Patents

Literature

629results about "Boring heads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

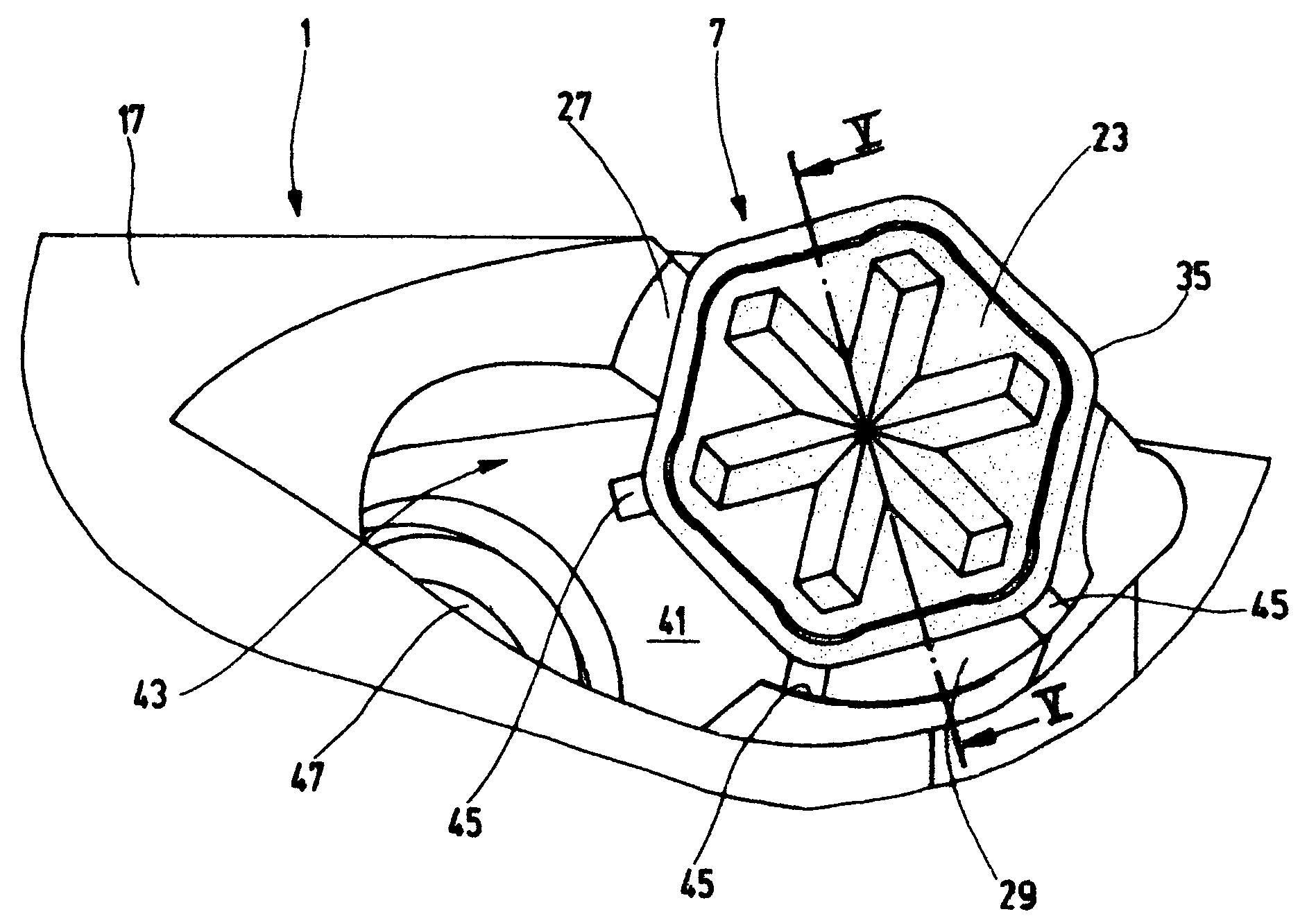

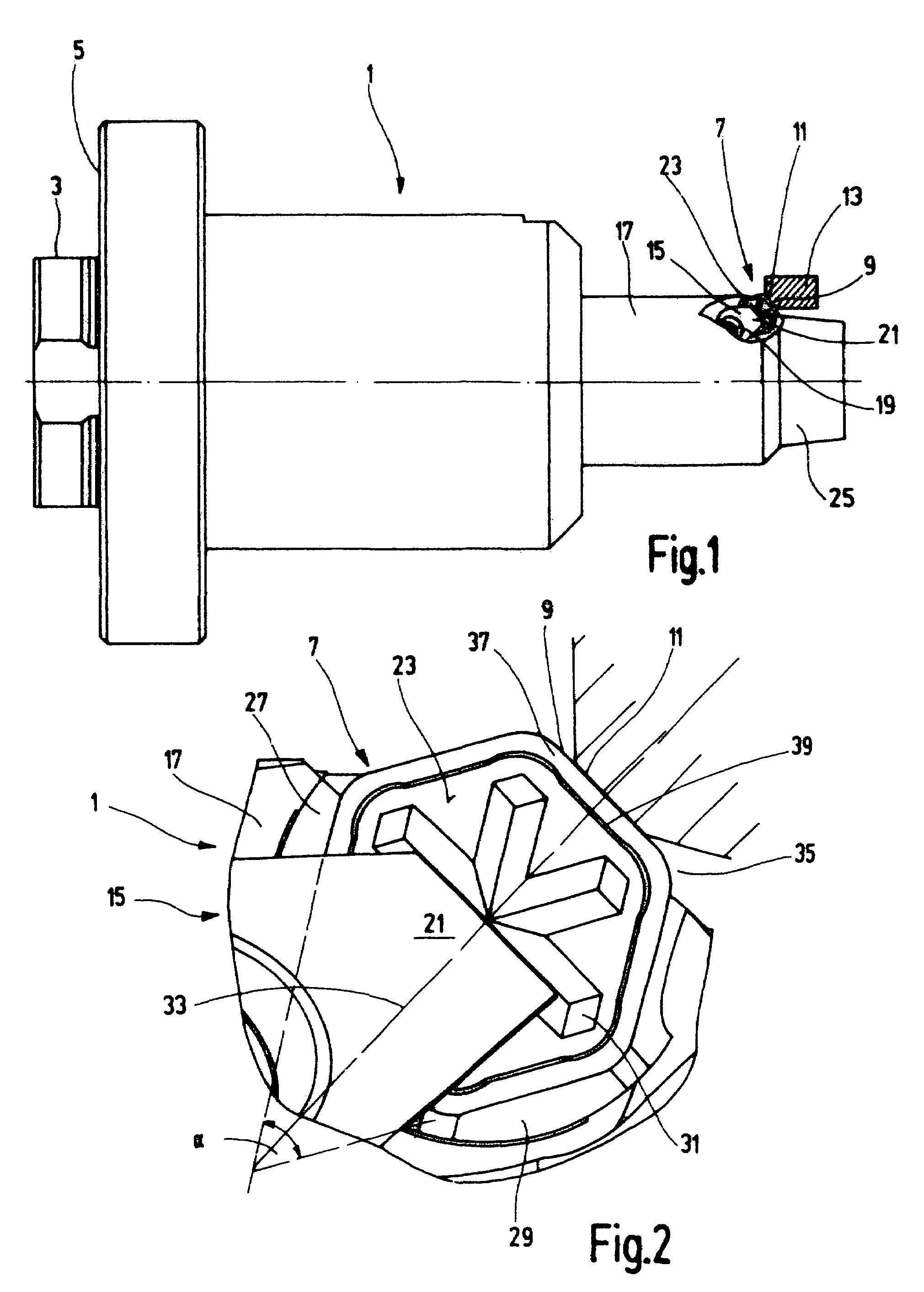

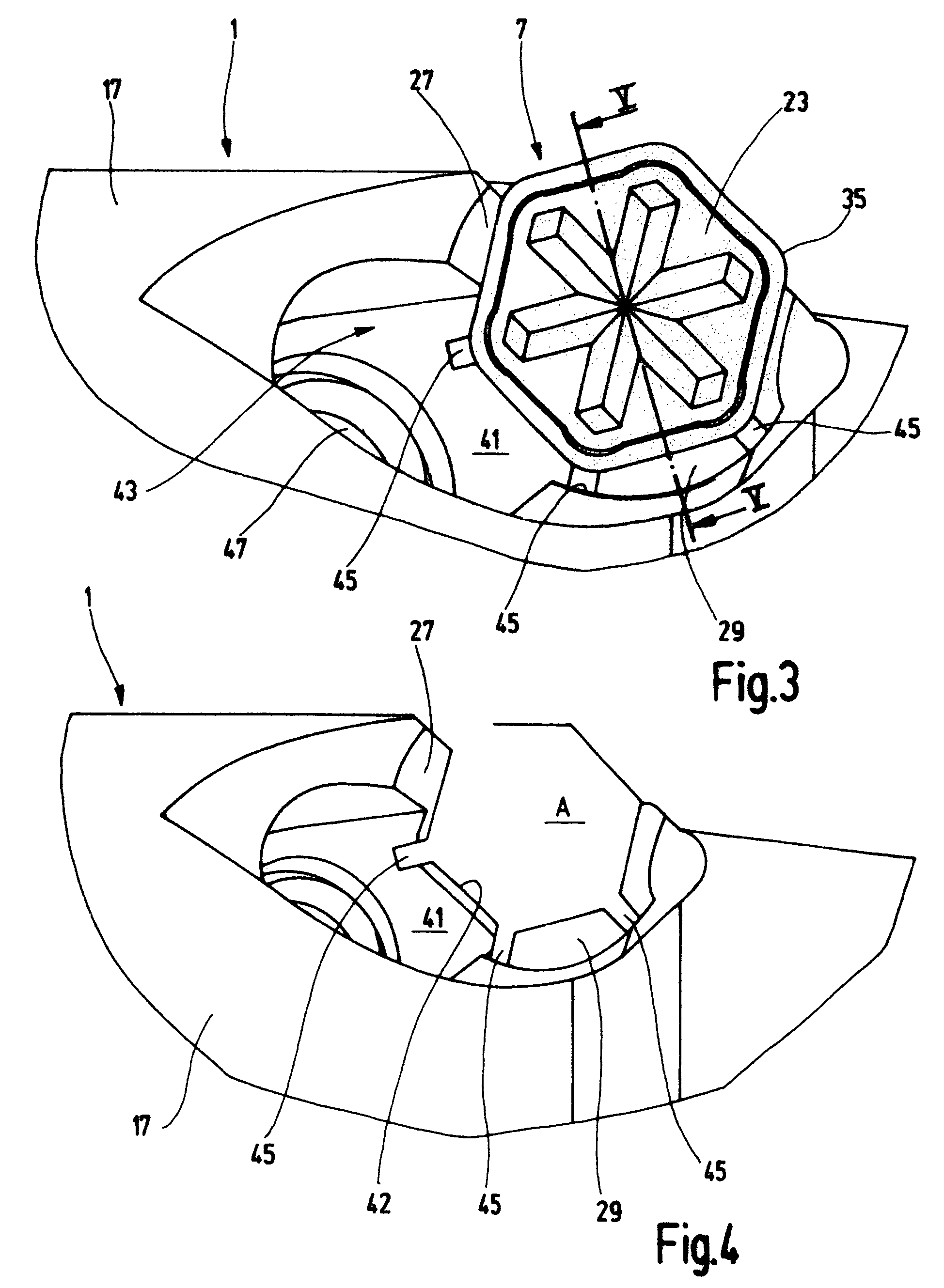

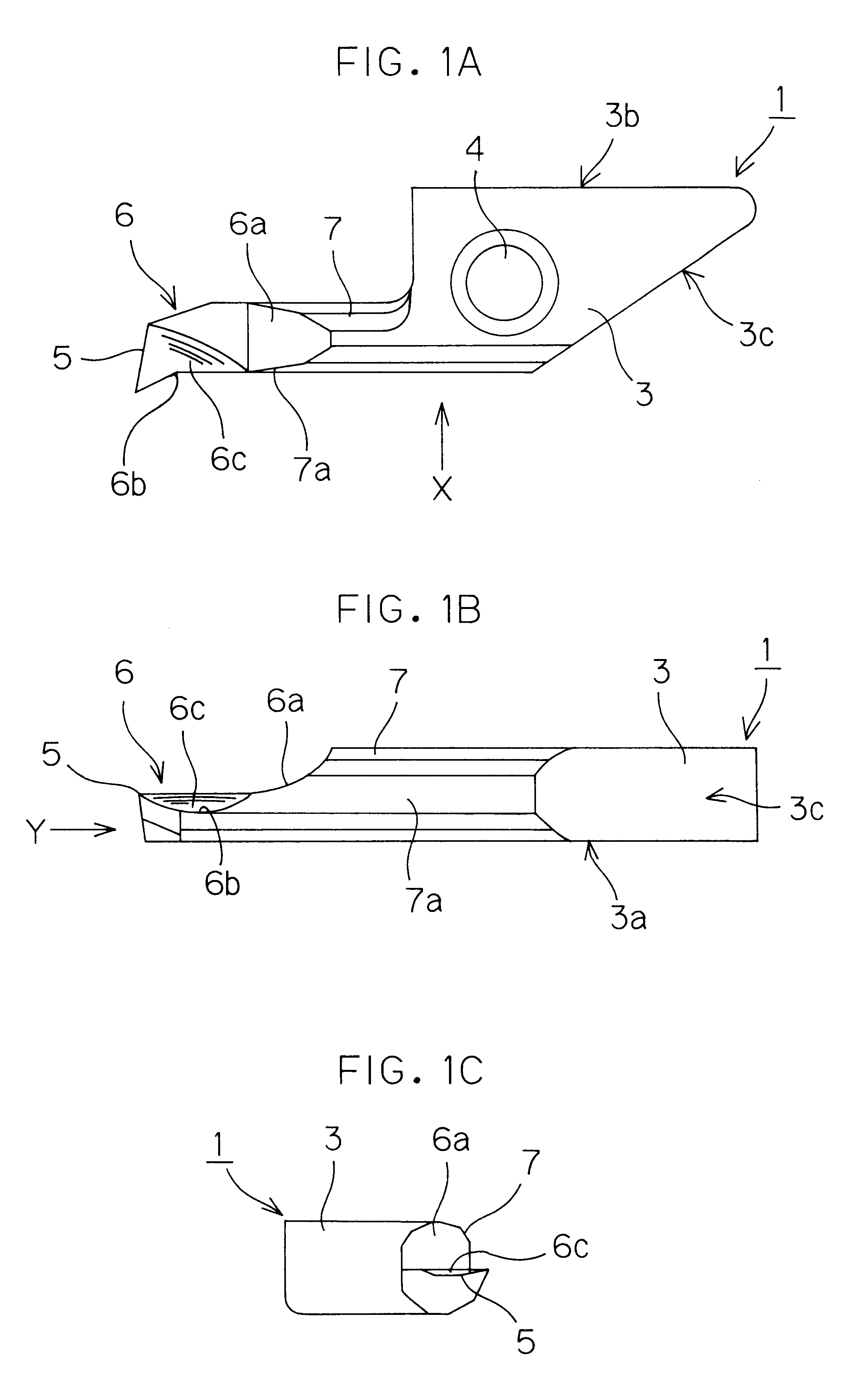

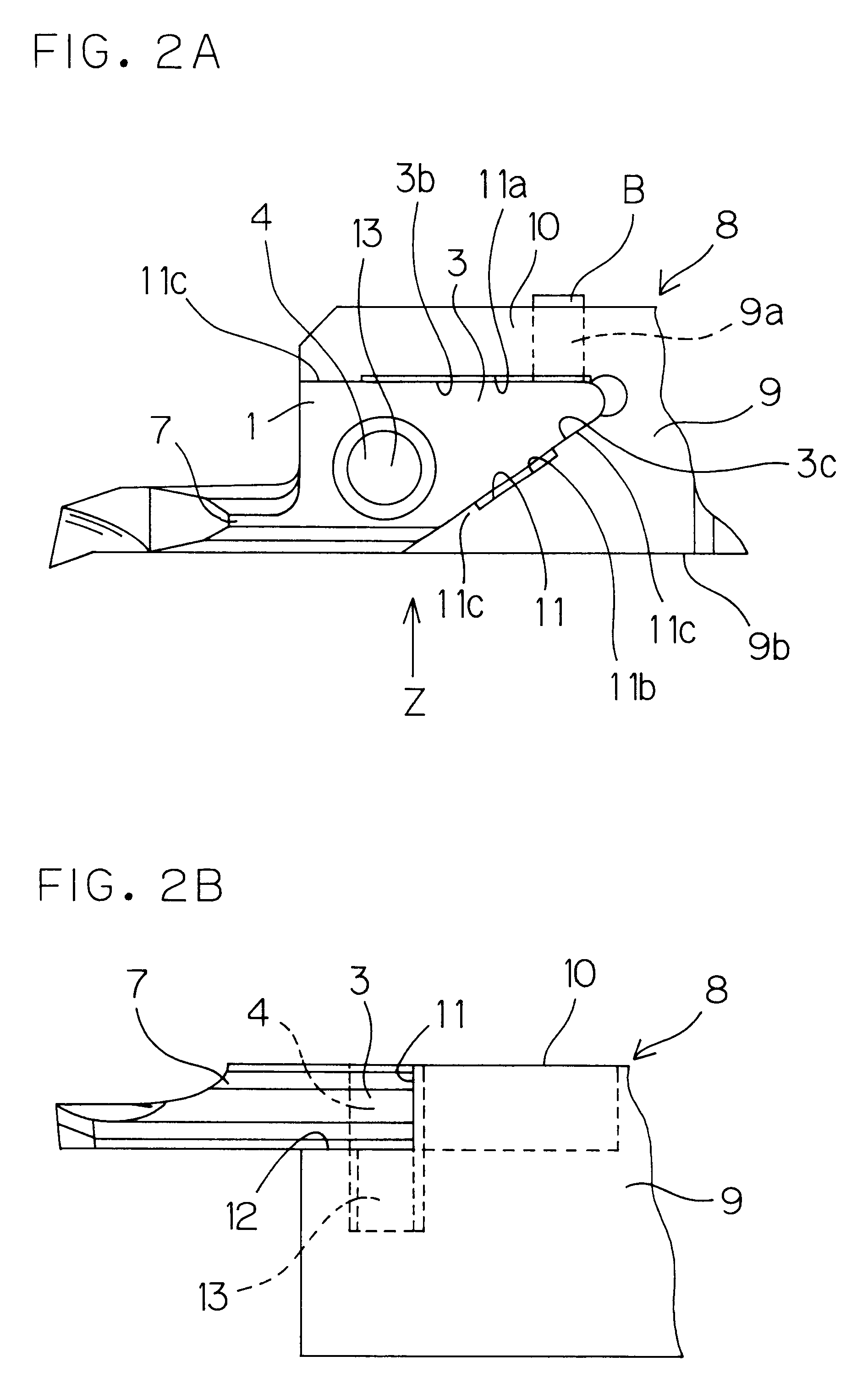

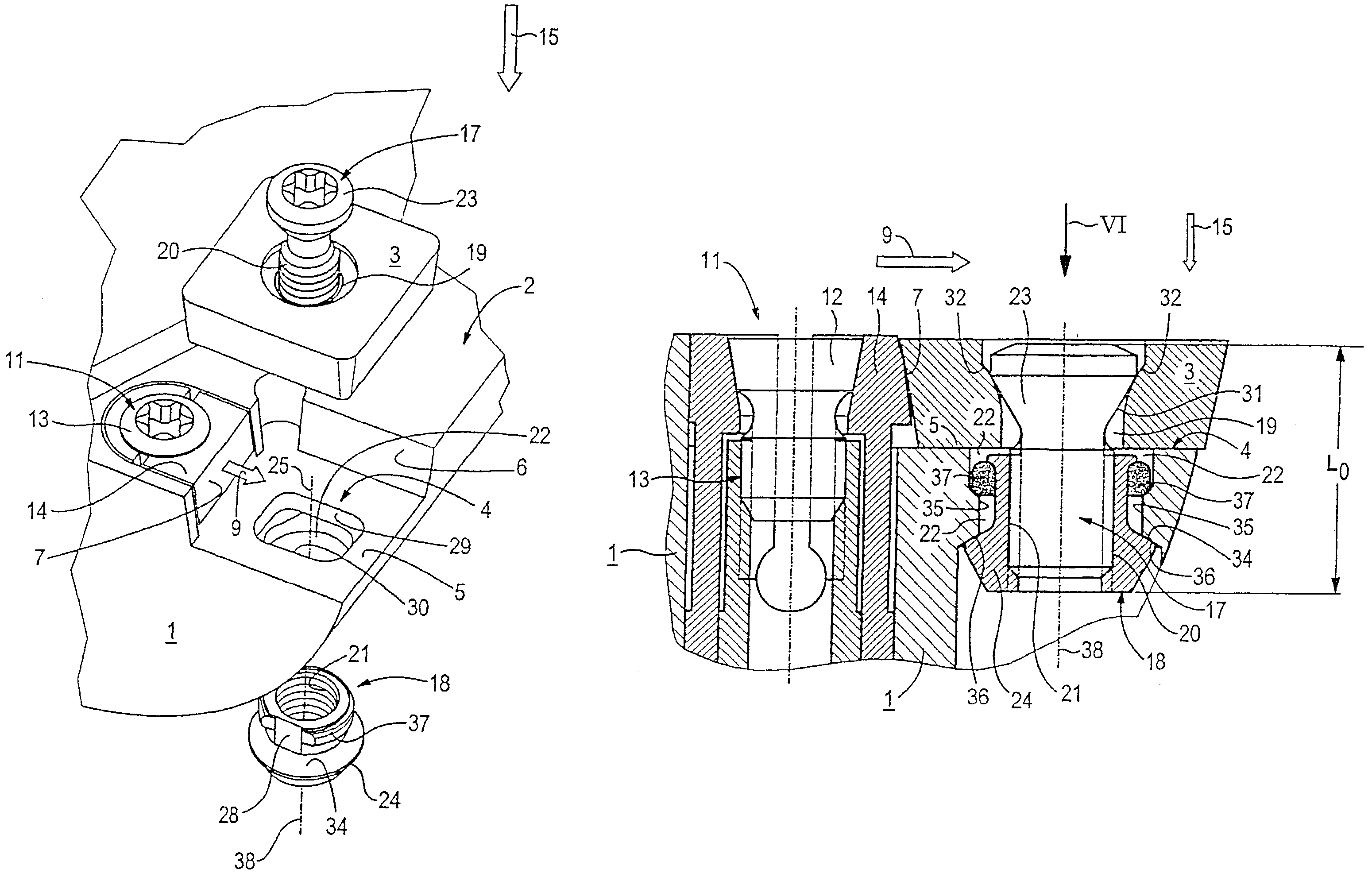

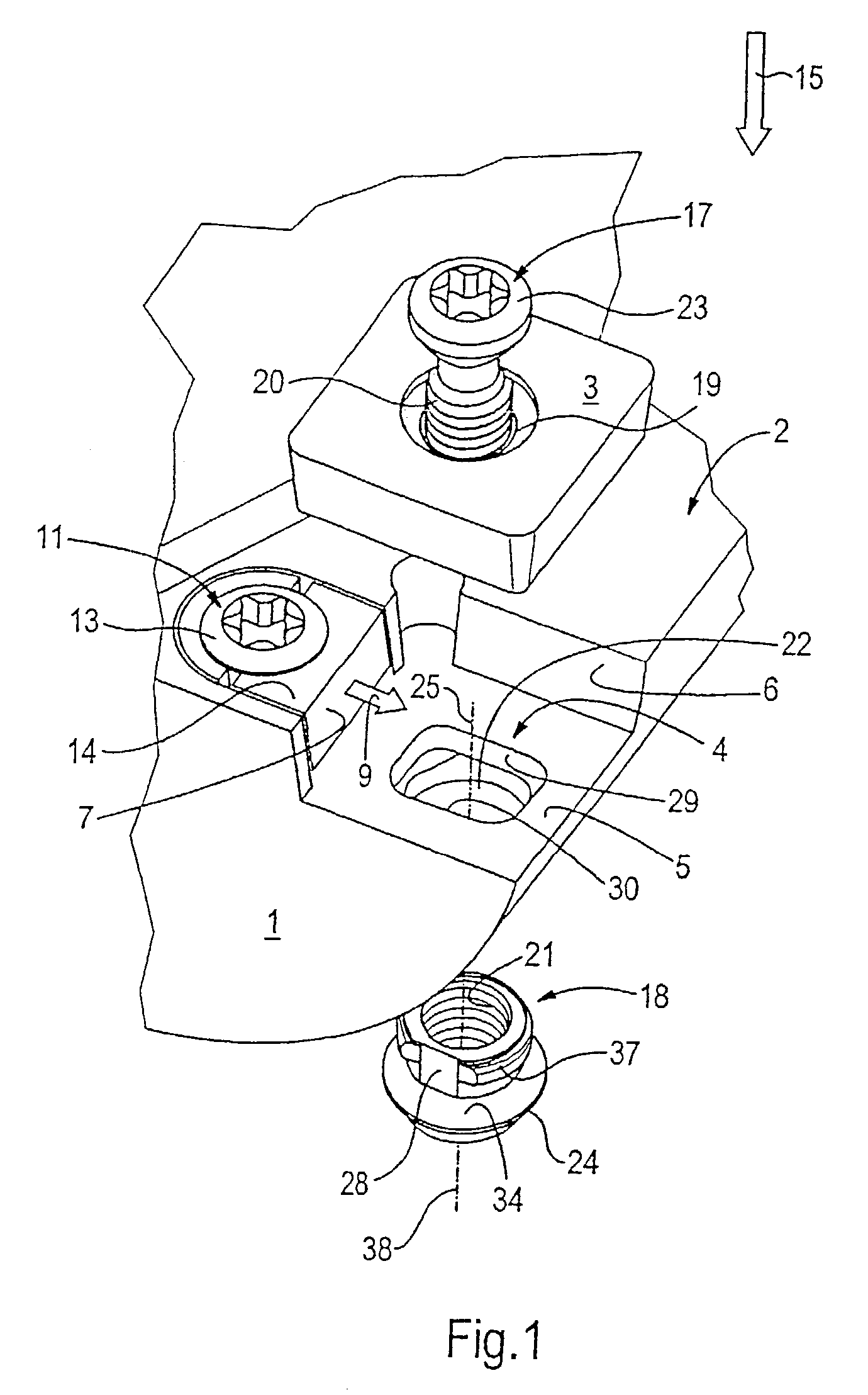

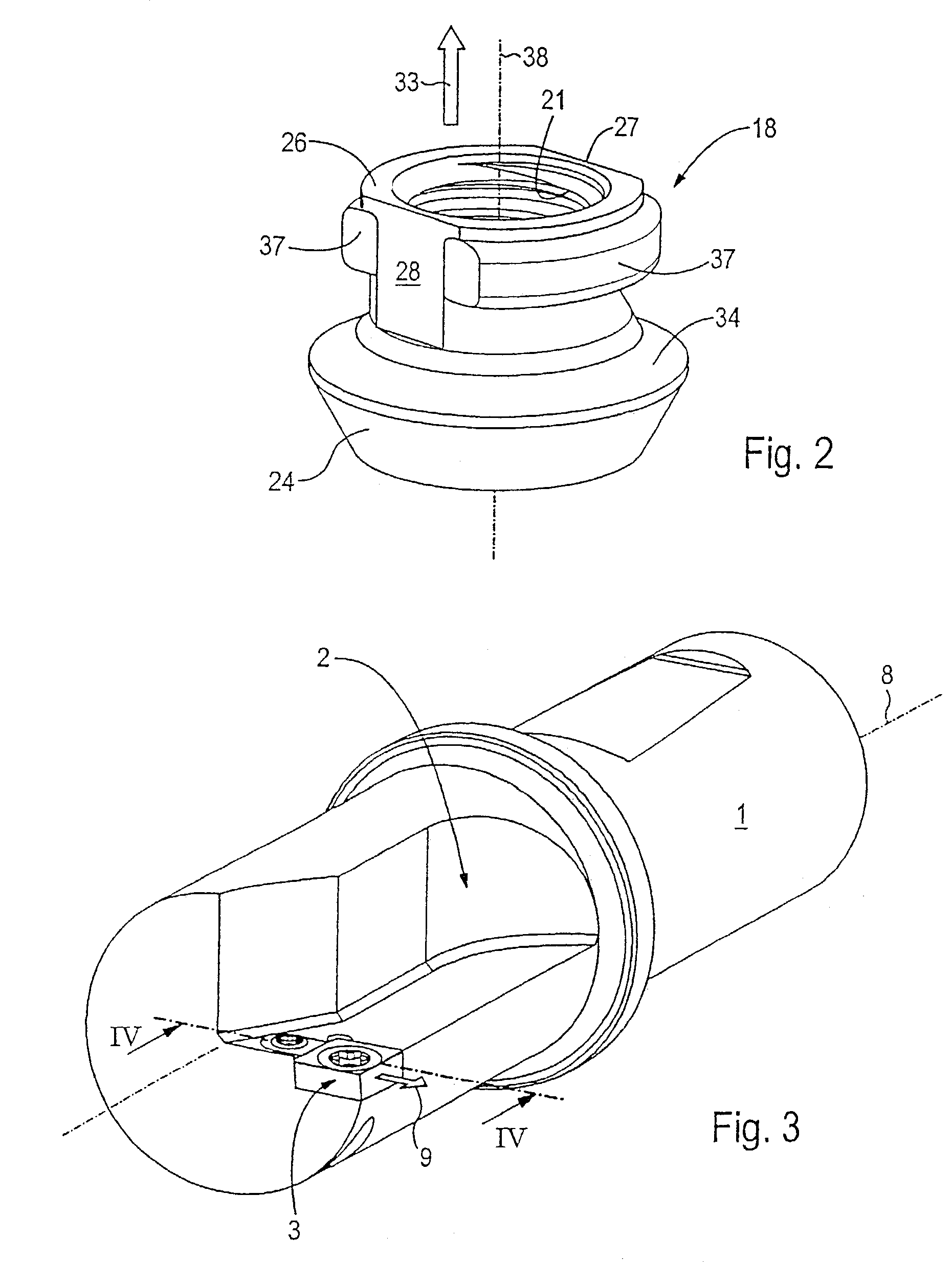

Tool for the metal cutting machining of valve seats

InactiveUS7530769B2Less-expensive solutionSimple methodThread cutting toolsTransportation and packagingCylinder headEngineering

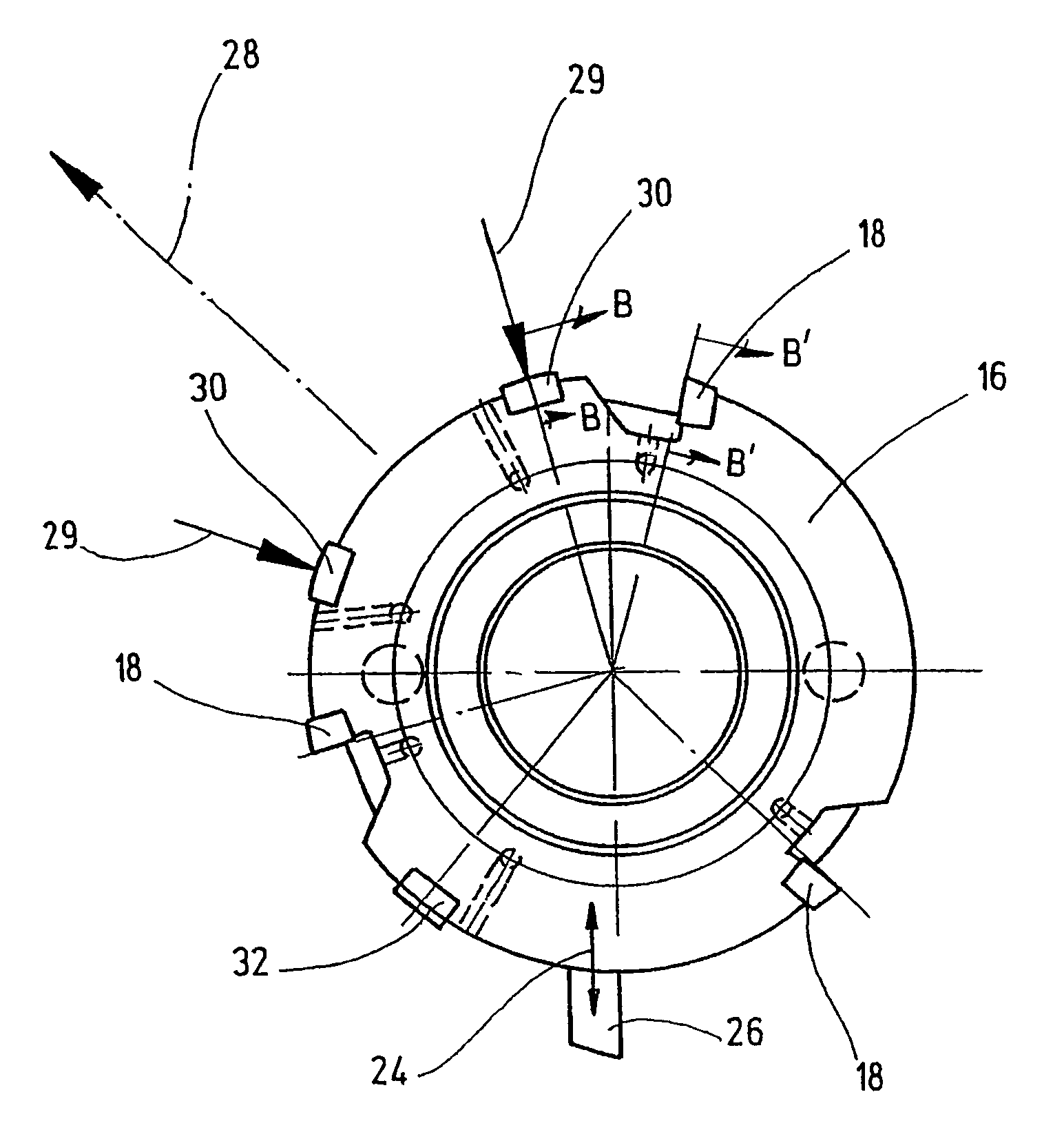

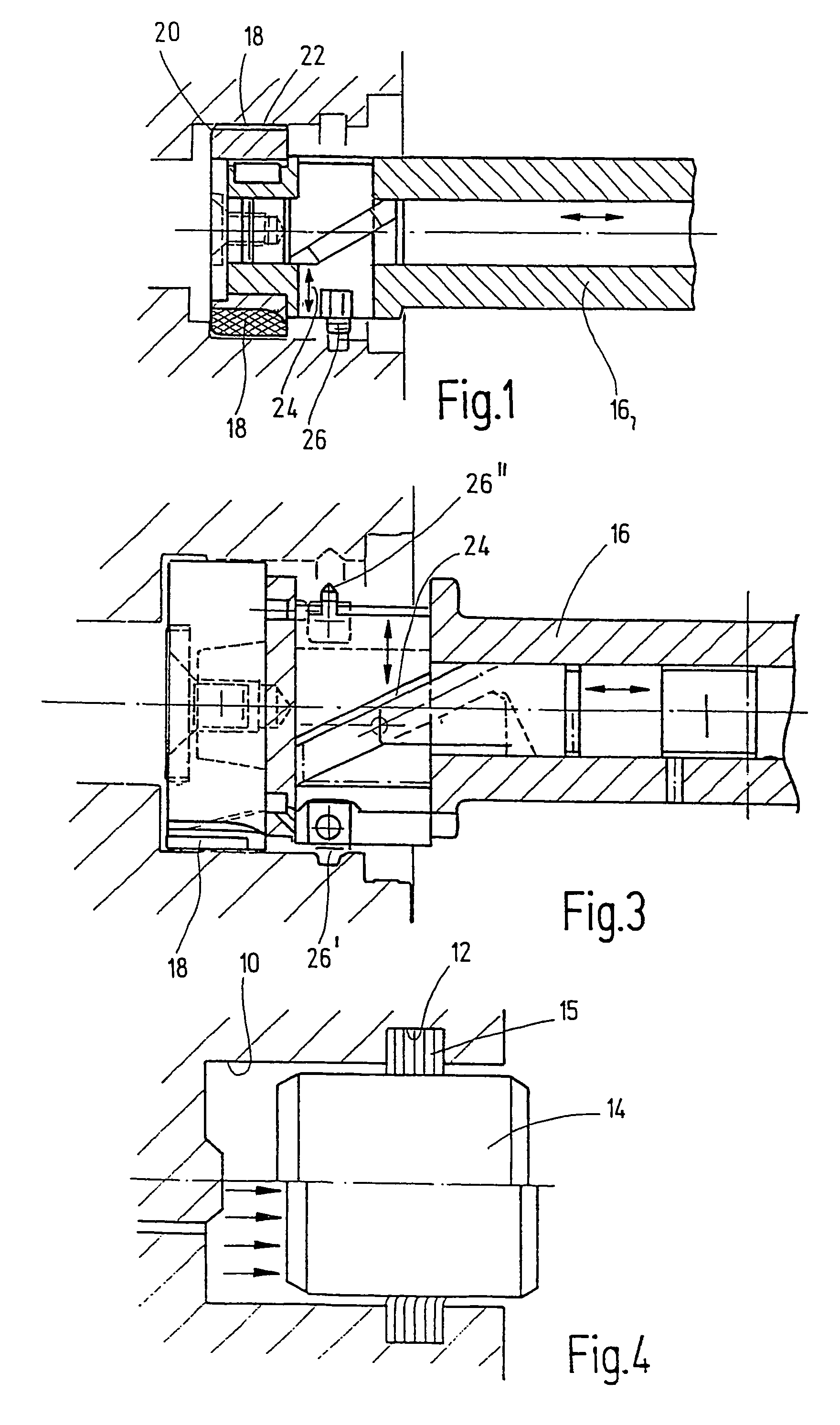

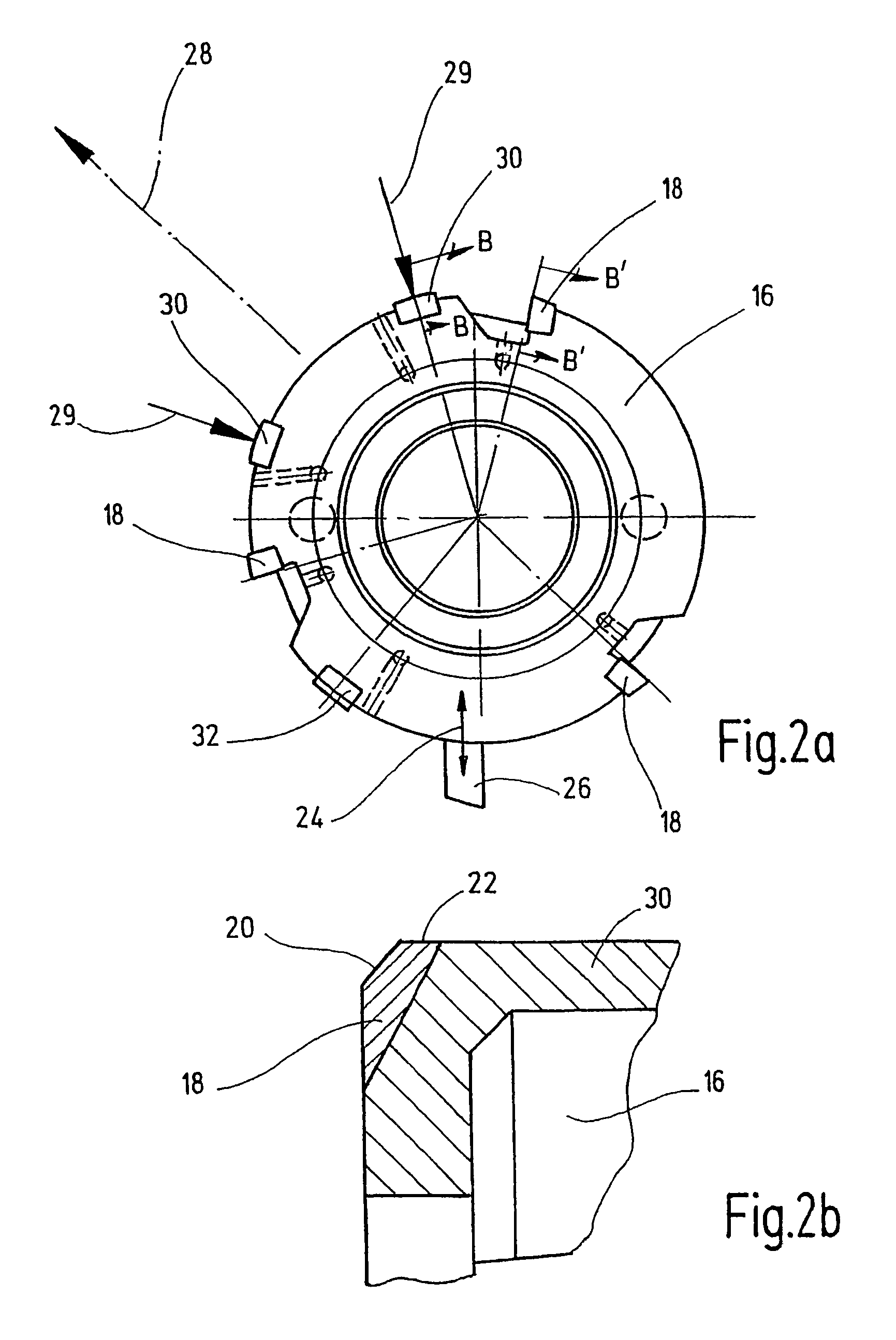

A tool for metal-cutting machining of a surface of an opening particularly of a valve seat in a cylinder head of an internal combustion engines. The tool has a cutter tip with at least one geometrically defined cutting edge. The cutter tip rests on two supporting regions in the tool which are arranged at an angle α, and an angle-bisecting line runs essentially perpendicularly with respect to the active cutting edge which then is removing chips from the valve seat. A claw holds the cutting tip to the tool end. Coolant and lubricant are supplied through an outlet from the claw.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

