Complete production unit of long glass fiber reinforcement polypropylene material

A polypropylene material and long glass fiber technology, which is applied in the field of equipment for producing long glass fiber reinforced polypropylene materials, can solve the problems of unsatisfactory glass fiber impregnation effect and high viscosity of polymer melt, and achieve enhanced impregnation effect and good Overall performance, the effect of increasing system pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

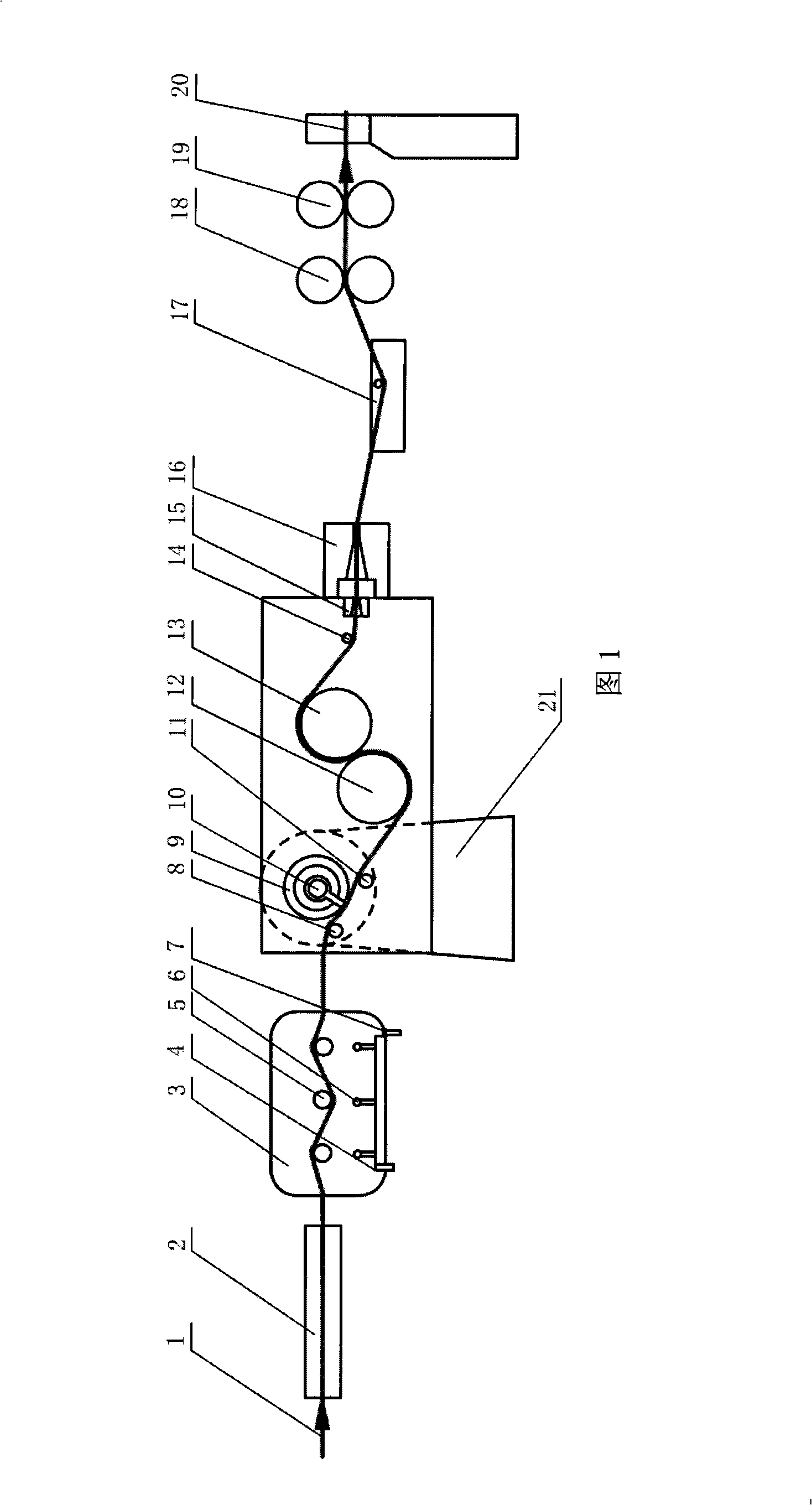

[0015] As shown in Figure 1, the equipment used to produce long glass fiber reinforced polypropylene materials is a first-class production line, including long glass fiber preheating device 2, long glass fiber surface treatment device 3, impregnation device, cluster coating device 15 and Twin-screw extruder 21, cooling device 17, traction device, pelletizing device 20, long glass fiber preheating device 2 and long glass fiber surface treatment device 3 transitionally connected, long glass fiber surface treatment device 3 and impregnation device transitionally connected, The impregnating device is transitionally connected with the cluster coating device 15 . Among them, the long glass fiber preheating device 2 has a closed box structure, and heating elements are installed in the box. The inner wall of the box is provided with an insulating layer, and the temperature in the box is uniform and controllable. The long glass fiber surface treatment device 3 includes a group of varia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com