Super-hydrophobic super-oleophobic anti-reflection glass surface layer and preparation method thereof

A super-hydrophobic super-oleophobic, glass surface technology, applied in the field of surface treatment, new materials, self-cleaning optical materials, can solve the problems of unstable performance, insufficient durability, poor mechanical properties, etc., to achieve high light transmittance and Hydrophobic and oleophobic, enhanced coating ability, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

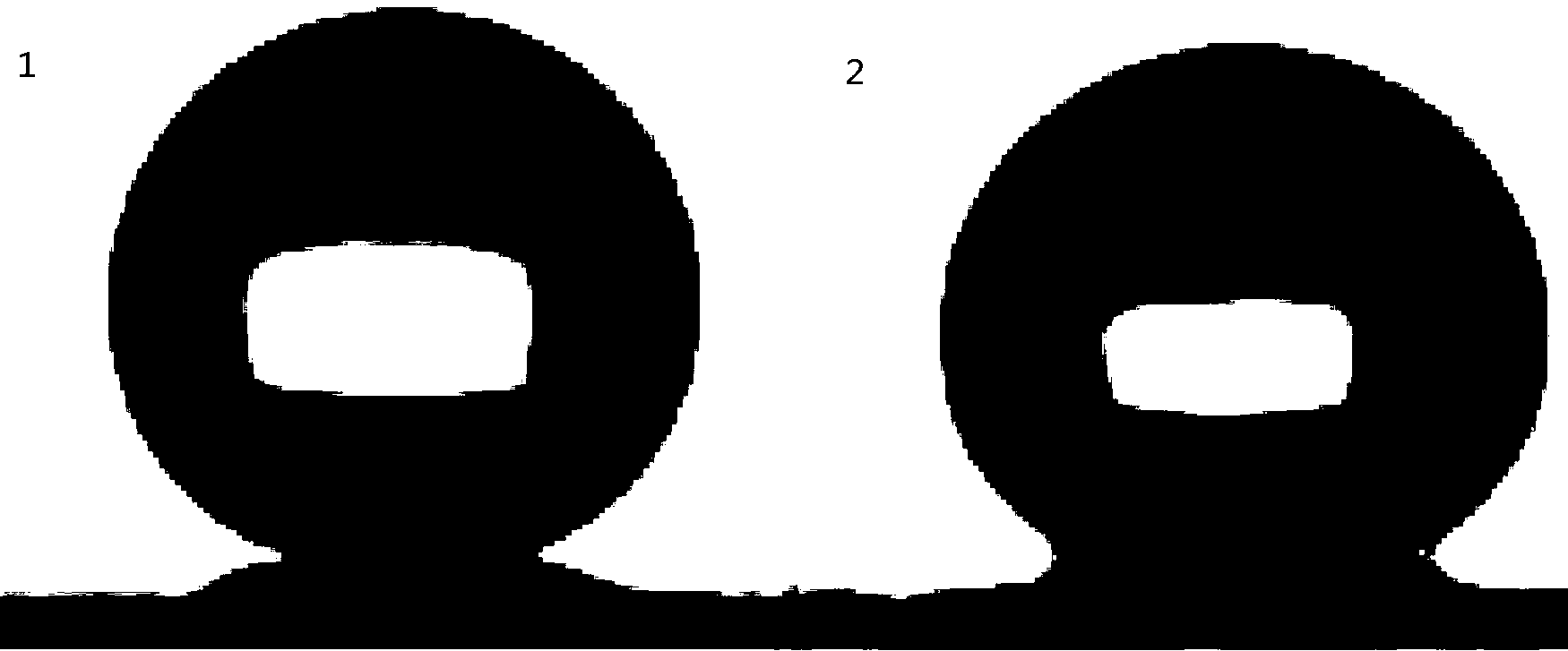

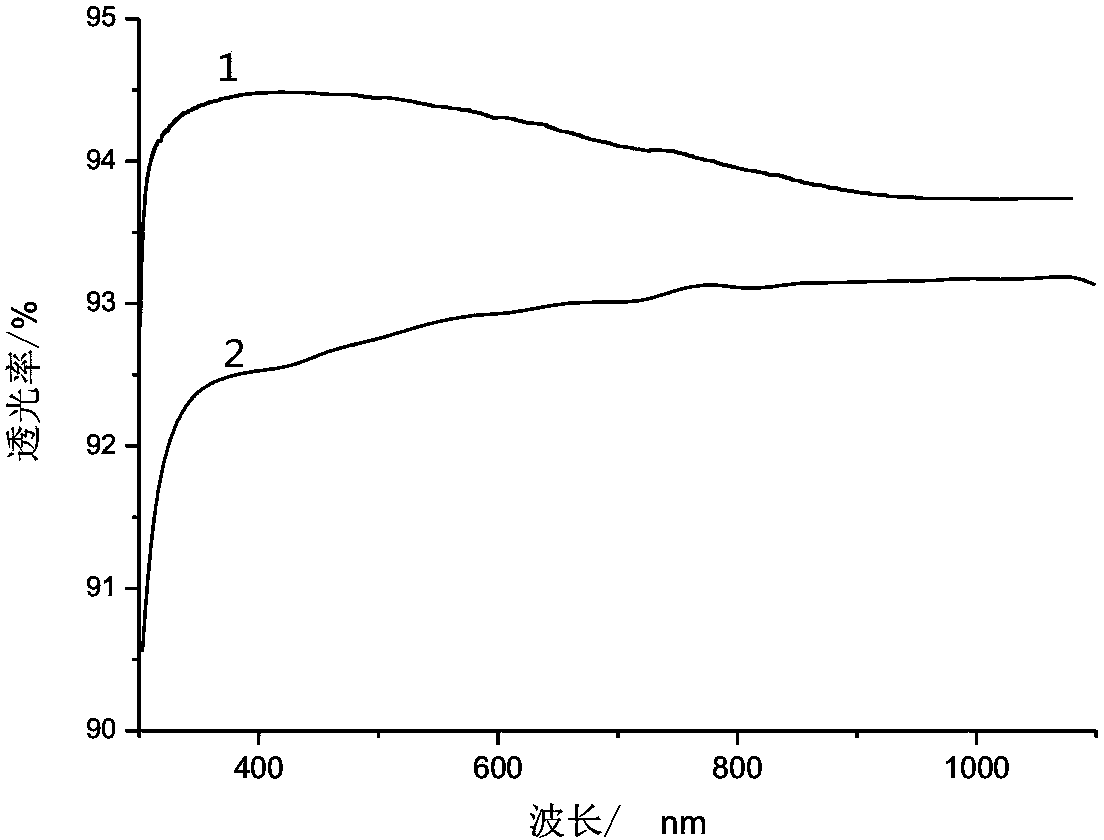

[0022] This example is the preparation of superhydrophobic superoleophobic anti-reflection glass surface layer. The specific process is as follows: the glass substrate is ultrasonicated in deionized water and absolute ethanol for 20 minutes respectively to clean the glass substrate; 3 :O 2 The volume ratio is 4:1, the gas mixture pressure is 80Pa, and the power is 1.8W / cm 2 Under certain conditions, plasma etching was performed on the clean glass surface to obtain a submicron-scale rough glass surface; 4 mL tetraethyl orthosilicate was added dropwise to a mixed solvent composed of 15 mL absolute ethanol and 8 mL water, and 20 wt % Pluronic F108 was added (BASF company) ethanol solution 4mL, stirred for 0.5h to obtain a mixed solution, dropwise added 1mL of concentrated hydrochloric acid (36wt%) to the above mixed solution; stirred at room temperature for 2h to obtain SiO 2 Sol dipping solution; the submicron rough glass surface is immersed in SiO at a speed of 50mm / min 2 St...

Embodiment 2

