One-dimensional manganese oxide/carbon coaxial hollow nanorod as well as preparation method and application of nanorod

A technology of manganese oxide and nanorods, applied in the field of nanomaterials and electrochemistry, to achieve good cycle stability, improve cycle stability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

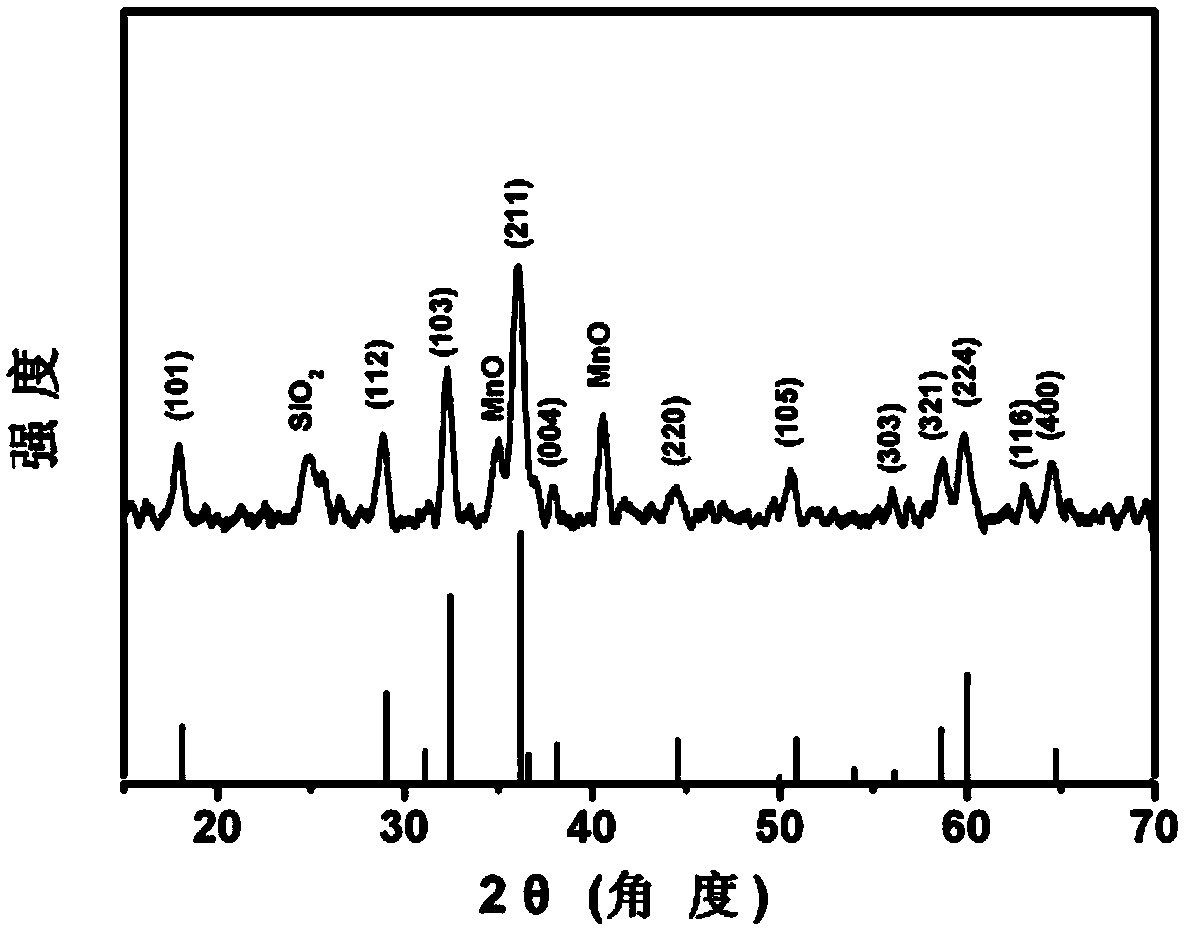

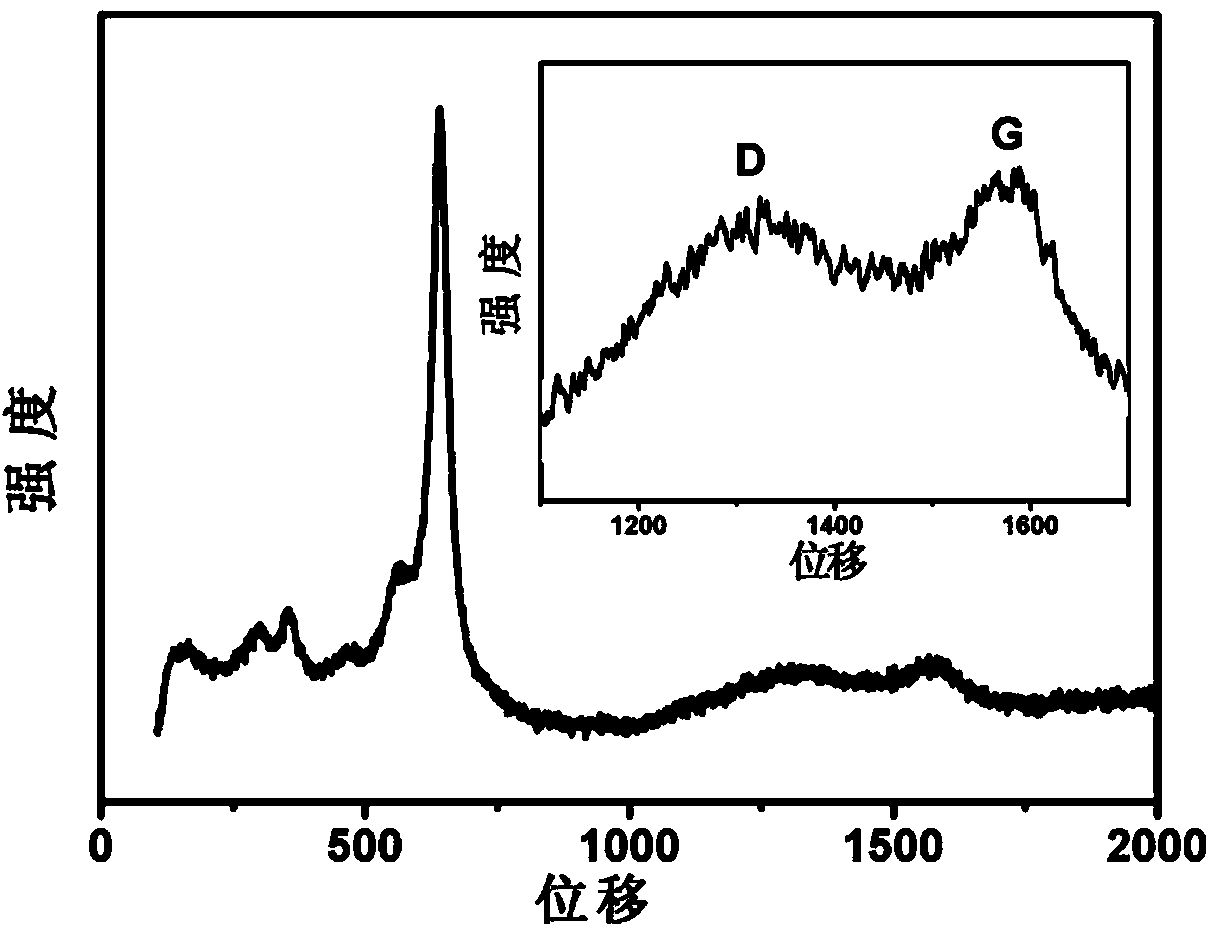

[0046] The preparation method of one-dimensional manganese oxide / carbon coaxial hollow nanorod comprises the following steps:

[0047] 1) Dissolve 8 mmol of manganese sulfate monohydrate and 8 mmol of ammonium thiosulfate in 70 ml of deionized water, and mix and stir for 30 minutes;

[0048] 2) Pour the solution obtained in step 1) into a 100ml reaction kettle, seal the reaction kettle well, and conduct a hydrothermal reaction at 120°C for 12 hours;

[0049] 3) Use deionized water and absolute ethanol to repeatedly centrifuge and wash the precipitate obtained in the step 2) hydrothermal reaction, and dry it in an oven at 70°C to obtain manganese oxide;

[0050] 4) Weighing 100 mg of step 3) The obtained manganese oxide nanorods are dispersed in 100 ml of 0.1 mol / L HCl solution, magnetically stirred for 1 hour, and the sample is acidified;

[0051] 5) The product obtained in step 4) was repeatedly washed with deionized water and ethanol until the pH value was 7;

[0052] 6) u...

Embodiment 2

[0067] The preparation method of one-dimensional manganese oxide / carbon coaxial hollow nanorod comprises the following steps:

[0068] 1) Dissolve 8 mmol of manganese sulfate monohydrate and 8 mmol of ammonium thiosulfate in 70 ml of deionized water, and mix and stir for 30 minutes;

