Automatic expansion and shrink type edge material winding drum

An edge material and reel technology, which is applied in the field of automatic expansion and contraction type edge material reels, can solve the problems of high work intensity and long time consumption, and achieve the effects of improved efficiency, short time consumption and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

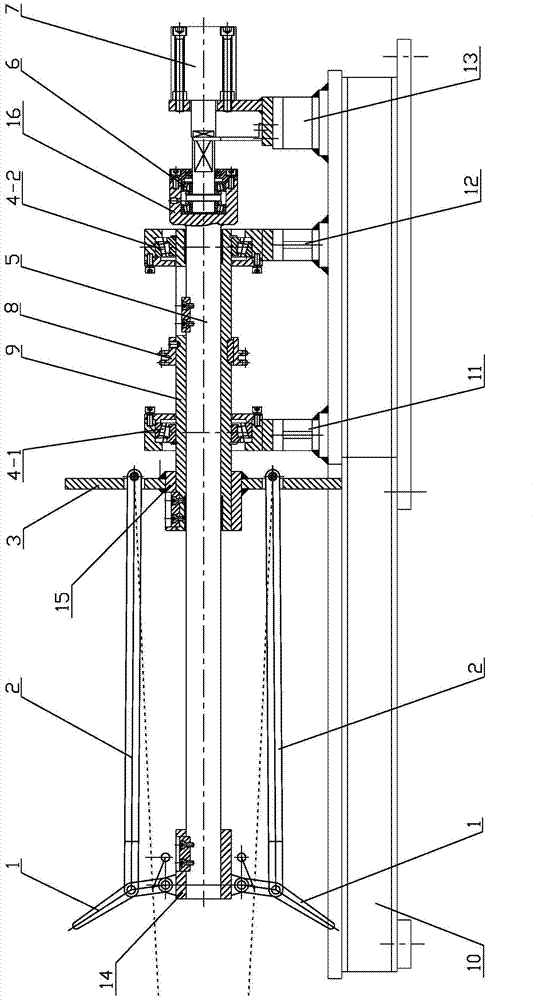

[0026] Such as figure 1 As shown, the present invention includes a base 10 and a first bearing support 11, a second bearing support 12 and a hydraulic cylinder support 13 arranged at intervals on the base 10, and the first bearing support 11 is provided with a first support Bearing 4-1, the second bearing support 12 is provided with a second support bearing 4-2, the first support bearing 4-1 and the second support bearing 4-2 are supported and installed with a shaft sleeve 9, so A sprocket 8 is fixedly connected to the bushing 9, a main shaft 5 is fixedly connected inside the bushing 9, and one end of the main shaft 5 protrudes to the outside of the first supporting bearing 4-1 and is fixedly connected to a bent plate for installation. Seat 14, a plurality of bent plates 1 are hinged on the bent plate mounting seat 14, and the shaft sleeve 9 is fixedly connected with a gear plate installed between the bent plate mounting seat 14 and the first support bearing 4-1 Seat 15, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com