Patents

Literature

79results about How to "Wrapped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

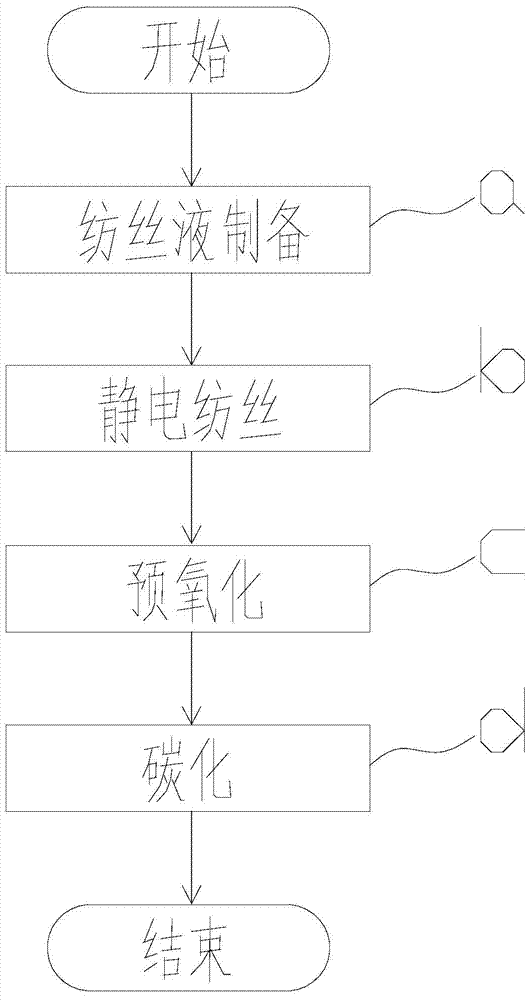

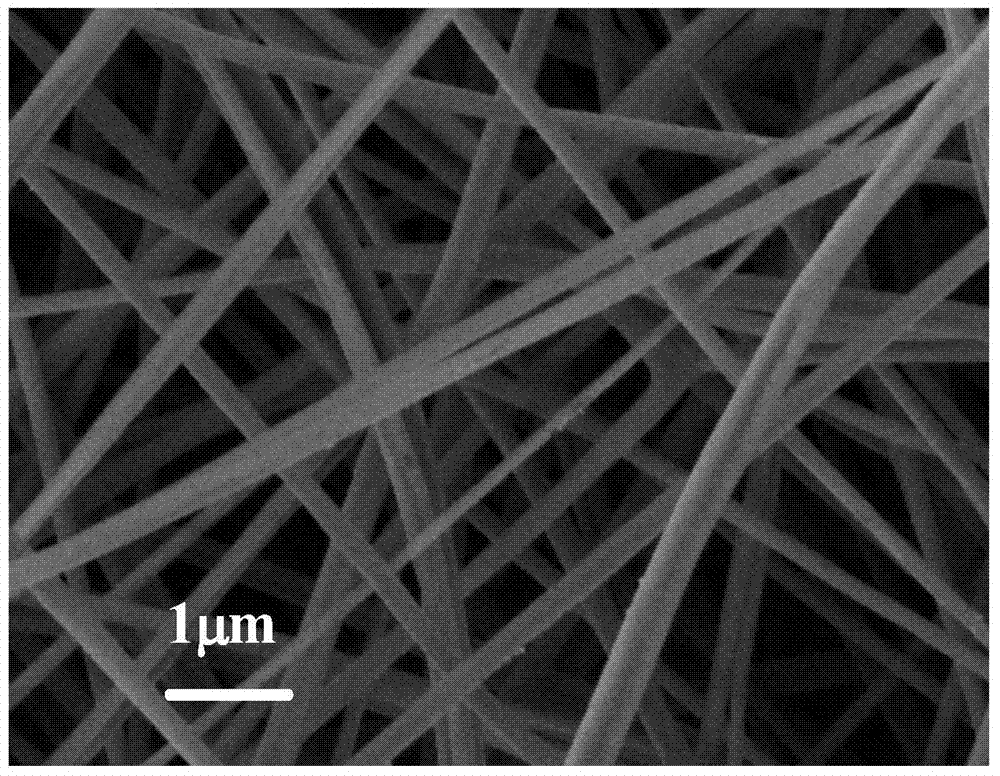

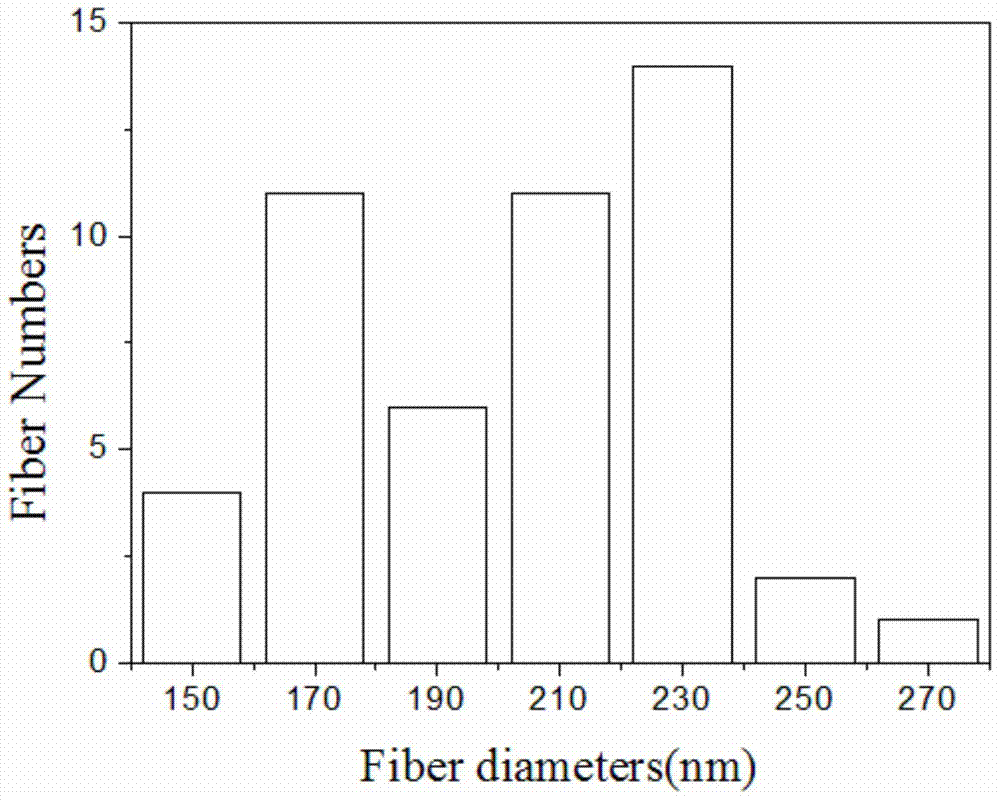

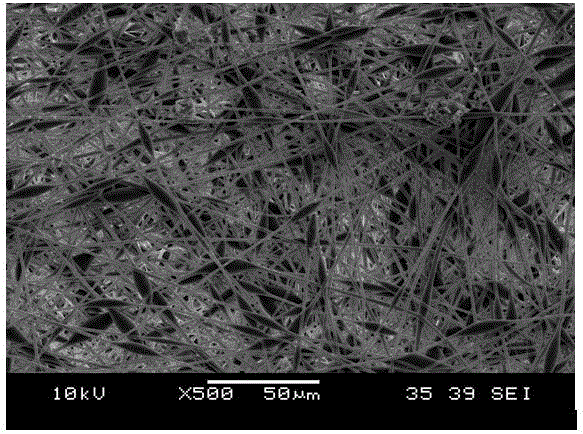

Method for preparing G/Sn/PAN-base carbon nanometer fiber membrane

InactiveCN103757823AEvenly distributedWrappedFilament/thread formingHeating/cooling textile fabricsPorosityAir atmosphere

The invention discloses a method for preparing a G / Sn / PAN-base carbon nanometer fiber membrane. The method for preparing the G / Sn / PAN-base carbon nanometer fiber membrane includes: 1) preparing spinning solution, to be more specific, weighing polyacrylonitrile, nanometer tin powder and graphene nanometer film according to certain mass ratio, blending and dissolving in N-N dimethyl formamide, and stirring to obtain the uniformly dispersed electrostatic spinning solution; b) electrostatic spinning, to be more specific, carrying out electrostatic spinning on the electrostatic spinning solution of the step a) to obtain a graphene / tin / polyacrylonitrile nanometer fiber membrane; c) pre-oxidizing, to be more specific, pre-oxidizing the graphene / tin / polyacrylonitrile nanometer fiber membrane of the step b) in air atmosphere to obtain the pre-oxidized nanometer fiber membrane; d) carbonizing, to be more specific, carbonizing the pre-oxidized nanometer fiber membrane in argon atmosphere to obtain the G / Sn / PAN-base carbon nanometer fiber membrane. The method for preparing the G / Sn / PAN-base carbon nanometer fiber membrane is easy to operate, the graphene coats the nanometer fiber well; the G / Sn / PAN-base carbon nanometer fiber membrane has advantages of large specific surface area, high porosity, and high electrical conductivity and so on, and has broad expanding space.

Owner:ZHEJIANG SANZHI TEXTILES

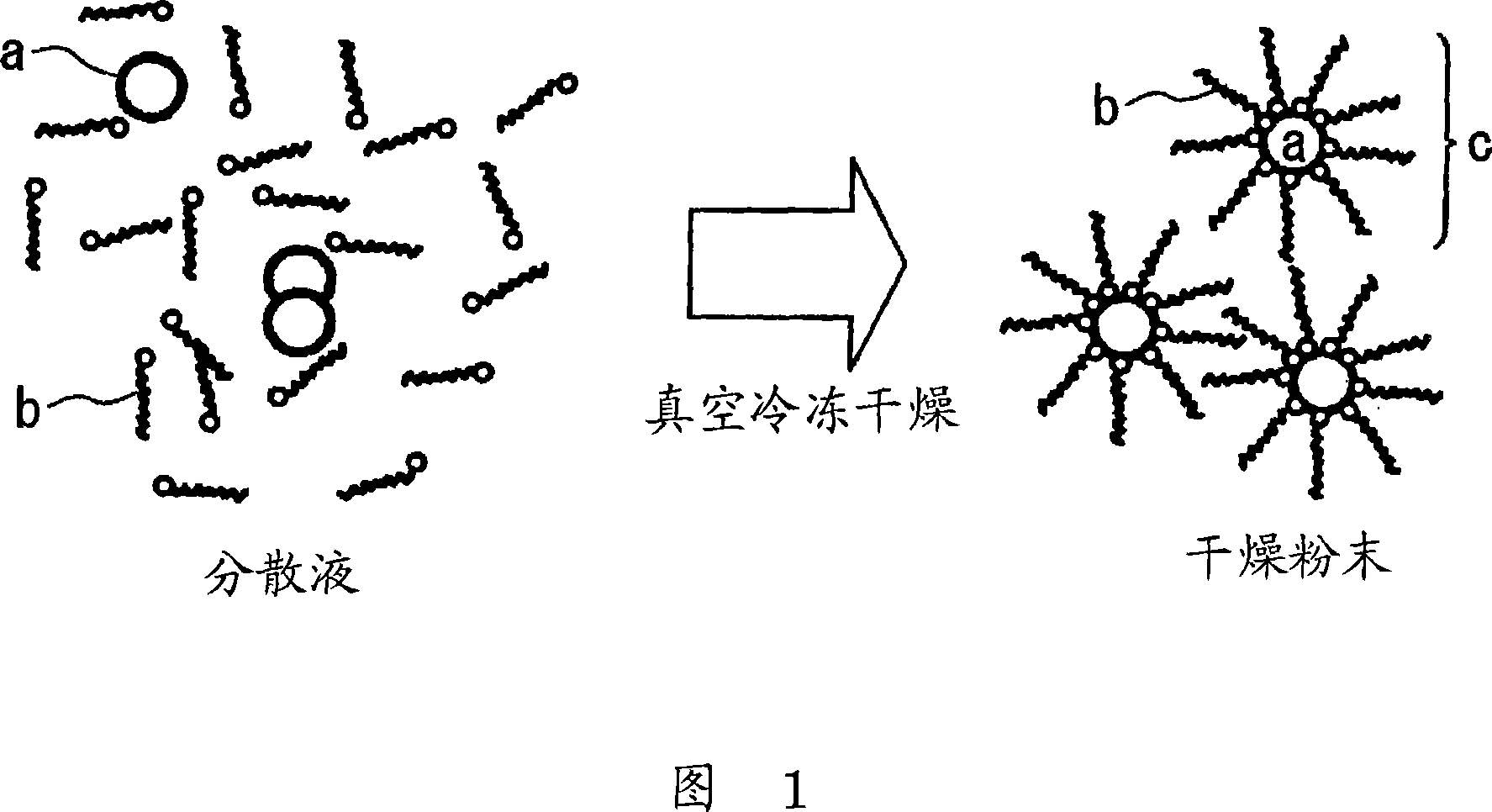

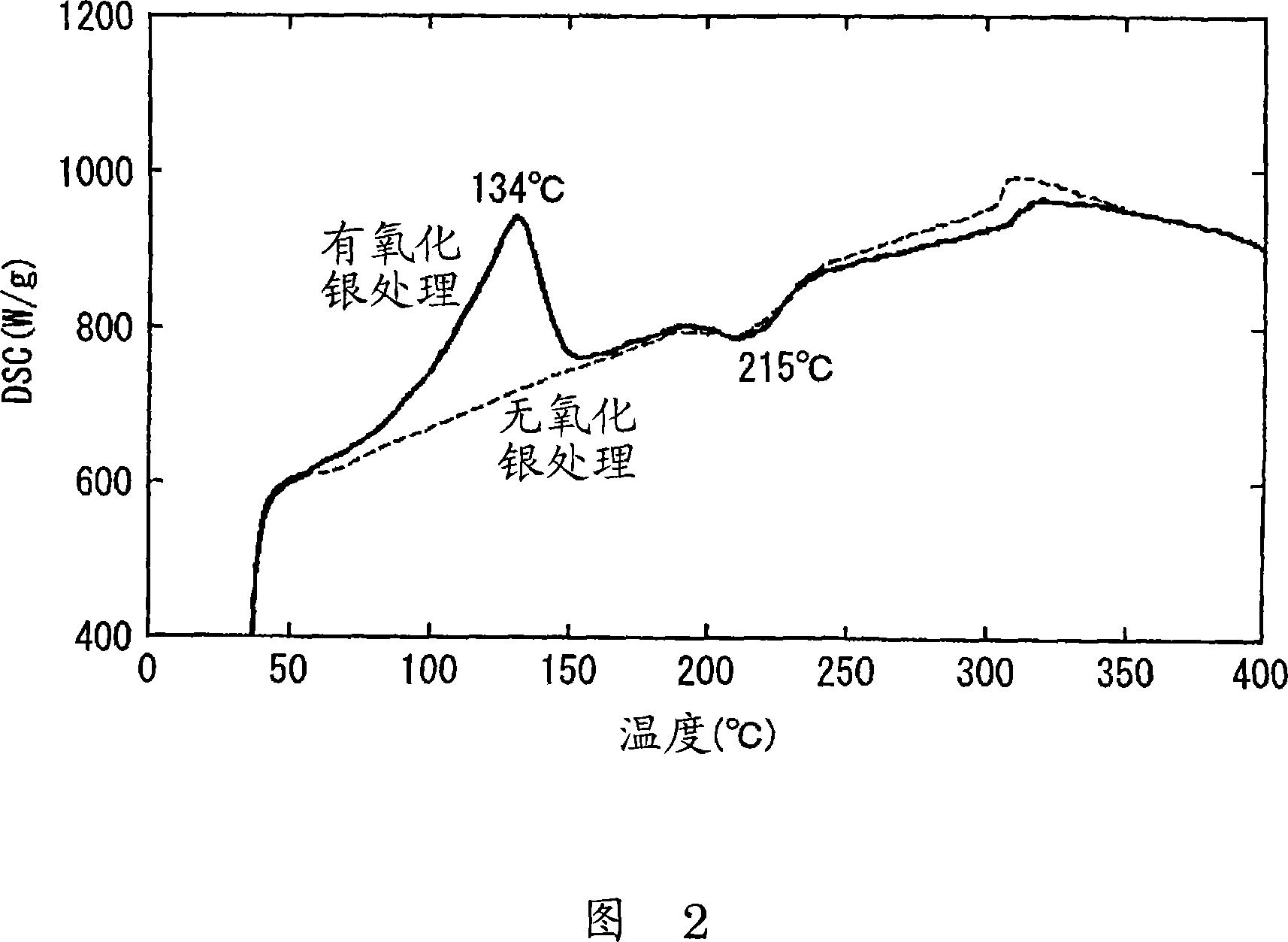

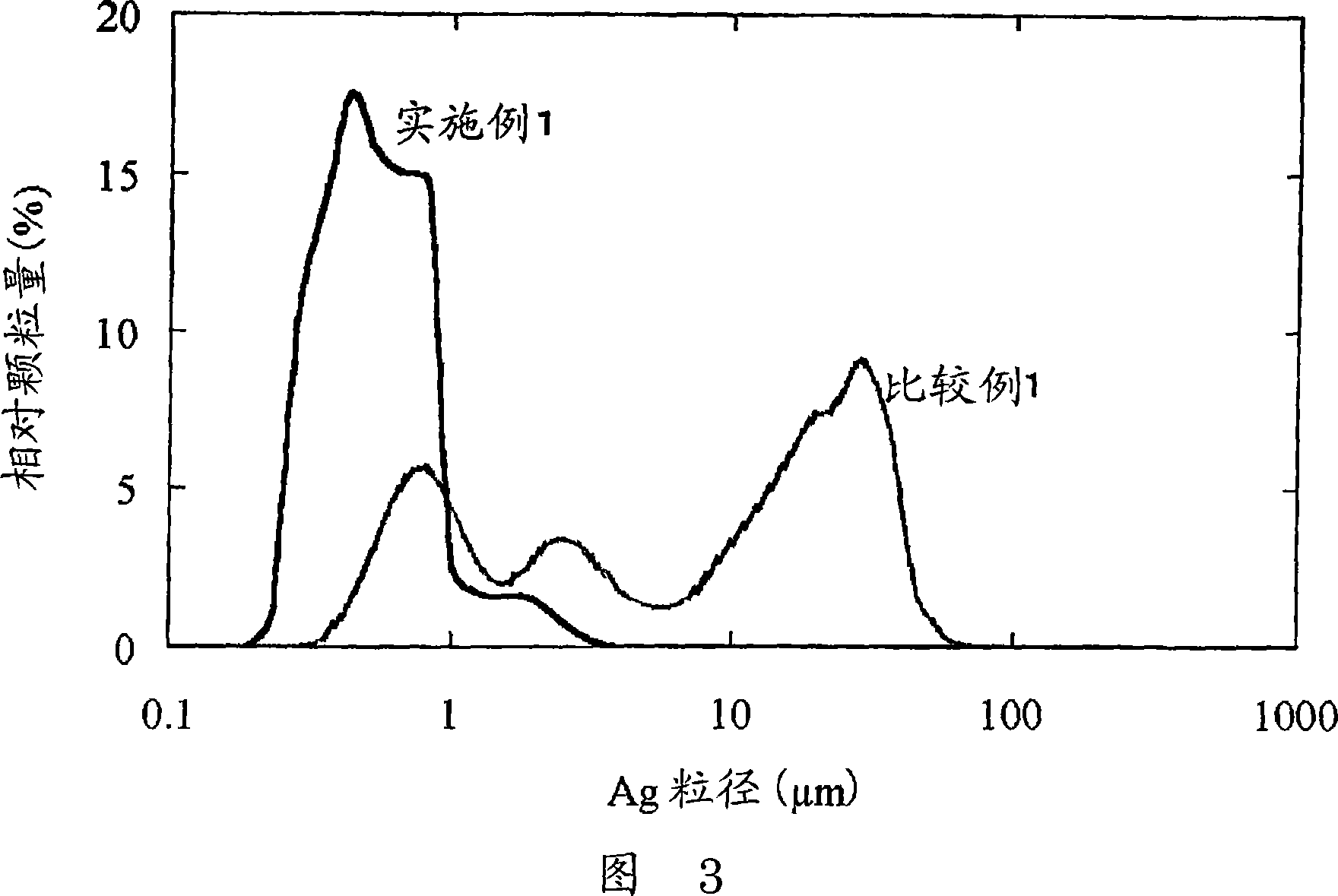

Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

InactiveCN101065203AWrappedImprove adsorption capacityNon-conductive material with dispersed conductive materialSilver pasteFreeze-drying

Disclosed is a method for producing a surface-treated silver-containing powder wherein a dispersion liquid, which is obtained by dispersing silver or silver compound particles (a) in a solvent together with a surfactant (b) of alkylamine type, alkylamine salt type or phosphate type having a phosphorus content of 0.5-10% by mass, is subjected to vacuum freeze drying for having the surfactant (b) adsorbed on the surfaces of the silver or silver compound particles (a), thereby producing a silver-containing powder (c) whose surface is treated with the surfactant (b). Also disclosed is a silver paste produced by dispersing the surface-treated silver-containing powder (c) in a solvent or in a solvent and a resin.