[0024] This example is the preparation of superhydrophobic superoleophobic anti-reflection glass surface layer. The specific process is as follows: the glass substrate is ultrasonicated in deionized water and absolute ethanol for 20 minutes respectively to clean the glass substrate; 3 :O 2 The volume ratio is 4:1, the gas mixture pressure is 90Pa, and the power is 1.9W / cm 2 Under certain conditions, plasma etching was performed on the clean glass surface to obtain a submicron-sized rough glass surface; 4 mL tetraethyl orthosilicate was added dropwise to a mixed solvent composed of 20 mL absolute ethanol and 9 mL water, and 20 wt % Pluronic F127 was added (BASF company) ethanol solution 6mL, stirred for 0.5h to obtain a mixed solution, dropwise added 1mL of concentrated hydrochloric acid (36wt%) to the above mixed solution; stirred at room temperature for 2.5h to obtain SiO 2 Sol dipping solution; the submicron rough glass surface is immersed in SiO at a speed of 50mm / min 2 ...

Embodiment 3

[0026] This example is the preparation of superhydrophobic superoleophobic anti-reflection glass surface layer. The specific process is as follows: the glass substrate is ultrasonicated in deionized water and absolute ethanol for 20 minutes respectively to clean the glass substrate; 3 :O 2 The volume ratio is 4:1, the gas mixture pressure is 100Pa, and the power is 2.0W / cm 2 Under certain conditions, plasma etching was performed on the clean glass surface to obtain a submicron-sized rough glass surface; 4 mL tetraethyl orthosilicate was added dropwise to a mixed solvent composed of 23 mL absolute ethanol and 10 mL water, and 20 wt % Pluronic P123 was added (BASF company) ethanol solution 8mL, stirred for 0.5h to obtain a mixed solution, dropwise added 1mL of concentrated hydrochloric acid (36wt%) to the above mixed solution; stirred at room temperature for 3h to obtain SiO 2 Sol dipping solution; the submicron rough glass surface is immersed in SiO at a speed of 50mm / min 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com