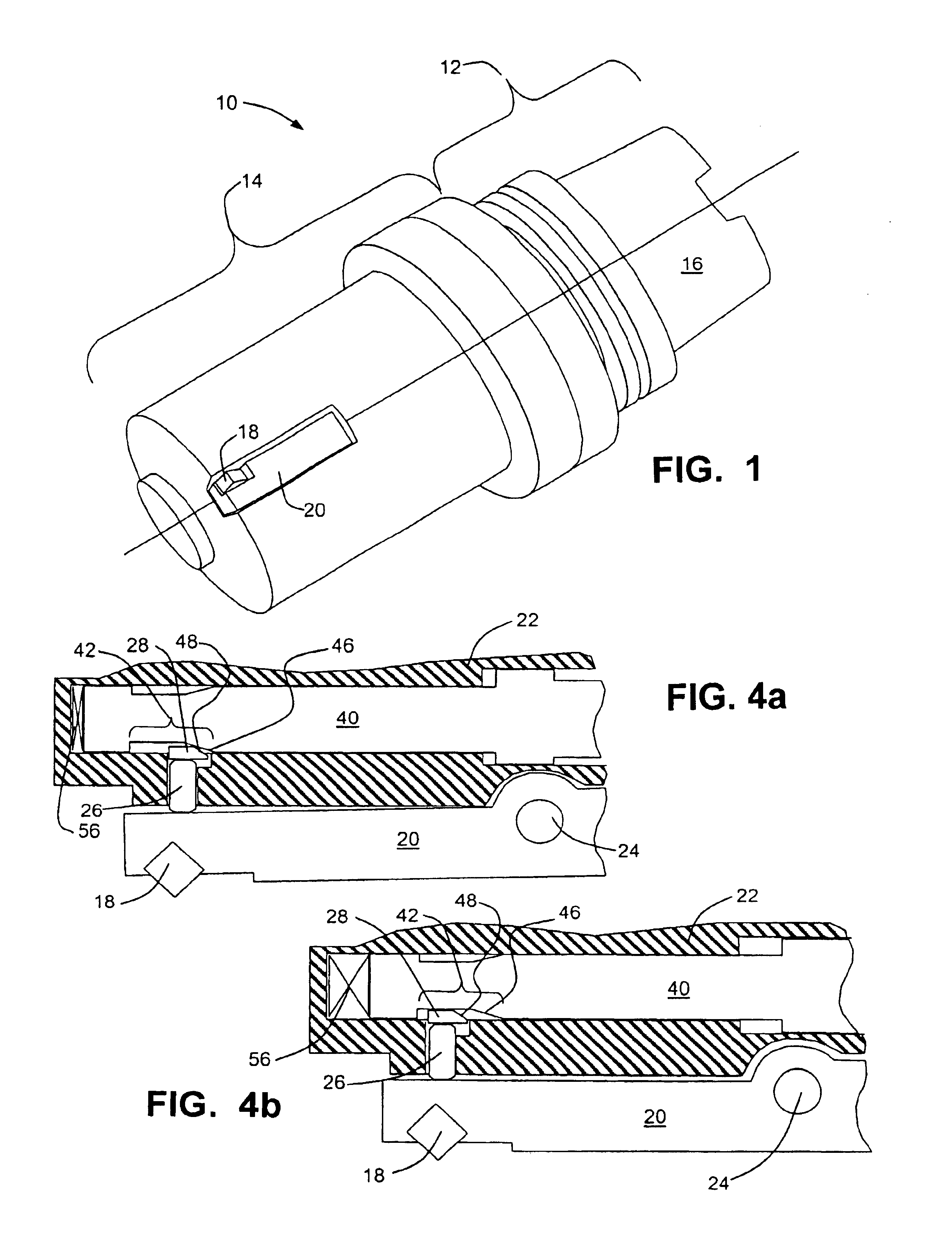

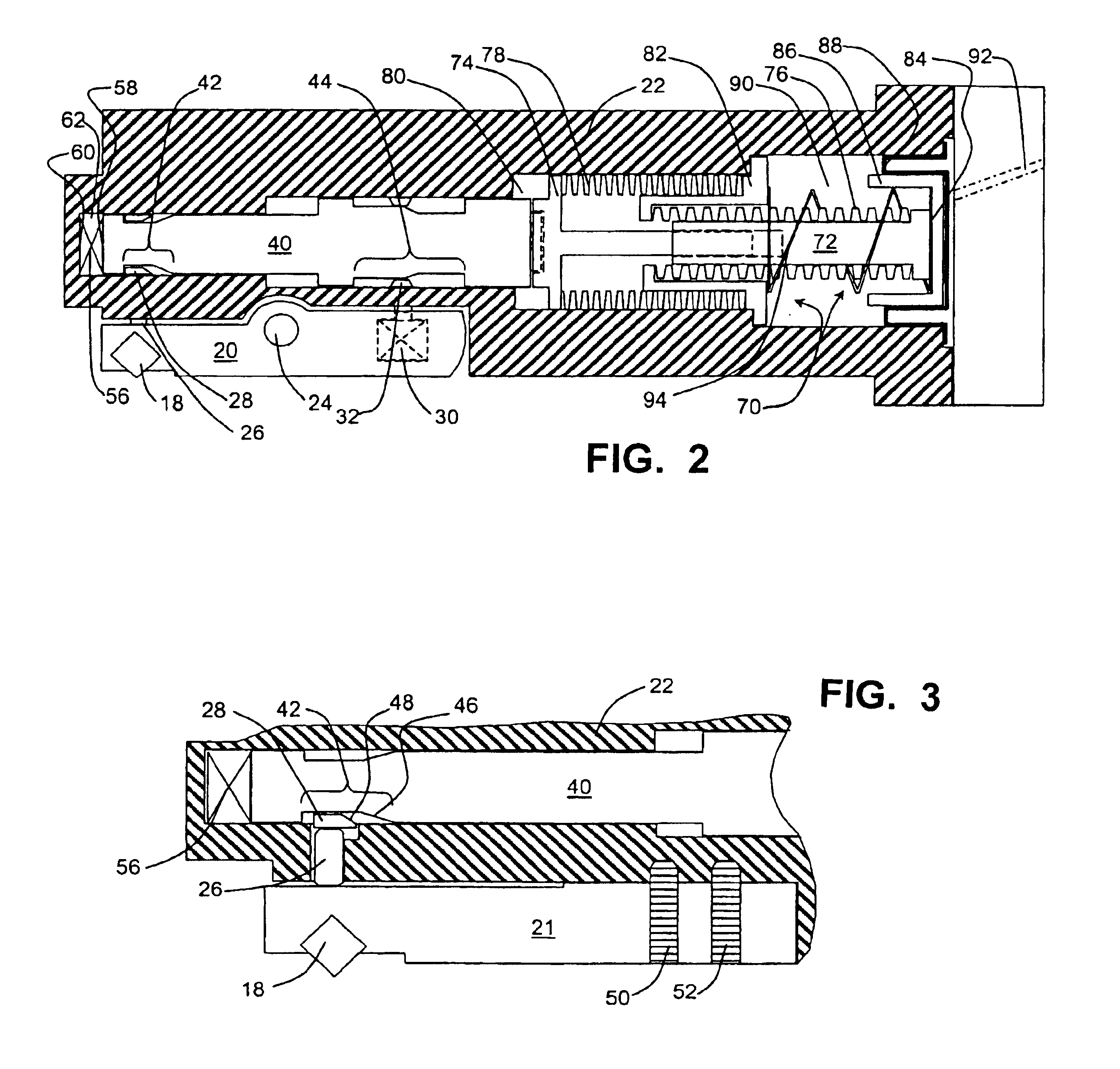

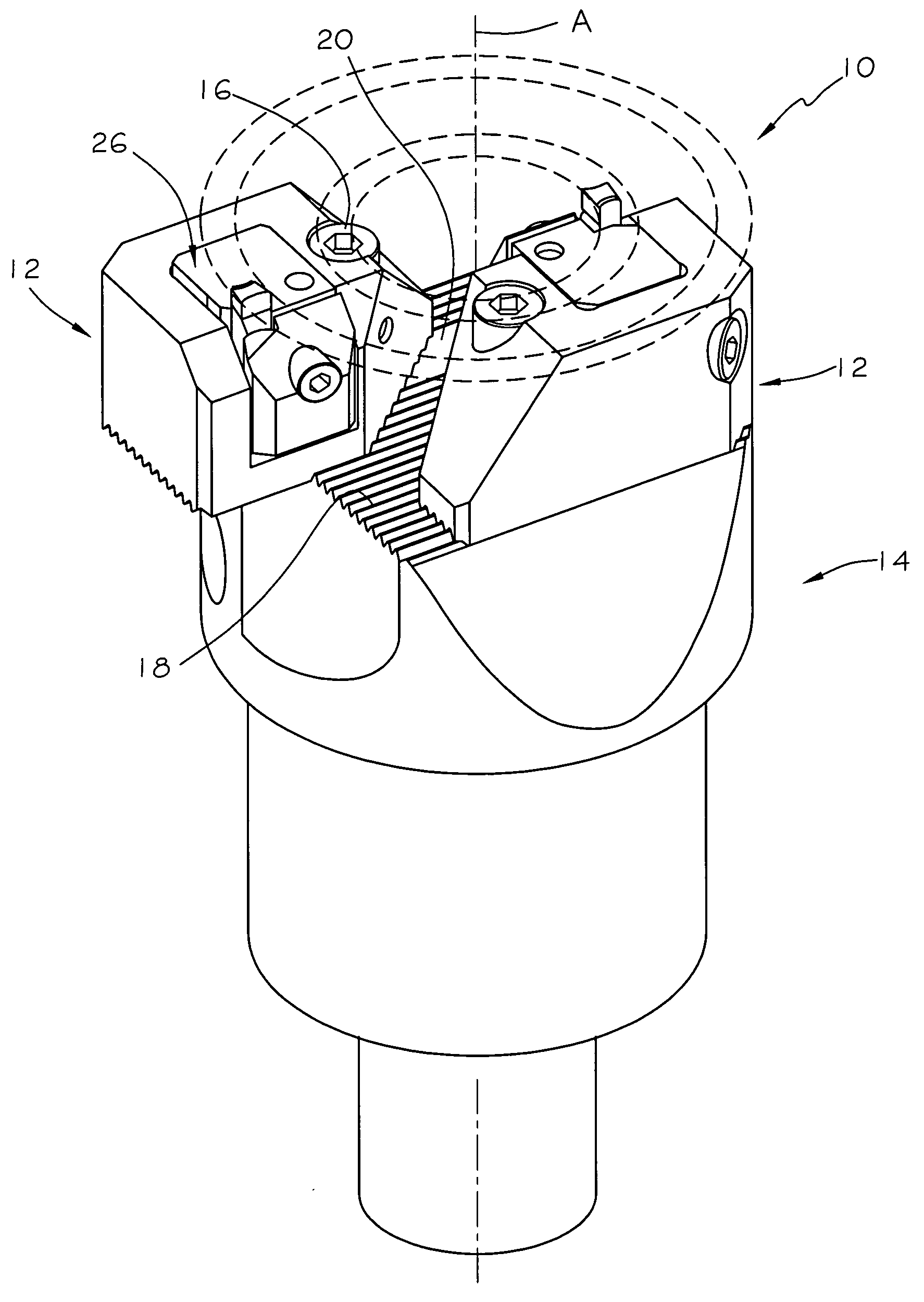

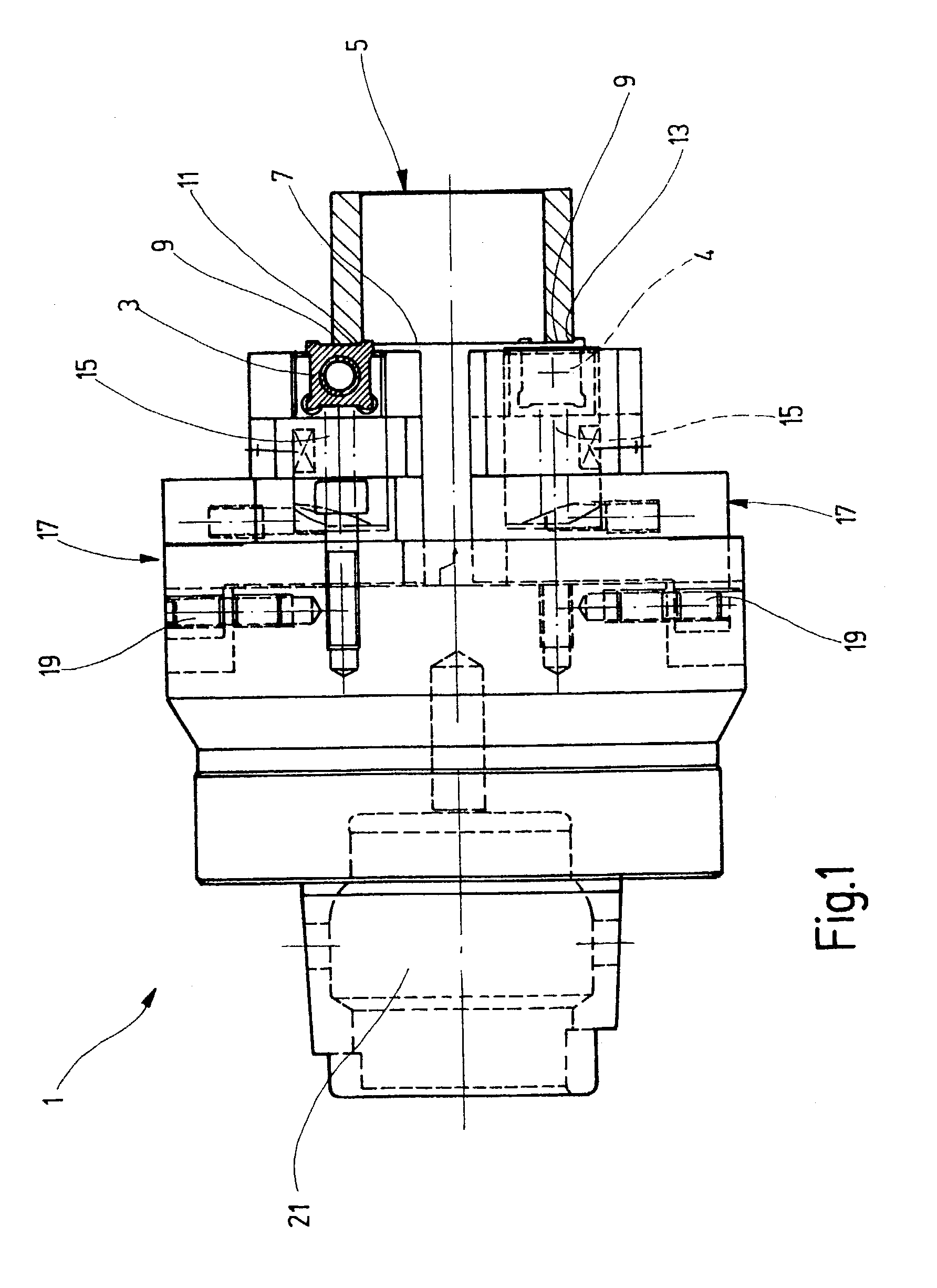

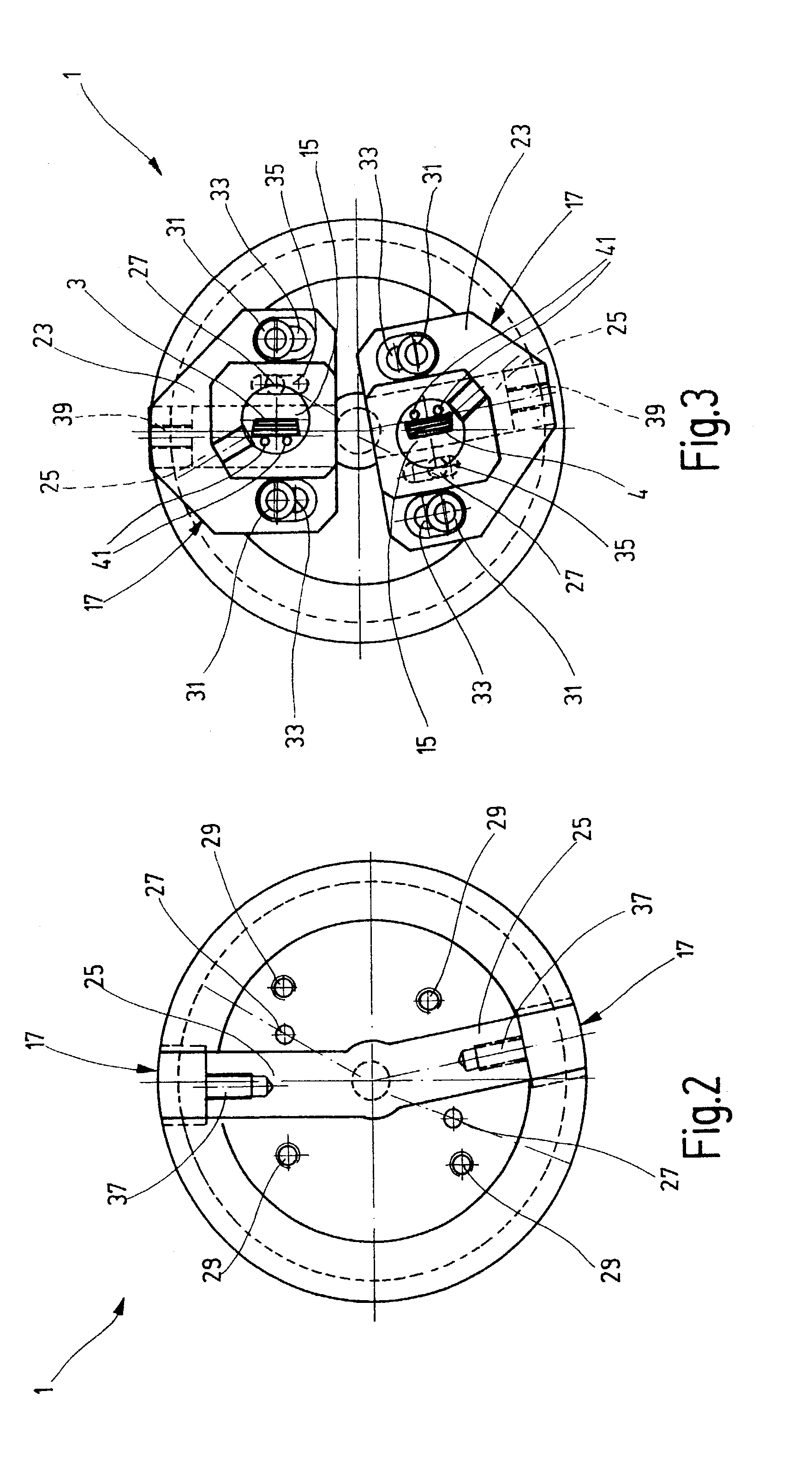

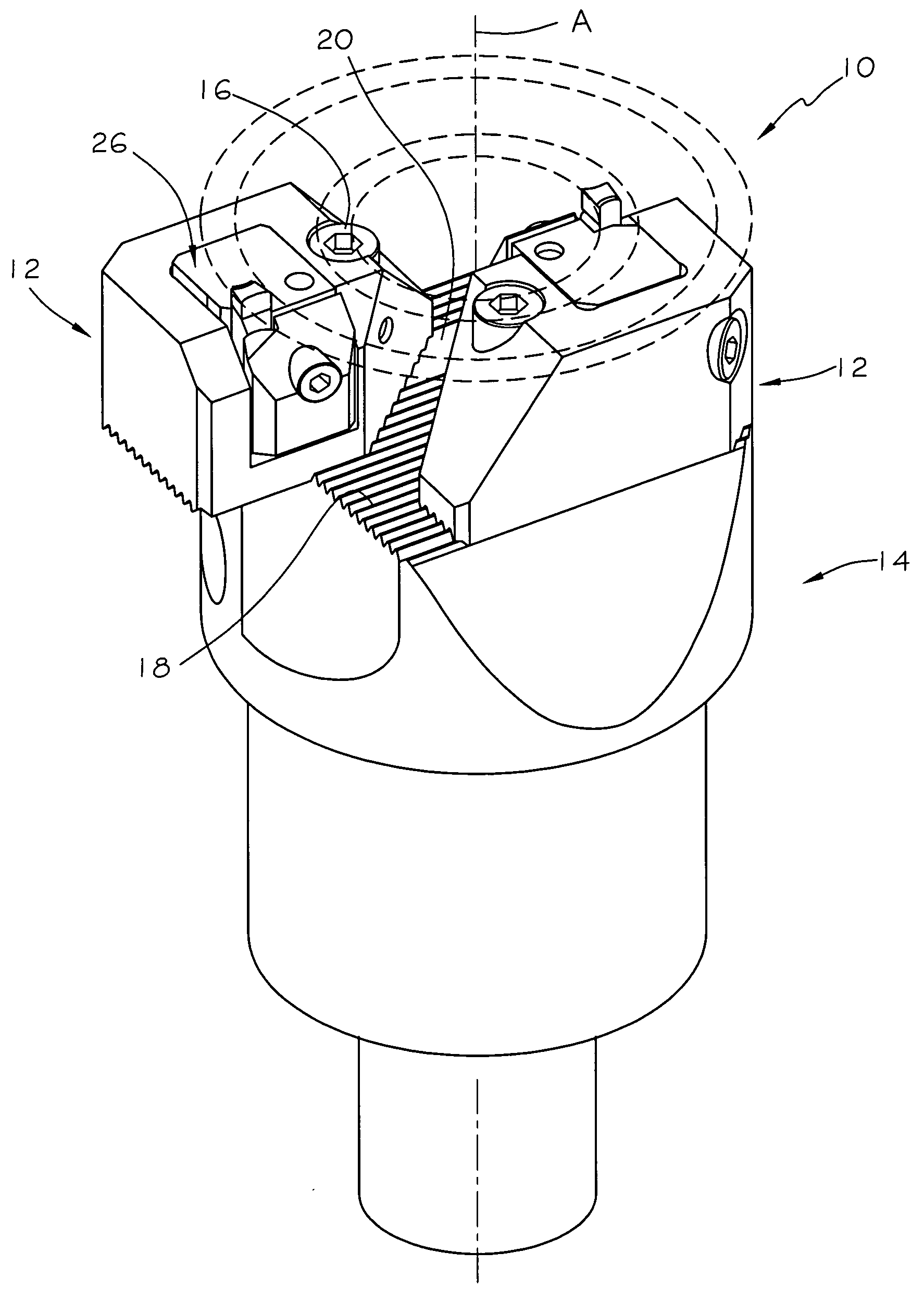

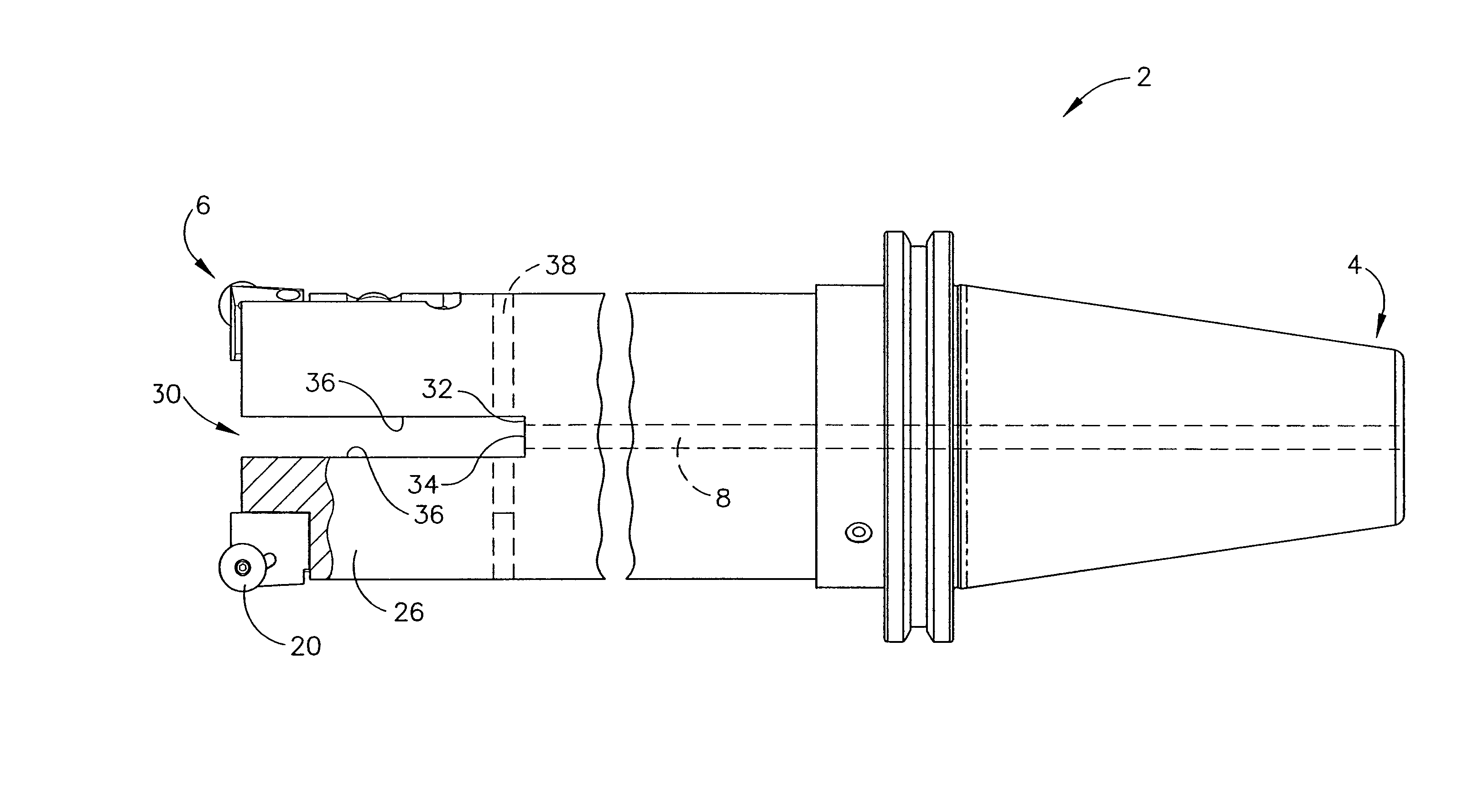

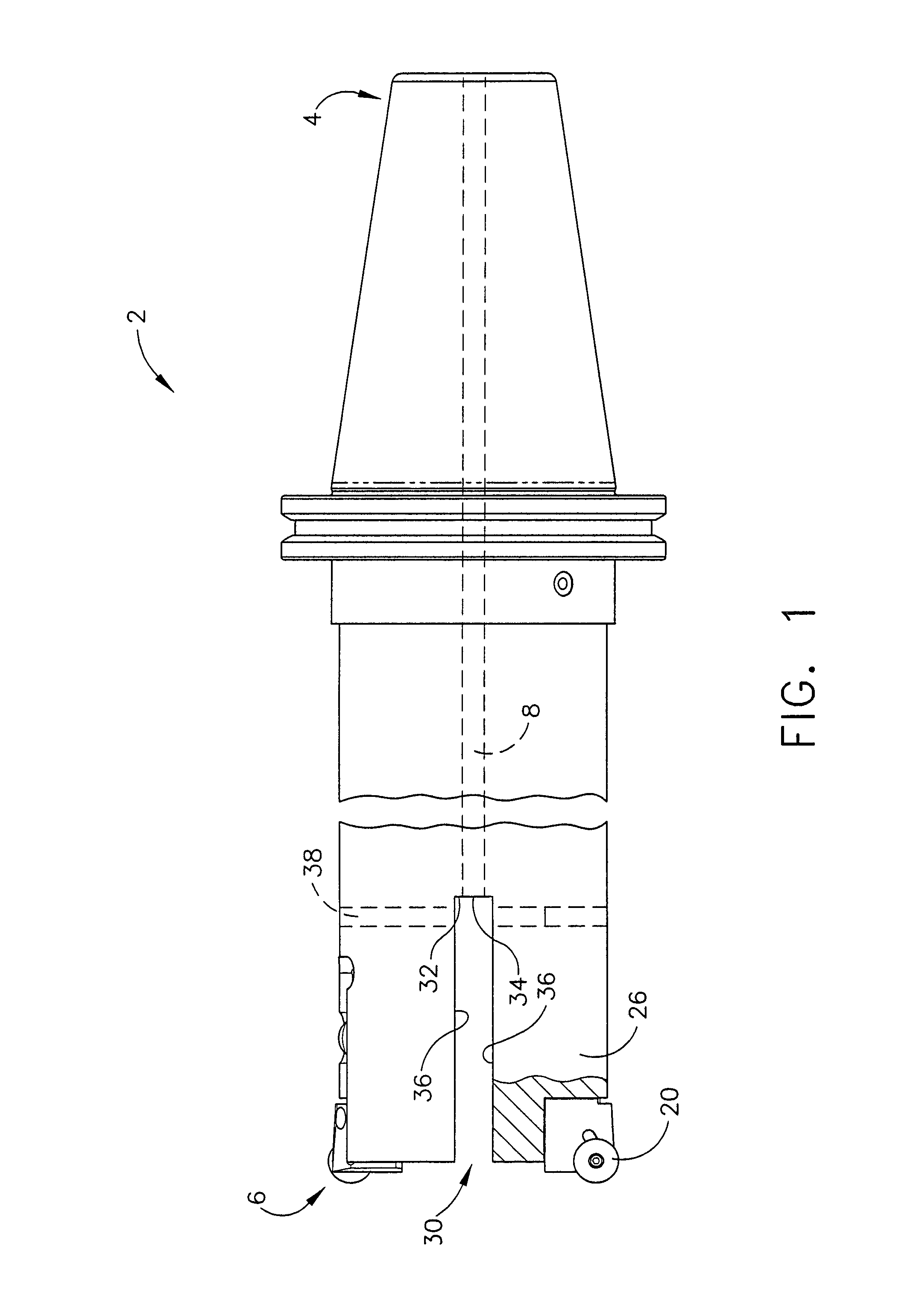

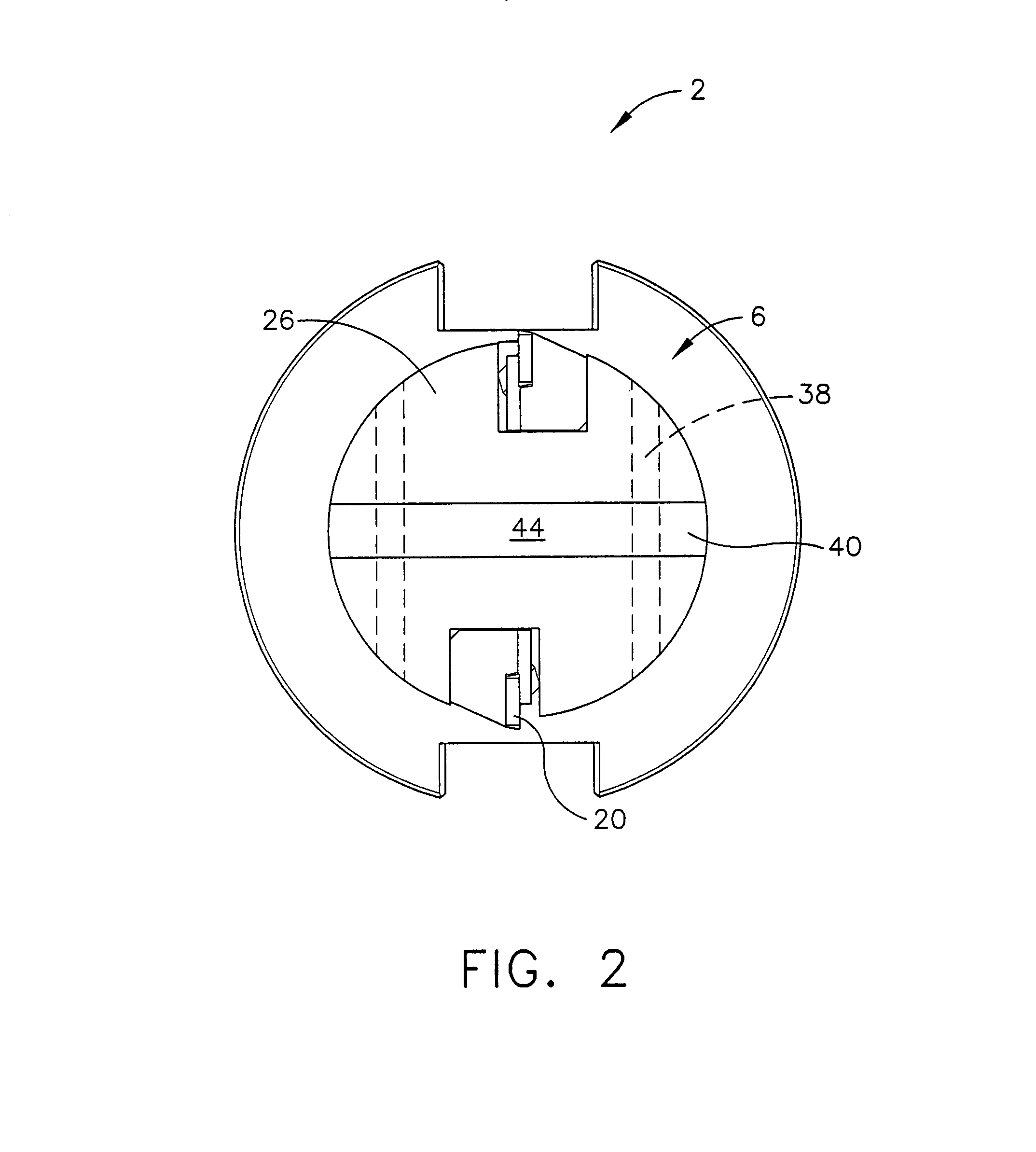

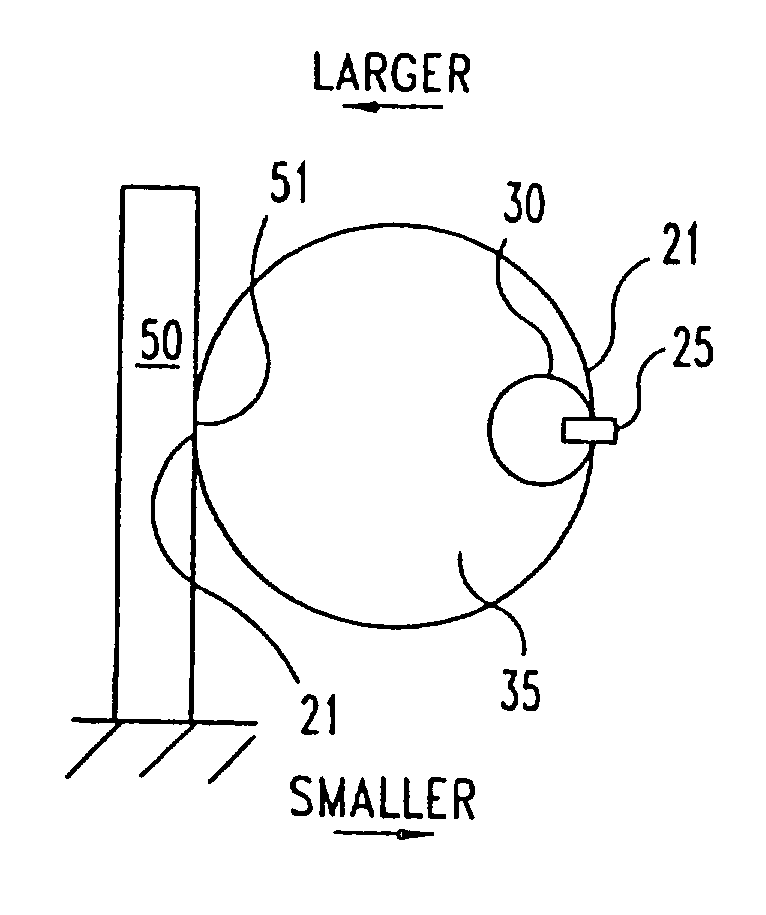

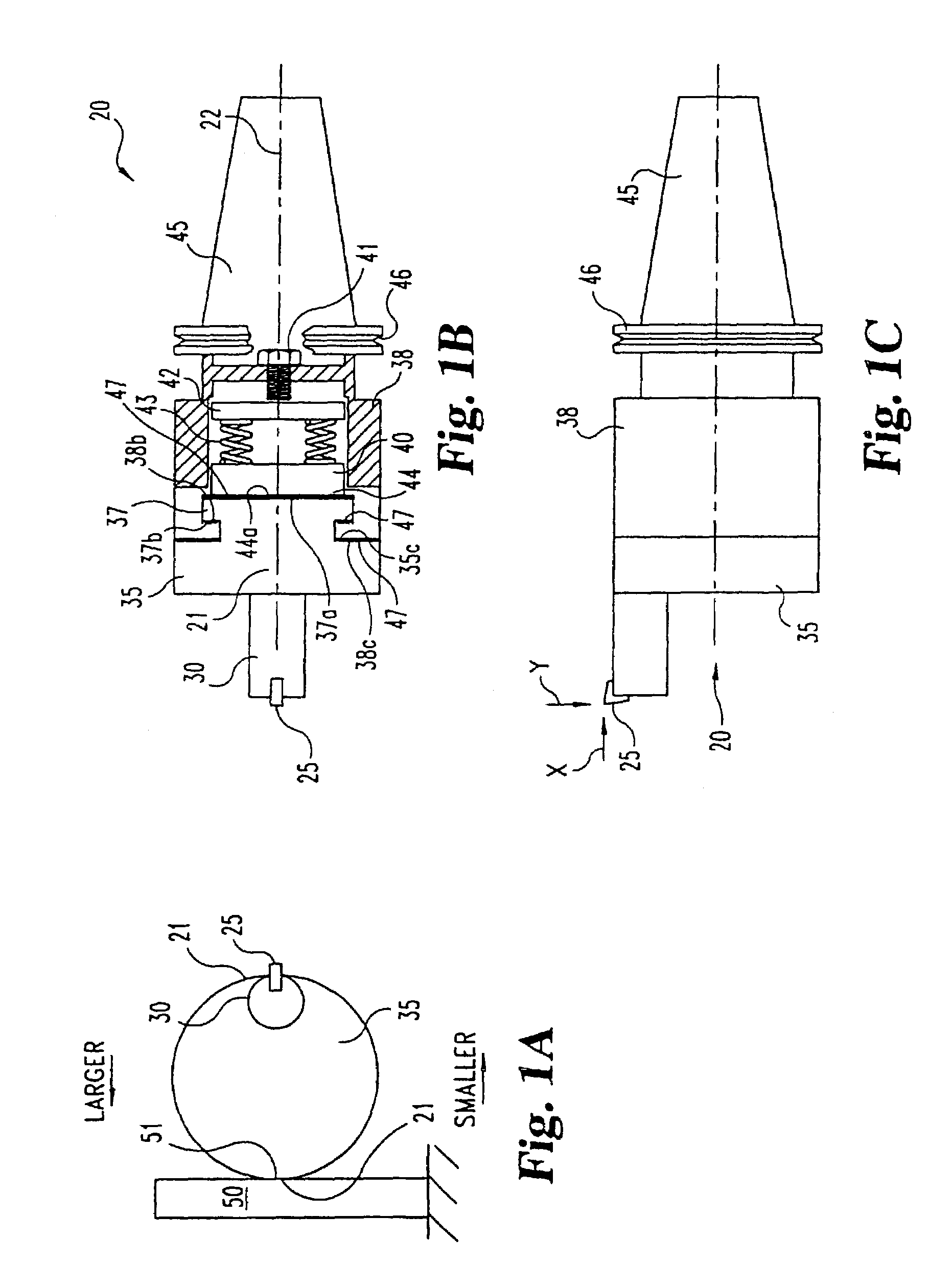

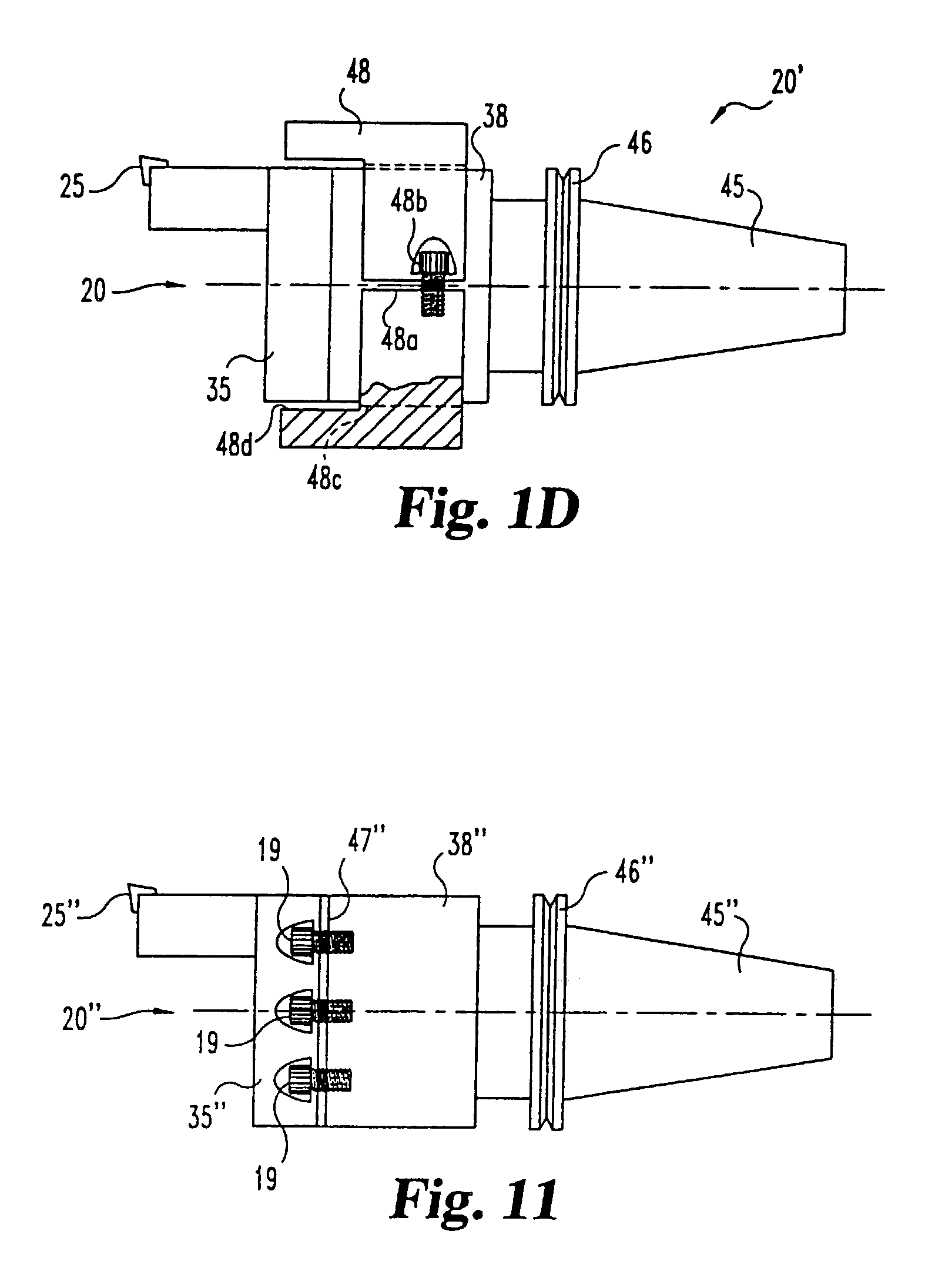

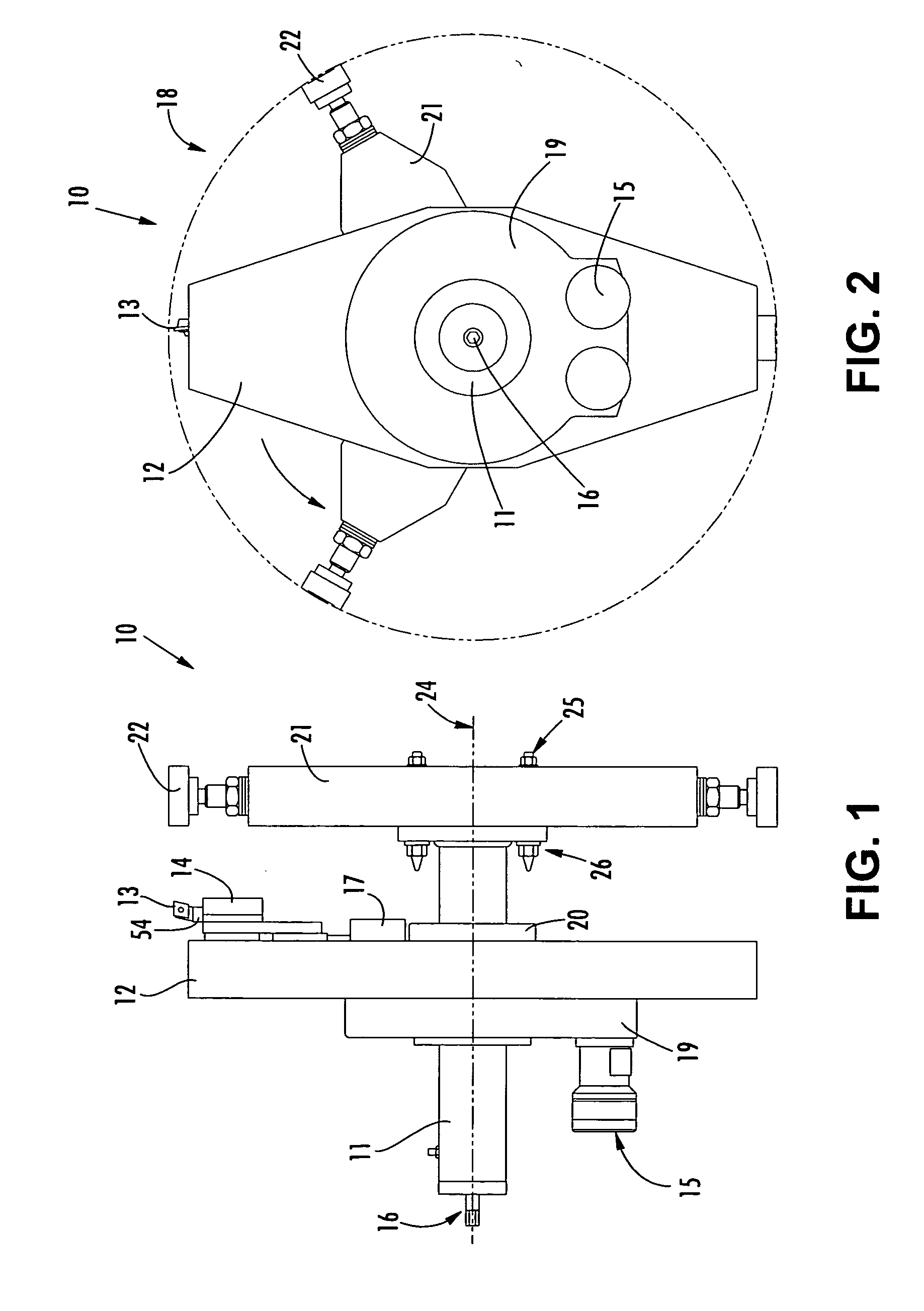

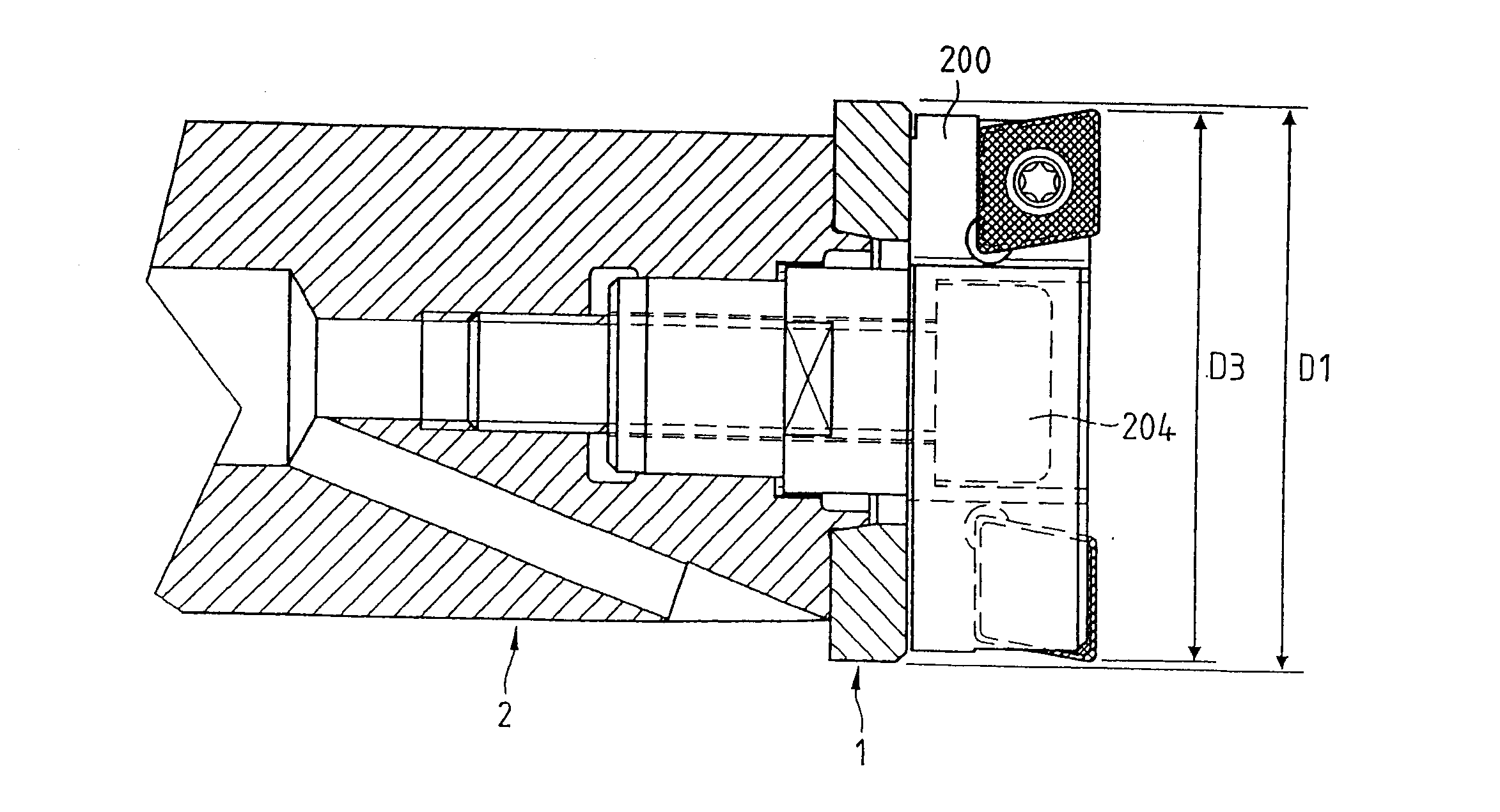

Rotatable cutting tool

A rotatable cutting tool has a shank portion for coupling to a tool driving device and a cutting portion to which is attached at least one support member for retention of a replaceable cutting element. The support member is so arranged to permit displacement of at least the portion thereof retaining the cutting element whereby the position of the cutting element relative to the body of the cutting tool may be changed by such displacement. A totally enclosed hydraulic force multiplier is mounted within an internal cavity of the cutting tool. The force multiplier is responsive to a control force to effect the displacement of the support member, the control force advantageously supplied by application of pneumatic pressure.

Owner:VALENITE

Guide pad

ActiveUS20130051944A1Convenient ArrangementAchieve improvementDrilling/boring measurement devicesThread cutting machinesEngineeringMechanical engineering

