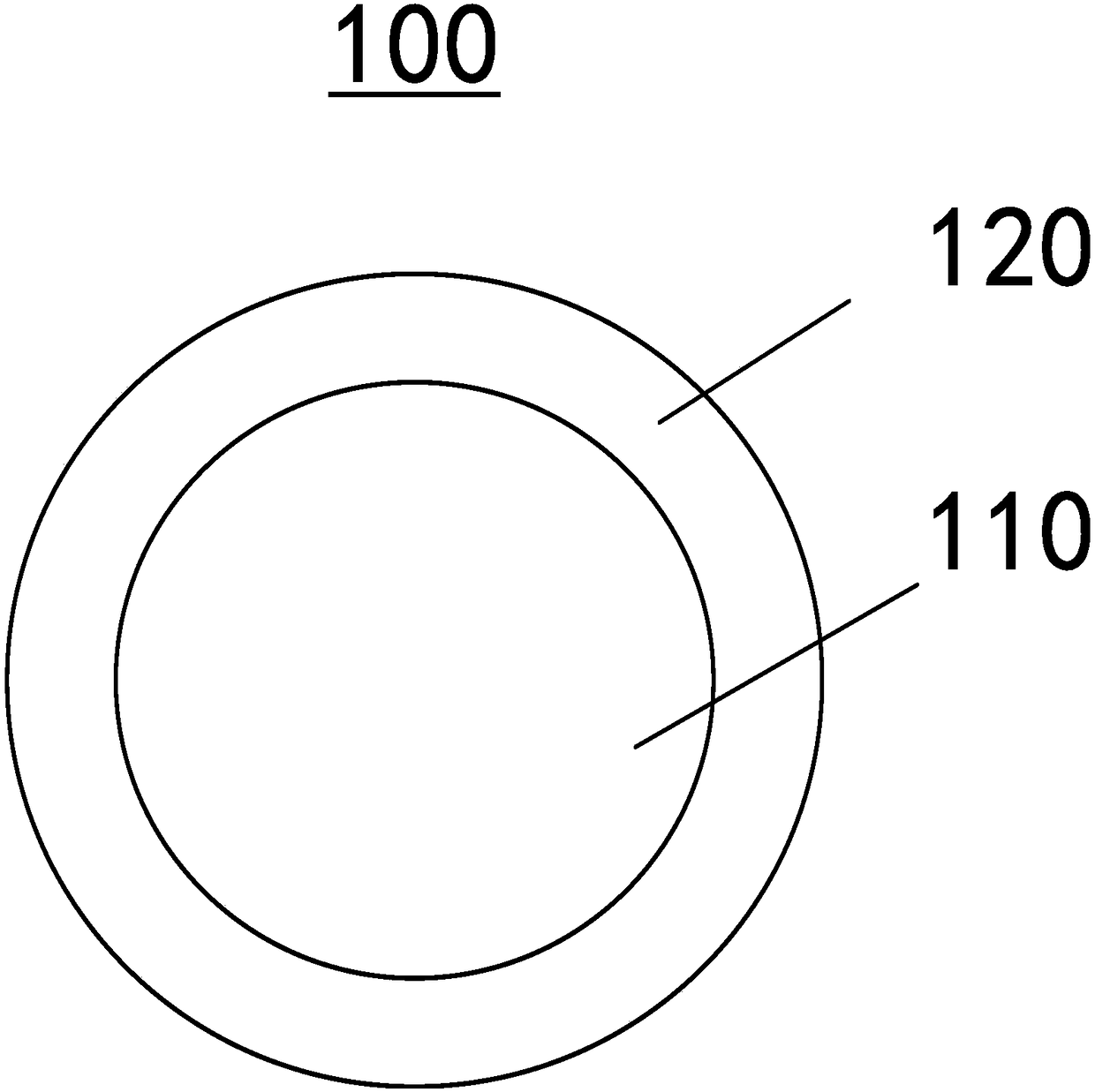

Lithium ion battery positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and their preparation, can solve problems such as limited structural stability effects, and achieve the effect of simple and easy methods and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

