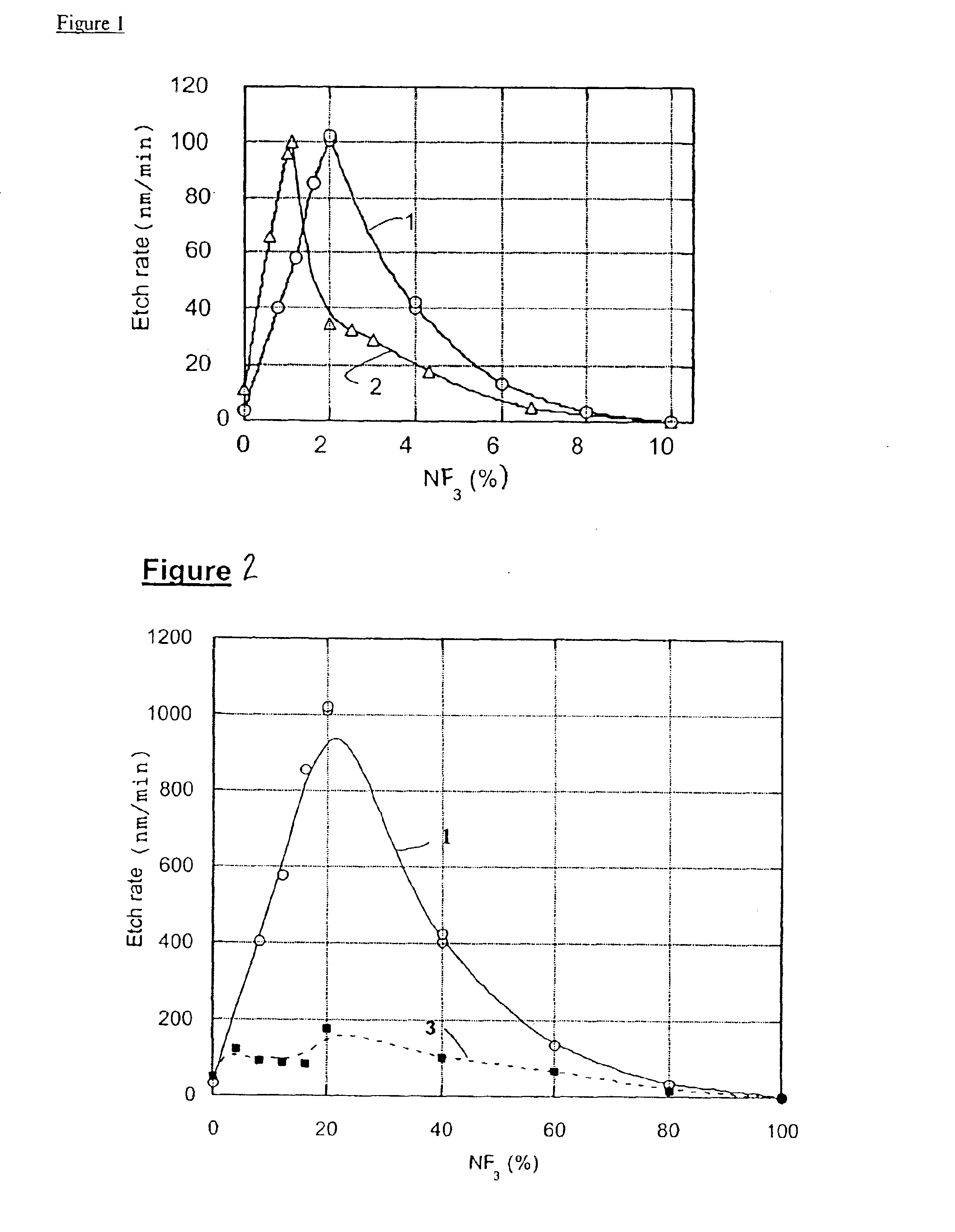

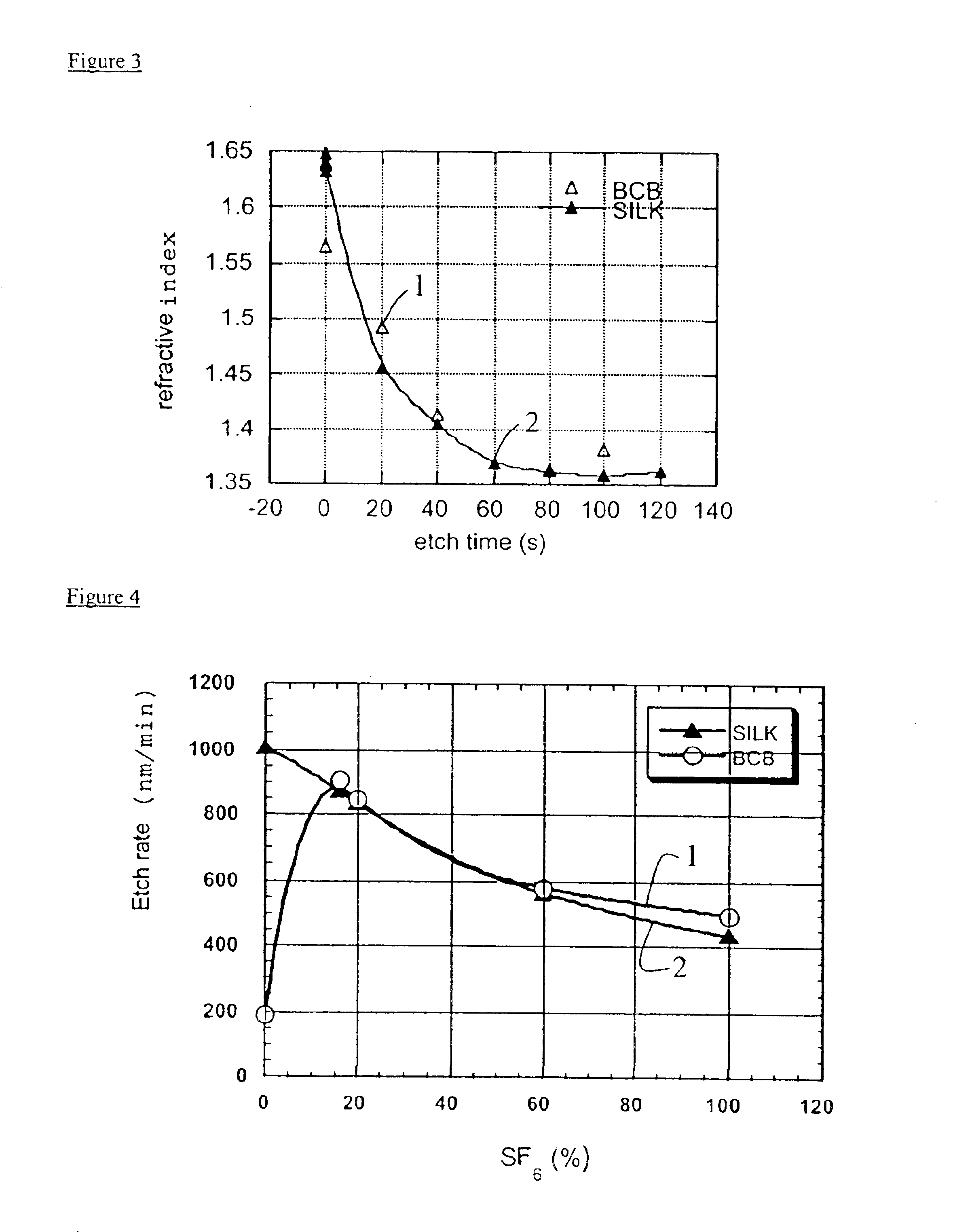

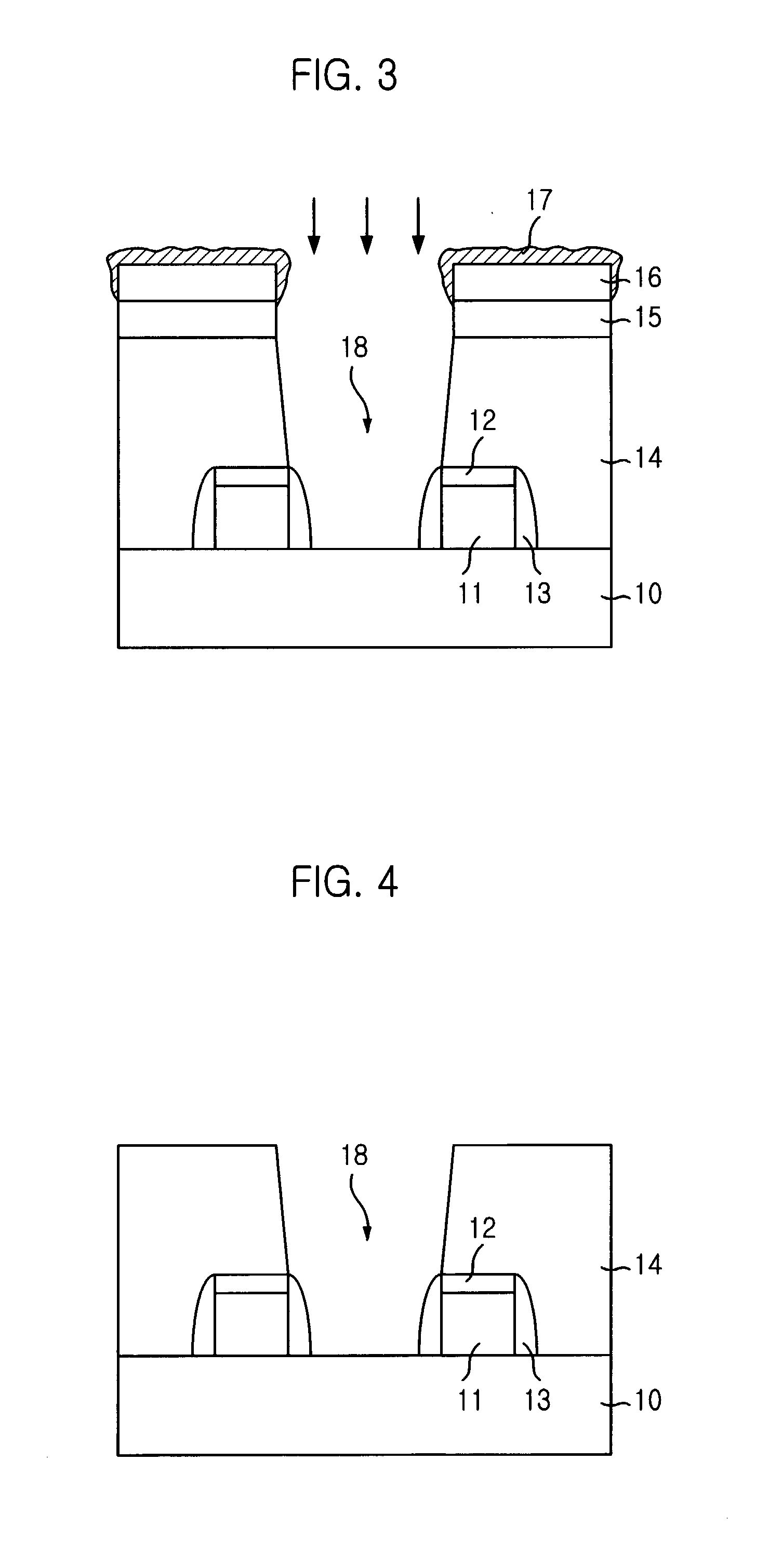

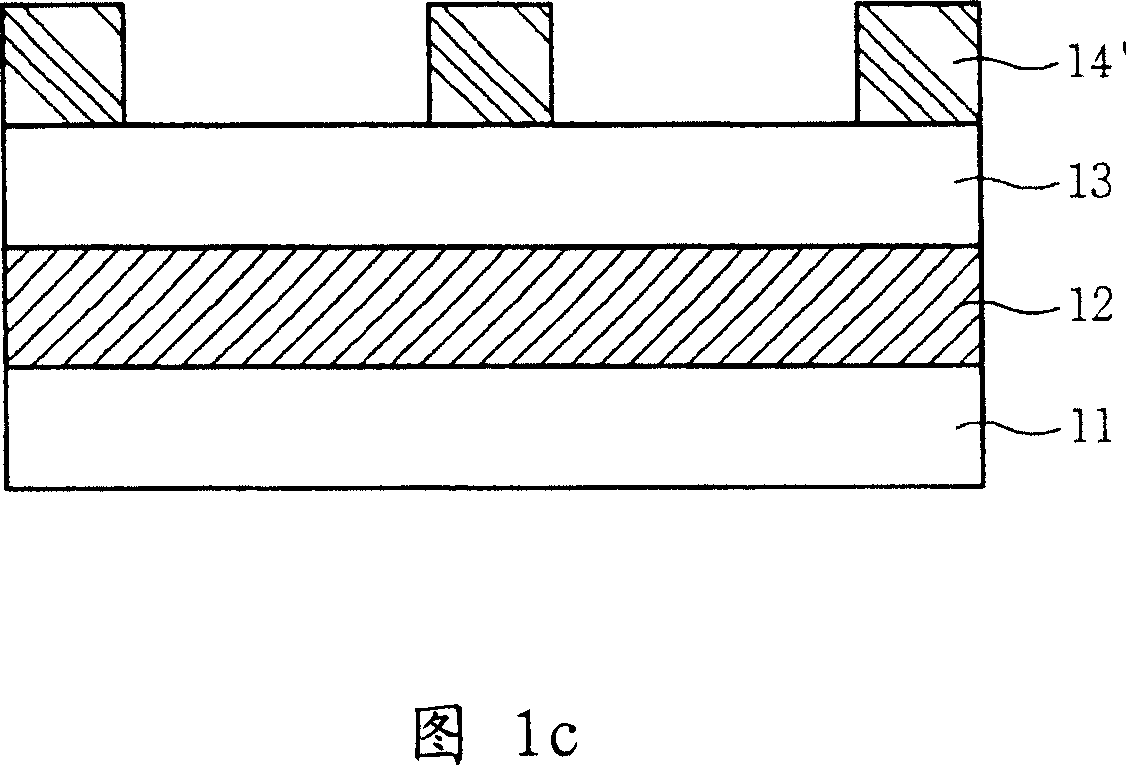

Anisotropic etching of organic-containing insulating layers

InactiveUS6844266B2Increase etch rateElectrostatic cleaningSemiconductor/solid-state device manufacturingResistO2 plasma

A method for anisotropic plasma etching of organic-containing insulating layers is disclosed. According to this method at least one opening is created in an organic-containing insulating layer formed on a substrate. These openings are created substantially without depositing etch residues by plasma etching said insulating layer in a reaction chamber containing a gaseous mixture which is composed such that the plasma etching is highly anisotropic. Examples of such gaseous mixtures are a gaseous mixture comprising a fluorine-containing gas and an inert gas, or a gaseous mixture comprising an oxygen-containing gas and an inert gas, or a gaseous mixture comprising HBr and an additive. The plasma etching of the organic-containing insulating layer can be performed using a patterned bilayer as an etch mask, said bilayer comprising a hard mask layer, being formed on said organic-containing insulating layer, and a resist layer being formed on said hard mask layer. A method is disclosed for forming a layer, protecting exposed surfaces of low-k dielectrics. More particularly the method comprises the steps of sealing exposed surfaces of a, preferably porous, low-k dielectric, by forming a protective layer on exposed surfaces during or after the step of patterning openings in the porous dielectric layers. Preferably this protective layer is formed by a N2 / O2 plasma treatment of the exposed surfaces.