A guide gib (500) for a deep drilling tool of a substantially rectangular shape with a longitudinal direction (L) and a width (B) and with at least one sliding surface (540) is characterized in that at least one lubricating groove, preferably a plurality of lubricating grooves (501, 502), is / are arranged at least in the region of a contact zone of the sliding surface.

Owner:BOTEK PRAEZISIONSBOHRTECHNIK GMBH

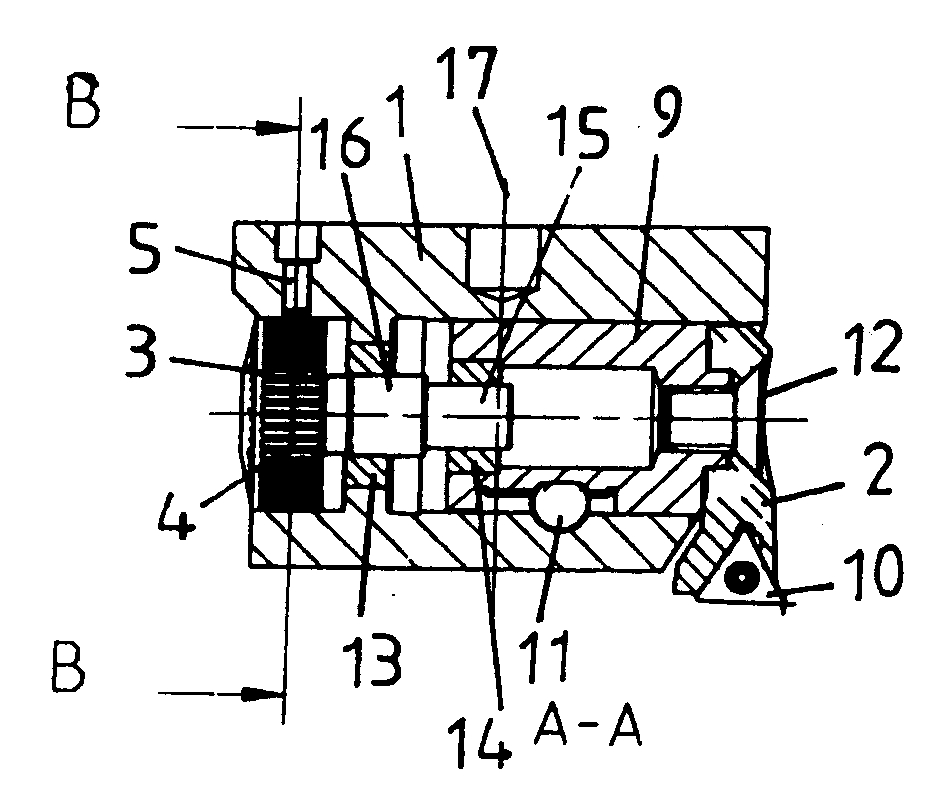

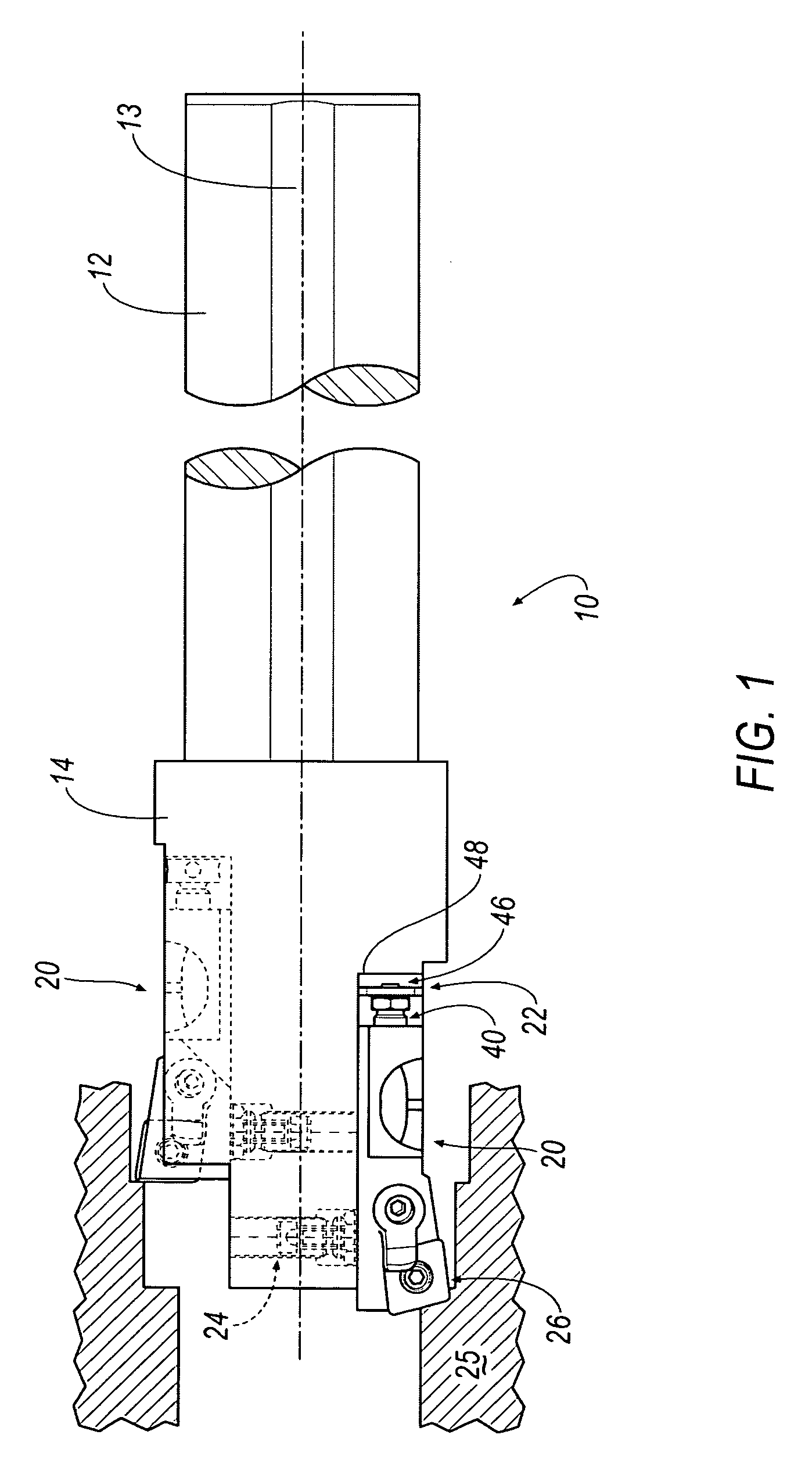

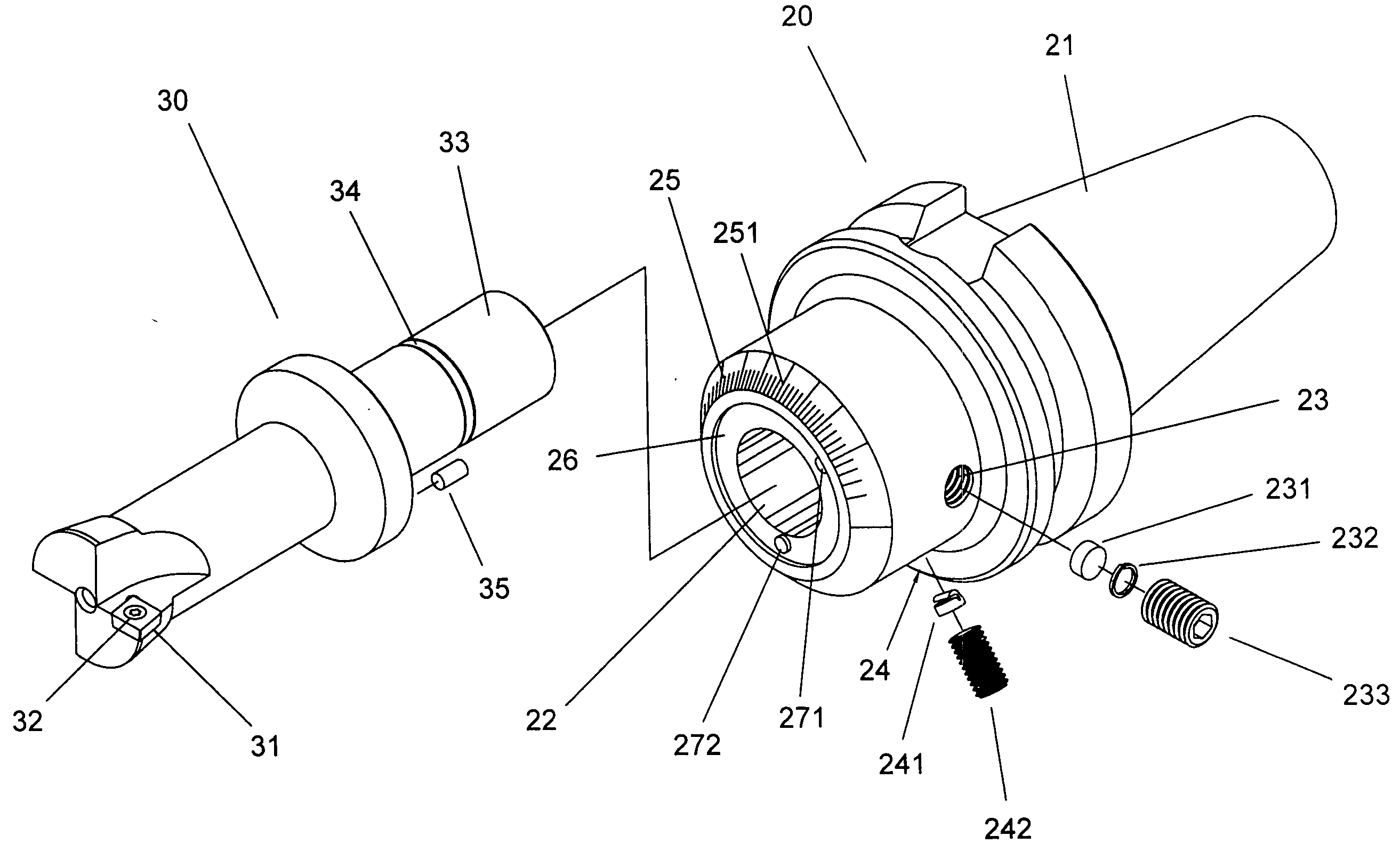

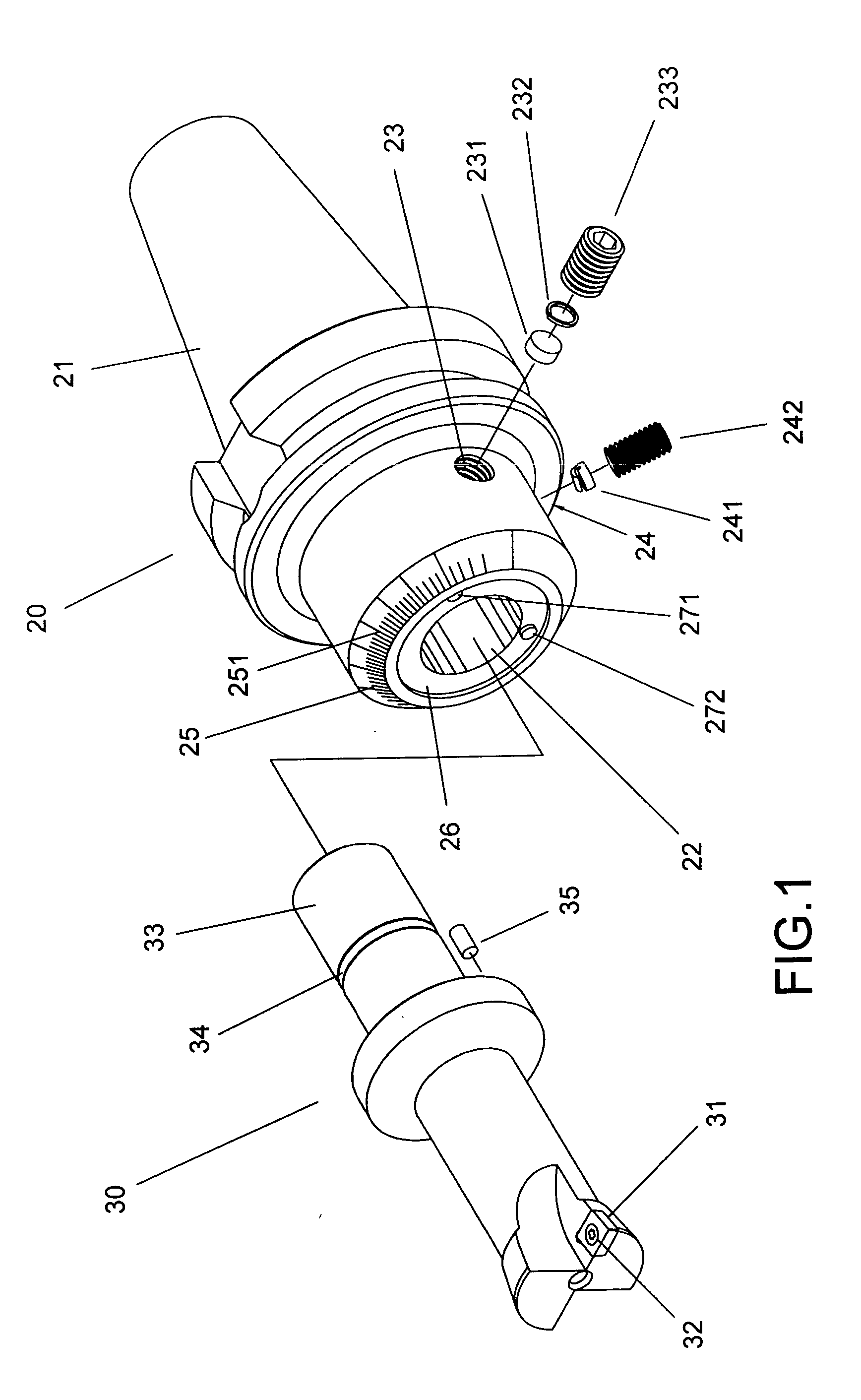

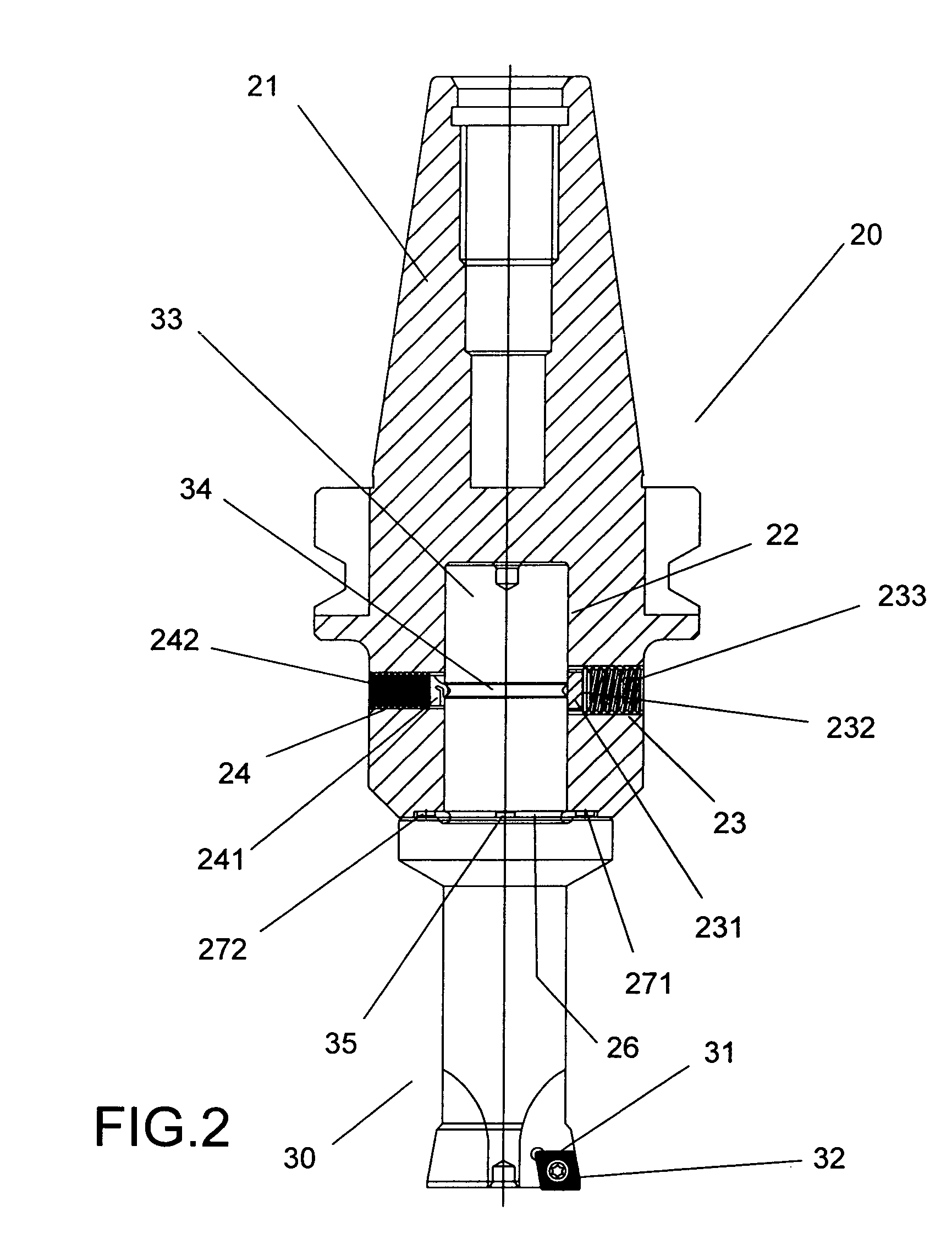

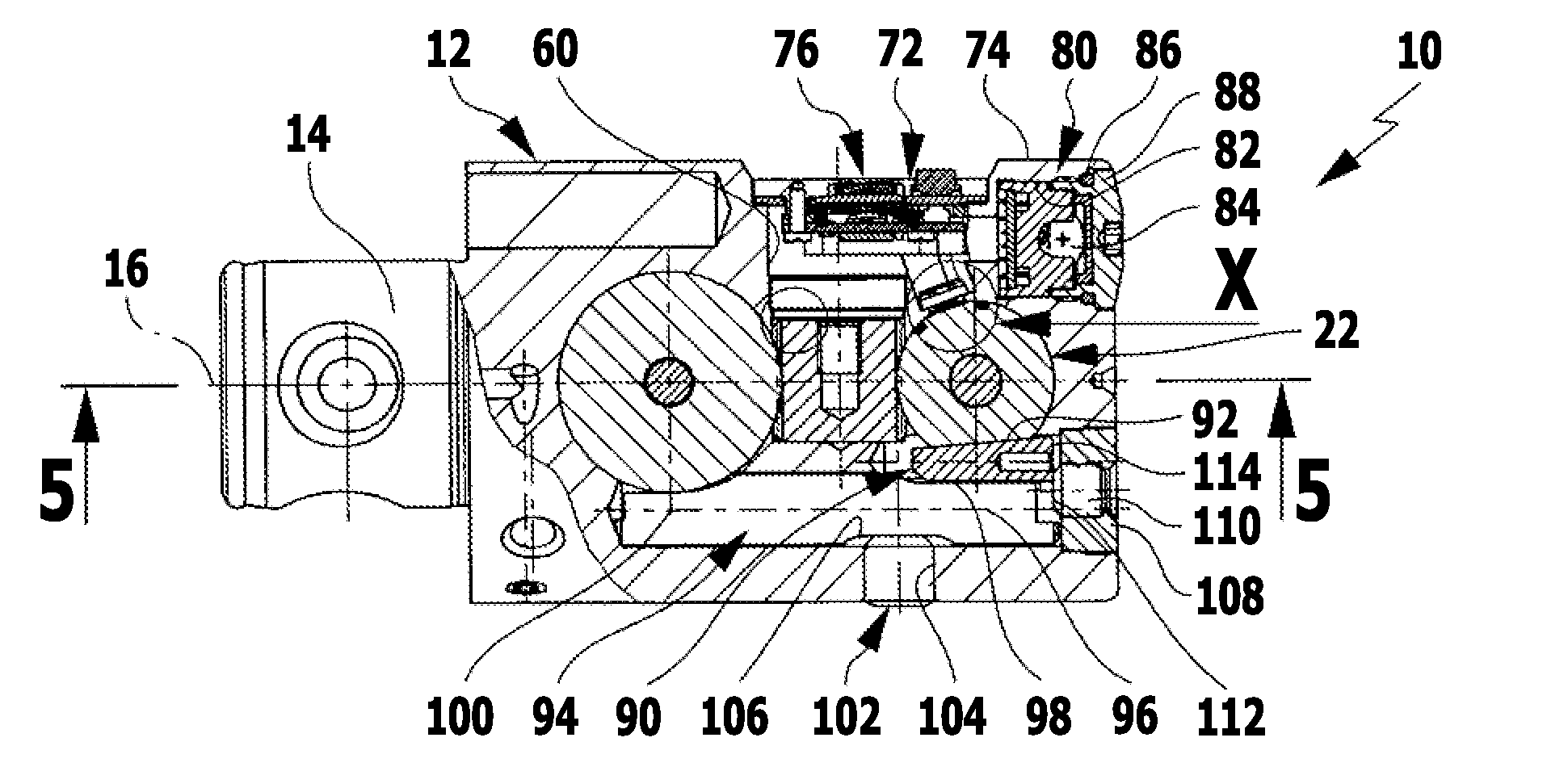

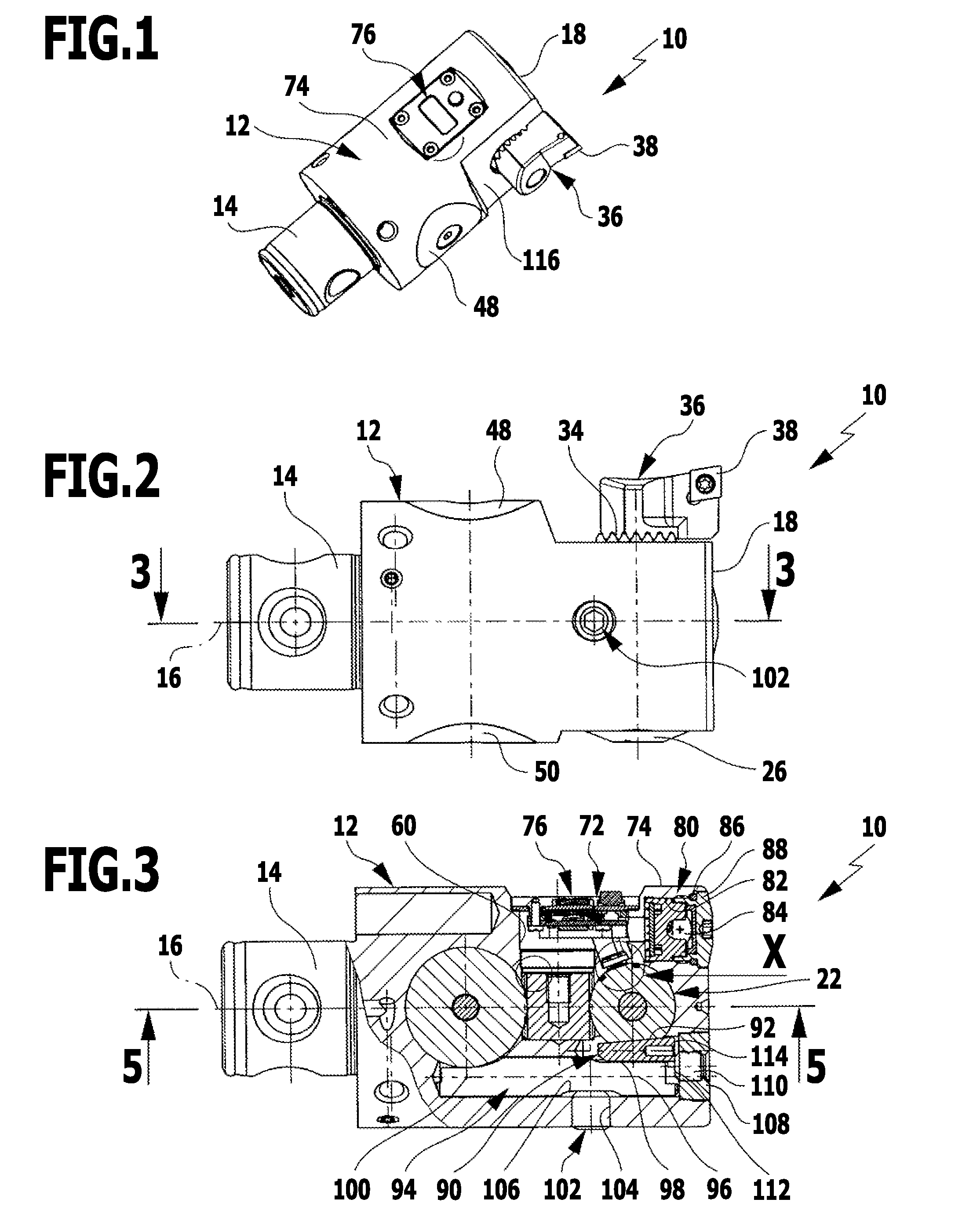

Cutting tool with very fine adjustment

InactiveUS20070084320A1Finely adjust positionFiner adjustable positioningLathesBoring headsDrive shaftEngineering

A cutting tool including a main tool body and a tool carrier which is movable relative thereto for accommodating a cutting bit. The tool carrier has a screwthreaded bore co-operating with a first screwthread on a drive shaft in such a way that the tool carrier can be moved relative to the main tool body by rotation of the drive shaft. The drive shaft has a second screwthread which is arranged in a screwthreaded bore in the main tool body, such that the two screwthreads differ in respect of their pitch and / or direction of rotation.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

