Method for producing non-elastic force composite yarn and device used by the method

A technology for elastic core-spun yarn and core-spun yarn, which is applied in the production of non-elastic core-spun yarn for the production of core-spun yarn, can solve the problem of increasing the tension of filament or yarn, increasing the labor intensity of operators, unwinding tension and drafting ratio Problems that are not easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

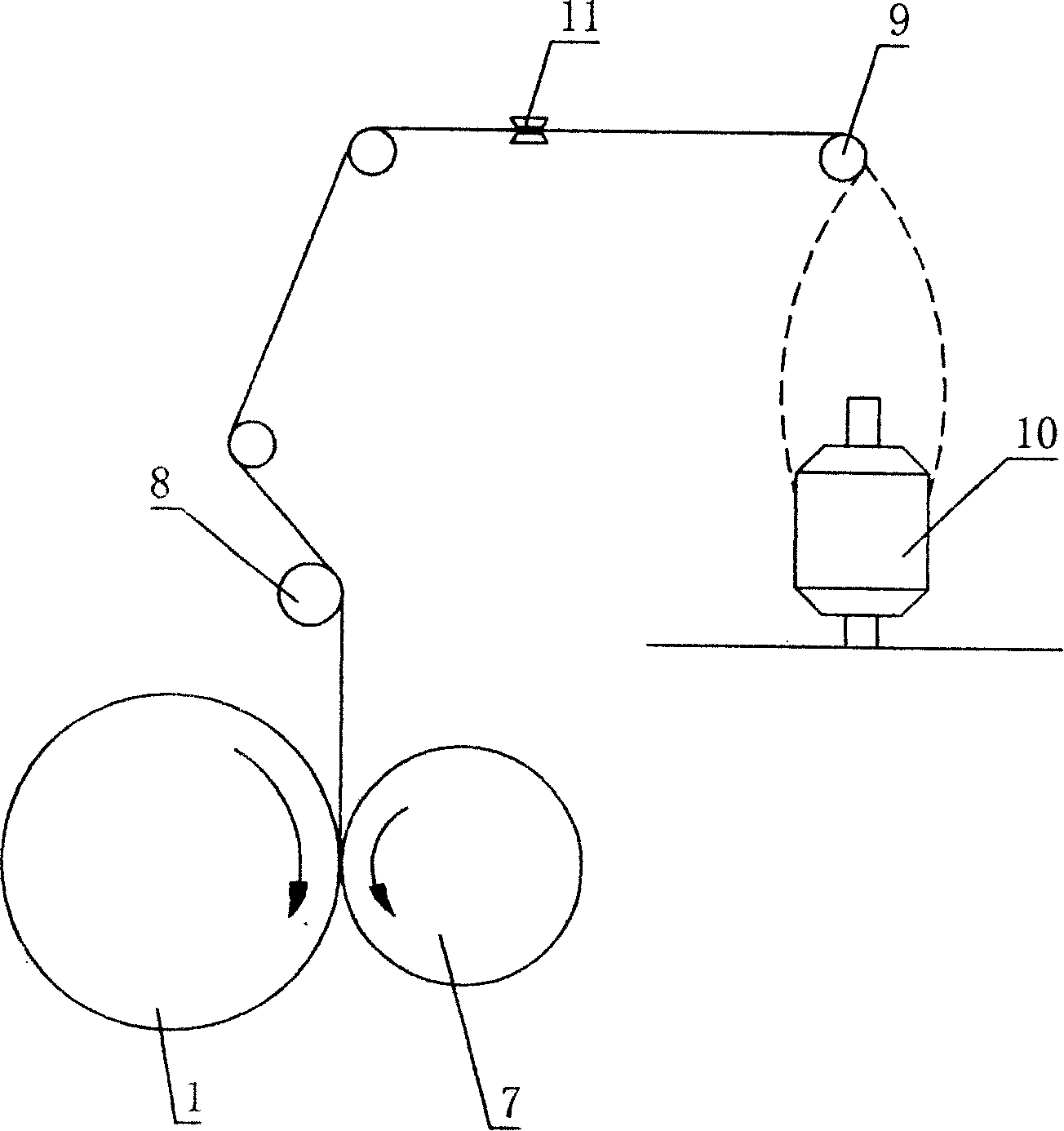

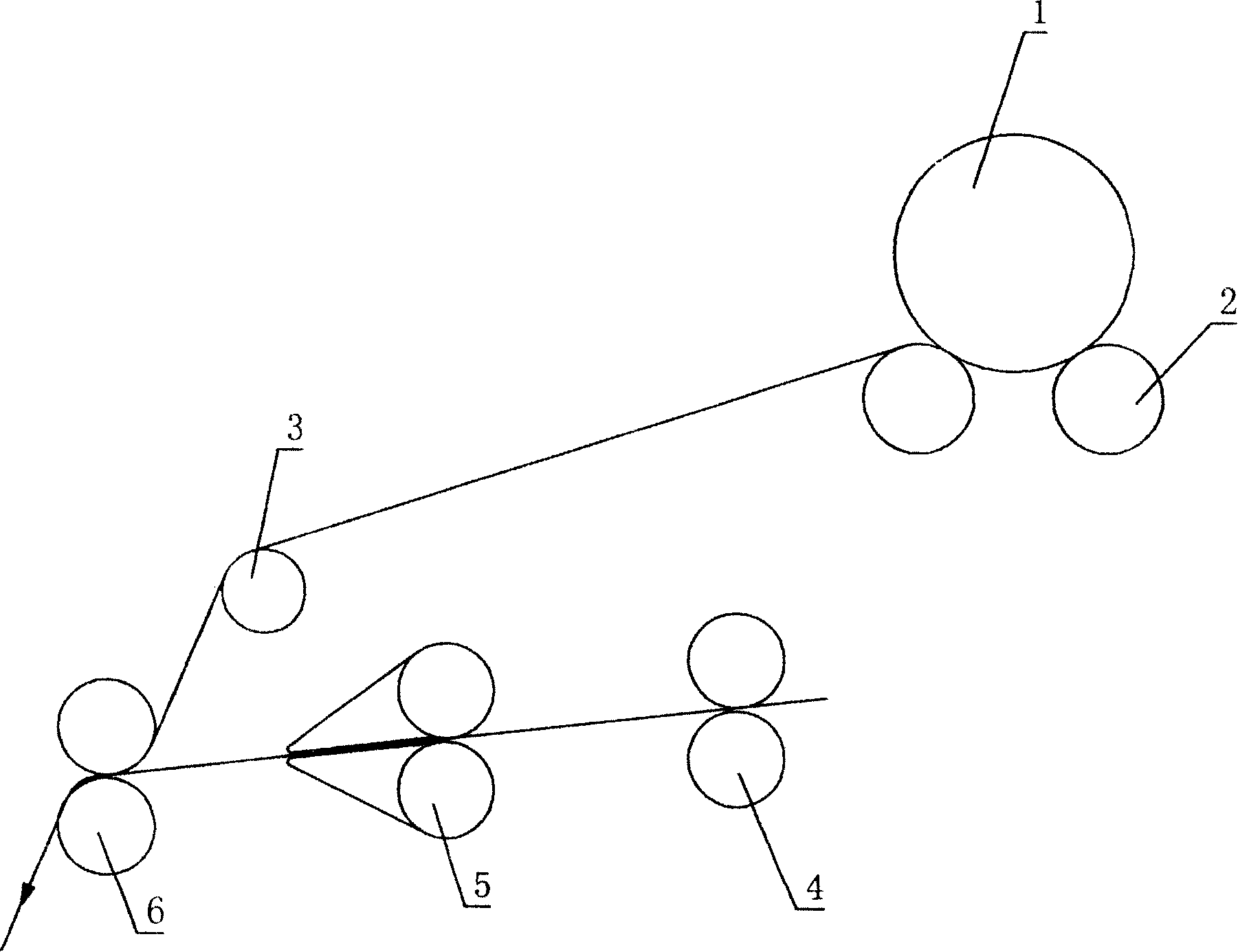

