A Boring Cutter Head with Adjustable Diameter Variable Speed

A speed and boring tool technology, applied in the direction of boring heads, etc., can solve the problems of complex adjustment methods, affect debugging efficiency, and lengthy time, and achieve the effects of fast operation, accurate adjustment, and improved speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

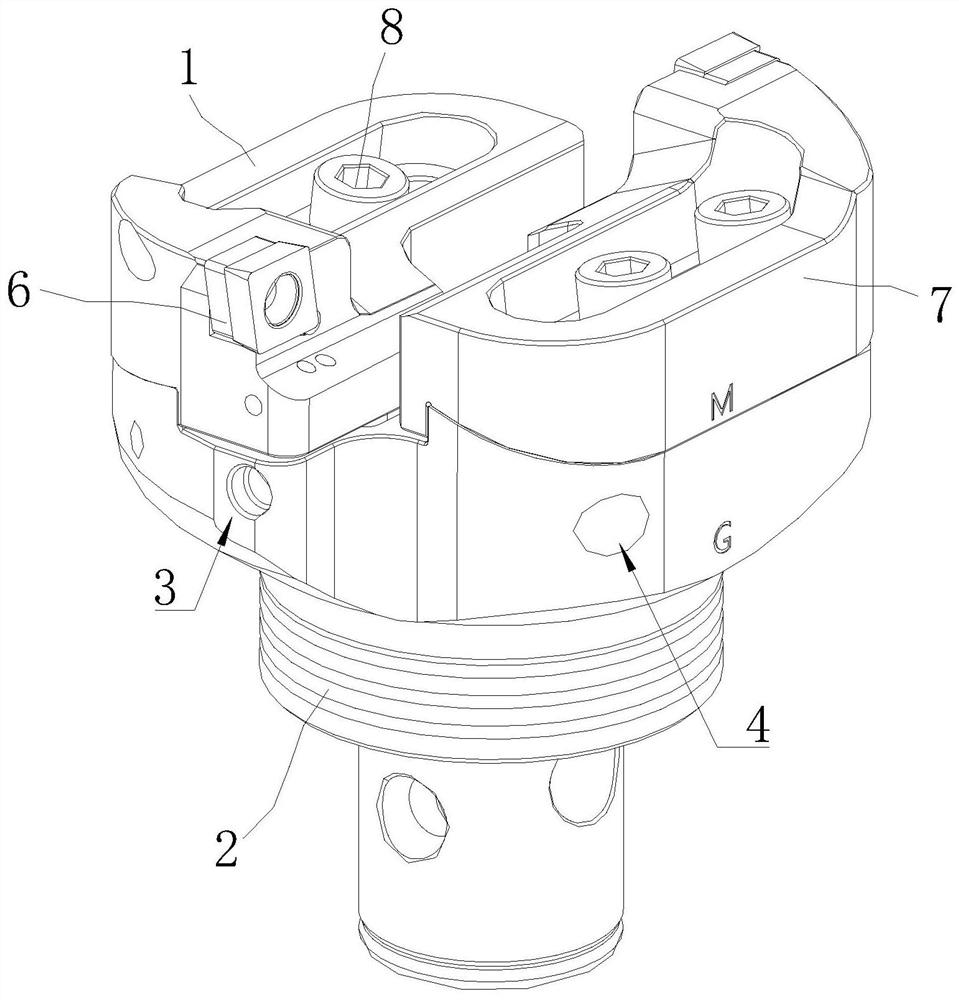

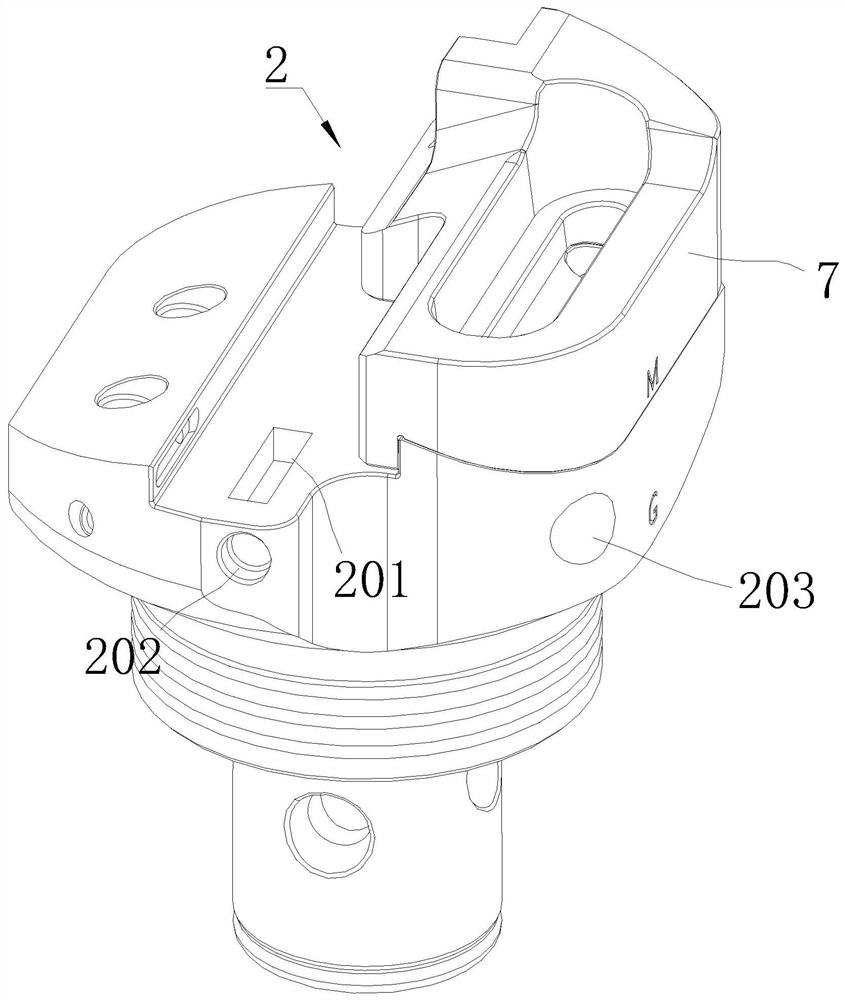

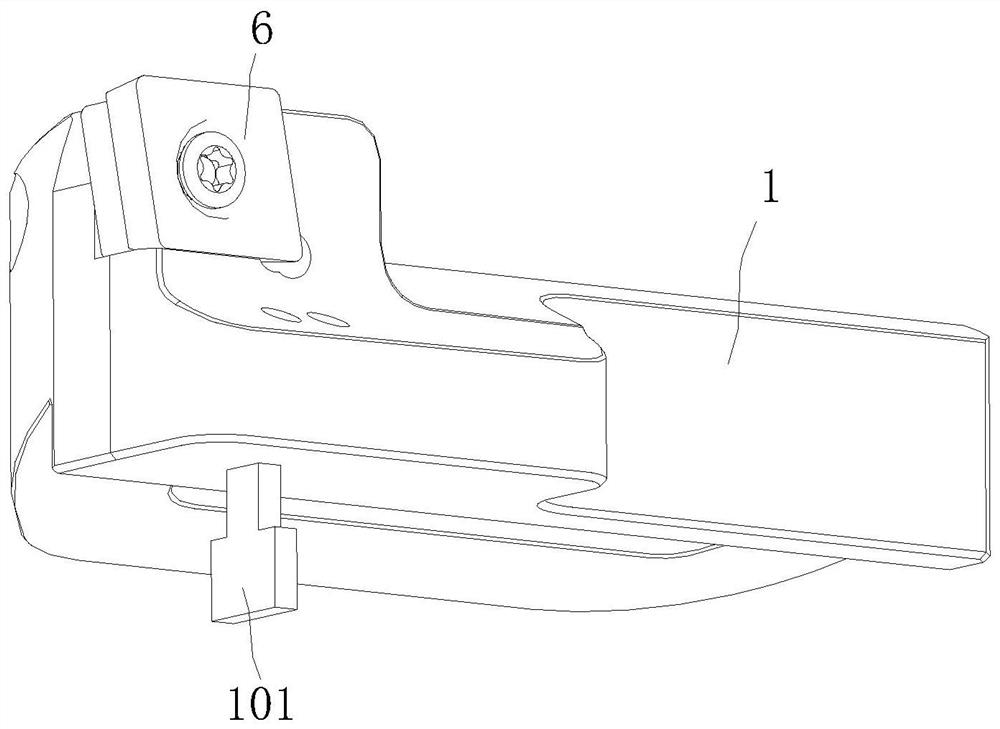

[0044] The lower ends of the left tool holder 1 and the right tool holder 7 are all fixed with a T-shaped slider 101. The left knife seat 1 and the right knife seat 7 are both slidably connected to the base

[0045] The base 2 is provided with a closed liquid channel 204, and the liquid channel 204 is filled with hydraulic oil.

[0048] The reducing unit 4 includes two groups of reducing components, and the reducing components are located in the corresponding reducing holes 203. A set of reducing components

specific Embodiment 2

[0054] The upper end of the base 2 is provided with a guide groove 207. A left guide column 102 is fixed on the lower end of the left knife holder 1 . The lower end of the right knife holder 7 is fixed

specific Embodiment 3

[0056] The specific embodiment three: on the basis of the specific embodiment one, the outer end face of the nail head is provided with a pointing arrow. Nail head cavity 202

[0057] The outer end face of the threaded plug is provided with a marking arrow. There is a scale on the inner wall of the variable diameter hole 203, and the scale content indicates the threaded plug

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com