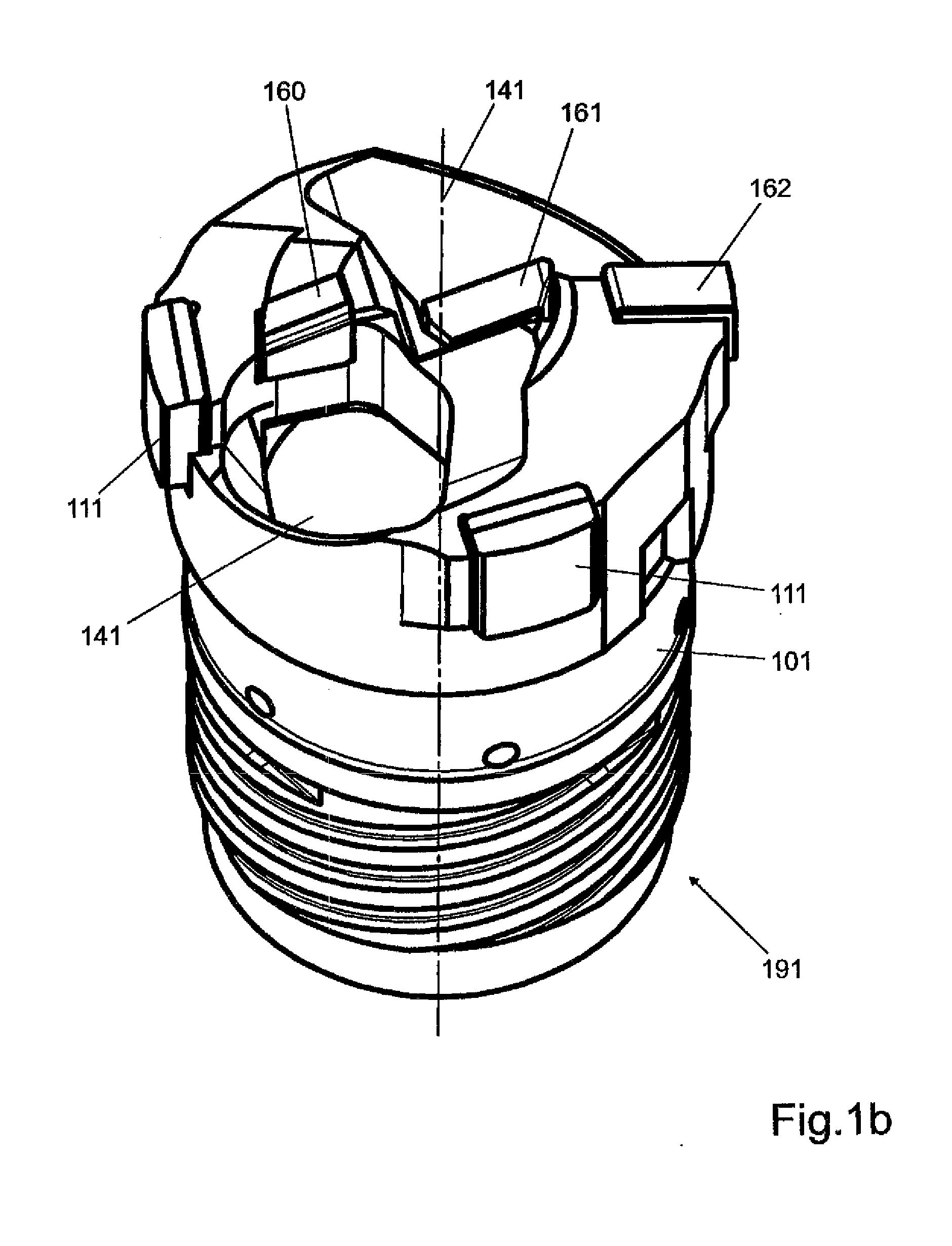

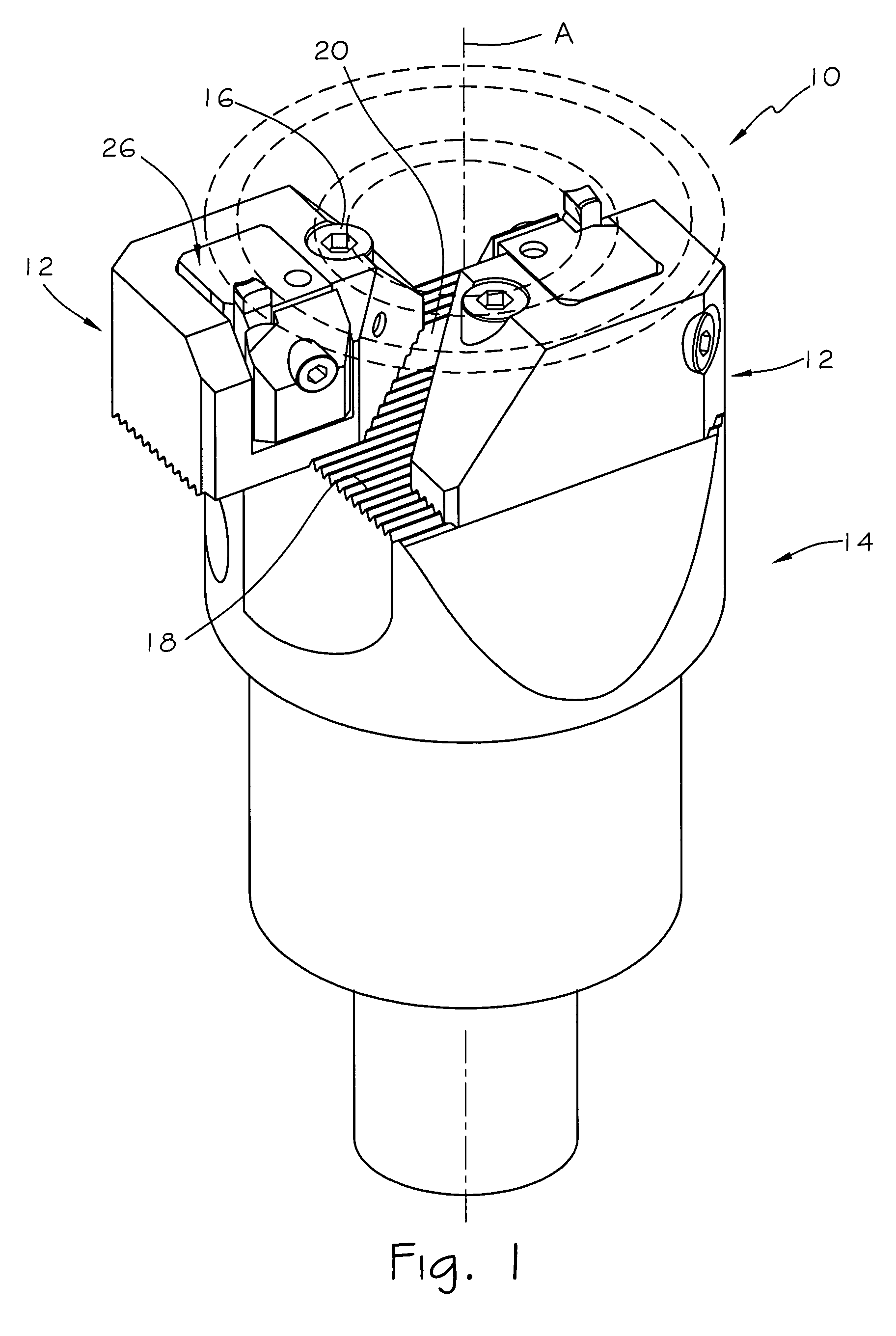

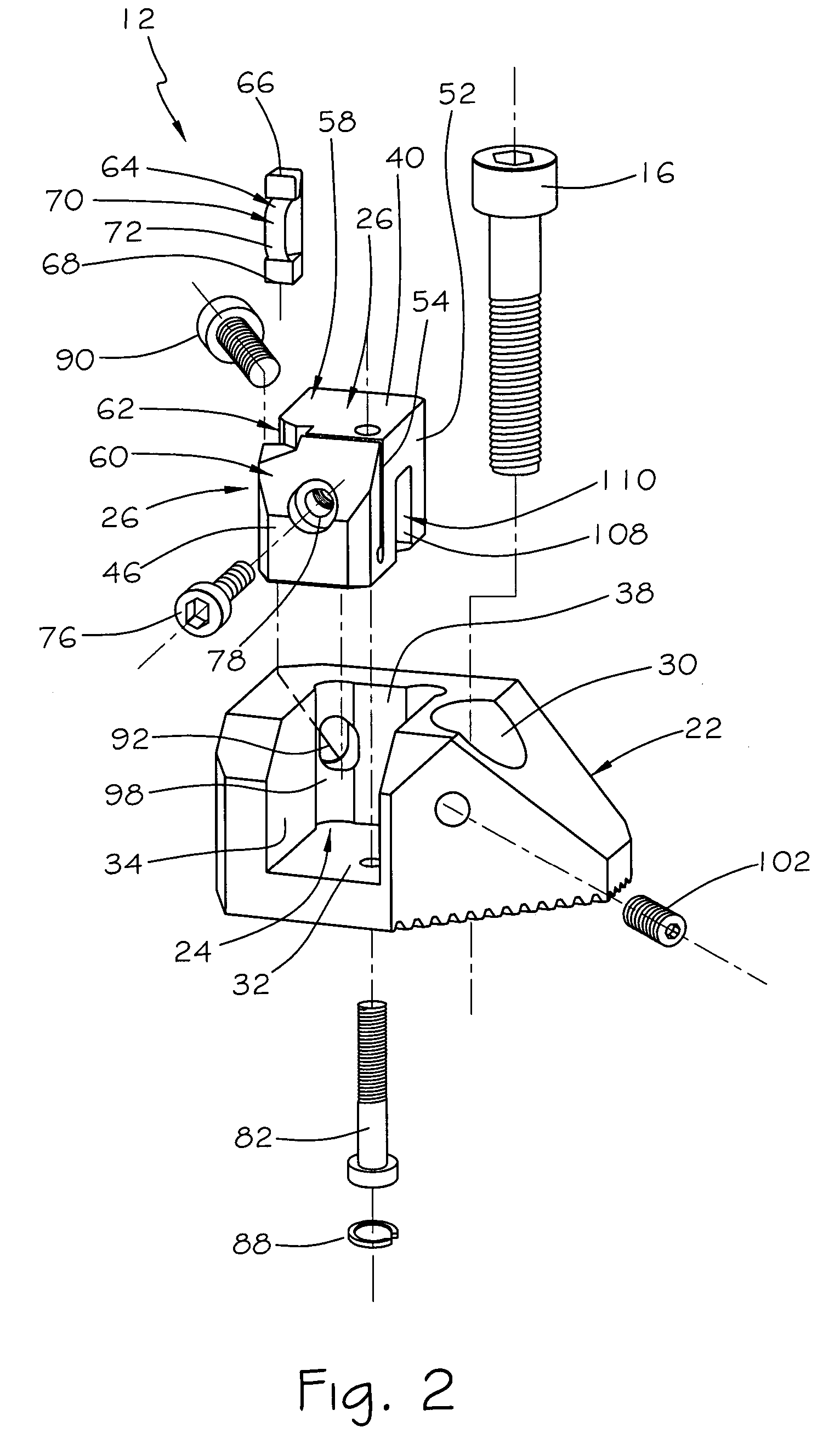

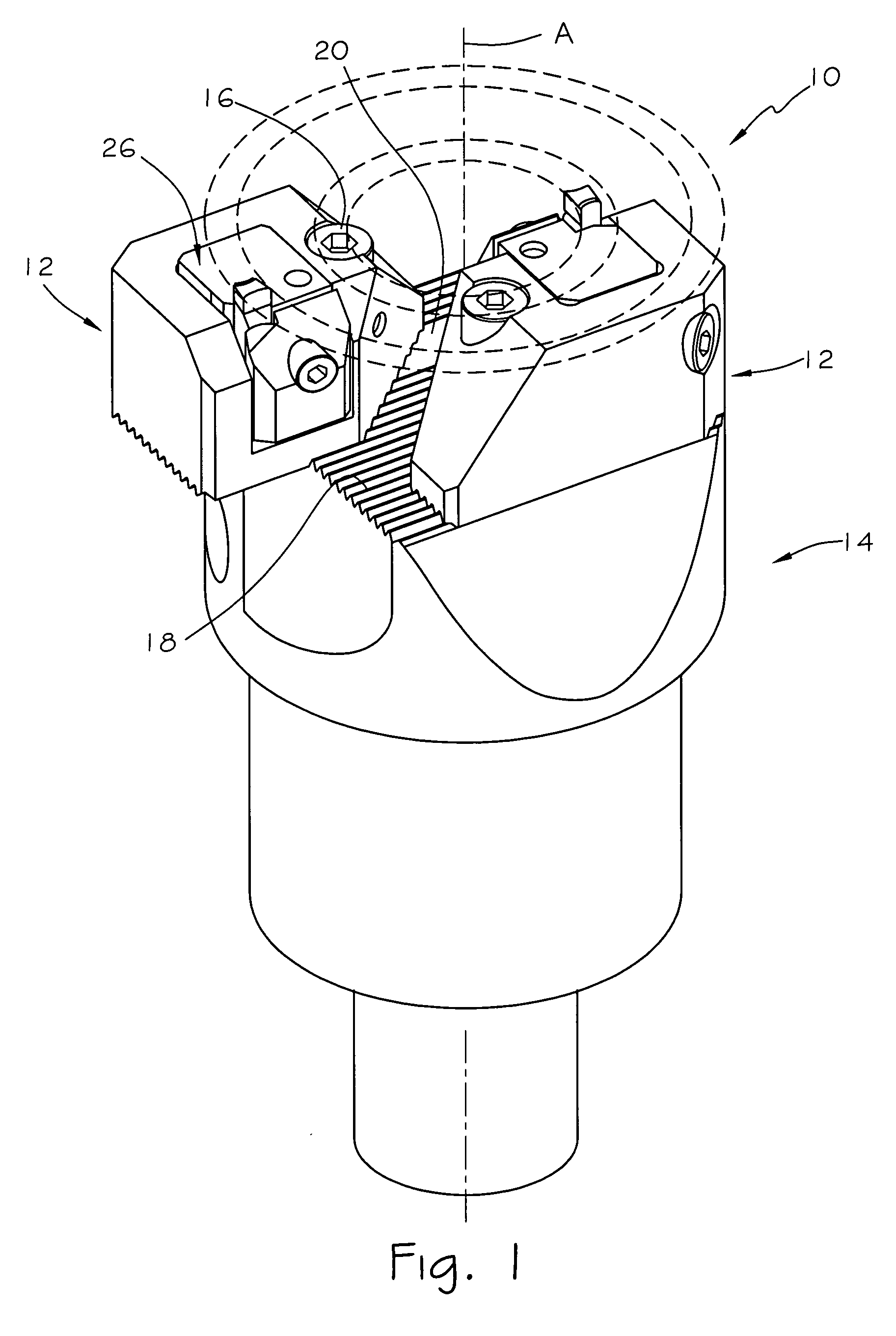

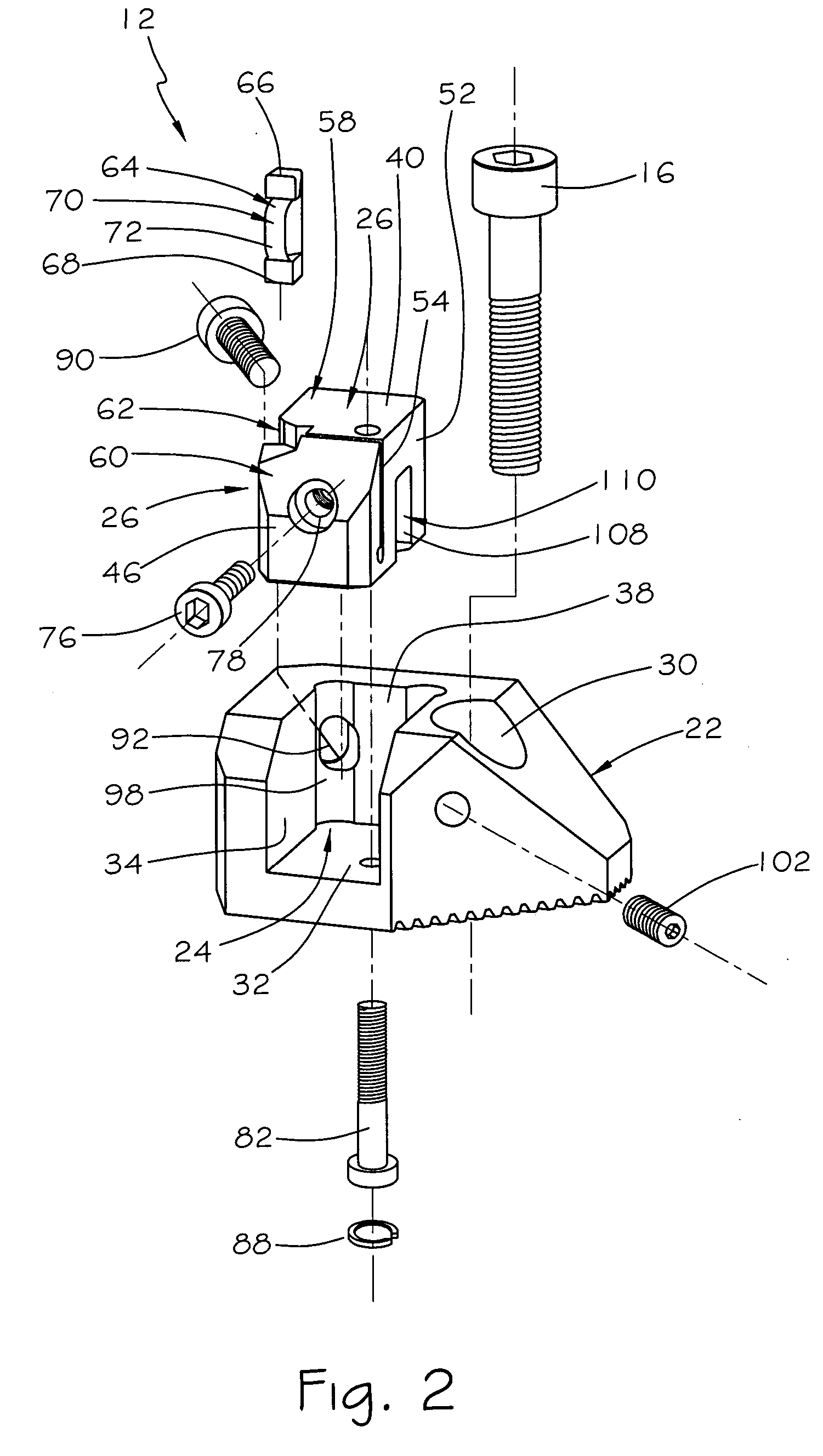

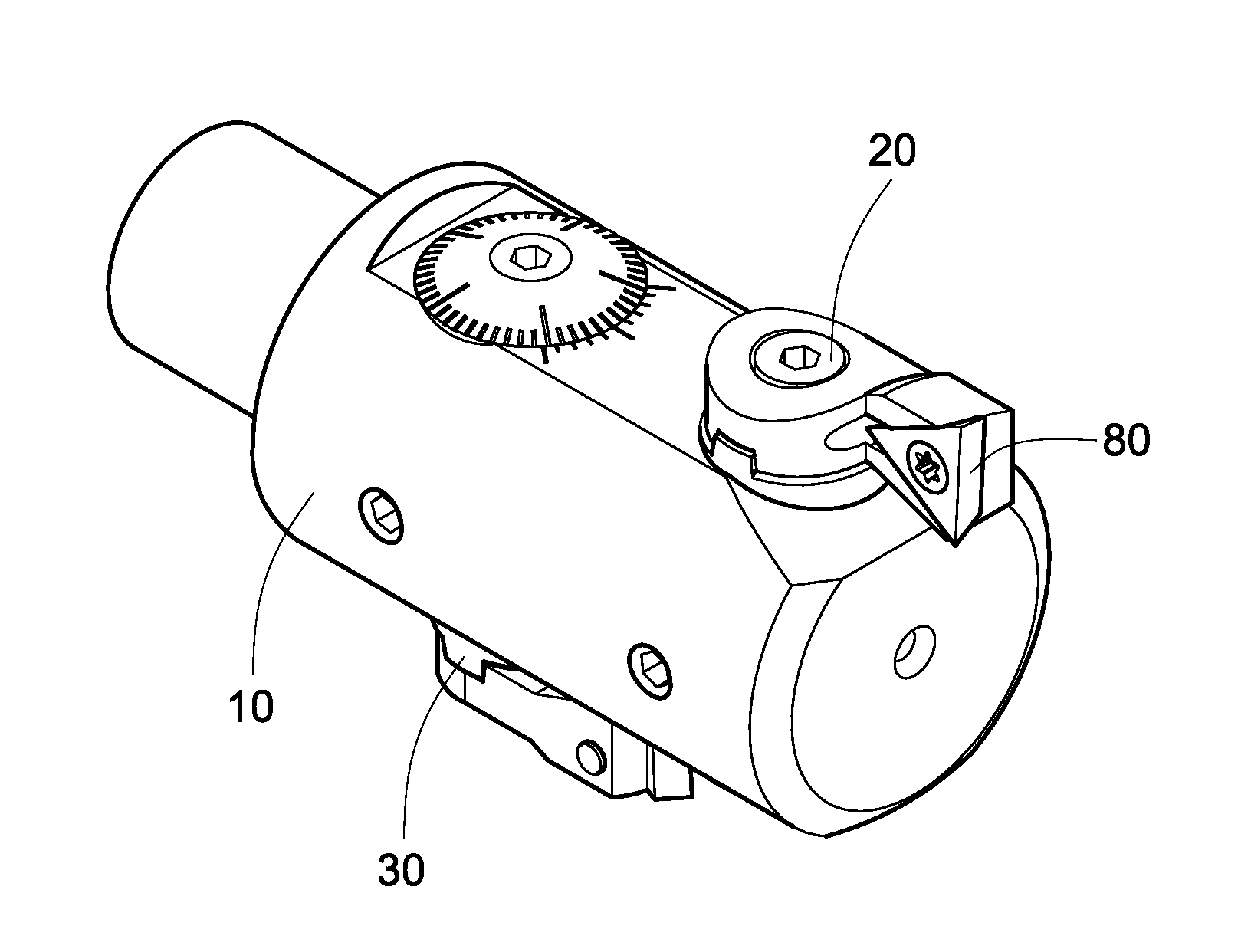

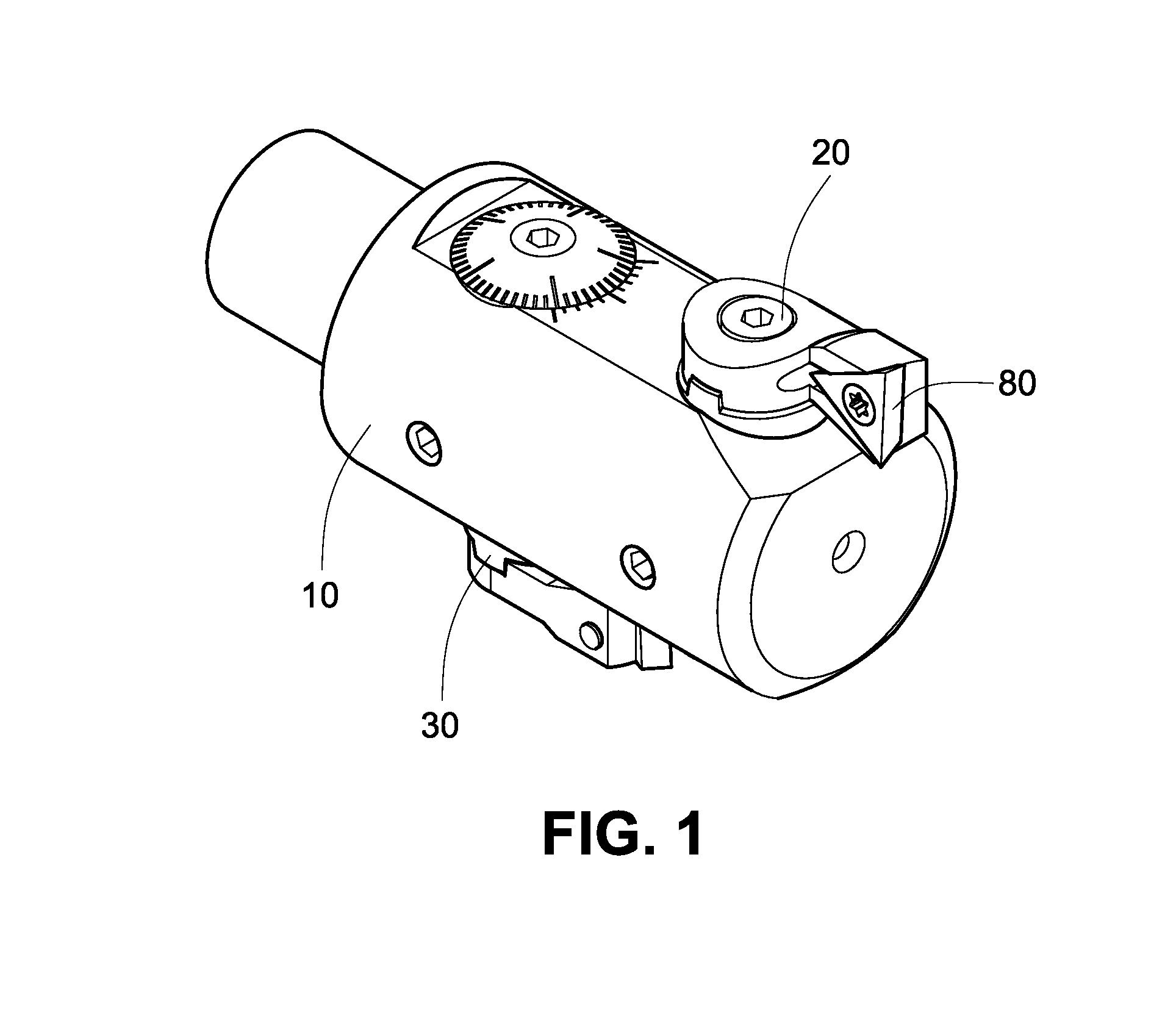

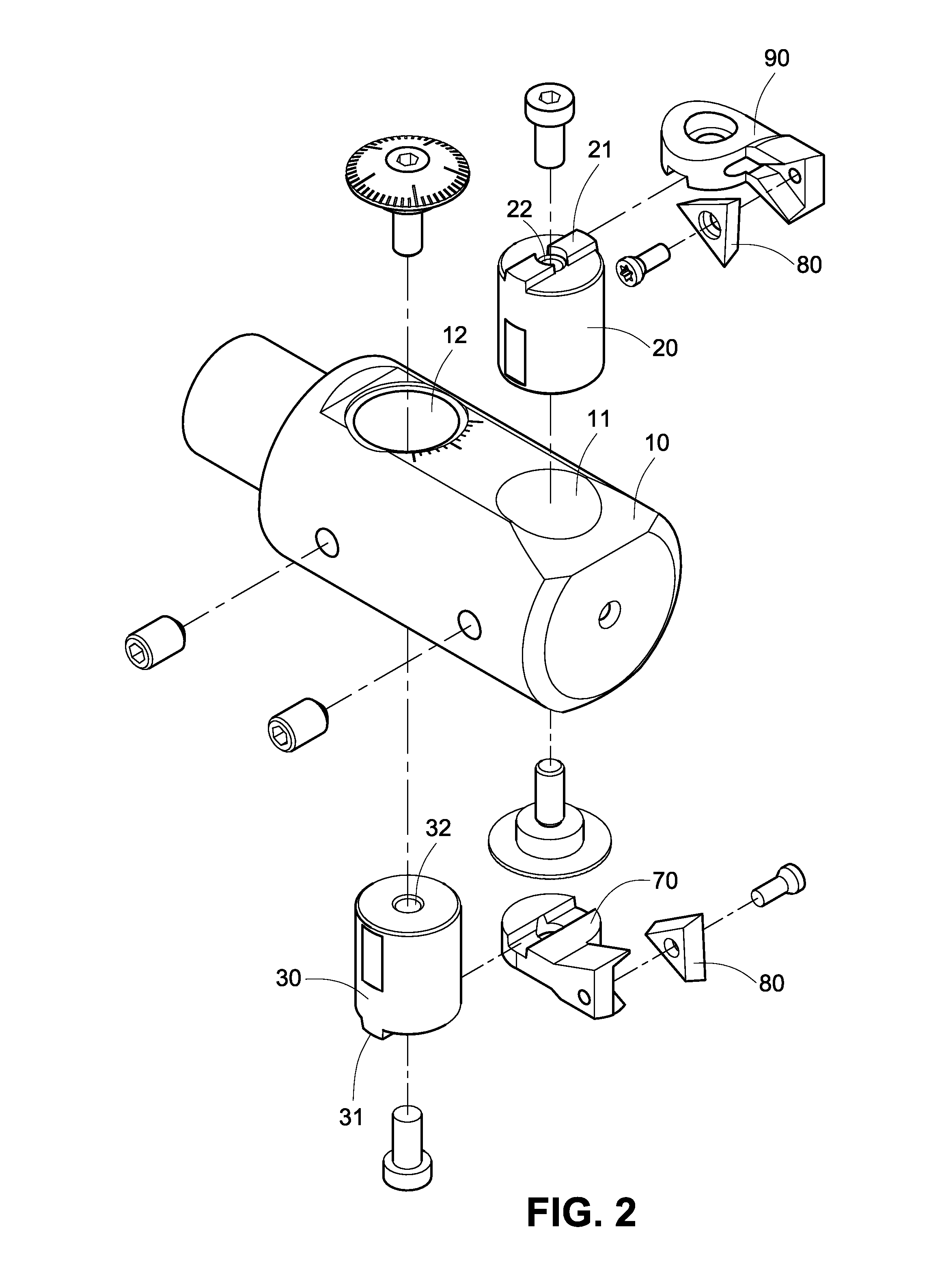

Cutting head for rotary cutting tool

ActiveUS7156588B2Secure retentionThread cutting toolsWood turning toolsEngineeringMechanical engineering

A cutting head for a rotating cutting tool for metal cutting operations. The cutting head has an axially adjustable cartridge which is an integral single piece. A slit divides the cartridge into a clamping portion and a main body portion, the clamping portion being resiliently connected to the main body portion. An insert pocket for retaining a cutting insert is formed by a widening of the slit so that the cutting insert is securely retained in the insert pocket between the main body portion and the clamping portion.

Owner:ISCAR LTD

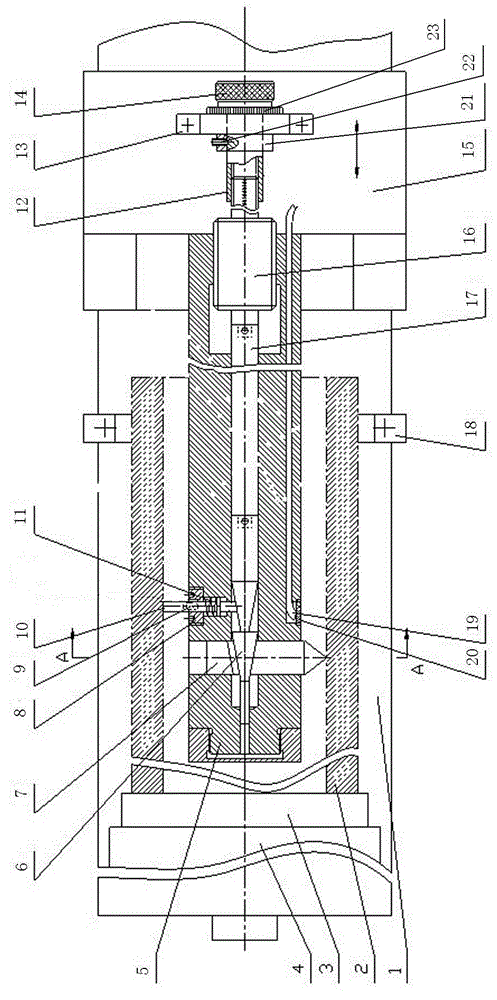

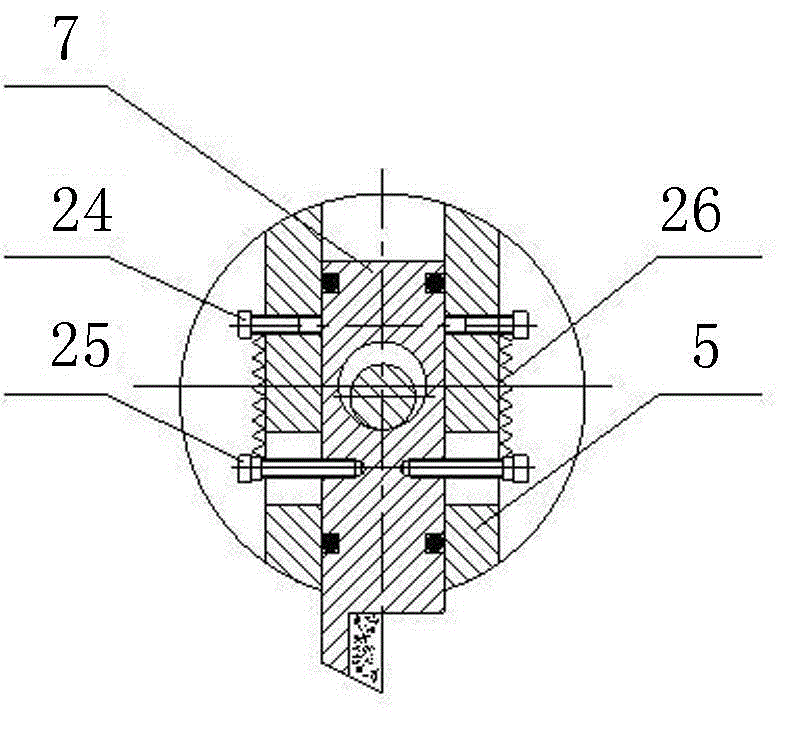

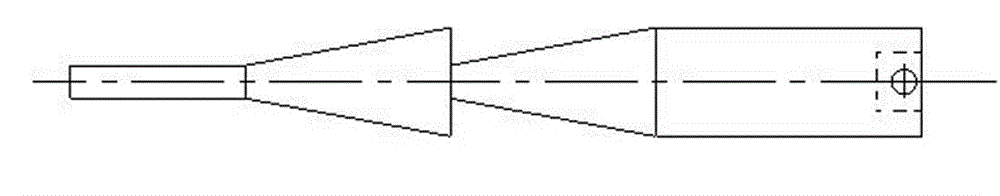

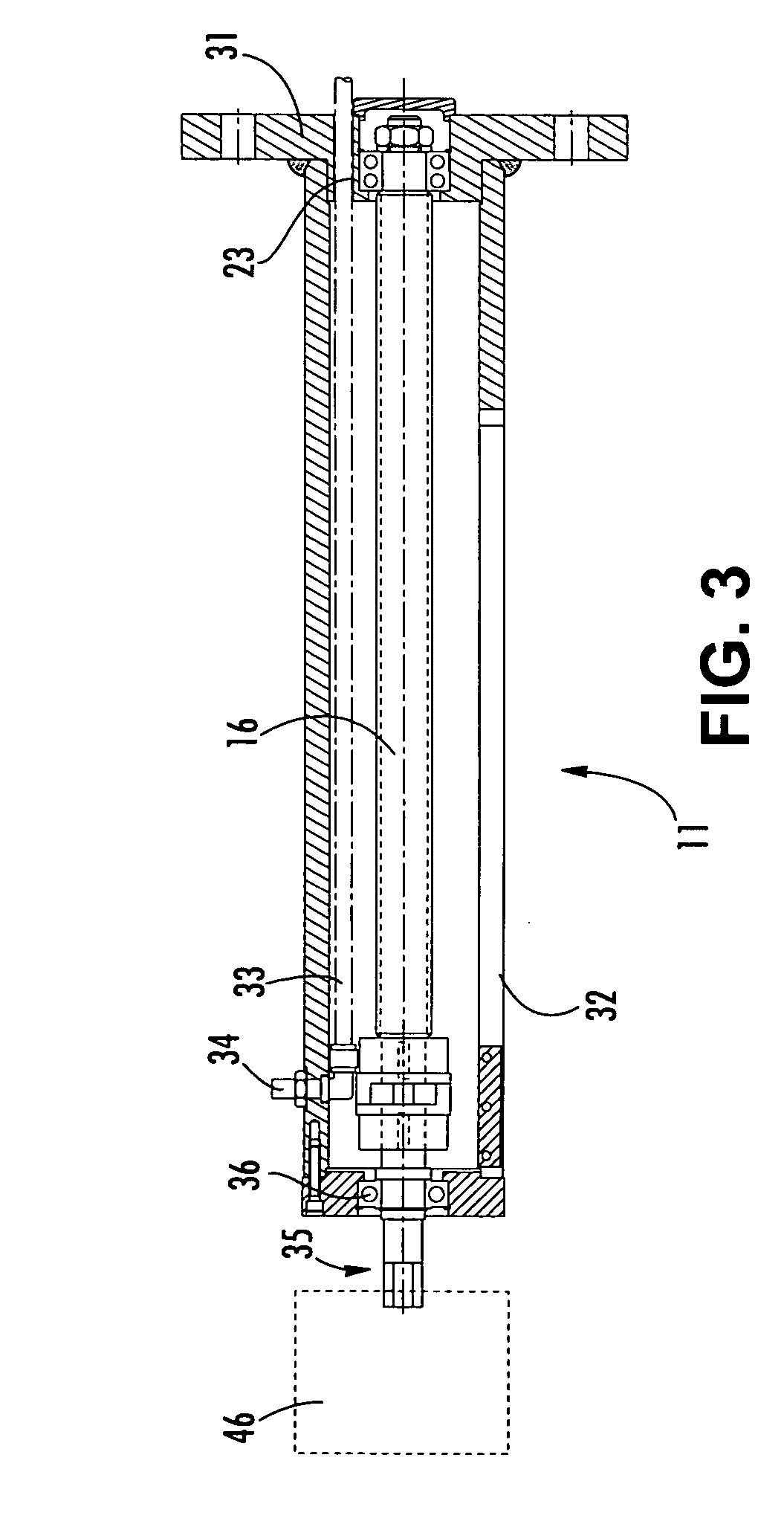

Cylindrical deep hole boring device with auxiliary supporting

ActiveCN102717118AMeet roughness quality requirementsAvoid scratchesBoring barsTool holdersMachined surfacePosition error

The invention relates to a cylindrical hole processing device, in particular to a cylindrical deep hole boring device with auxiliary supporting, which solves the problem that in the machining process of the current cylindrical hole processing device, a cutter can scratch the machined surface during returning, a boring rod is seriously deformed when a hole is deeper, and the shape and position errors of the bored hole is large. The cylindrical deep hole boring device comprises the boring rod and a boring cutter, wherein holes are formed in the axial center and the radial direction of the boring rod, and the boring cutter is installed in the radial hole of the boring rod; a double-cone core rod is arranged in the axial hole of the boring rod; two cone bodies are arranged at the front end of the double-cone core rod, and the tapers of the two cones of the two cone bodies are equal; a floating gripper is also installed on the boring rod; and a tapered hole is formed in the boring cutter, and the axis direction of the tapered hole is parallel to that of the boring rod. The cylindrical deep hole boring device has the beneficial effects that when the cutter returns, the cutter leaves the machined surface to avoid to scratch the surface; the quality requirement of the workpiece roughness is met; the shape and position errors of the bored hole is small; and the boring rod is not easily deformed.

Owner:ZHONGBEI UNIV

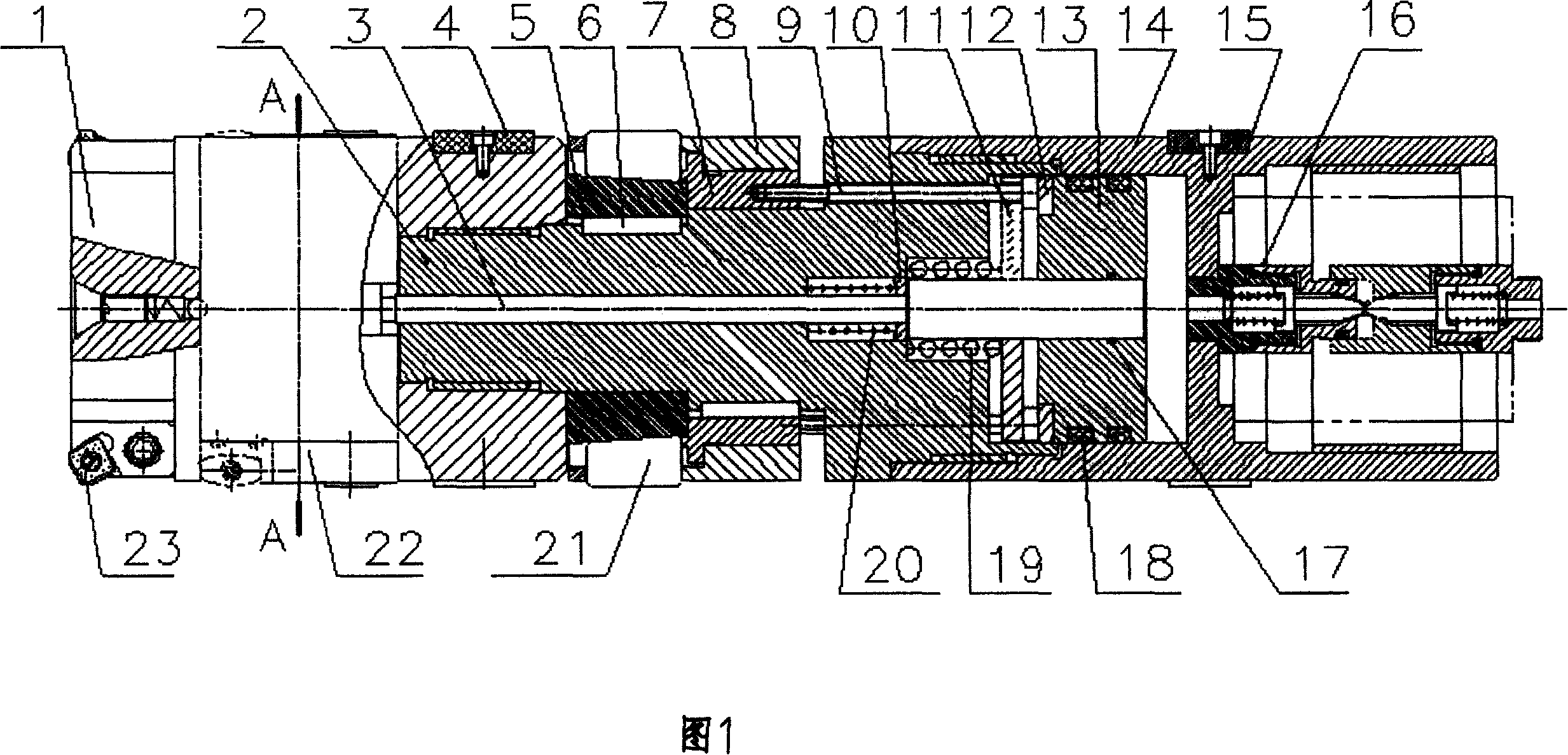

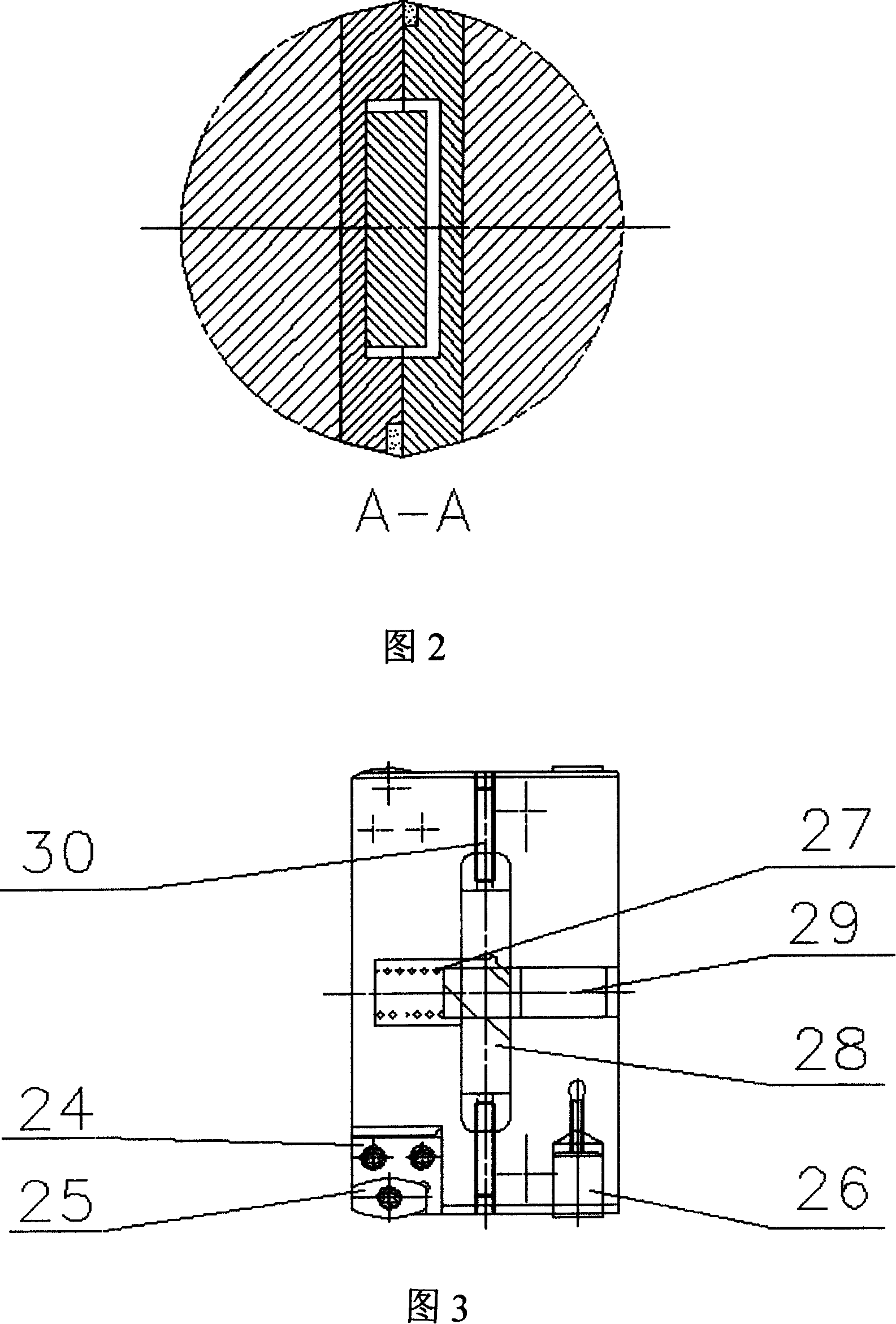

Combined boring head for deep hole

InactiveCN101091995ARealize automatic expansion and contractionReduce auxiliary timeTurning toolsTool holdersEngineeringPiston

The invention relates to a deep hole compound bore rolling head that has bore identity at left, connecting cutting tool in the middle and joint at right. The jogger is installed in the middle of connecting blade and big piston. Rollers are distributed around connecting cutter body on the right of bore identity. The right side of connecting cutter body has supporting disc installing on jogger. Bit piston is on the right side of supporting disc, and direction guiding block is installed on the joint outer circle. The rapid oil joint is installed in the joint. The upper and down half finish boring knife is installed on the left of bore identity. Two rectangle finish boring knife is installed on the left bore identity. The structure could make the efficiency to be 3-5 times of traditional deep hole machining cutting tools. And it has the advantages of high accuracy, high stability, compact structure, etc.

