Finite element simulation analysis and performance optimization method for non-pneumatic tire

A technology for non-pneumatic tires and simulation analysis, which is applied in the field of finite element simulation analysis and performance optimization of non-pneumatic tires. The effect of concentration phenomenon, uniform ground stress distribution, and increased ground stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0067] Aiming at the problems existing in the prior art, the present invention provides a method for finite element simulation and performance optimization of a non-pneumatic tire. The present invention will be described in detail below in conjunction with the accompanying drawings.

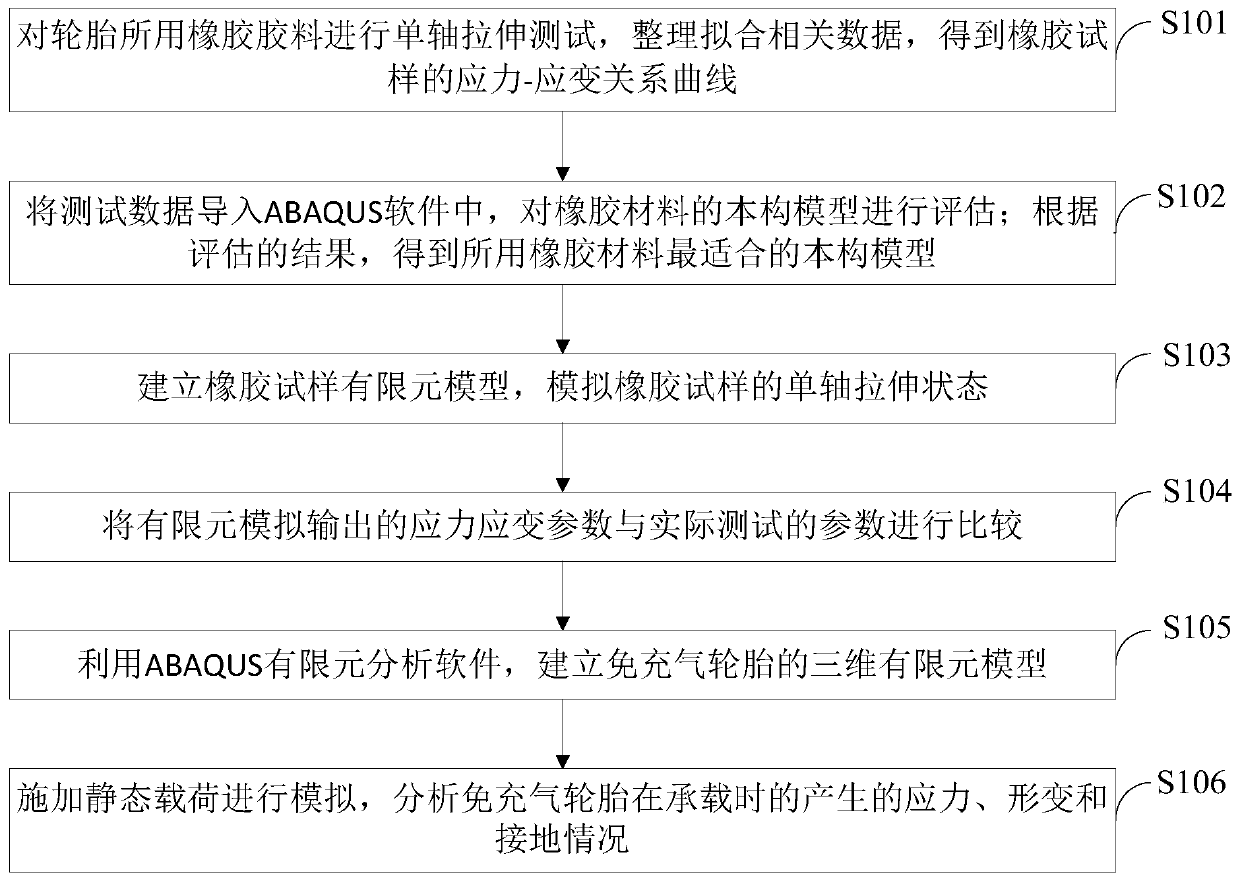

[0068] Such as figure 1 As shown, a finite element simulation analysis method for an air-free tire includes the following steps:

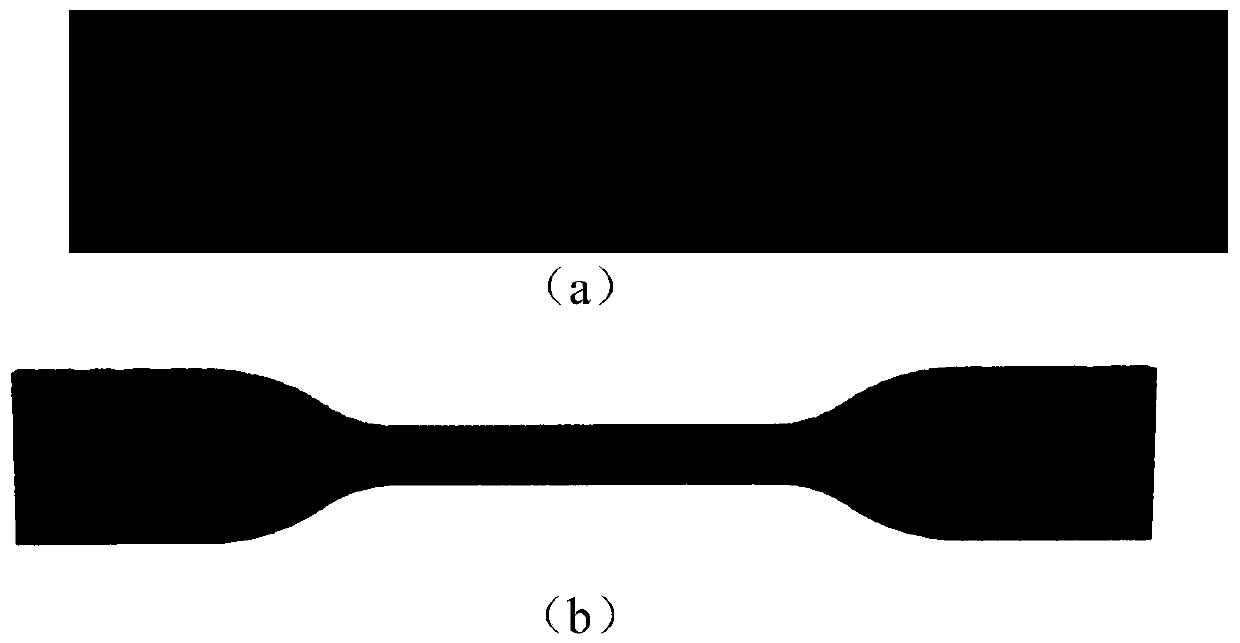

[0069] S101: Perform a uniaxial tensile test on the rubber compound used in the tire, arrange and fit relevant data, and obtain a stress-strain relationship curve of the rubber sample.

[0070] S102: Import the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com