Rotary cutting machine

A technology of rotary cutting machine and rotary cutter, which is applied to metal processing machinery parts, clamping, supporting and other directions, can solve the problems of poor performance, slow cutting speed, low efficiency, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

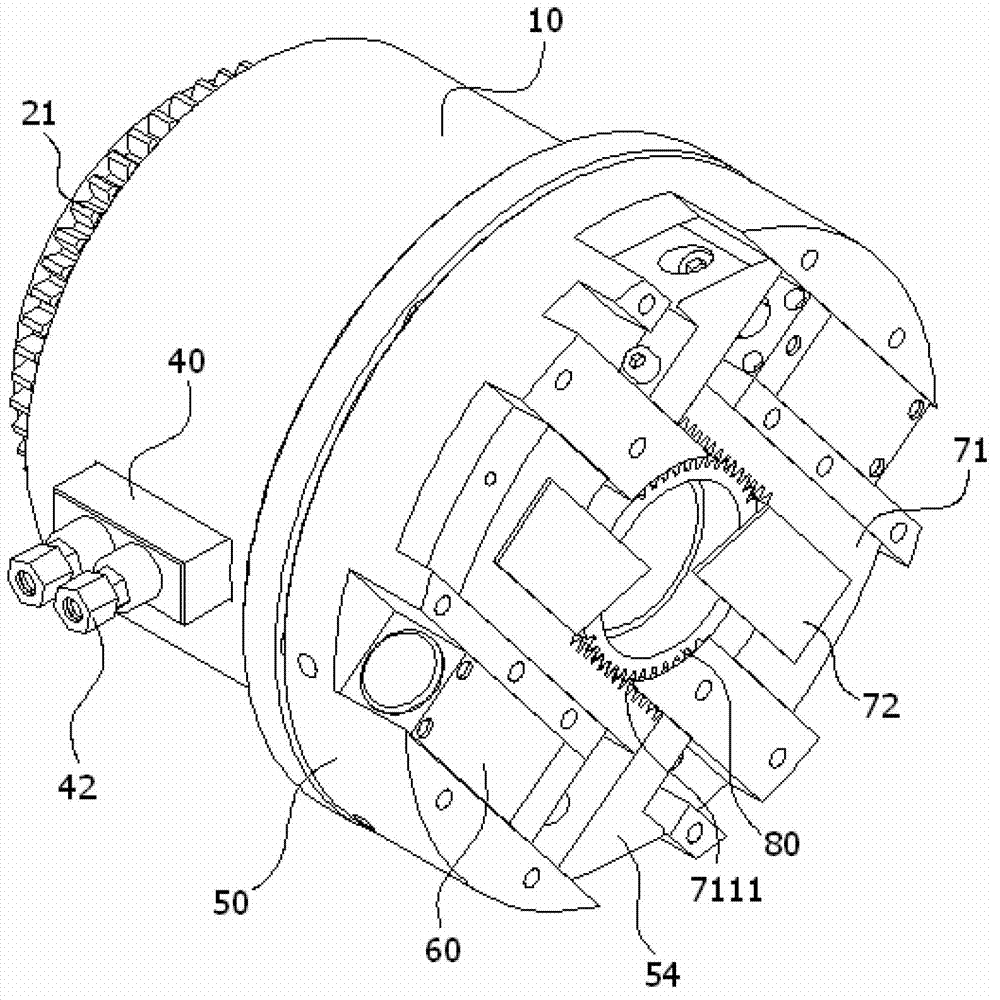

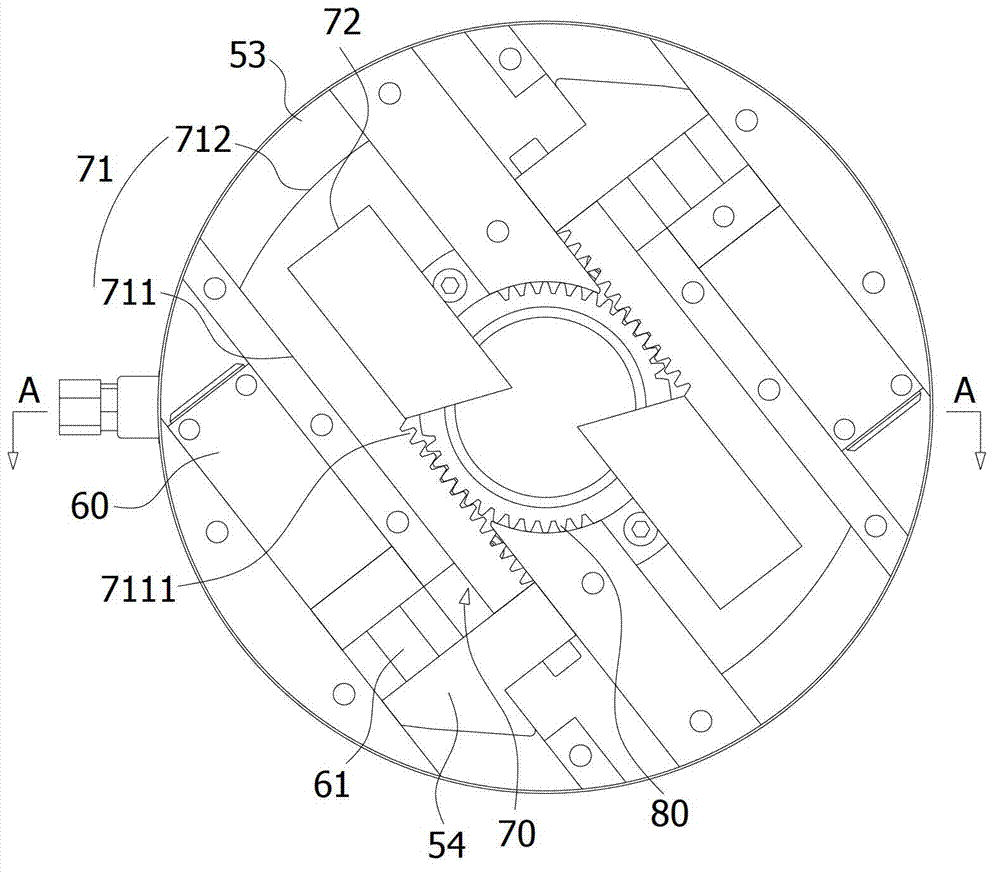

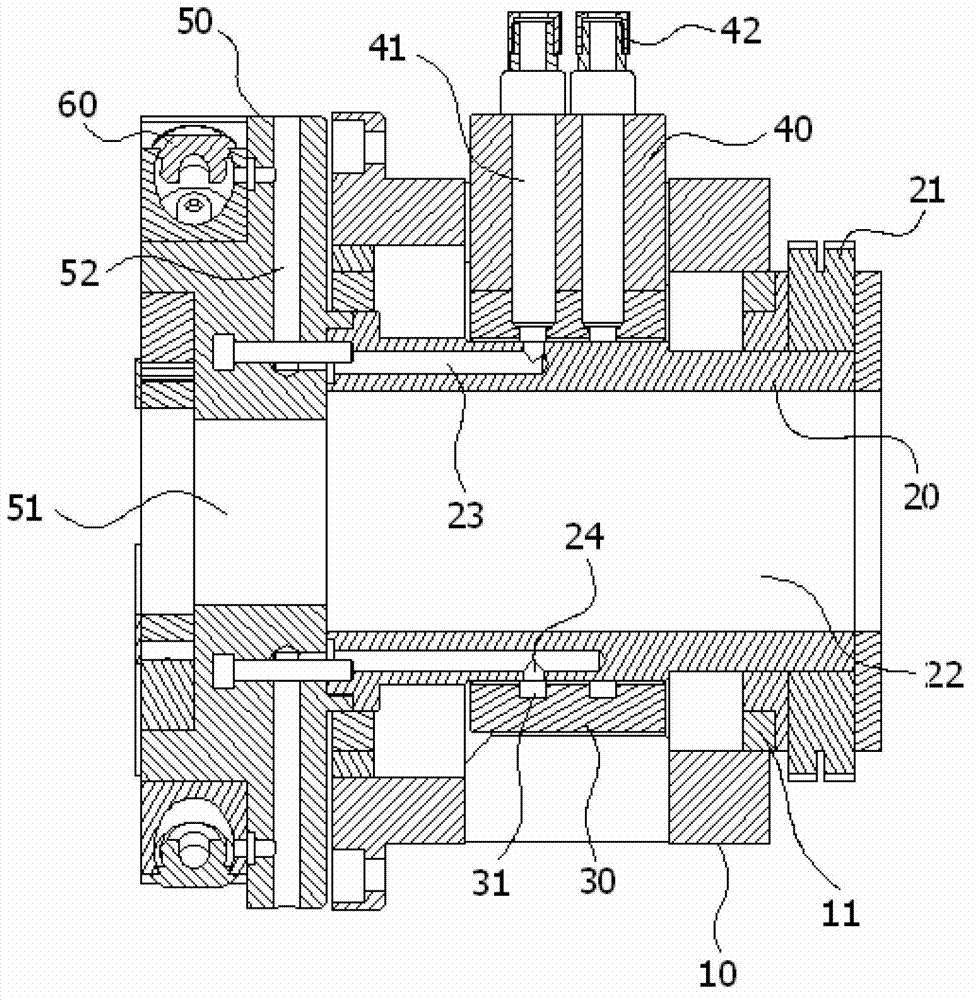

[0042] Please refer to Figures 1 to 3 As shown, it has shown the concrete structure of preferred embodiment of the present invention, rotary cutting machine, comprises main shaft outer cover 10, main shaft rotor 20, slip ring 30, rotating disk 50, oil cylinder 60 and at least one rotary cutter 70, wherein:

[0043] The main shaft cover 10 has an inner cavity, the main shaft rotor 20 is installed in the inner cavity of the main shaft cover 10, the main shaft cover 10 is provided with an opening, the main shaft rotor 20 is covered with a bearing 11 fixed on the main shaft cover 10, the main shaft rotor 20 has a first hollow passage 22 extending from its rear end to its front end, and a second oil passage 23 is arranged in the main shaft rotor 20, and a hole 24 communicating with the second oil passage 23 is opened on the main shaft rotor 20; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com