Owner:德州德隆(集团)机床有限责任公司

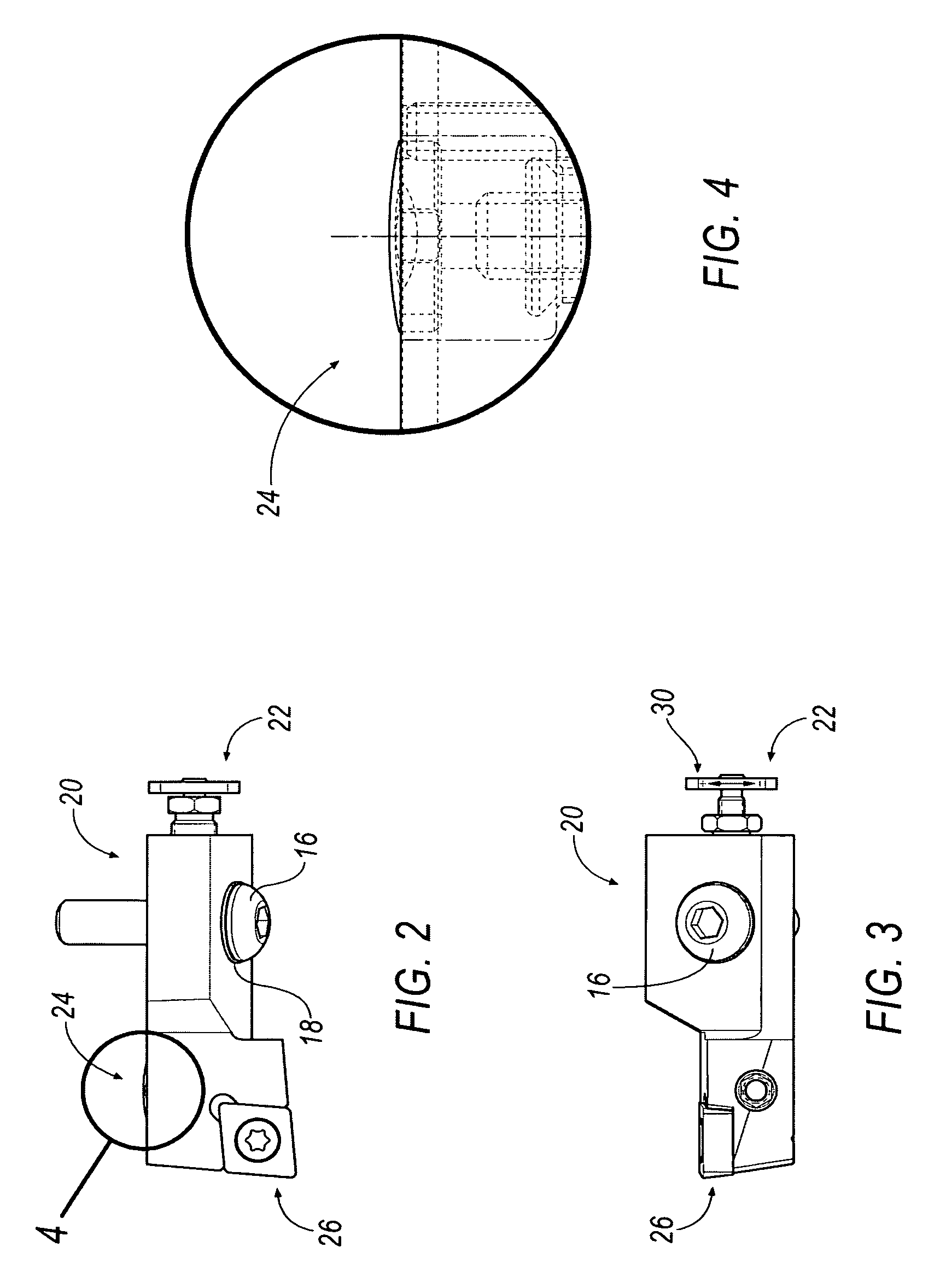

Micro-adjustable differential screw assembly

A micro-adjustable differential screw assembly for providing fine adjustment of the axial and / or radial position of a cutting insert is disclosed. The micro-adjustable differential screw assembly can be mounted directly to a boring bar or to a mounting cartridge, which in turn, can be mounted to the boring bar. An axial micro-adjustable differential screw assembly provides fine adjustment of an axial position of the cutting insert, while a radial micro-adjustable differential screw assembly provides fine adjustment of a radial position of the cutting insert. The differential screw assembly includes a rotatable drive screw with threads of different thread pitches, and a non-rotatable adjusting screw with threads for mating with the drive screw. The difference in the thread pitches of the drive screw causes a greatly reduced axial and radial movement of the boring cartridge in relation to the relative movement of the drive screw, thereby providing fine adjustment in the axial and radial position of the cutting insert.

Owner:KENNAMETAL INC

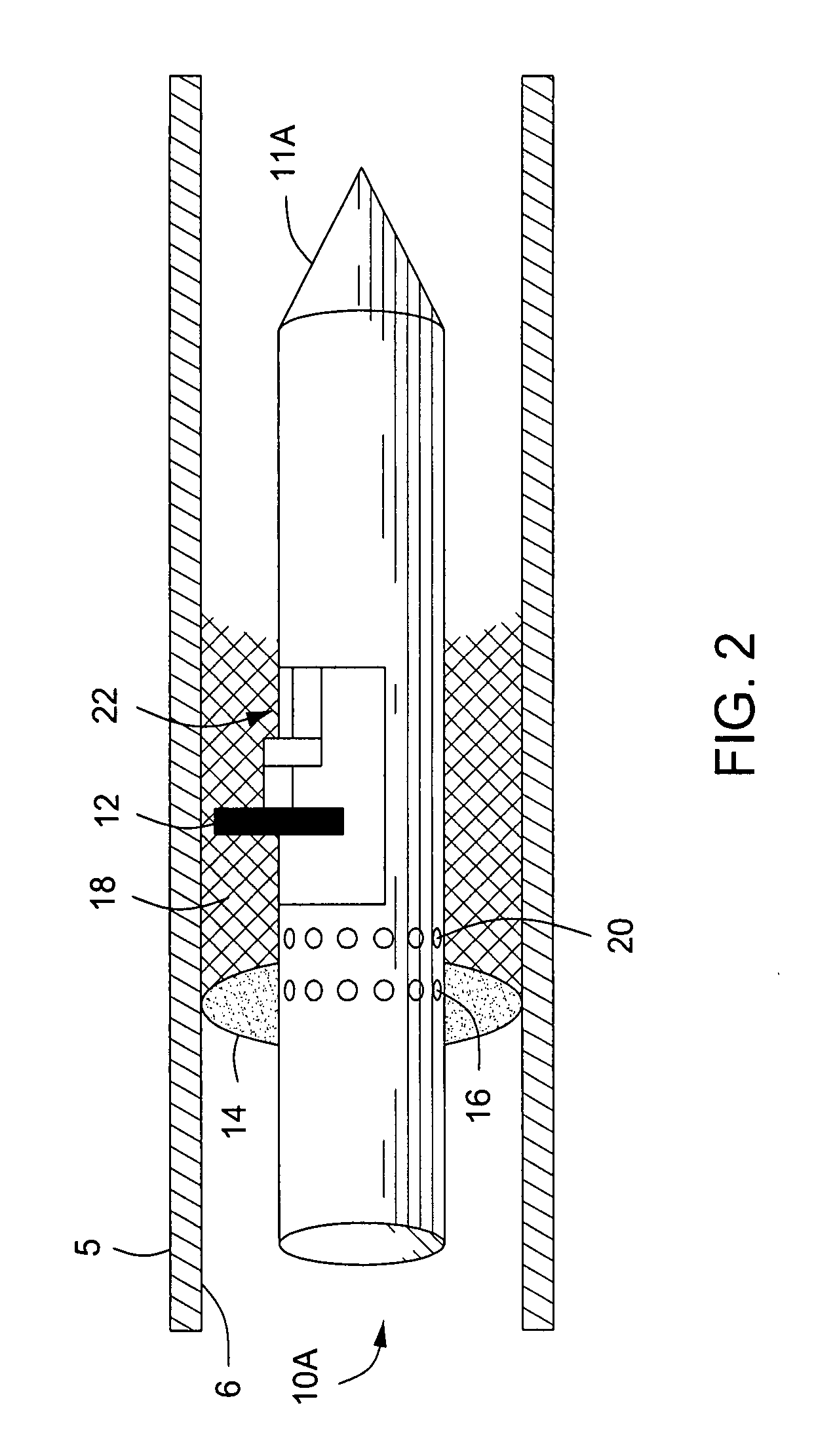

Optimized machining process for cutting tubulars downhole

Owner:BAKER HUGHES INC

Method for indexing a rotating tool and a tool for machining

A method of indexing a rotating cutting tool, and a tool for machining. The tool comprises a body, and one or more cutting parts, of which cutting parts at least one can be moved relative to the body at least into a first position and a second position. The cutting part is locked into the indexed positions by means of a pressure medium operated actuator.

Owner:MANDREL OY

Combination tool

InactiveUS7089837B2Increase cutting forceReduction of anti-penetration actionThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

Owner:KOMET GROUP GMBH

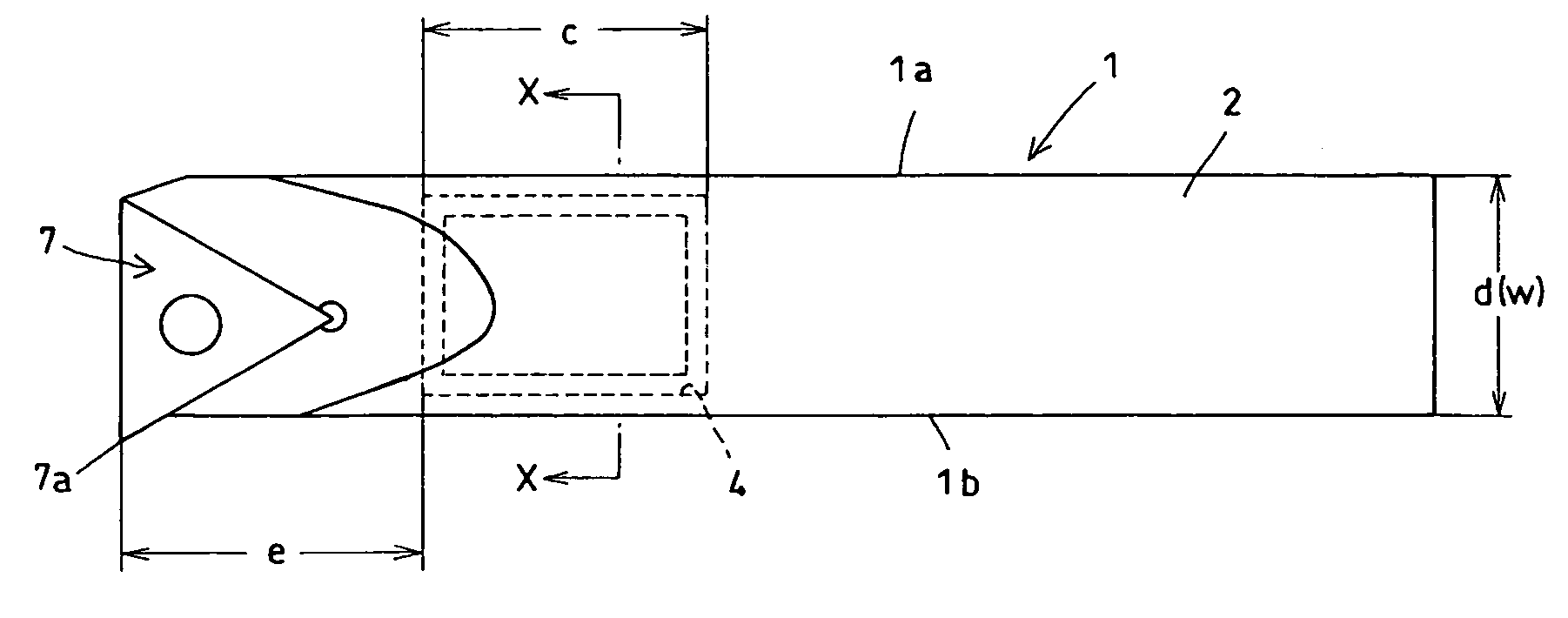

Tool for machining pipe ends

InactiveUS6957936B2Avoid disadvantagesIncrease valueThread cutting toolsTransportation and packagingBlade plateEngineering

A tool for removing material or machining the end of a pipe. The tool having at least one and preferably two blade plates. Each blade plate includes a first cutter for machining an end surface of the pipe, a second cutter adjacent the first cutter for producing an internal chamfer in the pipe end and a third cutter adjacent the first cutter positioned for producing an external chamfer adjoining the end surface of the pipe end. Devices guide and permit movement of the cutters either radially or axially. The shaping of the cutter is disclosed.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

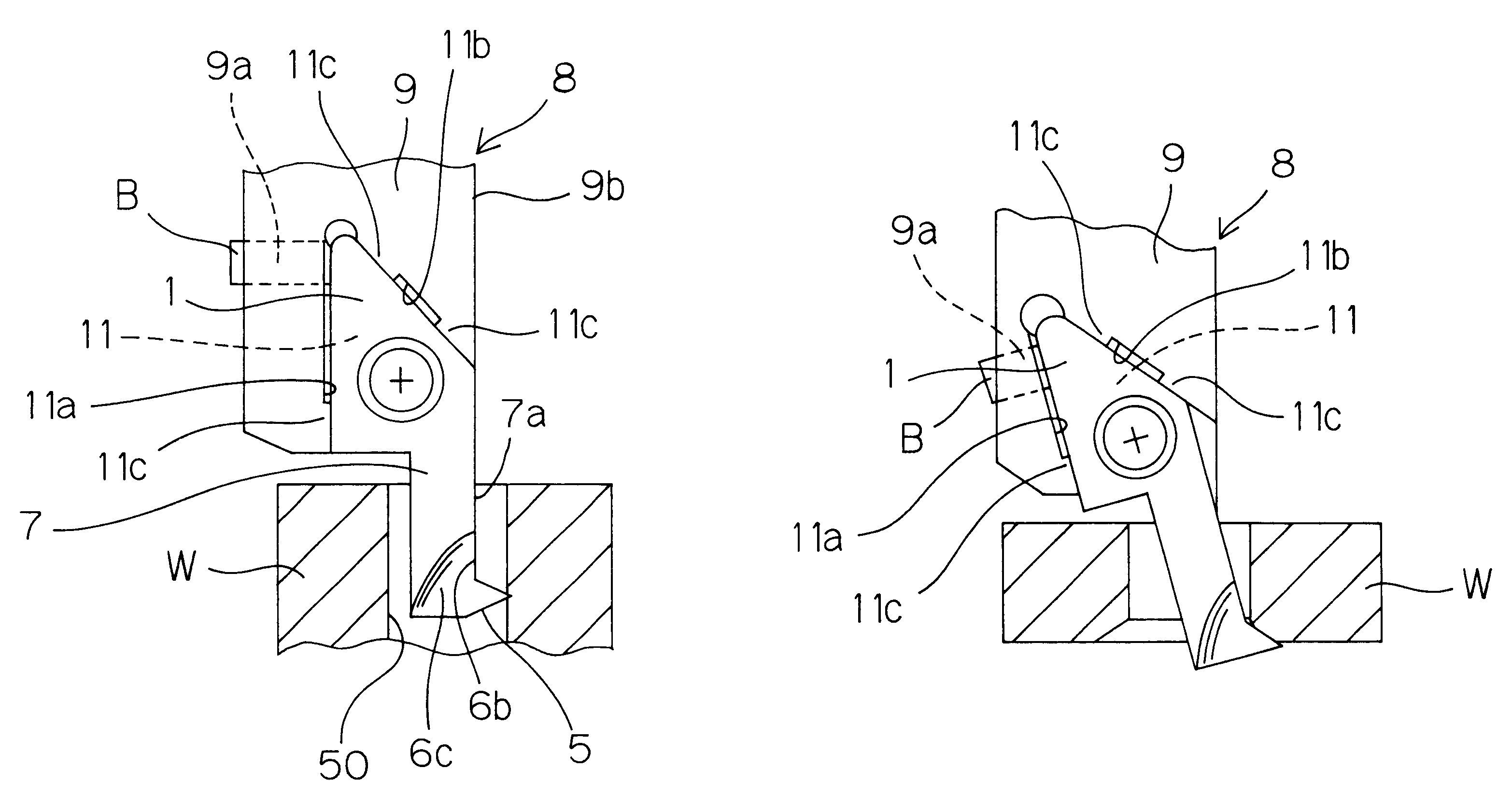

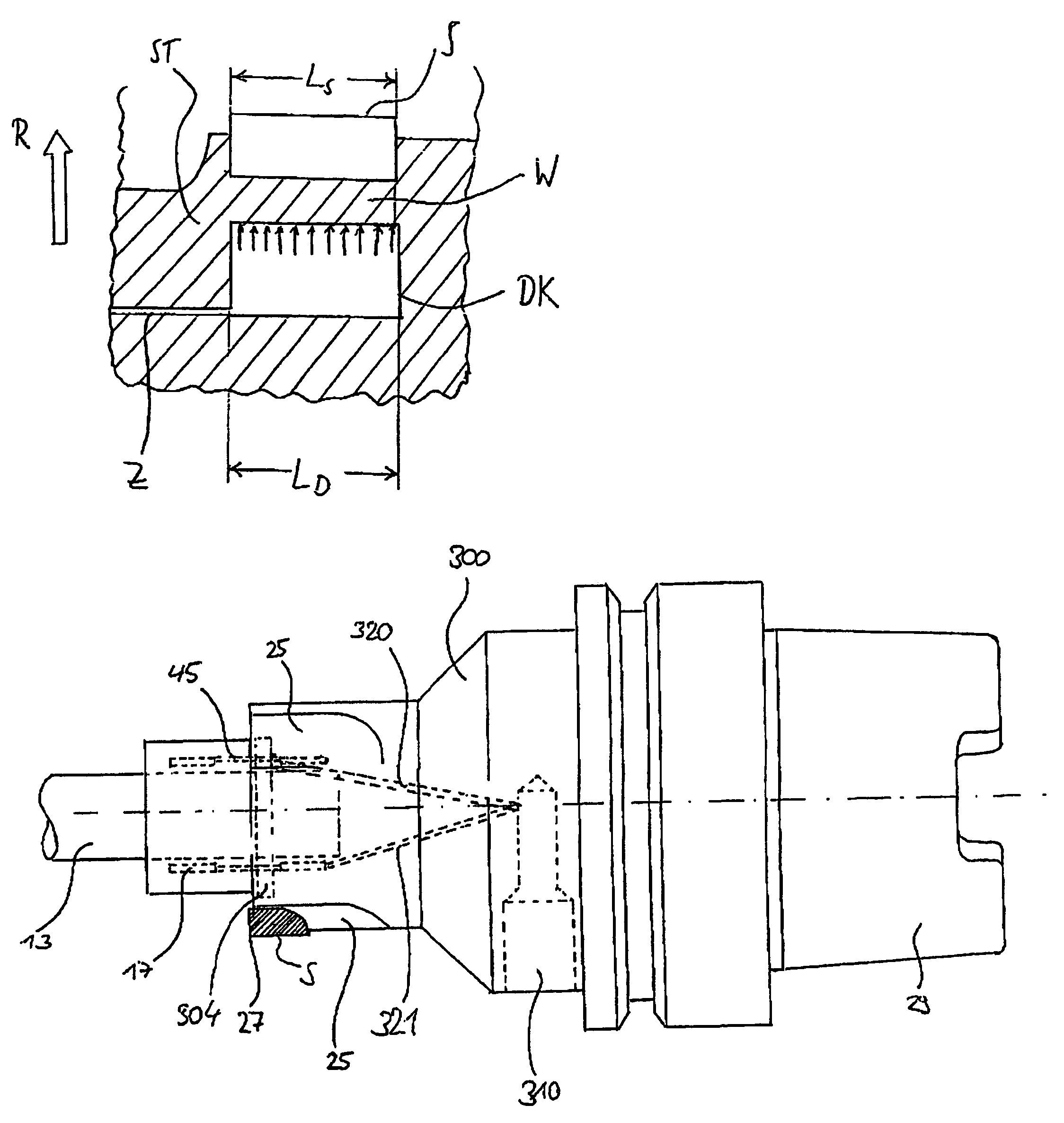

Indexable insert and cutting tool having indexable insert

InactiveUS6244789B1Easy to disassembleEasily attached to holderTurning toolsBoring headsEngineeringKnife blades

The indexable insert of the present invention has a cutting edge at the end of a stick-shaped portion projecting from a tool base. The base is shaped to ensure effective clamping, thereby avoiding chatter and backlash. A cutting edge and a rake face are provided at the end of the stick-shaped portion, which is also provided with a side relief face so that chips cut from the workpiece are smoothly carried away. The cutting edge extends sideways beyond the side relief face so that the insert can effectively cut the walls of small and deep holes.

Owner:KYOCERA CORP

Micro-adjustable boring bar

InactiveUS20050074305A1Improve practicalitySimple procedureThread cutting toolsTransportation and packagingDynamic balanceEngineering

The present invention provides a micro-adjustable boring bar, which includes boring bar body and an adapter, wherein said adapter has a micro-eccentric bore set upon one end for plugging in the boring bar body with the pivoting shaft, and a V-shaped ring groove is built upon the proper position of said pivoting shaft of the boring bar body, coordinating to said V-shaped ring groove, the adapter has a securing threaded hole and a locating threaded hole built on, therein said securing threaded hole is built on opposite side of the eccentric side of the micro-adjustment bore, said locating threaded hole is used to hold an elastic limiting block in, by securing the screw in, the elastic limiting block can generate an upward elastic force to push the pivoting shaft of boring bar body upward to touch against the adapter more tightly and improve the combined assembly's rigidity; by means of the eccentric design, turning the boring bar body in the micro-adjustment bore of the adapter can move the tip end of the cutter tool to change the boring size of the hole in positive or negative for increasing or decreasing the size of boring hole, and whatever turning the boring bar body in which direction for micro-adjusting, the dynamic balance will be kept in constant without any resetting dynamic balance.

Owner:CHANG

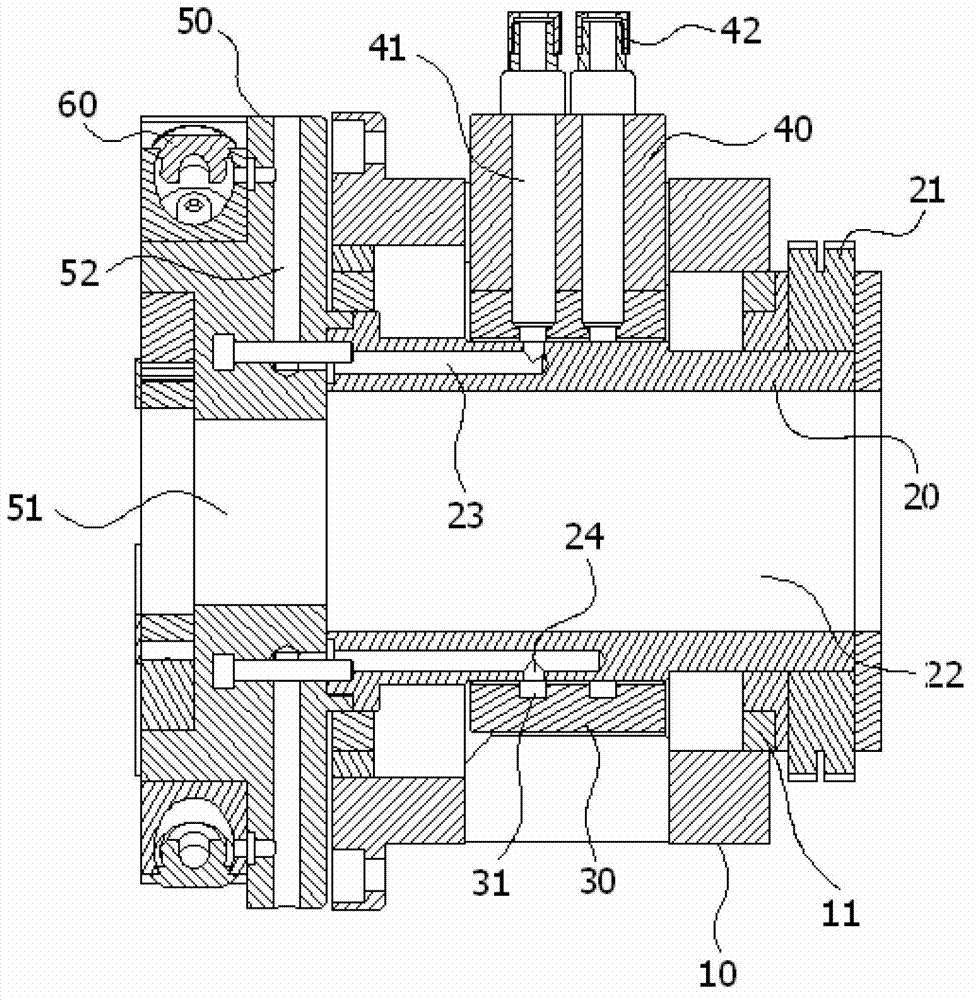

Rotary cutting machine

InactiveCN103203502AIncrease speedReduce frictional resistanceBoring headsMetal working apparatusMachineFriction force

The invention discloses a rotary cutting machine. The rotary cutting machine comprises a spindle jacket with an inner cavity, a spindle rotor, a slip ring, a rotary disc, oil cylinders and rotary cutters, wherein the spindle rotor is mounted in the inner cavity and provided with a first hollow channel extending from the rear end to the front end, a gap is reserved between the spindle rotor and the spindle jacket, and second oil ways are arranged in the spindle rotor, the slip ring is sleeved on the periphery of the spindle rotor and provided with a groove which extends circumferentially and communicated with the second oil ways, gaps are reserved between the slip ring and the spindle rotor as well as between the slip ring and the spindle jacket, a press block is connected with the slip ring via bolts, first oil ways are arranged in hollow interiors of the bolts, oil nozzles are mounted at the upper ends of the bolts, the first oil ways are respectively communicated with the oil nozzles and the groove, the rotary disc is provided with third oil ways communicated with the second oil ways, the oil cylinders are mounted on the rotary disc, oil ports of the oil cylinders are communicated with the third oil ways, and the rotary cutters comprise supports and cutting tools. During use, the spindle rotor of the rotary cutting machine is supported by hydraulic oil to be free of contact with the spindle jacket and the slip ring, so that friction force is reduced, rotating speed is increased, cutting speed is high, and efficiency is high.

Owner:帅家园 +1

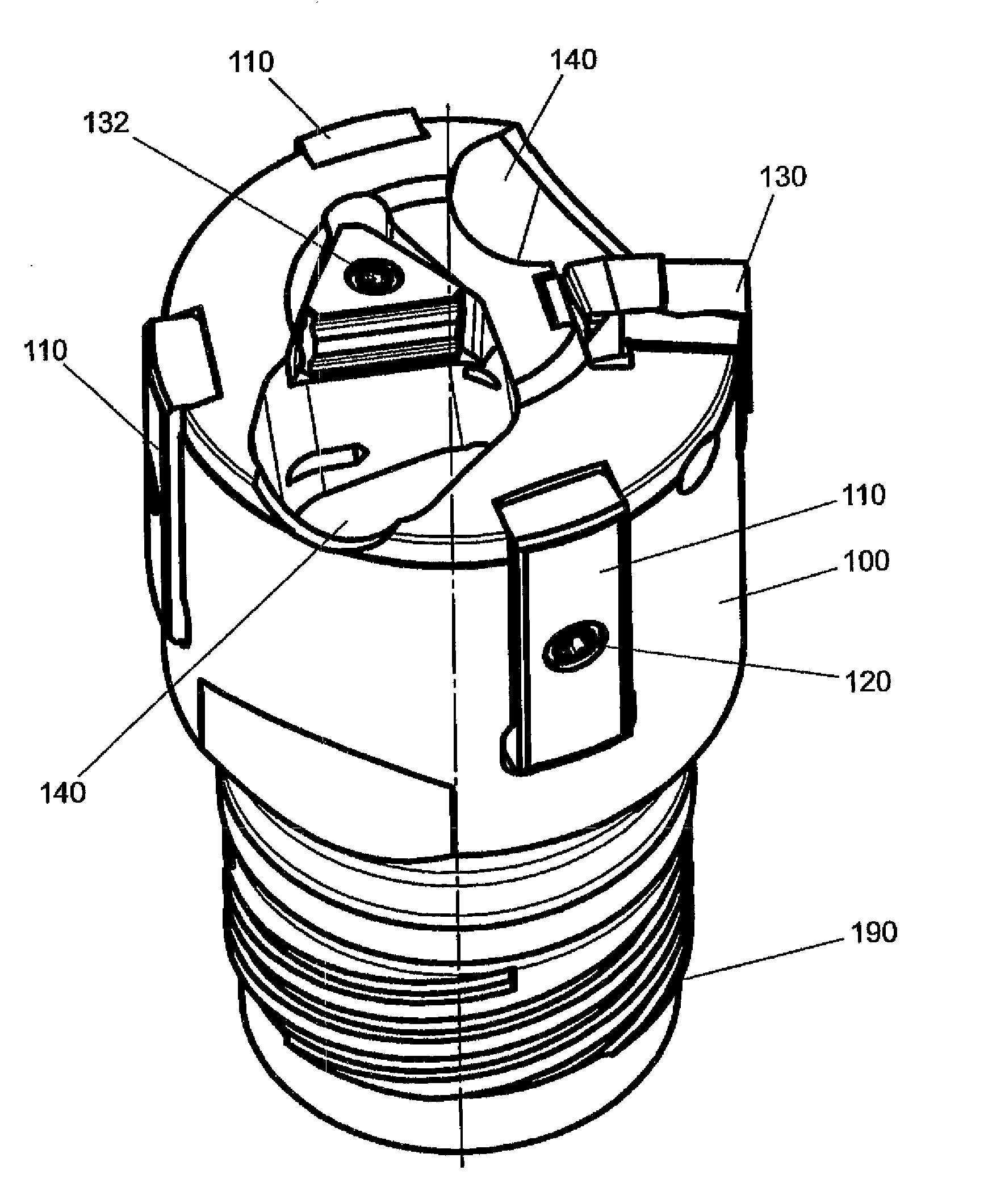

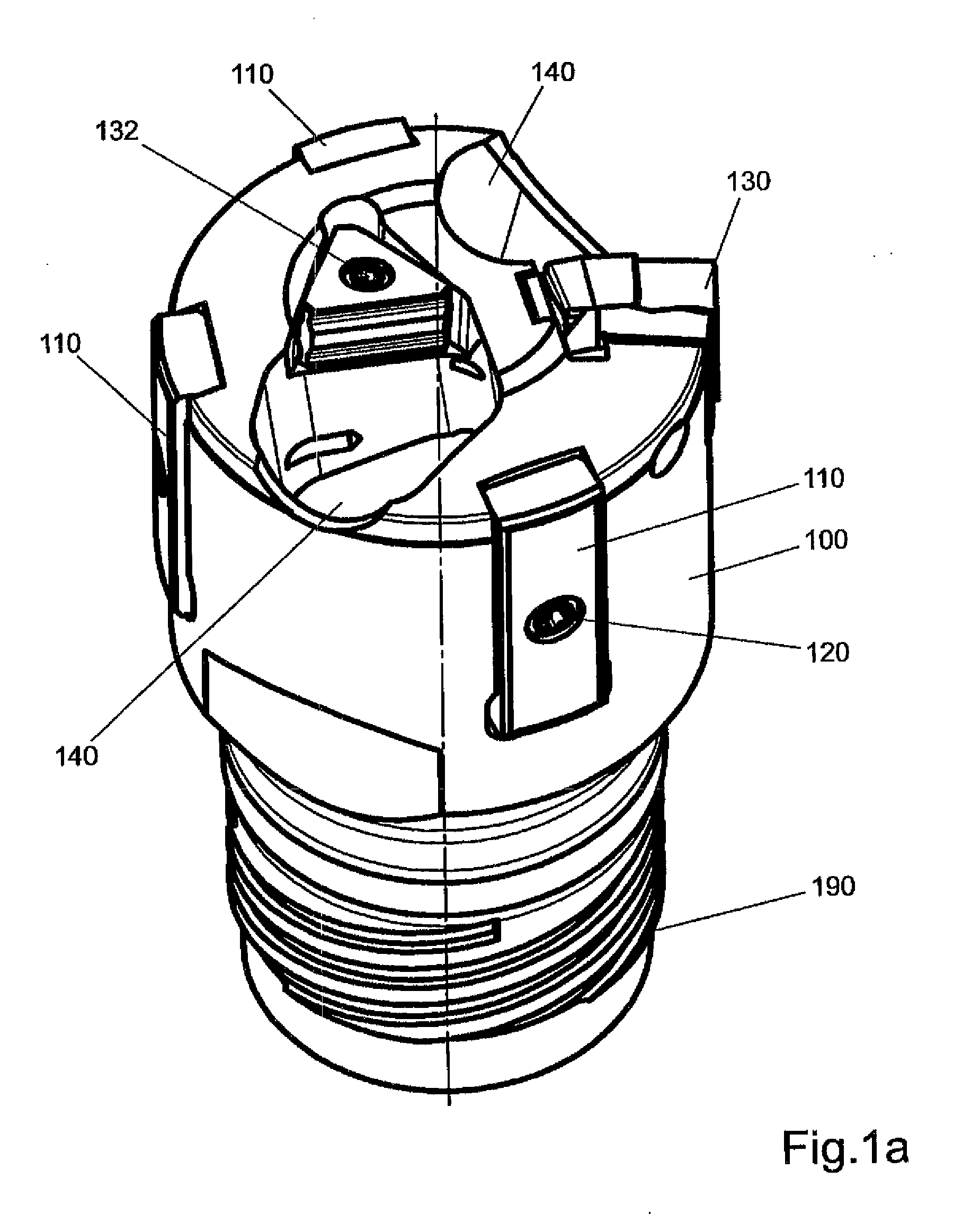

Cutting head for rotary cutting tool

ActiveUS20050019118A1Secure retentionThread cutting toolsTransportation and packagingEngineeringMetal cutting

A cutting head for a rotating cutting tool for metal cutting operations. The cutting head has an axially adjustable cartridge which is an integral single piece. A slit divides the cartridge into a clamping portion and a main body portion, the clamping portion being resiliently connected to the main body portion. An insert pocket for retaining a cutting insert is formed by a widening of the slit so that the cutting insert is securely retained in the insert pocket between the main body portion and the clamping portion.

Owner:ISCAR LTD

Tool with selectively-biased member

A tool for working a workpiece has a slot provided between a pair of extremities at its distal end. The extremities have cutting blades mounted thereon. The slot is configured to receive a plate. The tool has a conduit running along its axis for communication of pressurized fluid to the slot and plate. The plate directs flow of the pressurized fluid outward toward the extremities. The resulting outward force causes the extremities to bend outward, thereby urging the cutting blades outward for cutting, reaming, or other working of the workpiece. The resilience of the tool causes the extremities to return back inward when the fluid pressure is reduced. A plate may be configured to receive a wafer for transferring force from the pressurized fluid to the extremities.

