Method for preparing phase-changing fiber having core-shell beaded structure

A phase-change fiber and core-shell beading technology, which is applied in fiber processing, conjugated synthetic polymer rayon, textiles, and papermaking, can solve the problems of phase-change fibers such as flammability, poor coating, and low energy storage density , to achieve the effects of increasing energy storage density, improving cladding, and reducing preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

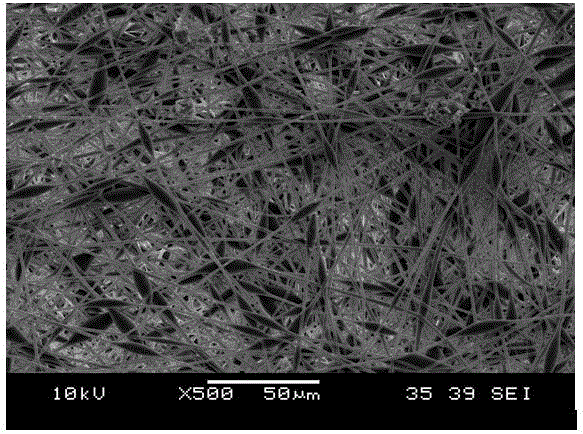

Image

Examples

Embodiment 1

[0023] A preparation method of a phase-change fiber with a core-shell beaded structure, specifically comprising the following steps:

[0024] (1) Dissolve thermoplastic phenolic resin (5g) and polyethylene glycol formal (10g) in methanol (100g), stir at room temperature for 10min to form a uniform solution, and pour it into a syringe connected to the spinning scalp;

[0025] (2) Use n-tetradecane as a phase change material and pour it into a syringe connected to the core layer of the spinning head;

[0026] (3) Connect the coaxial electrospinning device, set the injection rates of the core layer phase change material and the skin layer resin solution to 0.01mL / h and 0.3mL / h respectively, and the distance between the tip of the spinning head and the substrate to be 8cm , the voltage between the two is 5KV, the experimental environment temperature is set to 20°C, and the phase change primary fiber is obtained on the rotating receiving device;

[0027] (4) In hydrochloric acid a...

Embodiment 2

[0030] A preparation method of a phase-change fiber with a core-shell beaded structure, specifically comprising the following steps:

[0031] (1) Dissolve thermoplastic phenolic resin (60g) and polyethylene glycol formal (20g) in methanol (100g), stir at room temperature for 10min to form a uniform solution, and pour it into a syringe connected to the spinning scalp;

[0032] (2) Use n-hexadecane and n-docosane mixed at a weight ratio of 1:1 as a phase change material, and pour it into a syringe connected to the core layer of the spinning head;

[0033] (3) Connect the coaxial electrospinning device, set the injection rates of the core layer phase change material and the skin layer resin solution to 2mL / h and 6mL / h, respectively, and the distance between the tip of the spinning head and the substrate to be 40cm. The voltage between them is 30KV, the experimental environment temperature is set to 30°C, and the phase change primary fibers are obtained on the rotating receiving d...

Embodiment 3

[0038] A preparation method of a phase-change fiber with a core-shell beaded structure, specifically comprising the following steps:

[0039] (1) Dissolve thermoplastic phenolic resin (20g) and polyethylene glycol formal (15g) in methanol (100g), stir at room temperature for 10min to form a uniform solution, and pour it into a syringe connected to the spinning scalp;

[0040] (2) Using Na 2 SO 4 The aqueous solution is used as a phase change material and poured into a syringe connected to the core layer of the spinning head;

[0041] (3) Connect the coaxial electrospinning device, set the injection rates of the core layer phase change material and the skin layer resin solution to 1mL / h and 2mL / h, respectively, and the distance between the tip of the spinning head and the substrate to be 20cm. The voltage between them is 20KV, the experimental environment temperature is set at 25°C, and the phase change primary fibers are obtained on the rotating receiving device;

[0042] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com