An in-situ nitrogenous polymer nitrogen-doped active carbon nanofiber and a preparation method and use thereof

A nano-carbon fiber and polymer technology, applied in the field of nano-materials, achieves the effects of uniform distribution, high specific capacitance, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

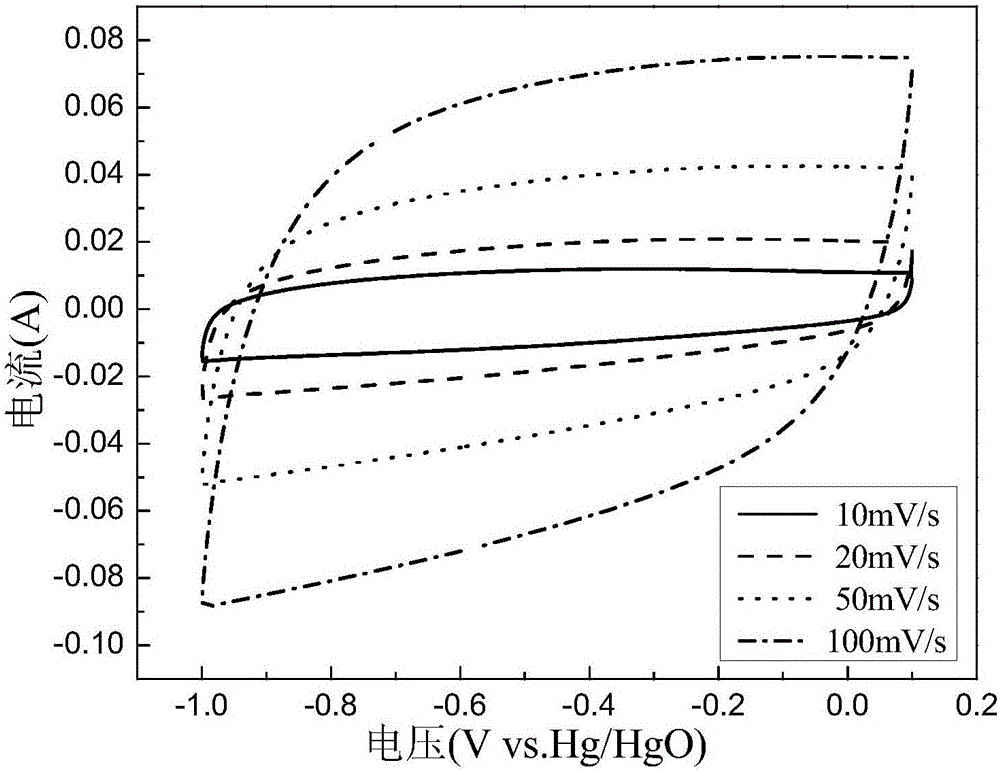

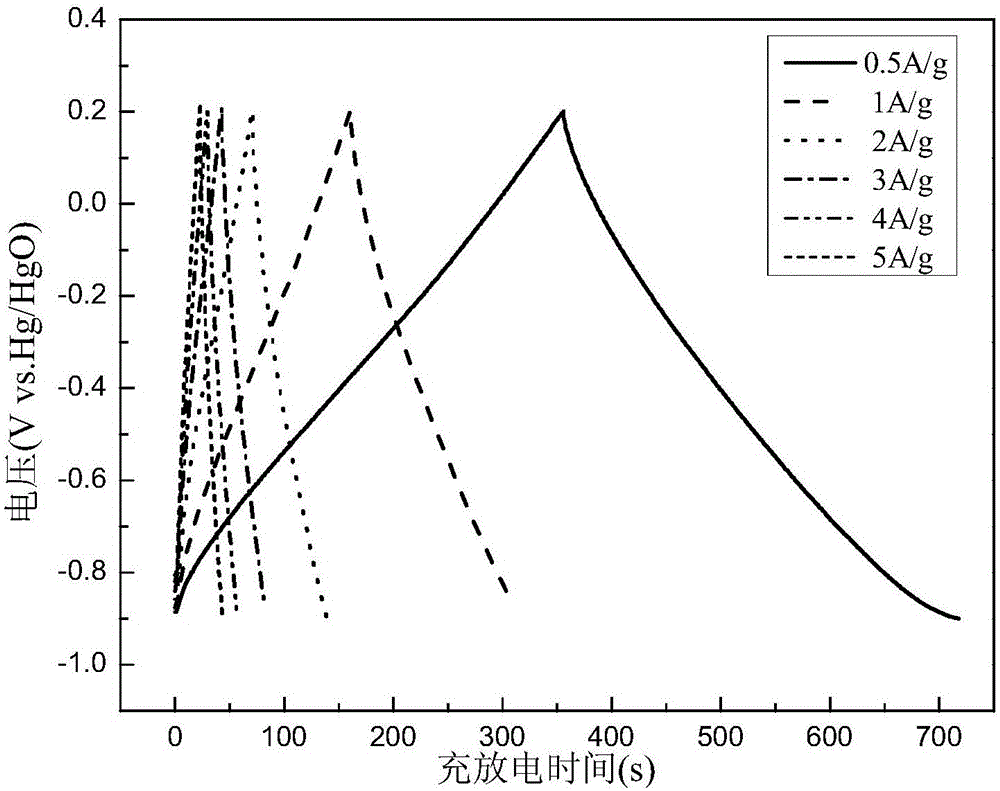

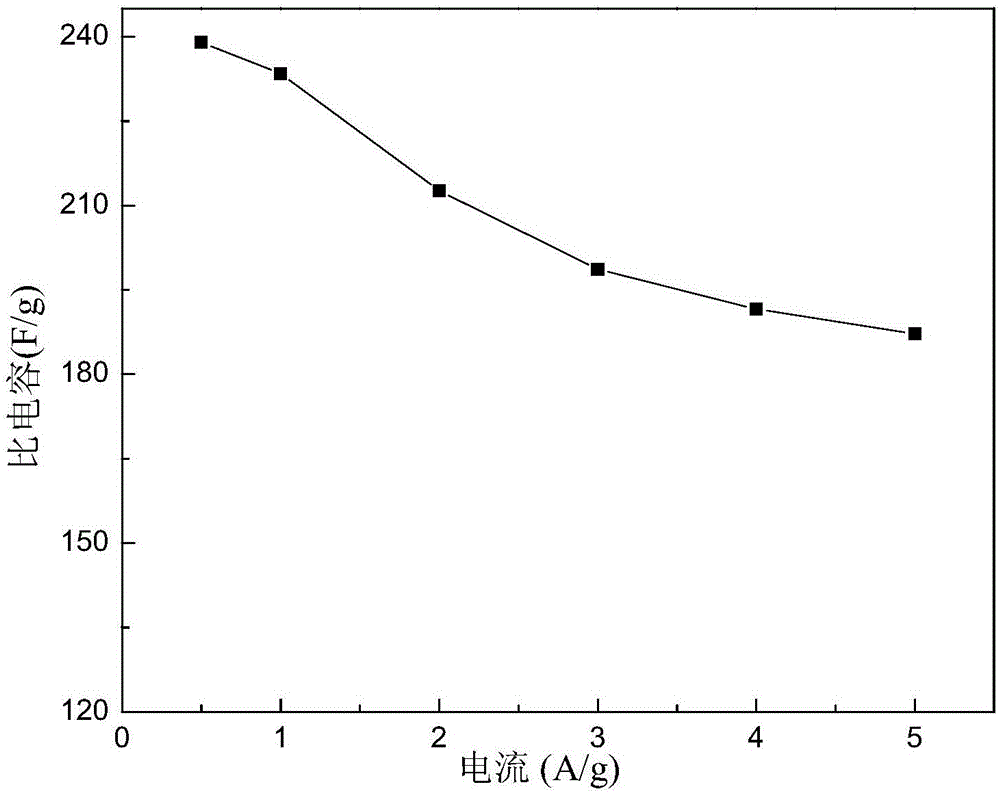

Examples

Embodiment 1

[0057] (1) Put 6g of gelatinous bacterial cellulose into a certain amount of water, stir it with a homogenizer to make it a 100mL bacterial cellulose homogenate; add a certain amount of pyrrole to the bacterial cellulose homogenate under stirring conditions, Wherein the mass ratio of pyrrole and bacterial cellulose is 1:5; continue to stir for 1 h to disperse pyrrole in the homogenate to obtain a mixed solution; weigh ammonium persulfate in an equimolar amount to pyrrole, and prepare 40 mL of persulfate with deionized water. Ammonium sulfate solution, put the homogenate and ammonium persulfate solution in ice water to keep the ambient temperature at about 0°C, then slowly add ammonium persulfate to the mixture at a controlled rate, and the time for adding 40mL of this solution is controlled at about 50min , continue to react for 9h, obtain in-situ polypyrrole-coated bacterial cellulose; filter and wash with deionized water and ethanol;

[0058] (2) Soak the above product with ...

Embodiment 2

[0067] The mass ratio of pyrrole and bacterial cellulose in Example 1 was changed to 1:1, and other preparation processes were unchanged, and the doped modified carbon nanofiber was prepared. The performance of the obtained material was tested according to the electrochemical performance test in Example 1. According to the specific capacitance-current curve calculation, the prepared electrode has a specific capacitance of 250F / g at a current density of 0.5A / g, and a cycle charge-discharge curve at a current density of 4A / g, wherein the specific capacitance of the first discharge is 150F / g, The specific capacitance of the 5000th cycle is 124F / g, and the specific capacity retention rate is 82.67%.

Embodiment 3

[0069] The mass ratio of pyrrole and bacterial cellulose in Example 1 was changed to 1:10, and other preparation processes were unchanged, and the doped modified carbon nanofiber was prepared. The performance of the obtained material was tested according to the electrochemical performance test in Example 1. According to the specific capacitance-current curve calculation, the specific capacitance of the prepared electrode reaches 228F / g at a current density of 0.5A / g, and the cycle charge-discharge curve is carried out at a current density of 4A / g, wherein the specific capacitance of the first discharge is 187F / g, The specific capacitance of the 5000th cycle is 166F / g, and the specific capacity retention rate is 88.77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com