Owner:MAKINO MILLING MASCH CO LTD

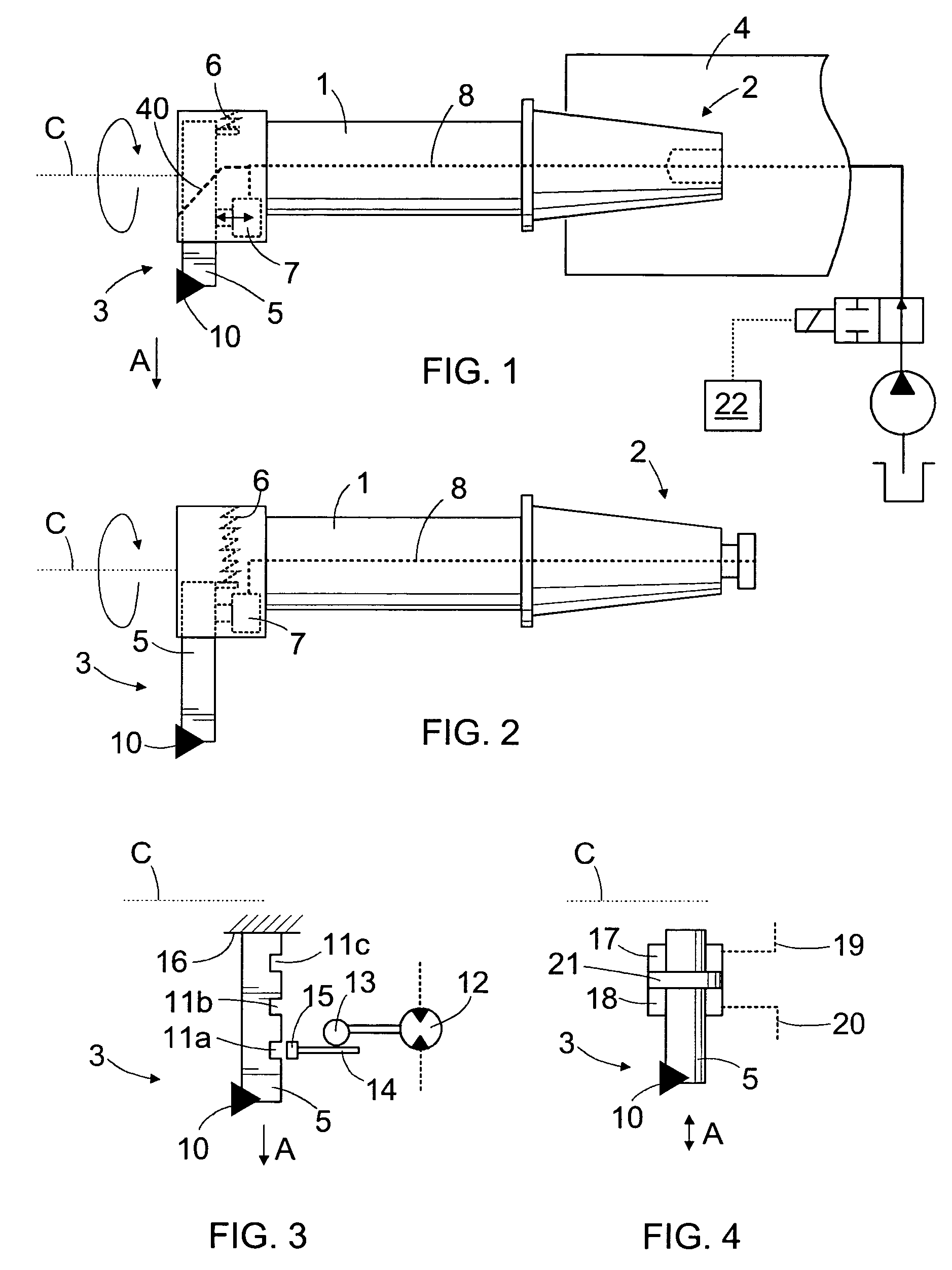

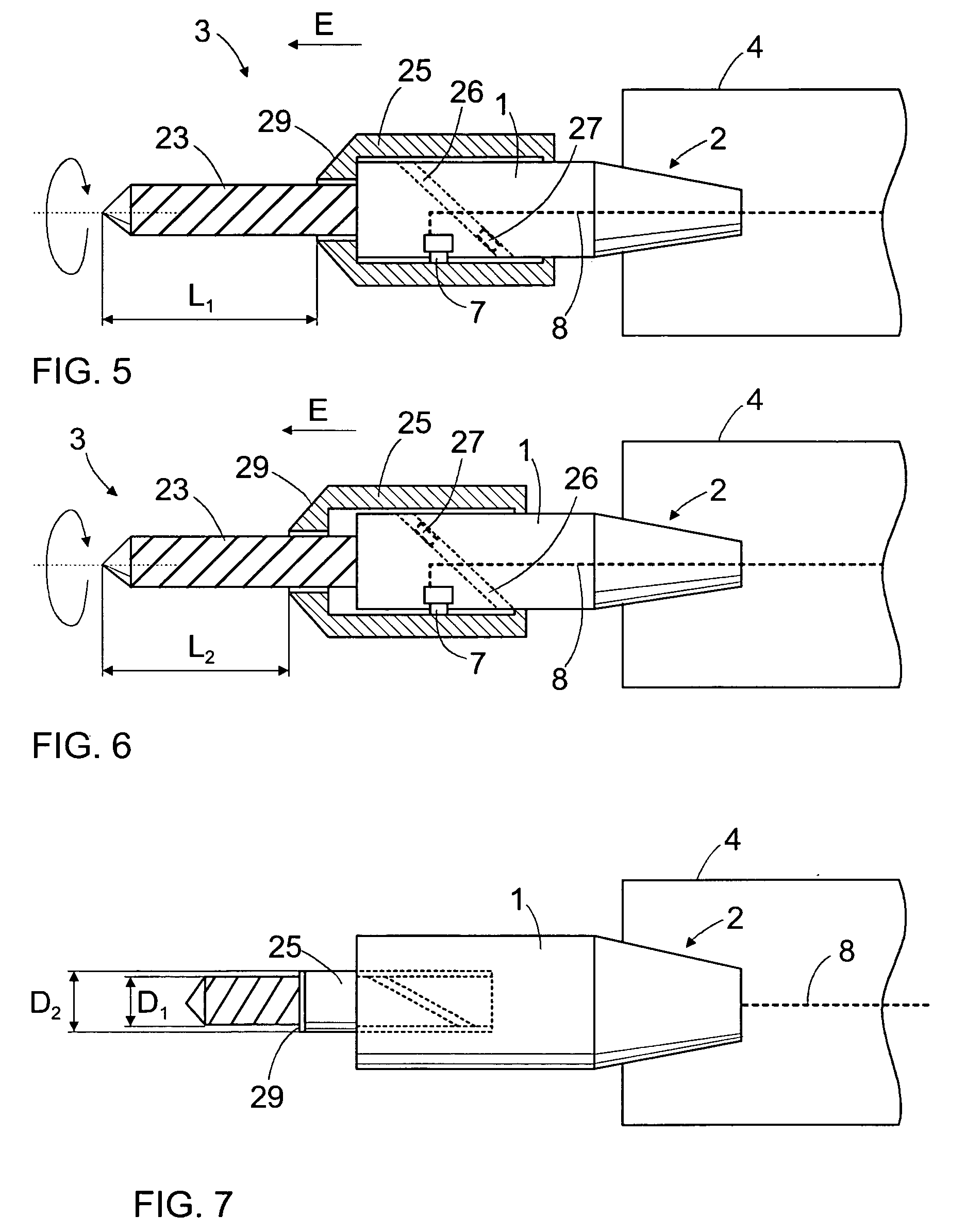

Slidable boring tool with fine adjustment

Methods and apparatus for fine adjustment of the position of the cutting tool. In one embodiment, a boring tool includes a coupling member driven by a CNC boring machine, a cutting tool which is slidably coupled to the coupling member, and a slidable adjustment member. A frictional force resists sliding movement of the cutting tool. The frictional force is sufficient to retain the position of the cutting tool during machining operations. However, the frictional force is insufficient to resist an adjusting force applied by the adjustment member. Sliding motion of the adjustment, either by pulling or pushing it, results in movement of the cutting tool. In one embodiment, the cutting tool and the adjustment member are slidable in different directions. In another embodiment, the boring tool is adapted and configured to convert a first, greater amount of movement by the adjustment member to a second, lesser amount of movement by the cutting tool.

Owner:CARDEMON INC D B A CAR TEC +1

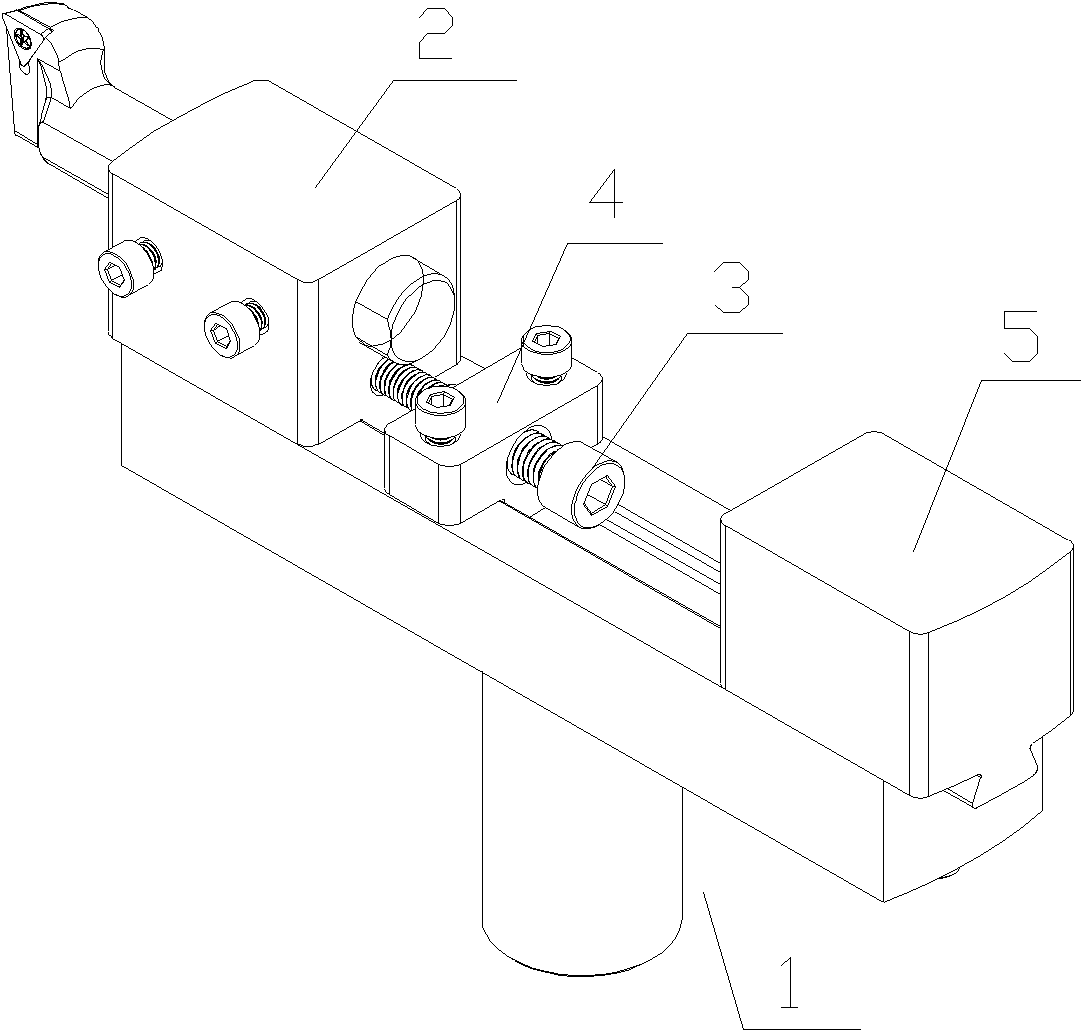

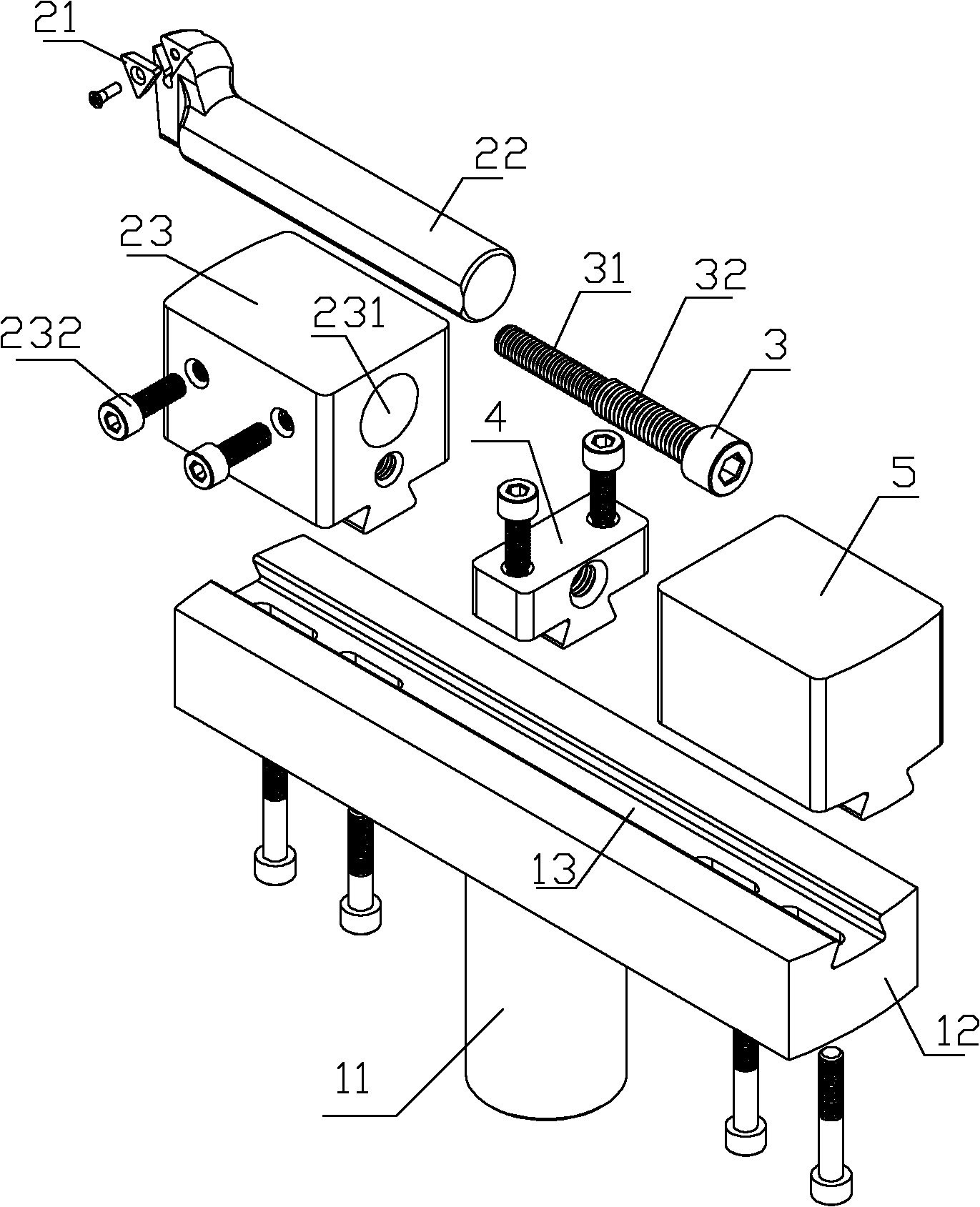

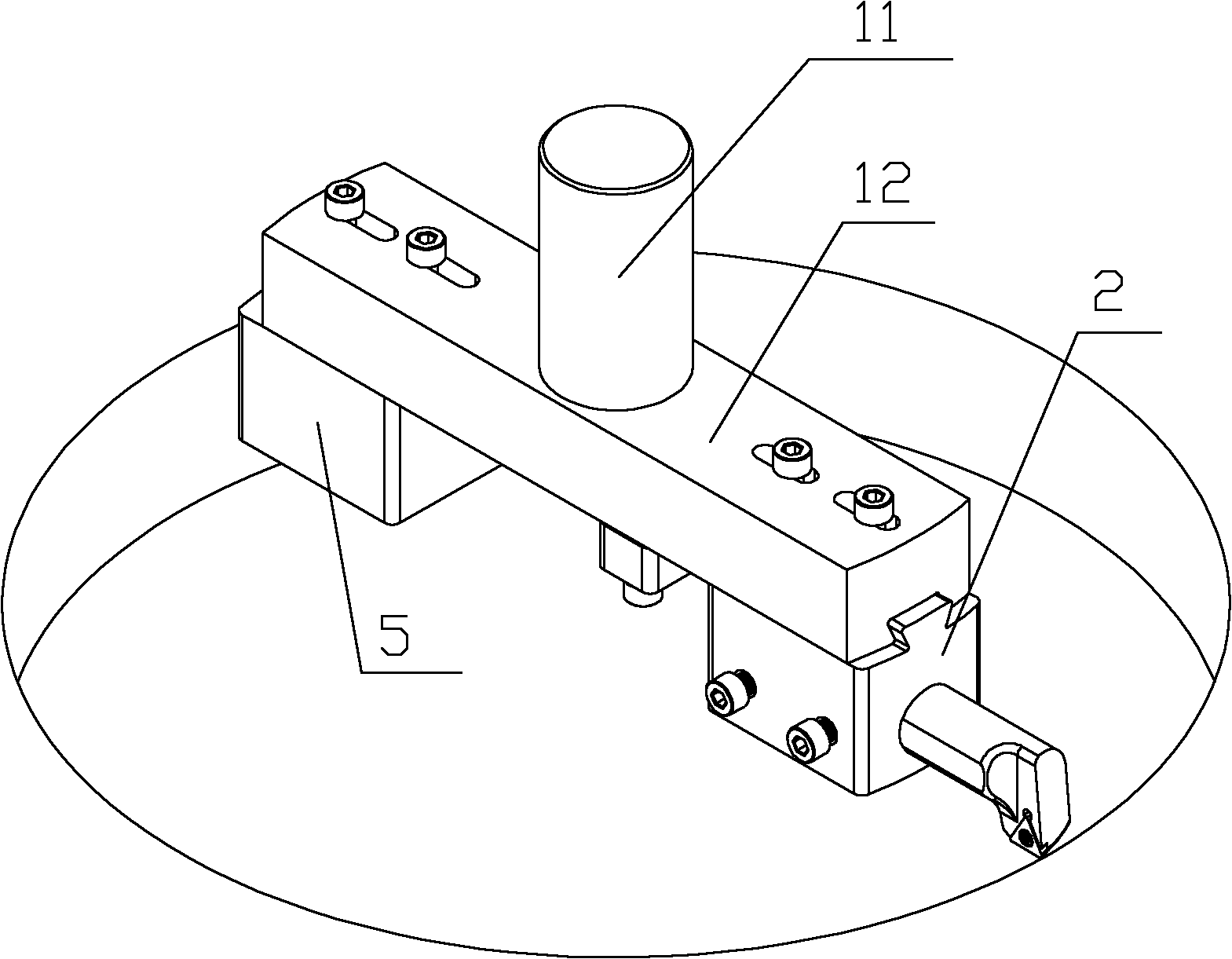

Large-pore diameter precision boring tool for machining center

InactiveCN102069202AGuaranteed uptimeImprove machining accuracyTurning toolsBoring headsEngineeringMachining

The invention discloses a large-pore diameter precision boring tool for a machining center. The tool comprises a T-shaped base, an adjustable boring head mechanism provided with a boring cutter, an adjusting screw linked with the adjustable boring head mechanism, and a screw seat provided with the adjusting screw, wherein the T-shaped base consists of a vertical rod part connected with the machining center and a transverse rod part provided with the adjustable boring head mechanism; a guide groove allowing the adjustable boring head mechanism to slide upwards is formed on the transverse rod part; the adjustable boring head mechanism is connected with the transverse rod part through a screw; an adjusting screw rod is inserted into the adjustable boring head mechanism so as to push the mechanism to move back and forth; and the adjusting screw rod passes through the screw seat. The boring tool has the advantages of simple structure and high machining accuracy.

Owner:NINGBO HONGDA MOTOR DIE

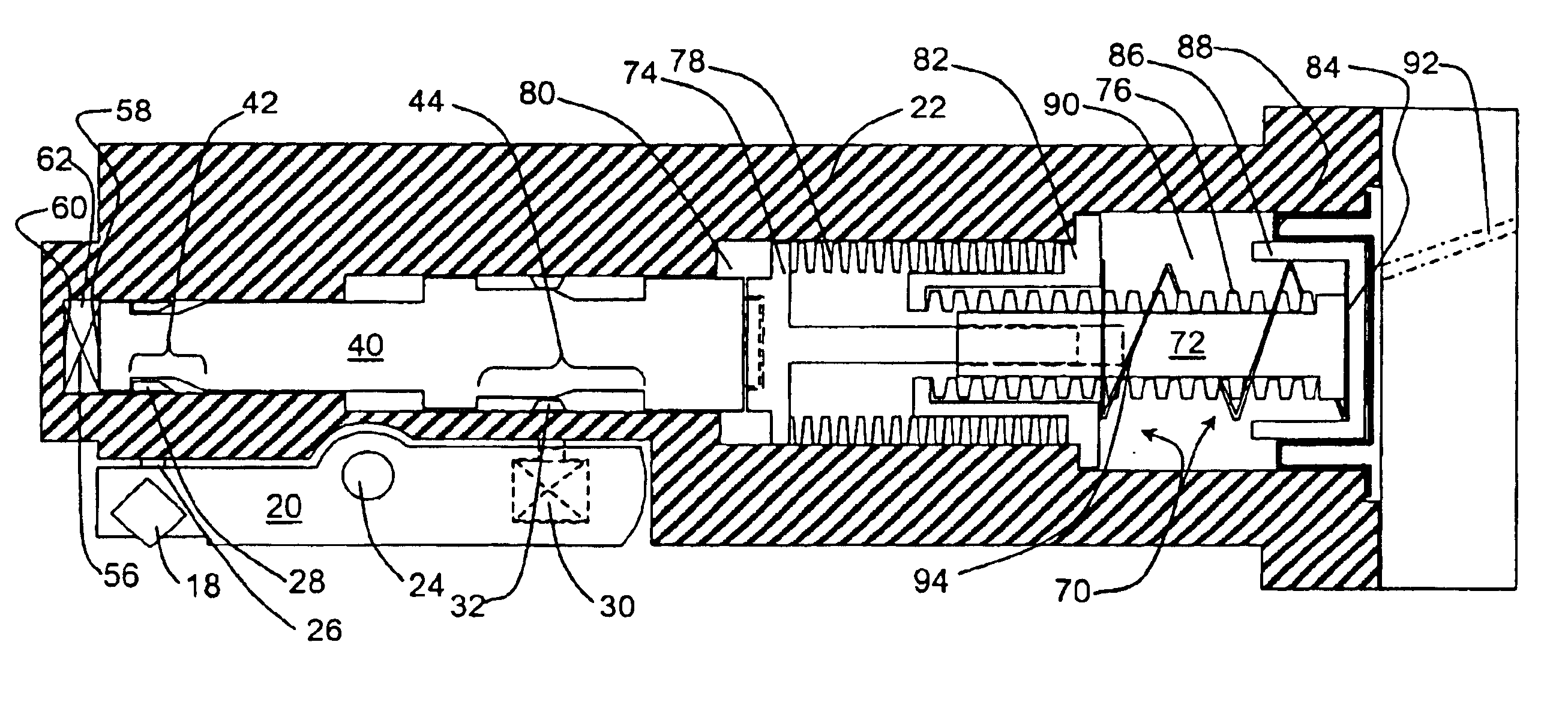

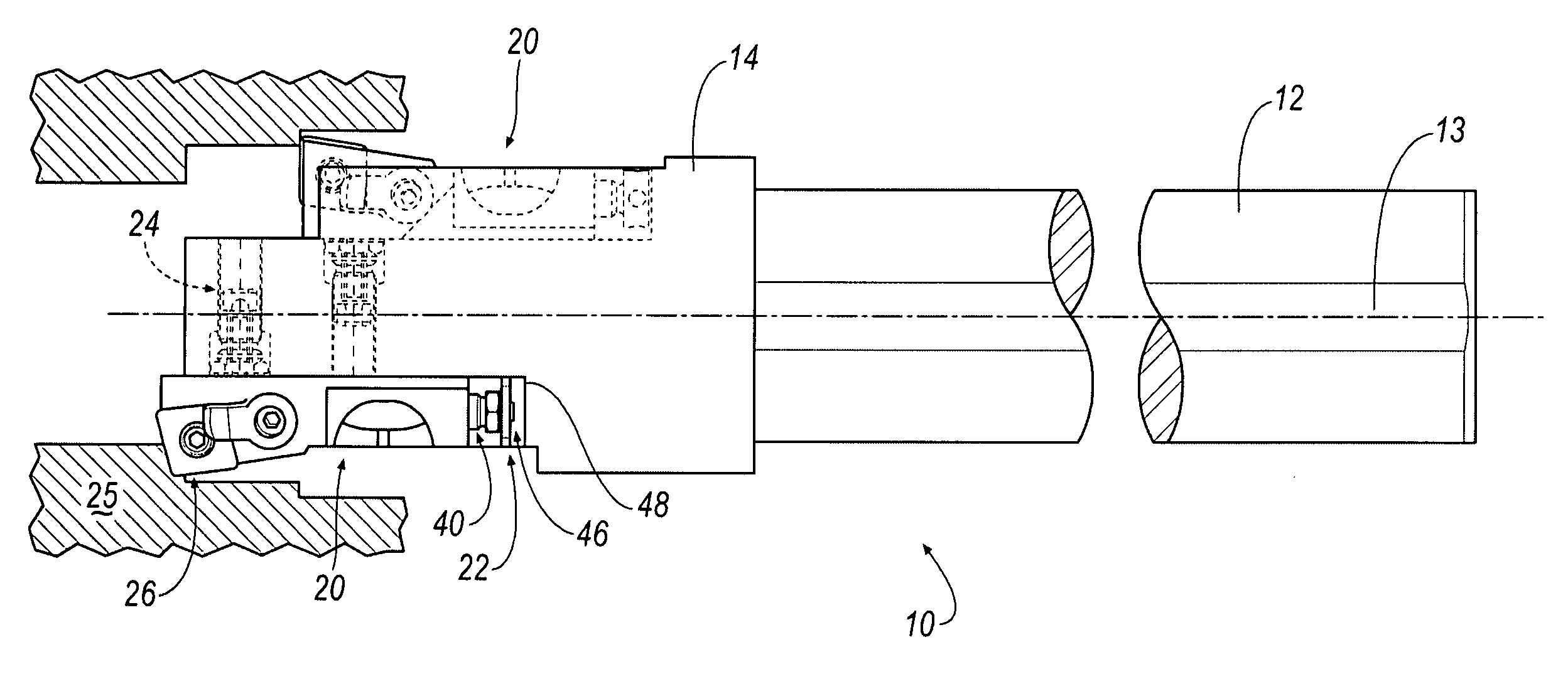

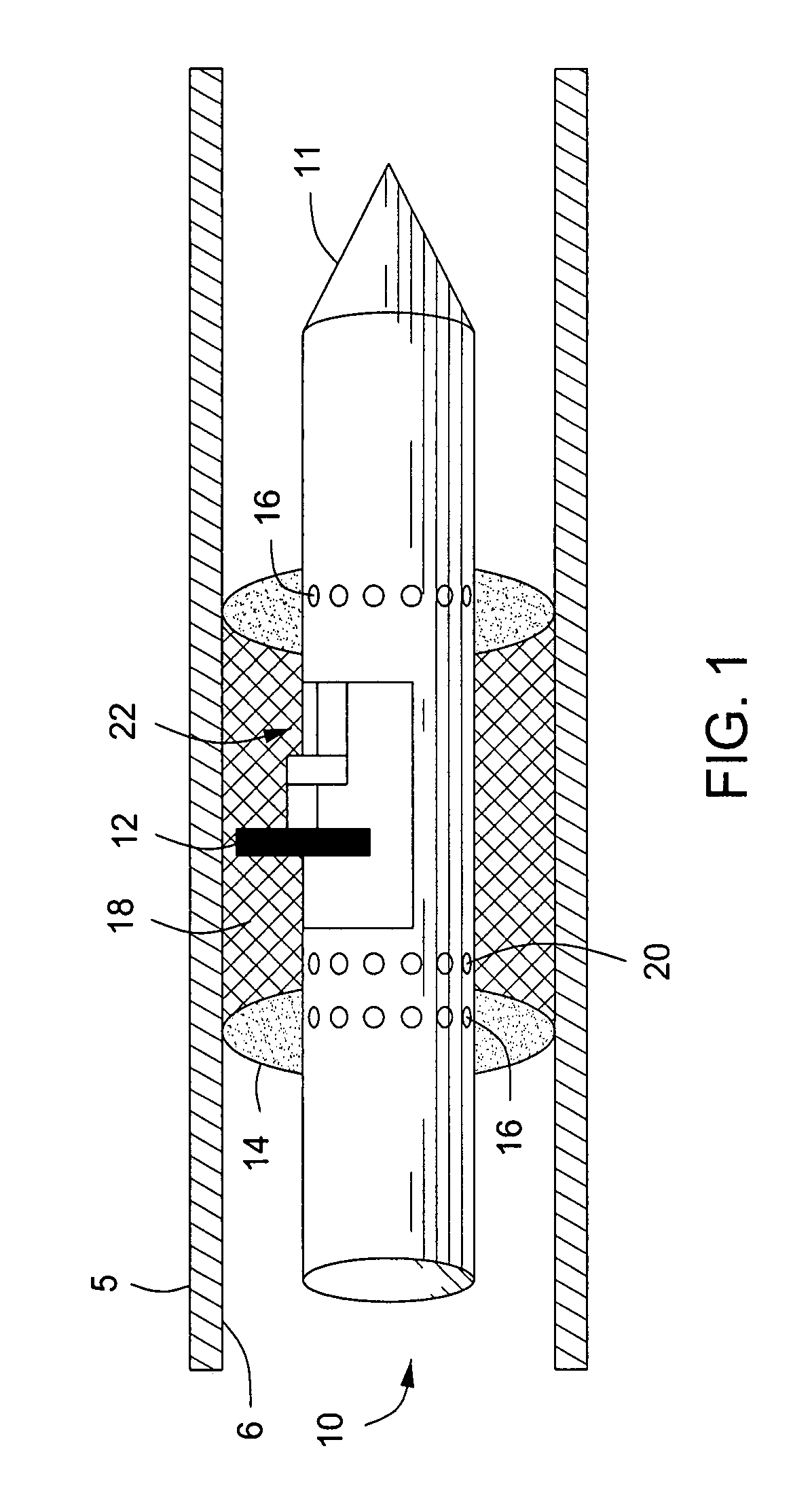

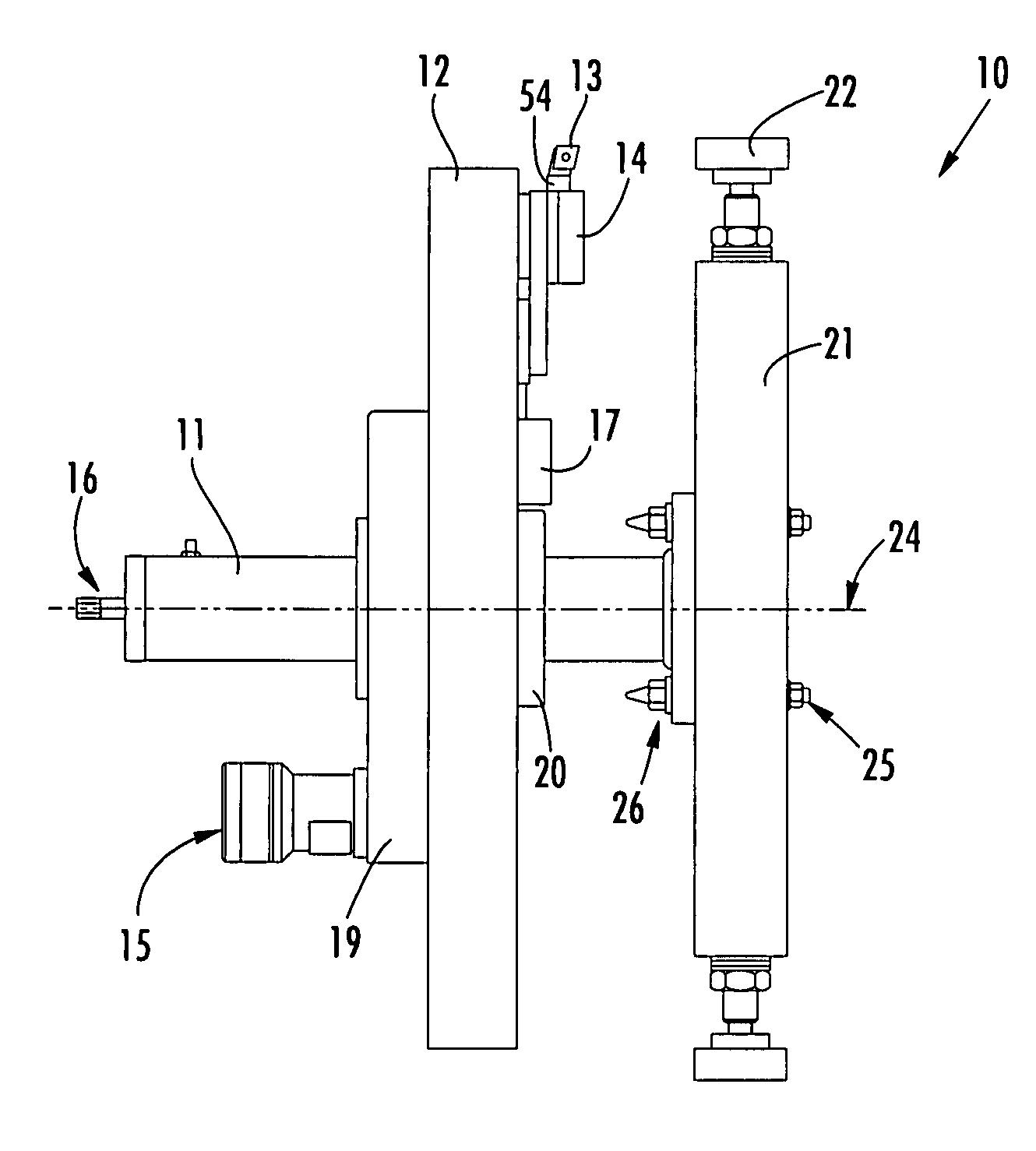

Automated boring bar

InactiveUS20050204879A1Eliminate inaccuraciesReduce dependenceBoring barsBoring headsGear systemEngineering

The present invention relates to an improved apparatus and method for machining pipe. In one aspect, the multifunction apparatus is an improved device for machining the inside diameter and outside diameter of pipe, as well as shaping the wall of pipe. In another aspect, the invention is an improved method for machining pipe. In particular, the method employs a one-to-one communication ratio between the geared components that control the position of the cutting tool in order to eliminate rounding errors associated with conventional gearing systems.

Owner:WACHS TECHN SERVICES

Reamer with clamping arrangement for adjusting cutting insert and other cutting tools with clamping arrangements for adjusting cutting inserts

InactiveUS7322777B2Avoid OverloadingIncreased bending loadThread cutting toolsTool workpiece connectionEngineeringReamer

A cutting tool with a cutting insert and a pivotable screw and nut combination for holding the cutting insert. The cutting tool also has a feed mechanism to adjust the position of at least one cutting edge of the cutting insert in the cutting tool.

Owner:KENNAMETAL INC

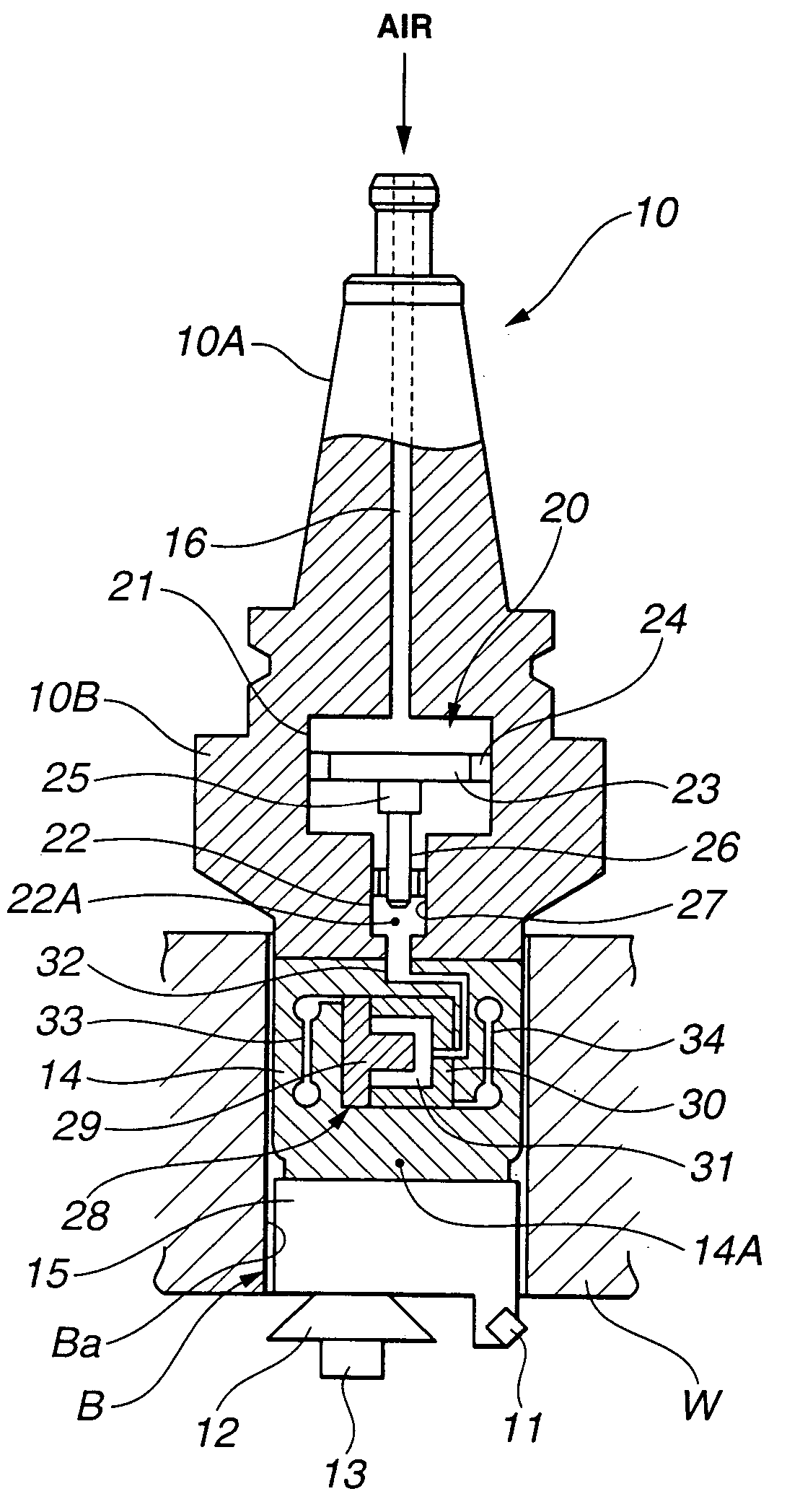

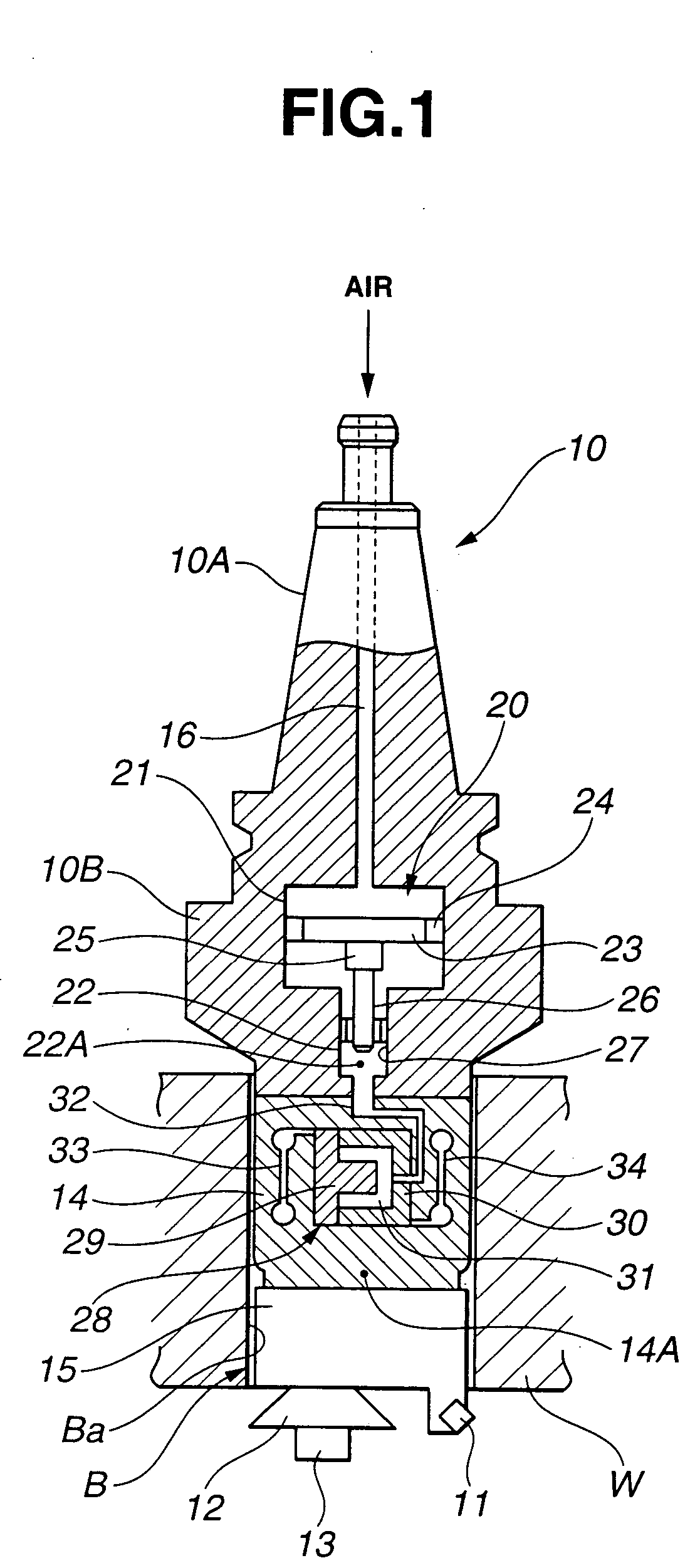

Apparatus for machining a cylinder bore surface and method of machining the cylinder bore surface using the apparatus

InactiveUS20050245178A1Reduce processing timeImprove productivityThread cutting toolsInternal combustion piston enginesEngineeringTool holder

An apparatus for machining a circumferential surface defining a cylindrical bore of a workpiece, the apparatus including a tool holder rotatable about a first rotation axis, and a form roller supported on the tool holder so as to be rotatable about a second rotation axis parallel to a central axis of the cylindrical bore of the workpiece. The form roller has a diameter smaller than a diameter of the cylindrical bore of the workpiece and is adapted for forming a plurality of microscopic recesses on the circumferential surface defining the cylindrical bore of the workpiece.

