A kind of acid and alkali resistant fluorine-free opalescent glass and its preparation method and application

A technology for opal glass and glass, applied in the field of opal glass and its preparation, can solve the problems of poor acid and alkali resistance of the opal glass, and achieve the effects of good acid and alkali resistance, high whiteness, and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Raw material formula is as shown in table 1, wherein SiO 2 Pickled Quartz Introduced, Al 2 o 3 , ZnO are industrial pure raw materials, Na 2 O with industrial pure Na 2 CO 3 Introduce, B 2 o 3 With industrial pure H 3 BO 3 Introduced, P 2 o 5 Introduced with industrial pure calcium phosphate, CaO introduced with industrial pure calcite:

[0036] Table 1

[0037]

[0038] Weigh the reagents according to the raw material formula in Table 1 and ball mill for 2 hours to mix the raw materials evenly, then place the raw materials in a quartz crucible and heat up to 1550 °C for high temperature melting and keep it for 2 hours, then pour the glass liquid into it and preheat it to 510 °C Molded in a mold at ~520°C, and annealed in a 580°C annealing furnace for 4 hours to eliminate internal stress, and finally cooled to room temperature to obtain an opalescent glass block.

Embodiment 2

[0040] Raw material formula is as shown in table 2:

[0041] Table 2

[0042]

[0043] Weigh the reagents according to the raw material formula in Table 2 and ball mill for 2 hours to mix the raw materials evenly, then place the raw materials in a quartz crucible and heat up to 1530°C for high temperature melting and heat preservation for 2 hours, then pour the glass liquid into it and preheat it to 480°C ℃ mold, and annealed in a 560 ℃ annealing furnace for 3 hours to eliminate internal stress, and finally cooled to room temperature to obtain opal glass blocks.

