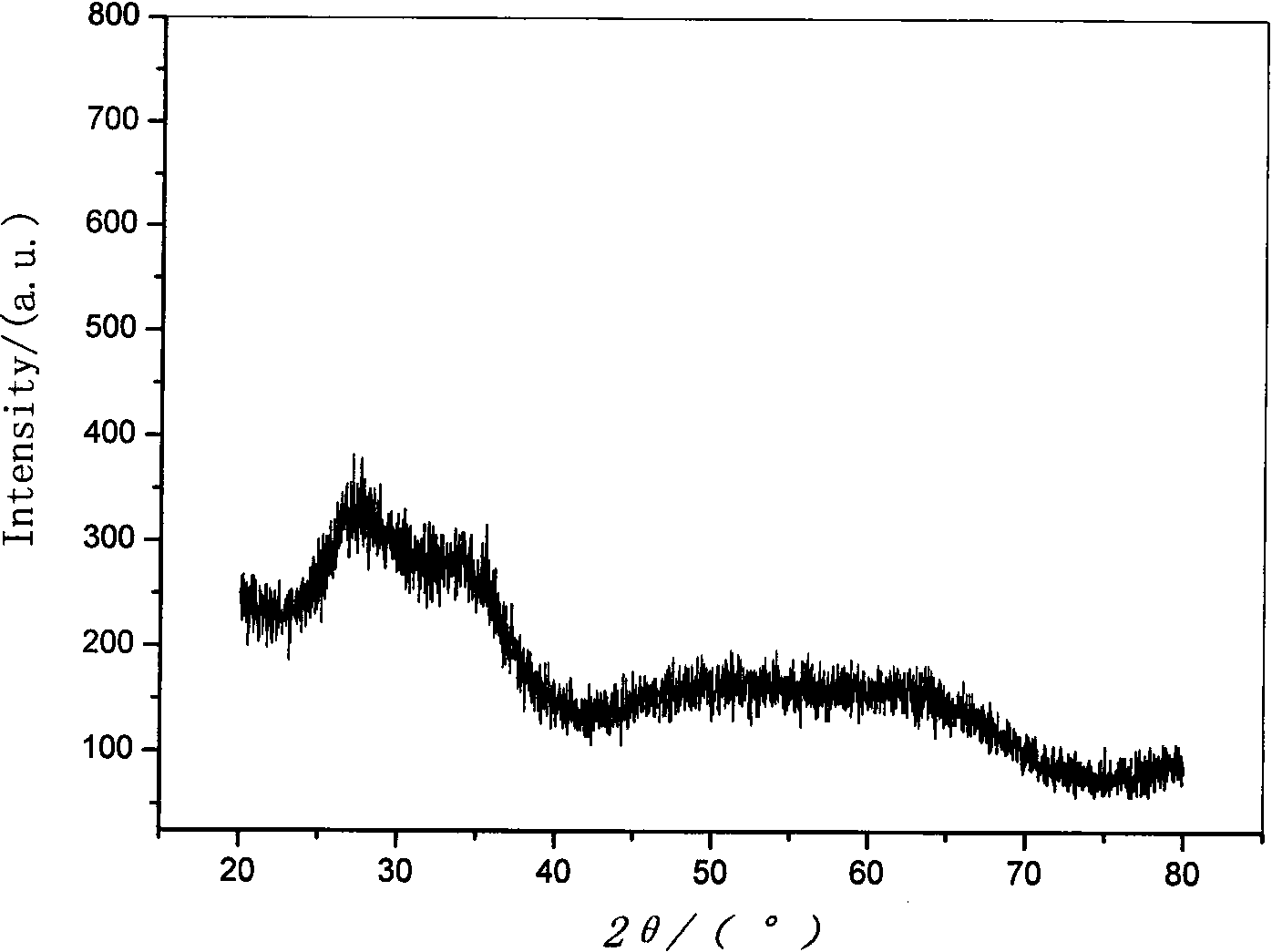

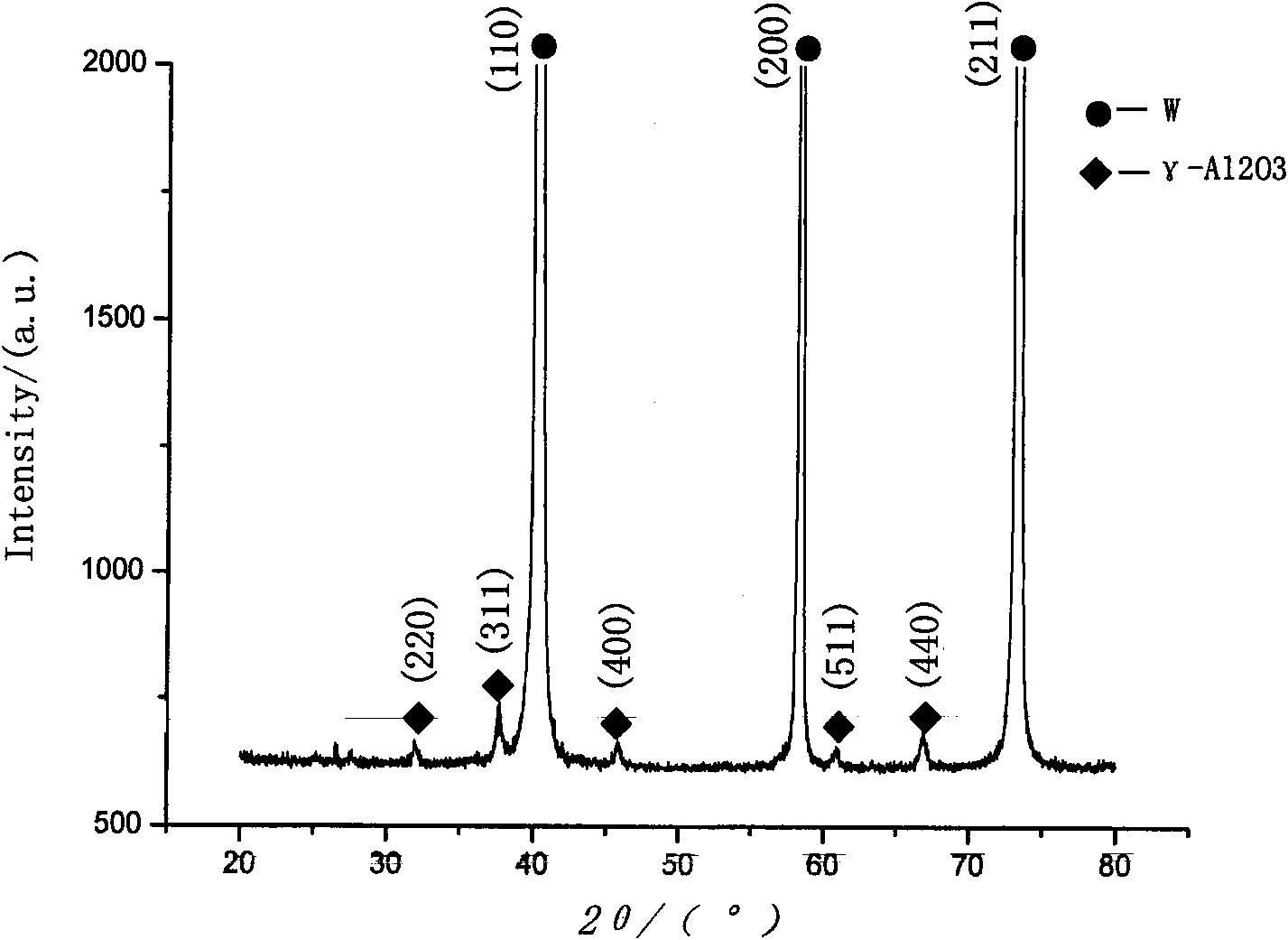

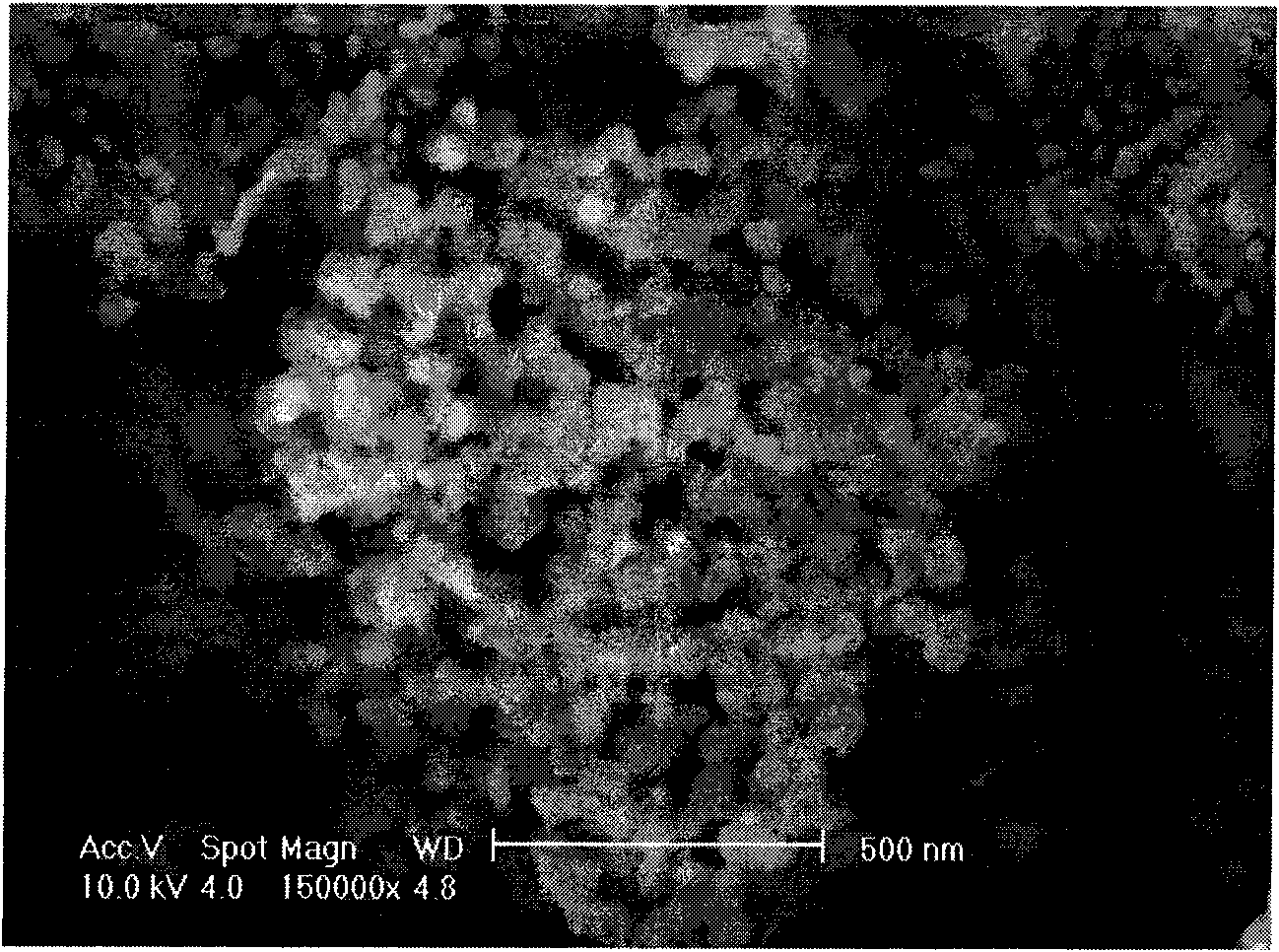

Method for preparing nano aluminum oxide coated tungsten powder

A technology of nano-alumina and coating tungsten powder, which is applied to the preparation of composite powder coated with nano-alumina on the surface of tungsten powder, and the field of preparation of nano-alumina-coated tungsten powder, which can solve the problem of expensive raw materials and coating powder. Agglomeration, harsh preparation conditions and other problems, to achieve the effect of preventing single-phase particle segregation, cheap and easy to obtain raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) According to the final molar ratio of alumina and tungsten powder is 2: 8, weigh 3.567 grams of ammonium metatungstate white crystal powder and 2.222 grams of aluminum sulfate white crystal powder respectively, dissolve the two in 250 milliliters of distilled water, wait clarify;

[0023] (2) Use a nitrogen spray gun to disperse the clarified mixed solution in liquid nitrogen to obtain a frozen substance, and the spray gun pressure is 1.5 atmospheres;