Owner:NISSAN MOTOR CO LTD

Precision turning tool

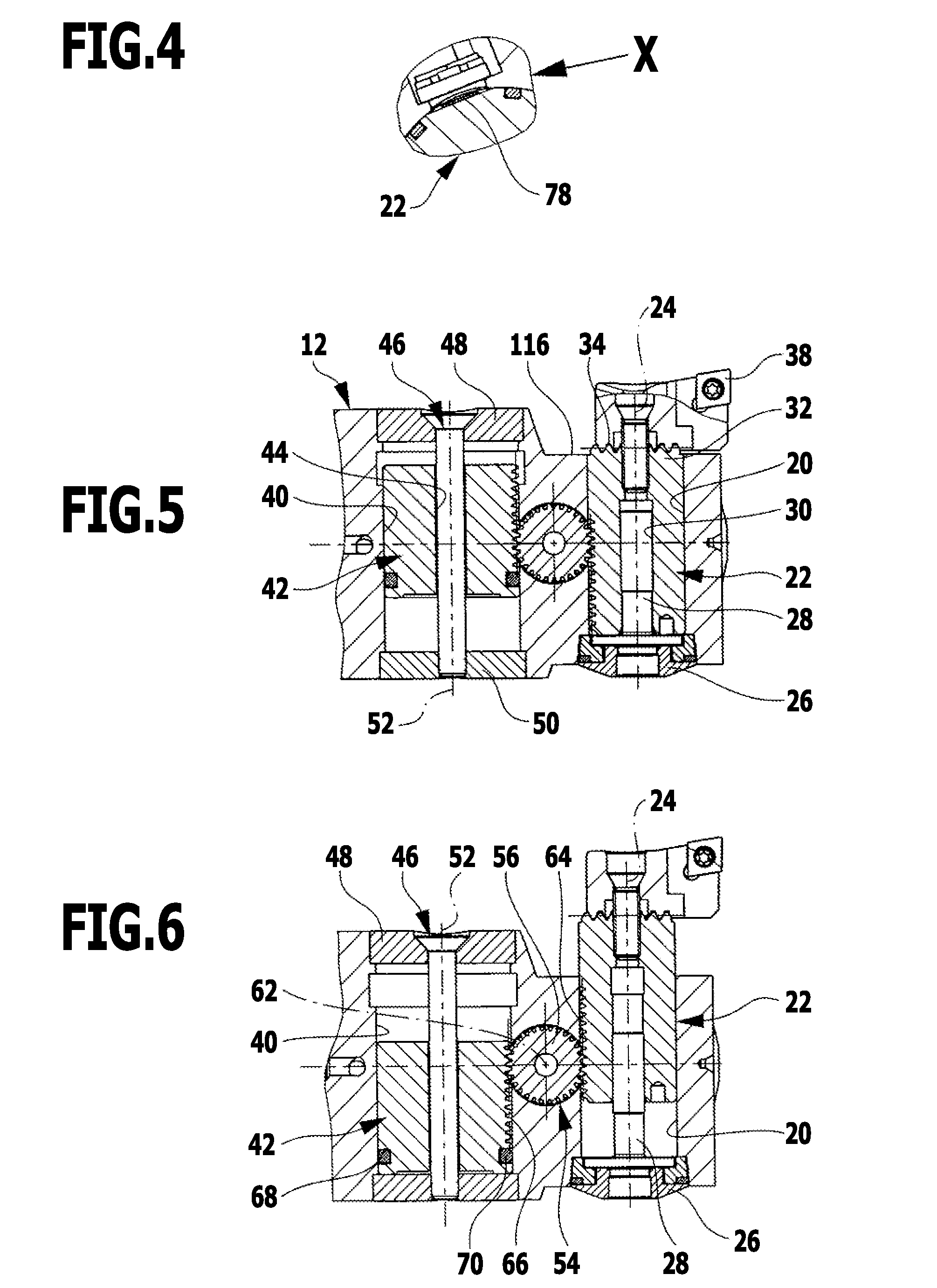

ActiveUS20120269590A1Solve the complicated productionEasy to assembleDrilling/boring measurement devicesThread cutting machinesTool bitEngineering

A precision turning tool has a rotatingly drivable tool body. A tool slide and corresponding compensating slide are displaceably mounted in the tool body. The tool slide is displaceable along an axis of adjustment aligned at right angles to an axis of rotation of the tool body. The compensating slide is automatically displaceable along an axis of compensation aligned parallel to the axis of adjustment contrary to the movement of the tool slide to compensate for any imbalance. At an end projecting out of the tool body in the direction of adjustment the tool slide has a mounting surface, on which a cutting plate carrier can be mounted. An electronic distance measuring system is provided with a display unit and an energy supply device, wherein the distance of adjustment of the tool slide can be detected by means of the distance measuring system and displayed.

Owner:WOHLHAUPTER

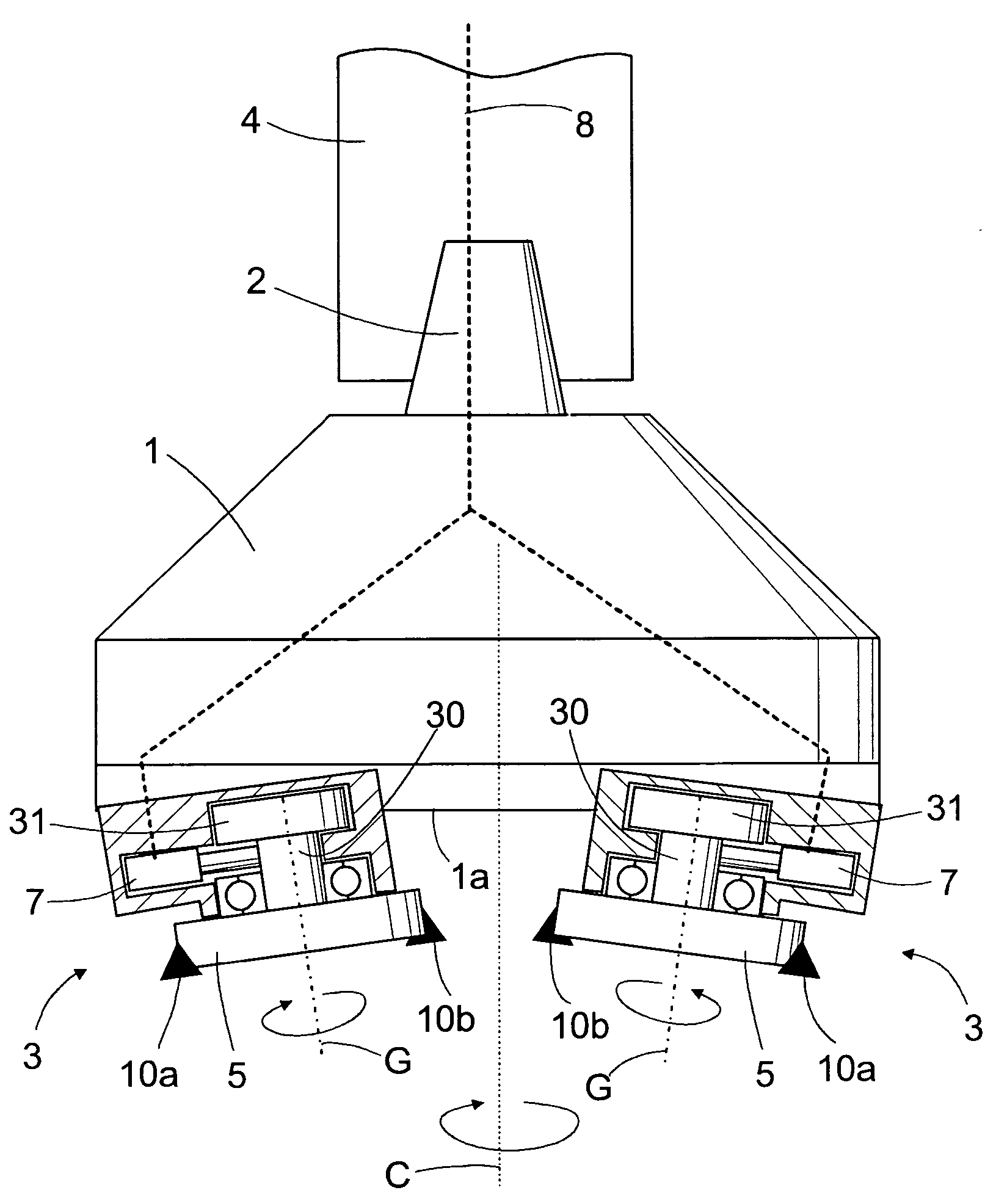

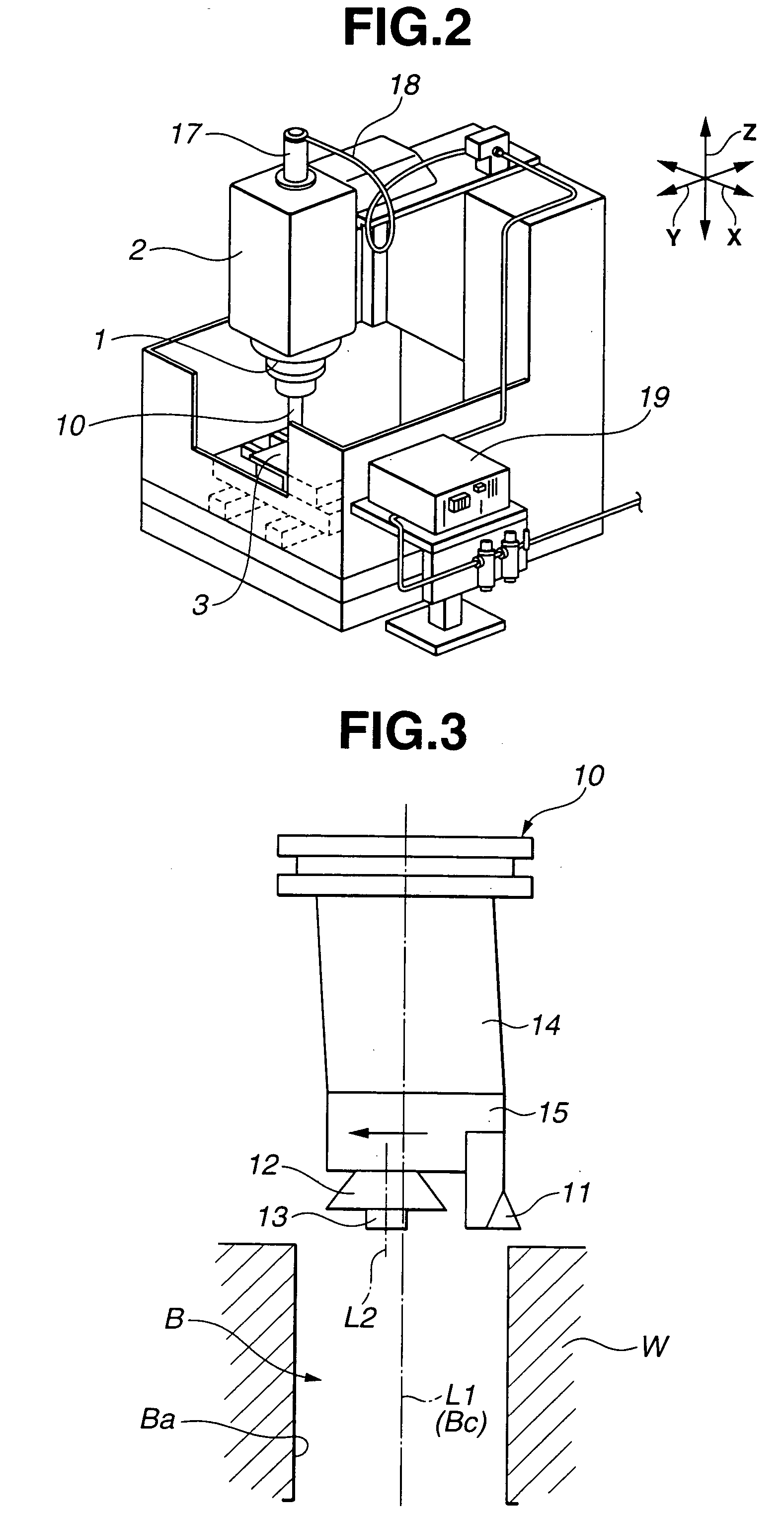

Rotary tool

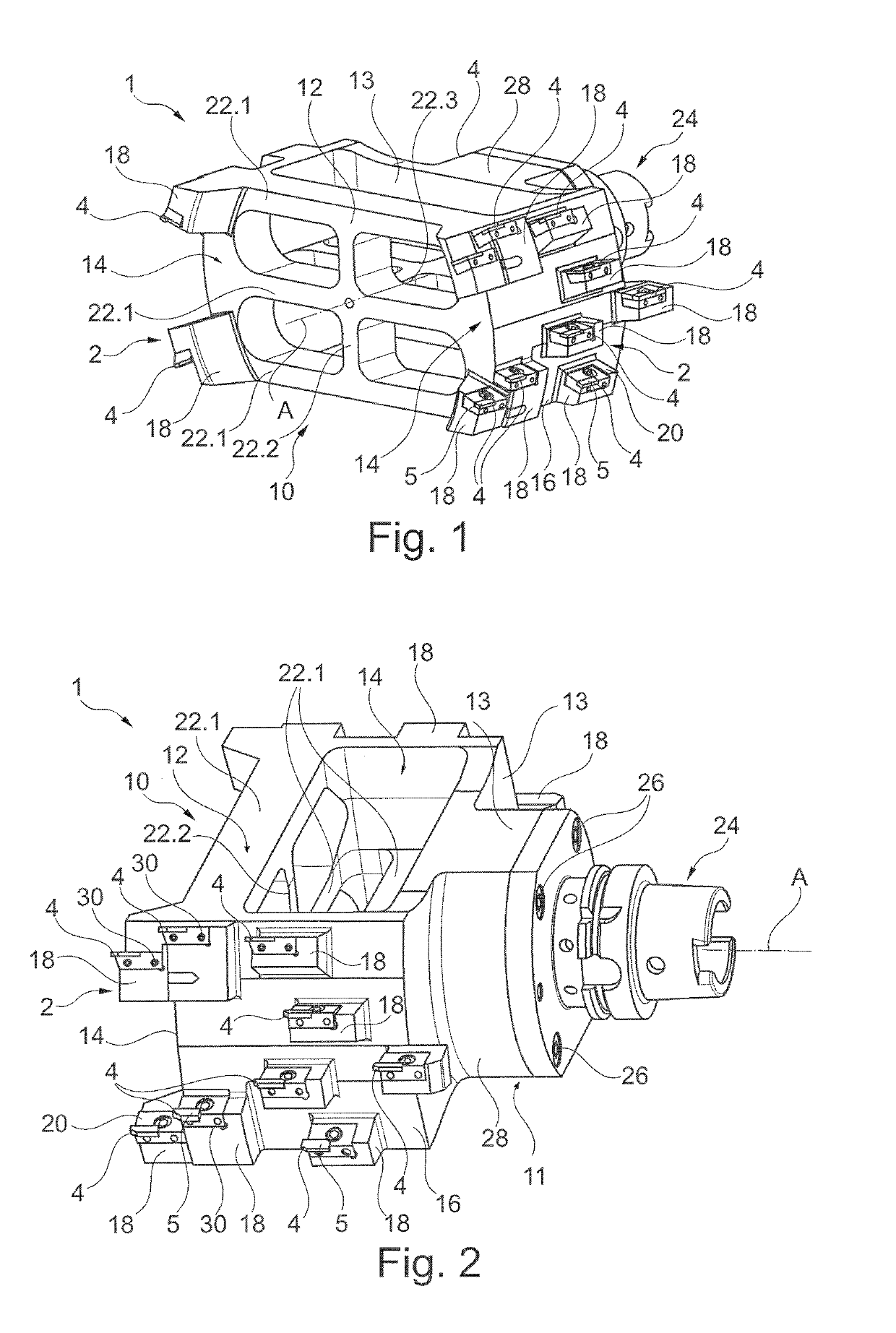

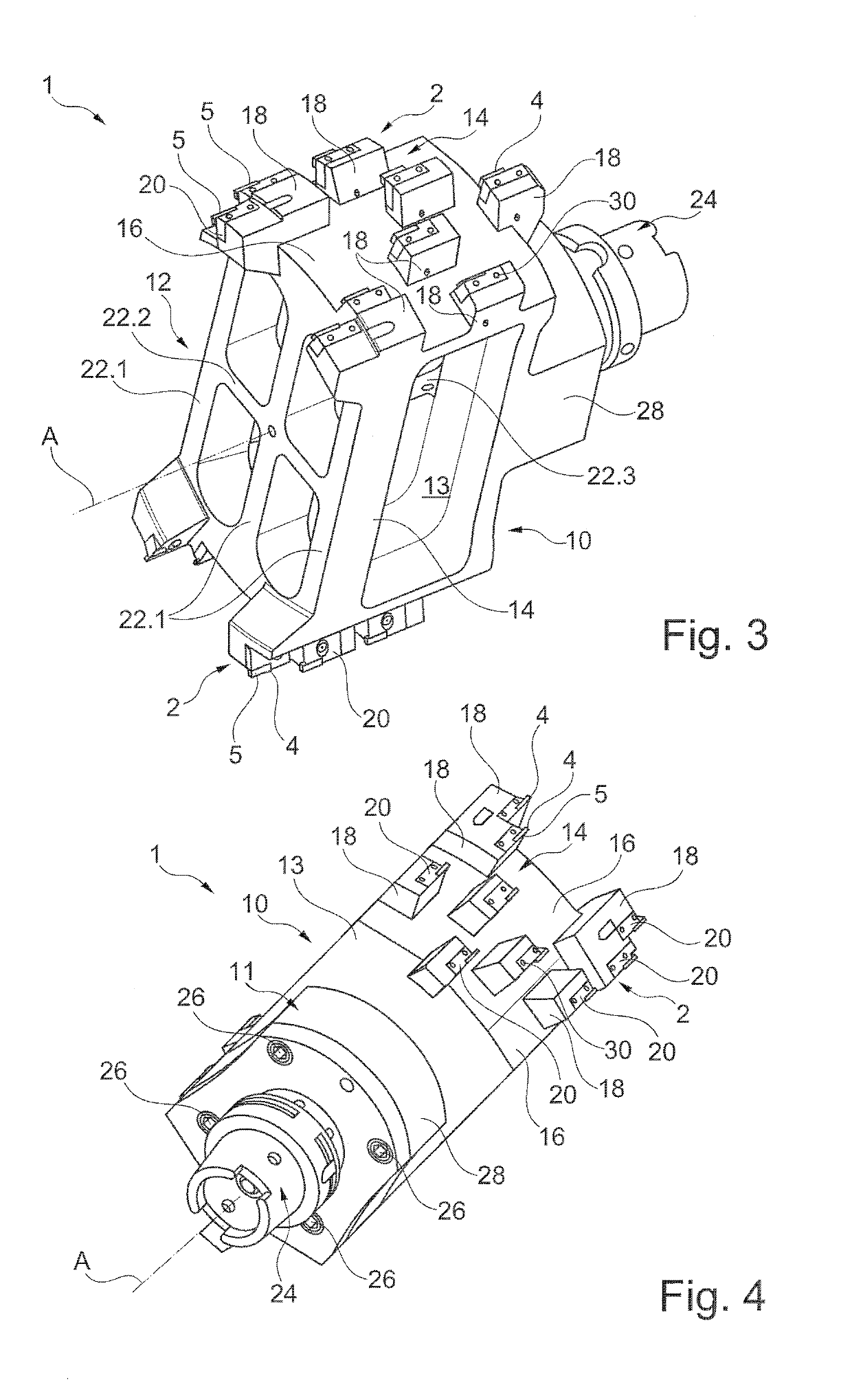

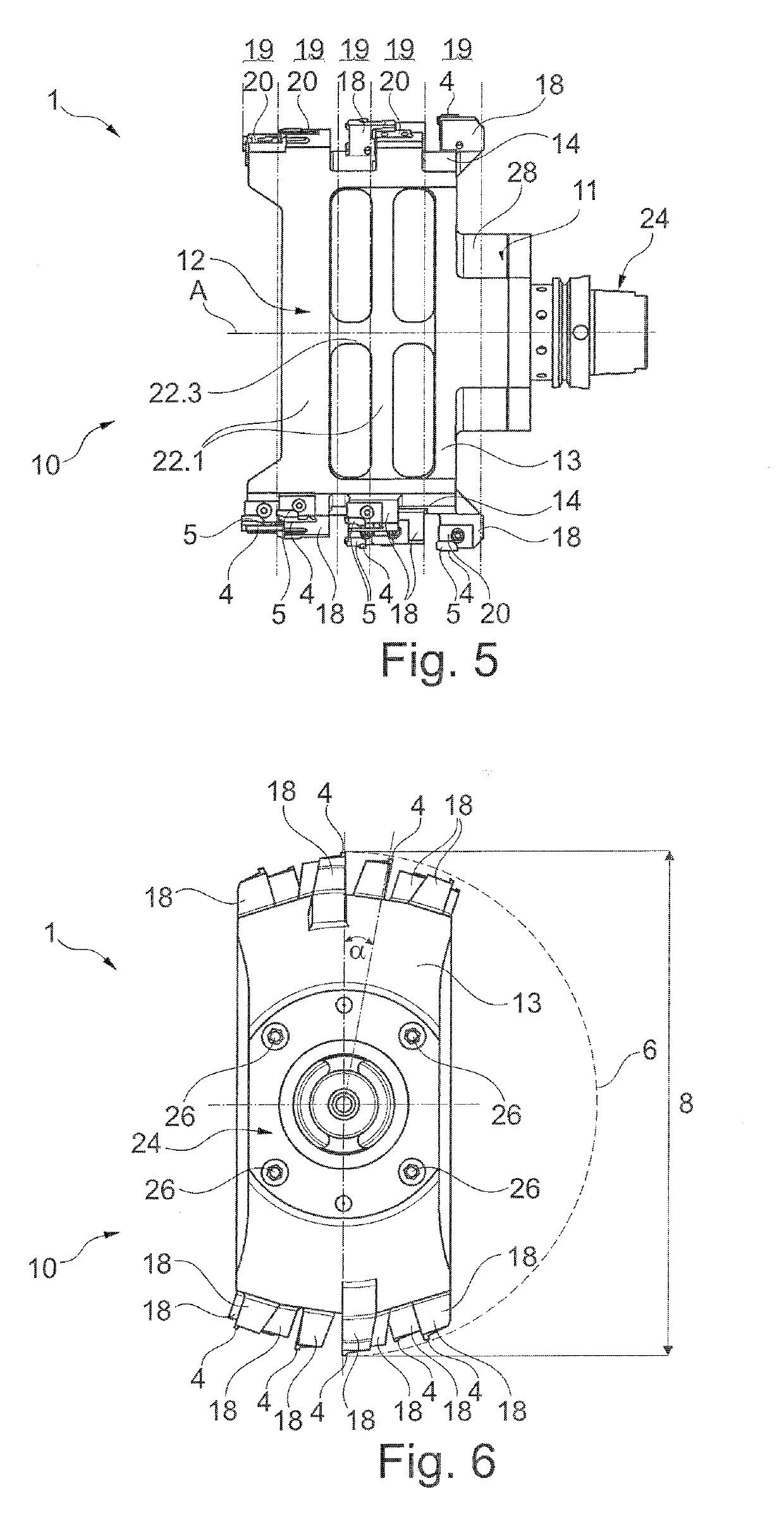

The invention relates to a rotary tool (1; 101; 201) for cutting large inside diameters at the outer circumference (2) of which at least one cutting edge (4) is arranged, comprising a support structure (10; 110; 210) which indirectly or directly supports the at least one cutting edge (4), and comprising a chucking portion (24) for coupling to a tool holder, wherein the support structure (10; 110; 210) widens in an umbrella-type manner starting from a coupling portion (11) adjacent to the chucking portion (24) and is radially stiffened by a stiffening structure (12).

Owner:GUEHRING OHG

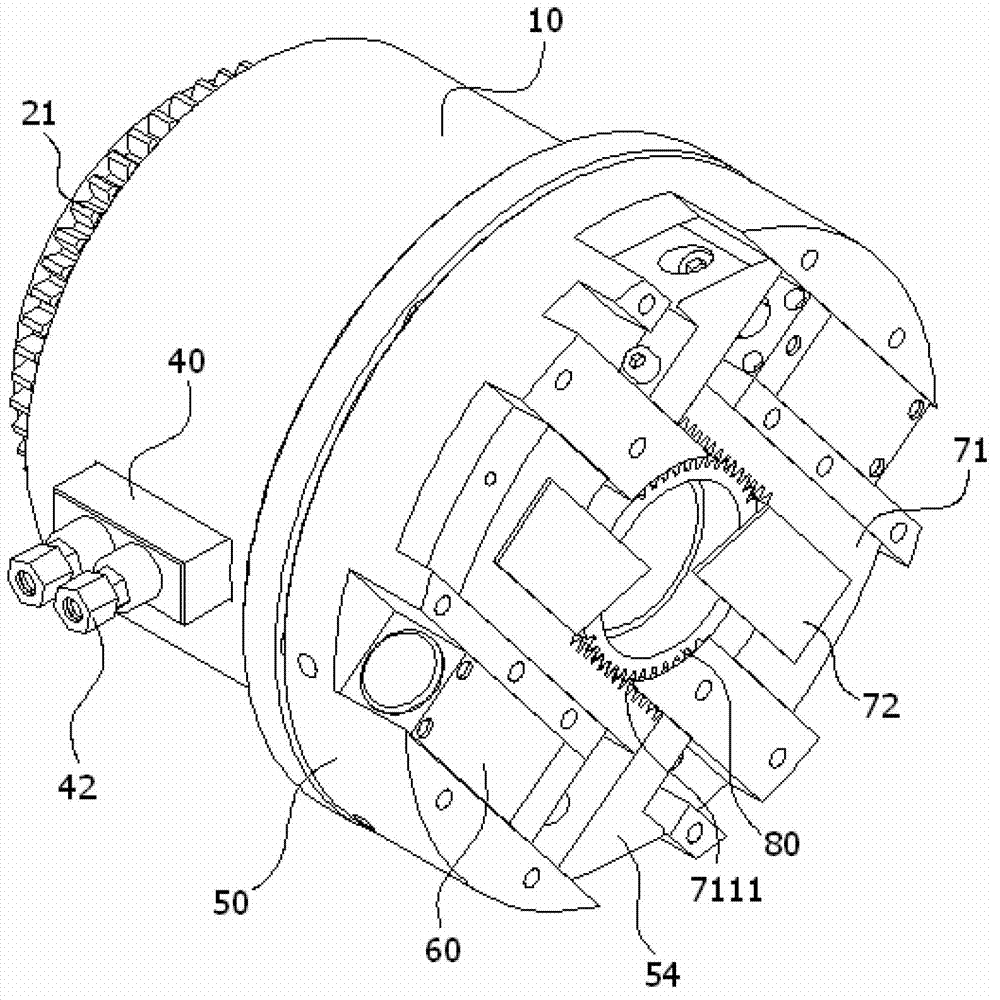

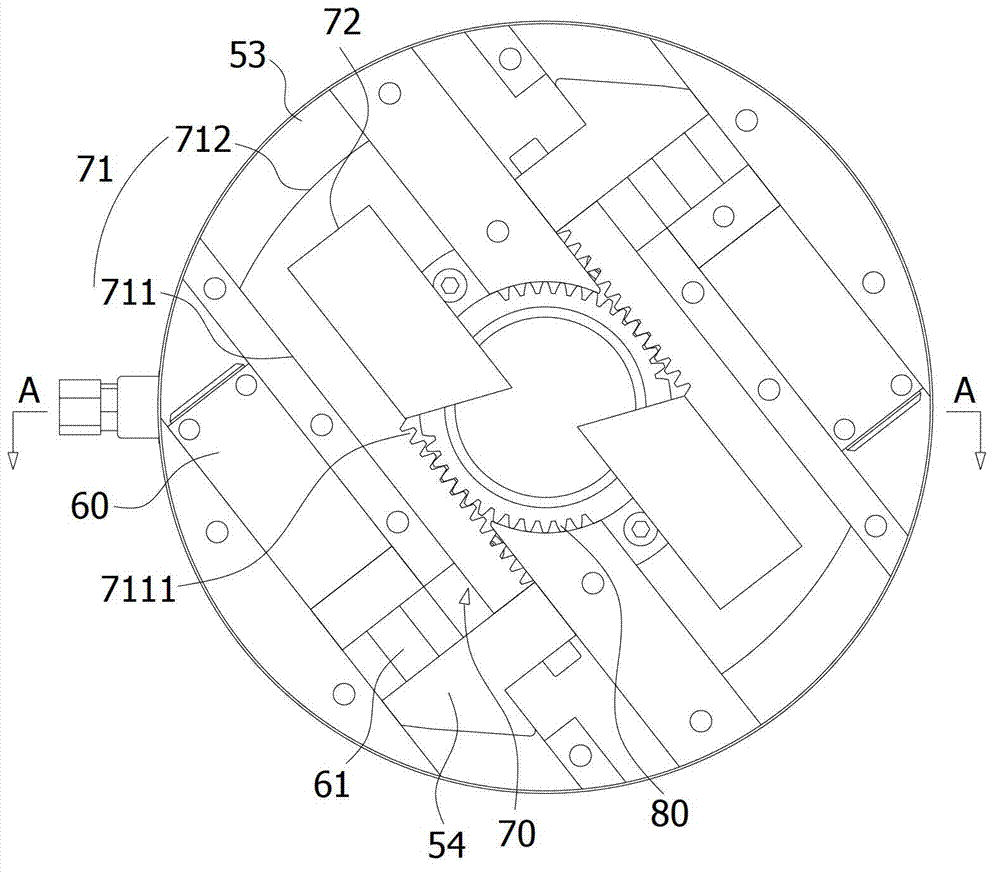

Automatically expanding and shrinking scraping-rolling combined deep hole cutter

ActiveCN102152118AImprove static stiffnessImprove dynamic stiffnessOther manufacturing equipments/toolsBoring headsMatched pairEngineering

The invention discloses an automatically expanding and shrinking scraping-rolling combined deep hole cutter. A scraping part of the cutter comprises at least one pair of scrapers, a top block, and a reset device; the top block is positioned in the centre of a thick boring head body and is provided with a taper structure, and a corresponding conical surface is jacked by an endocentric end of the scraper; and the reset device is arranged between each matched pair of scrapers for resetting the scrapers; and a rolling part of the cutter comprises a rolling path and a keeper. The combined boring head also comprises a manipulating device which comprises a first driving part and a second driving part, wherein the first driving part drives the keeper to move axially along a spindle, and the second driving part penetrates a centre hole and acts on the top block in order to drive the top block to move axially along the spindle. The cutter disclosed by the invention is compact in structure, high in processing precision, convenient to use, and can expand and shrink automatically.

Owner:德州普利森机床有限公司

Boring bar fastening device for single or double blade

InactiveUS20160114402A1Reduce vibrationGuaranteed uptimeThread cutting toolsTransportation and packagingEngineeringMechanical engineering