Owner:APPLIED MATERIALS INC

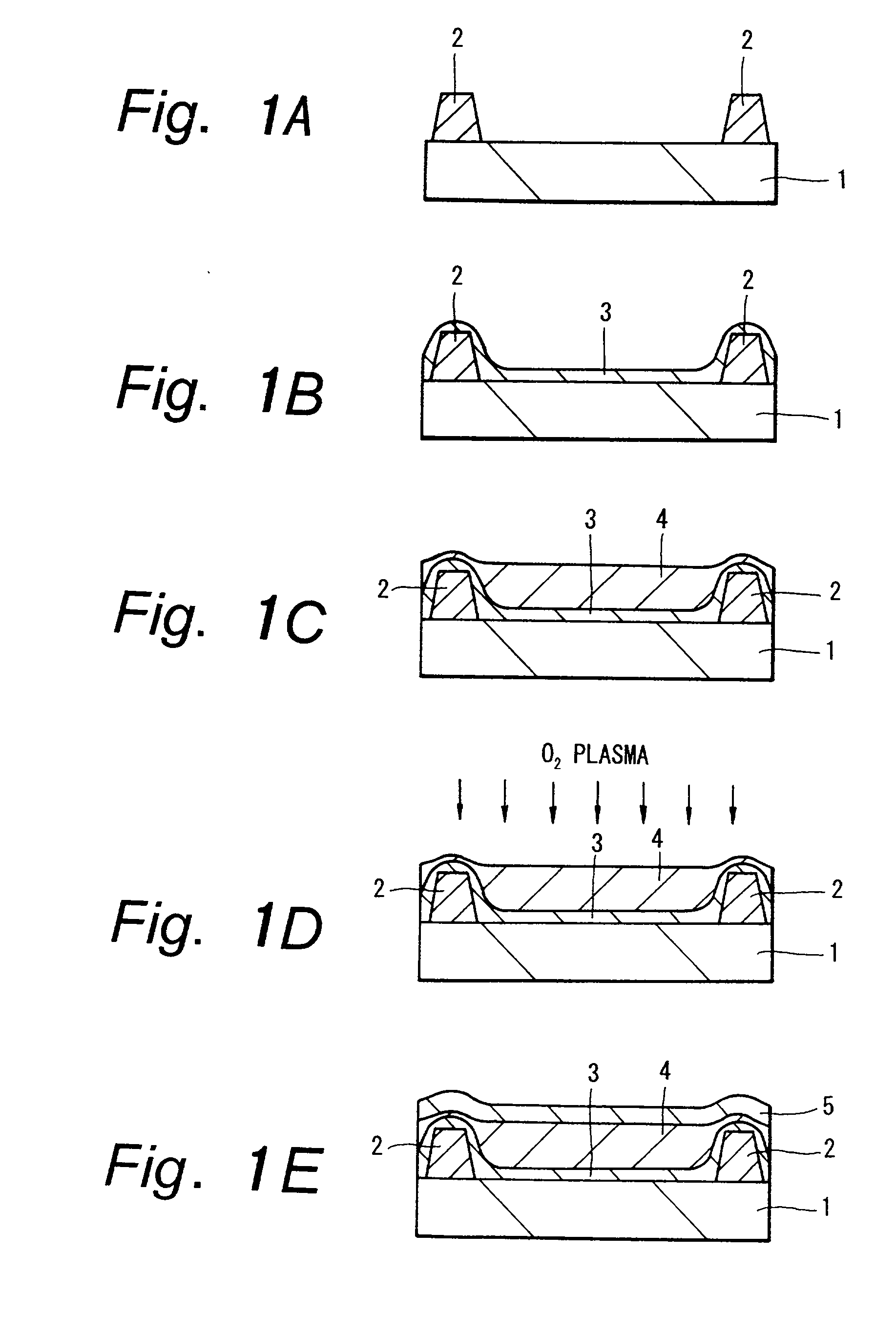

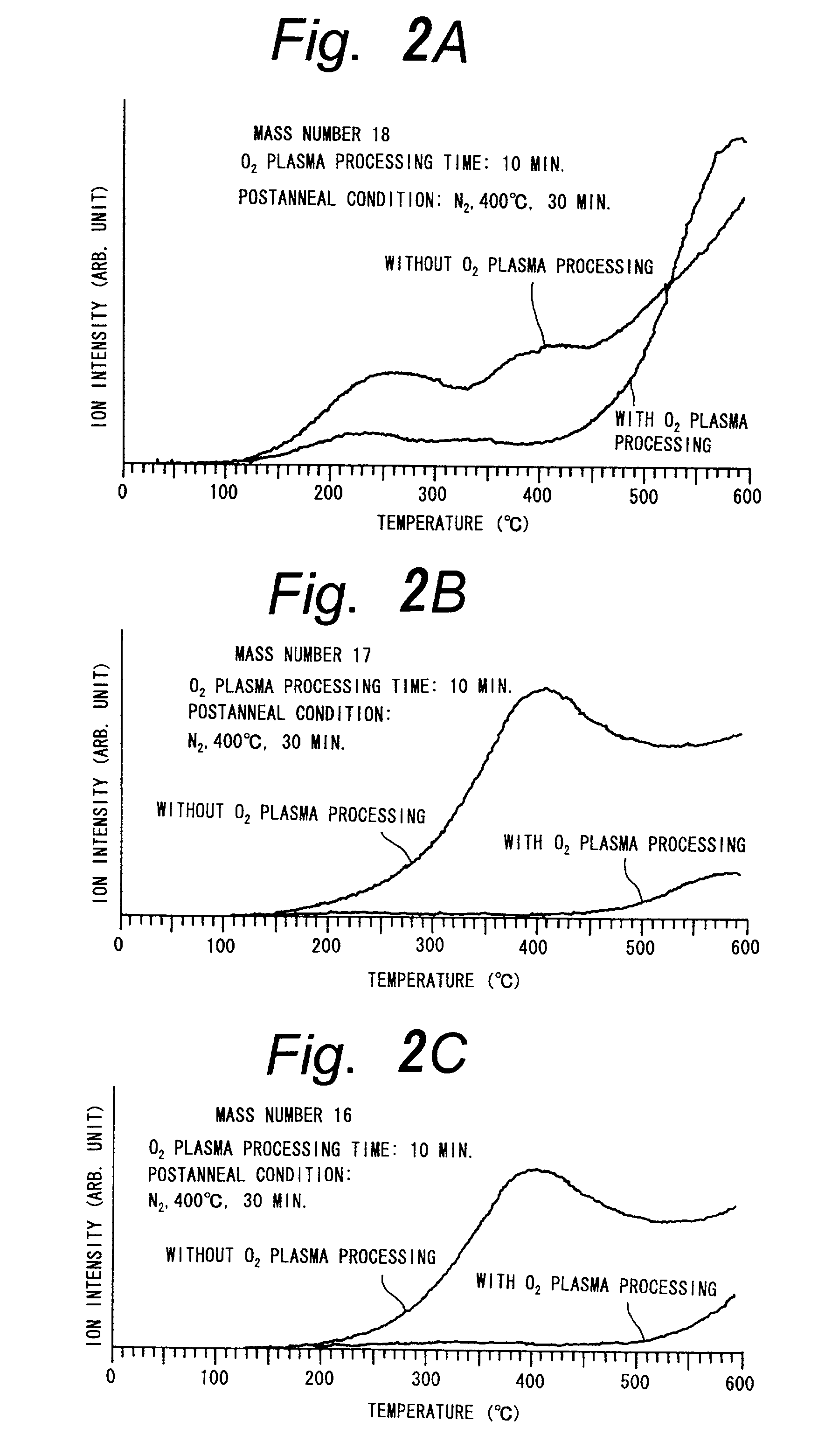

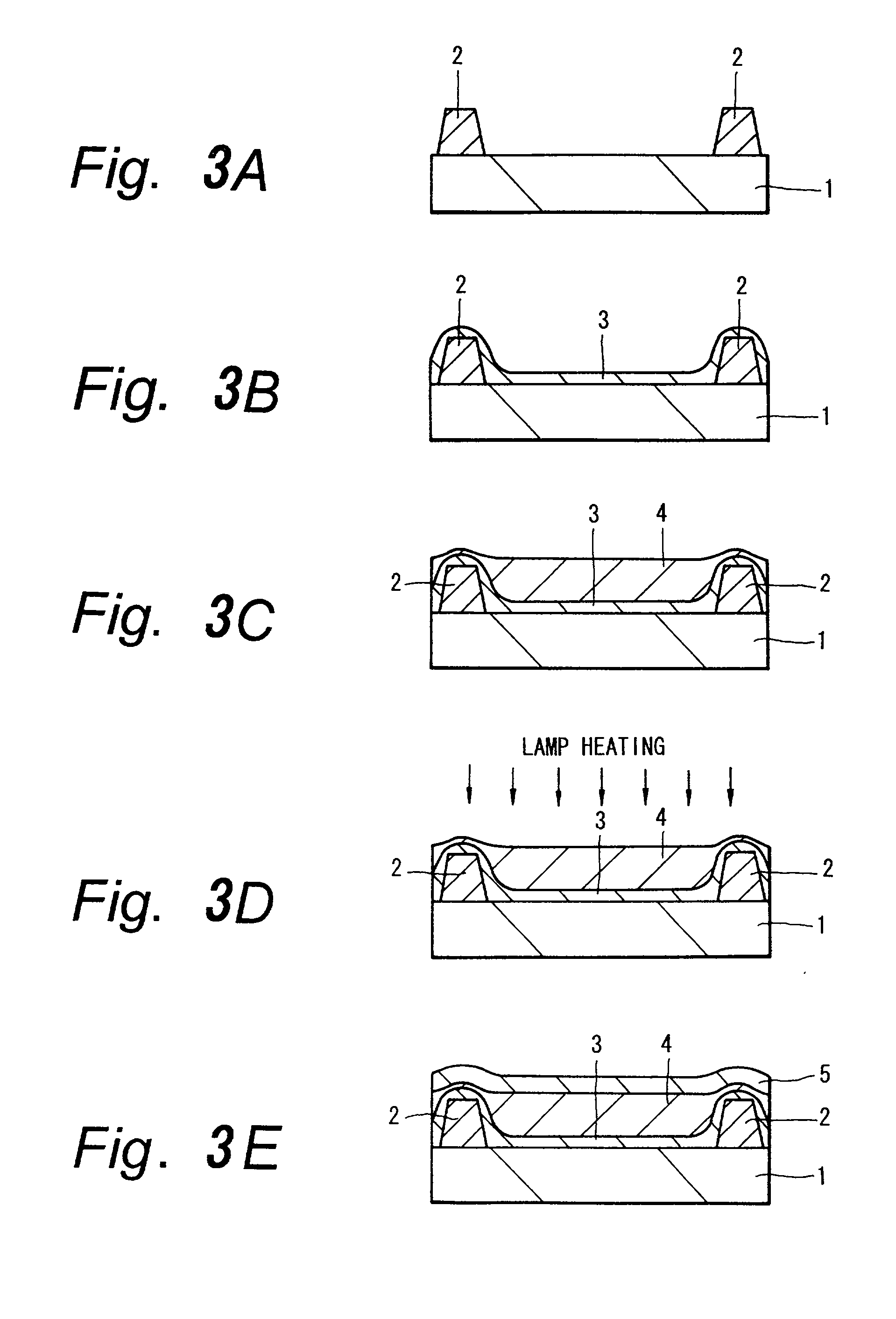

Method for making an insulating film

InactiveUS6429147B2Rapid thermal annealingAvoid problemsSemiconductor/solid-state device detailsSolid-state devicesInter layerSource material

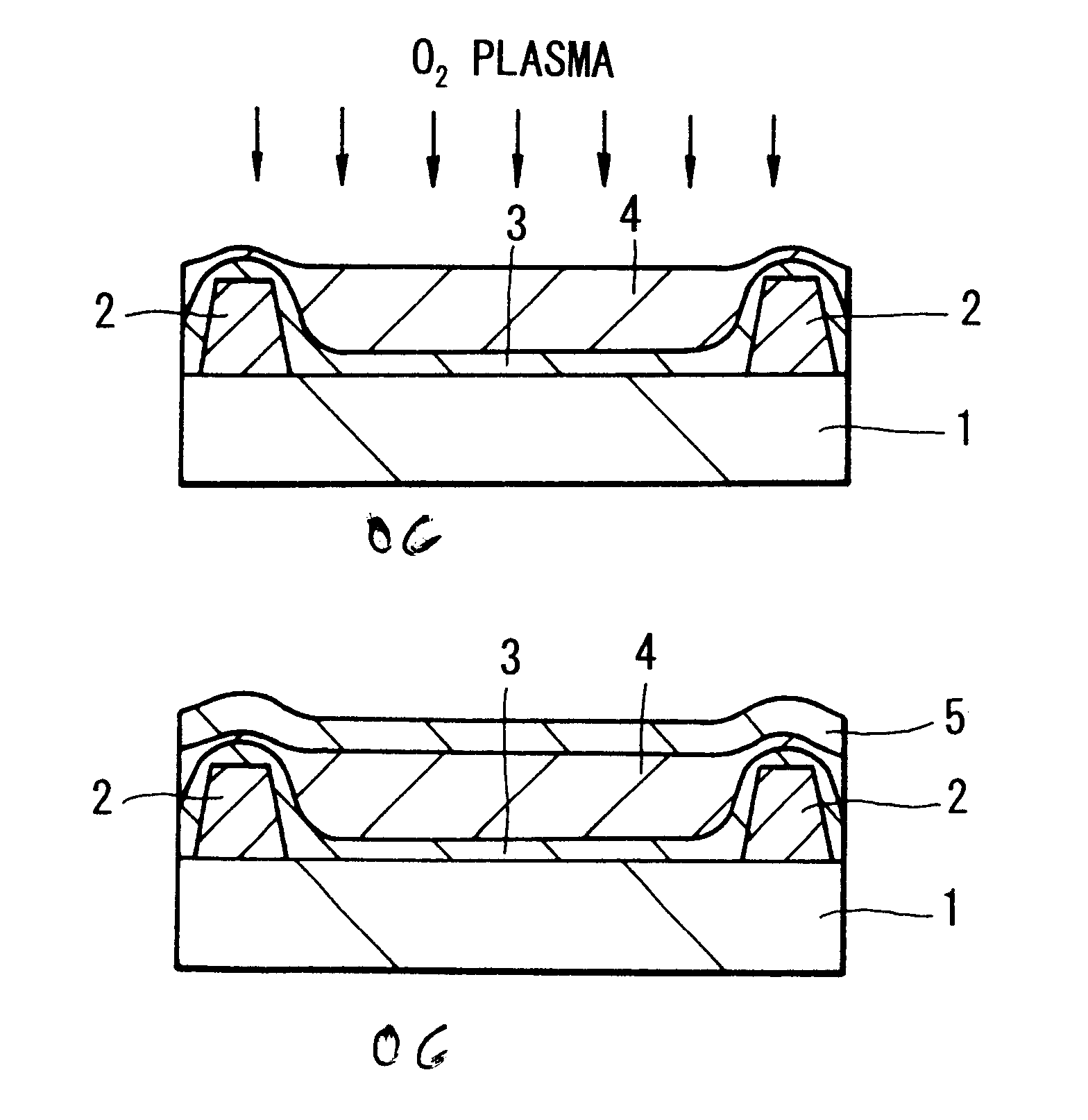

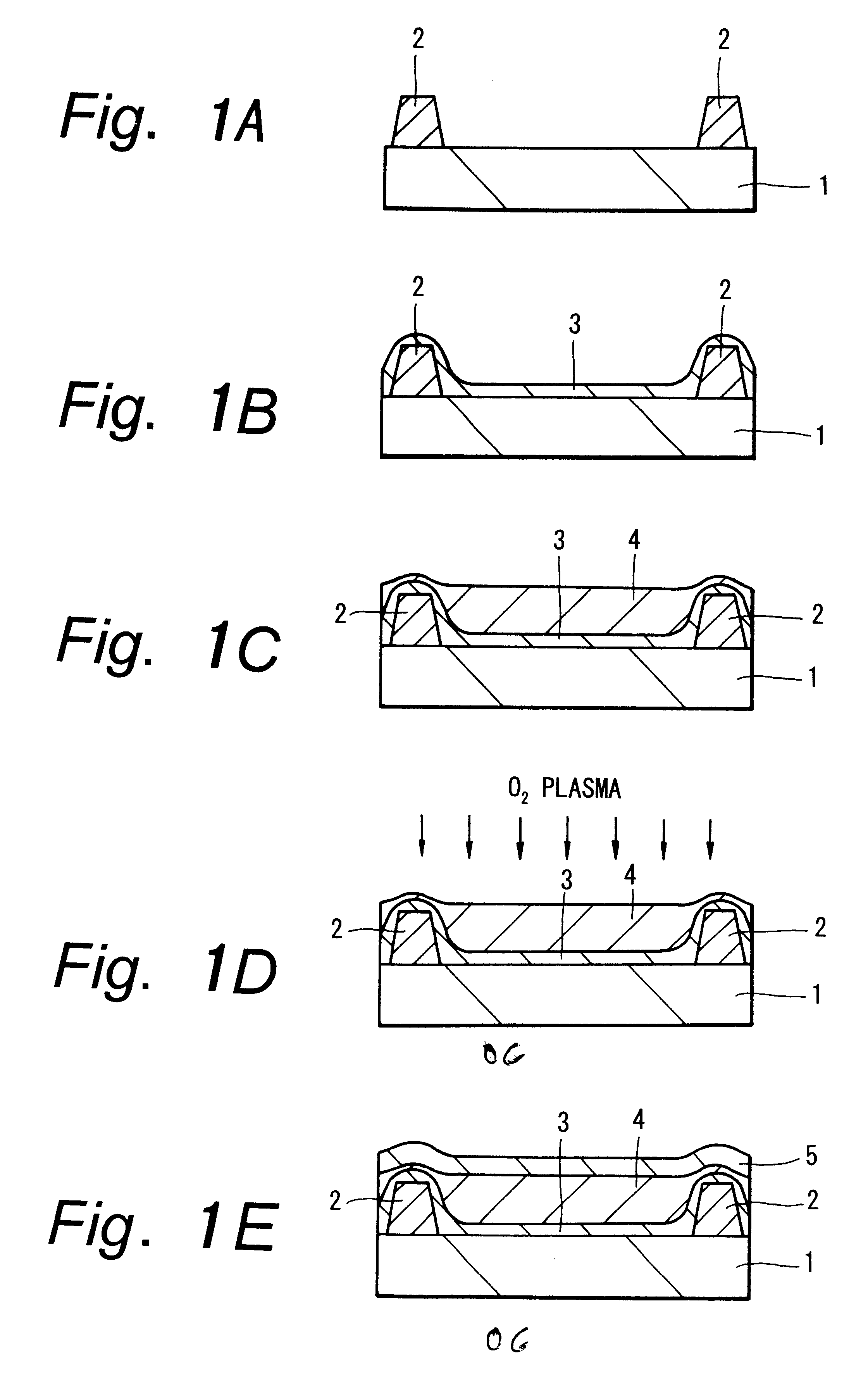

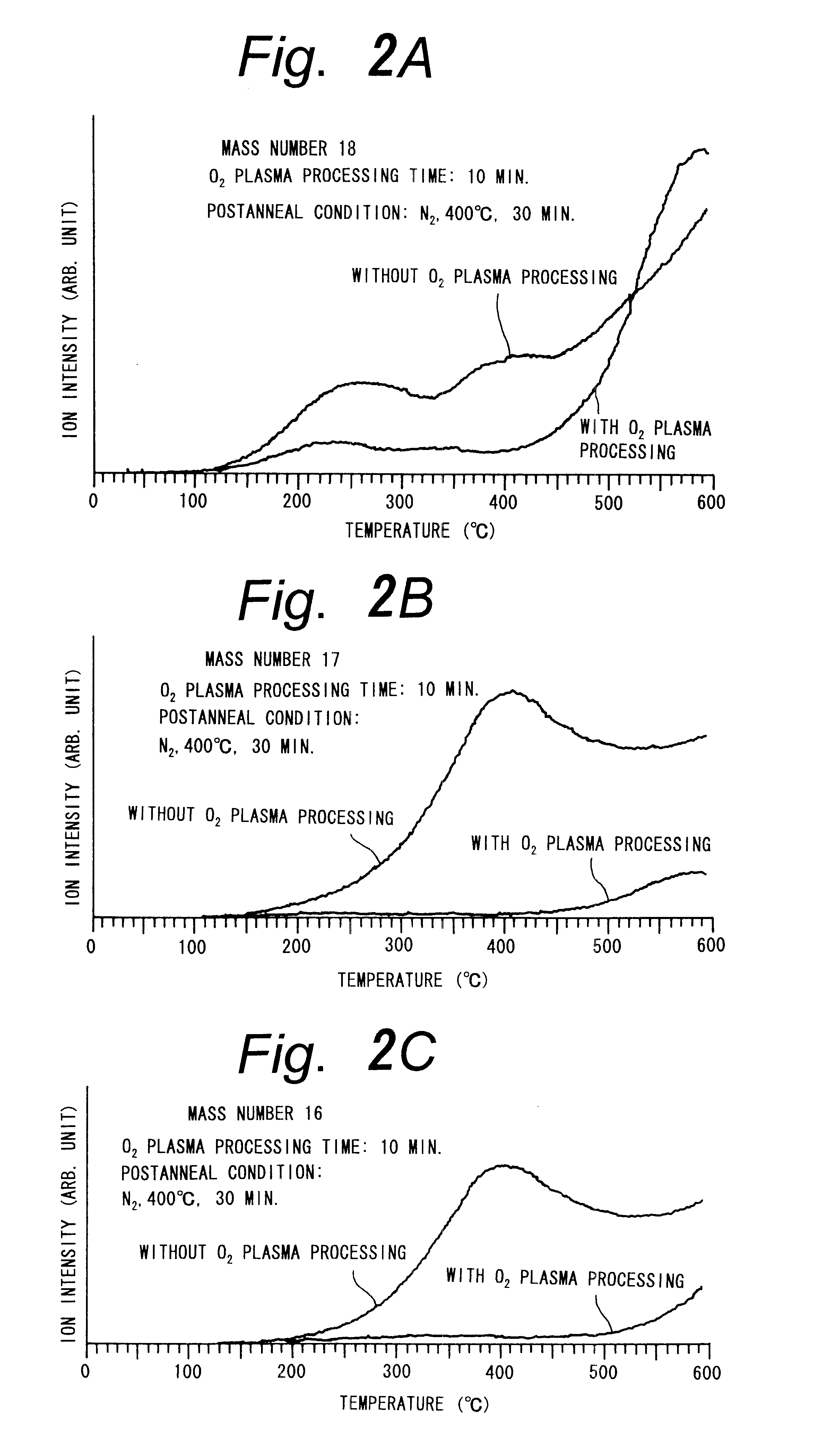

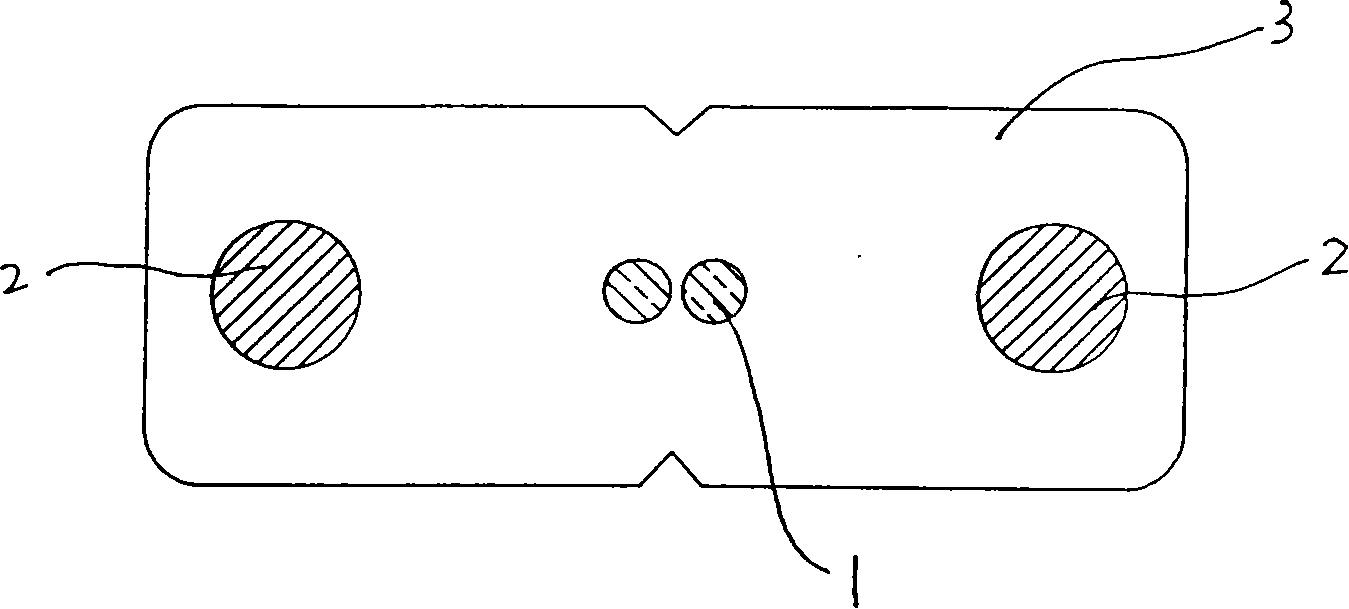

In a method for manufacturing an insulating film using a fluid source material without inviting corrosion of metal wiring or the problem of poisoned via, after making a SiO2 film as a base layer on an Si substrate defining an uneven surface with an Al alloy wiring by plasma CVD using SiH4 and N2O, and further making an inter-layer insualting film having a fluidity on the SiO2 film by low pressure CVD using SiH4 or organosilane and H2O2, O2 plasma processing is applied to the inter-layer insulating film. After that, a SiO2 film as a cap layer is made on the inter-layer insulating film by plasma CVD using SiH4 and N2O. Rapid thermal annealing using lamp heating or O3 annealing may be done in lieu of O2 plasma processing.

