Military vehicle flexible antimine ground plate

A technology for military vehicles and floors, which is applied to vehicle components, superstructure sub-assemblies, transportation and packaging, etc., can solve the problems of close explosion points, large space occupation, and large vibration noise, etc., to improve workability, reduce leg The effect of reducing external damage and increasing static stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

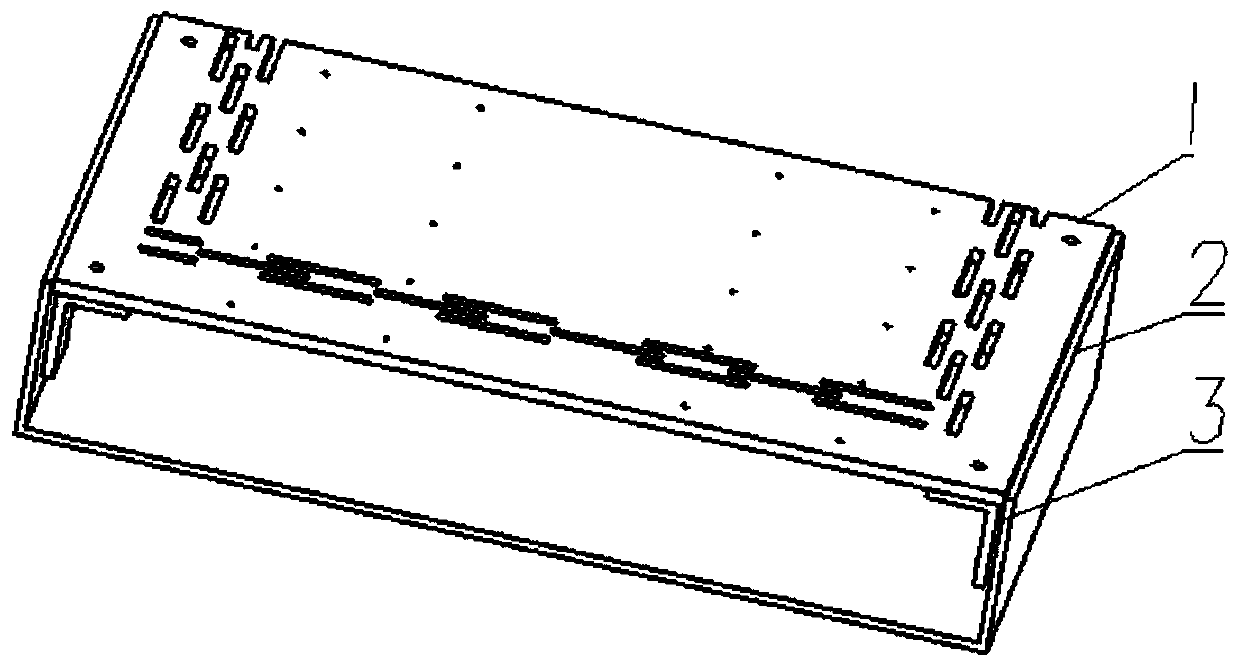

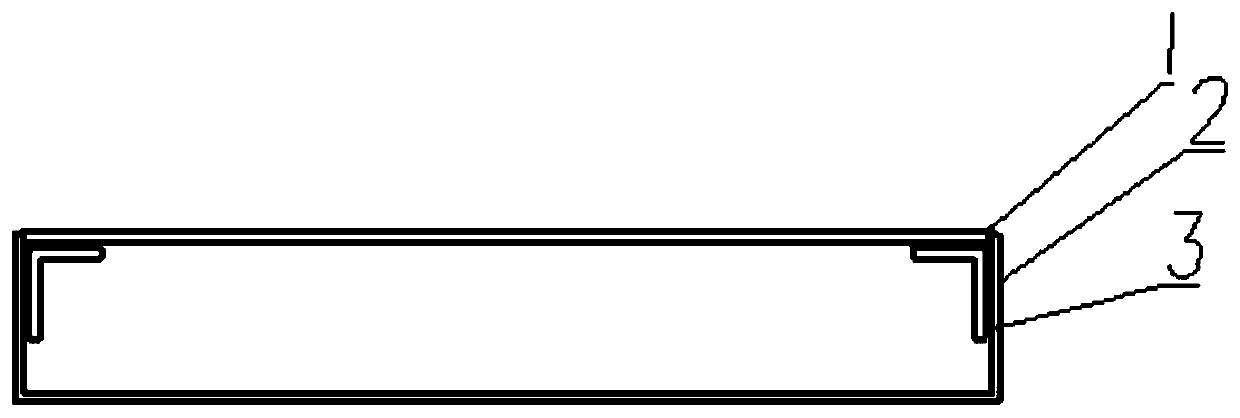

[0030] Such as Figure 1-3 As shown, a flexible lightning protection floor for military vehicles includes three parts: an upper plate 1 , a bracket 2 and a bottom limit connection frame 3 . Wherein