Method for synthesizing ZSM-5/Silicalite core-shell molecular sieve by using vapor phase process

A synthesis method, the technology of ZSM-5, is applied in the direction of molecular sieve characteristic polymorphic crystalline silicon, silicon compounds, silicon dioxide, etc., which can solve the problems of difficult environmental impact treatment of template agents, low product shell coverage, etc. The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 20 grams of TEOS to 55 grams of water and hydrolyze for 8 hours to form solution A. Add 10 grams of ZSM-5 molecular sieve (nuclear phase silicon-aluminum ratio = 30, particle size = 0.1 micron) to solution A to form suspension B. Put B in an 80°C water bath and stir for 4 hours to make dry glue C, put C in the upper layer of the crystallization kettle, put 4.56g of TPAOH and 60g of water in the lower layer of the crystallization kettle, and crystallize at 150°C After 2 days, after the crystallization, the solid in the upper layer was washed until the pH was 6-8, and then dried. The obtained sample can be seen through the SEM spectrum. On the outer surface of ZSM-5, fine particles are evenly distributed, and the shell coverage is 90%, which can confirm that the obtained molecular sieve material is ZSM-5 in the core phase and Silicalite-1 in the shell layer. Zeolite ZSM-5 / Silicalite-1 core-shell zeolite molecular sieve. Denoted as core-shell molecular sieve CS1.

...

Embodiment 2

[0027] Add 20 grams of silica sol to 60 grams of water and hydrolyze for 10 hours to prepare solution A. Add 15 grams of ZSM-5 molecular sieve (nuclear phase silicon-aluminum ratio = 30, particle size = 0.5 microns) to solution A to prepare suspension B. Put B in an 85°C water bath and stir for 2 hours to make dry glue C, put C in the upper layer of the crystallization kettle, put 5.23 grams of TPABr and 65 grams of water in the lower layer of the crystallization kettle, and crystallize at 140°C After 3 days, after the crystallization, the solid in the upper layer was washed until the pH was 6-8, and then dried. The obtained sample can be seen through the SEM spectrum. On the outer surface of ZSM-5, fine particles are evenly distributed, and the shell coverage is 85%, which can confirm that the obtained molecular sieve material is ZSM-5 in the core phase and Silicalite-1 in the shell layer. Zeolite ZSM-5 / Silicalite-1 core-shell zeolite molecular sieve. Denoted as core-shell ...

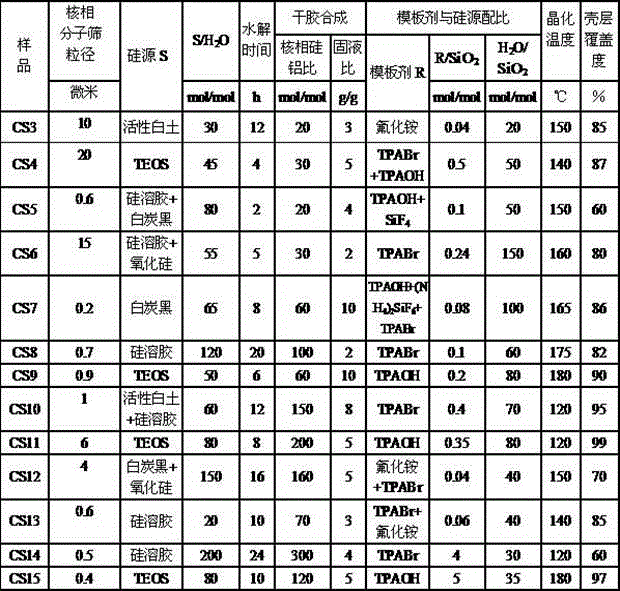

Embodiment 3~15

[0030] Examples 3-15 were synthesized according to the synthesis ratio and synthesis conditions in Table 1, and the core-shell molecular sieves CS3~15# were synthesized according to the similar method and steps of Embodiment 1, see Table 1 for details.

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com