Owner:DAINIPPON INK & CHEM INC

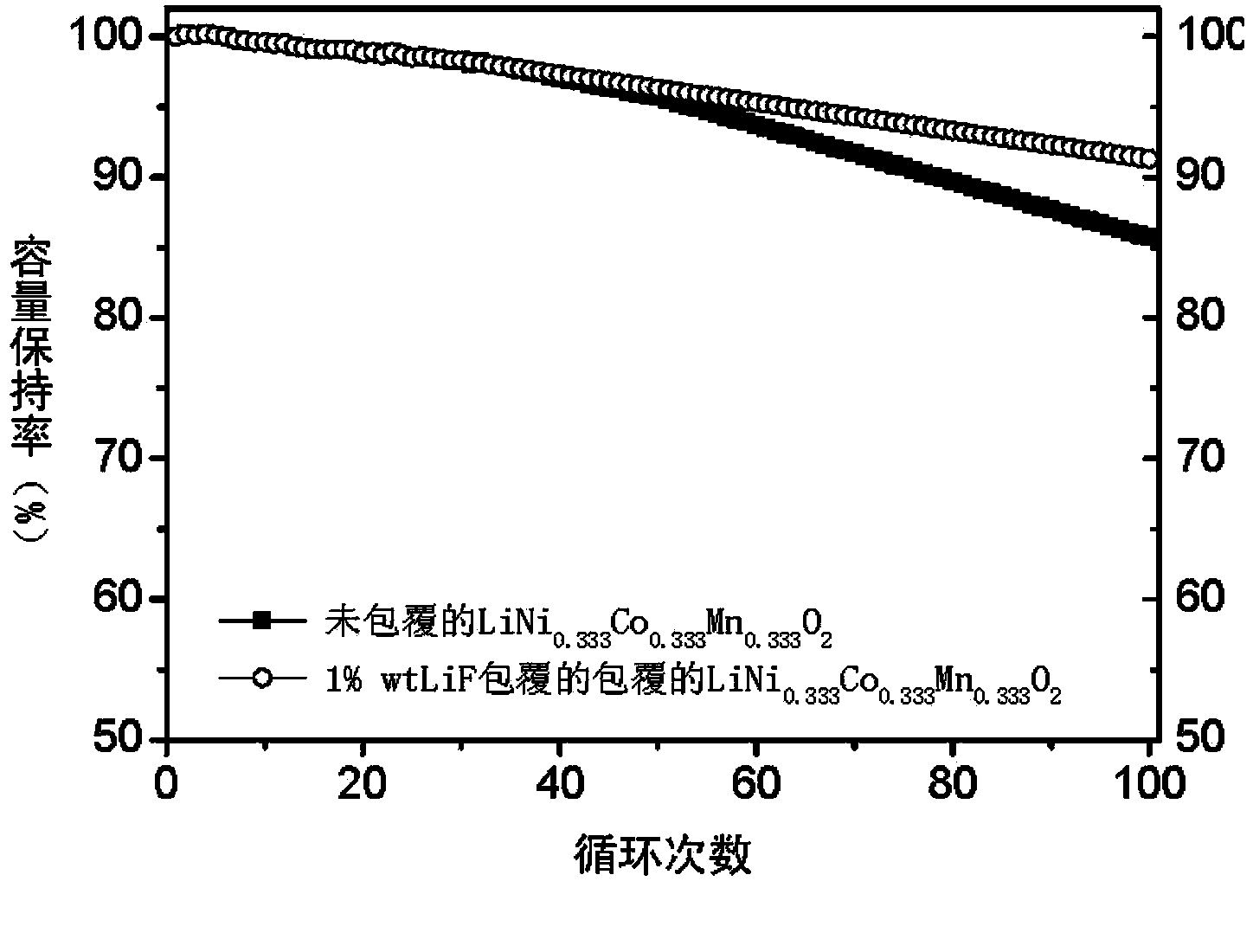

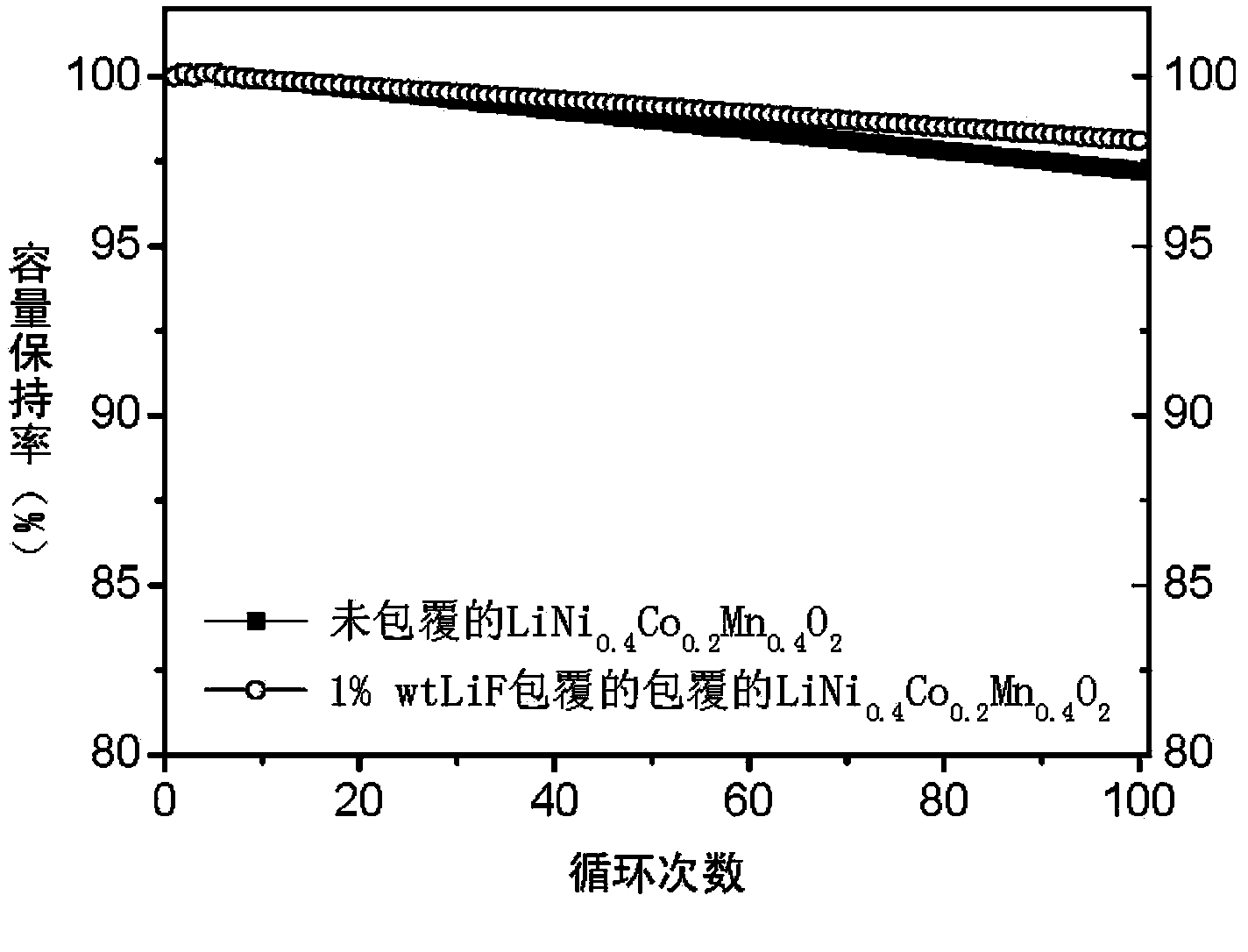

Surface coating method for ternary positive material of lithium ion battery

ActiveCN104112851AReduce contact surfaceImprove electrochemical performanceCell electrodesSecondary cellsCapacitanceMass ratio

The invention discloses a surface coating method for a ternary positive material of a lithium ion battery. The surface coating method comprises the following steps: 1, mixing lithium fluoride with a strong polar solvent in the mass ratio of (0.1-100) to 100, and stirring to form a homogeneous solution A; 2, transferring the ternary material into the solution A in the mass ratio of lithium fluoride to the ternary material of (0.05-10) to 100 and continuously stirring to form a turbid liquid B; 3, adding a poor solvent to the turbid liquid B which is stirred in the mass ratio of the turbid liquid B to the poor solvent of (0.1-100) to 1, thereby forming a turbid liquid C, and aging for 0.5-48 hours; 4, filtering the turbid liquid C, washing a filter cake by use of a volatile lithium fluoride poor solvent and drying the filter cake at 50-100 DEG C; and 5, calcining the filter cake, thereby obtaining the lithium fluoride coated ternary positive material. The surface coating method is capable of realizing relatively even coating, effectively inhibiting side reactions of an electrode, prolonging the cycle life of the electrode, lowering the safety risk of the battery and reducing the capacitance loss of the battery.

Owner:厦门太和动力电源科技有限公司

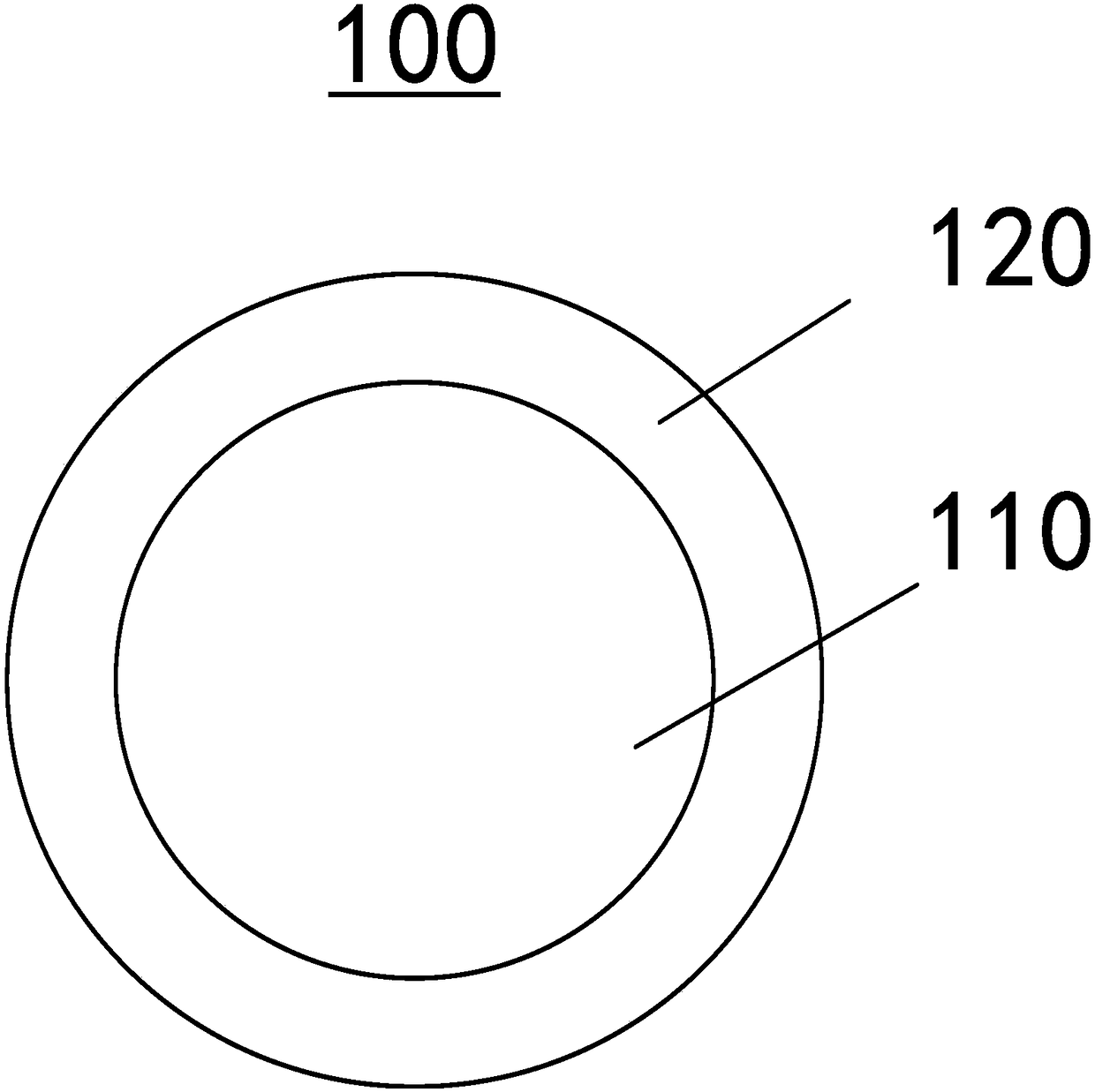

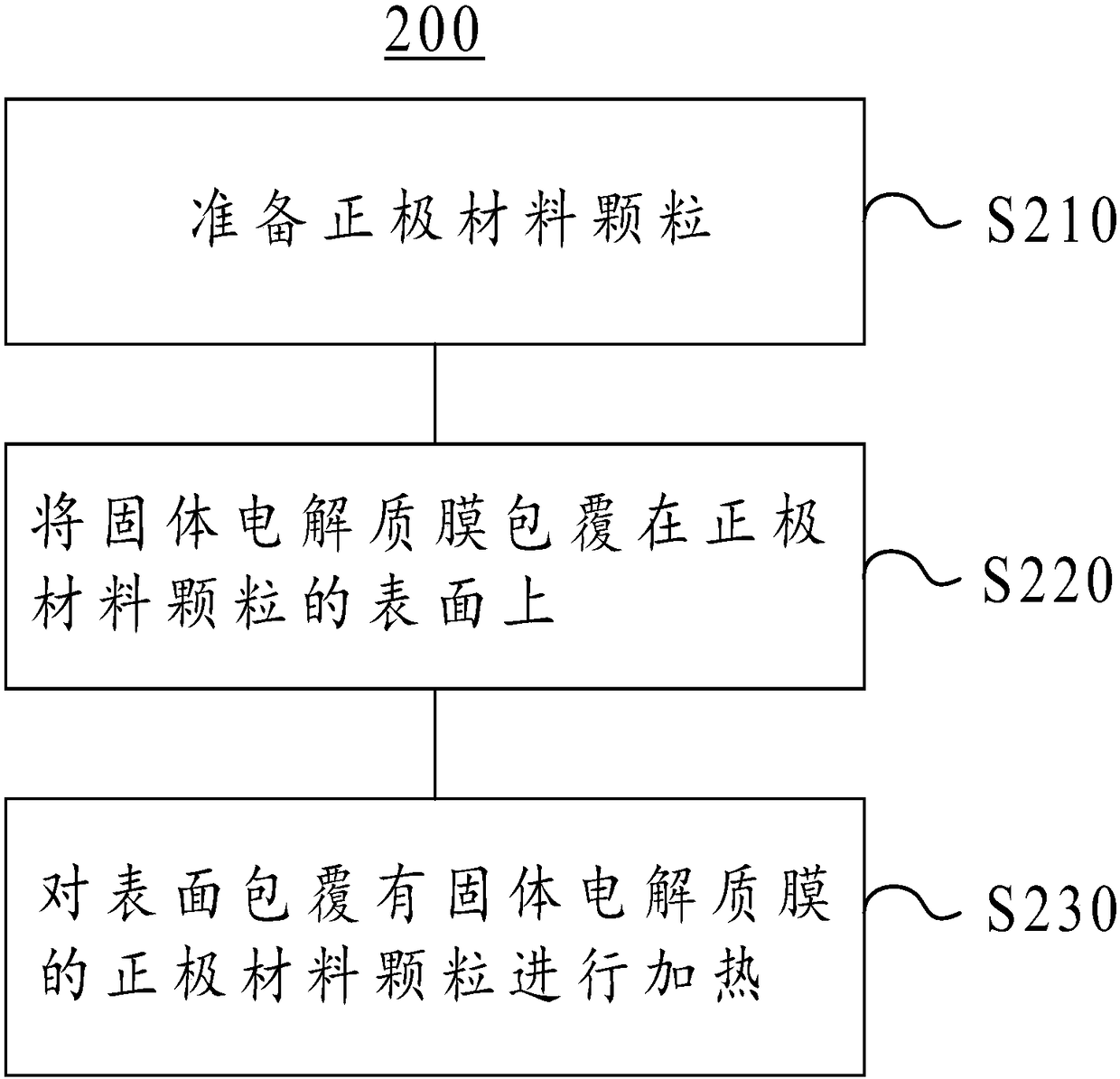

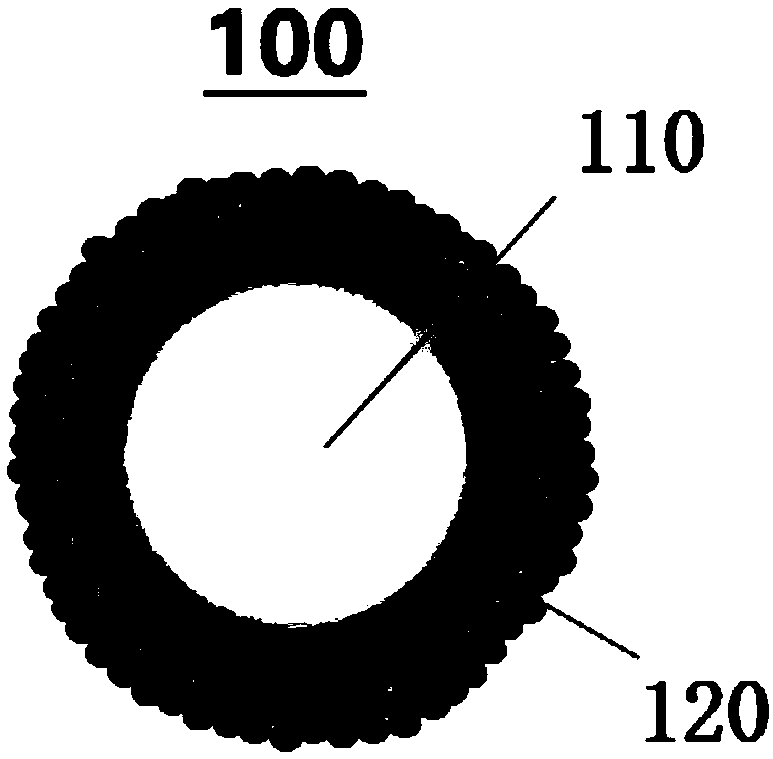

Lithium ion battery positive electrode material and preparation method thereof

InactiveCN108448055ASimple and easy way to make cathode material for lithium-ion batteriesSimple methodNon-aqueous electrolyte accumulator electrodesAmorphous phaseDissolution

The invention relates to a lithium ion battery positive electrode material and a preparation method thereof. According to an embodiment, the lithium ion battery positive electrode can comprise a positive electrode material particle and a solid electrolyte film, wherein the solid electrolyte film is coated on an outer surface of the positive electrode material particle, is a continuous film havingthickness within a range of 1-50 nanometers and comprises an amorphous phase and a crystal phase which coexist, the grain size is within a range of 1-40 nanometers, and no new phase is formed betweenthe solid electrolyte film and the positive electrode particle. By the lithium ion battery positive electrode material, the electrochemical stability can be improved, meanwhile, the problems of volumeexpansion of the positive electrode particle and dissolution-out of transition metal can be prevented, and thus, the lithium ion battery positive electrode material has the advantages of high electrochemical stability, favorable cycle property, high structure stability, good high-voltage performance, high safety and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

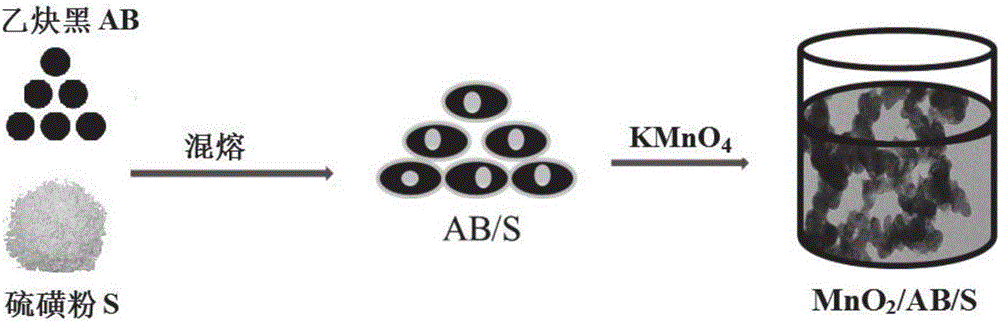

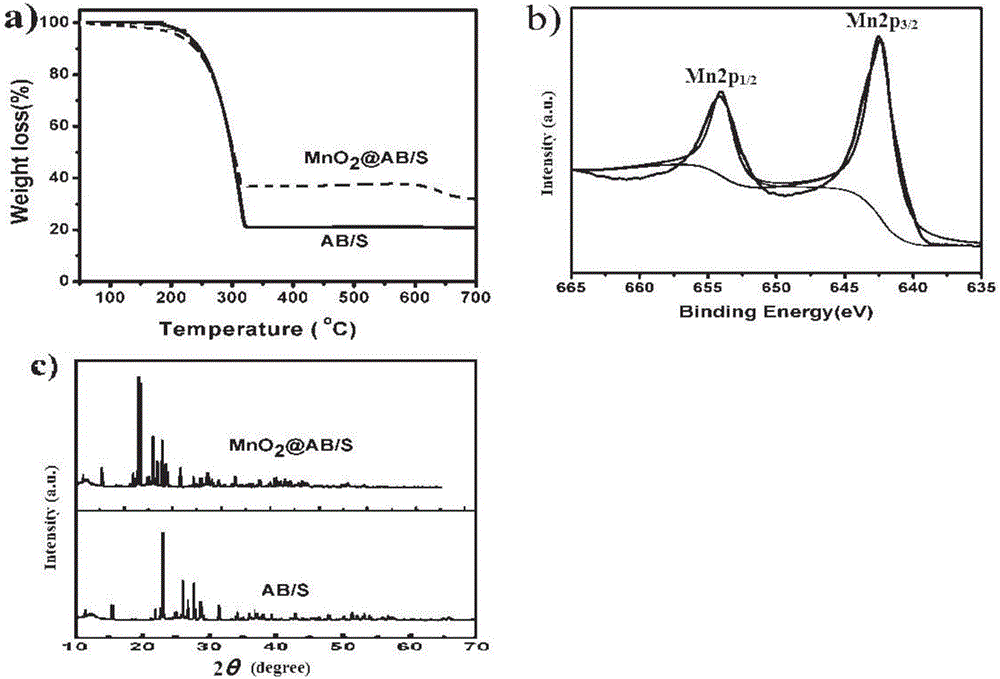

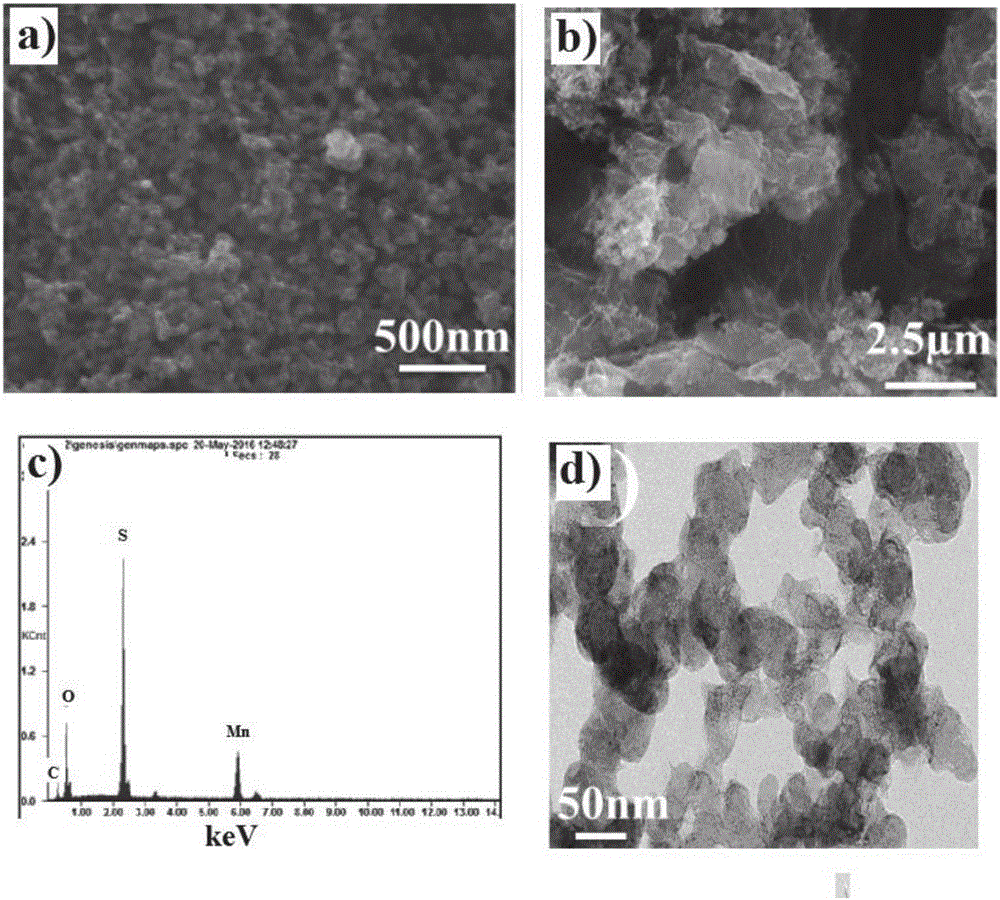

Manganese dioxide nanosheet coated carbon/sulphur compound, preparation method and application thereof

InactiveCN106129384AWrappedIncrease the speed of electron transferCell electrodesLi-accumulatorsSulphur compoundCathode material

The invention discloses a method for preparing a manganese dioxide nanosheet coated carbon / sulphur (MnO2@C / S) compound. The method comprises the following steps: firstly heating and melting a carbon material and sulphur simple substance to obtain a carbon / sulphur compound, then adding permanganate solution into aqueous phase dispersion liquid of the carbon / sulphur compound, heating, stirring, reacting, then carrying out solid-liquid separation, washing, and drying, so that the manganese dioxide nanosheet coated carbon / sulphur compound is obtained. Besides, the invention also discloses the manganese dioxide nanosheet coated carbon / sulphur compound obtained by adopting the method and application thereof. When the manganese dioxide nanosheet coated carbon / sulphur compound is applied to a lithium sulphur battery cathode material, and initial discharge capacity, cycle performance and rate capability of the obtained battery are respectively greatly improved.

