Large-pore diameter precision boring tool for machining center

A machining center and precision boring technology, which is applied to lathe tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low machining accuracy, low efficiency, large tolerance deviation of inner hole shape, etc., and achieve operation Smooth, simple structure, high processing precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] With reference to accompanying drawing, further illustrate the present invention:

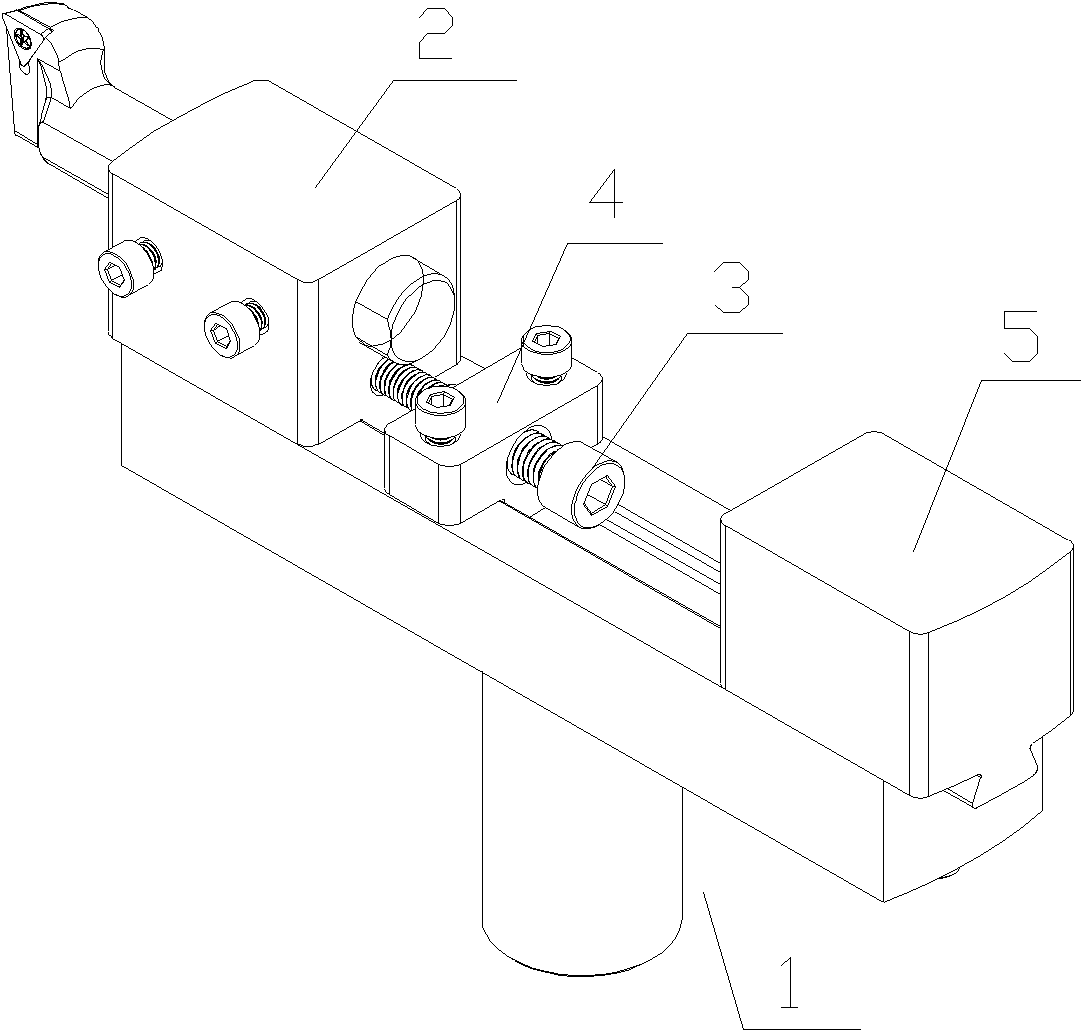

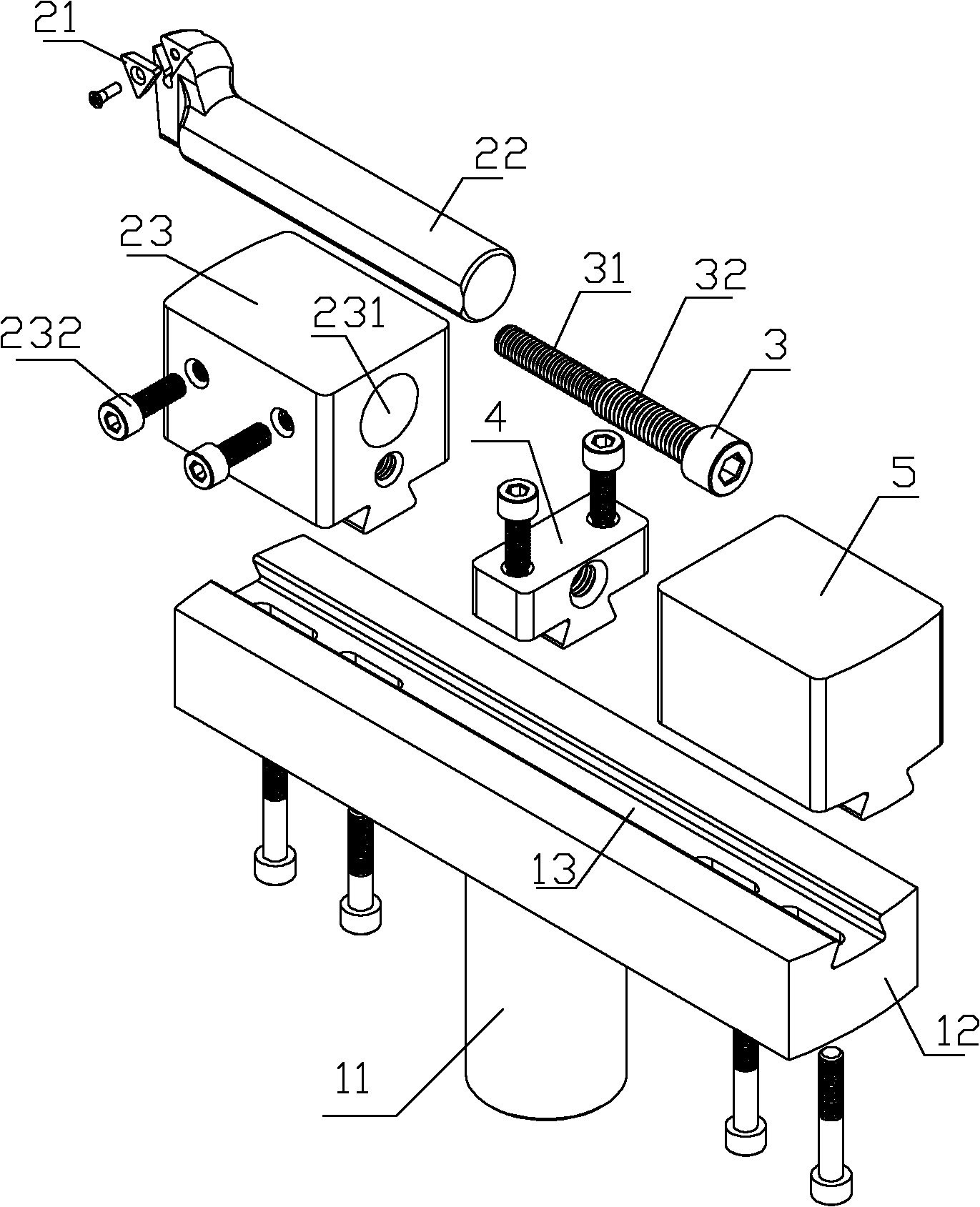

[0045] The machining center uses a large-diameter precision boring tool, including a T-shaped base 1, an adjustable boring head mechanism 2 equipped with a boring tool, an adjusting screw 3 linked with the adjustable boring head mechanism 2, and the installation of the The screw seat 4 of the adjusting screw 3;