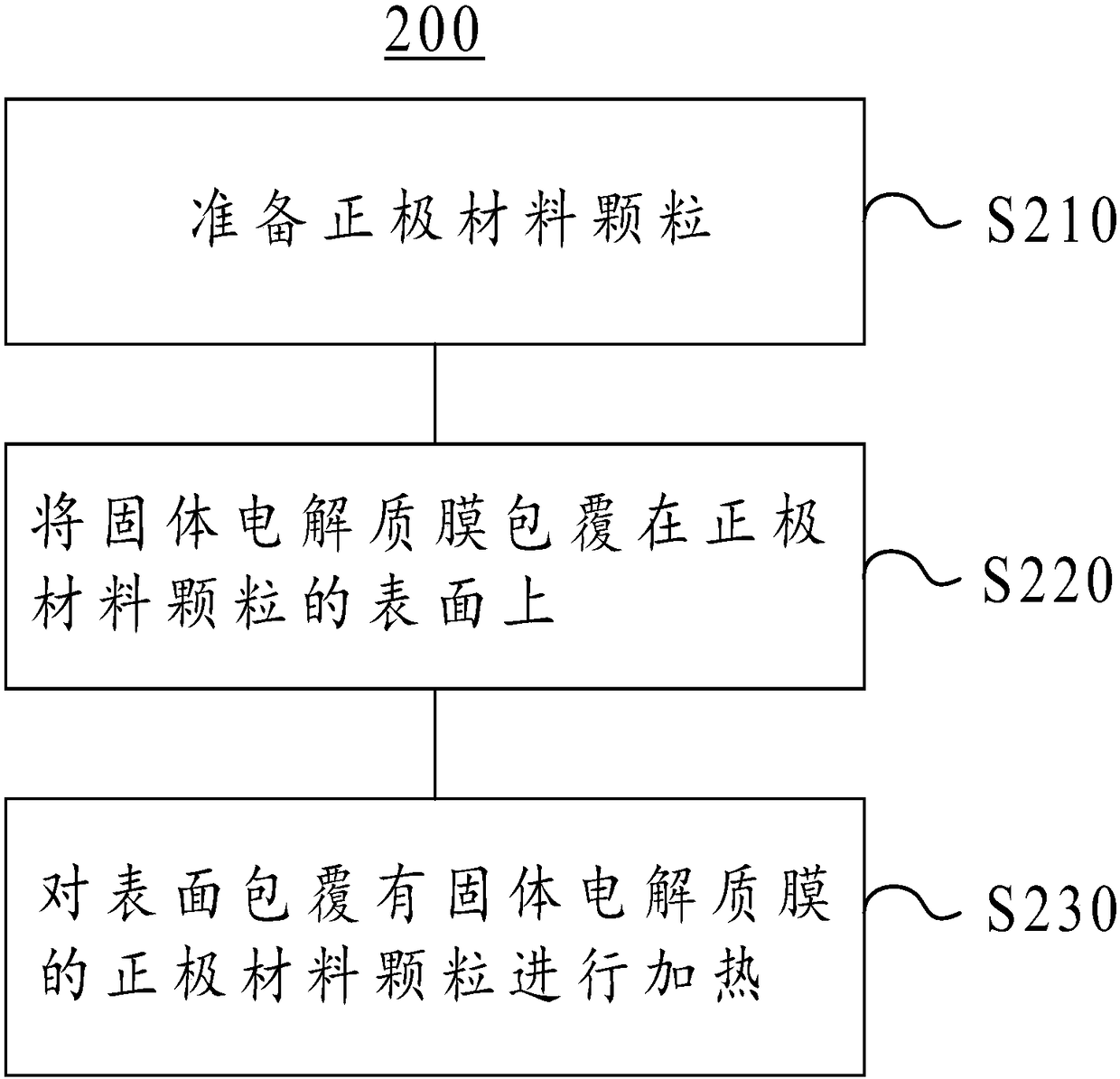

Method used

Image

Examples

Embodiment 1

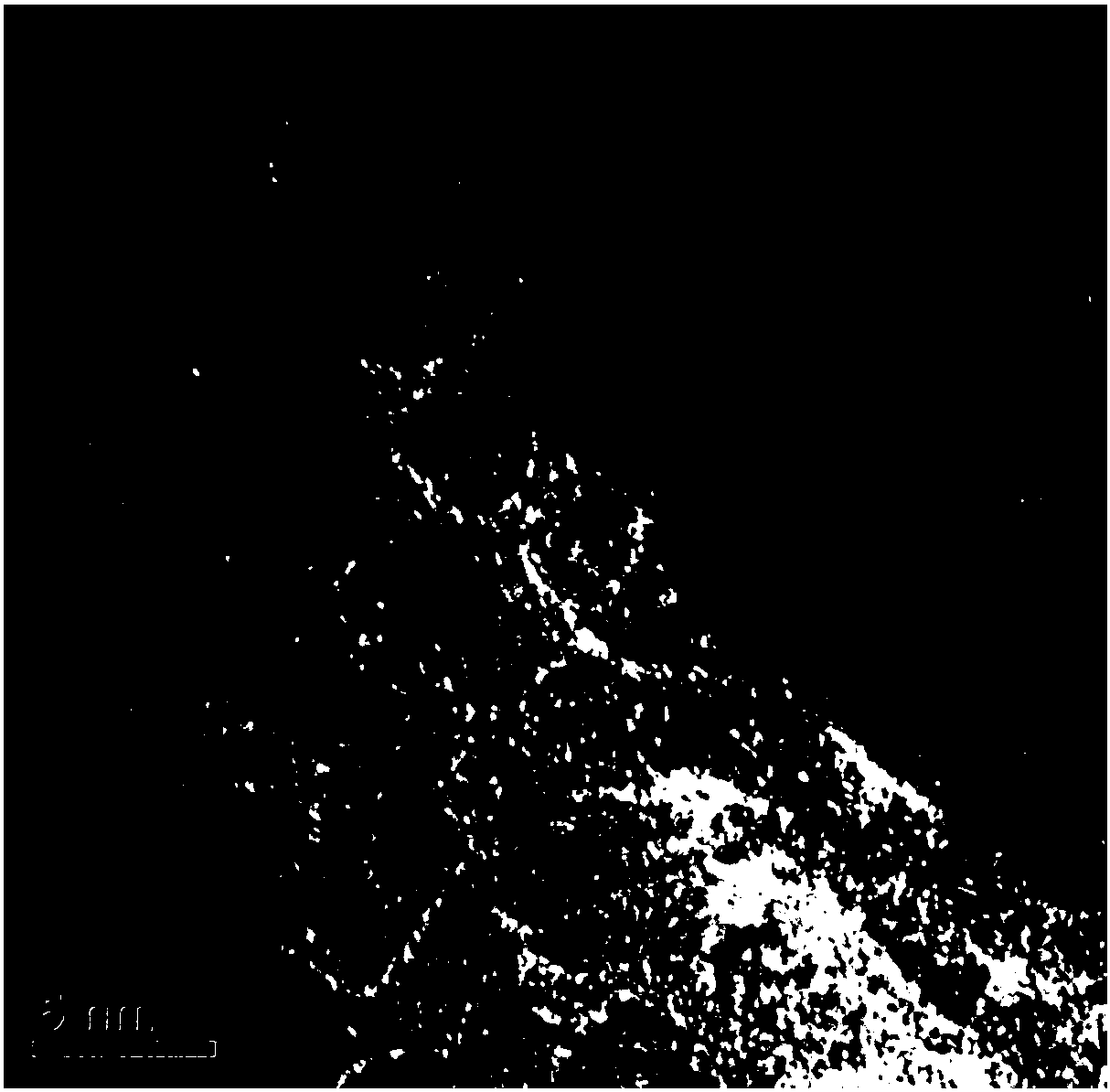

[0041] Coating Li on the surface of traditional cathode particles by atomic layer deposition 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 (LATP) thin layer: spread 1g of traditional cathode particles on the substrate, and use LATP raw material Li 2 CO 3 、Al 2 o 3 、TiO 2 and NH 4 h 2 PO 4 as the target, in a vacuum of 10 -2 torr, voltage 24V, Ar atmosphere, depositing 28 seconds, 8 seconds, 64 seconds and 12 seconds respectively, different raw materials were deposited on the surface of the traditional positive electrode, and then the deposited powder was taken out and fired at a temperature of 450°C in air for 3 hours, you can get the LCoO 2 (LCO) coated cathode powder with 0.2% LATP.

[0042] The above-mentioned LCO particles coated with LATP on the surface are packed into a metal lithium battery with a liquid electrolyte. Specifically: mix LCO particles coated with LATP on the surface with Super P and binder PVDF at a mass ratio of 8:1:1, add an appropriate amount of solvent NMP...

Embodiment 2

[0046] Coat the LATP thin layer on the surface of traditional cathode particles by precipitation method: disperse 8g of traditional cathode in 300ml of acetonitrile, stir in a beaker for 1 hour, add LATP raw material Li 2 CO 3 (0.011g),Al 2 o 3 (0.0041g), TiO 2 (0.026g) and NH 4 h 2 PO 4 (0.07g), after stirring for 3 hours, stop stirring, add propanol as a settling aid, afterward, the precipitate was vacuum-dried in an oven at 120°C for 12 hours, and finally burned for 3 hours at a temperature of 480°C in air, The positive electrode powder coated with LATP can be obtained.

[0047] The specific steps of preparing the coated positive electrode particles into a liquid electrolyte lithium metal battery and a polymer metal lithium battery are the same as the method for assembling the battery in Example 1, and will not be repeated here.

Embodiment 3

[0049] A thin layer of LATP is coated on the surface of traditional positive electrode particles by pulsed laser deposition: 1g of traditional positive electrode particles is spread on the substrate, and the raw material of LATP is Li 2 CO 3 、Al 2 o 3 、TiO 2 and NH 4 h 2 PO 4 As the target material, turn on the cooling water and pump it to a vacuum degree of 10 - 2 When torr is below, pass O 2 As a protective atmosphere, the number of deposition layers of these raw materials is set to 28 layers, 8 layers, 64 layers and 12 layers respectively. After the deposition is completed, the powder is taken out and burned in the air at a temperature of 450°C for 3 hours. A cathode powder coated with LATP was obtained.

[0050] The specific steps of preparing the coated positive electrode particles into a liquid electrolyte lithium metal battery and a polymer metal lithium battery are the same as the method for assembling the battery in Example 1, and will not be repeated here. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com