Owner:CENT SOUTH UNIV

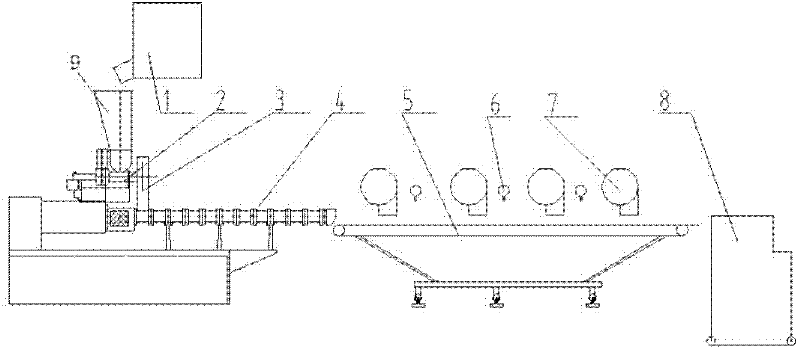

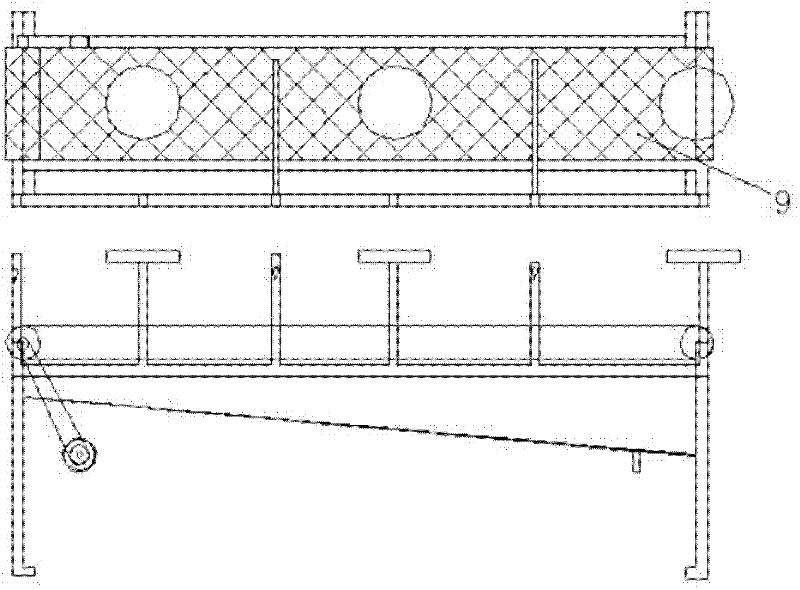

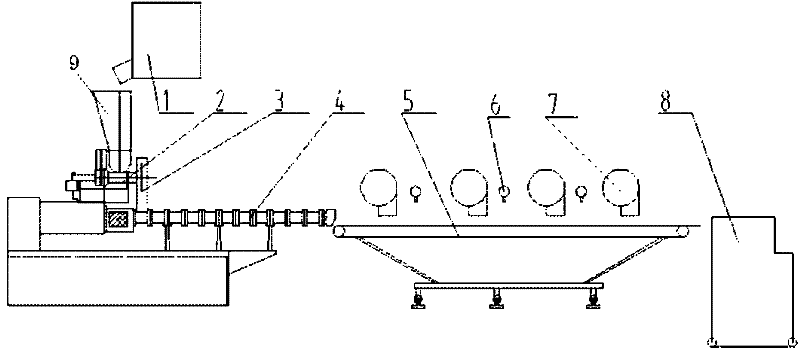

Superfine talcum powder-polypropylene filled master batch, preparation method and equipment thereof

The invention discloses a talcum powder-polypropylene filled master batch. The talcum powder-polypropylene filled master batch comprises the following components in percentage by weight: 75-85% of talcum powders, 10-15% of polypropylene materials, 0.5-0.7% of antioxidants and 1-5% of processing agents. Production equipment of the talcum powder-polypropylene filled master batch comprises a high-speed mixer, a feeding machine, a double-screw extrusion machine, a caterpillar track conveying and cooling device and a hob granulator, wherein the high-speed mixer is arranged above the feeding machine, a material outlet of the feeding machine is connected with a material inlet of the double-screw extrusion machine, a material outlet of the double-screw extrusion machine is connected with a material inlet of the caterpillar track conveying and cooling device, and a material outlet of the caterpillar track conveying and cooling device is connected with a material inlet of the hob granulator. Compared with the technology that an internal mixer is used for producing the superfine talcum powder master batch, the production equipment provided by the invention has the following advantages: the proper raw material formula, the forcing of the feeding machine, the double-screw extrusion with a deep spiral groove and a caterpillar track conveying and cooling granulation mode are adopted, so that the low-stacking-density powder can be fed into the double-screw extrusion machine with high efficiency; as the talcum powder-polypropylene filled master batch contains high inorganic powder content and the adopted spiral groove is deep, the talcum powder-polypropylene filled master batch can be conveyed conveniently; the plasticized dispersing efficiency of the talcum powder-polypropylene filled master batch is high; and the talcum powder-polypropylene filled master batch is not easy to break when adopting a water-cooling brace to granulate; and the normal granulation can be ensured.

Owner:KINGFA SCI & TECH CO LTD +1

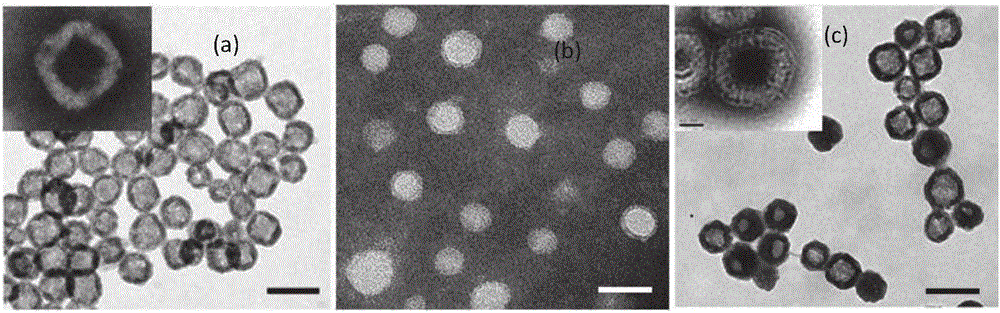

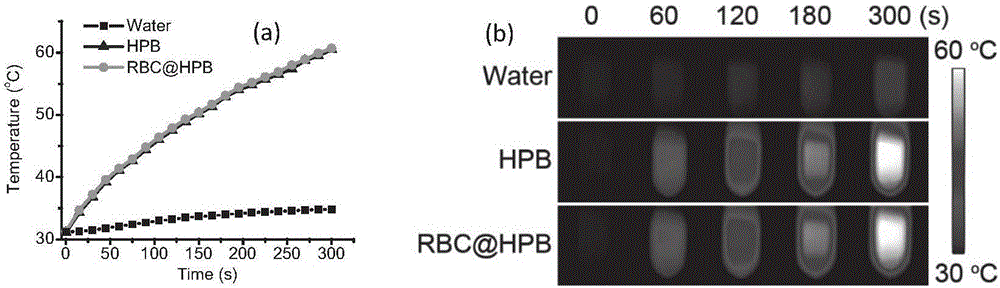

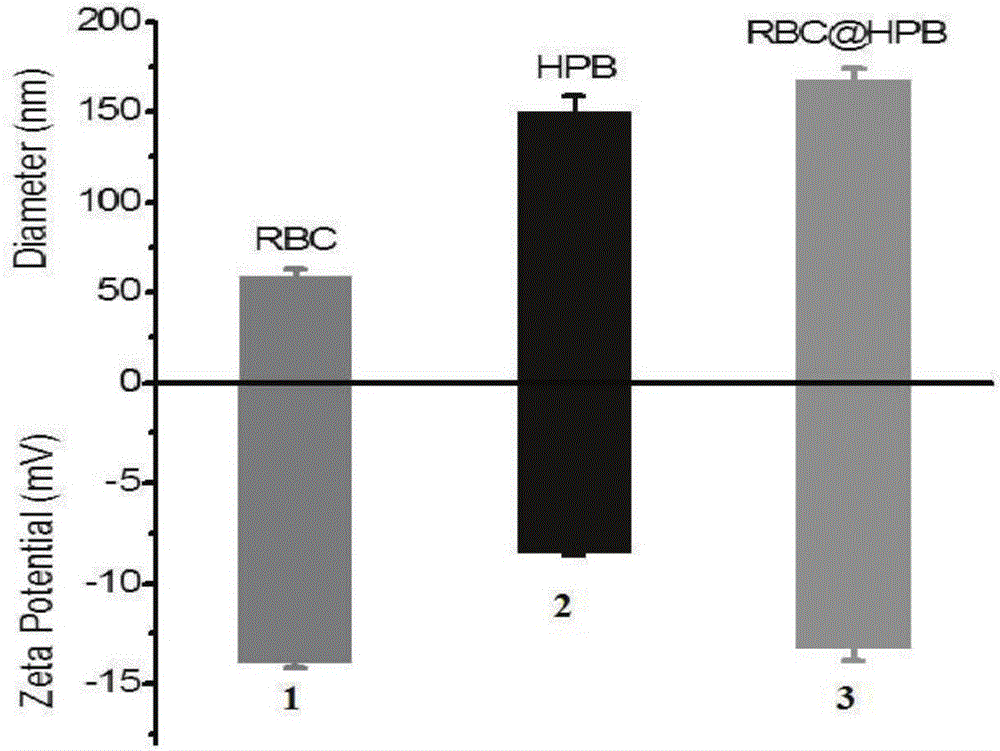

Coating and modification method for prussian blue nanometer mesocrystal cytomembrane

InactiveCN106362148AEasy to operateShort timeEnergy modified materialsPharmaceutical non-active ingredientsMesocrystalPrussian blue

The invention discloses a coating and modification method for a prussian blue nanometer mesocrystal cytomembrane. The method comprises the steps that biological membrane and prussian blue nanometer mesocrystal are coated with ultrasonic waves at the pH of 7.4-8.0, and then the prussian blue nanometer mesocrystal coated with the biological membrane is obtained through centrifugalization, wherein the ultrasonic power is 150-300 w, and the ultrasonic frequency is 20-40 kHz. In the coating and modification method, the biological membrane and the prussian blue nanometer mesocrystal are coated efficiently by the coating and modification method with ultrasonic waves at the pH. Moreover, according to the method, the hydrophobic treatment or other pretreatments of the prussian blue nanometer mesocrystal are not needed, the operation is simple, the coating effects are good, and after the prussian blue nanometer mesocrystal is coated and modified, the effects of the prussian blue in the body are improved greatly.

Owner:CENT SOUTH UNIV

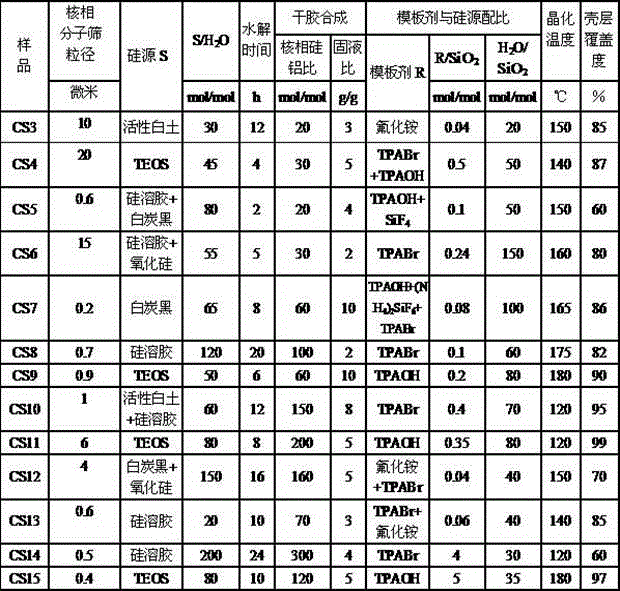

Method for synthesizing ZSM-5/Silicalite core-shell molecular sieve by using vapor phase process

ActiveCN104556130AFull play heatingHeating evenlySilicaMolecular-sieve silica-polymorphsCore shellAqueous solution

The invention relates to a method for synthesizing a ZSM-5 / Silicalite core-shell molecular sieve by using a vapor phase process, mainly solving the technical problems that the product shell layer is low in coverage degree and the influence on the environment caused by a template agent is hard to process in the prior art for synthesizing the core-shell molecular sieve by using an epitaxial growth method. The method for synthesizing the ZSM-5 / Silicalite core-shell molecular sieve by using the vapor phase process comprises the following steps: (a) mixing and stirring a silicon source with water according to a mole ratio of 20-200, and hydrolyzing for 2-24 hours; (b) adding a ZSM-5 nuclear phase molecular sieve into a solution prepared by the step (a), then drying the solution at 100-120 DEG C; (c) putting a solid product prepared by the step (b) in an upper layer of a crystallization kettle, adding a template agent water solution into a lower layer of the crystallization kettle, and crystallizing at 120-180 DEG C for 0.5-5 days; and (d) preparing a ZSM-5 / Silicalite-1 core-shell type zeolite molecular sieve after the crystallization is ended. The method can be applied to industrial production for preparing paraxylene by disproportionating methylbenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing phase-changing fiber having core-shell beaded structure

InactiveCN106048757AFew preparation stepsHigh energy storage densityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberOrganic solvent

The invention discloses a method for preparing phase-changing fiber having a core-shell beaded structure. The method includes: dissolving phenolic resin and polymer component in an organic solvent to form a resin solution, and putting the resin solution in an injector connected to a spinning head skin layer; putting a lower temperature phase changing material in an injector connected to a spinning head core layer; acquiring phase-changing nascent fiber on a rotation or flat plate receiving device; and putting the obtained phase-changing nascent fiber in a curing solution to be cured, and washing and drying the cured phase-changing nascent fiber to obtain the phase-changing fiber having the core-shell beaded structure. The beaded phase-changing fiber having a special structure is prepared through a single-step coaxial electrostatic spinning method, and the preparation steps of the phase-changing fiber are reduced; the connected core-shell structure is obtained through the coaxial electrostatic spinning method, secondary load can be reduced, the energy density of the phase-changing fiber is improved, and the efficacy of the phase-changing fiber can be improved; and skin and core beads prepared by the electrostatic spinning method can coat the phase-changing material well, and the coating performance of the phase-changing fiber can be improved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

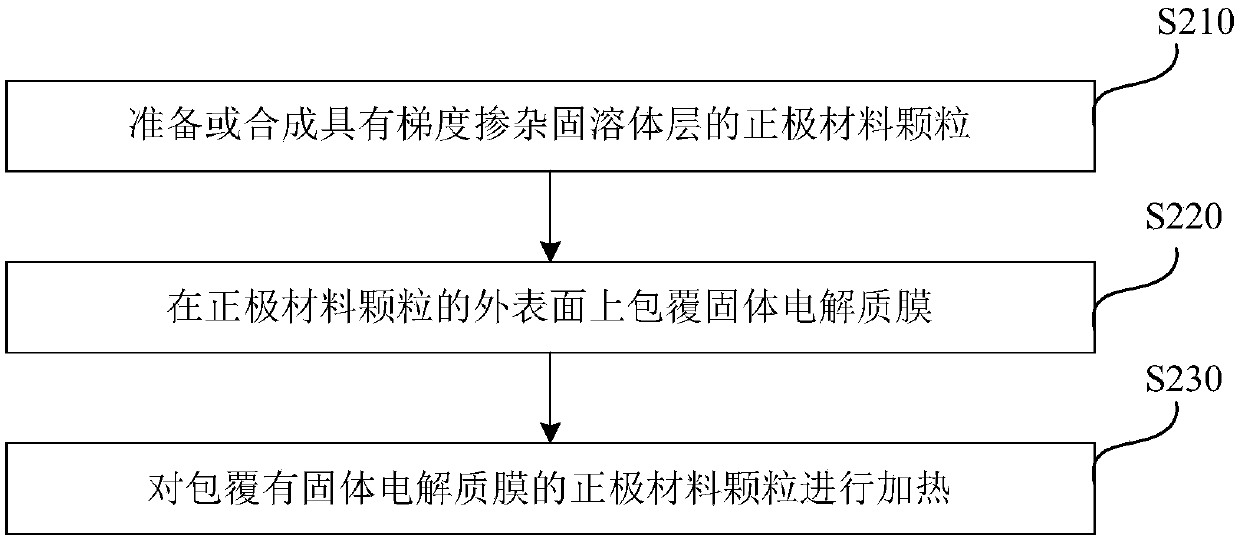

Lithium ion battery cathode material and preparation method thereof and lithium battery

InactiveCN110767896AStress reliefImprove stabilityLi-accumulatorsElectrolyte layer coatingChemical physicsPhysical chemistry

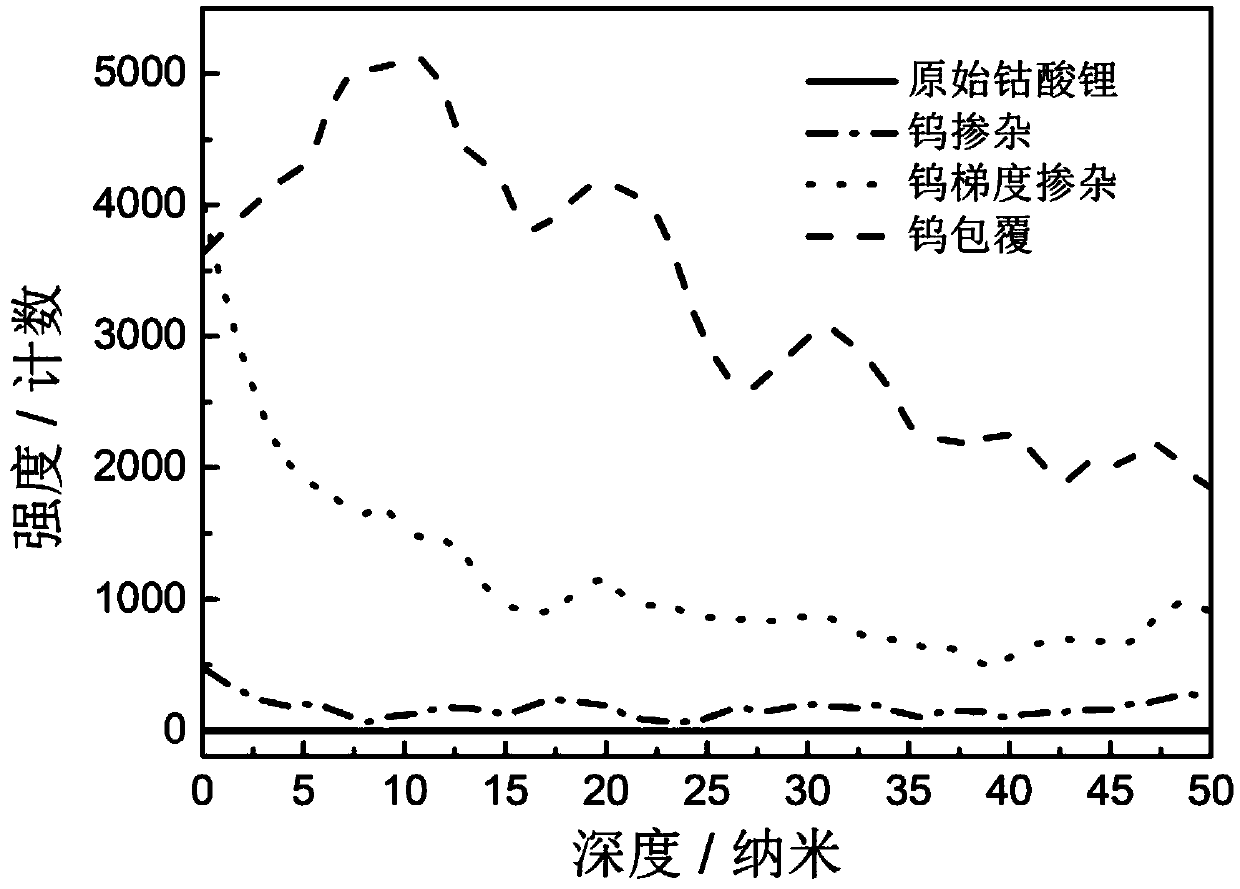

The invention relates to a lithium ion battery cathode material and a preparation method thereof and a lithium battery. The lithium ion battery cathode material comprises cathode material particles and an inorganic solid electrolyte membrane covering the outer surface of the cathode material particles; doping elements are distributed on the surface of the cathode material particles from outside toinside to form a gradient solid solution layer, and the concentration of the doping elements in the gradient solid solution layer gradually decreases from the surface to the inside; the doping elements are 4d and 5d metals; the outer surface of the cathode material particles is covered with the inorganic solid electrolyte membrane, the inorganic solid electrolyte membrane is a continuous membranehaving a thickness of 1 to 200 nm, the inorganic solid electrolyte membrane comprises an amorphous phase and a crystalline phase that coexist, and the crystalline grain size is in a range of 1 to 40nm. The lithium ion battery cathode material has the advantages of high electrochemical stability, high voltage resistance, good cycle performance, strong structural stability, high safety, and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for industrially preparing nanometer calcium carbonate for solvent type ink addition agent

ActiveCN101531391AGood dispersionHigh transparencyCalcium/strontium/barium carbonatesNanostructure manufactureCarbonizationSolvent

The invention discloses a method for industrially preparing nanometer carbonate for a solvent type ink addition agent. The method obtains the nanometer carbonate with cubic particles of 70 to 90nm by adopting a synthesis process of step carbonization, intensively shearing emulsification disperse and composite coating which are carried out simultaneously. The surface of the particle has amphipathic property; and the nanometer calcium carbonate has excellent dispersion and cannot be easily sedimentation, and the transparency and lustrousness of the solvent type ink addition agent is obviously improved.