[0069] 2) Pour the solution obtained in step 1) into a 100ml reaction kettle, seal the reaction kettle well, and conduct a hydrothermal reaction at 120°C for 12 hours;

[0070] 3) Use deionized water and absolute ethanol to repeatedly centrifuge and wash the precipitate obtained in the step 2) hydrothermal reaction, and dry it in an oven at 70°C to obtain manganese oxide;

[0071] 4) Weighing 100 mg of step 3) The obtained manganese oxide nanorods are dispersed in 100 ml of 0.1 mol / L HCl solution, magnetically stirred for 1 hour, and the sample is acidified;

[0072] 5) The product obtained in step 4) was repeatedly washed with deionized water and ethanol until the pH value was 7;

[0073] 6) u...

Embodiment 3

[0085] The preparation method of one-dimensional manganese oxide / carbon coaxial hollow nanorod comprises the following steps:

[0086] 1) Dissolve 8 mmol of manganese sulfate monohydrate and 8 mmol of ammonium thiosulfate in 70 ml of deionized water, and mix and stir for 30 minutes;

[0087] 2) Pour the solution obtained in step 1) into a 100ml reaction kettle, seal the reaction kettle well, and conduct a hydrothermal reaction at 120°C for 12 hours;

[0088] 3) Use deionized water and absolute ethanol to repeatedly centrifuge and wash the precipitate obtained in the step 2) hydrothermal reaction, and dry it in an oven at 70°C to obtain manganese oxide;

[0089] 4) Weighing 100 mg of step 3) The obtained manganese oxide nanorods are dispersed in 100 ml of 0.1 mol / L HCl solution, magnetically stirred for 1 hour, and the sample is acidified;

[0090] 5) The product obtained in step 4) was repeatedly washed with deionized water and ethanol until the pH value was 7;

[0091] 6) u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com