Owner:SONY CORP

Aramid fiber reinforced plastic reinforcement, and its preparing process and use

ActiveCN101071191ACompact structureSmall sizeOptical articlesFibre mechanical structuresYarnPolymer science

A strengthening of aramid fiber reinforced plastic pieces. Composed by the line of aramid fiber reinforced plastics and outer coating, coating is 0.02-0.10 mm thick, the strengthening is 0.5-0.8 mm diameter. Minimum bend radius is less than the six times of their diameter. Process: use O2 plasma modified aramid yarn; enter solution slot, vinyl resin impregnation; enter the mold, mold, heating and molding completely cured, a system of aramid fiber-reinforced plastics; fibre reinforced plastics for preheating; preheating entered extrusion mold, coating; coating after rapid cooling system in the aramid fiber reinforced plastics strengthening of which, coating materials for ethylene acrylic acid copolymer. Advantages are: small compact size, flexible, and tensile performance, a waterproof coating function, and the strengthening of the overall cable closely integrated with the dimensional stability, organization dense and have a certain rigidity, resistance to a rope in the process of heat shrink to help reduce fiber attenuation.

Owner:江苏晓宝复合材料有限公司

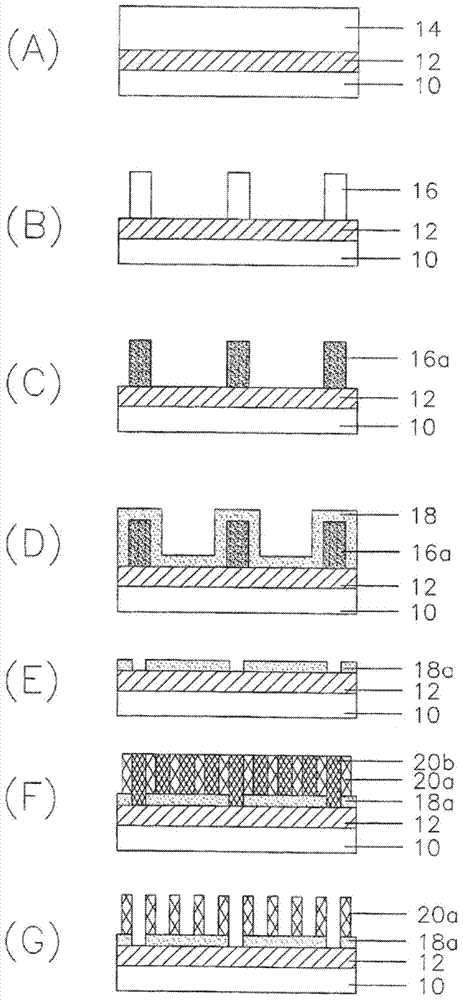

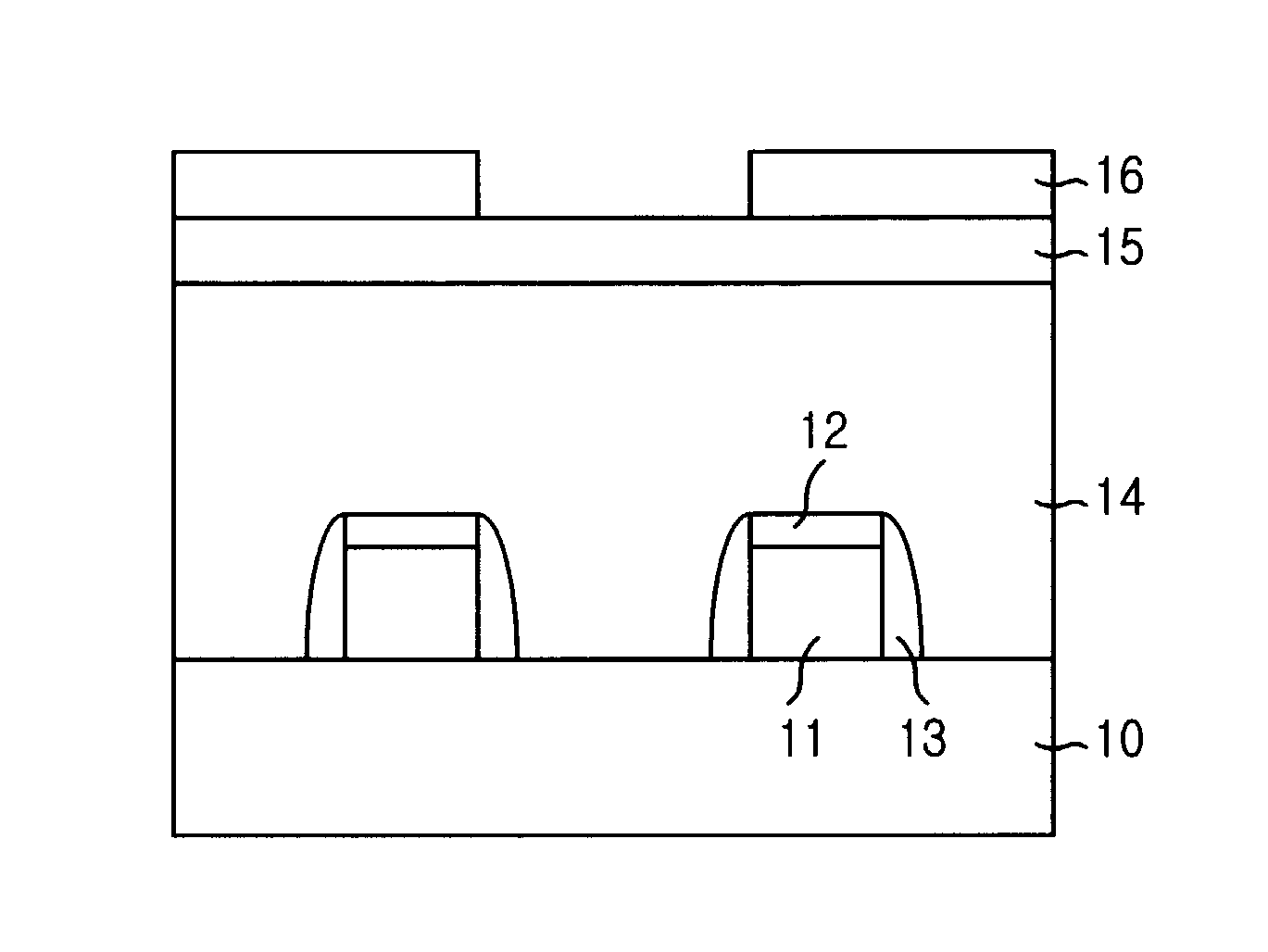

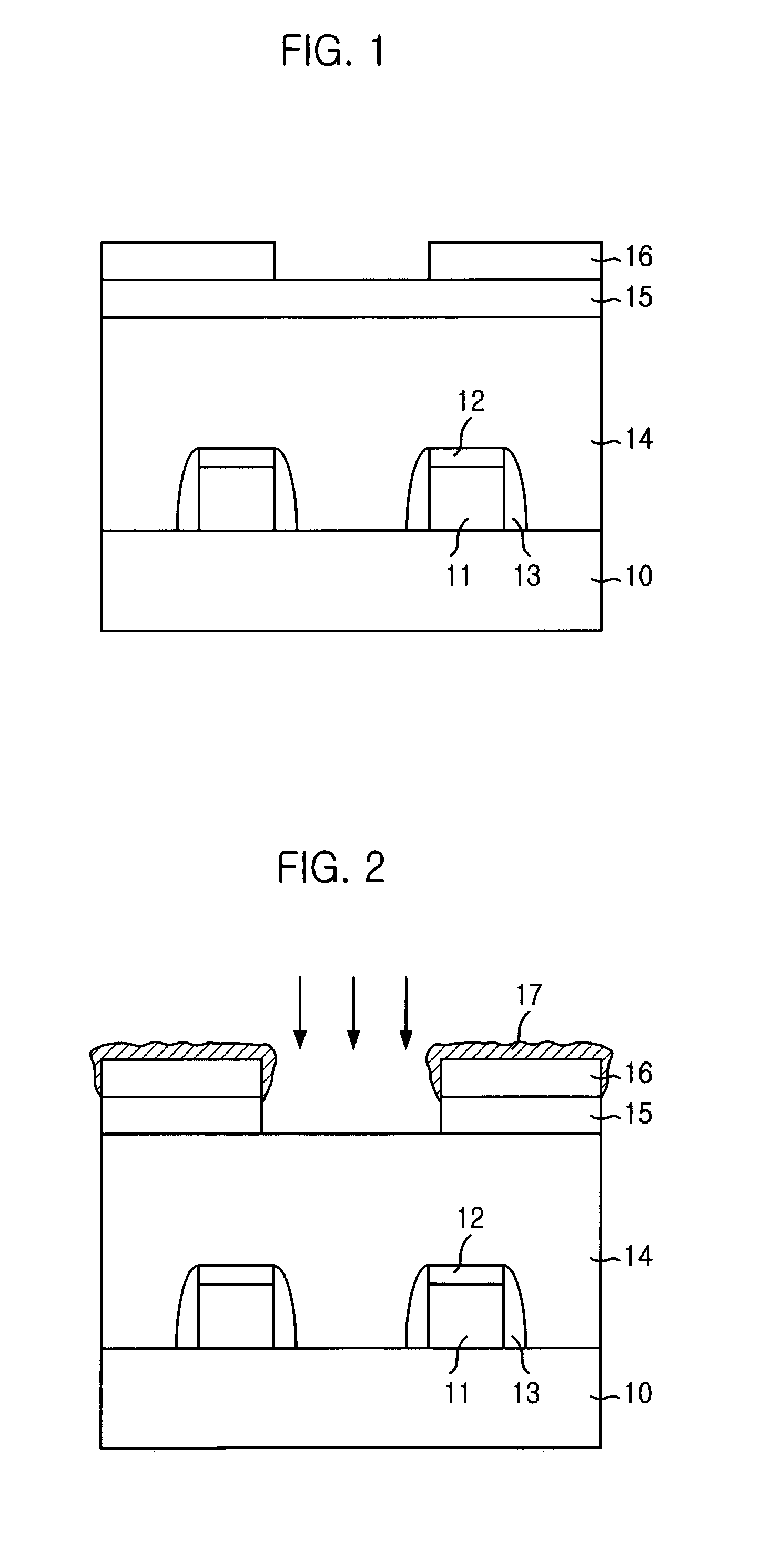

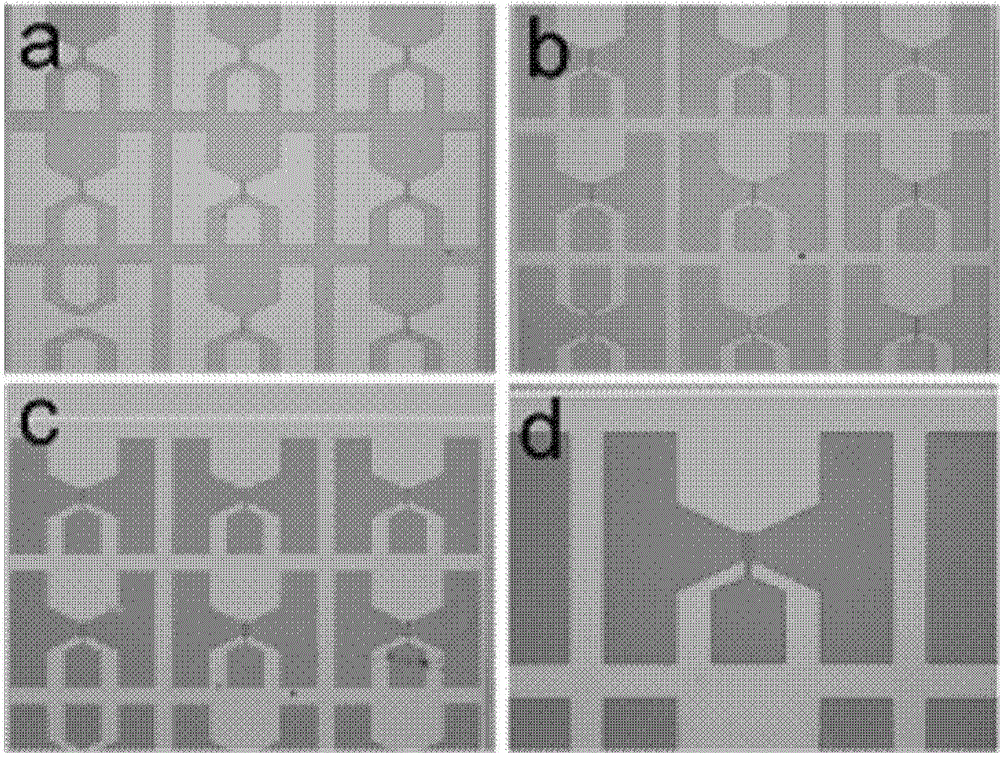

Method for forming fine patterns of semiconductor device using directed self assembly process

InactiveCN103843112AEfficient formationEasy to removePhotomechanical apparatusSemiconductor/solid-state device manufacturingPower semiconductor deviceO2 plasma

A method for forming fine patterns of a semiconductor device, which can form patterns having a size of pattern line width of 20nm or less without a bulk exposure and hardening process for a guide pattern, includes: an (a) step of forming a photoresist layer on a substrate having an organic anti-reflection layer; a (b) step of forming a guide pattern by exposing the photoresist layer and developing the exposed photoresist layer using a negative tone developer; (c) step of forming a self assembly conductive layer on the substrate having the guide pattern; a (d) step of forming the self assembly conductive layer by removing the guide pattern using the developer; an (e) step of coating a block copolymer as a directed self assembly (DSA) material on the substrate coated with the self assembly conductive layer from which the guide pattern is removed, and forming self-assembled patterns by heating the block copolymer at the glass transition temperature or higher; and a (f) step of forming the fine patterns by selectively etching a part having a low resistance against the etching (or having a high etching speed) among the self-assembled patterns using O2 plasma.

Owner:DONGJIN SEMICHEM CO LTD

Method for making an insulating film

InactiveUS20010039125A1Readily apparentSemiconductor/solid-state device detailsSolid-state devicesInter layerSource material

In a method for manufacturing an insulating film using a fluid source material without inviting corrosion of metal wiring or the problem of poisoned via, after making a SiO2 film as a base layer on an Si substrate defining an uneven surface with an Al alloy wiring by plasma CVD using SiH4 and N2O, and further making an inter-layer insualting film having a fluidity on the SiO2 film by low pressure CVD using SiH4 or organosilane and H2O2, O2 plasma processing is applied to the inter-layer insulating film. After that, a SiO2 film as a cap layer is made on the inter-layer insulating film by plasma CVD using SiH4 and N2O. Rapid thermal annealing using lamp heating or O3 annealing may be done in lieu of O2 plasma processing.

Owner:SONY CORP

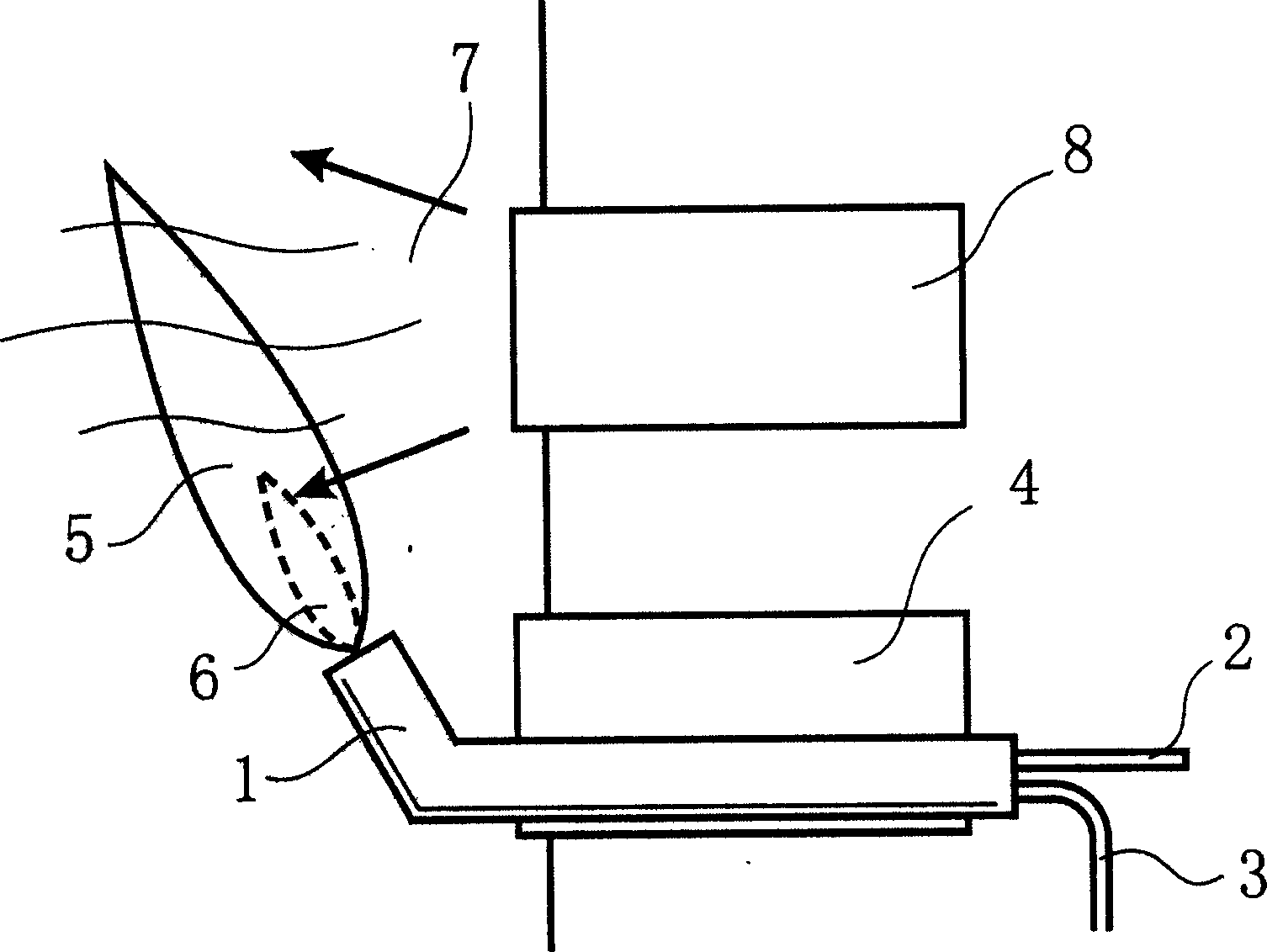

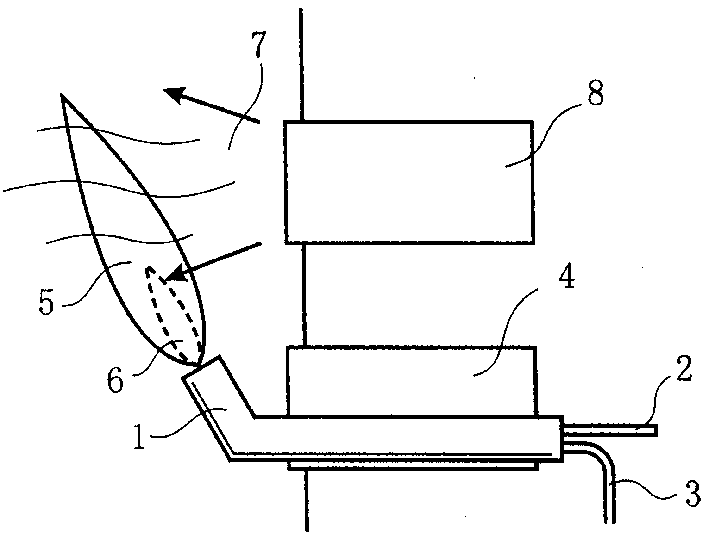

Method and device for igniting boiler powder coal by using water high temperature electrolysis technology

A method for igniting the powdered coal in boiler features that the plasma arc generated by plasma generator and the water steam are simultaneously delivered in an energy converting chamber for plasma ionizing to generate H2-O2 plasmas, and the high-energy H2-O2 plasmas are sprayed from igniter into powdered coal stream to generate flame and water, so igniting powdered coal and forming a stable burning kernel. Its apparatus is composed of igniter and the primary air and powdered coal channel.