Owner:WUHU ZHUOYUE NANO NEW MATERIALS

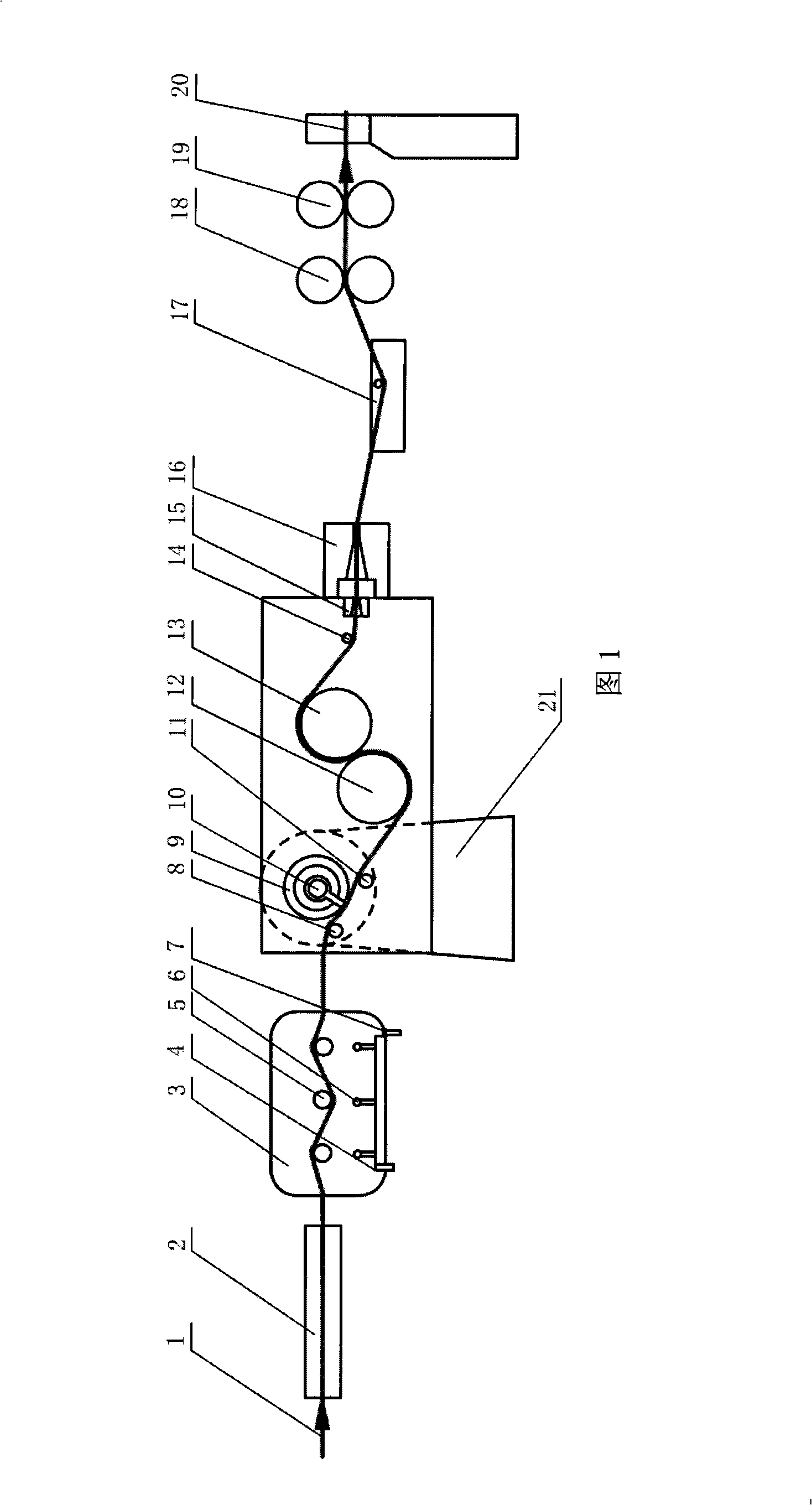

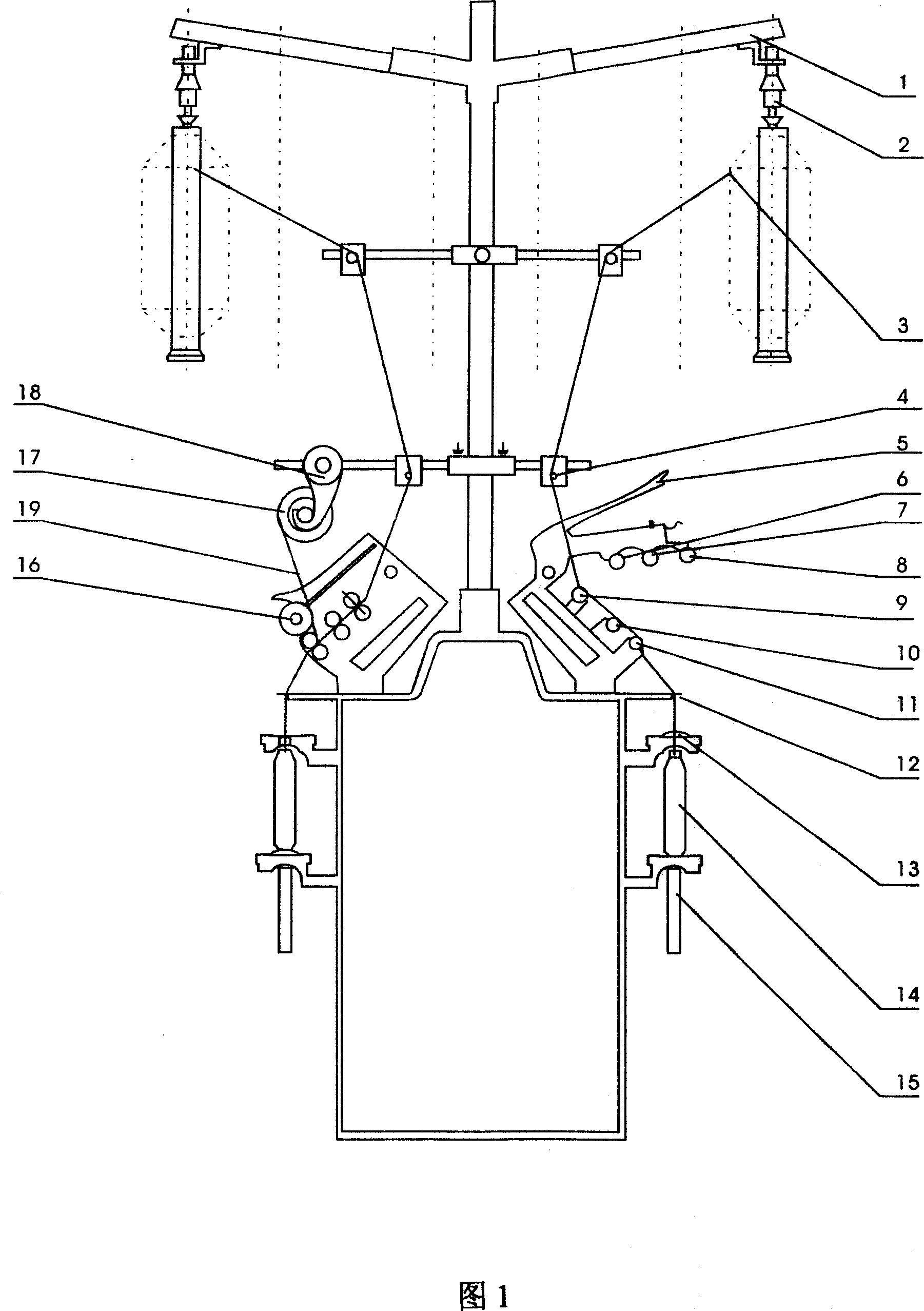

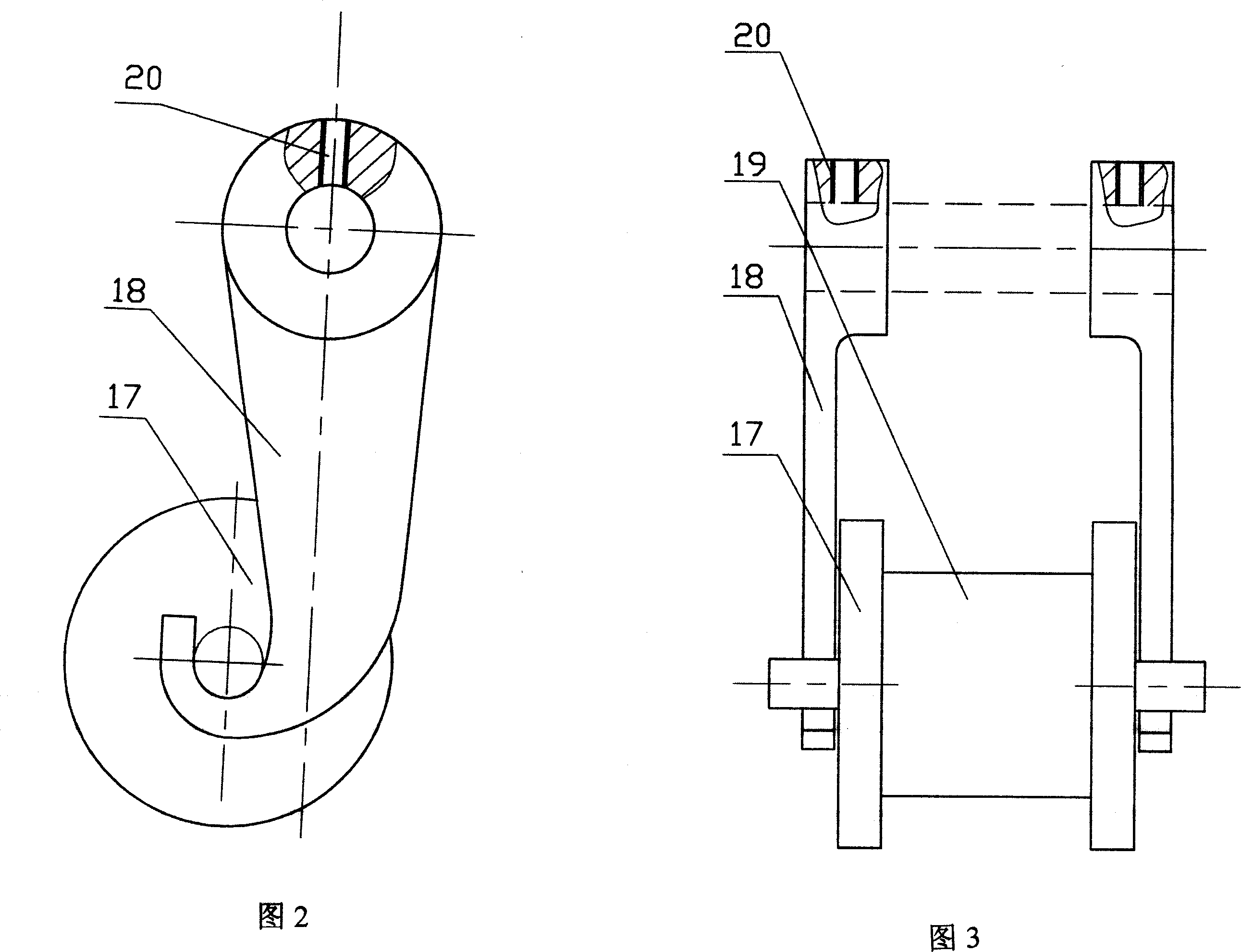

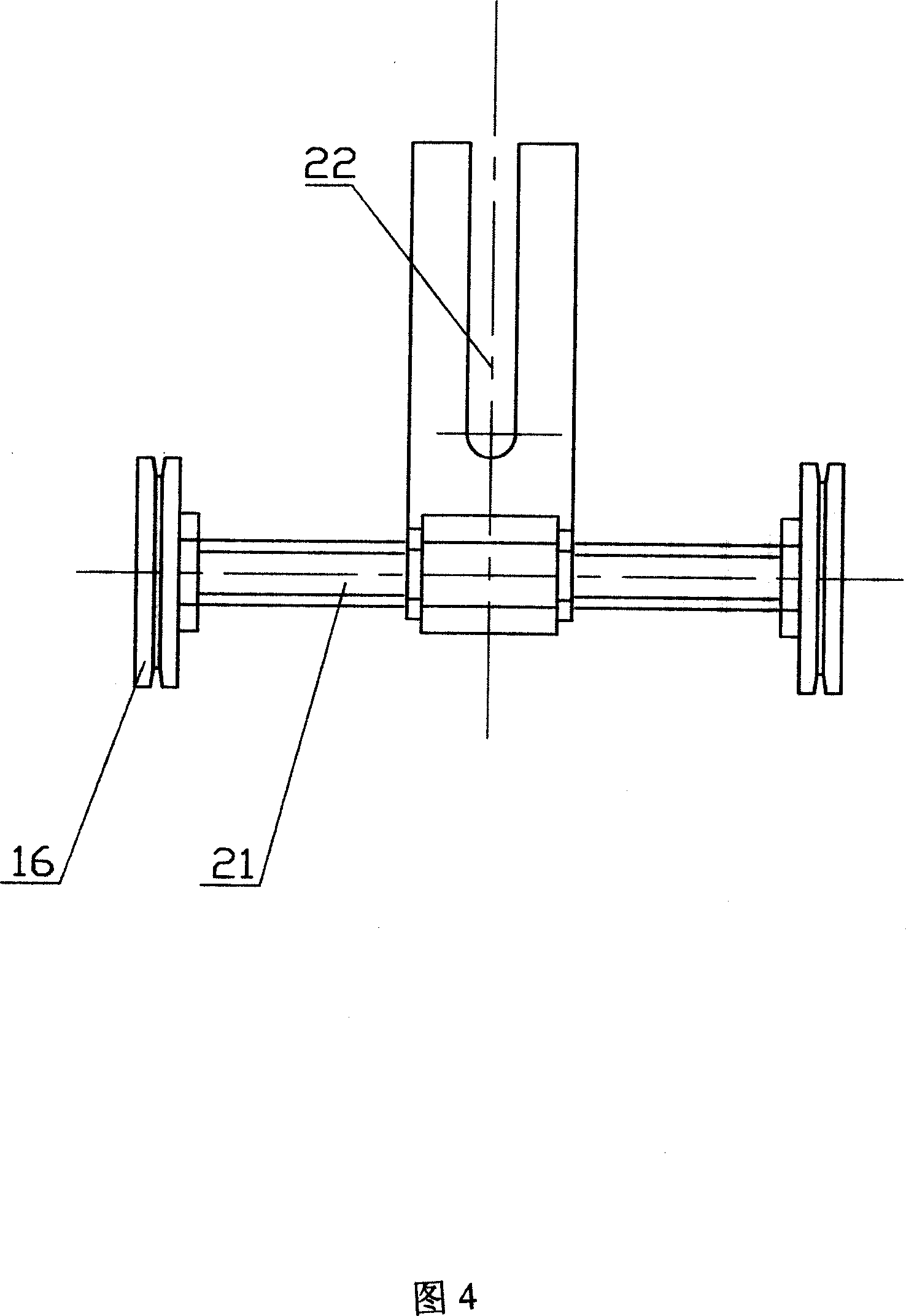

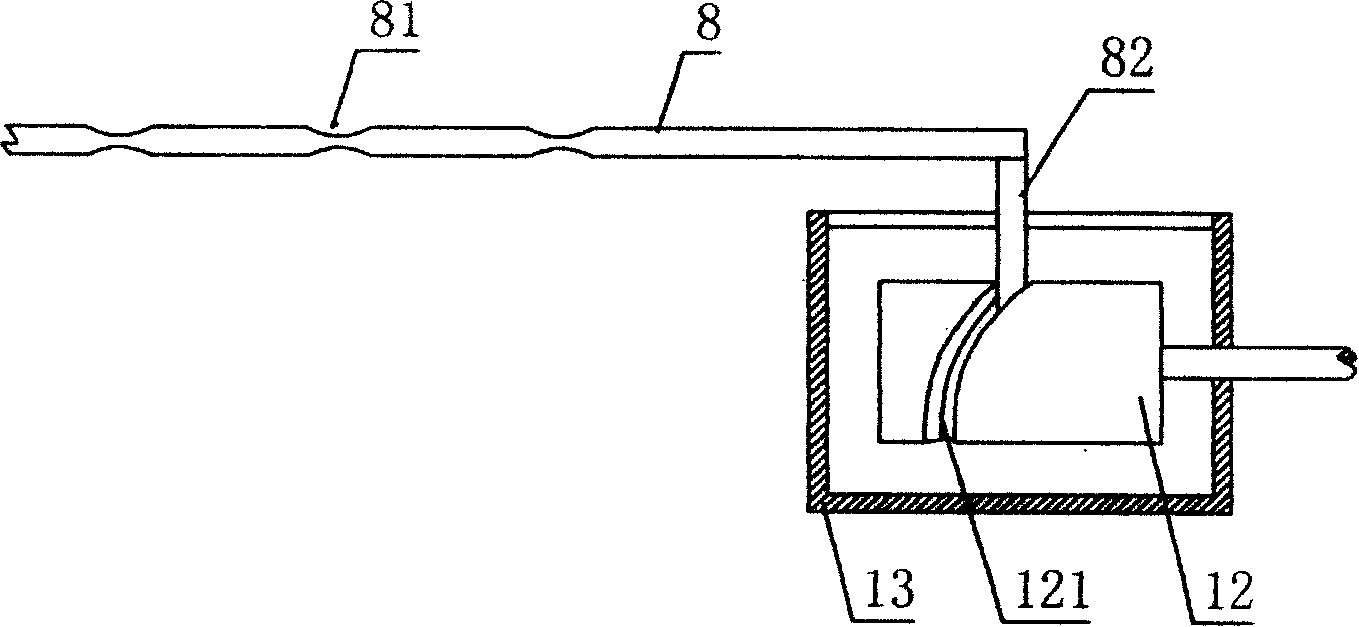

Complete production unit of long glass fiber reinforcement polypropylene material

The invention relates to a complete production unit for long glass fiber reinforced polypropylene materials, which comprises a long glass fiber pre-heating device, a long glass fiber surface treating device, an immersion device, and a bunching and coating device. The long glass fiber pre-heating device is connected with the long glass fiber surface treating device in a transition manner; the long glass fiber surface treating device is connected with the immersion device in a transition manner; the immersion device is connected with the bunching and coating device in a transition manner; the long glass fiber surface treating device comprises a variable diameter pressing roll and a liquid coupling agent atomizer; the immersion device has a box-type structure; an extruder connector, a melting stock allocator, a front guide roll, a middle guide roll, a back guide roll, a pair of pressing rolls are arranged in the immersion device; a double screw extruder and the melting stock allocator form a melting stock conveying passage through the extruder connector; the front guide roll, the middle guide roll, the pair of pressing rolls and the back guide roll are connected sequentially in a transition manner; and a cooling device, a pulling device and a grain-sized dicing device are sequentially distributed at the outlet end of the bunching and coating device. Therefore, a production line is formed. The process is widely used for producing long glass fiber reinforced polypropylene materials.

Owner:SUZHOU HECHANG POLYMERIC MATERIALS

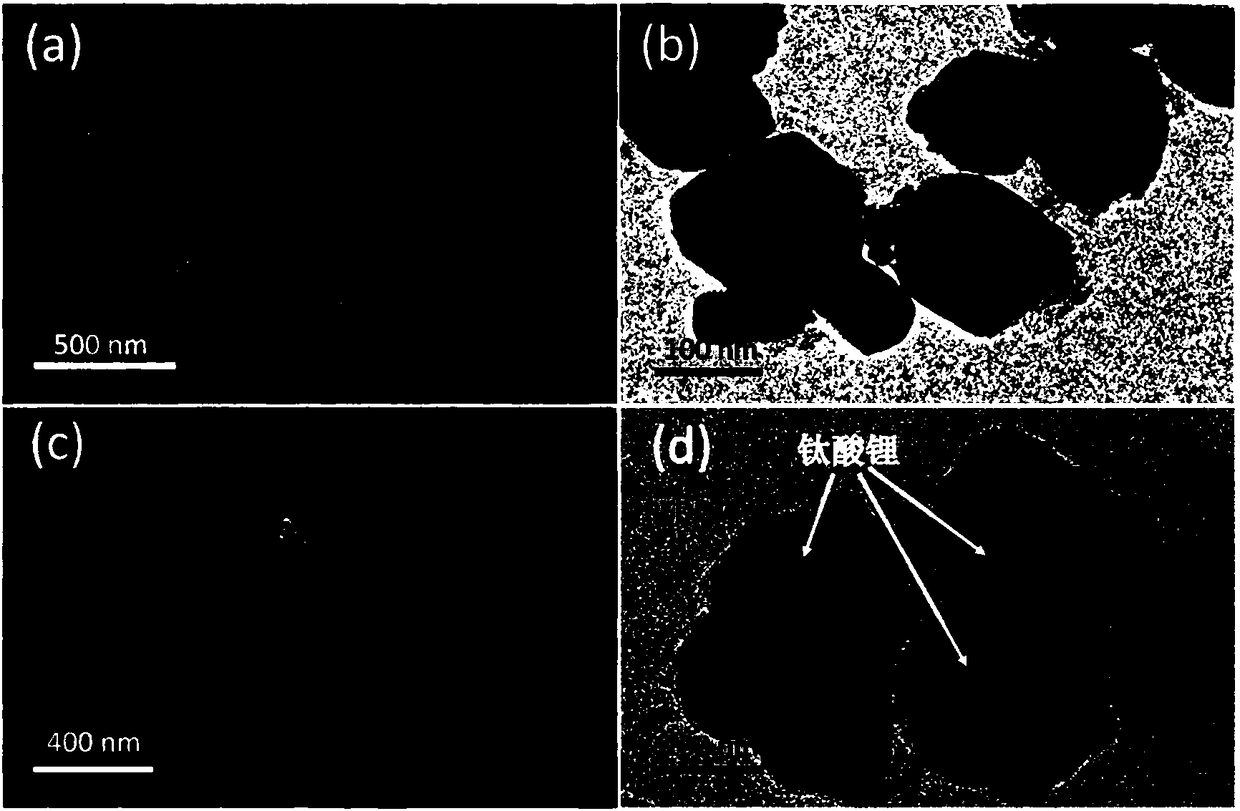

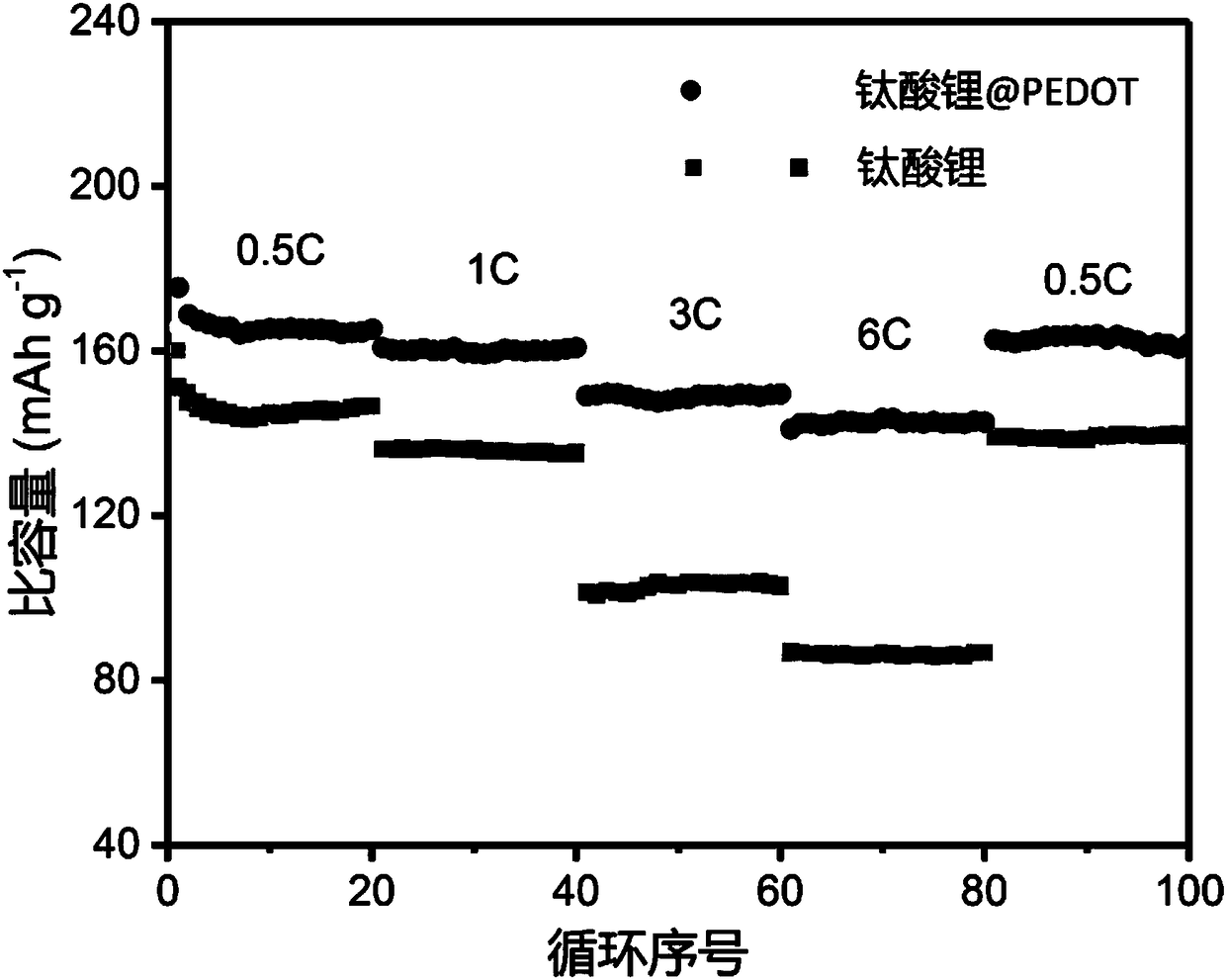

PEDOT-coated lithium titanate nano particles preparation method and application thereof

The invention discloses a PEDOT-coated lithium titanate nano particles preparation method and an application thereof. The preparation method comprises the following steps: grinding a lithium source and titanium dioxide nano particles, performing high-temperature calcining to obtain the lithium titanate nano particles; preparing a 3,4-ethylenedioxythiophene disperse aqueous solution, adding the prepared lithium titanate nano particles in the disperse aqueous solution, and uniformly dispersing the materials; adding ammonium persulfate and hydrochloric acid in the disperse solution, and stirringthe materials; performing centrifugation on mixed liquor, washing an obtained precipitate, and drying the precipitate to obtain the 3,4-coated lithium titanate nano particles. The method guarantees excellent performance of the product, simplifies the technology, reduces cost, and is suitable for large scale. The prepared PEDOT-coated lithium titanate nano particles can be used for a negative polepiece of a lithium battery, and has the advantages of excellent cycle performance, high efficiency and high magnification performance.

Owner:SHEYANG RES INST OF NANJING UNIV

Production method of chromatic metallic yarn and spinning apparatus

The invention provides a manufacturing method for color metal yarn and the spinning equipment. It makes metal wires and color roving yarn of other fibers spin into color metal yarn directly. The invention is provided with simple process, short period, low cost, good metal wire performance, good covering performance to metal wire by other fibers and beautiful figuration. The spinning equipment for the color metal yarn adopting said method has a thread guide mechanism for metal wire on the base of any domestic spinning machine and the thread guide mechanism for metal wire comprises wire disk roller, frame for wire disk roller, thread guide wheel and frame for thread guide wheel. The upper end of frame for wire disk roller is fixed on the thread guide cylinder and the wire disk roller is set at the lower end of frame for wire disk roller. The thread guide wheel is set at two ends of transversal bar of frame for thread guide wheel, which is reverted T-shape and the vertical bar is fixed with the cradle of spinning machine so that front retaining roller of thread guide wheel and spinning machine is faced to the front roller. The structure is in reason and there is no need to change the existing structure of spinning machine. It is provided with strong generality.