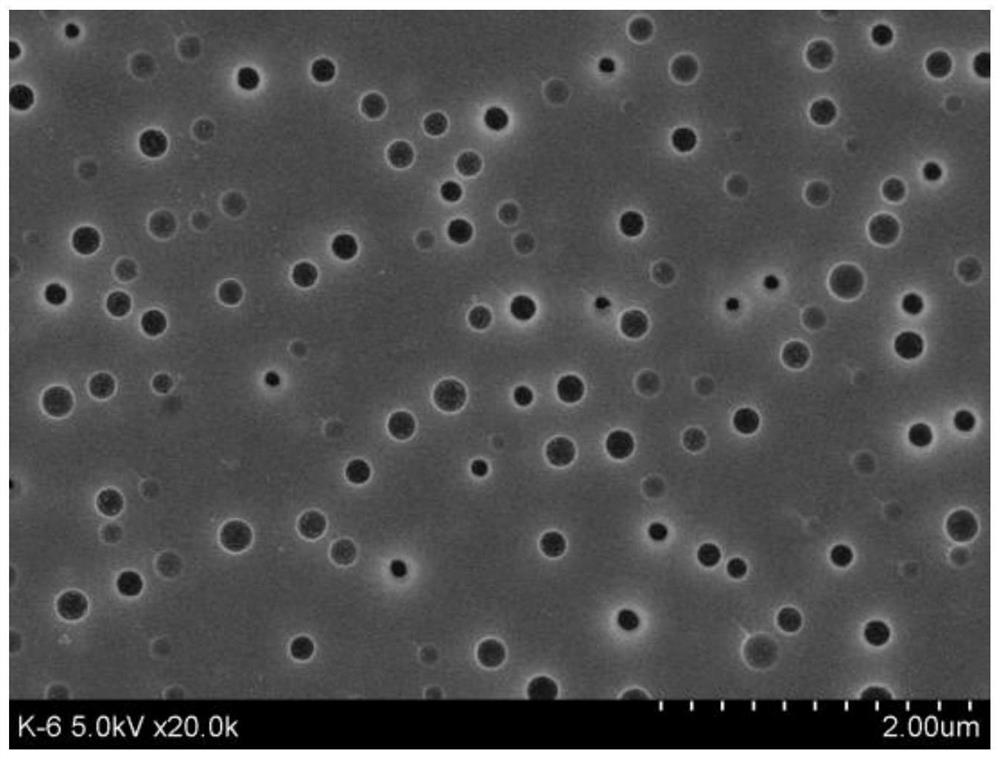

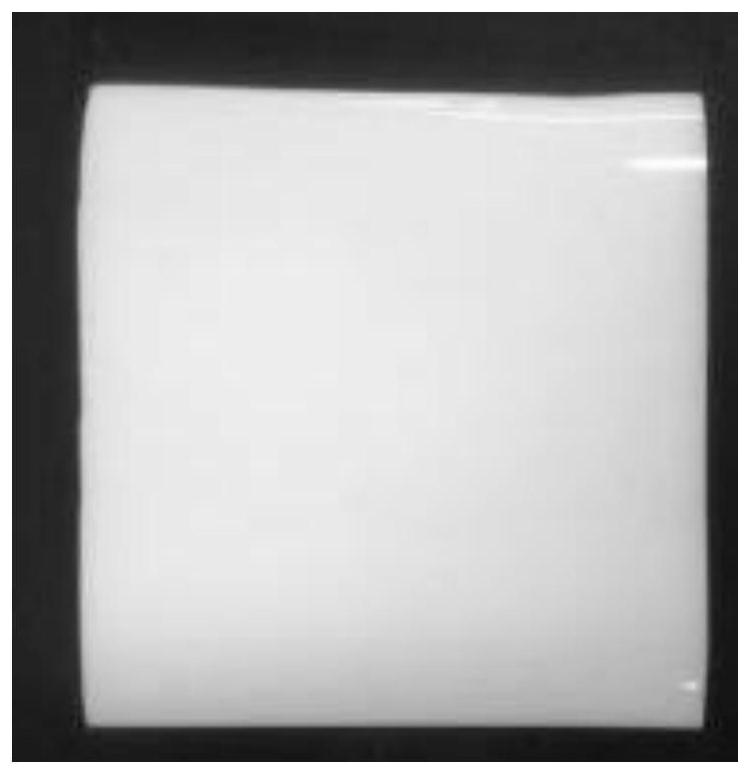

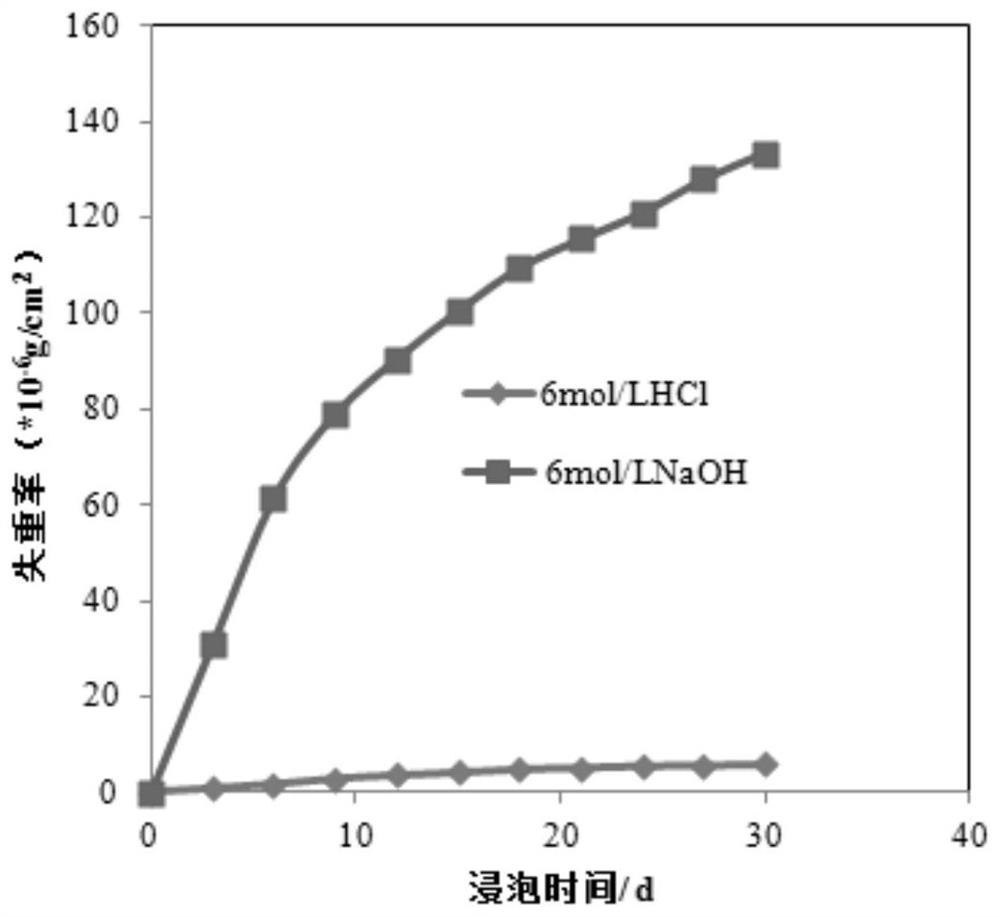

[0044] The photo taken directly of the sample of the obtained opalescent glass is as follows: figure 2 As shown, the product directly tested its whiteness and found that its whiteness reached 89. Crush the sample and cut it into small pieces and send it to the scanning electron fiber microscope to check the cross-section fiber morphology and obtain the SEM image (such as figure 1 Shown); The sample is directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com