Owner:王满家 +2

Method for dyeing, modifying and decorating surface of polypropylene material

InactiveCN101092793AIncrease the number ofIncrease loadUltrasonic/sonic fibre treatmentFiberO2 plasma

This invention relates to a method for modifying dye of surface of a polypropylene material, which first of all uses different gas plasma to process the fiber material including: preprocessing the surface of the fiber material then processing the material with N2, H2 and O2 plasma and then uses graft to process it including: applying a tree-like monomer graft liquid to modify the processed polypropylene material.

Owner:苏远

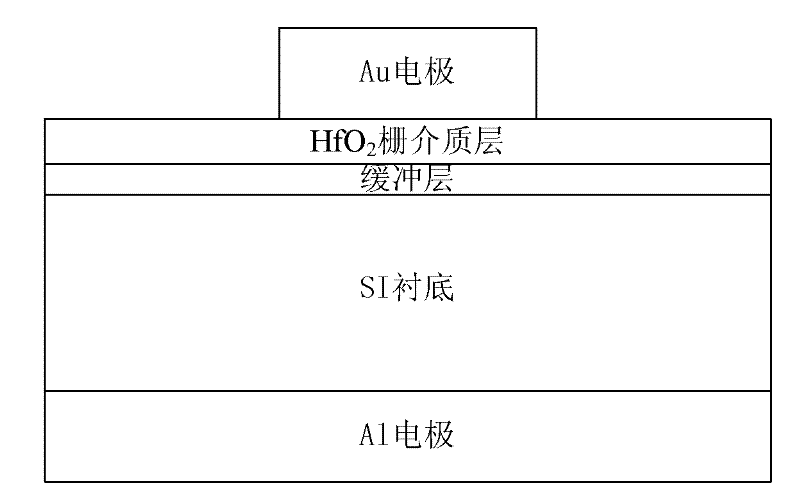

Method for depositing gate dielectric, method for preparing MIS capacitor and MIS capacitor

InactiveCN102226270AReduce the equivalent gate oxide thicknessImprove electrical performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricCapacitance

The invention provides a method for depositing a gate dielectric, a method for preparing a MIS capacitor and a MIS capacitor. The method for depositing the gate dielectric comprises the following steps: first, pretreating the surface of a semiconductor substrate by using O2 plasma and plasma containing nitrogen so as to form a nitrogenous oxide layer on the surface of the semiconductor substrate; and then, growing a gate dielectric layer with high dielectric constant on the surface of the nitrogenous oxide layer using a plasma enhanced atomic layer deposition process, wherein, the oxide layer converts into a buffer layer with higher dielectric constant than SiO2 in the process of growth of the gate dielectric layer. Based on the method for depositing the gate dielectric, a MIS capacitor is prepared by forming a metal electrode on the upper and lower surface of the formed semiconductor structure. The invention has the advantages that: the existence of the buffer layer is capable of improving the interface characteristic between the semiconductor material and the high K gate dielectric layer, reducing the increasement of equivalent oxide thickness (EOT) and improving the electric properties.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

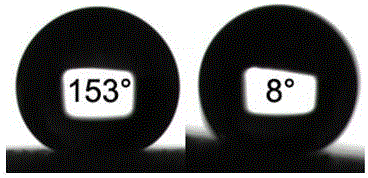

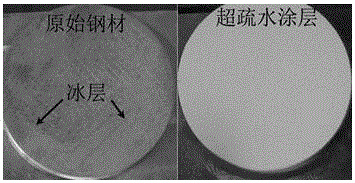

Durable ice-resistant super-hydrophobic coating and preparation method thereof

ActiveCN106423789AImprove wear resistanceExcellent ice resistancePretreated surfacesSpecial surfacesMolten stateNanoparticle

The invention discloses a durable ice-resistant super-hydrophobic coating and a preparation method thereof. The durable ice-resistant super-hydrophobic coating consists of a metal trench structure at the bottom, a macromolecule layer in the middle and a nanoparticle-macromolecule composite layer on the upper part, smooth steel is used as a substrate, after a trench structure is etched by laser, a pure macromolecule coating coats the trench structure, and then a macromolecule-nano composite coating is sprayed on the pure macromolecule coating to obtain the durable ice-resistant super-hydrophobic coating. The preparation method comprises the following steps: firstly, etching the regular trench structure in the surface of the smooth steel by laser; secondly, after carrying out O2 plasma treatment on the steel, spraying ultra high molecular weight polyethylene in a molten state at high temperature, and drying to form a film; and finally, spraying an ultra high molecular weight polyethylene and hydrophobic nano Al2O3 mixture, and drying to obtain the required coating. The super-hydrophobic coating has good mechanical stability and environmental persistence, and has excellent ice resistance.

Owner:NANJING UNIV OF SCI & TECH

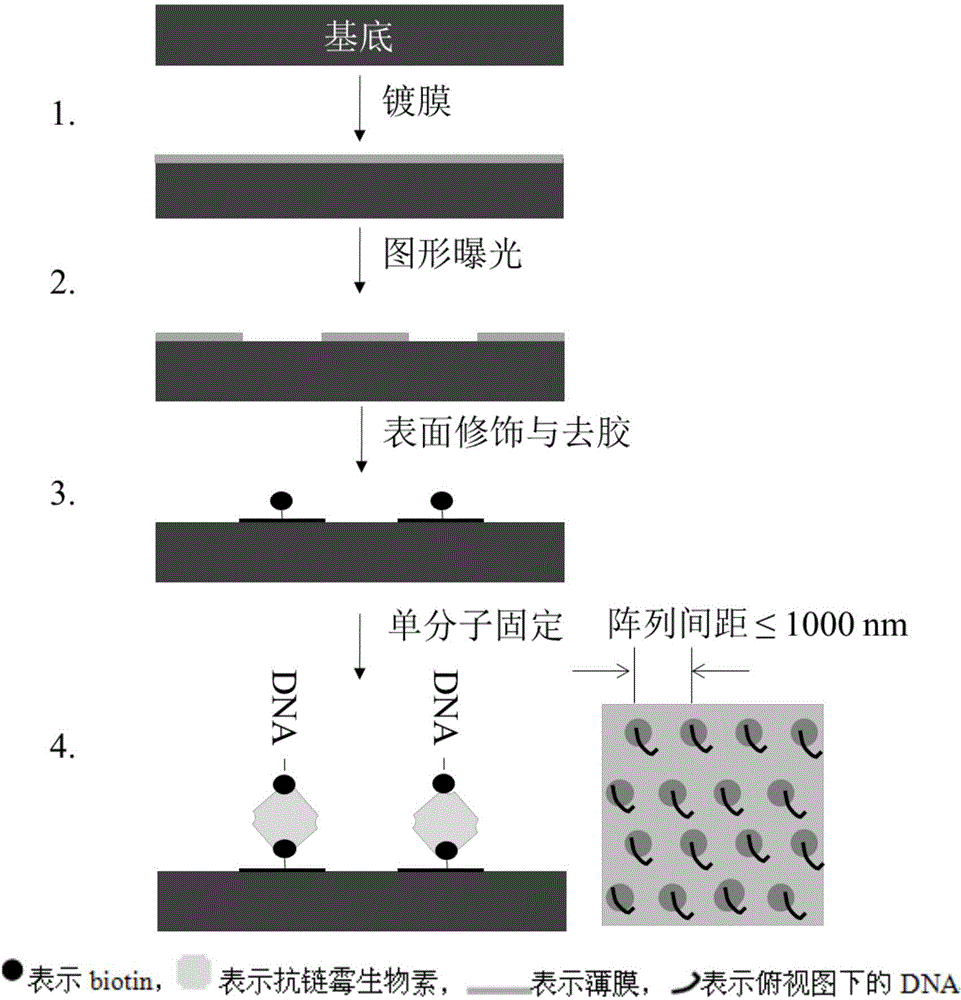

Method for preparing bio-macromolecular monomolecular chips by virtue of high-density nano-dot arrays

ActiveCN104531853ASimple preparation processSample spacing controllablePeptide librariesNucleotide librariesSubstrate modificationO2 plasma

The invention discloses a method for preparing bio-macromolecular monomolecular chips by virtue of high-density nano-dot arrays. The method comprises the following steps: firstly, laying a layer of thin films on a substrate, then preparing nano-hollow arrays on the thin films, performing further substrate modification (performing hydroxylation on the substrate which is subjected to O2 plasma treatment, and then modifying the substrate to be biotinylated), and removing the thin films to form active nano-dot arrays which can be connected with bio-macromolecules, wherein only one bio-macromolecule can be connected with each nano-dot because the nano-dots are small enough; and finally cleaning the substrate to obtain high-density monomolecular biological chips. Objective biological chips obtained by using the method disclosed by the invention are mainly characterized in that the objective biological chips are monomolecular, have high throughput and multiple functions, and can be applied to the fields of ultra-sensitive monomolecular enzyme-linked immunosorbent assay, hybridization based DNA variation detection, monomolecular DNA synthesis and connection sequencing, single-cell RNA sequencing and the like.

