Split type four-roller corrugated plate rolling machine

A plate rolling machine, split-type technology, applied in the direction of presses, manufacturing tools, push-out equipment, etc., can solve the problems of high difficulty in assembly of four-roll plate rolling machines, difficulty in ensuring welding accuracy of the frame, and difficulty in removing curved plates. , to achieve the effects of compact structure, simple and ingenious structural design, and improved assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

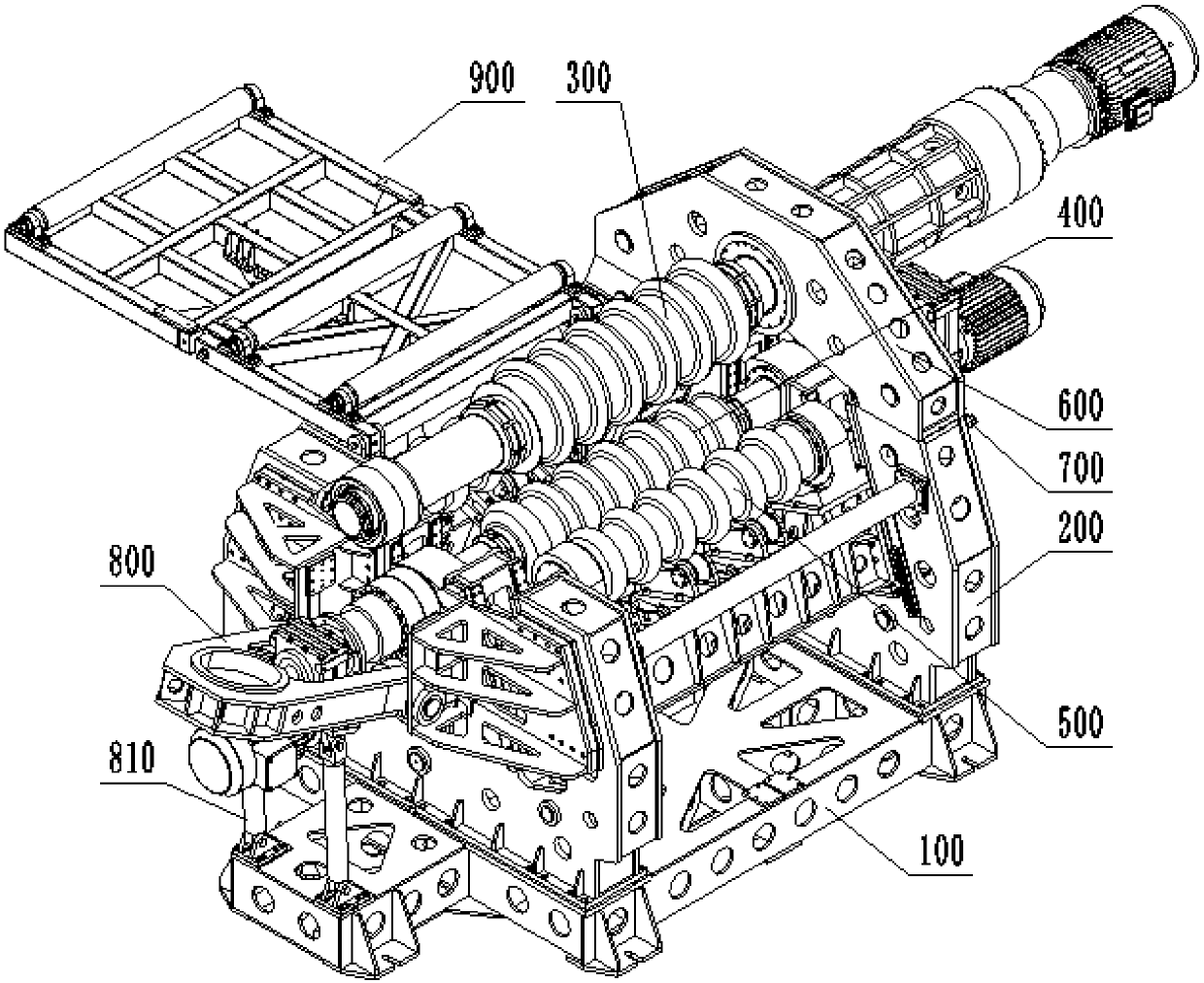

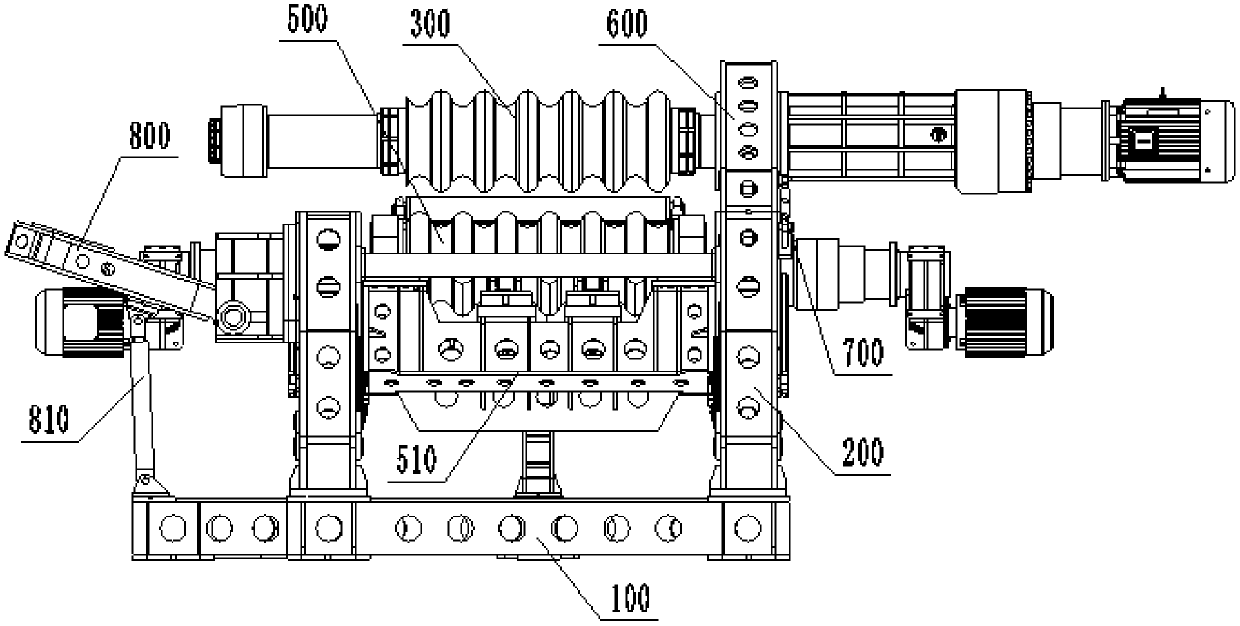

[0069] like figure 1 , figure 2 , image 3 As shown, a split-type four-roller corrugated plate bending machine in this embodiment mainly includes a base 100, a pair of racks 200, an upper roll 300, a lower roll 400, a pair of side rolls 500, a top frame 600 and tensioning Agency 700. Wherein, a pair of frame 200 is arranged on the opposite two sides on the base 100, and the base 100 and the frame 200 are welded by plates, and there are a plurality of stiffener plates inside, to enhance their strength, and the frame 200 passes through The bolts are fixed on the base 100, and the two ends of the lower roller 400 are respectively supported on the frame 200 by a lower roller oil cylinder 410. A side roller oil cylinder 520 is also supported and arranged on the frame 200 .

[0070] In the traditional plate rolling machine, the upper roll 300 is also directly installed on the frame. Because the pressure of the working roll of the plate rolling machine is very high, the support ...

Embodiment 2

[0076] In this embodiment, a split type four-roller corrugated plate bending machine is designed on the basis of Embodiment 1 to optimize the installation form of each roll. In the traditional plate rolling machine, each roller is driven by an oil cylinder, that is, the oil cylinder is connected to the slider, and the two ends of the roller are installed on the slider. In order to ensure the stability of the up and down movement of each roller, the supporting surface of the slider has a certain length requirement. As a result, the height of the rack is relatively high, the weight of the whole machine is relatively heavy, and the manufacturing cost is also high.