the bottom limiting connection frame 3 and the upper plate 1 are connected through a bracket 2, and the bracket 2 is respectively connected with the bottom limiting connection frame 3 and the upper plate 1 through bolts. Wherein the support 2 is an L-shaped support, and the L-shaped support not only serves as a connection, but also buffers and absorbs energy.

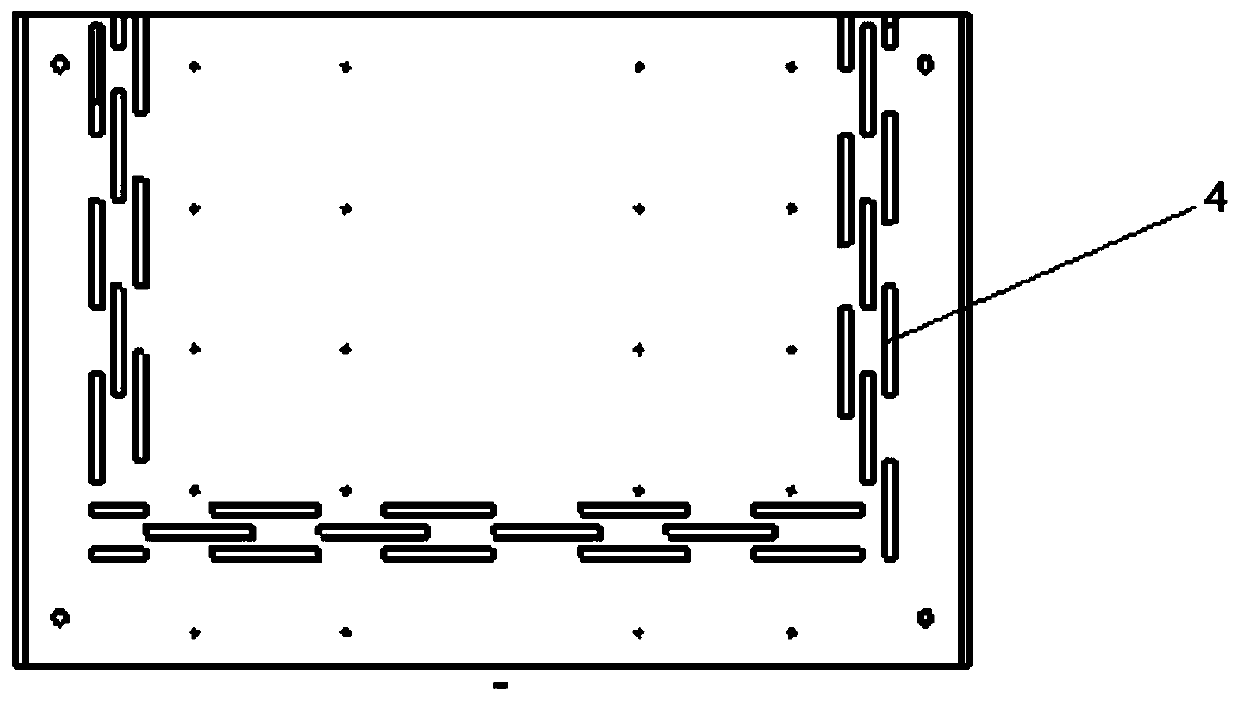

[0031] The upper plate 1 is partly installed on the upper side of the bracket 2, and its staggered parallel hollow design separates the outer ring of the upper plate 1 from the inner part. During the explosion, the force transmitted by the outer circle of the upper plate 1 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com