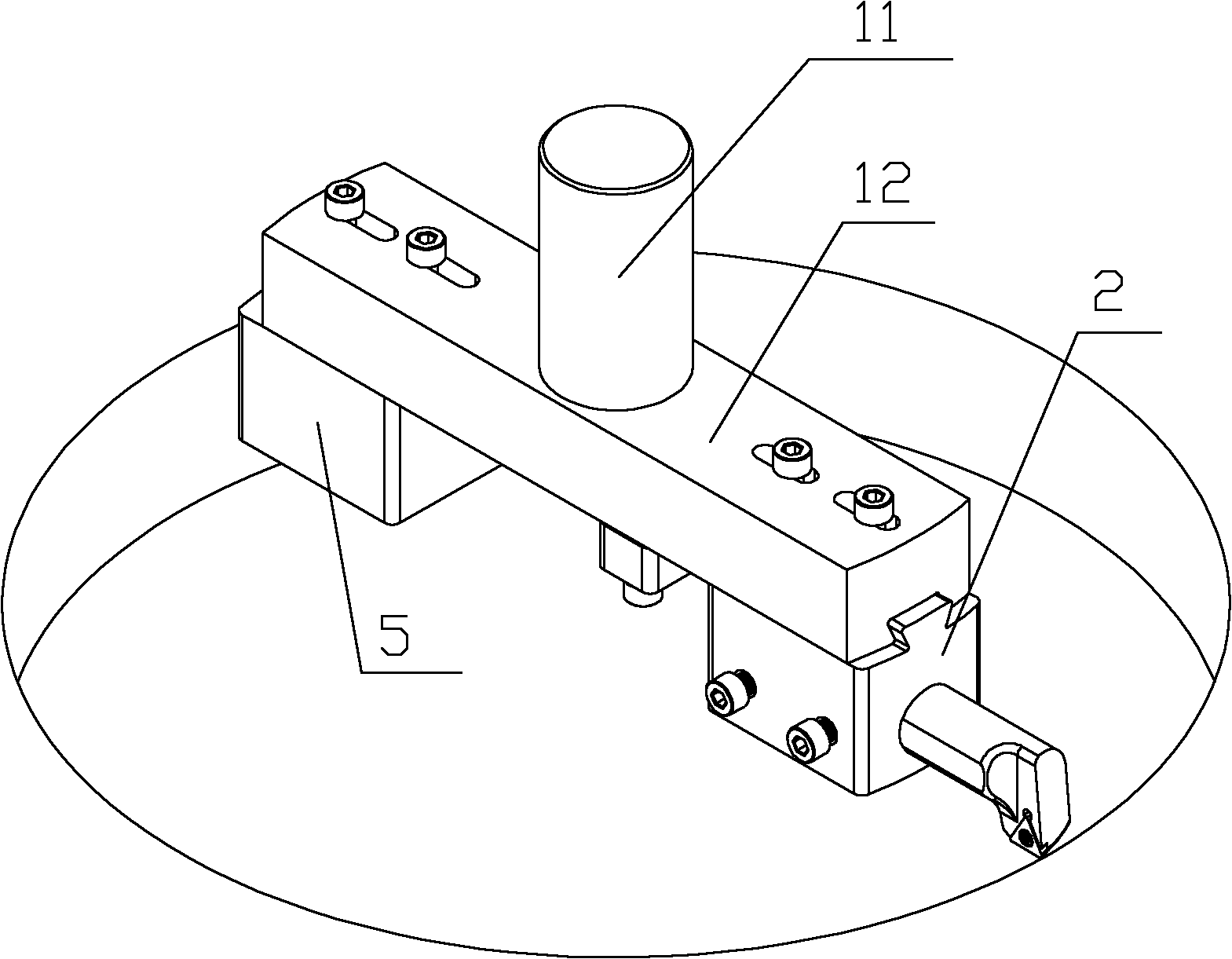

[0046] The T-shaped base 1 is composed of a vertical bar part 11 connected to the machining center and a cross bar part 12 on which the adjustable boring head mechanism 2 is installed. The adjustable boring head mechanism 2 slides the guide groove 13 thereon, and the adjustable boring head mechanism 2 is connected to the cross bar part 12 by screws;

[0047] The adjusting screw 3 passes through the adjustable boring head mechanism 2 to push it forward and backward; the adjusting screw 3 runs through the screw seat 4 .

[0048] The balance weight 5 for balancing the quality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com