High-strength light foamed aluminium steel pipe

A lightweight foam and aluminum steel pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of few types of foamed aluminum products, limited use range, and inability to popularize applications, etc., to achieve low price, Reduce production costs and design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

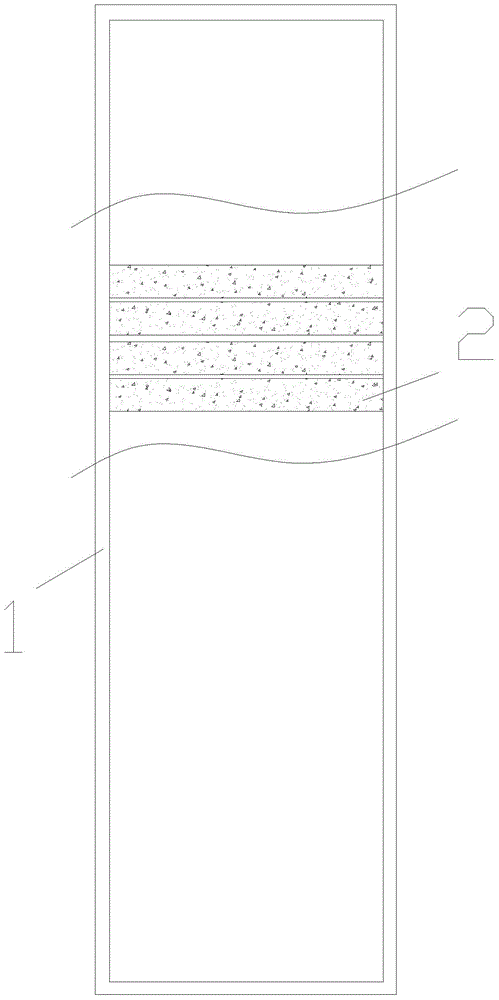

[0020] Such as figure 1 As shown, a high-strength lightweight foamed aluminum steel pipe includes a hollow steel pipe body 1, the wall thickness of the steel pipe body 1 is between 0.1-0.5cm, and the steel pipe body 1 is filled with foamed aluminum 2. The cross-section is made of foamed aluminum plate with a thickness of 1-3cm, which is squeezed into the steel pipe body 1 to enrich the inner space of the steel pipe body 1; the steel pipe with this structure is light in weight, not easy to bend and deform, and has good bearing capacity , the pressure on the steel pipe is absorbed by the foamed aluminum;

[0021] Aluminum foam is composed of the following components in parts by weight: 100 parts of aluminum powder, 5 parts of magnesium powder, 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com