Owner:徐国华

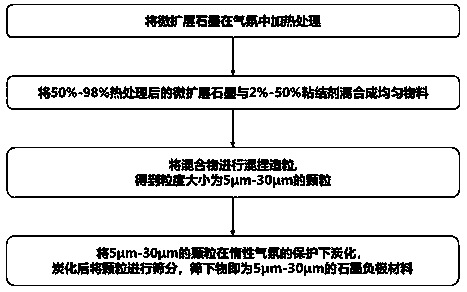

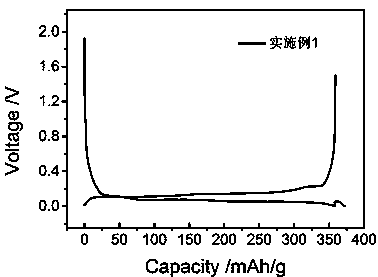

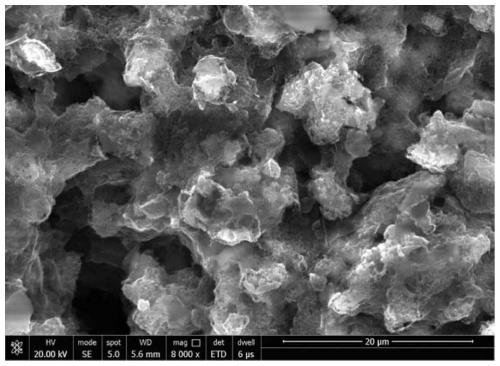

Preparation method of graphite anode material

InactiveCN109742356AIncrease spacingLow insertion resistanceCell electrodesSecondary cellsGraphite anodeHeat treating

The invention provides a preparation method of a graphite anode material. The preparation method comprises the following steps: firstly performing heat treatment on slightly layer-expanded natural graphite, then mixing the slightly layer-expanded natural graphite subjected to the heat treatment with a binder, performing kneading and pelletizing on mixture, and then carbonizing and screening in aninert atmosphere, so that the graphite anode material is obtained. The preparation method provided by the invention solves the problems that surface morphology of graphite becomes rough after layer expansion in the prior art, tap density is reduced and processing of anode slurry is not facilitated.

Owner:HUNAN SHINZOOM TECH

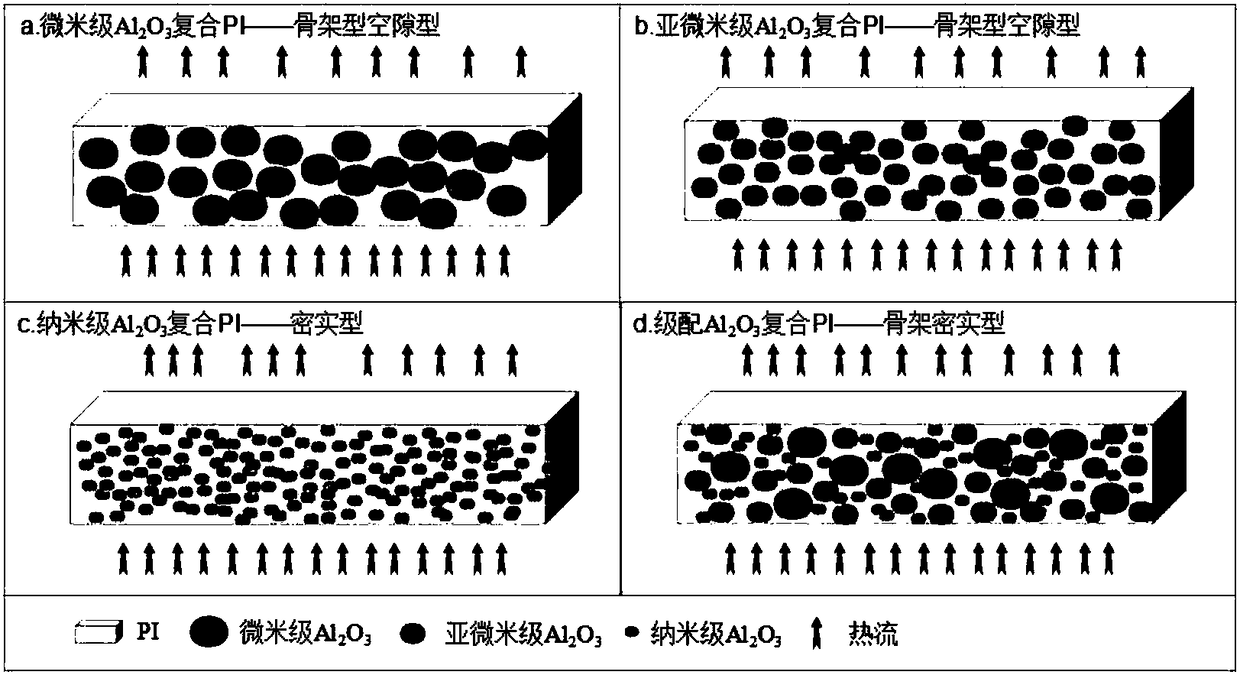

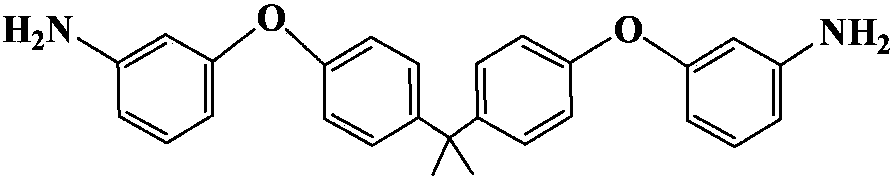

High-heat-conduction polyimide film and preparation method thereof

The invention discloses a high-heat-conduction polyimide film. The high-heat-conduction polyimide film comprises a polyimide matrix and inorganic heat-conducting filler uniformly distributed in the polyimide matrix; the mass of the inorganic heat-conductive filler accounts for 30-60% of the total mass of the high-heat-conduction polyimide film; and the grain sizes of the inorganic heat-conductingfiller comprise three grain sizes of micron-grade grain size, submicron-grade grain size and nano-grade grain size, wherein the mass of micron-grade inorganic heat-conducting filler accounts for 40-90% of the total mass of the inorganic heat-conducting filler, the mass of submicron-grade inorganic heat-conducting filler is not more than 30% of the total mass of the inorganic heat-conducting filler, and the mass of the nano-sized inorganic heat-conductive filler is not more than 30% of the total mass of the inorganic heat-conducting filler. The invention also correspondingly provides a preparation method of the high-heat-conduction polyimide film. The polyimide film provided by the invention has the high comprehensive performance of high heat conductivity, good tear resistance and film forming performance and the like.

Owner:株洲时代华鑫新材料技术有限公司

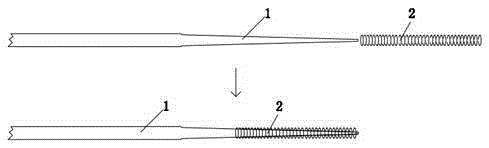

Guide wire applicable to clinical intravascular interventional therapy and manufacturing method of guide wire

InactiveCN105268084AExcellent push performanceGood X-ray trackingGuide wiresSurgeryTungstenInterventional therapy

The invention discloses a novel guide wire applicable to clinical intravascular interventional therapy and a manufacturing method of the guide wire. The guide wire comprises a nickel-titanium memory alloy wire core rod, a tungsten-wire spring and a polymer outer coating layer, wherein a conical spring sleeving part is disposed at the front end of the nickel-titanium memory alloy wire core rod, the tungsten-wire spring sleeves the spring sleeving part, and the front end and the rear end of the tungsten-wire spring are fixed on the spring sleeving part through PU glue; the polymer outer coating layer sleeves the nickel-titanium memory alloy wire core rod and the tungsten-wire spring after the tungsten-wire spring sleeves the spring sleeving part; a hydrophilic coating coats the surface of the polymer outer coating layer. The novel guide wire applicable to the clinical intravascular interventional therapy has the excellent pushing performance of a spring guide wire, has extremely good X-ray traceability, and has the advantages of small vascular irritation, good blood and biological compatibility and easiness in blood vessel passing of a polymer super-smooth guide wire.

Owner:深圳麦普奇医疗科技有限公司

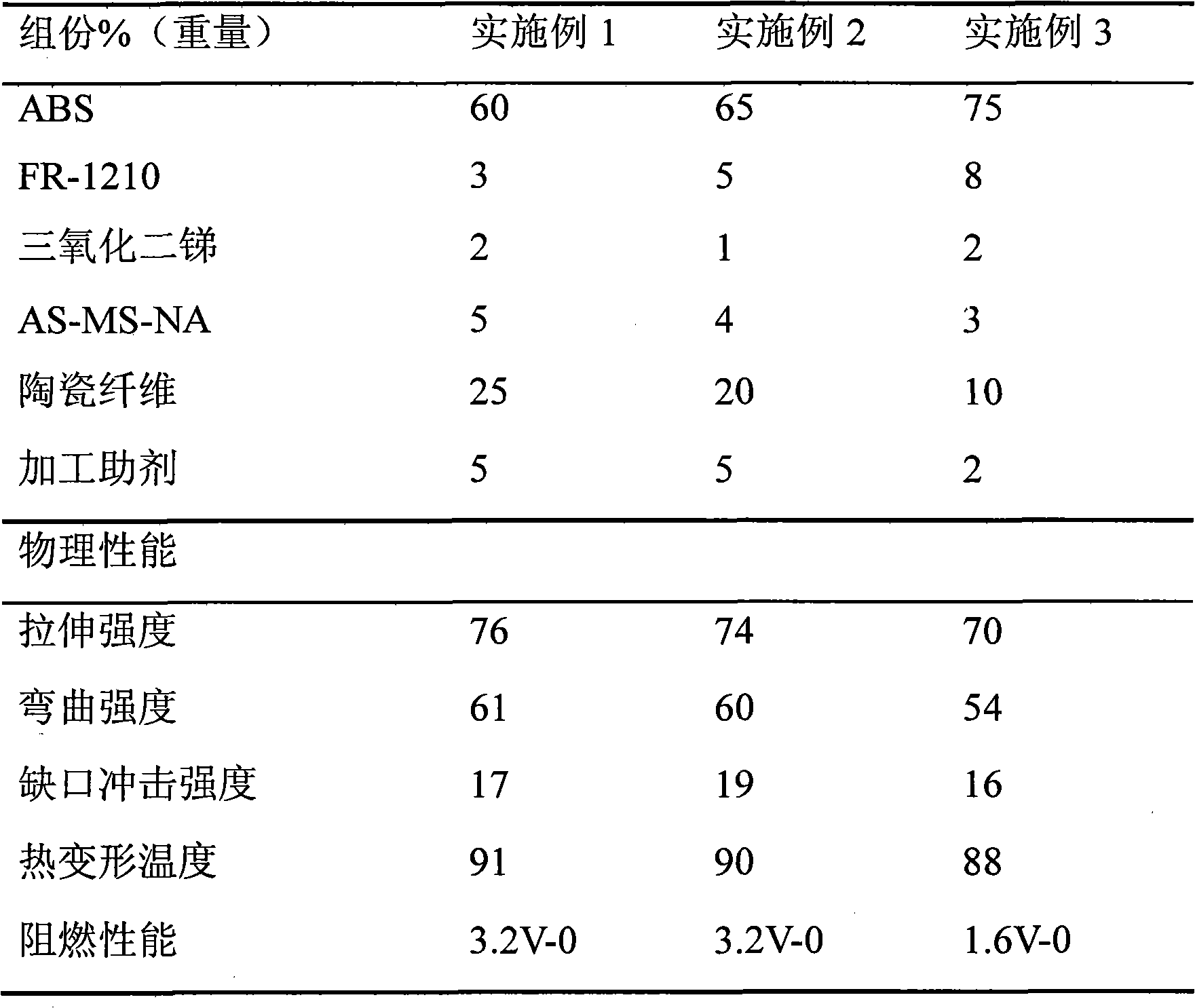

Flame-retarding reinforced acrylonitrile-butadiene-styrene (ABS) composite containing ceramic fibers and preparation method thereof

The invention relates to ceramic fiber reinforced ABS and a composite prepared by flame-retarding and heat-resistance modification of ABS. The composite is characterized by comprising the following raw materials in part by weight: 55 to 80 parts of ABS resin, 10 to 25 parts of ceramic fibers, 3 to 10 parts of flame retardant, 1 to 5 parts of heat-resistant modifier and 2 to 5 parts of processing assistant. The composite has the advantage that the ceramic fibers serving as a functional modifying component have high flame-retarding performance and have the characteristics of high heat resistance, high surface hardness, high rigidity and the like. The composite can be used in electrical appliance shells and internal structure products, which have high flame retardance and heat resistance requirements and high performance requirements.

Owner:崔贵府

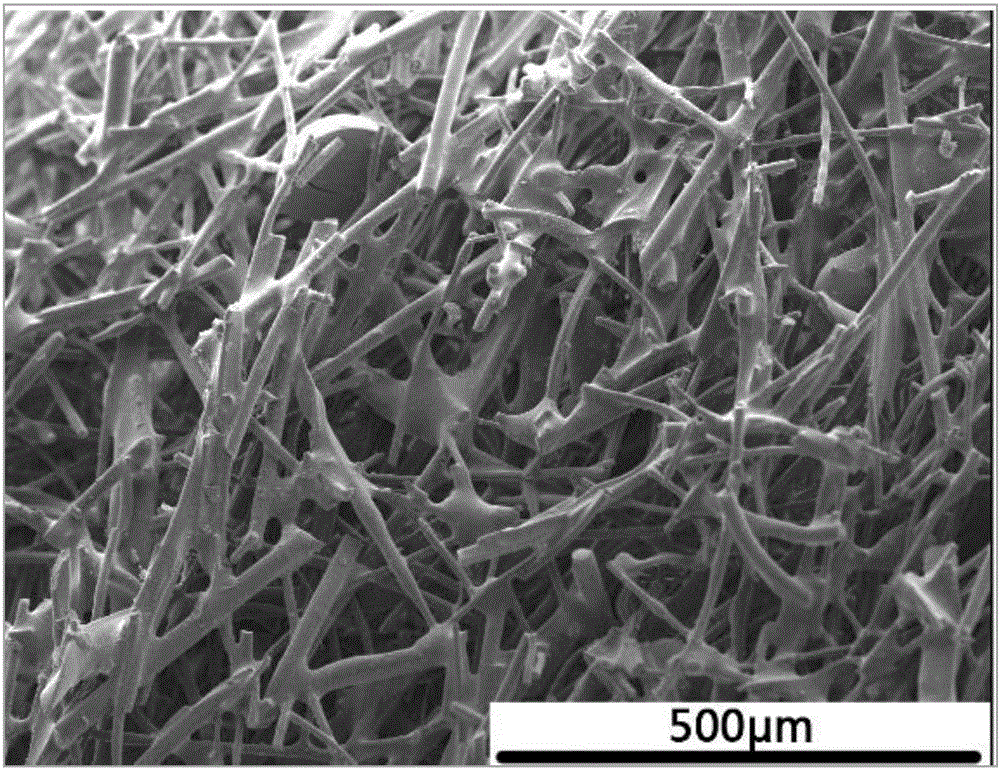

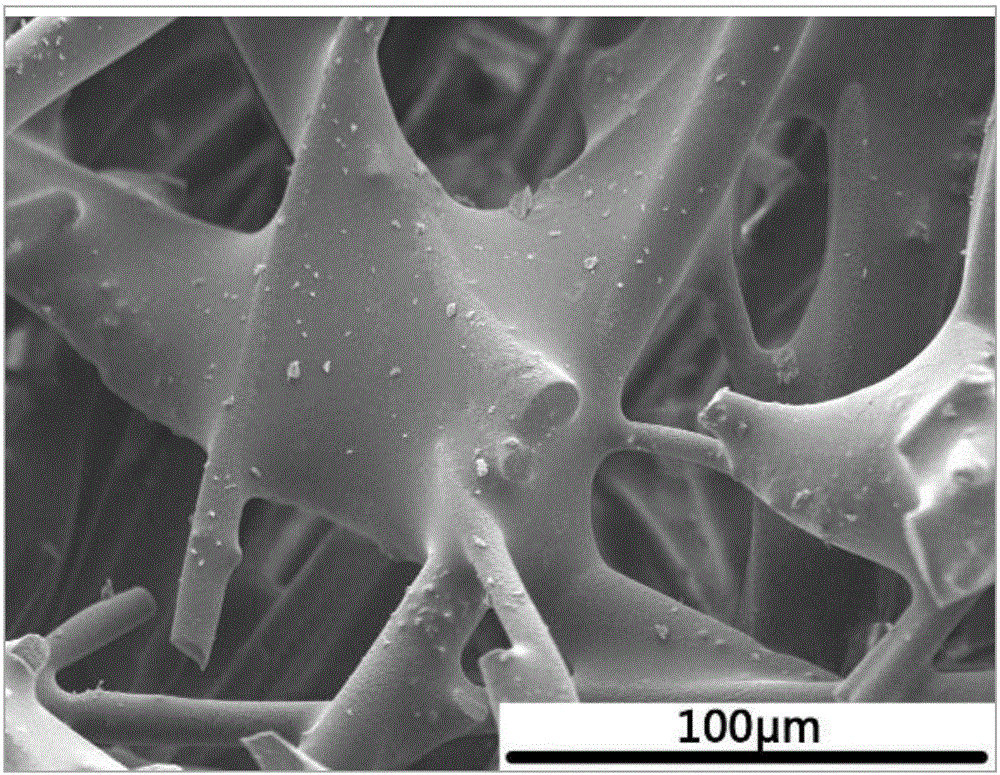

Preparation method of high temperature-resisting mullite fiber porous heat insulation tile

The invention relates to a preparation method of high temperature-resisting mullite fiber porous heat insulation tile. The preparation method comprises the following steps of shearing ceramic fiber by utilizing a fiber pulverizer, thus obtaining chopped fiber; mixing acrylamide, tert butyl alcohol and methylene bisacrylamide, thus obtaining a premixed solution; adding silicon powder, thus obtaining premixed slurry; putting the premixed slurry in a ball mill for carrying out ball milling, thus obtaining uniformly dispersed ceramic slurry; adding mullite fiber in the ceramic slurry, and stirring by using an electromagnetic stirrer, thus obtaining fiber slurry; adding a catalyst and an initiator in the fiber slurry, and pouring the fiber slurry in a mold for curing; drying the mold and a rough body, demolding, thus obtaining a dried rough body; putting the dried rough body in a high-temperature furnace for debonding and sintering, thus obtaining a ceramic fiber porous heat insulation tile. According to the preparation method of the high temperature-resisting mullite fiber porous heat insulation tile, disclosed by the invention, the technical problems that the temperature resistance of a binder of a mullite fiber heat insulation tile is not high enough, and fiber cannot be well coated are solved; the prepared mullite fiber heat insulation tile can bear 1500 DEG C of high temperature and can be used for hypersonic speed aerospace crafts.

Owner:TIANJIN UNIV

Novel electric wire coating device

The invention provides a novel wire and cable covering device. The novel wire and cable covering device includes a frame, a wire releasing device, an impurity removal device, a guiding device, a covering device, a wire take-up device and a control device. The frame is configured to be composed of a bracket and a bottom plate, so The bracket is vertically arranged on the bottom plate, the side of the upper surface of the bottom plate away from the bracket is sequentially provided with the wire-releasing device, the impurity removal device and the guide device, and the covering device is configured by a The winding mechanism is composed of a shielding tape frame, the winding mechanism is horizontally arranged on the support, and the shielding tape frame is arranged on the side of the winding mechanism away from the support, and the winding mechanism is also provided with a winding pressure wheel. The line device is arranged on the top of the support, and the control device is arranged on the bottom plate. The present invention adopts the coating machine, which can meet the coating requirements of electric wires and cables of various specifications, guarantees a good coating effect, has a simple structure, and has a relatively high degree of automation.