Owner:SHANGHAI BEION MEDICAL TECH CO LTD

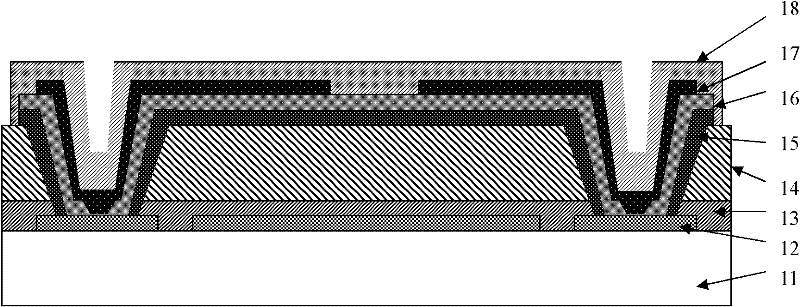

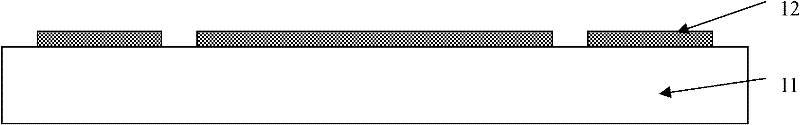

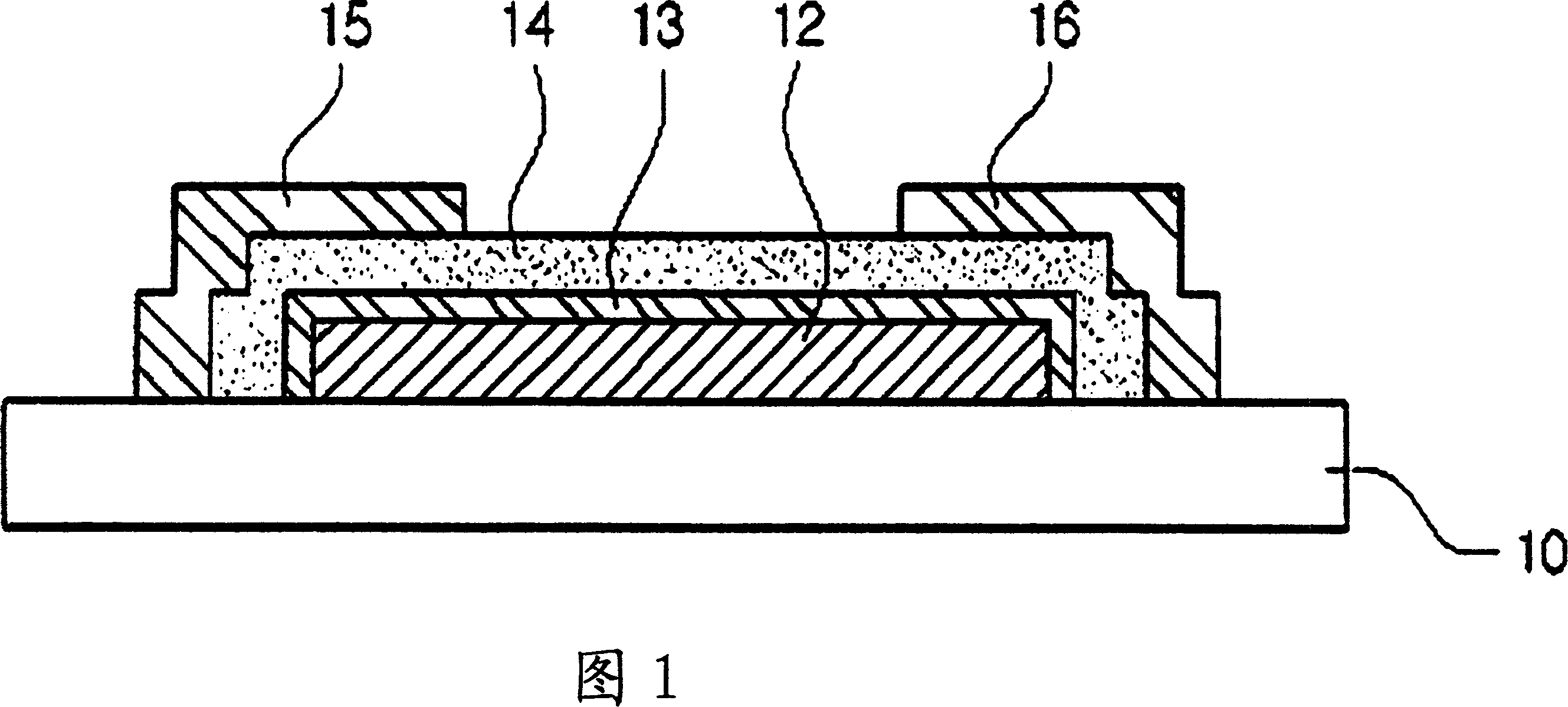

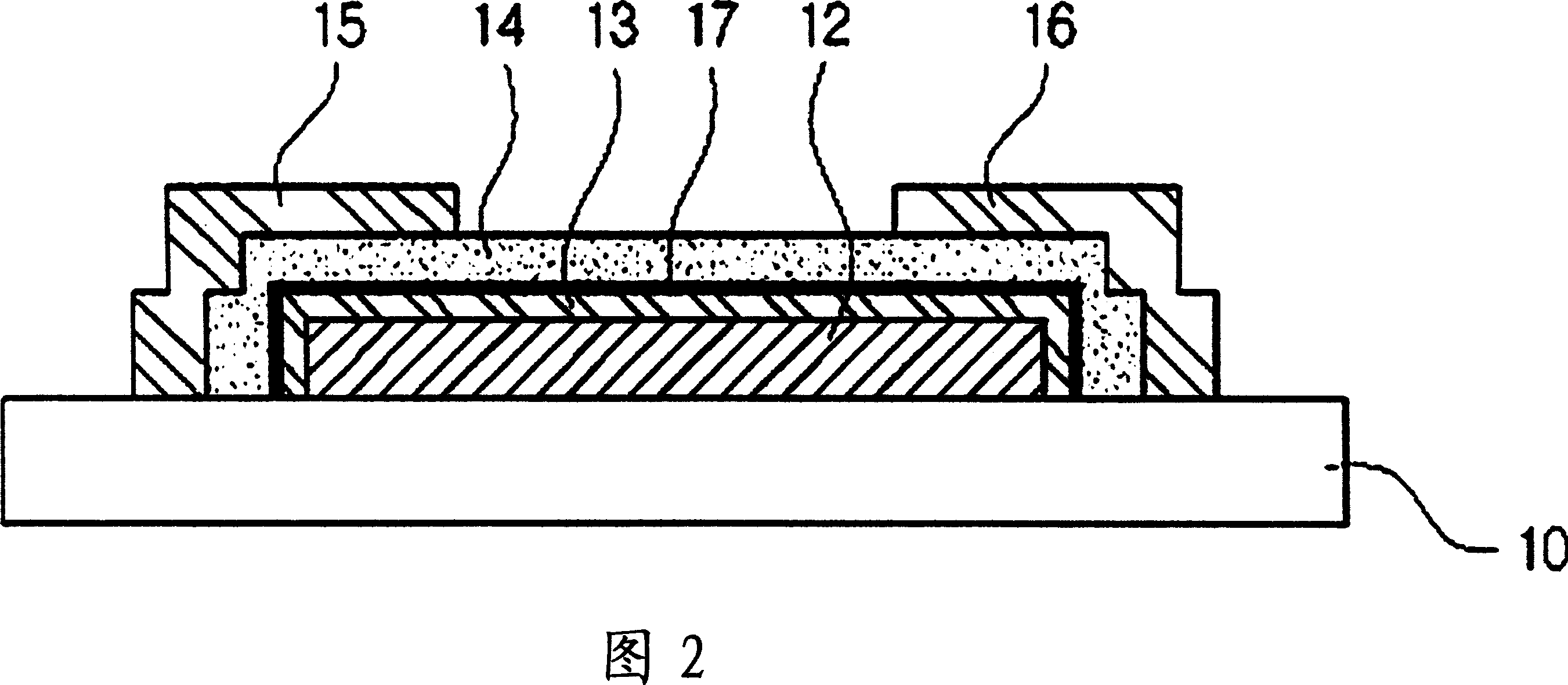

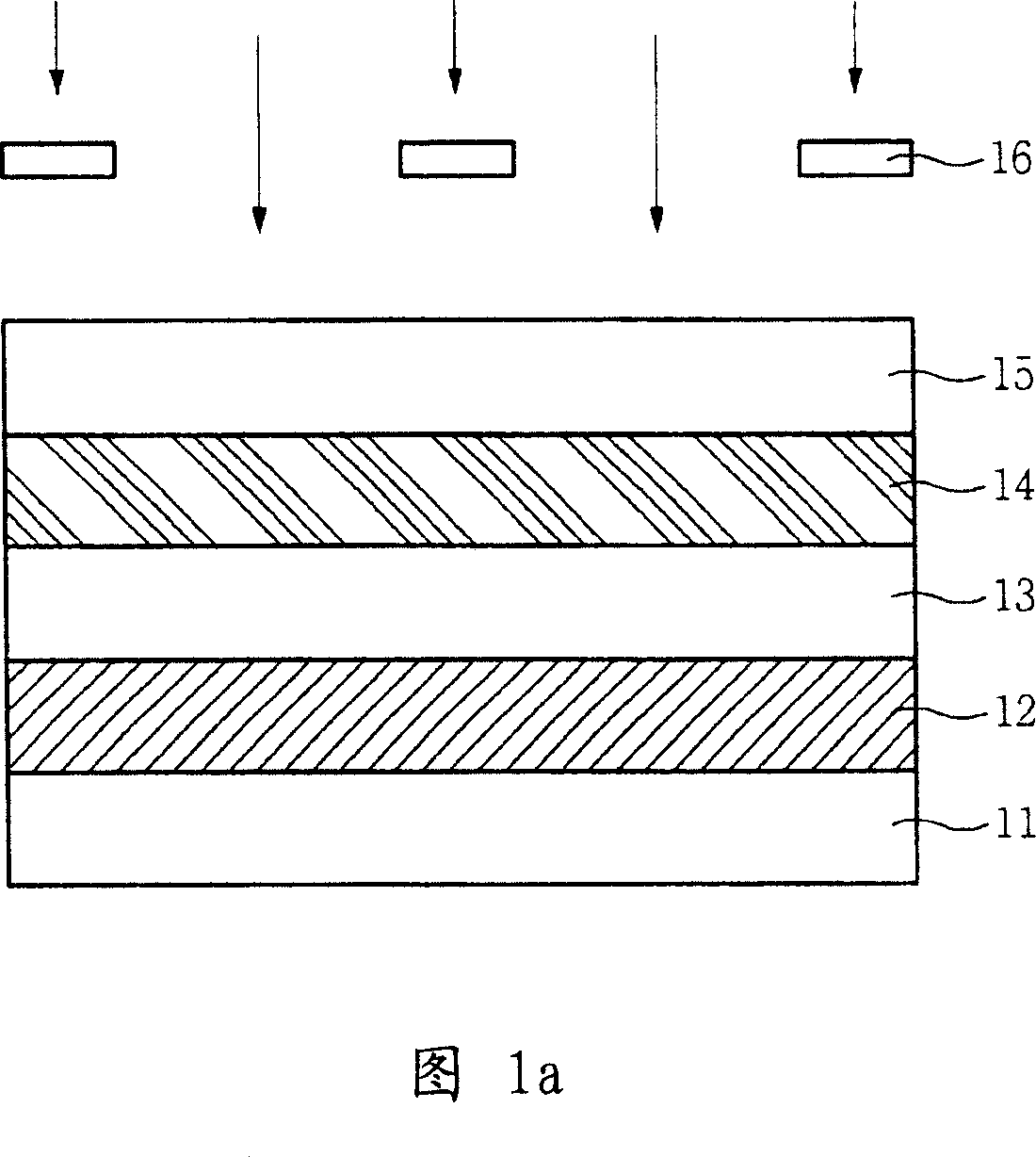

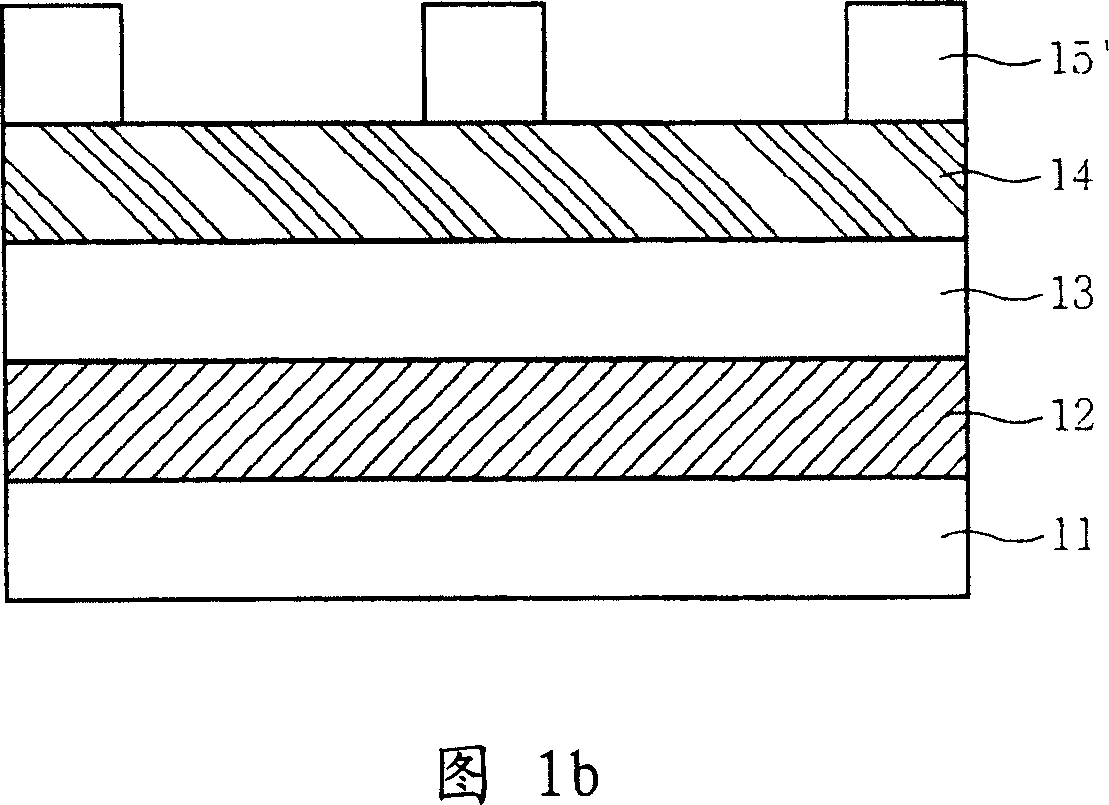

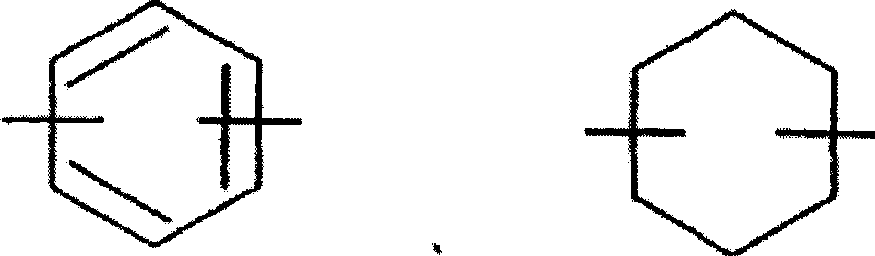

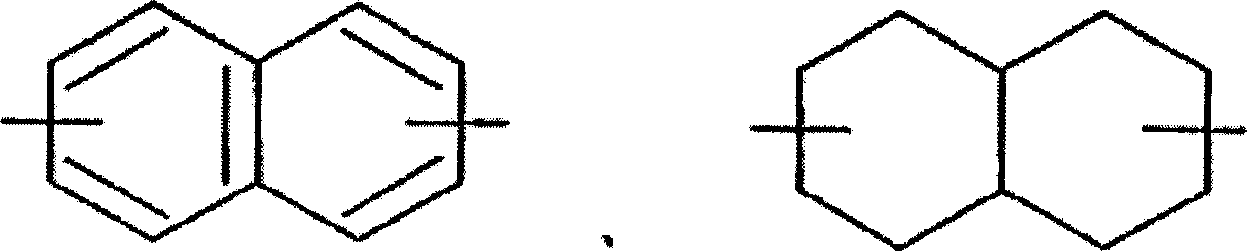

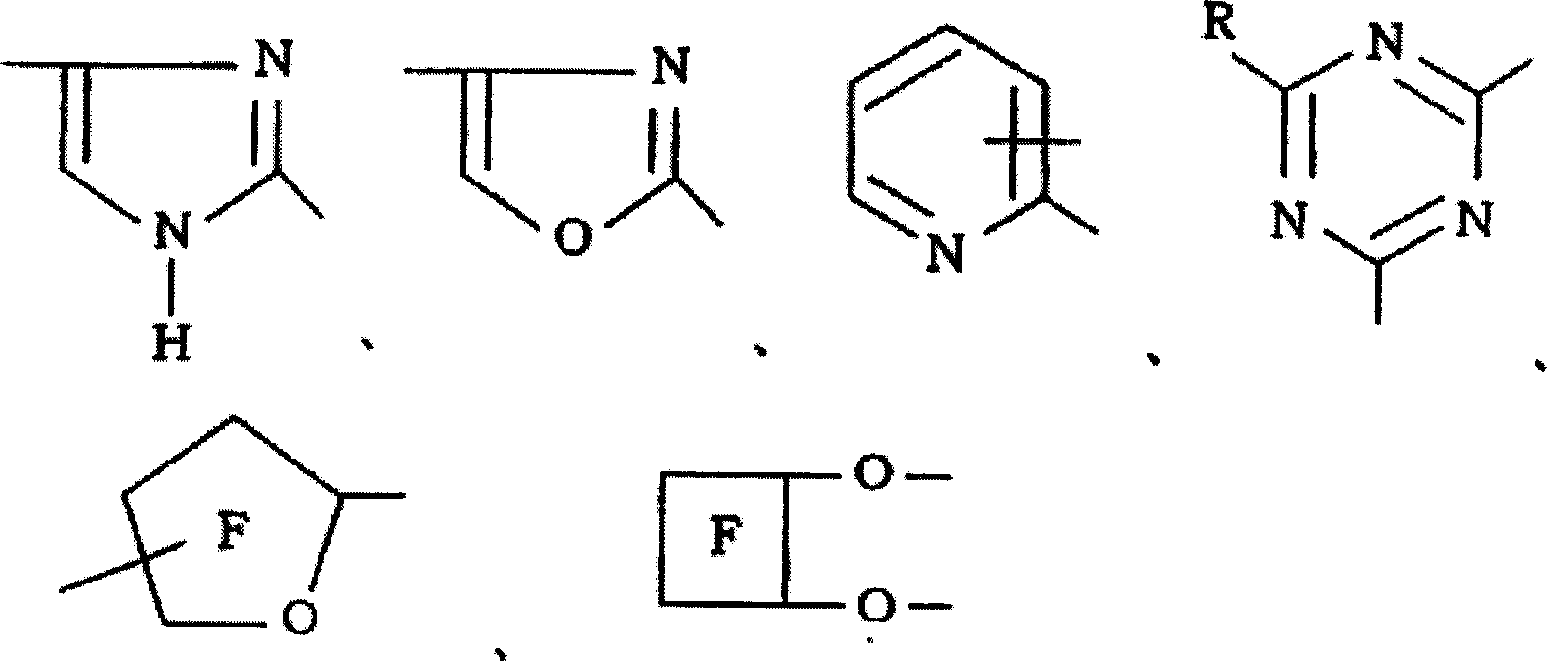

Low-voltage organic thin film transistor and fabrication method thereof

InactiveCN101017881ASolid-state devicesSemiconductor/solid-state device manufacturingThin metalLow voltage

The present invention provides a low-voltage organic thin film transistor having a gate dielectric layer of ultra-thin metal oxide self-grown on a metal gate electrode by O2 plasma process. The metal gate electrode is deposited on a plastic or glass substrate. By directly oxidizing the gate electrode by using O2 plasma process, the gate dielectric layer of metal oxide is formed with a thickness of several nanometers on the gate electrode. The organic semiconductor layer is deposited on the gate dielectric layer, and source / drain electrodes are formed on the organic semiconductor layer. Before the organic semiconductor layer is formed, an organic molecular monolayer may be formed on the gate dielectric layer by using molecular self-assembly technique. The gate dielectric layer may be formed at room temperature to about 100 DEG C.

Owner:梁在宇

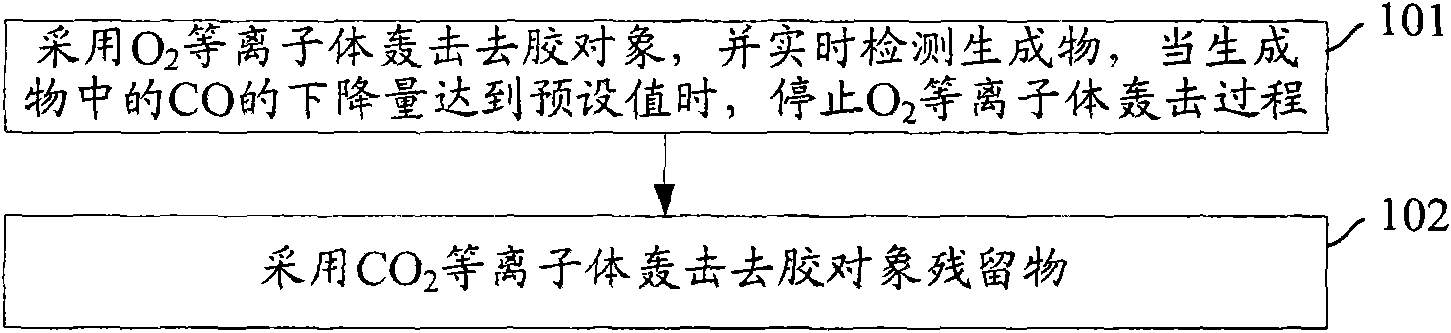

Photoresist-removing method

InactiveCN102033437AEfficient removalAvoid damagePhotosensitive material processingSoftware engineeringO2 plasma

The invention discloses a photoresist-removing method, which comprises the following steps of: bombarding a photoresist-removing object by utilizing an O2 (oxygen) plasma and detecting a CO (carbon monoxide) product; stopping the bombardment of the photoresist-removing object by utilizing the O2 plasma when the decreased amount of CO reaches a preset value; and then bombarding the residue in the photoresist-removing object by utilizing a CO2 (carbon dioxide) plasma. The invention can effectively remove the photoresist of the photoresist-removing object, and can reduce the damage to low-k mediums.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

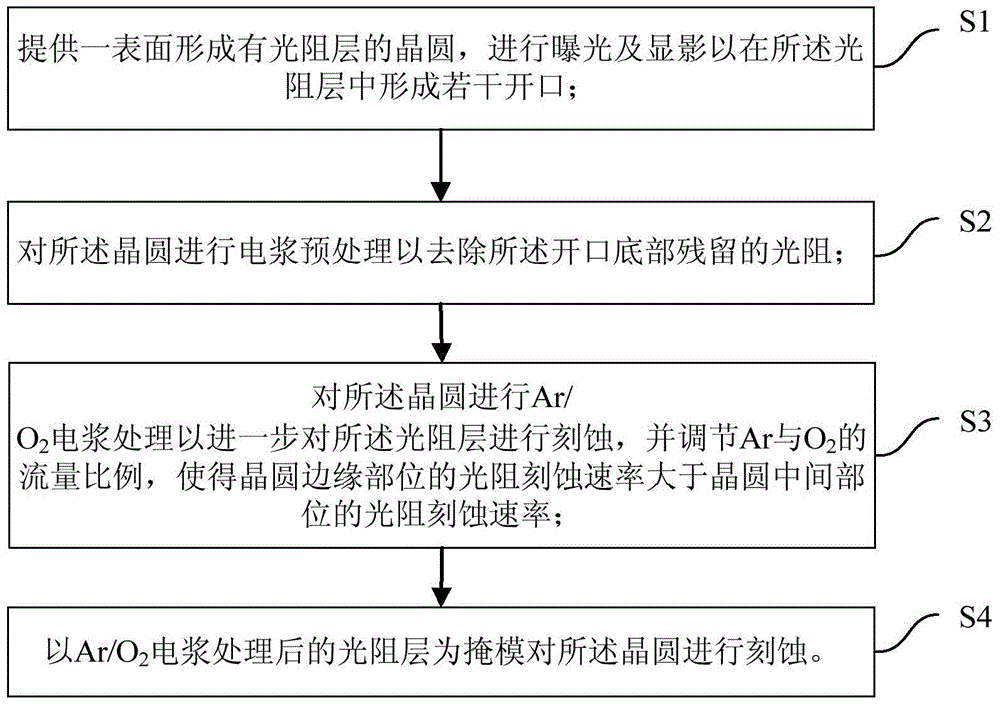

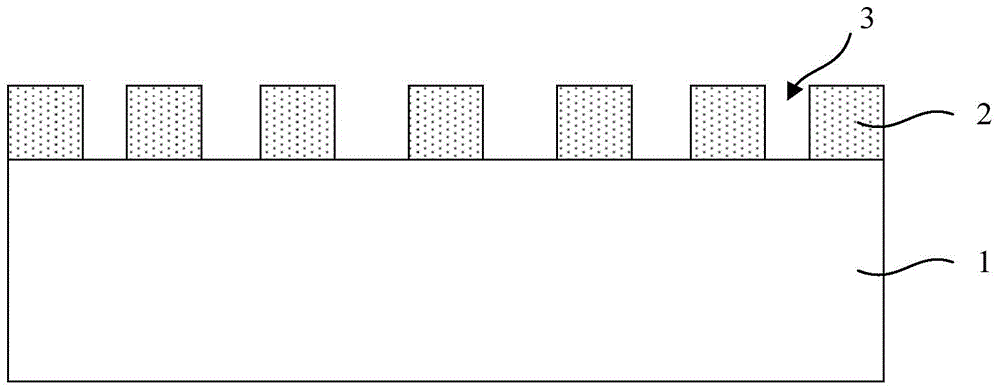

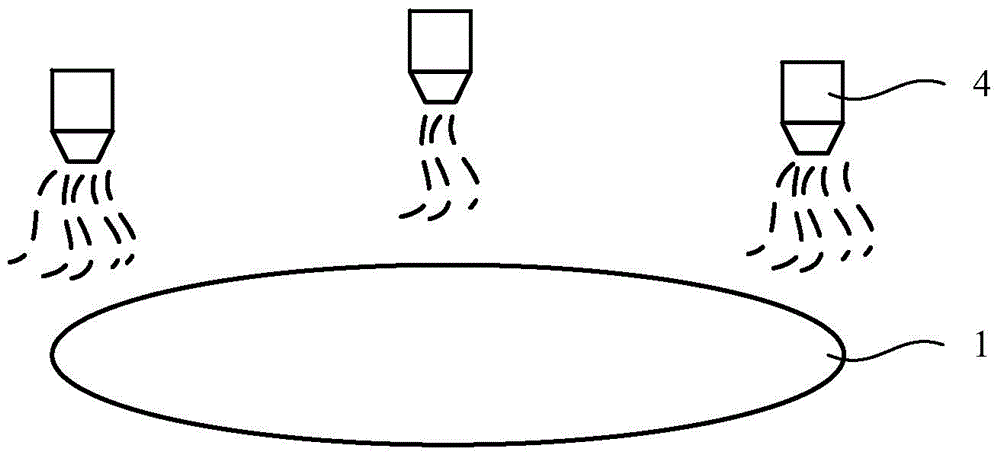

Method for improving evenness of critical size

InactiveCN105097454AImprove uniformityReduce the number of RC parameter exceptionsSemiconductor/solid-state device manufacturingO2 plasmaEngineering

The present invention provides a method for improving an evenness of a critical size, including at least the steps as follows: S1: providing a wafer, wherein, the wafer has a photoresist layer formed on a surface of the wafer for exposing, developing and forming a plurality of openings in the photoresist layer; S2. performing a plasma pre-treatment to the wafer for removing residual photoresistances on the bottoms of the openings; S3. performing a Ar / O2 plasma treatment to the wafer for further etching the photoresist layer, and adjusting a flow proportion of Ar and O2 so that an etching rate of the photoresist on the edge part of the wafer is larger than an etching rate of the photoresist on the middle part of the wafer; S4. and etching the wafer by utilizing the photoresist after Ar / O2 plasma treatment as a masking film. The method further includes the step of Ar / O2 plasma treatment after the step of plasma pre-treatment, the etching rate of the photoresist on the edge part of the wafer is larger than the etching rate of the middle part of the wafer by the adjustment of the flow proportion of Ar and O2, and thereby adjusting the opening size of the photoresists on the edge part of the wafer and the middle part of the wafer so as to improve the evenness of the critical size of an etched through hole.