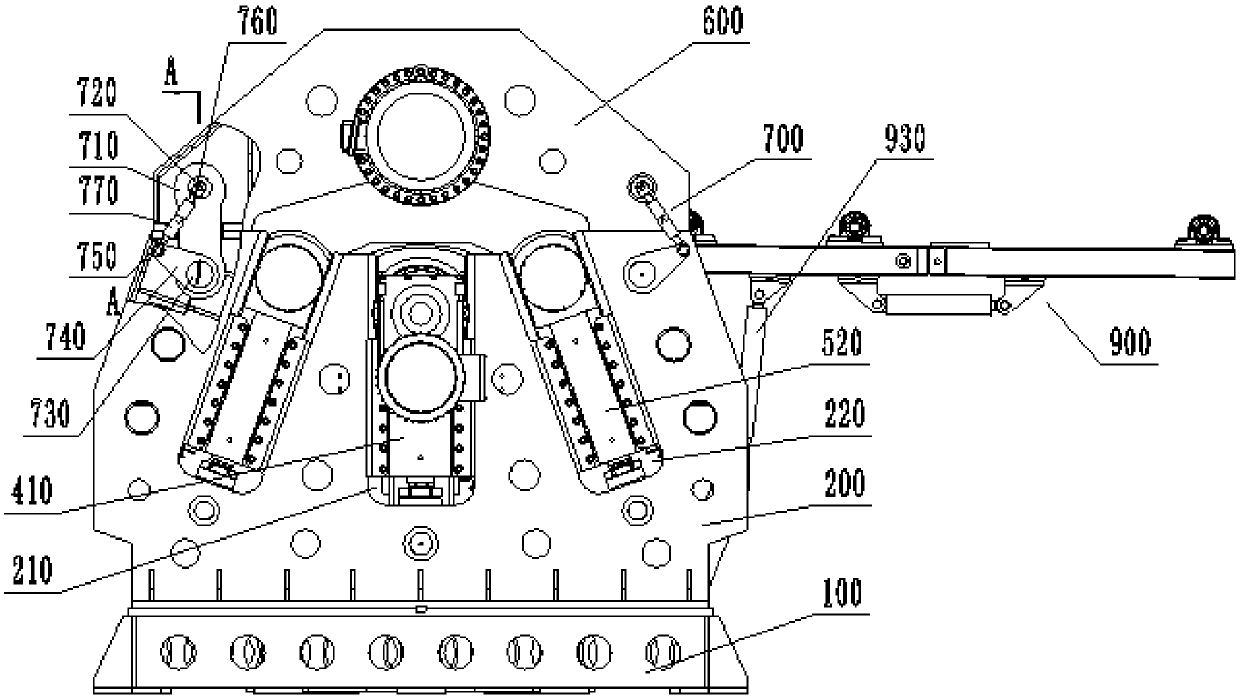

[0077] To solve this problem, as image 3 As shown, in the present embodiment, a lower roller groove 210 and side roller grooves 220 located on both sides of the lower roller groove 210 are provided on the frame 200, and the lower roller cylinder 410 and the side roller cylinder 520 are respectively arranged in the lo...

Embodiment 3

[0083] A split-type four-roller corrugated plate bending machine in this embodiment is further improved on the basis of Embodiment 1 or 2, so as to facilitate the removal of rolled parts.

[0084] When rolling a full-round pipe, the overturning cylinder 810 is used to drive the overturning bracket 800 to overturn downwards, so that one end of the upper roller 300 is opened, so that the workpiece can be removed; while when rolling a curved plate, generally For convenience and quickness, the workpiece is directly removed from the discharge side; however, since the arc-shaped plate has no reliable force point and is easy to slide, after the rolling is completed, if the lower roller cylinder 410 and the side roller cylinder 520 are directly driven When the lower roller 400 and the side roller 500 go down to release the workpiece, the workpiece will slide directly between the upper roller 300 and the lower roller 400, and it is difficult to take it out, or the rollers continue to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com