Owner:天津市宝鼎线缆有限公司

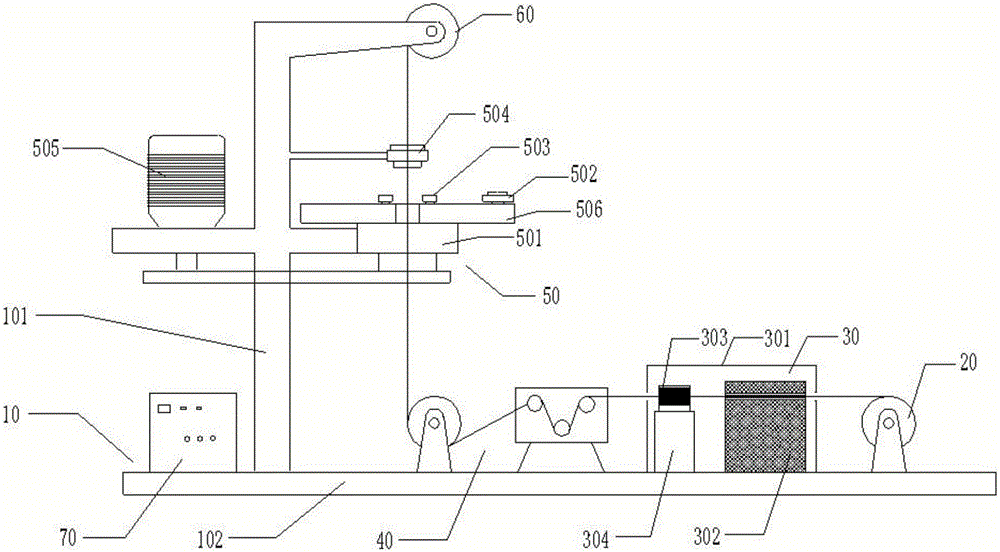

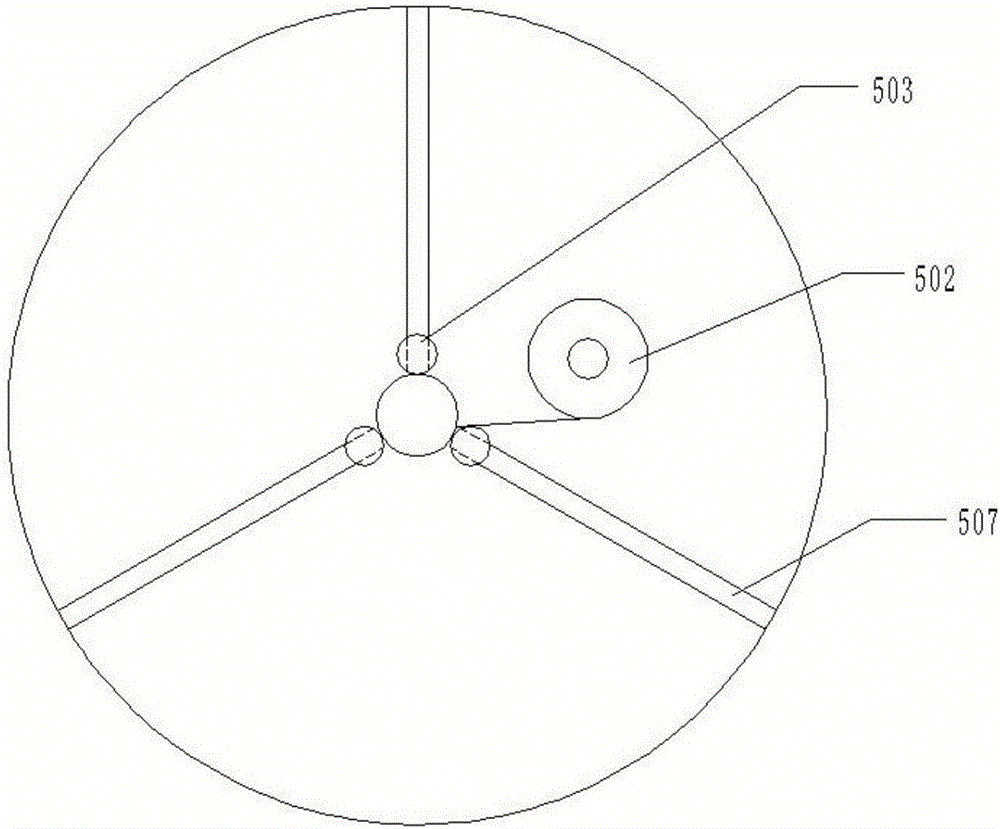

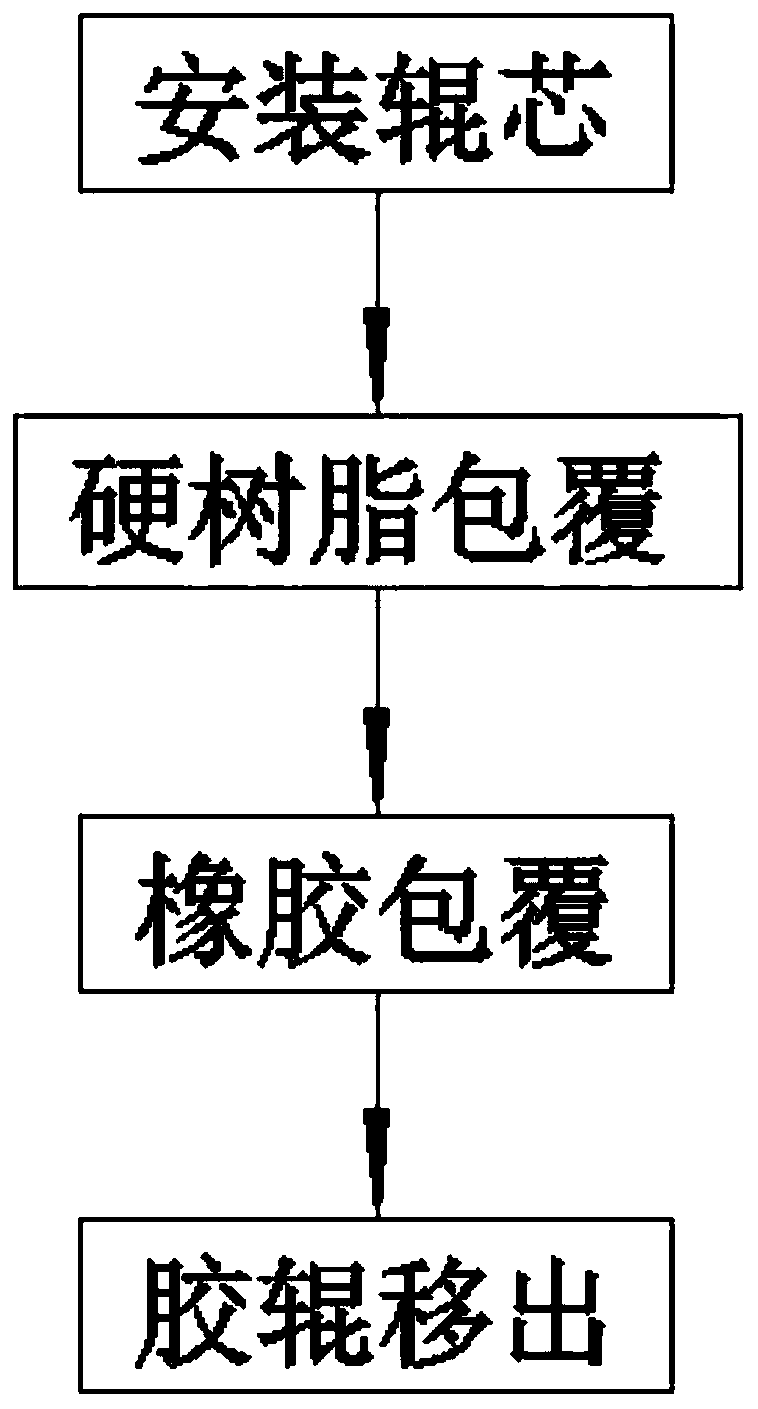

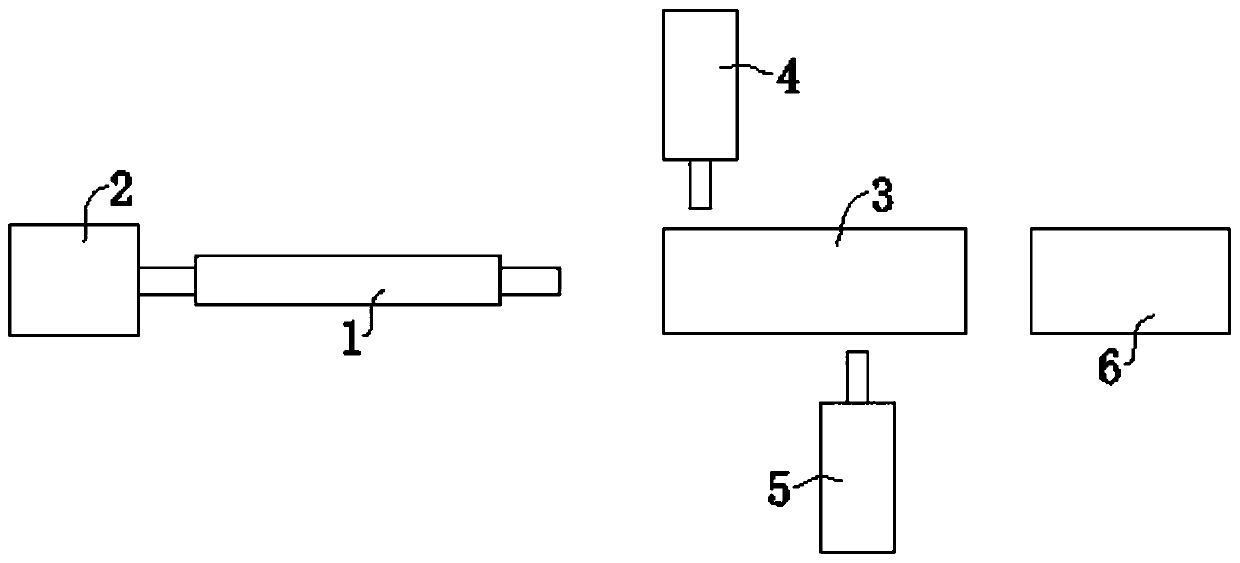

Production method of squeezing type rubber roller

The invention discloses a production method of a squeezing type rubber roller, and belongs to the technical field of rubber roller machining. The production method includes the following steps of mounting of a roller core, wherein the roller core is pushed through a dragger, the roller core enters a die, and under dragging of the dragger, the roller core advances in the die in parallel; coating ofhard resin, wherein while the roller core advances in parallel, the hard resin is extruded by a first extruder, and therefore the circumference surface of the roller core is completely stably coatedwith the hard resin; coating of rubber, wherein after the roller core is coated with the hard resin, the rubber is extruded by a second extruder, the surface of the hard resin is completely stably coated with the rubber in a fused manner, and a rubber roller is obtained; and moving out of the rubber roller, wherein after the rubber roller is cured and formed, the rubber roller is arranged on a roller supporting platform, the rubber roller is supported by a roller on the roller supporting platform, and the rubber roller moves forwards in parallel. A vulcanizing process and post-machining (turning, grinding and polishing) procedures are omitted, the production efficiency can be conveniently improved, the production cost is reduced, environmental pollution is reduced, and the production energy consumption is reduced.

Owner:益阳市思创传动部件制造有限公司

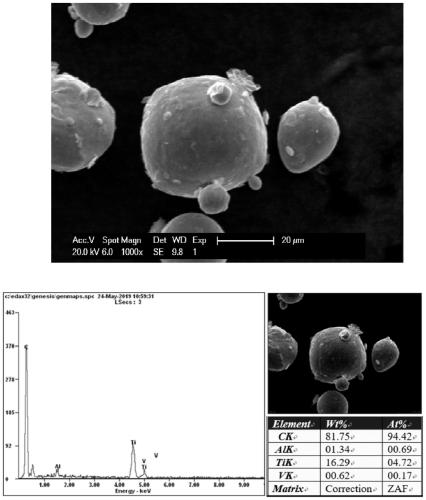

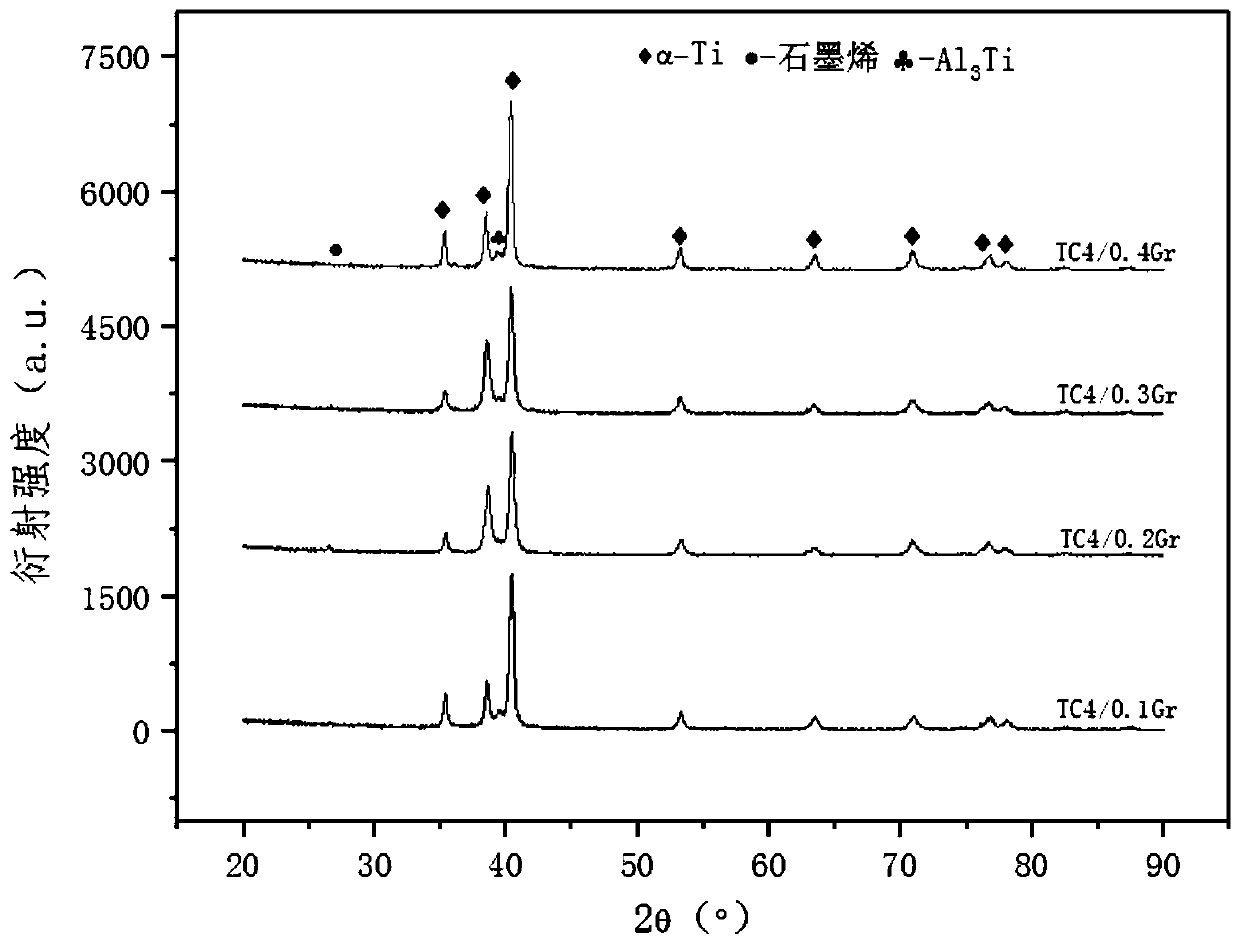

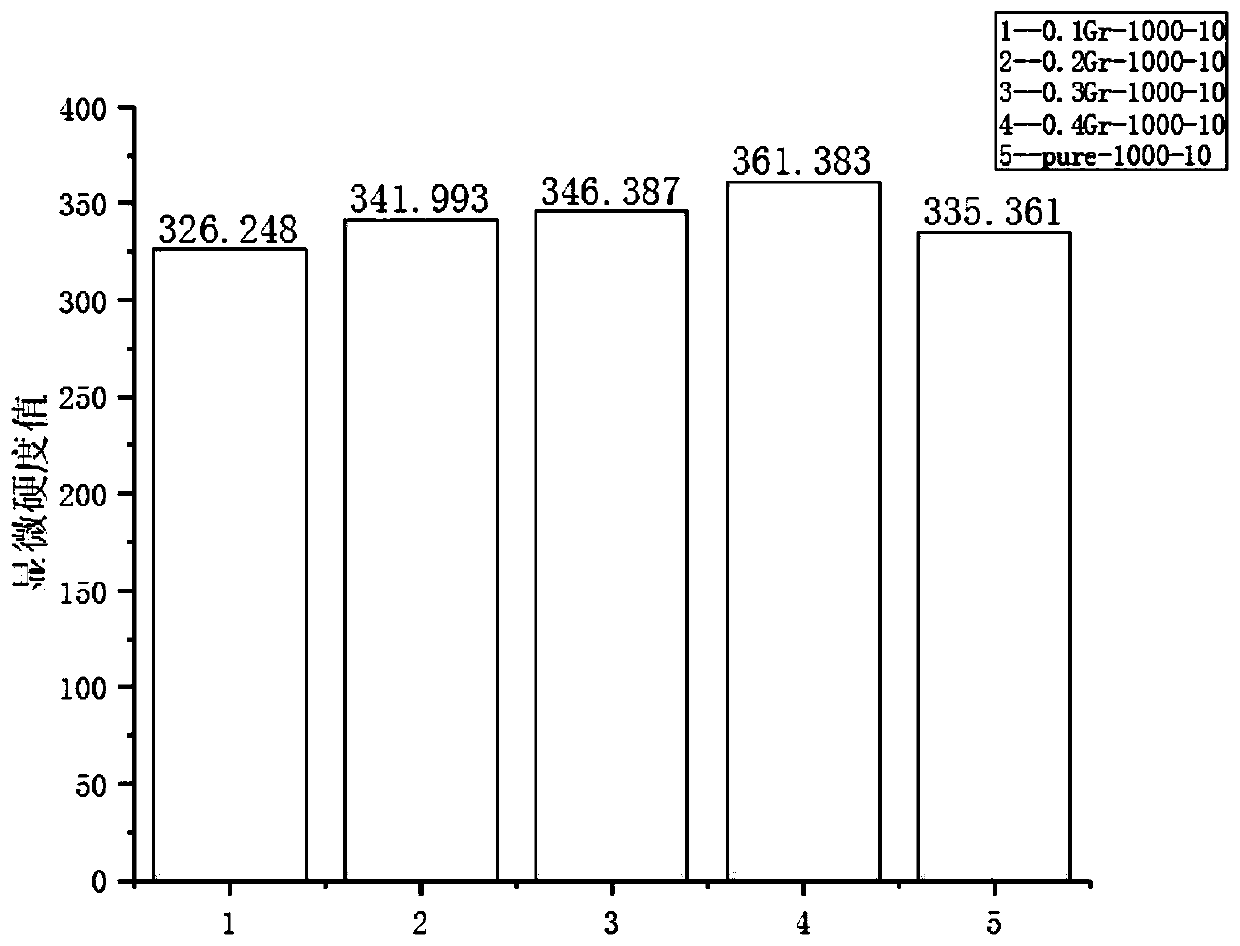

Nanometer TiC modified graphene reinforced titanium-matrix composite material, and preparation method and application thereof

ActiveCN110331314APromote sheddingEasy to fall off and suspendTitanium matrix compositesSurface layer

The invention discloses a nanometer TiC modified graphene reinforced titanium-matrix composite material, and a preparation method and the application thereof. According to the composite material, titanium or titanium alloy serves as a titanium matrix, graphene with surfaced modified with nanometer TiC serves as a reinforced phase, and the modified graphene is evenly distributed around titanium matrix particles to from a network structure. According to the nanometer TiC modified graphene reinforced titanium-matrix composite material, and the preparation method and the application thereof, one layer of nanometer TiC is used for covering the surface of each titanium matrix particle with a three-dimensional mechanical mixing method, then the surface, with one layer of nanometer TiC, of each titanium matrix particle is covered with one layer of graphene, and then a core and shell structure with one titanium particle as the core, the nanometer TiC as the intermediate layer and graphene as the surface layer is obtained. With the preparation method, the problem that according to traditional wet milling, it is difficult to cover the surfaces of titanium particles with graphene evenly is solved. Because of the nanometer TiC, interface reaction between graphene and the titanium matrix in the preparation process is reduced to a certain degree, and the titanium-matrix composite material reinforced with graphene modified with nanometer TiC is obtained through sintering. The composite material is high in strength and plasticity, and good in forming and processing performance, and therebybeing capable of applied to aerospace and the ship and warship manufacturing industry.

Owner:SOUTHEAST UNIV

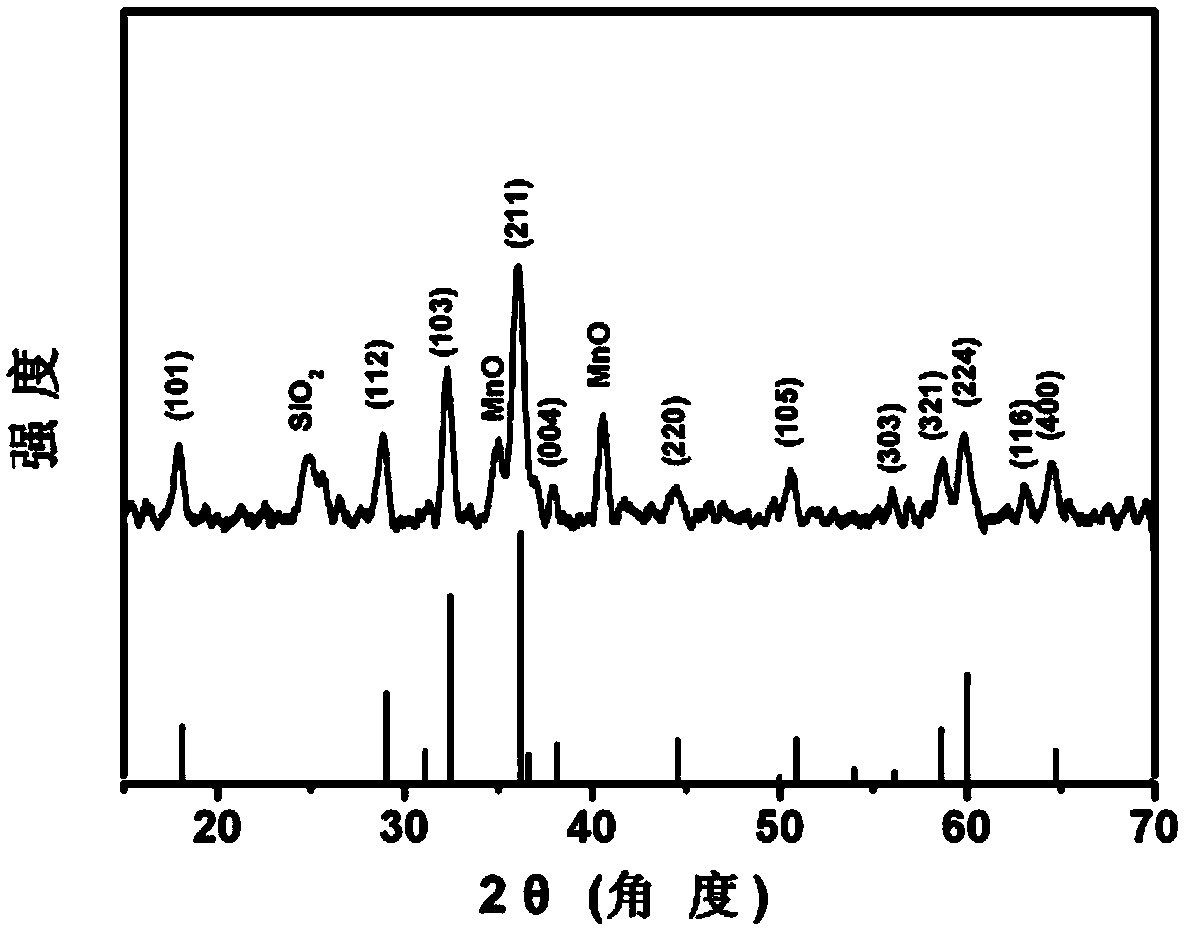

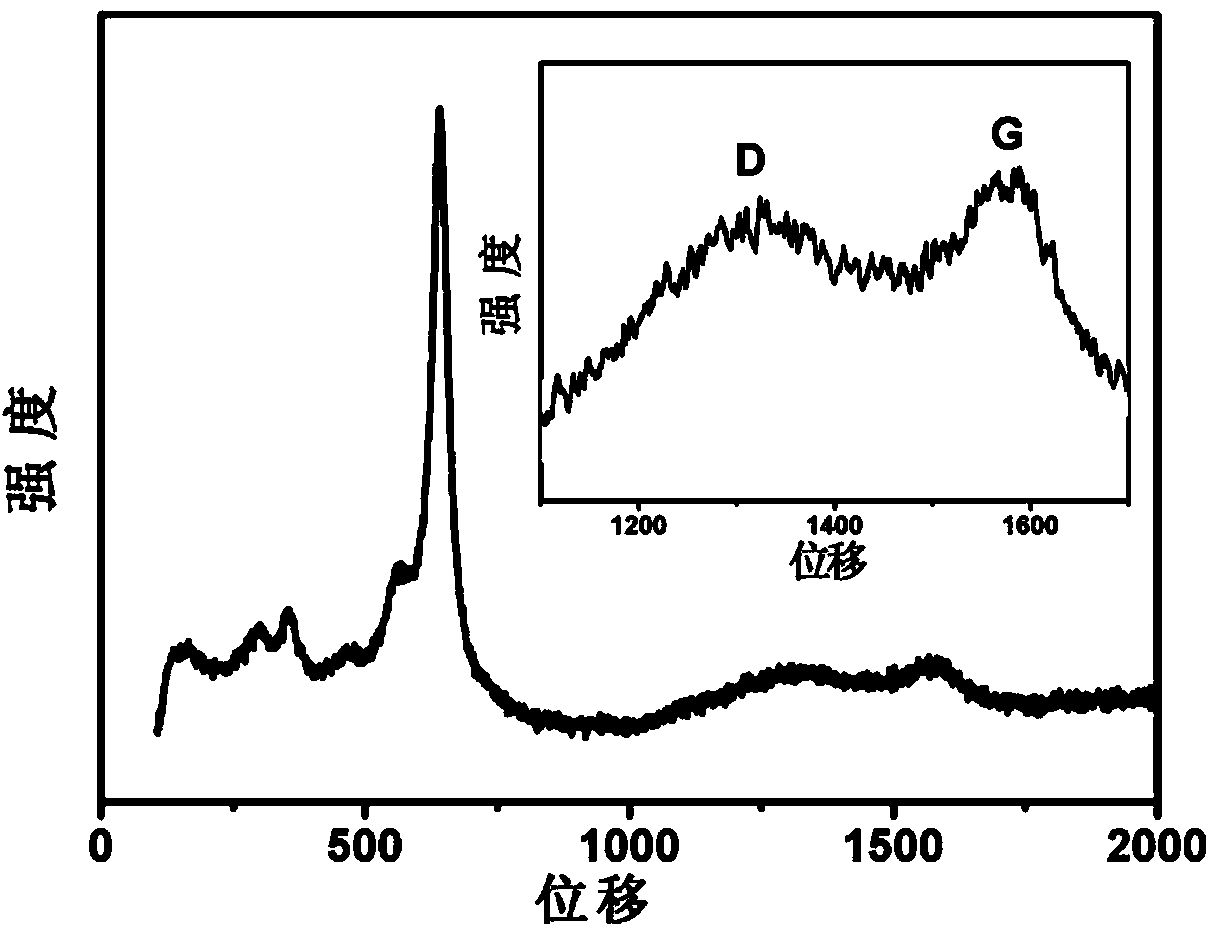

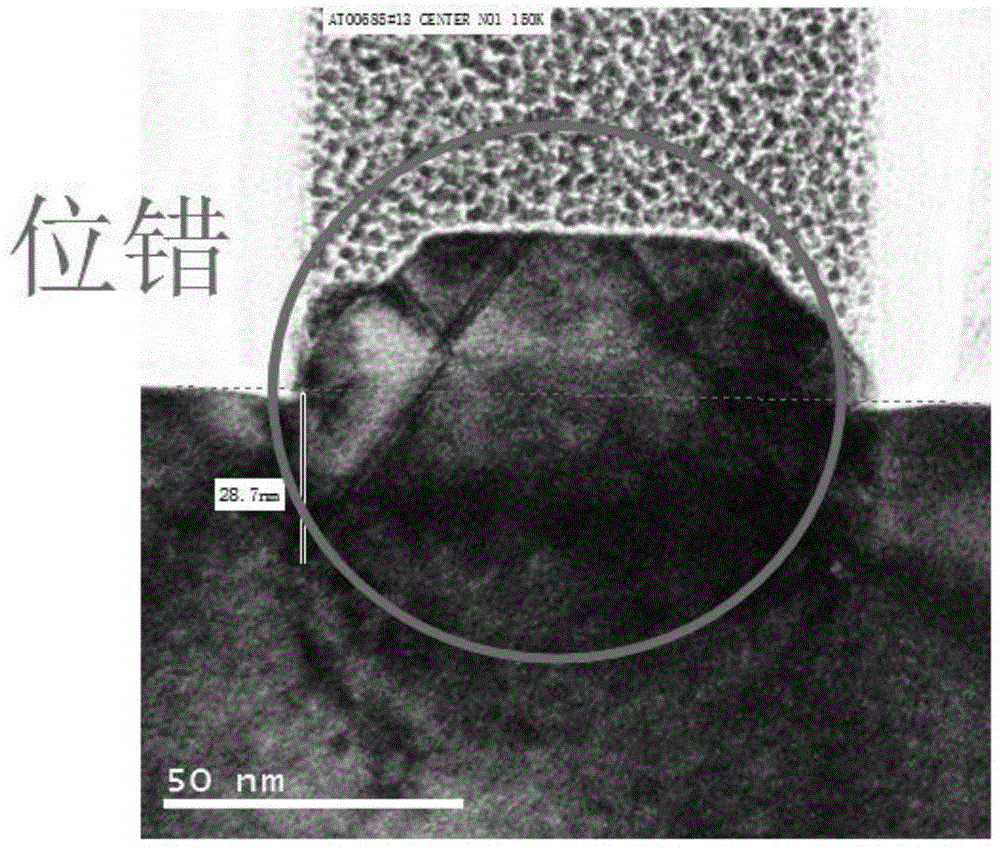

One-dimensional manganese oxide/carbon coaxial hollow nanorod as well as preparation method and application of nanorod

ActiveCN104300136ACoated evenlyAvoid structural damageCell electrodesElectrolyte accumulators manufactureWater bathsHigh rate

The invention relates to a one-dimensional manganese oxide / carbon coaxial hollow nanorod and a preparation method of the nanorod. The length of the nanorod is 2-3 microns; the diameter of the nanorod is 100-200nm; the thickness of carbon is 25-35nm; the thickness of a hollow structure is 10-20nm. The nanorod is prepared by the method which comprises the following steps: (1) dispersing a manganese oxide / silicon dioxide / carbon compound nanorod in a 1.0-2.0mol / L sodium hydroxide solution, stirring and uniformly mixing the solution; (2) slowly stirring the mixed solution obtained by the step (1) for 18-24 hours under the condition with a constant-temperature water bath at 70-90 DEG C; and (3) repeatedly washing a product obtained by the step (2) with water and absolute ethyl alcohol until the pH value is 7, and drying to obtain the one-dimensional manganese oxide / carbon coaxial hollow nanorod. The one-dimensional manganese oxide / carbon coaxial hollow nanorod has the beneficial effects of high specific capacity, high rate capability and high cycling stability, and can be used as a potential application material of a lithium ion battery.