[0024] (3) Place the frozen material in a freeze dryer for vacuum drying. The execution procedure of the freeze dryer is as follows: the working pressure is 250 millitorr and the temperature is -24°C within 0 to 2400 minutes; The working pressure is 150 millitorr and the temperature is -14°C; the working pressure is 80 millitorr and the temperature is -1°C within 3800 to 4600 minutes; the working pressure is 0 millitorr and the temperature is 4600 to 4800 minutes 20°C;

[0025] (4) Put the freeze-dried mixed powder...

Embodiment 2

[0027] (1) According to the final molar ratio of alumina and tungsten powder is 2: 8, weigh 4.28 grams of ammonium metatungstate white crystal powder and 2.666 grams of aluminum sulfate white crystal powder respectively, dissolve the two in 300 milliliters of distilled water, wait clarify;

[0028] (2) Use a nitrogen spray gun to disperse the clarified mixed solution in liquid nitrogen to obtain a frozen substance, and the spray gun pressure is 2 atmospheres;

[0029] (3) Place the frozen material in a freeze dryer for vacuum drying. The execution procedure of the freeze dryer is as follows: the working pressure is 300 millitorr and the temperature is -26°C within 0 to 2400 minutes; The working pressure is 160 millitorr and the temperature is -13°C; the working pressure is 50 millitorr and the temperature is 0°C within 3800 to 4600 minutes; the working pressure is 0 millitorr and the temperature is 25 within 4600 to 4800 minutes ℃;

[0030] (4) Put the freeze-dried mixed pow...

Embodiment 3

[0033] (1) According to the molar ratio of final alumina and tungsten powder is 2: 8, weigh 5.35 grams of ammonium metatungstate white crystal powder and 3.332 grams of aluminum sulfate white crystal powder respectively, dissolve the two in 400 milliliters of distilled water, wait clarify;

[0034] (2) Use a nitrogen spray gun to disperse the clarified mixed solution in liquid nitrogen to obtain a frozen substance, and the spray gun pressure is 2.5 atmospheres;

[0035] (3) Place the frozen material in a freeze dryer for vacuum drying. The execution procedure of the freeze dryer is as follows: the working pressure is 350 millitorr and the temperature is -28°C within 0 to 2400 minutes; The working pressure is 180 millitorr and the temperature is -15°C; the working pressure is 100 millitorr and the temperature is -3°C within 3800 to 4600 minutes; the working pressure is 20 millitorr and the temperature is 4600 to 4800 minutes 15°C;

[0036] (4) Put the freeze-dried mixed powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com