Owner:SEMICON MFG INT (SHANGHAI) CORP

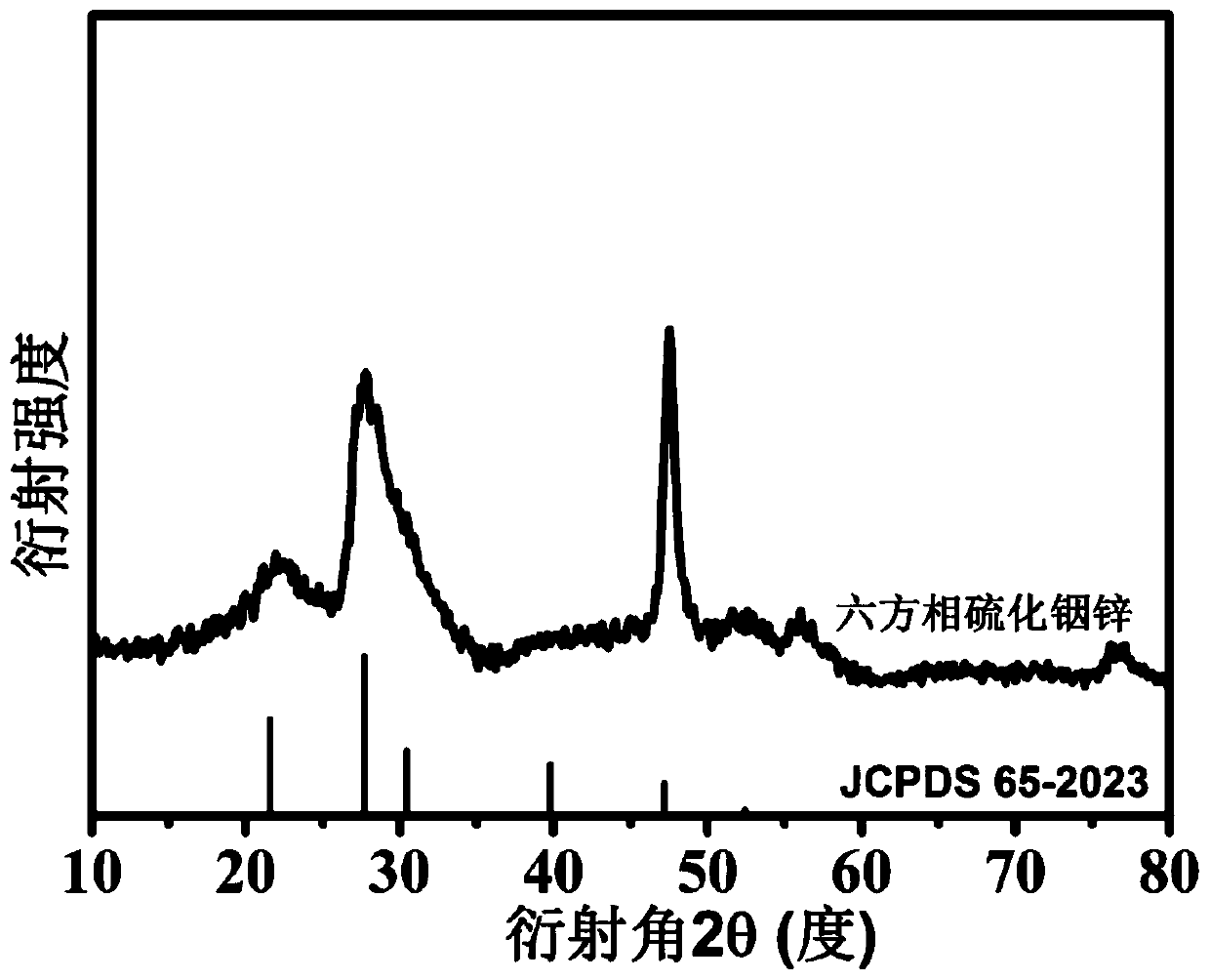

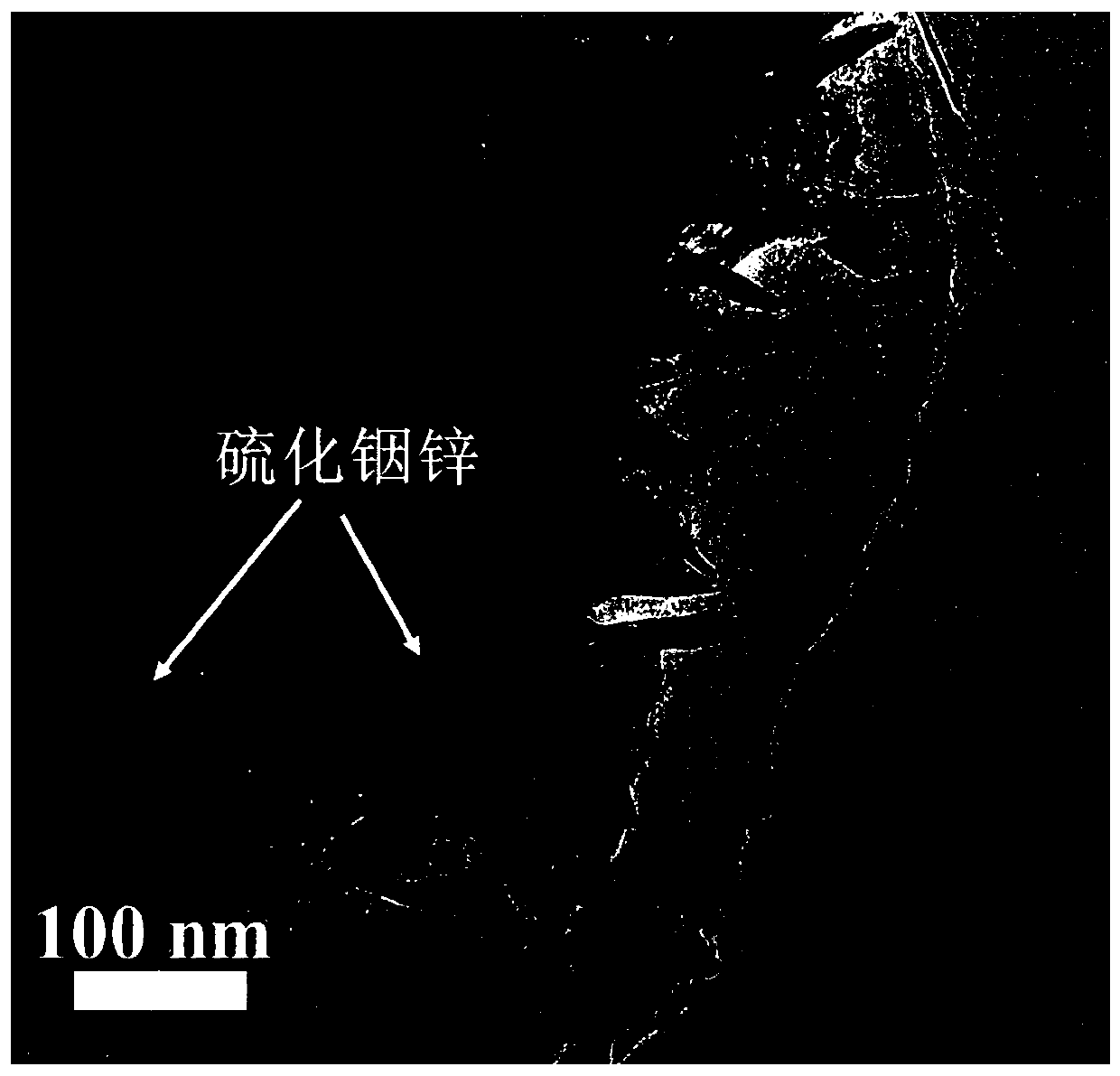

Zinc indium sulfide-nitrogen doped graphene foam composite photocatalytic material, and preparation method and application thereof

ActiveCN110975918AImprove utilization efficiencyStable structureHydrocarbon from carbon oxidesCatalyst activation/preparationDoped grapheneO2 plasma

The invention relates to a zinc indium sulfide-nitrogen doped graphene foam composite photocatalytic material, and a preparation method and an application thereof. The composite photocatalytic material comprises three-dimensional nitrogen-doped graphene foam and two-dimensional zinc indium sulfide nanosheets vertically arranged on the surface of the nitrogen-doped graphene foam. The preparation method comprises the following steps: carrying out hydrophilic treatment on polyurethane sponge, soaking the polyurethane sponge in a graphene oxide suspension, drying the foam, calcining the dried foam, and carrying out O2 plasma cleaning to obtain three-dimensional nitrogen-doped graphene foam; and then mixing the three-dimensional nitrogen-doped graphene foam with an inorganic zinc salt, an inorganic indium salt and a sulfur-containing organic matter, carrying out a hydrothermal reaction, and carrying out post-treatment to obtain the zinc indium sulfide-nitrogen doped graphene foam compositephotocatalytic material. The composite material shows excellent photocatalytic activity under the irradiation of simulated sunlight, has enough ultraviolet-visible-near-infrared light photothermal conversion efficiency, enhances the utilization efficiency of sunlight, and has a good catalytic effect when being used for photocatalytic reduction of carbon dioxide.