Owner:WUHAN UNIV OF TECH

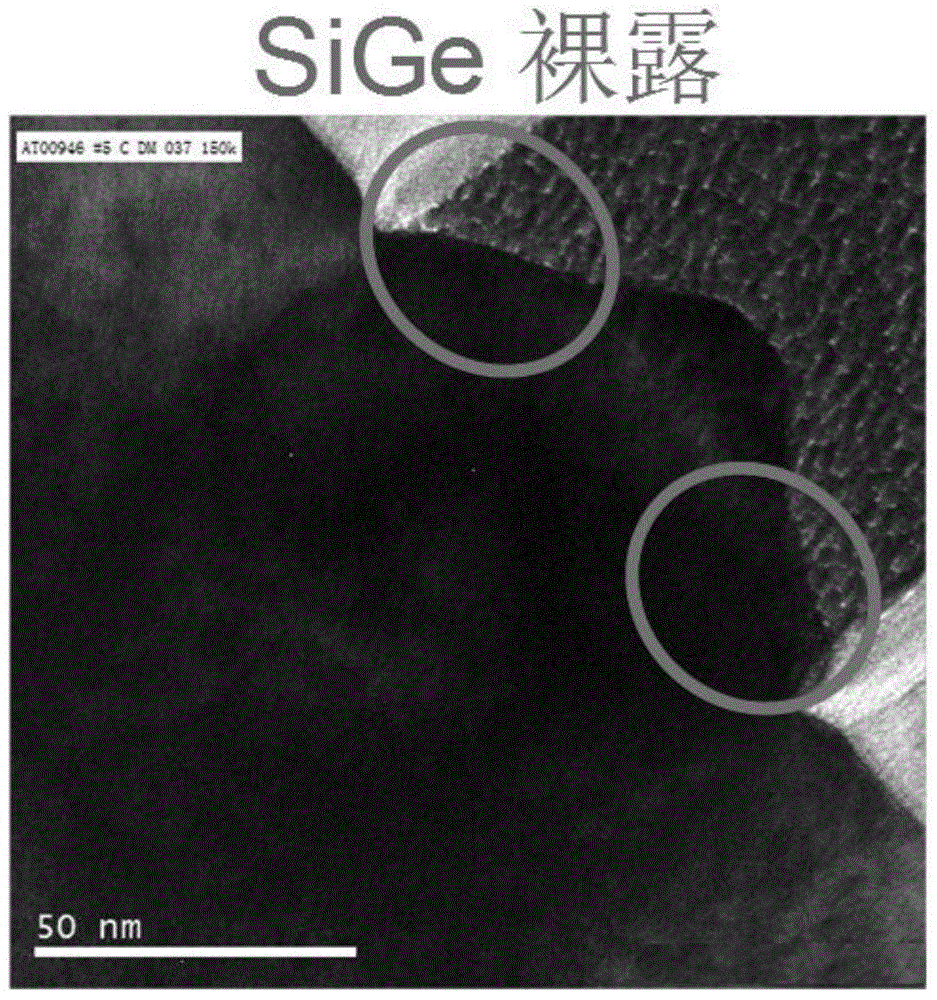

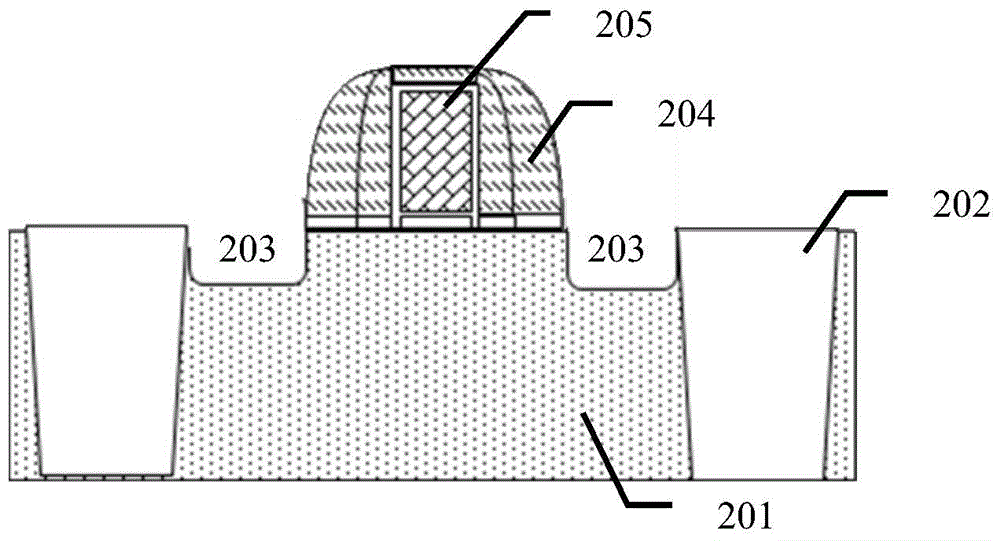

PMOS structure with SiGe source and drain area and manufacturing method thereof

InactiveCN104538448AIncrease stressImprove device yieldSemiconductor/solid-state device manufacturingSemiconductor devicesDislocationEngineering

The invention discloses a PMOS structure with a SiGe source and drain area. A first main layer with the Ge concentration gradually increased and a second main layer with the Ge concentration gradually reduced are arranged in a SiGe main layer, the change of gradient of the Ge concentration is formed so that dislocation and stress release caused by the sudden change of the Ge concentration at the interface position of the main layer and a buffering layer can be avoided, the low Ge concentration is restored at the interface position of the main layer and a cap layer and serves as the growth end concentration, and therefore it is ensured that the cap layer well wraps the main layer. The highest position of Ge concentration is the interface layer of the first main layer and the second main layer or the middle layer position in the middle and used for improving the stress of a channel, and therefore the yield of devices is increased, and the performance of the devices is improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

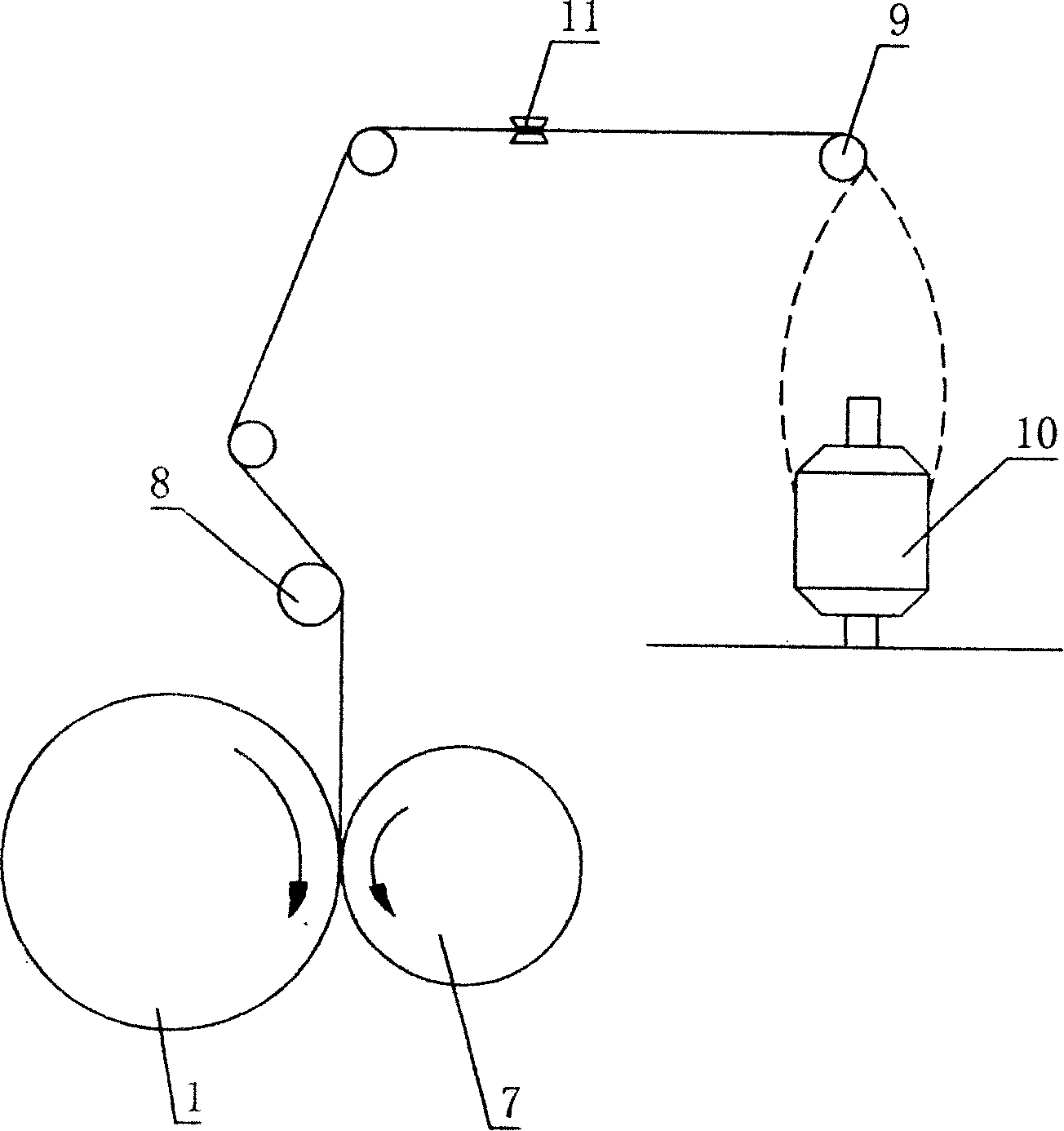

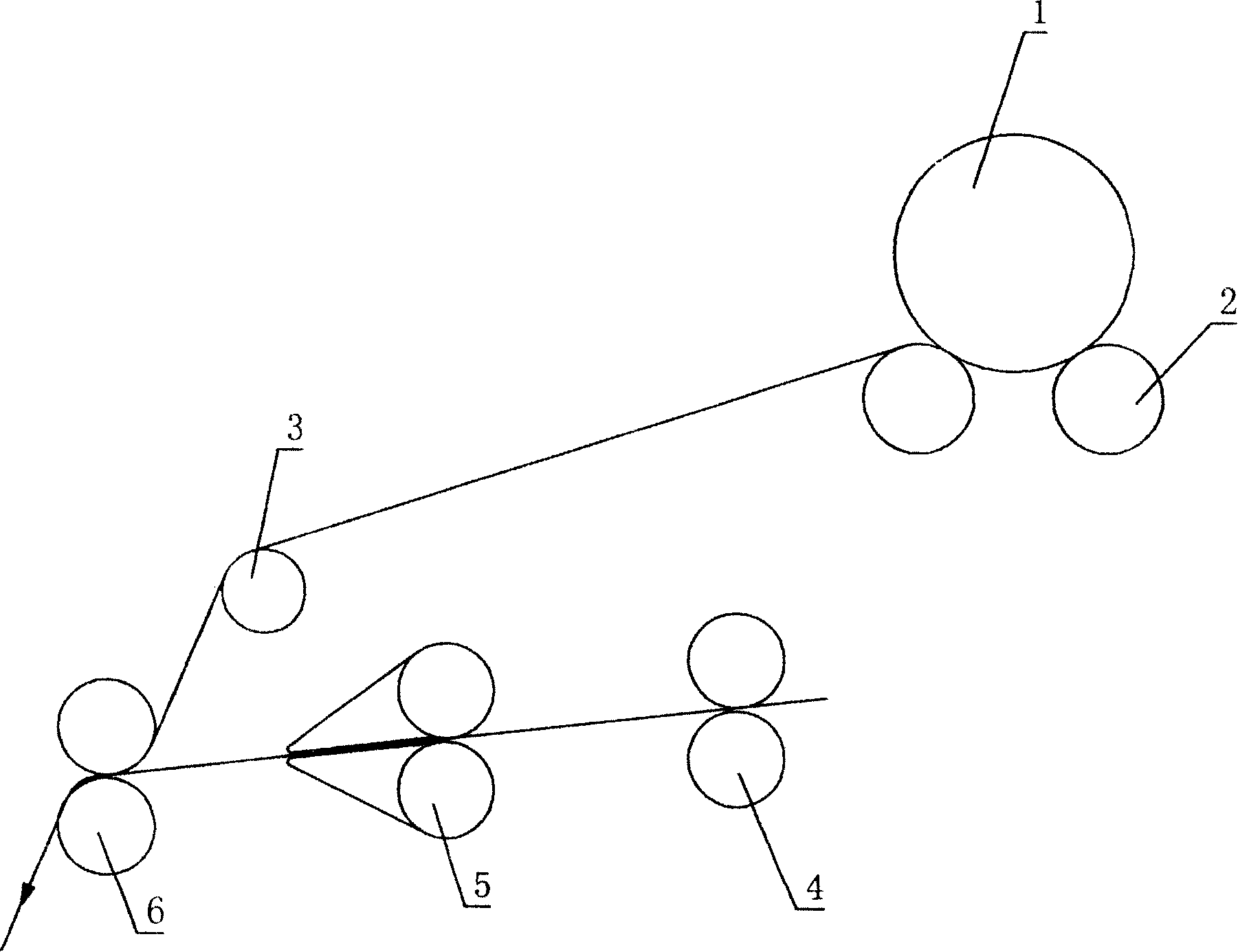

Method for producing non-elastic force composite yarn and device used by the method

The invention discloses a method used for producing inelastic core-spun yarn and a device adopted with the method, which comprises a plurality of steps of unwinding the yarn used as core-spun yarn from the large silk rolls to small silk rolls, positioning the small silk rolls on the spinning frame, and guiding the yarn after unwound to the front roller drafting zone joining and twisting with the outer wrapping fibre guided to the zone forming the core-spun yarn. The surfaces of the small silk rolls always possess a constant linear speed when the yarn used as core-spun yarn is unwound from the large silk rolls to the small silk rolls, and the core-spun yarn is wound on the small silk rolls reciprocatingly swinging as a helical line with a swing distance of 40 to 50mm. The invention has the advantages of offering the well formed silk rolls for the production of the inelastic core-spun yarn on the spinning frame, making the traveling route of the core-spun yarn on the spinning frame shorten, avoiding the phenomena of the hollow yarn of finished product caused by the end breaking of winding, convenience for the production of the inelastic core-spun yarn, and reducing the labor intensity of operators.

Owner:丁宏利

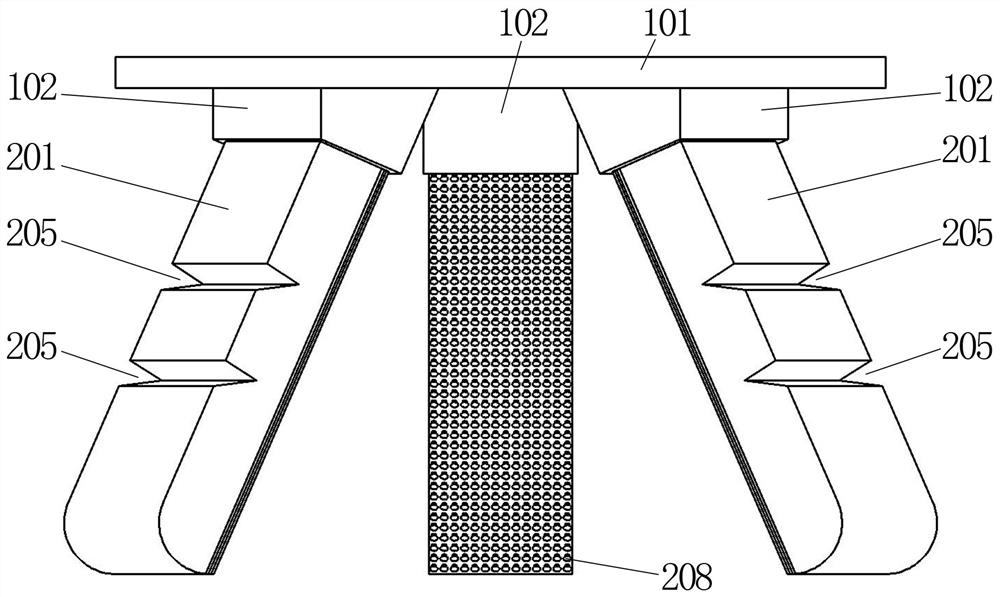

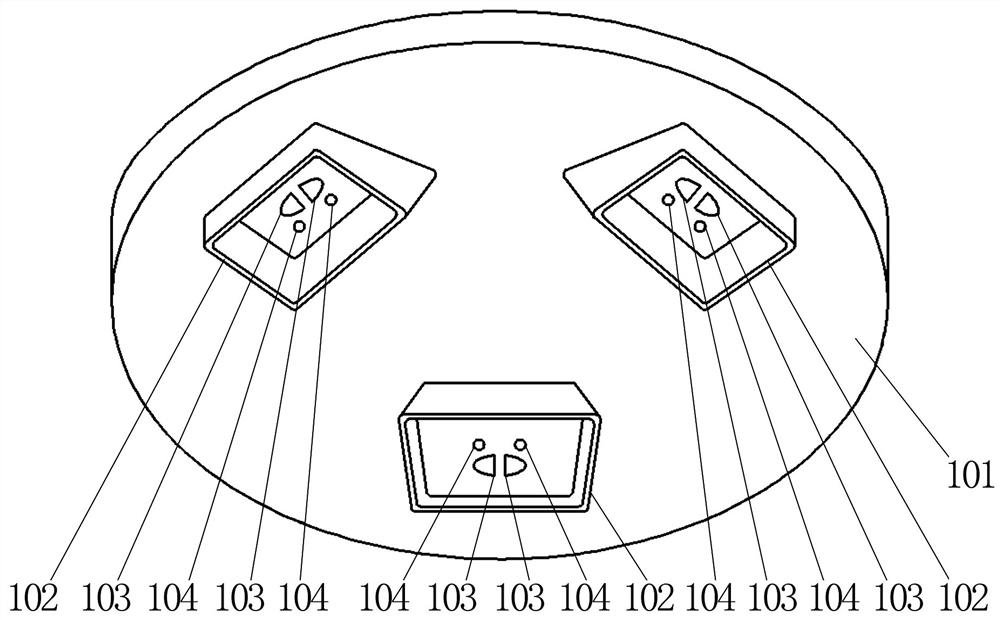

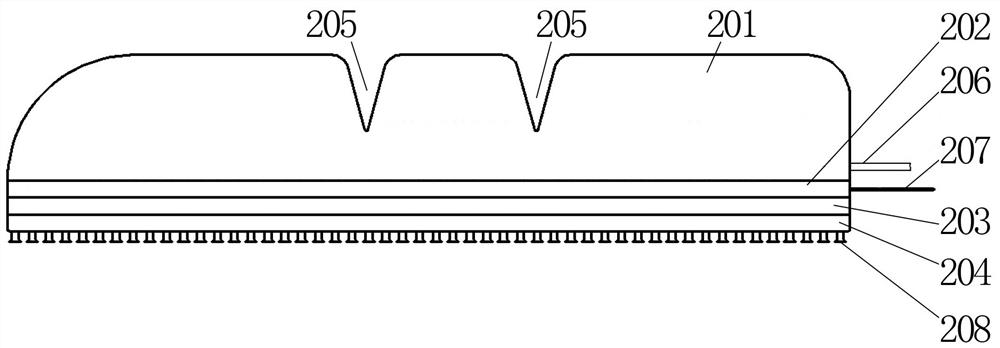

Electric heating driving-type soft gripper capable of simulating gecko toes and preparation method thereof

ActiveCN113070896AImprove ductilityImprove heat transfer performanceGripping headsCircular discRobot hand

The invention relates to a manipulator, in particular to an electric heating driving-type soft gripper capable of simulating gecko toes and a preparation method thereof. The electric heating driving-type soft gripper solves the problems that when a traditional manipulator grabs the objects with complex shapes, grabbing is not firm, and when soft and fragile objects are grabbed, safe grabbing cannot be achieved easily. The electric heating driving-type soft gripper capable of simulating the gecko toes comprises a base and three bionic fingers with the consistent size. The base comprises a disc-shaped base body. Three inserting grooves are formed in the front face of the disc-shaped base body in an extending mode, and the three inserting grooves are symmetrically distributed around the center line of the disc-shaped base body. A pair of outer side threading holes and a pair of inner side threading holes are formed between the groove bottom of each inserting groove and the back face of the disc-shaped base body in a penetrating mode. Each bionic finger comprises a strip-shaped artificial muscle layer, a strip-shaped flexible heat transfer layer, a strip-shaped variable rigidity layer and a strip-shaped flexible contact layer. The electric heating driving-type soft gripper capable of simulating the gecko toes is suitable for industrial robots.

