Automatically expanding and shrinking scraping-rolling combined deep hole cutter

An automatic and cutting tool technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, boring heads, etc., can solve the problems of inconvenient use and complex structure of the retraction structure, and achieve the effect of improving work efficiency, improving static stiffness and improving dynamic stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

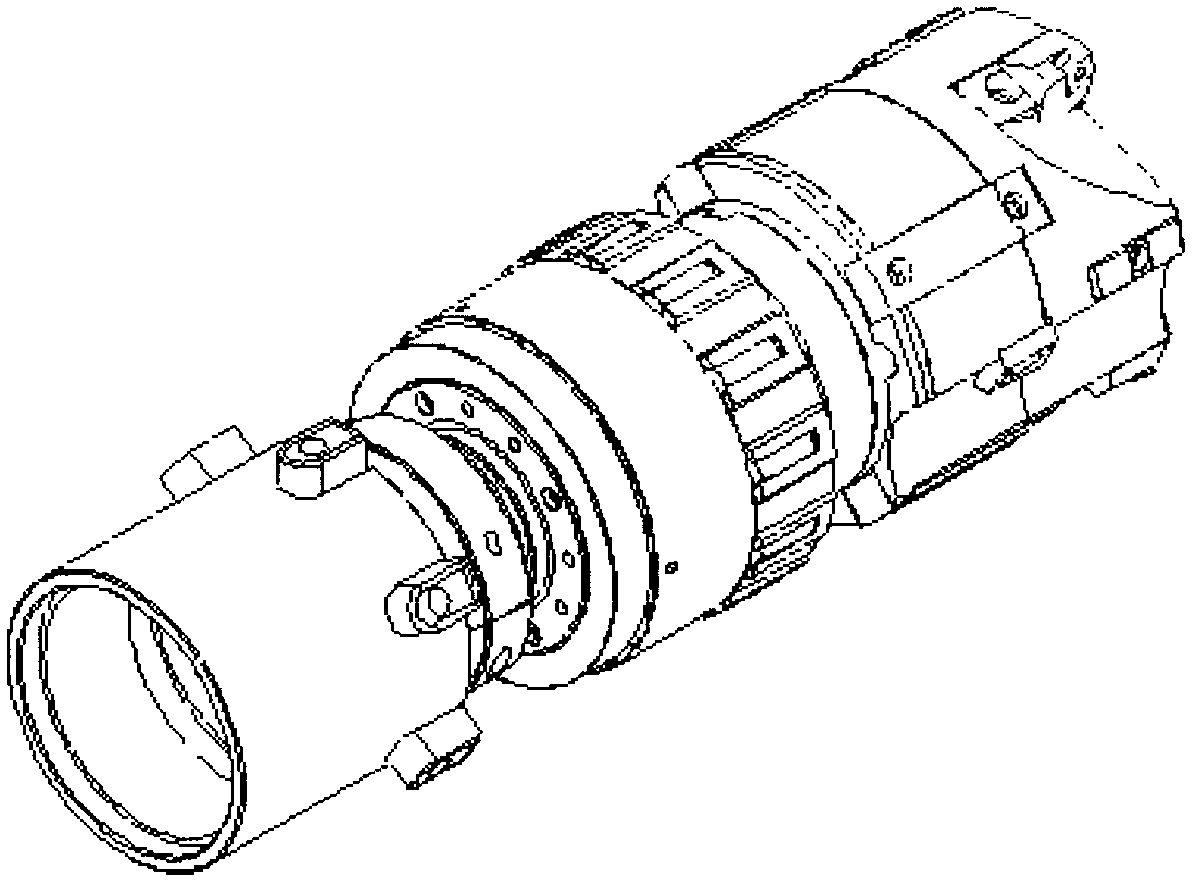

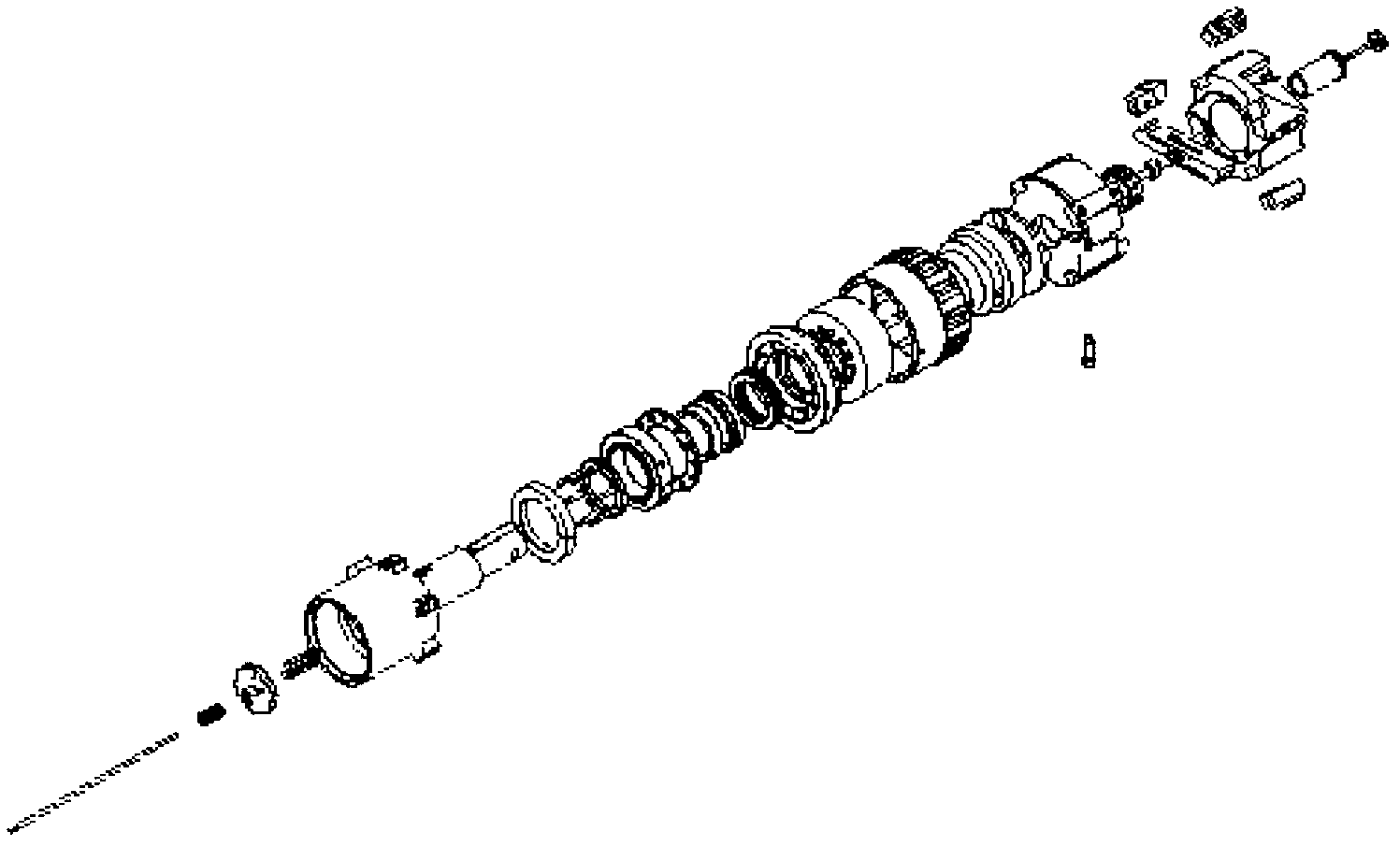

[0039] Refer to the attached figure 1 The shown automatic expansion-contraction scraping-rolling combined boring head includes a rough boring head 1 with a rough boring head body 3 and a connection part for connecting to a boring bar, and is characterized in that it also includes a scraping part and a rolling part, And a mandrel 9 with a center hole that coaxially assembles the rough boring head, the scraping part and the rolling part sequentially from front to back; wherein:

[0040] The scraper includes:

[0041] At least one pair of scraping blades, each pair is symmetrically arranged in the radial direction of the rough boring head body;

[0042] The top block 30 is located at the center of the rough boring head body and has a tapered structure, and the corresponding tapered surface is supported by the centripetal end of the scraper;

[0043] The reset device is located between each pair of paired scraping knives for its reset; it is reset by pressing the spring installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com