Owner:WUHAN UNIV OF TECH

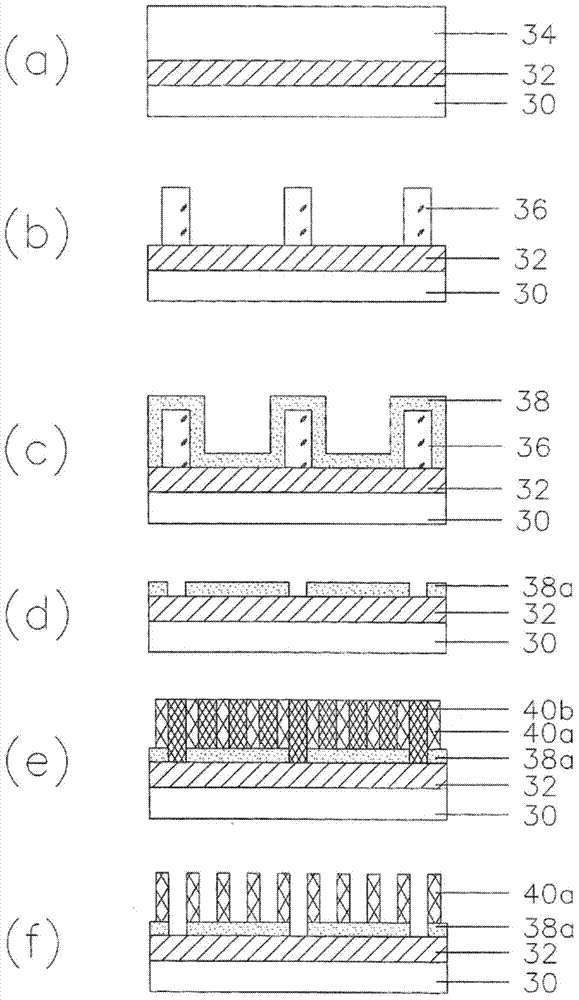

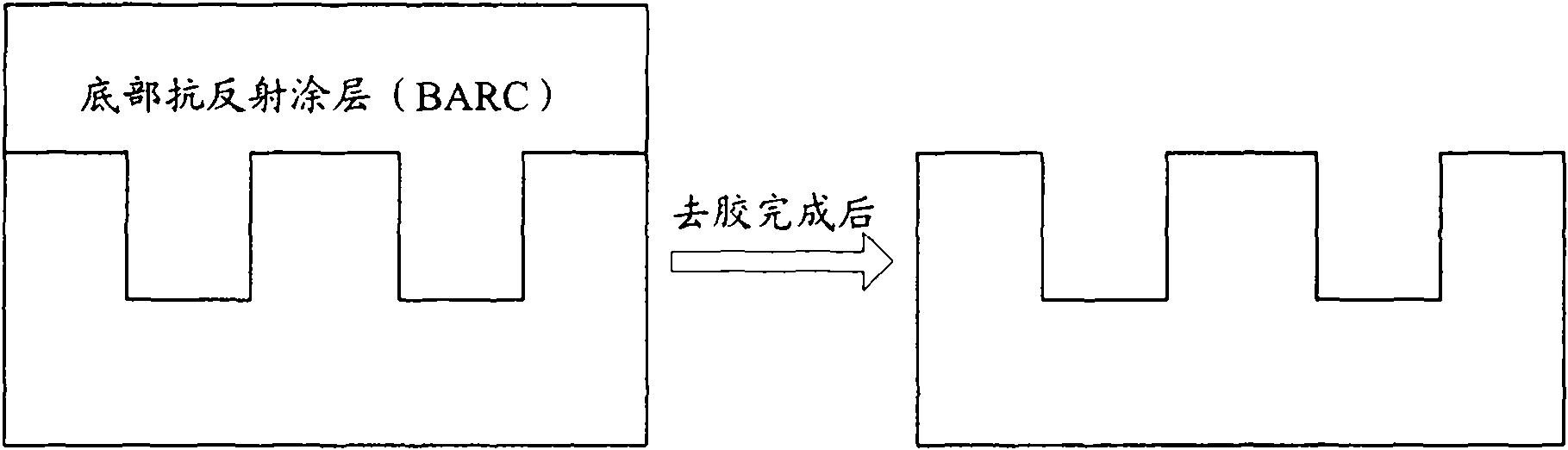

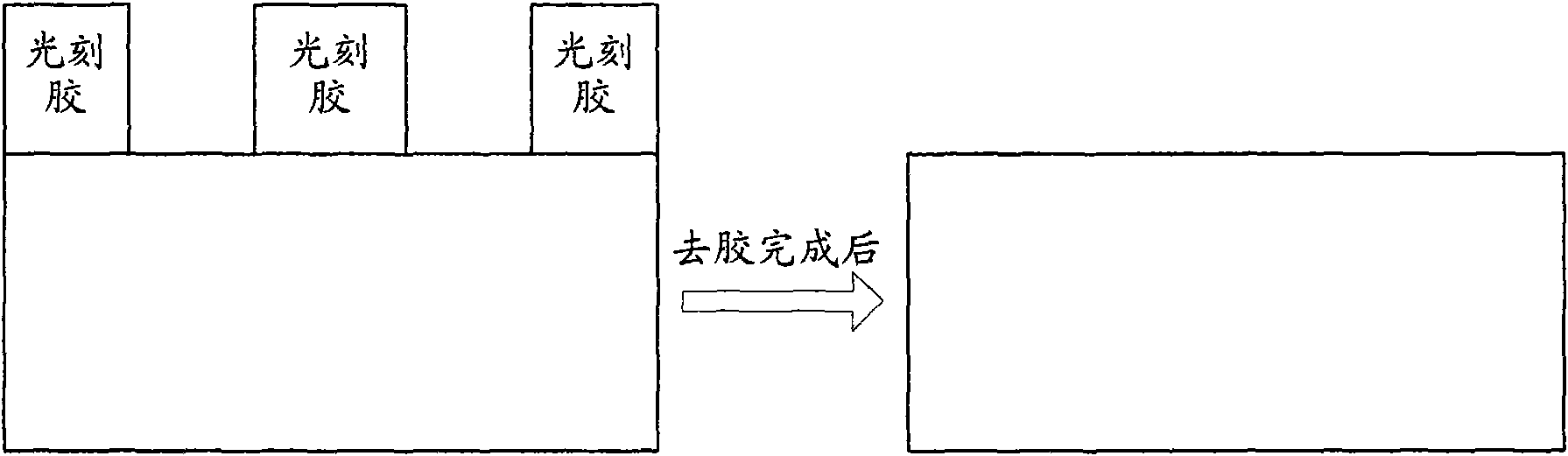

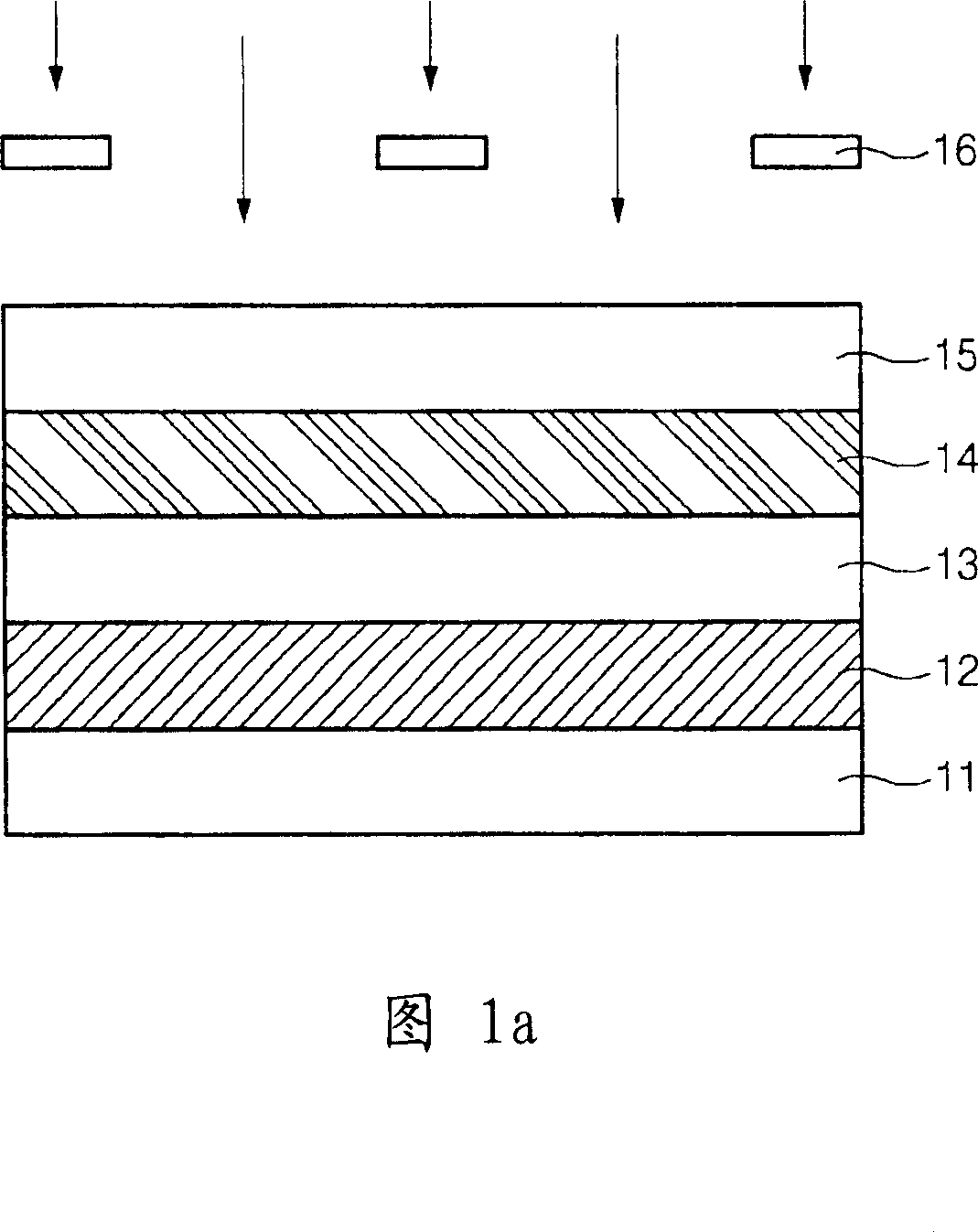

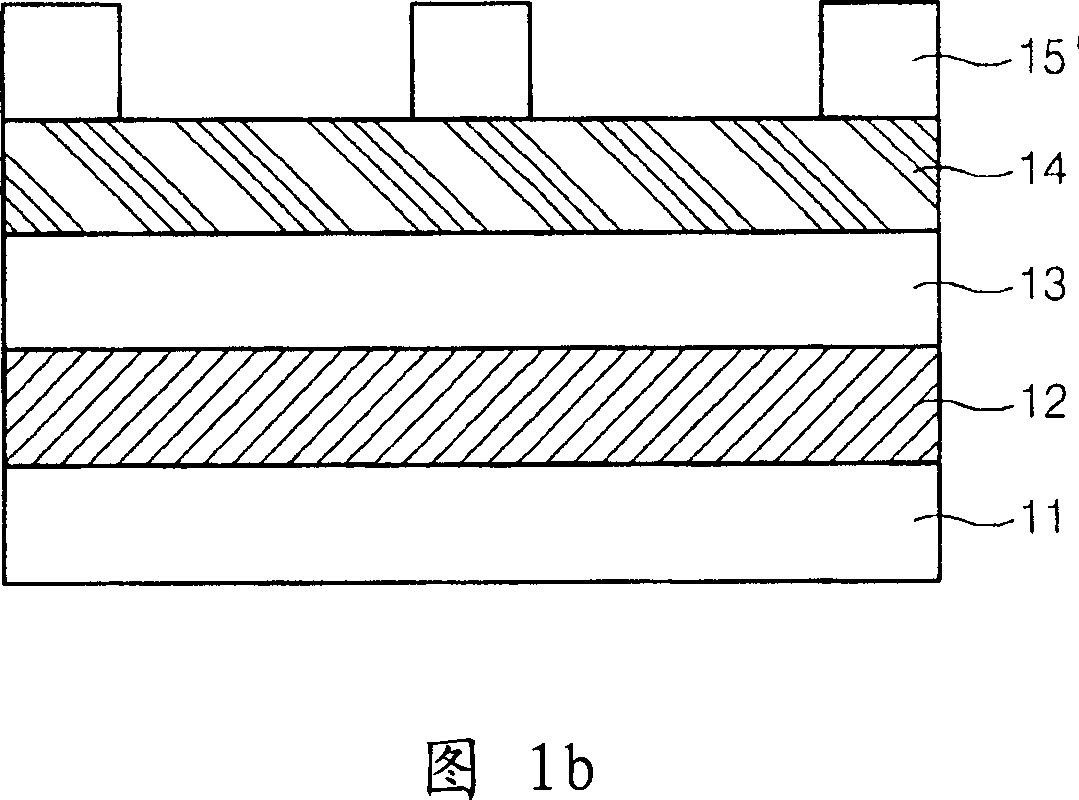

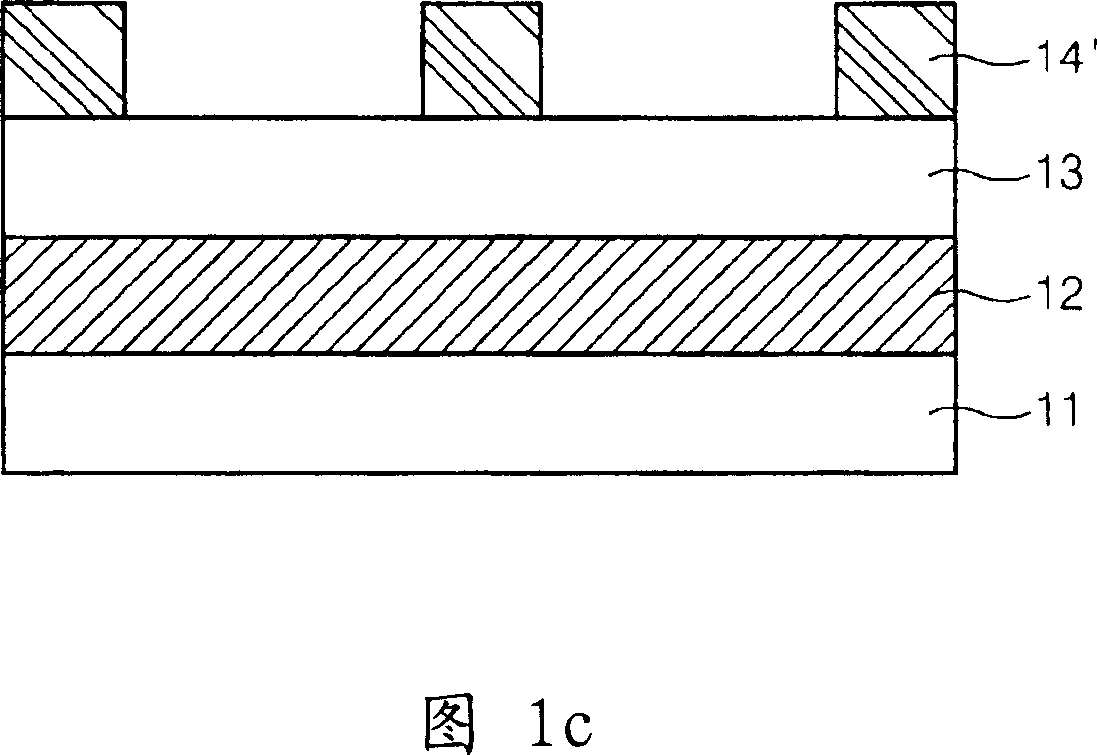

Method for forming pattern using argon fluoride photolithography

InactiveUS20030114012A1Decorative surface effectsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

A method for forming a photoresist pattern with minimally reduced transformations through the use of ArF photolithography, including the steps of: forming an organic anti-reflective coating layer on a an etch-target layer already formed on a substrate; coating a photoresist for ArF on the organic anti-reflective coating layer; exposing the photoresist with ArF laser; forming a first photoresist pattern by developing the photoresist, wherein portions of the organic anti-reflective coating layer are revealed; etching the organic anti-reflective coating layer with the first photoresist pattern as an etch mask and forming a second photoresist pattern by attaching polymer to the first photoresist pattern, wherein the polymer is generated during etching the organic anti-reflection coating layer with an etchant including O2 plasma; and etching the etch-target layer by using the second photoresist pattern as an etch mask.

Owner:SK HYNIX INC

Method for manufacturing semiconductor device

InactiveCN1992156ASemiconductor/solid-state device manufacturingPhotosensitive material processingO2 plasmaEngineering

Disclosed herein is a method for manufacturing a semiconductor device that includes performing an O2 plasma treatment step after forming a Si-containing anti-reflection film.

Owner:SK HYNIX INC

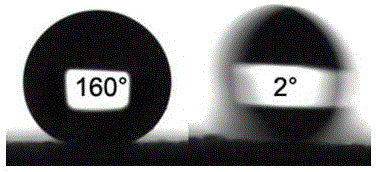

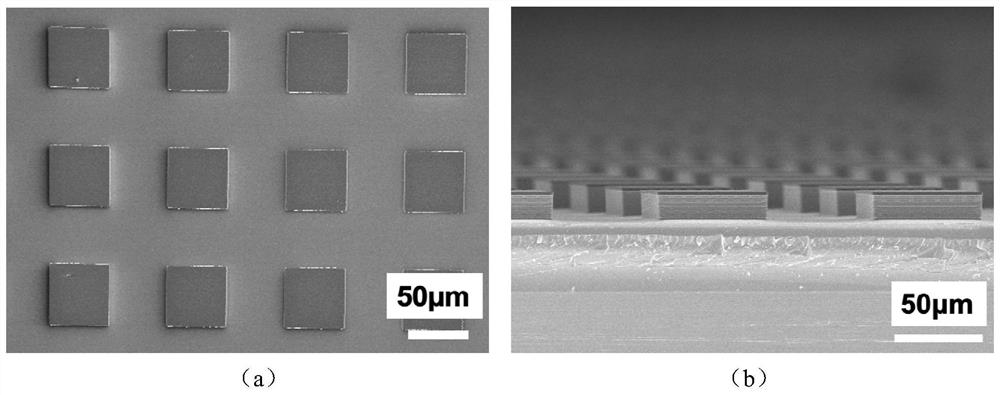

Preparation method of super-hydrophobic and super-oleophobic surface with micro-nano composite structure

PendingCN112744783ALarge and stable Laplace forceLarge and stable Cassie stateDecorative surface effectsNanotechnologyNano structuringO2 plasma

The invention discloses a preparation method of a super-hydrophobic and super-oleophobic surface with a micro-nano composite structure. The method comprises the following steps: firstly, preparing a suspended micron column array on a silicon surface by utilizing photoetching and deep silicon etching processes in a micro-nano processing technology, then depositing nano-silver particles at the tops of micron columns through a silver mirror reaction, and carrying out O2 plasma etching treatment to obtain a nano-composite structure; and finally, the obtained micro-nano composite structure being subjected to low surface energy modification through perfluoroalkyl chlorosilane, so that the super-hydrophobic and super-oleophobic functional surface is obtained. The micro-nano composite structure prepared by the method disclosed by the invention is adjustable in micron / nano structure shape, height and density, has the advantages of simplicity in operation, easiness in implementation, low cost and the like, can obtain very good mechanical properties, and has wide application prospects in the aspects of antifouling, self-cleaning, water-oil separation and the like.

Owner:NANJING UNIV

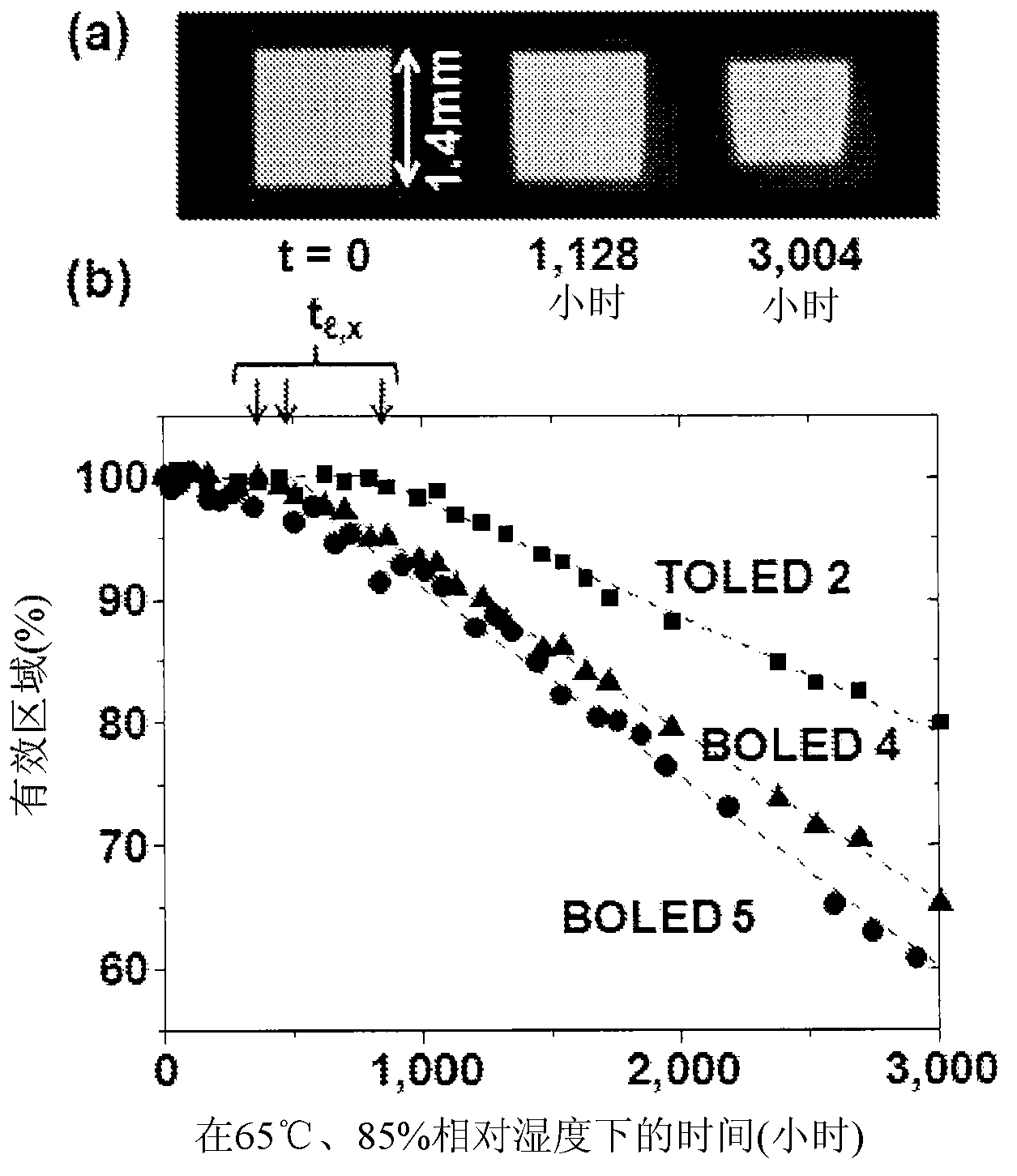

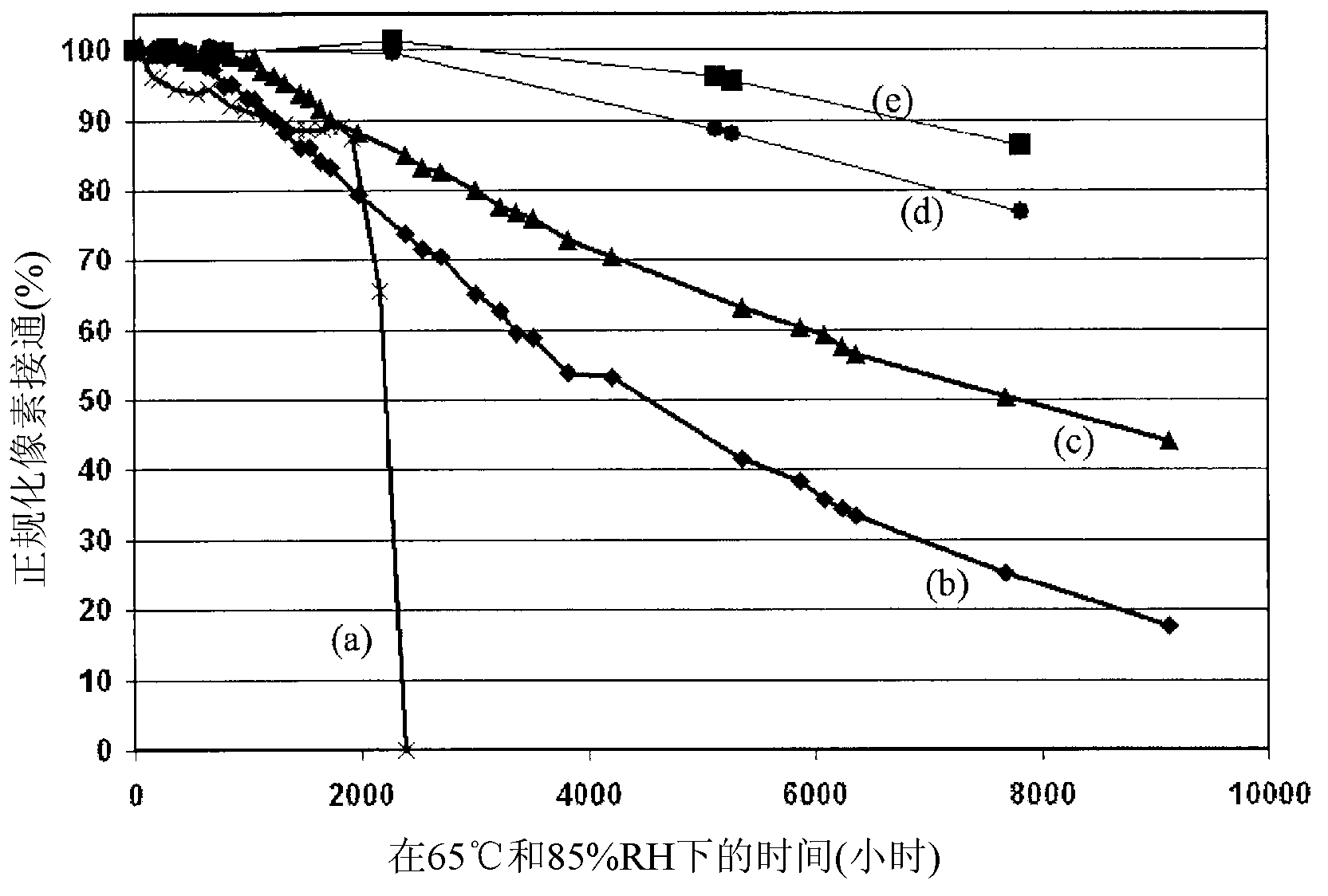

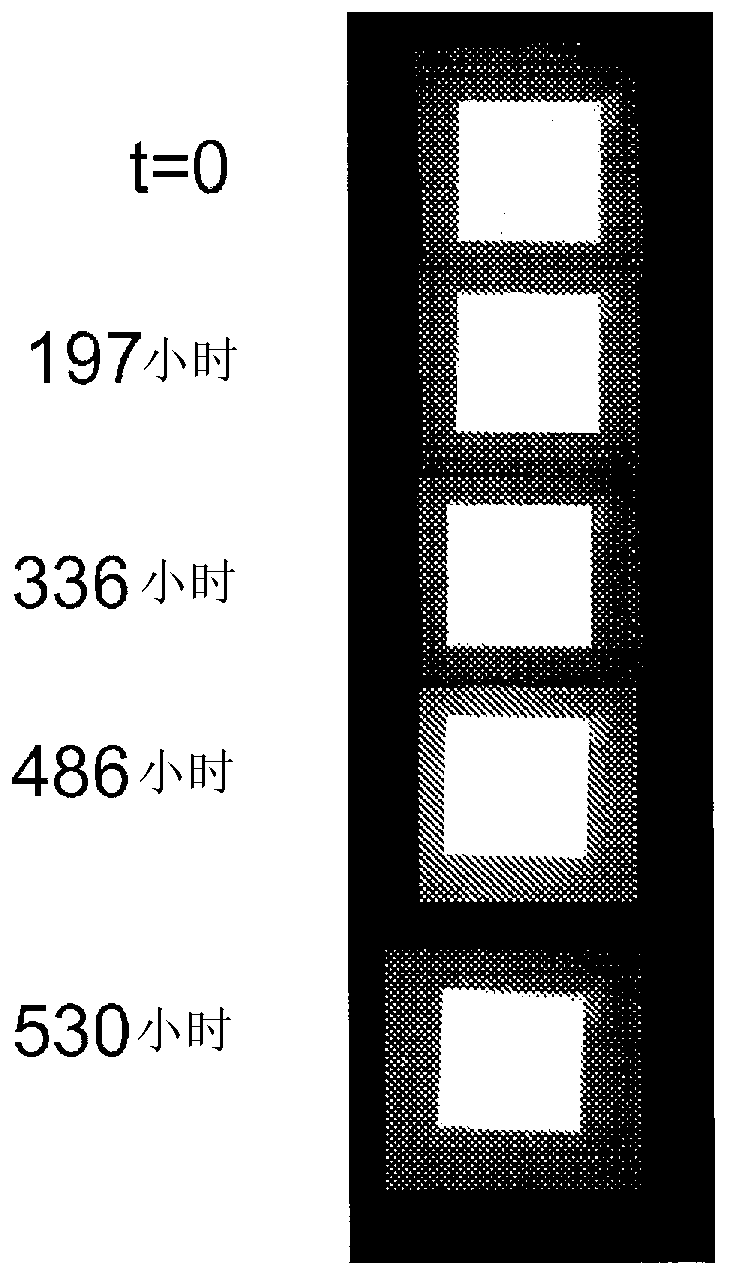

Permeation barrier for encapsulation of devices and substrates

A permeation barrier film structure for organic electronic devices includes one or more bilayers having a hybrid permeation barrier composition. Each of the one or more bilayers includes a first region having a first composition corresponding to a first CF4-O2 Plasma Reactive Ion Etch Rate and a second region having a second composition corresponding to a second CF4-O2 Plasma Reactive Ion Etch Rate, wherein the second Etch Rate is greater than the first Etch Rate by a factor greater than 1.2 and the hybrid permeation barrier film is a homogeneous mixture of a polymeric material and a non- polymeric material, wherein the mixture is created from a single precursor material.