Owner:ZHONGBEI UNIV

High-sulfur-loading-capacity lithium-sulfur battery positive plate and production method thereof

ActiveCN111446418AUniform depositionGood flexibilityPositive electrodesLi-accumulatorsCarbon compositesLithium–sulfur battery

The invention discloses a high-sulfur-loading-capacity lithium-sulfur battery positive plate and a production method thereof. The positive plate comprises a sulfur-carbon composite material, graphene,a binder (PVDF) and an aluminum foil current collector. The production method comprises the following steps: firstly, adding a proper amount of PVDF glue solution and a graphene conductive slurry into a planetary stirrer, and stirring and dispersing for enough long time; then adding a sulfur-carbon composite material, and stirring and dispersing for enough long time; transferring into a ball mill, carrying out high-temperature ball milling for a long enough time, vacuumizing and filtering to obtain a final positive electrode slurry; and coating an aluminum foil with the slurry by using a transfer coating machine, and drying at a low temperature to obtain a pole piece. The produced positive plate is high in sulfur loading capacity, good in flexibility and outstanding in electrochemical performance, and energy density of a lithium-sulfur battery assembled by adopting the positive plate can reach above 400wh / kg. The production method of the positive plate is simple, and industrial large-scale production can be realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

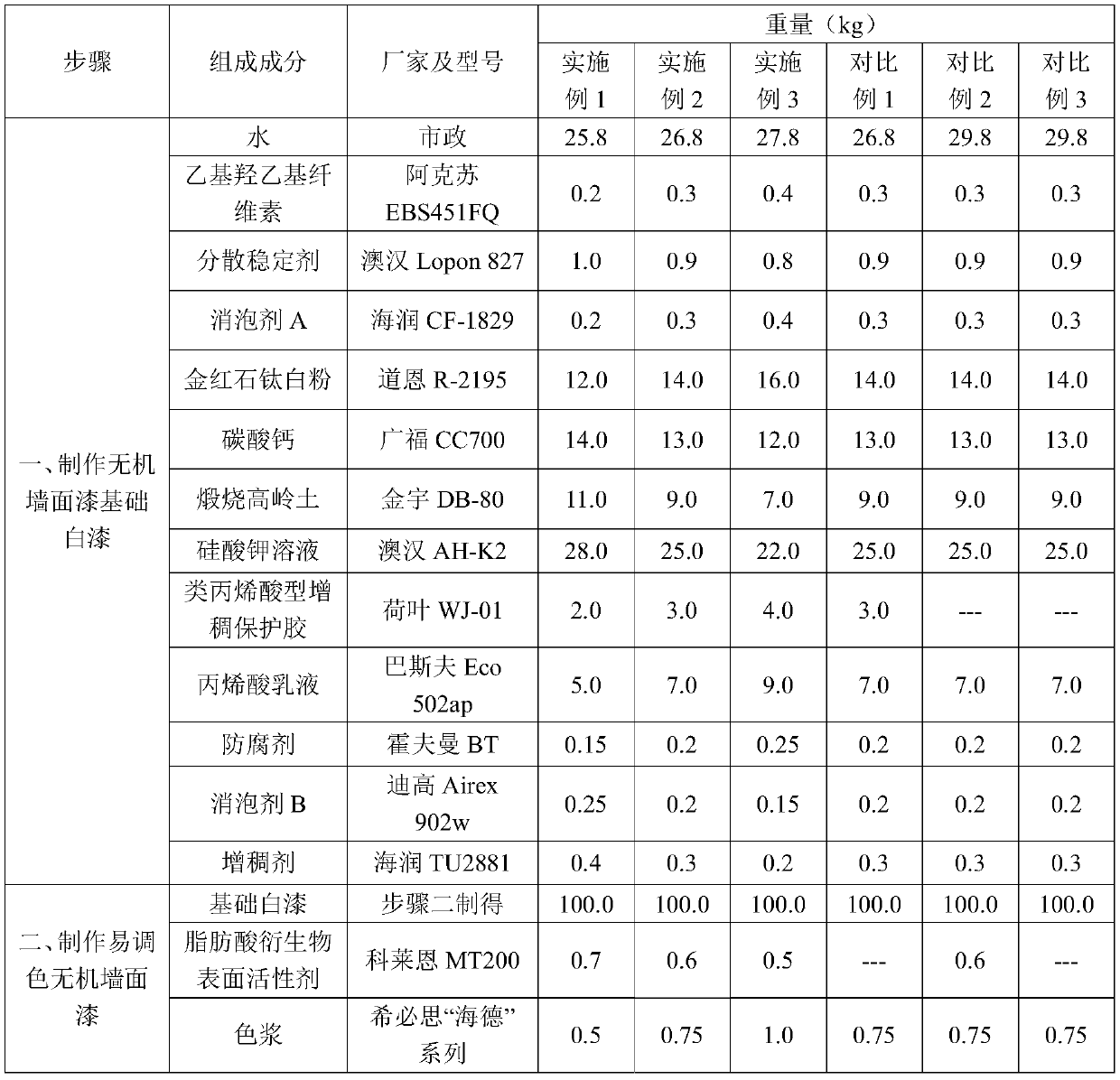

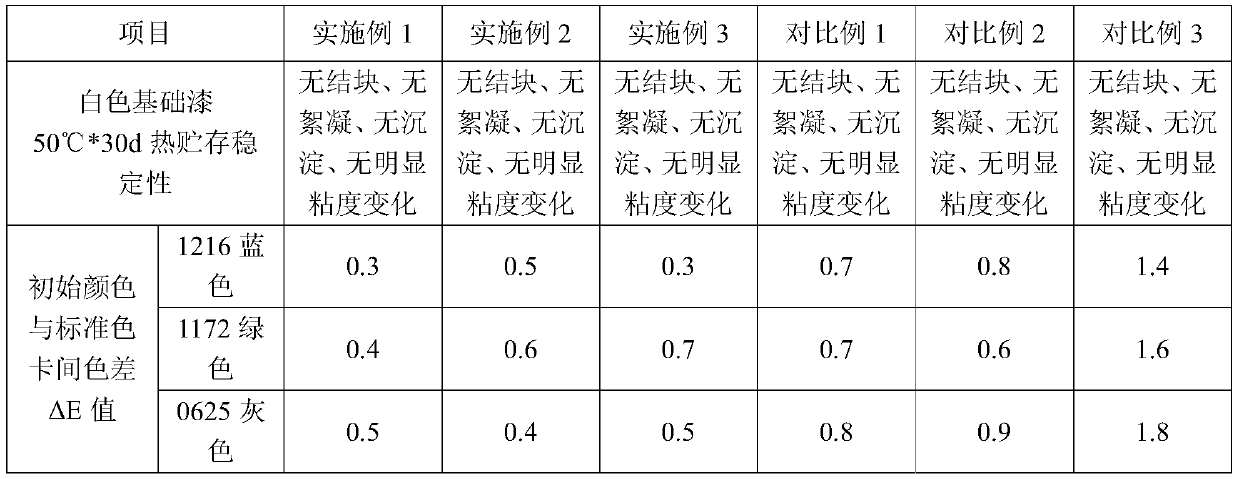

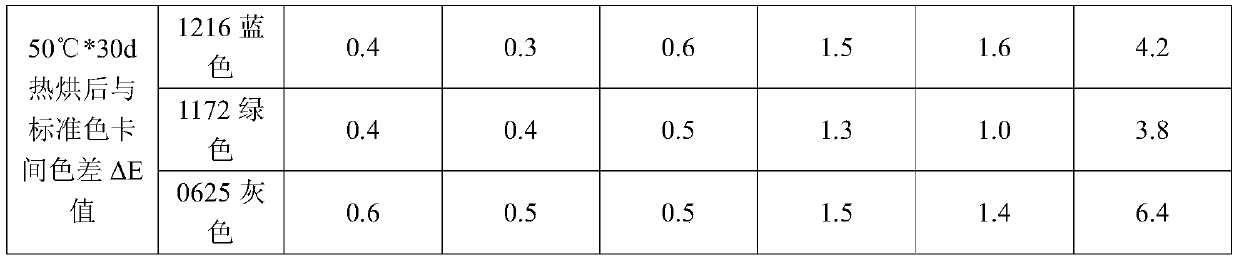

Inorganic wall paint easy for color matching and preparation method thereof

ActiveCN110669367AImprove stabilitySolve the easy migration of colorAlkali metal silicate coatingsEthyl(hydroxyethyl)celluloseActive agent

The invention provides an inorganic wall paint easy for color matching. The inorganic wall paint is prepared by mixing of the following components by weight: 100 parts of basic white paint, 0.5-0.7 part of a fatty acid derivative surfactant and 0.5-1 part of a color paste, wherein the basic white paint is prepared by mixing of the following components by weight: 25.8-27.8 parts of water, 0.2-0.4 part of ethyl hydroxyethyl cellulose, 0.8-1.0 part of a dispersion stabilizer, 0.2-0.4 part of a defoaming agent A, 12-16 parts of rutile titanium dioxide, 12-14 parts of calcium carbonate, 7-11 partsof calcined kaolin, 22-28 parts of an inorganic potassium silicate solution, 2-4 parts of an acrylic acid-like thickening protective glue, 5-9 parts of an acrylic emulsion, 0.15-0.25 part of a preservative, 0.15-0.25 part of a defoaming agent B and 0.2-0.4 part of a thickening agent. The inorganic wall paint provided by the invention solves the problems that after use of common color paste for color matching, the color is easy to migrate, the color batching properties are poor, and the price is high due to the use of an inorganic special color paste.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

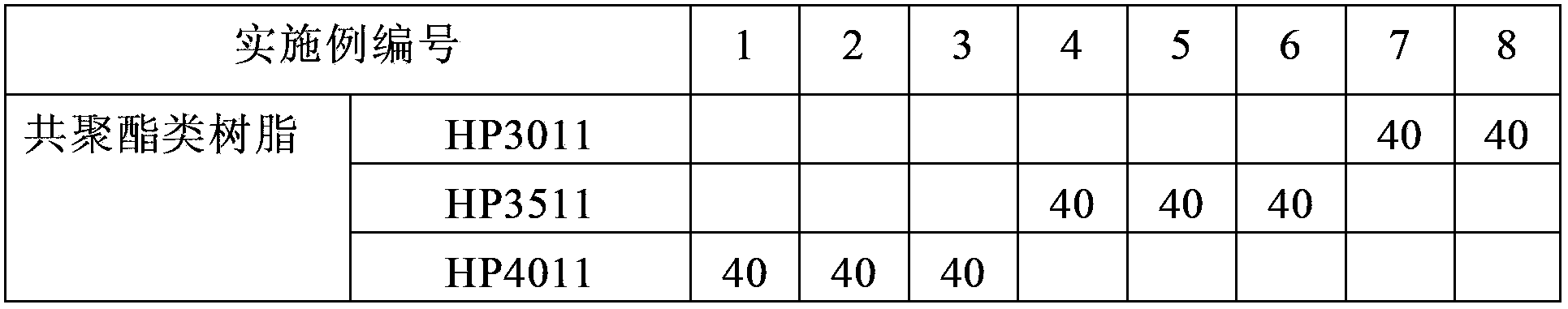

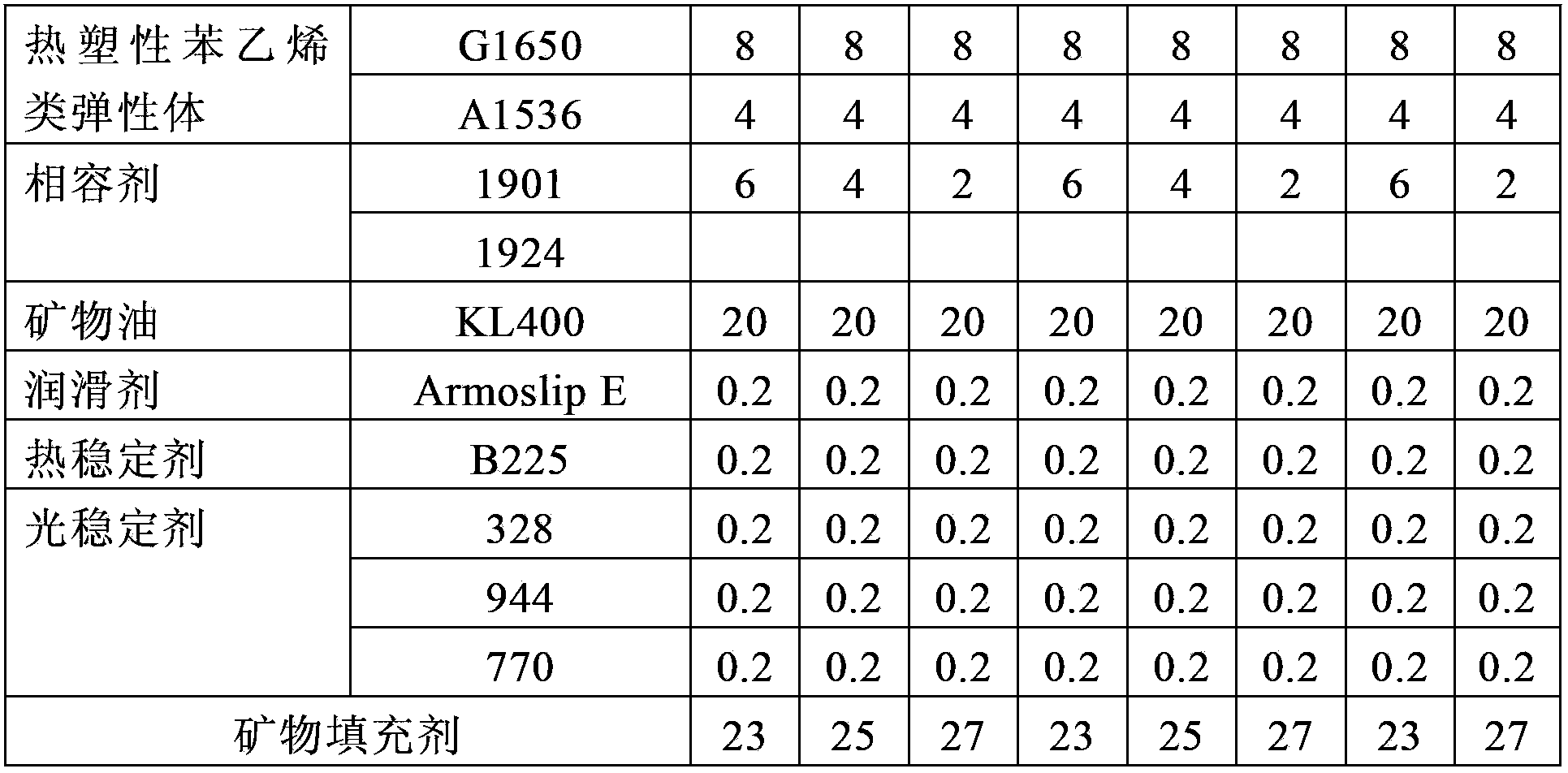

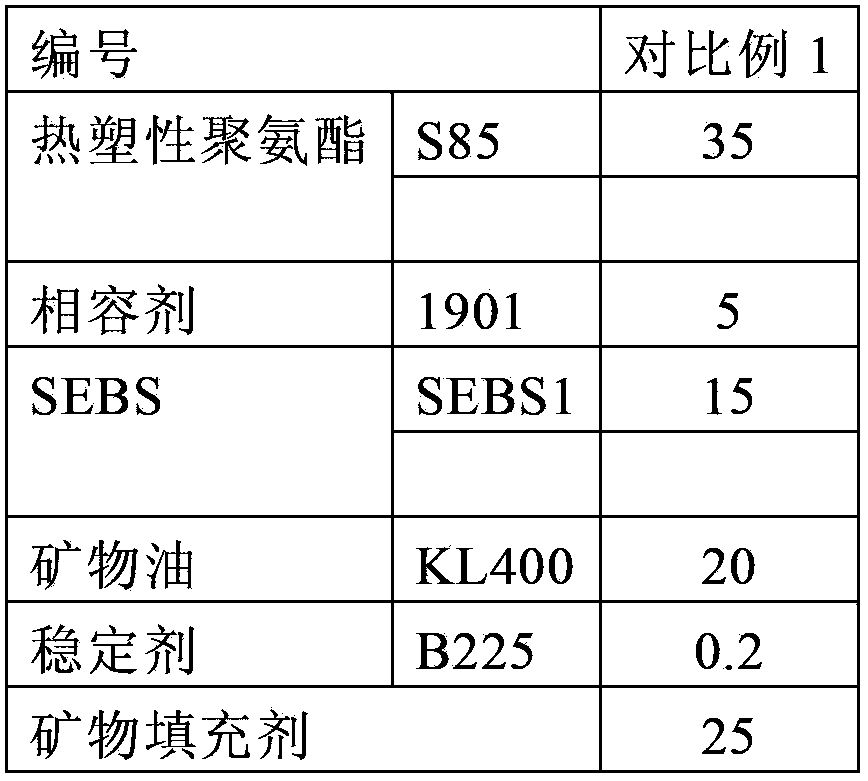

Weather-resisting injection molding and over-molding thermoplastic elastomer composition

The invention provides a thermoplastic elastomer composition. The thermoplastic elastomer composition comprises following components in parts by weight: 5-20 parts of a styrene type thermoplastic elastomer, 10-30 parts of mineral oil, 30-50 parts of co-polyester resin, 1-10 parts of a compatilizer, 15-35 parts of a mineral filling agent, 0-2 parts of a stabilizer and 0-2 parts of a lubricant. The hardness of the thermoplastic elastomer composition provided by the invention can be freely adjusted in a range of 40-85A; a processing window is wide; the thermoplastic elastomer composition has an excellent surface effect under an injection molding temperature of 180-250 DEG C and has good hand feel comfort. The thermoplastic elastomer composition can be rapidly injected and molded and has a good anti-scratching performance. The weather resistance is good. The thermoplastic elastomer composition has a good covering performance on the surface of a product which takes ABS (Acrylonitrile Butadiene Styrene), ABS / PC (Polycarbonate) and other materials modified by taking the ABS as a base material.

Owner:SINOTEX INVESTMENT & DEV CO LTD

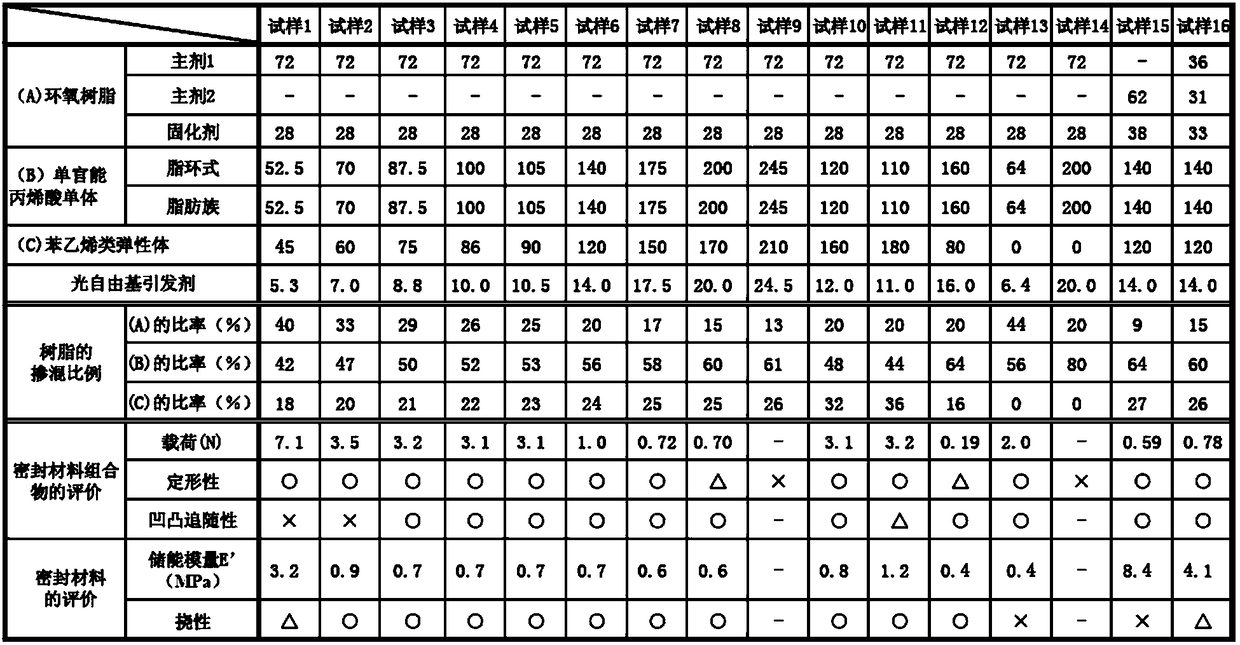

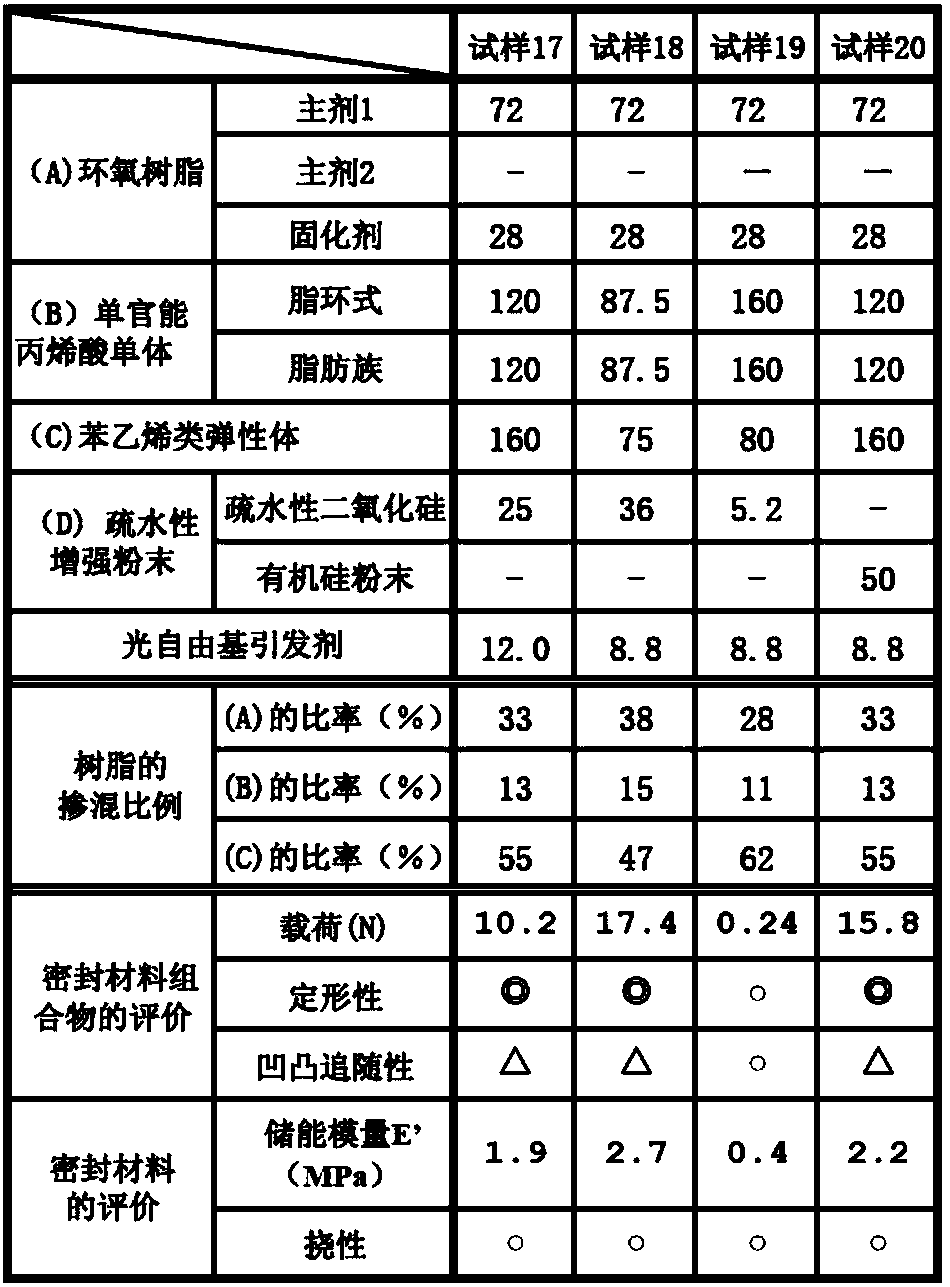

Sealing material composition and sealing material

InactiveCN109153842AFlexibleShapedSemiconductor/solid-state device detailsSolid-state devicesEpoxyElastomer

To provide a sealing material for affixing to an electronic element provided to an electronic substrate or the like or a portion where metal is exposed and protecting the electronic element or other adherend from moisture and the like, and an uncured sealing material composition for the same, the sealing material and the sealing material composition having fixed-shape properties, flexibility, andadhesive properties. The present invention is a sealing material composition having as essential components an epoxy resin cured material having a flexible skeleton, a monofunctional (meth)acrylate ester monomer, a photoradical polymerization initiator, and a styrene-based elastomer, the monofunctional (meth)acrylate ester monomer being curable by photoirradiation, and the sealing material composition having fixed-shape properties and flexibility whereby the load is 0.19-3.2 N when a 1-mm thickness thereof is 25% compressed by a columnar probe in which the distal end thereof forms a bottom surface having a diameter of 10 mm. The present invention is also a sealing material obtained by photocuring the sealing material composition.

Owner:SEKISUI POLYMATECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com