Automatic expanding and shrinking waste edge coiling machine drum

A technology of expansion and contraction and edge rolling, which is applied in the field of waste edge coiling, can solve the problems of cylinder body and clamping head wear, failure to realize cylinder expansion and contraction, and automatic blanking, so as to avoid scratches and prolong unloading. The effect of reducing the roll cycle and processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

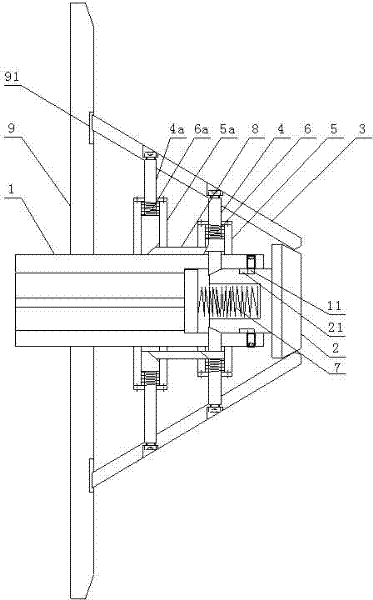

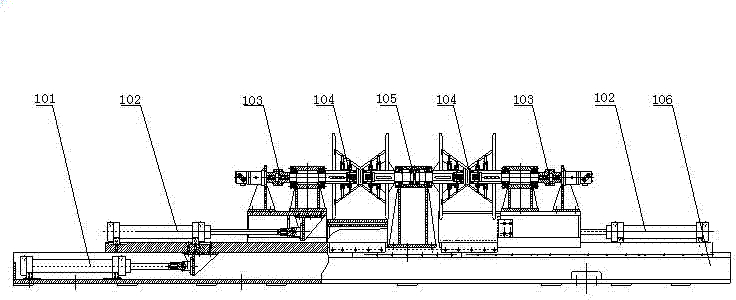

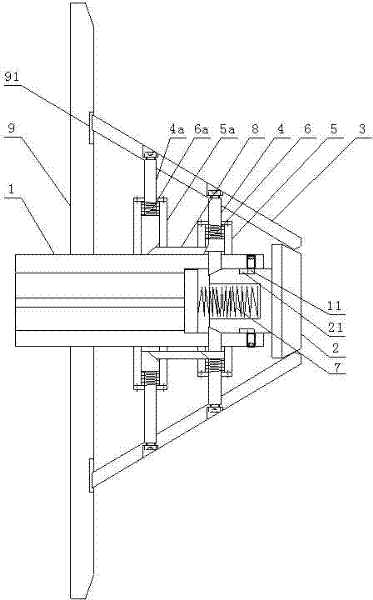

[0016] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0017] figure 1 It is a schematic diagram of the structure of the present invention; as shown in the figure, the automatically expanding and shrinking waste edge coiler reel of the present invention includes a main shaft 1 connected to the transmission shaft of the transmission device and an outer sleeve on the main shaft 1 for winding waste edges. A cylinder 3, the cylinder 3 is composed of at least two cylinder petals, each cylinder petal is connected to the main shaft 1 through a telescopic mechanism, and the telescopic mechanism is used to drive the cylinder petals to expand and contract radially along the cylinder 3; Before starting to take up waste edges, the telescopic mechanism drives the flaps of the cylinder body to expand, thereby expanding the cylinder body 3. After the waste edge winding is completed, the telescopic mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com