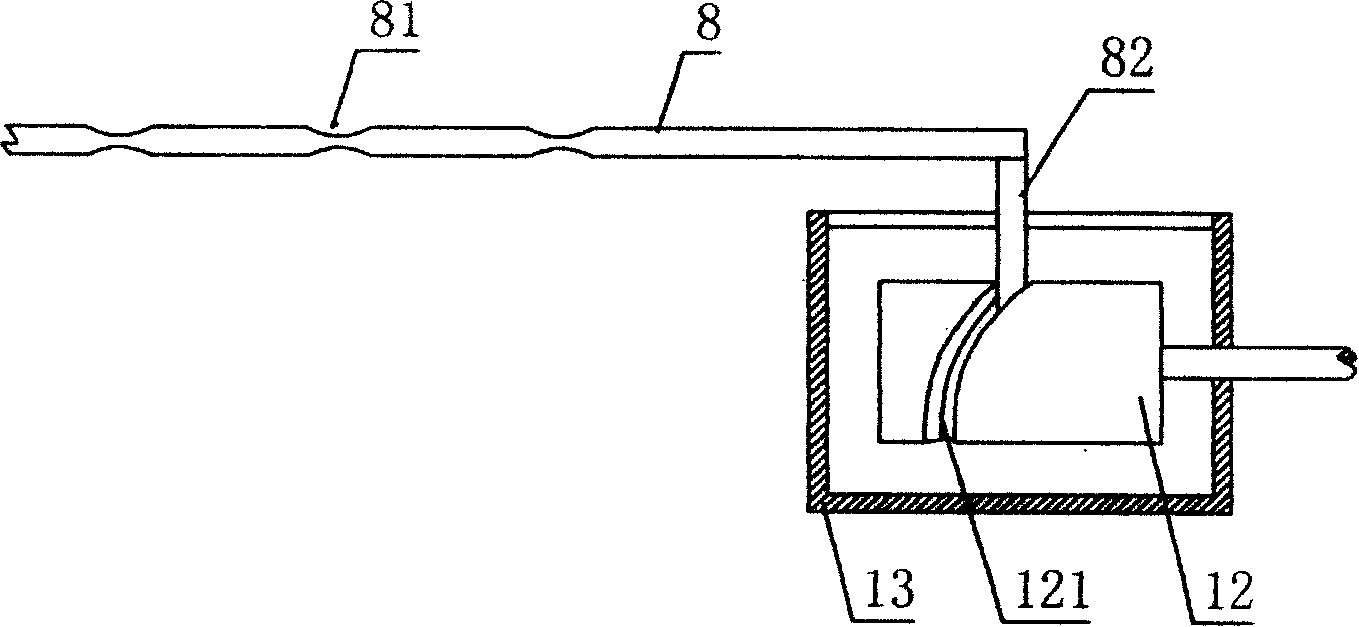

[0019] Such as figure 1 and figure 2 As shown, a method for producing a non-elastic core-spun yarn in the present invention includes passing the large package silk roll 10 of the yarn as the core yarn through the tension rod 9 and the disc tension device 11 on the winder successively, The rod 8 is guided to the paper tube driven by the groove drum 12 for winding to form a small packaged silk roll 1, and then the small packaged silk roll 1 is placed between a pair of silk rollers 2 rotating in the same direction on the spinning frame, so that the small packaged silk roll 1 The loaded silk reel 1 is rotated at a certain surface linear speed by the external force acting on its circumferential surface by the silk roller 2, so that the yarn is unwound in an active manner, and is introduced into the 6 drafting areas of the front roller and the outsourcing here. Steps such as fibers converging and wrapping into core-spun yarns, etc., wherein, when unwinding the large package silk r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com