Combined boring head for deep hole

A boring head and rolling head technology, which is applied in the field of special tools for deep hole processing, can solve the problems of low work efficiency, large number of tools, and time-consuming guide sleeves, and achieve the effects of improving work efficiency, reducing auxiliary time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

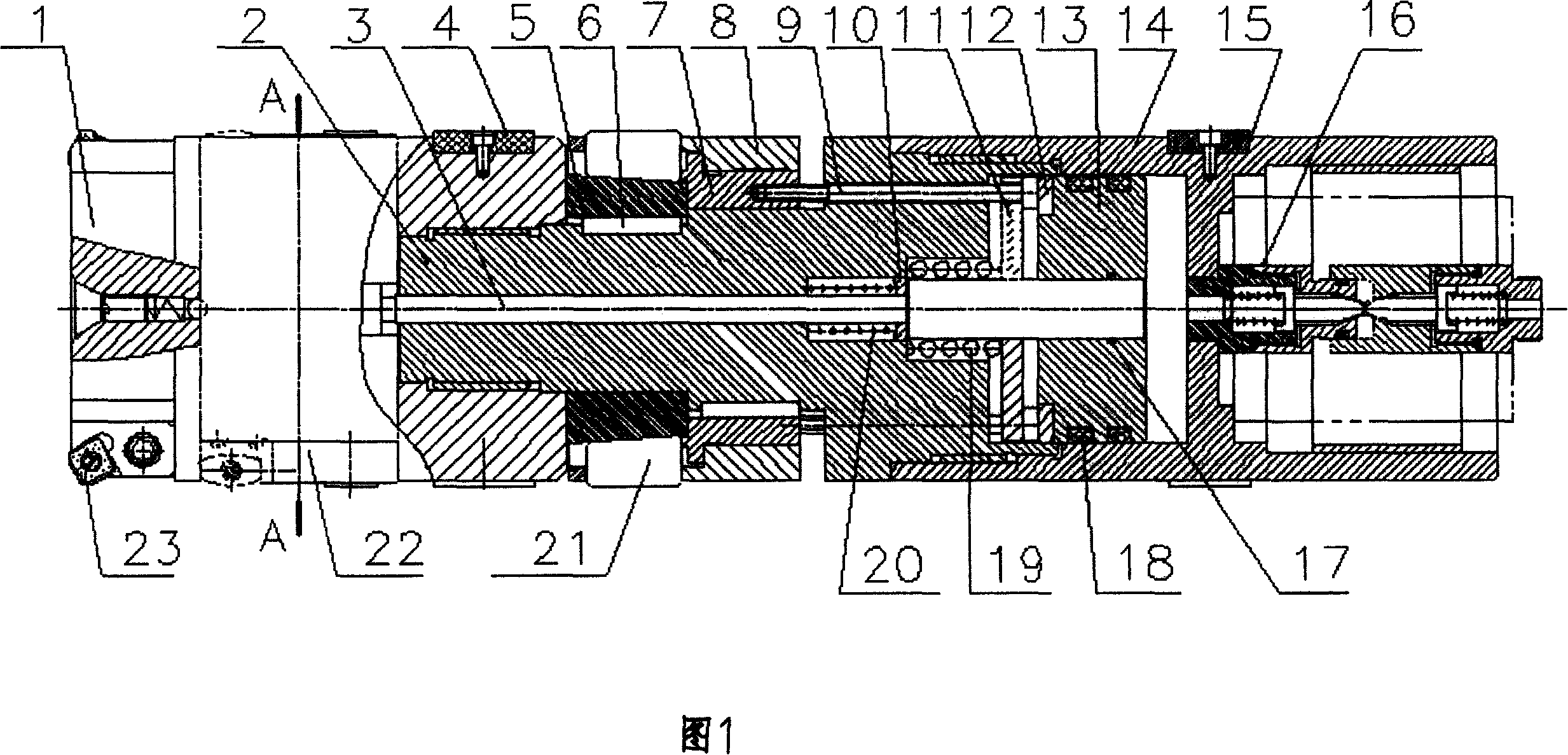

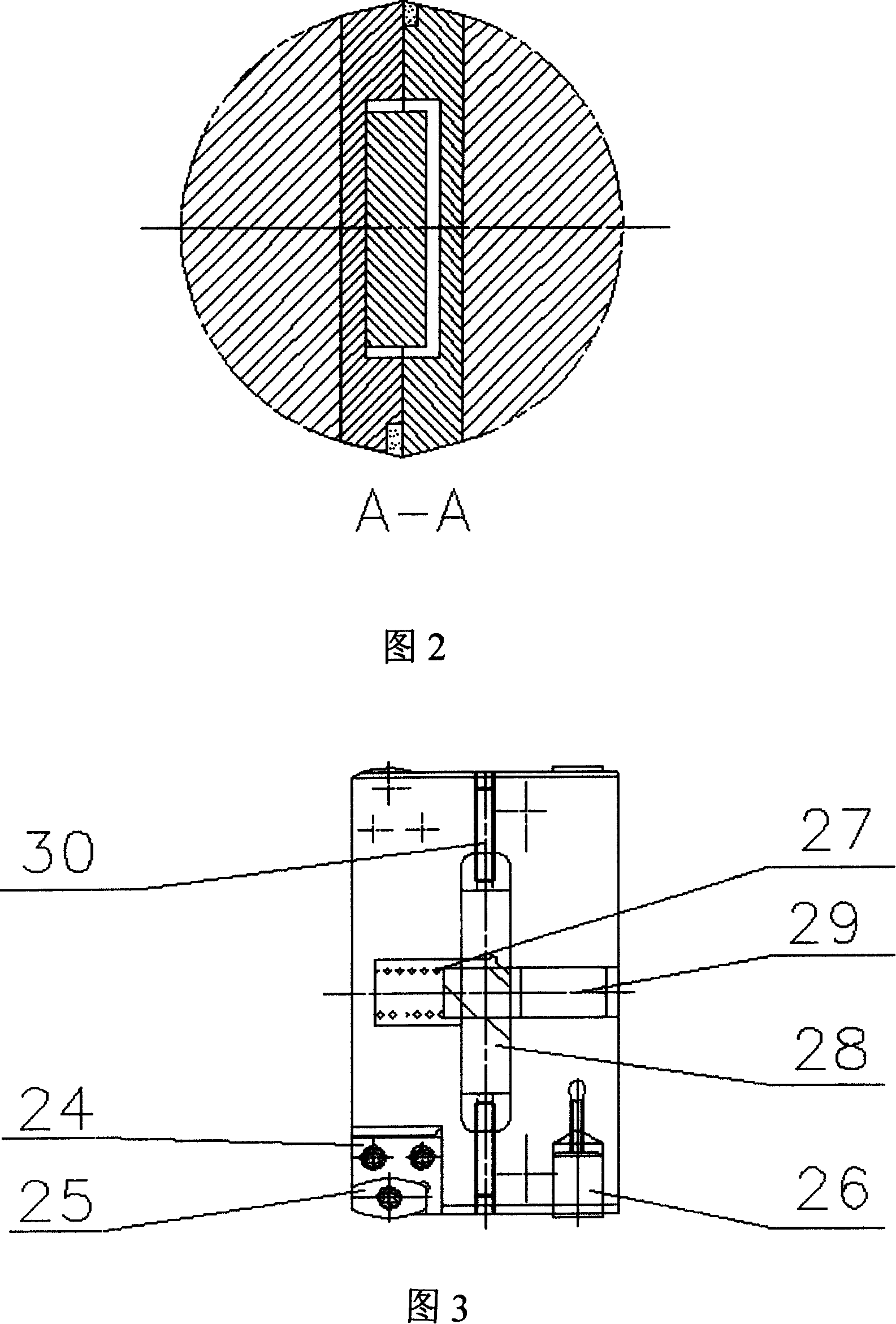

[0016] In Fig. 1, 2, 3, the deep hole combined boring and rolling head has a boring head body (1) on the left side, a connecting cutter body (2) in the middle, and a joint (14) on the right side. The ejector rod (3) is installed at the center connecting the cutter body and the large piston; the guide block (4) is installed on the left boring head body; Roller (21) on the taper sleeve (5); Taper sleeve right side has support sleeve (7), and retainer (8) is arranged on it; Connecting cutter body right side has the support plate (11) that is contained on the ejector rod ), use bolts (9) to pass through the support plate, and connect the cutter body to be fixed on the support sleeve; there is a large piston (13) on the right side of the support plate, a copper pad (12) on the left side of it, and O-rings on the inner and outer circles (17), (18), the intermediate push rod is covered with a washer (10), and is covered with a large spring (19) and a small spring (20); the guide bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com