Owner:UNIVERSAL DISPLAY

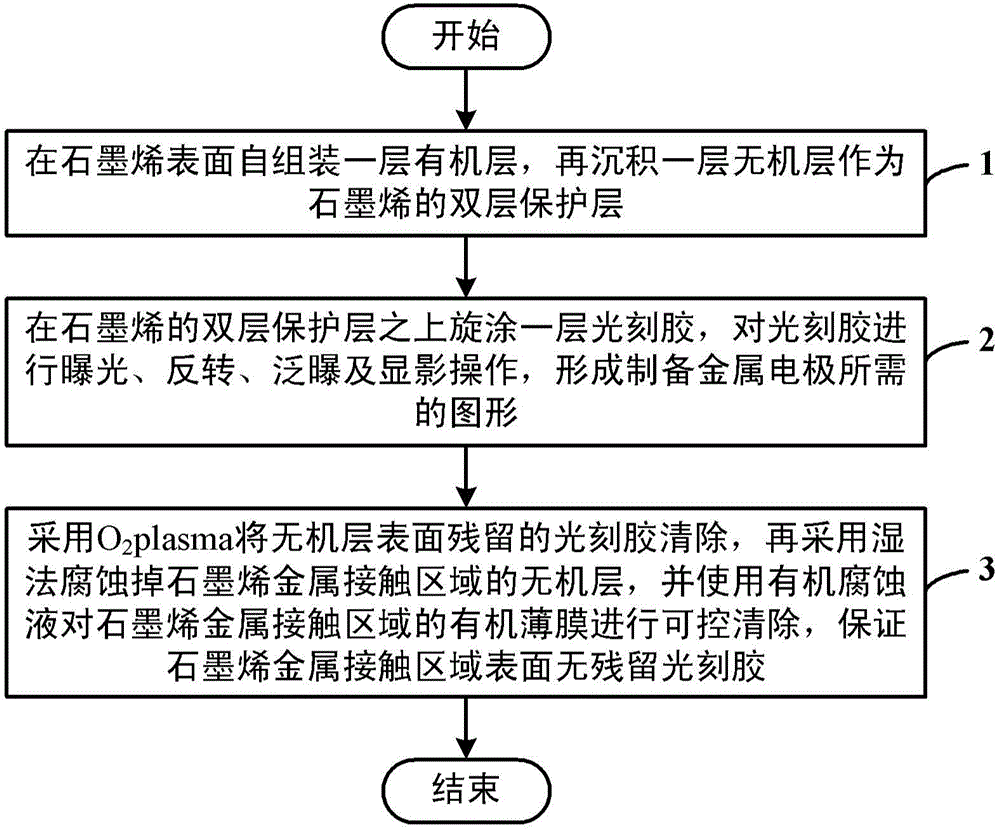

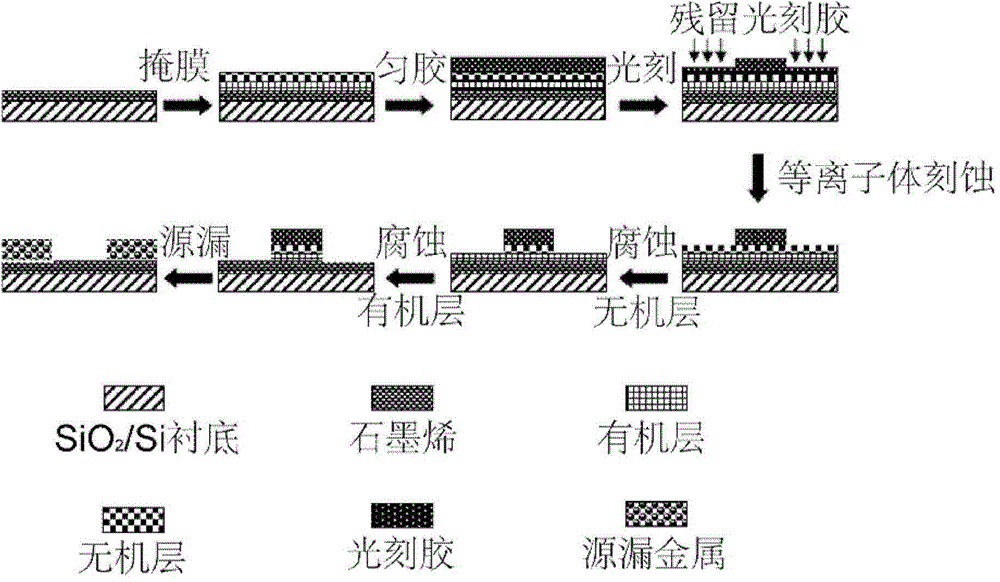

Method for controllably removing residual optical photoresist in graphene-metal contact region

InactiveCN104465328AAvoid direct contactWon't hurtSemiconductor/solid-state device manufacturingSelf assembleCharge carrier mobility

The invention discloses a method for controllably removing residual optical photoresist in a graphene-metal contact region. The method includes the steps that an organic layer is self-assembled on the surface of graphene, an inorganic layer is deposited, and the organic layer and the inorganic layer serve as double protective layers of graphene; the double protective layers of graphene are spin-coated with a layer of photoresist, the photoresist is exposed, reversely rotated, flooded and developed, and patterns needed for manufacturing a metal electrode are formed; residual photoresist on the surface of the inorganic layer is removed through O2 plasma, the portion, in the graphene-metal contact region, of the inorganic layer is etched away through a wet method, the portion, in the graphene-metal contact region, of an organic thin film is controllably removed through organic corrosive liquid, and it is guaranteed that no residual photoresist exists on the surface of the graphene-metal contact region. The problem that the photoresist is prone to be left on the surface of graphene is solved, graphene is not damaged, the doping degree of graphene is reduced, and an established graphene field effect transistor can keep the high carrier mobility of graphene materials and the performance of a device.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

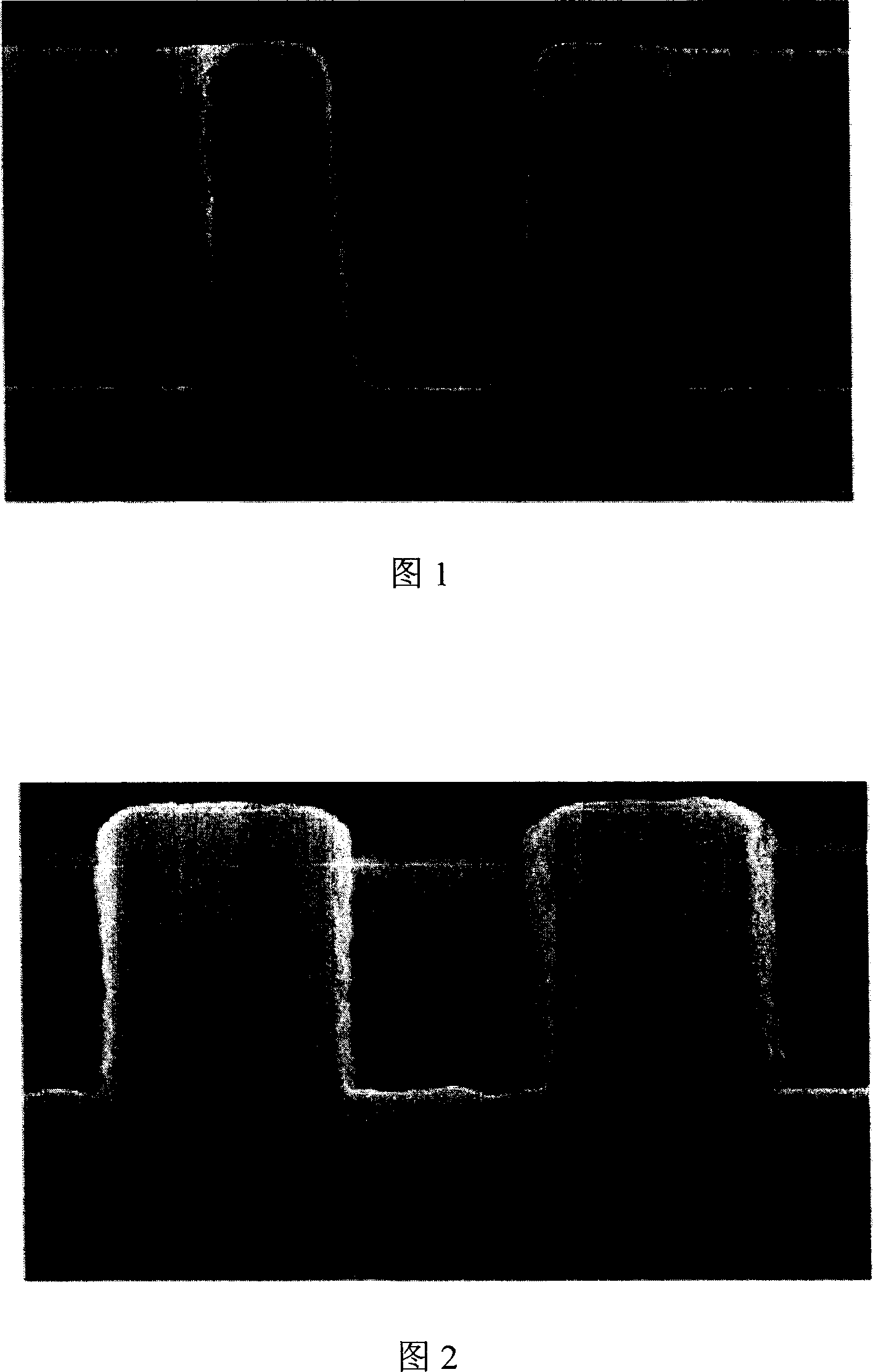

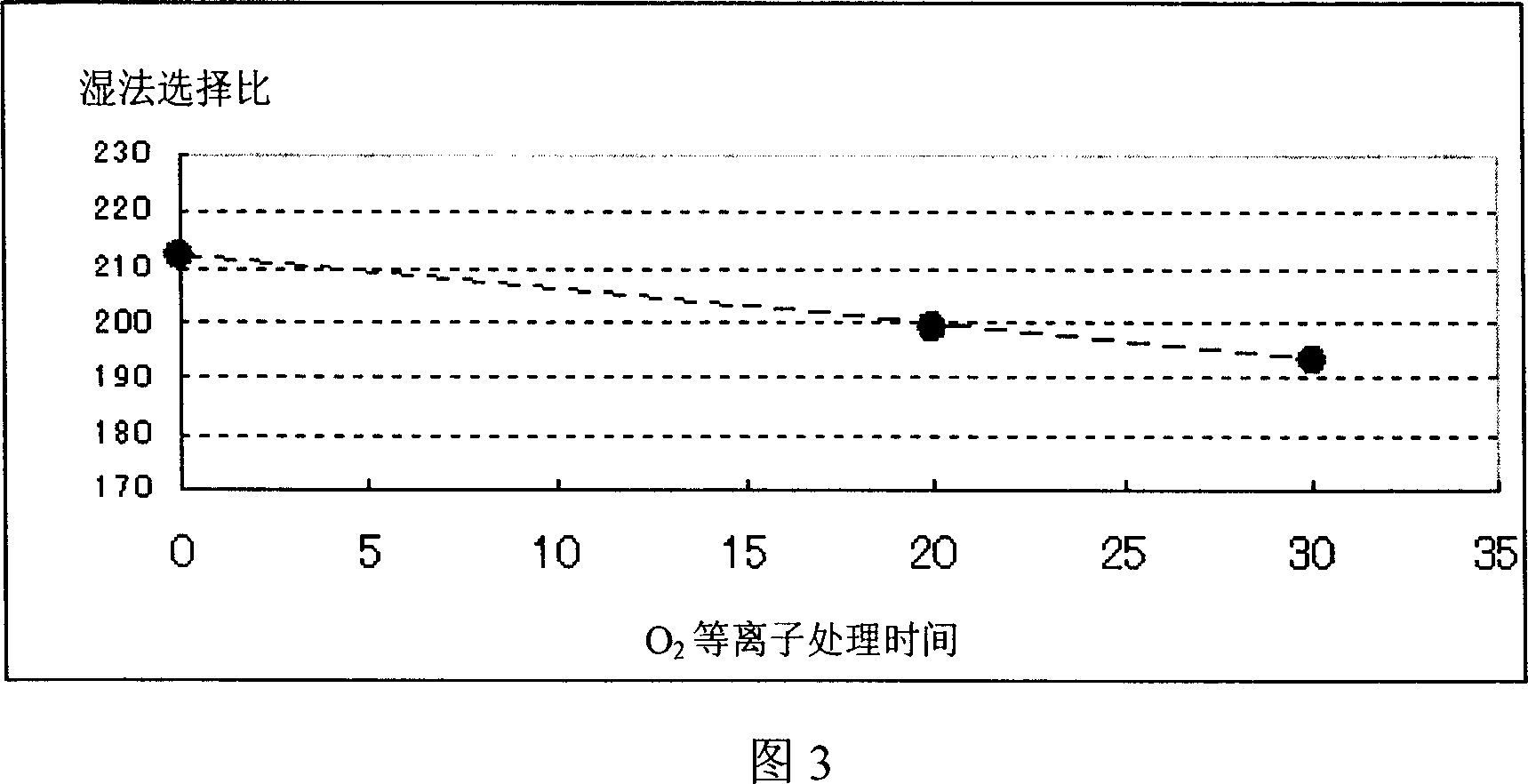

Production of semiconductor anti-reflective layer

InactiveCN1983520AHigh humidity selection ratioSimple methodPhotomechanical apparatusSemiconductor/solid-state device manufacturingDirect touchHigh volume manufacturing

The invention is concerned with the manufacture method of semiconductor anti-reflection layer, includes two steps that are the growth and the photo-etching of the anti-reflection layer, and a step that processes O2 plasma processing to the anti-reflection layer between the growth and the photo-etching steps. The invention can remove the footing or scumming phenomenon that creates by the direct touch of SiON and the DUV photo-etching pastern on the ARL with NH3, and have higher aqueous wet method selective rate for SiO2.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

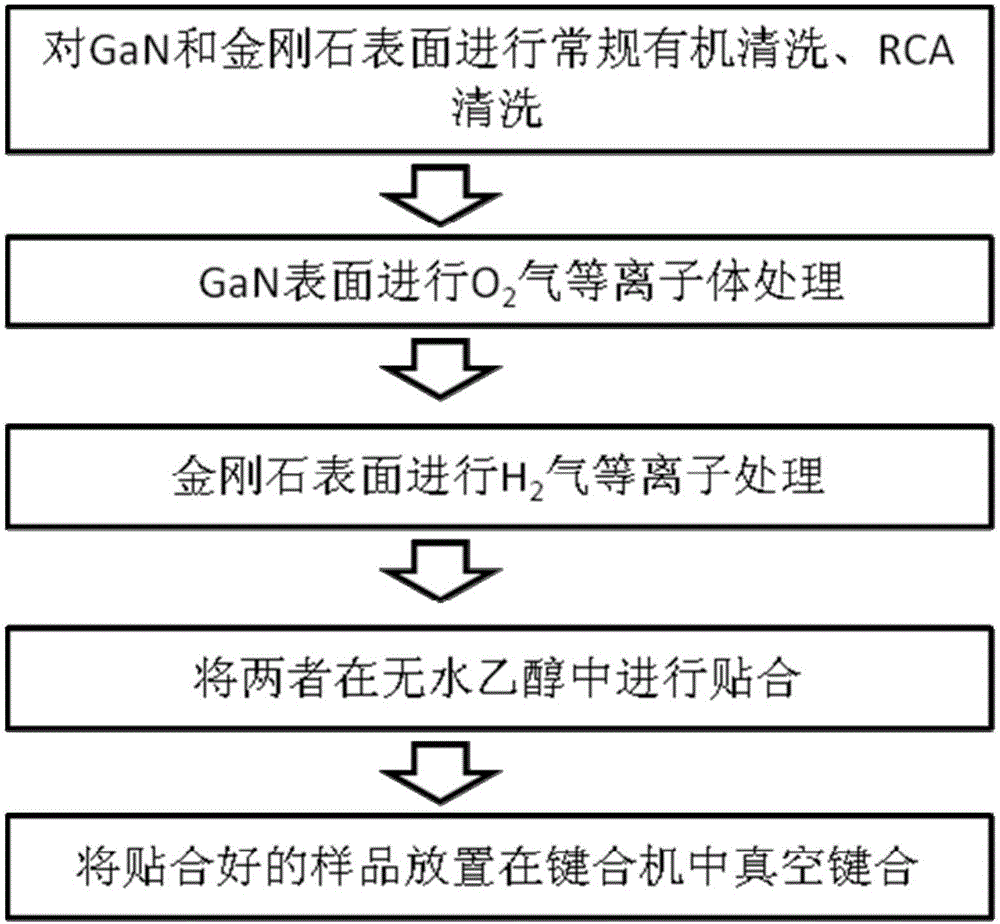

Diamond and GaN wafer direct bonding method

InactiveCN106783645AAchieve dense distributionSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingAlcoholO2 plasma

The invention discloses a damond and GaN wafer direct bonding method. The method comprises the following steps that: (1) organic cleaning and RCA cleaning are performed on a diamond surface and a GaN surface; (2) O2 plasma treatment is performed on the GaN surface; (3) H2 plasma treatment is performed on the diamond surface; (4) the treated diamond surface and the GaN surface are attached to each other in absolute ethyl alcohol; and (5) an obtained attached sample is arranged in a bonding machine so as to be subjected to bonding under high vacuum environment.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD +1

A kind of superhydrophobic superoleophobic anti-reflection glass surface layer and preparation method thereof

Owner:JIANGNAN UNIV

Organic electroluminescent device

InactiveUS7592635B2Improve luminous performanceImprove efficiencyElectroluminescent light sourcesSolid-state devicesO2 plasmaOrganic electroluminescence

Owner:SAMSUNG DISPLAY CO LTD

Method for manufacturing semiconductor device

InactiveCN1992155ASemiconductor/solid-state device manufacturingPhotosensitive material processingO2 plasmaEngineering

Disclosed herein is a method for manufacturing a semiconductor device that includes performing an O2 plasma treatment step after forming a Si-containing photoresist film.

Owner:SK HYNIX INC

Cross-linked elastomer composition and formed product composed of such cross-linked elastomer composition

ActiveCN1735662ASmall weight changeSignificant plasma toleranceOther chemical processesElastomerCross-link

There is provided a crosslinkable elastomer composition, which has small decrease in weight to all of high concentration F radical irradiation, O2 plasma treatment and fluorine plasma treatment which are conducted in a semiconductor manufacturing process and significant plasma resistance, and a molded article comprising the crosslinkable elastomer composition.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com