Owner:XPOLE PRECISION TOOLS

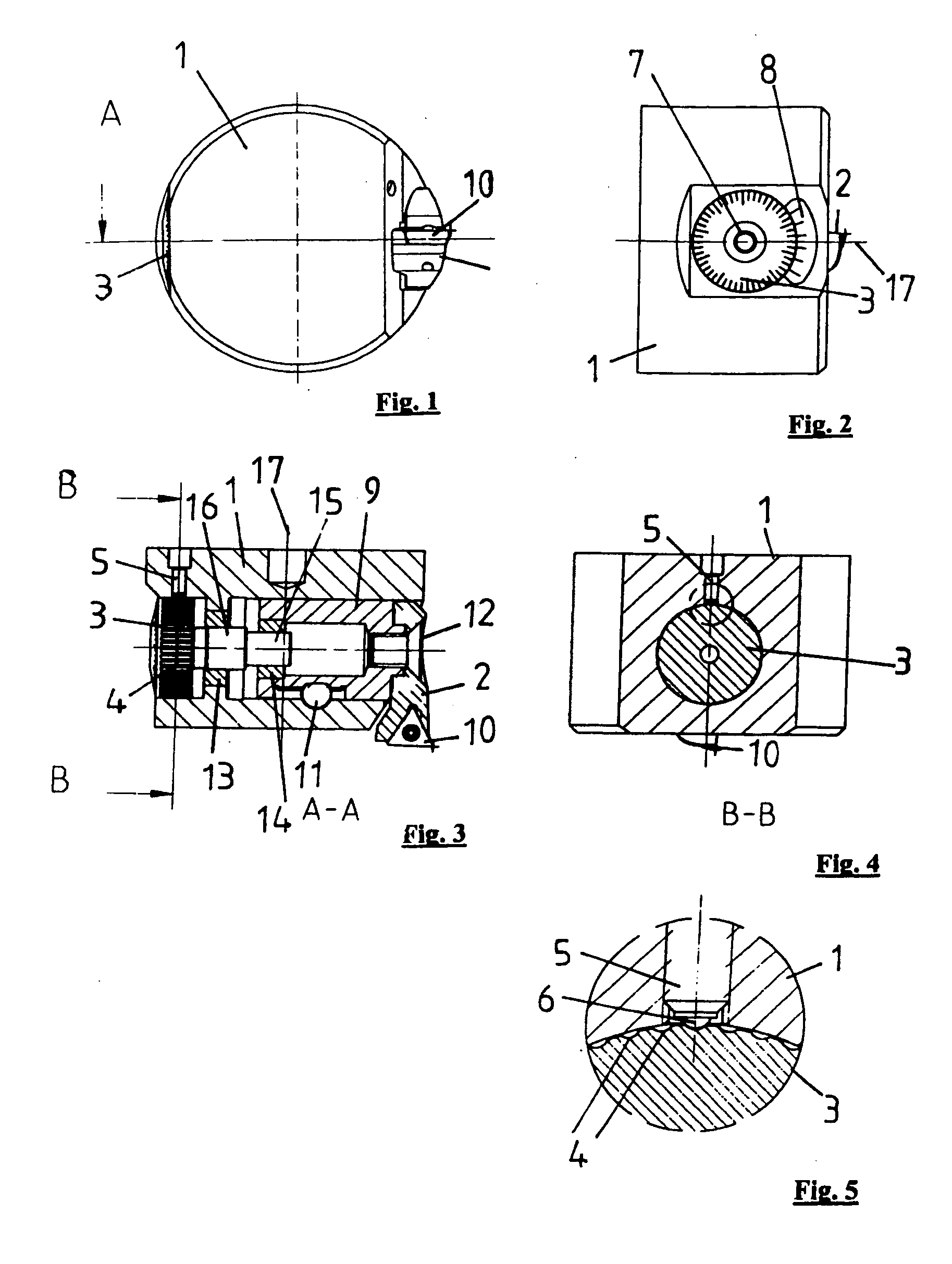

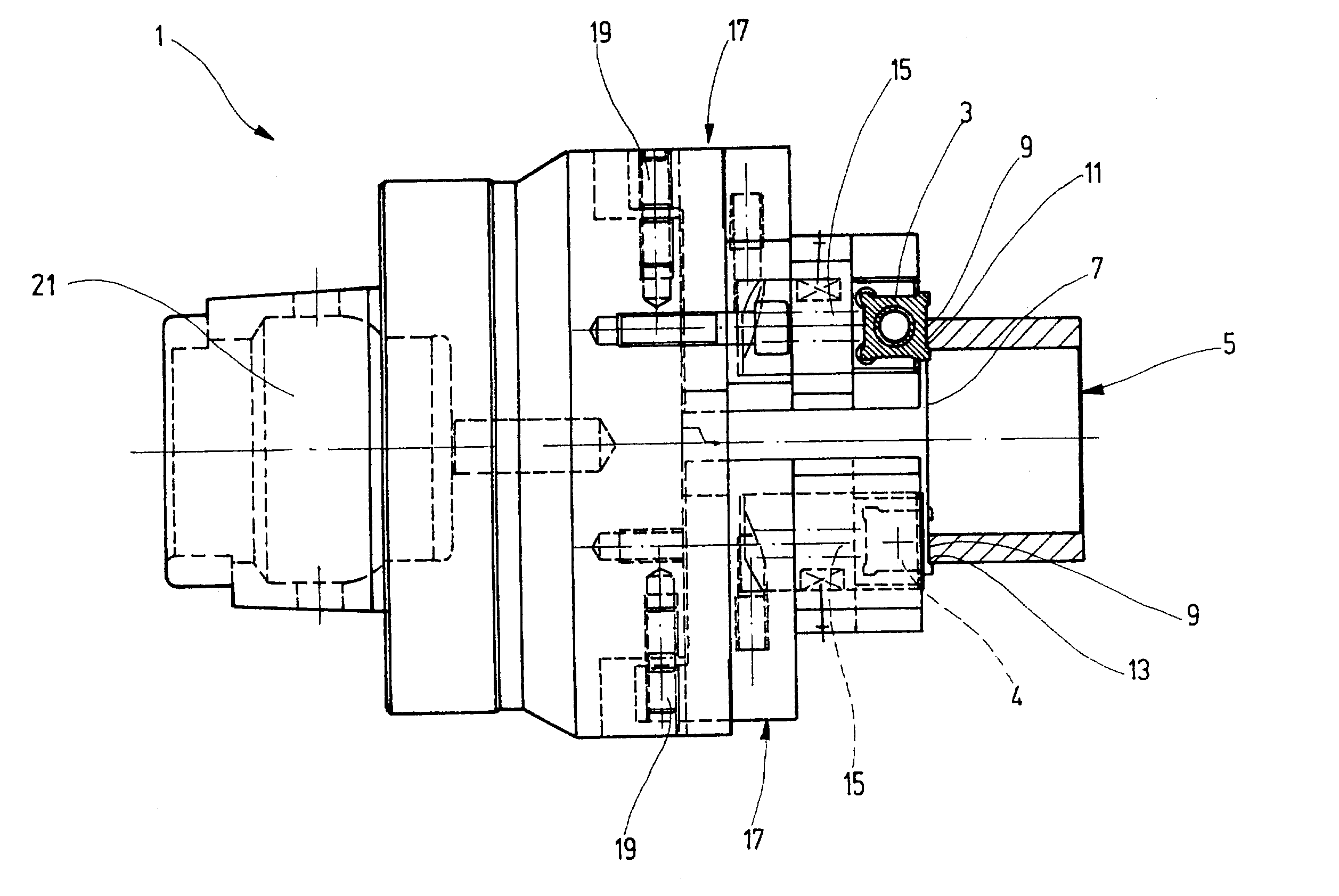

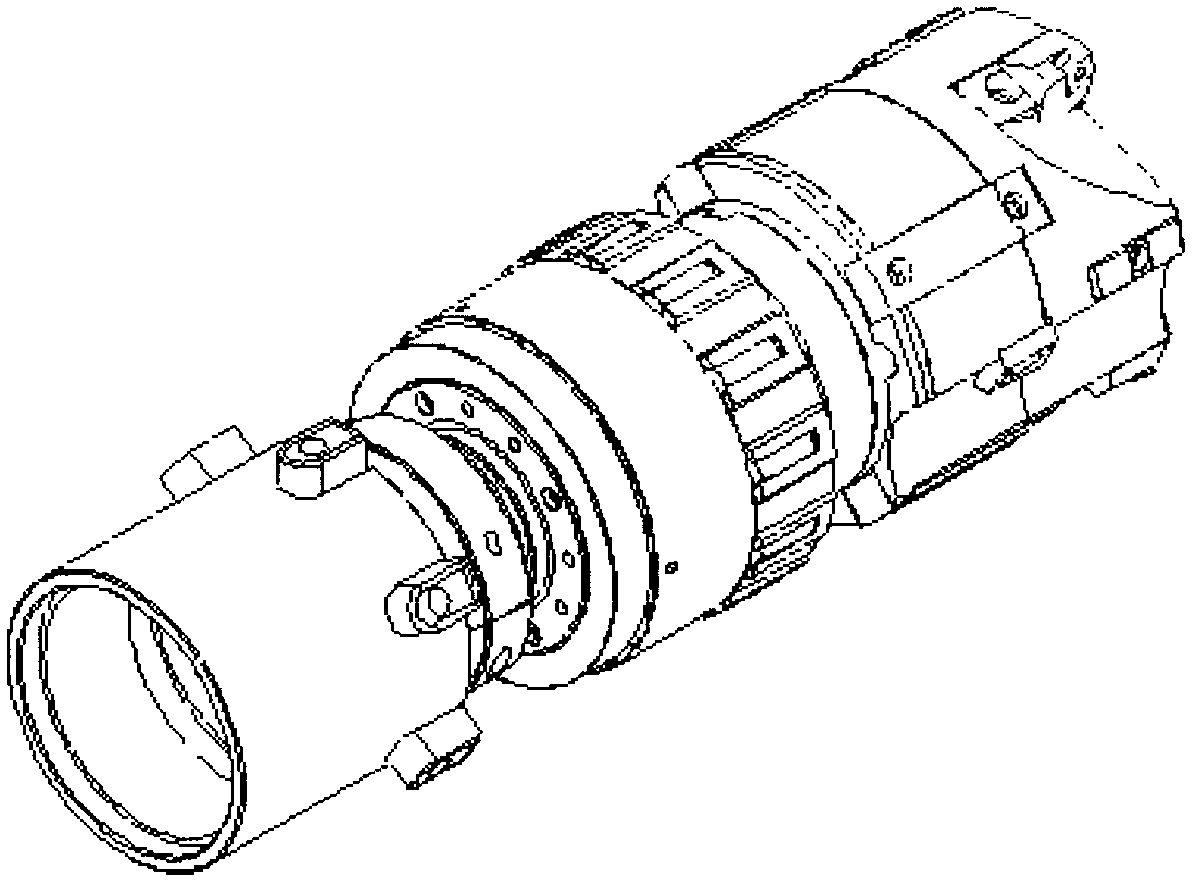

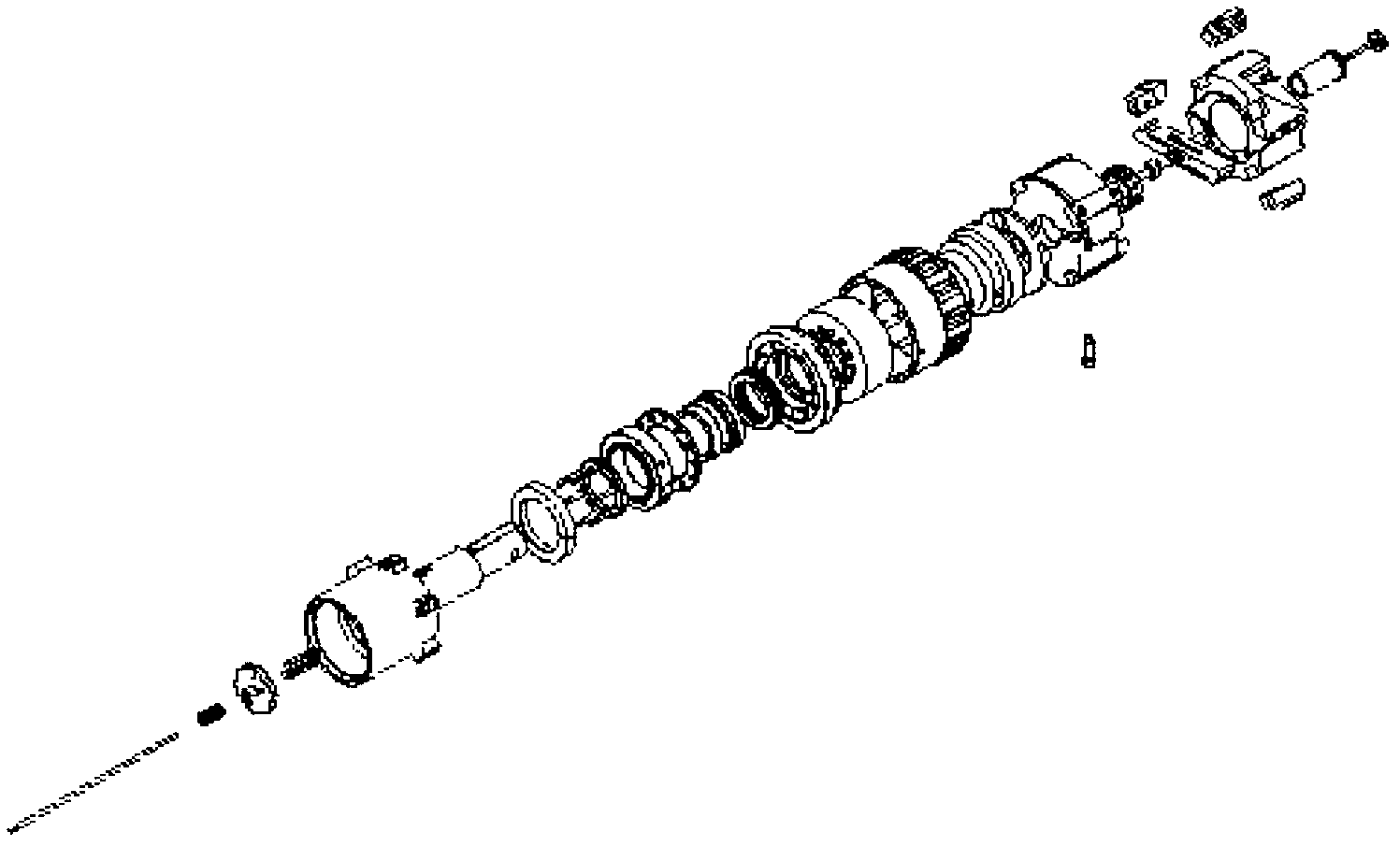

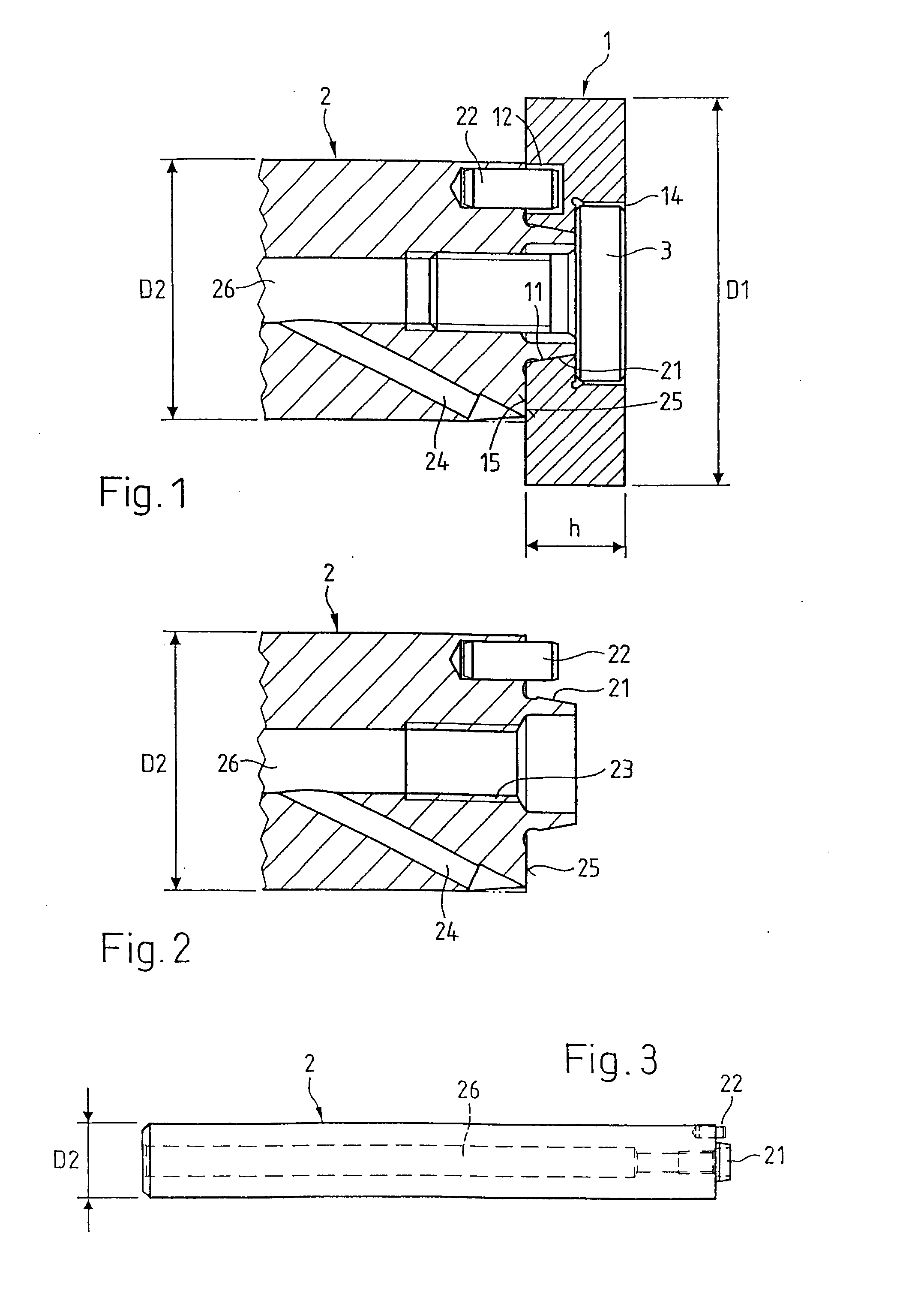

Machine friction tool, interchangeable head and shaft

ActiveUS20070067979A1Reduce manufacturing costSimple designTransportation and packagingAttachable milling devicesMaterial requirementsMillimeter

A machine reaming tool comprises a reaming head or interchangeable head (1) and a shaft (2), wherein the interchangeable head (1) is of one piece and may be exchanged, and in the axial direction and at each location, thus including means for the exchange adaptation, is thinner than a maximal thickness hmax, wherein this maximal thickness hmax is computed in millimetres from a diameter D1 of the interchangeable head in millimetres as hmax =6 mm+(1 / 10)·(D1−12 mm). On account of this, a guide portion (18) for cutters of the reaming head (1) becomes very much shorter than usual, but despite this ensures an adequate quality of machining. In a preferred embodiment of the invention, the interchangeable head (1) in a plane shaft-side end-face side end-face (15) comprises cutout (11) for the centring fastening on the shaft (2). The shaft (2) on an end-side plane surface (25) comprises a connection lug (21) which projects out of this plane surface in the axial direction and to which the cutout (11) of the interchangeable head (1) corresponds. The interchangeable head (1) thus has no axially projecting lug. The material requirement is further reduced, the manufacture of the interchangeable head (1) is simplified, and the material and manufacturing costs are reduced on account of this.

Owner:URMA

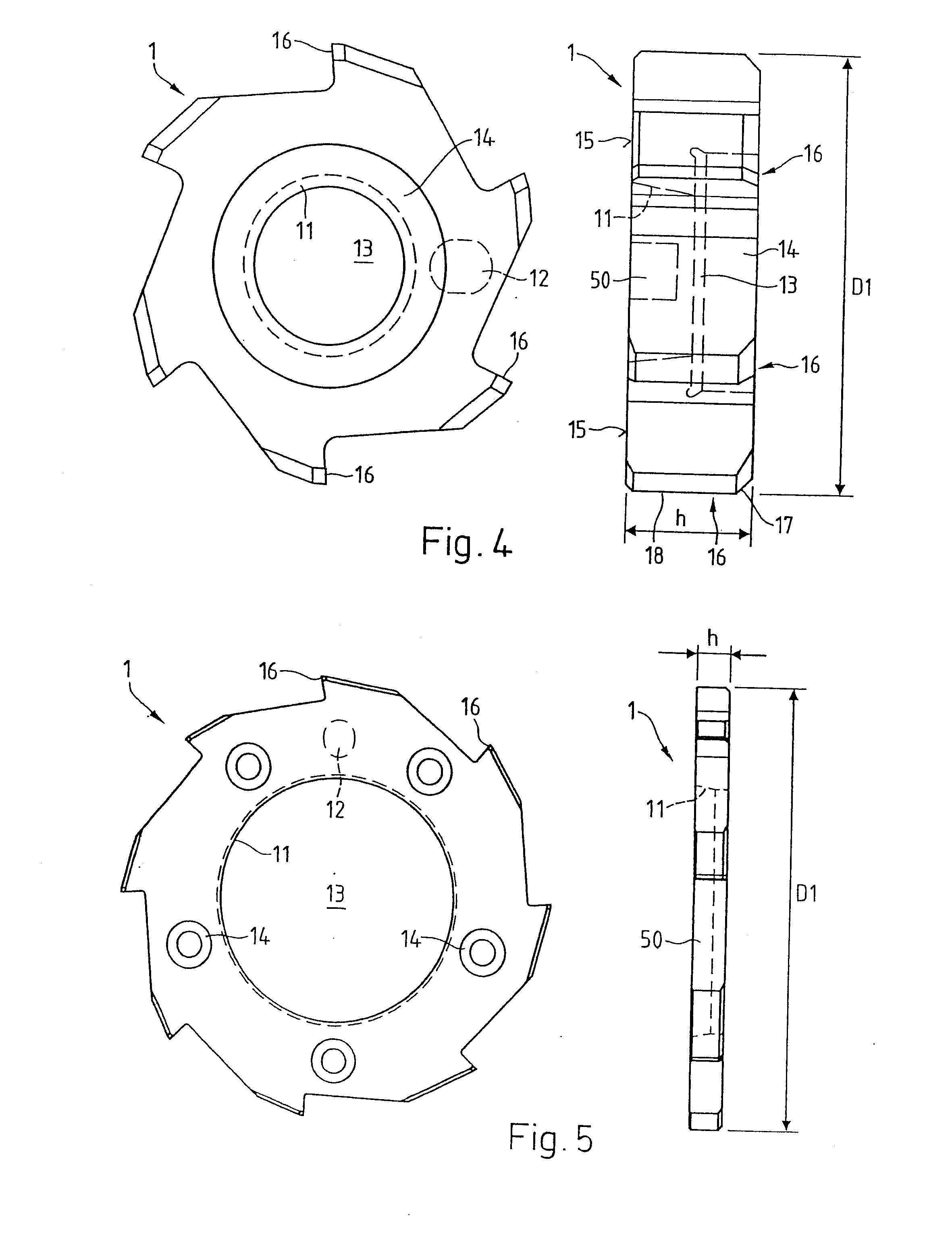

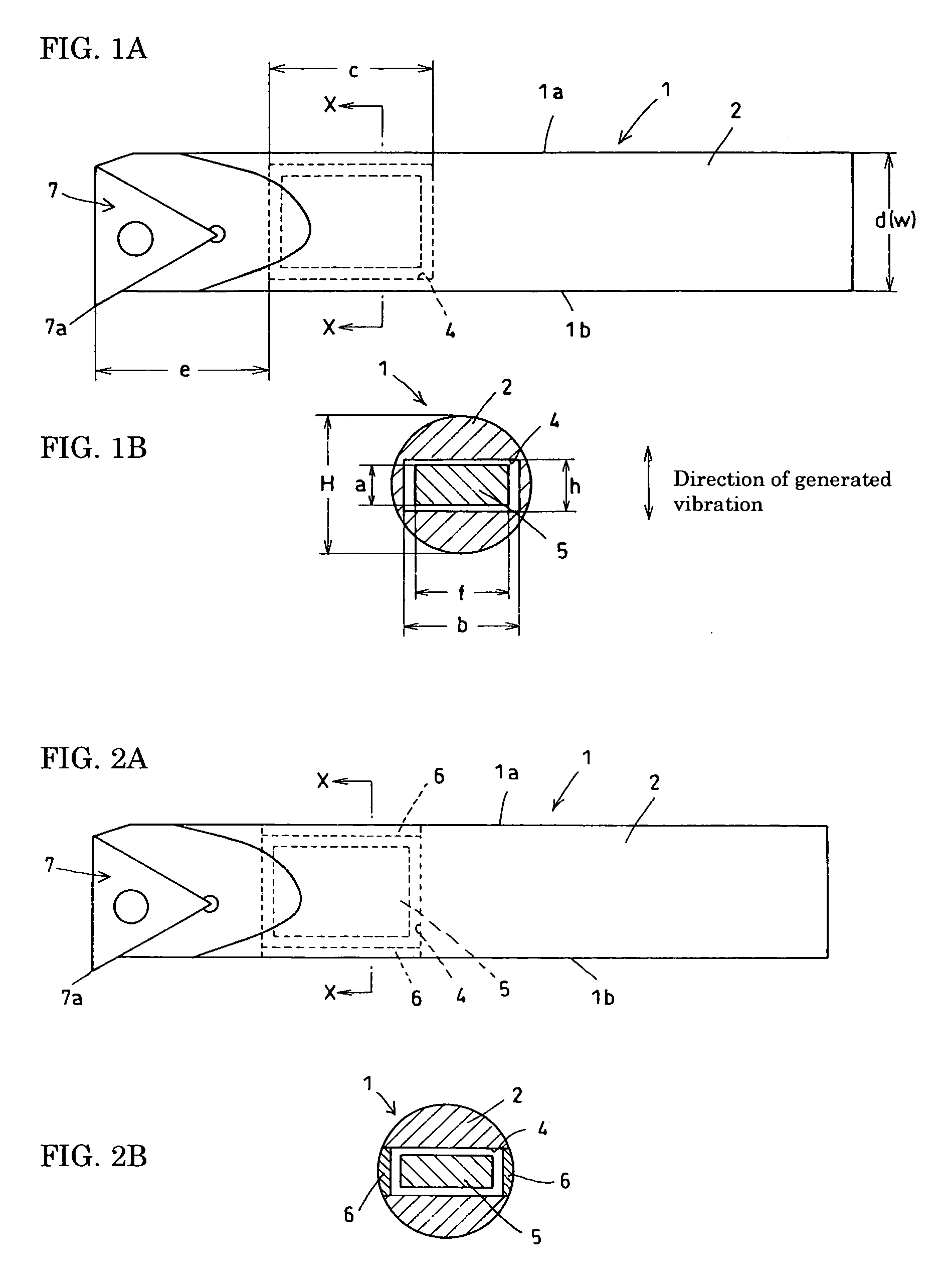

Vibration-suppressing cutting tool

ActiveUS20050109182A1High effect in suppressing chatter vibrationSimple structureLathesMetal sawing devicesEngineeringMechanical engineering

A holder 1 has a shank portion 2 provided with a pocket 4 having the shape of a nearly rectangular solid. The pocket 4 is placed at a position relatively close to the tip of the tool. In the cross section of the shank, the pocket 4 has a width of 50% to 100% of the shank diameter or width, a height of 20% to 50% of the shank height, and a length of 50% to 250% of the shank diameter or height. A weight 5 is inserted into the pocket 4 such that the weight is movable but unable to rush out. The weight 5 has the shape of a nearly rectangular solid and is made of a material having a specific gravity comparable to or greater than that of the material of the shank portion.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

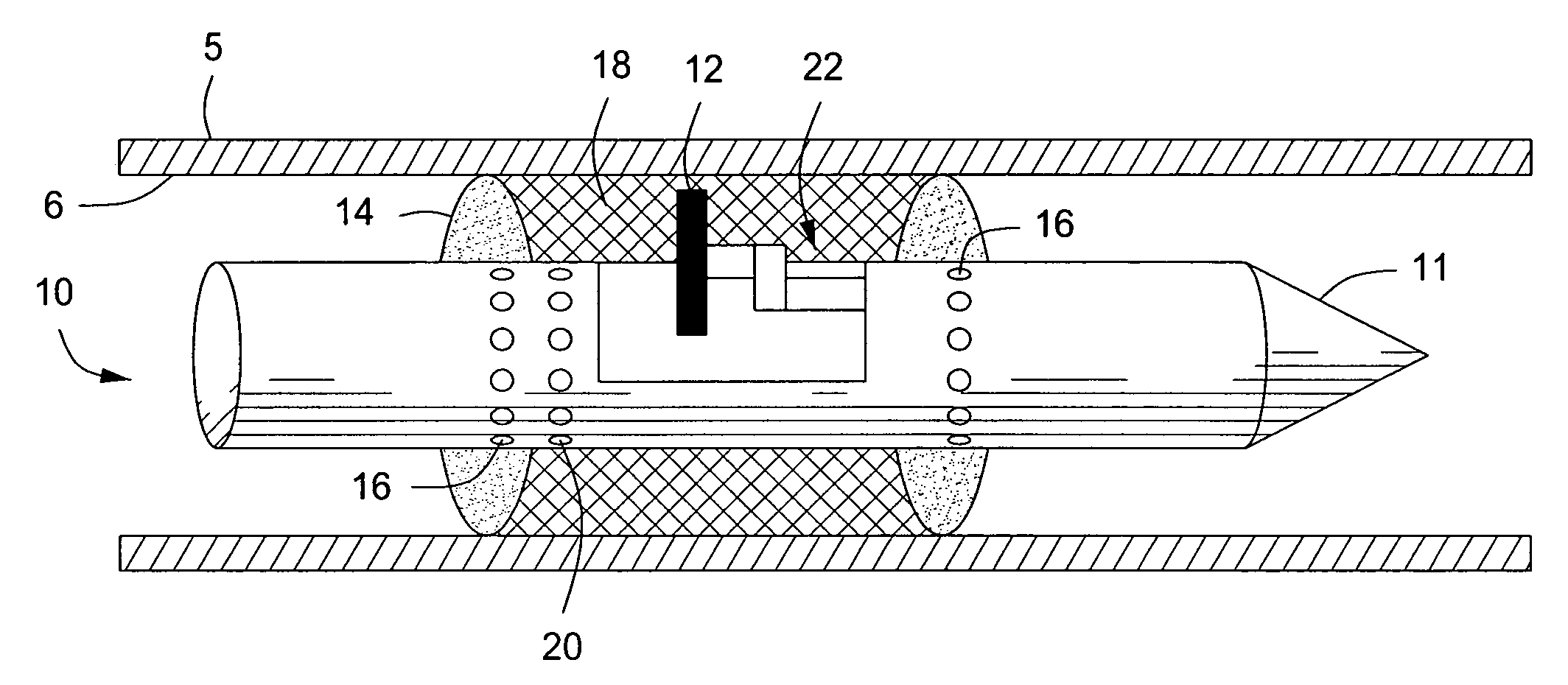

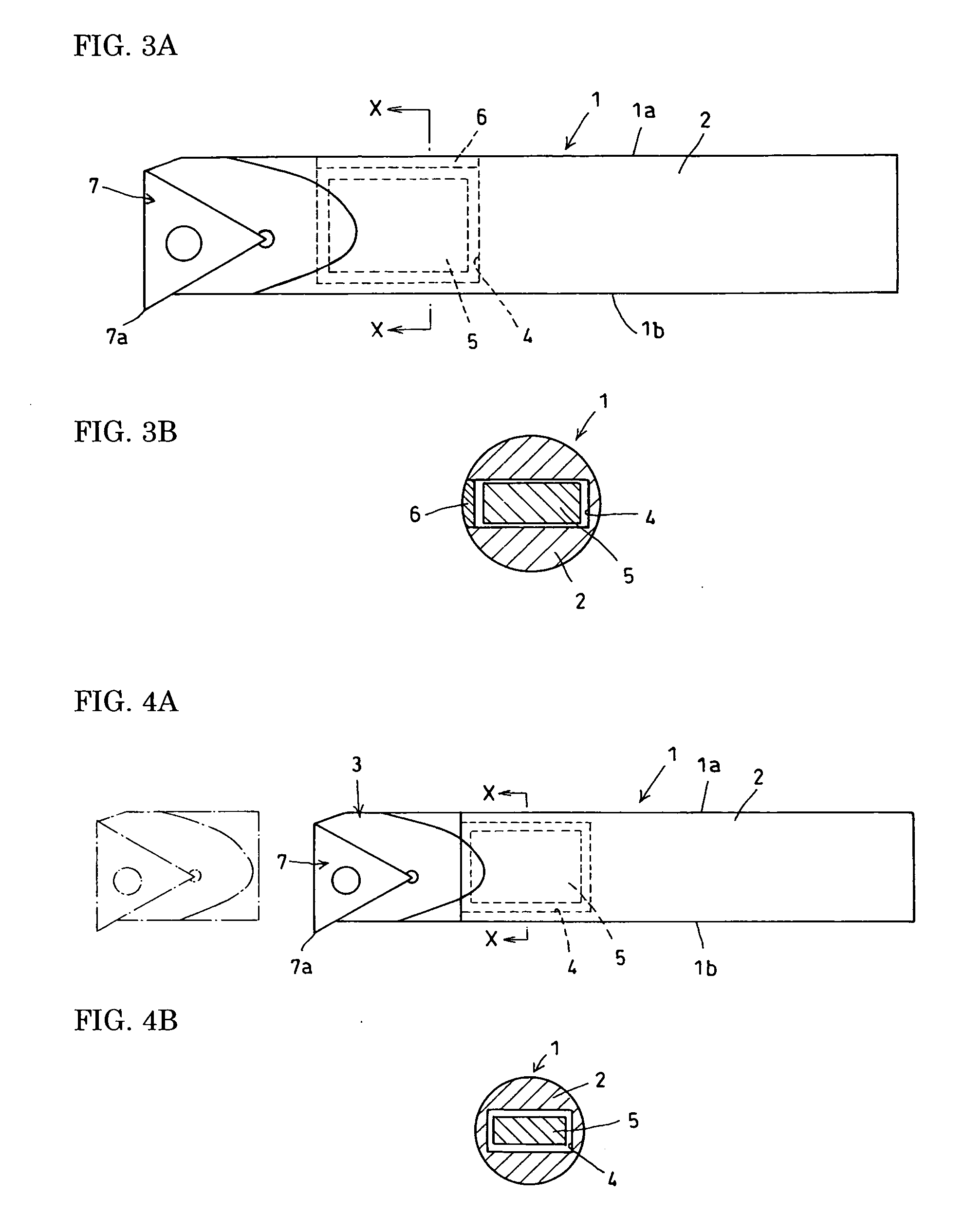

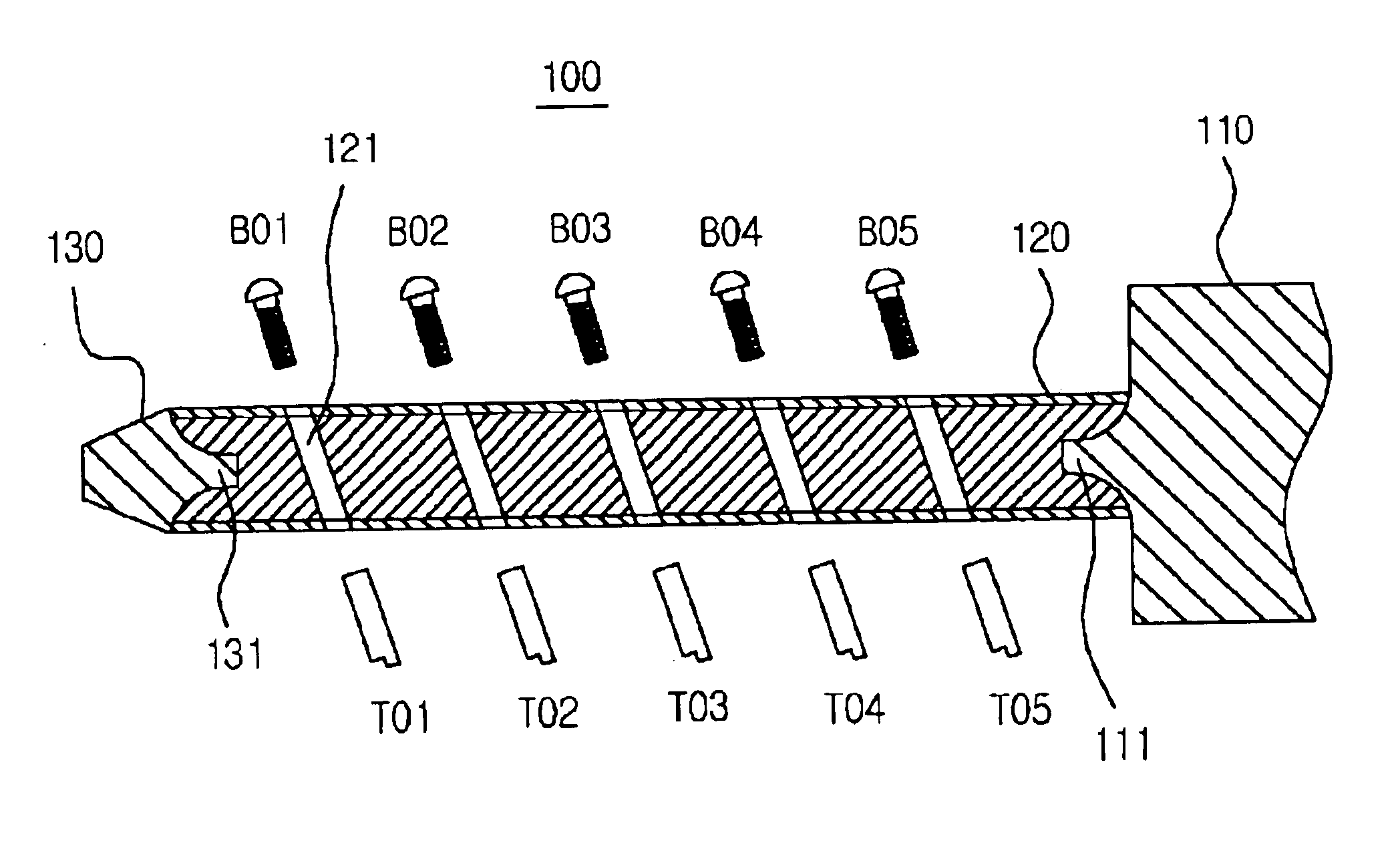

High stiffness composition tool bar

The present invention is to provide a machining tool bar in which mechanical machining properties are improved by using high stiffness composite material.According to the present invention, the tool bar includes an adaptor constructed to be coupled to a driving device, a body constructed to be mounted with cutting tools and a tip constructed to be supported by a workpiece, said body is constructed to be mounted with one or more cutting tools, wherein the adaptor and tip are made of metal material, the body is made of composite material having high stiffness, the composite material constructing the body is formed to surround at least a portion of the adaptor and at least a portion of the tip, and the metal material constructing the adaptor and tip and the composite material constructing the body are securely joined to each other in an interface therebetween.

Owner:KOREA ADVANCED INST OF SCI & TECH +1

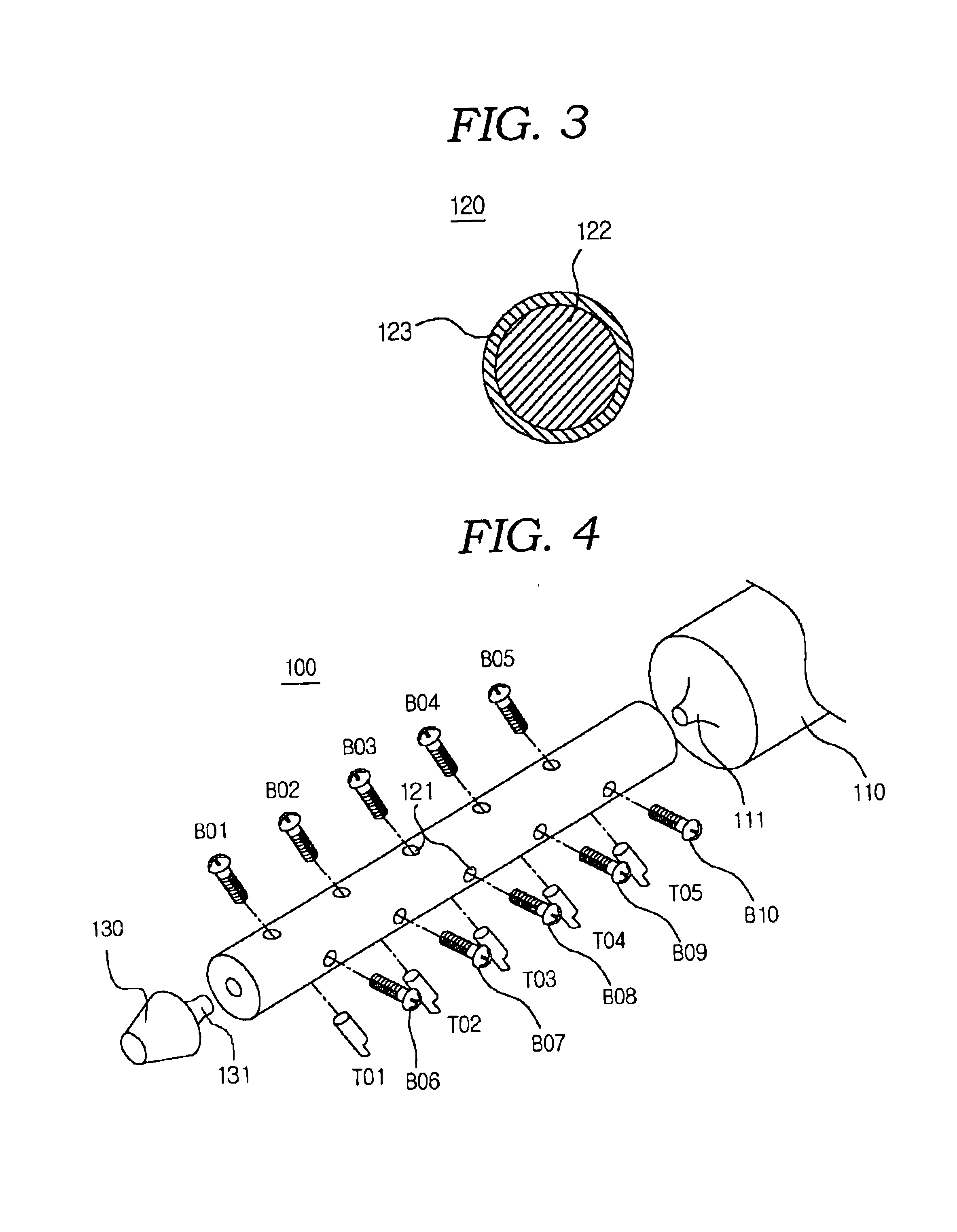

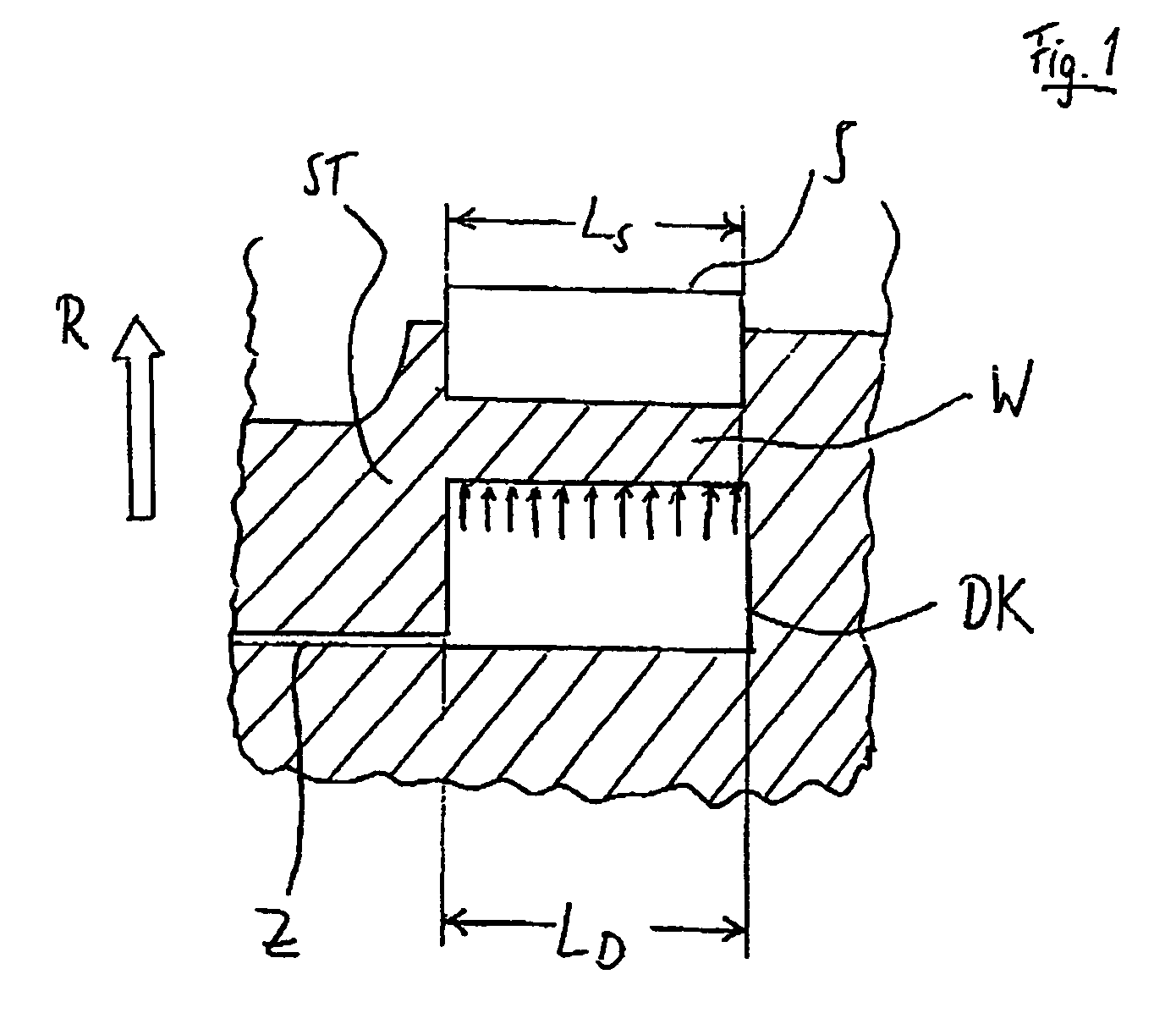

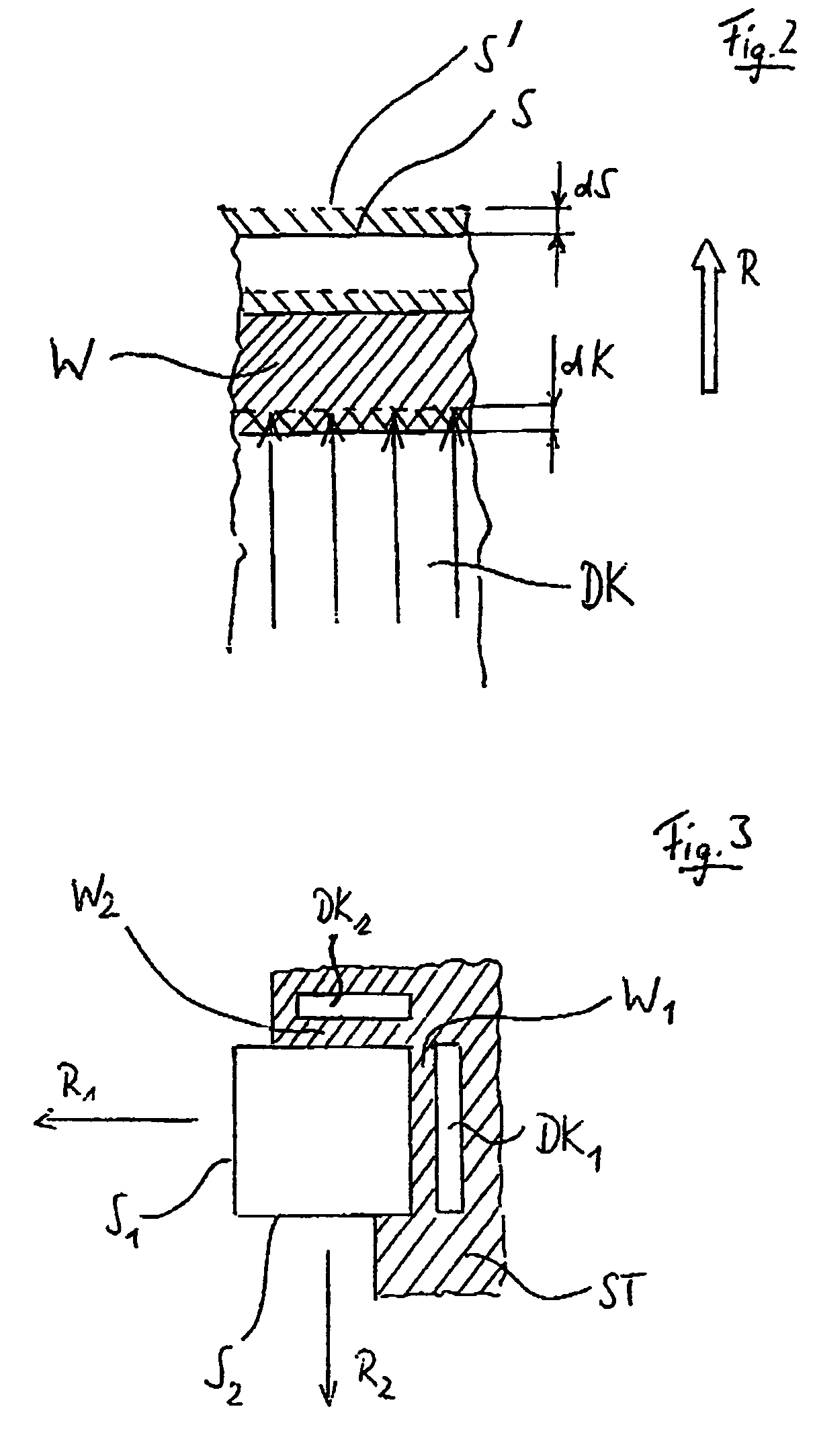

Adjustment device for a fine machining tool

ActiveUS7140819B2Precise positioningAccurate settingThread cutting toolsThread cutting machinesPressure generationPressure transmission

An adjustment device for adjusting the position of at least one cutter of a fine machining tool, particularly a reamer, with respect to a cutter support (ST) is described. To allow the cutter to be adjusted as precisely as possible, the cutter support (ST) borders at least one pressure chamber (DK) which is arranged in the adjustment direction of the cutter (S) with a displacement with respect to it and which is filled with a pressure medium which can be placed under pressure using a pressure generation device. Between the cutter (S) and the pressure chamber (DK), a cutter support wall (W) remains which is elastically deformable upon application of pressure by the pressure transfer means to adjust the cutter position.

Owner:GUHRING JORG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com