Production method of chromatic metallic yarn and spinning apparatus

A colored metal and production method technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of high production cost, inability to weave knitted fabrics, and inability to make warp yarns, etc., and achieve the effect of simple production process, reasonable structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: take cotton, dyed cotton and metal wire as raw material to produce colored metallic yarn as example.

[0019] Cotton and dyed cotton (proportioned according to customer requirements) are loaded into the A002D automatic disc plucking machine for mixing, and then mixed by the A045B cotton condenser, A002D automatic disc plucking machine and A045B cotton condensor are fully mixed , opened by the A035B mixed opener, and then inhaled by the A045B condenser, FA106A porcupine opener mixed, FA046A oscillating cotton box oscillating and mixed, A076E single hand lapping machine to make cotton laps, cotton laps The A186F carding machine is carded into sliver, and the sliver is drawn twice by FA304 drawing frame, and the drawn sliver is spun into colored roving by A454E roving frame.

[0020] The colored metallic yarn spinning device of the present invention is used to spin the colored rovings and metal filaments into colored metallic yarns.

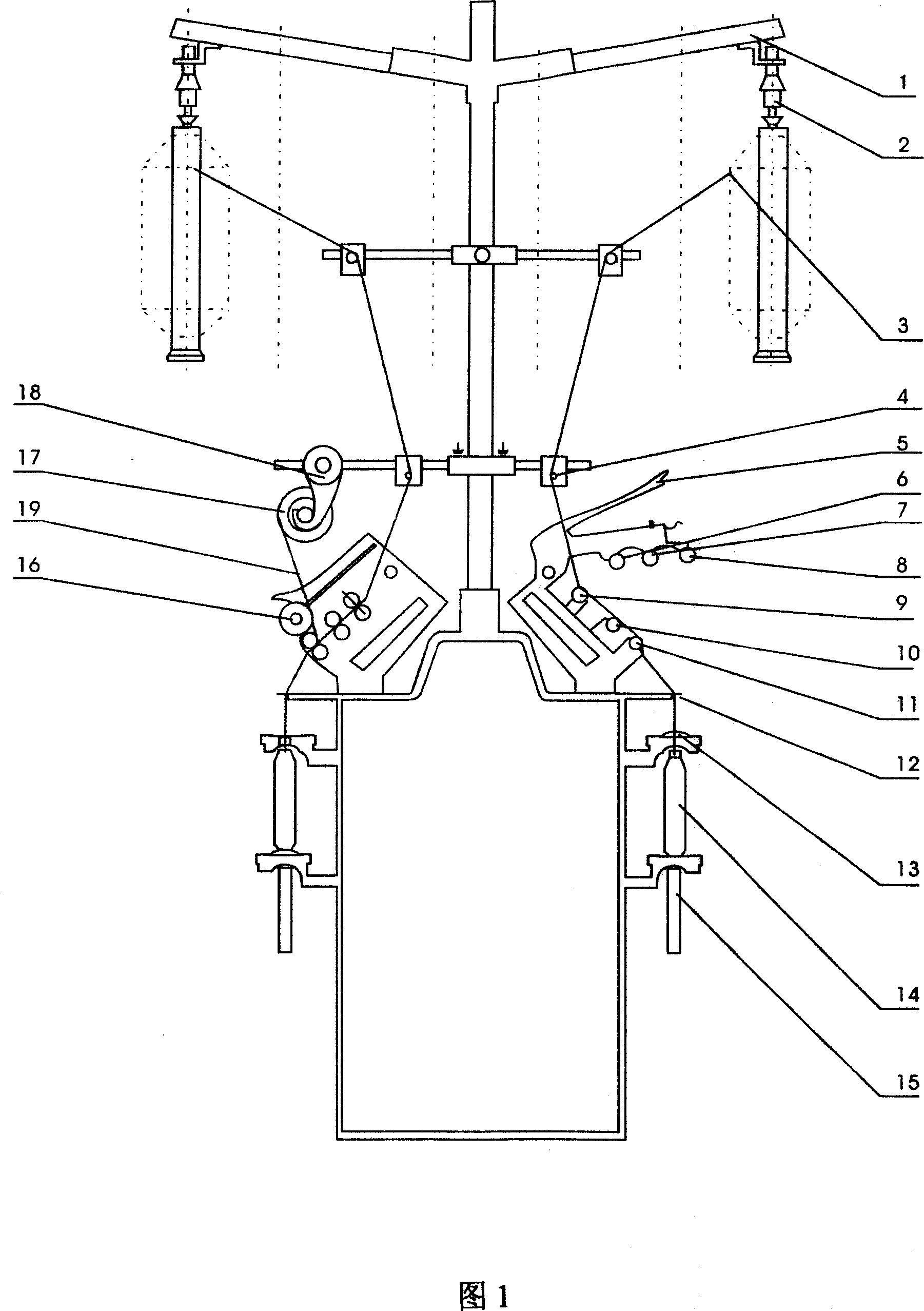

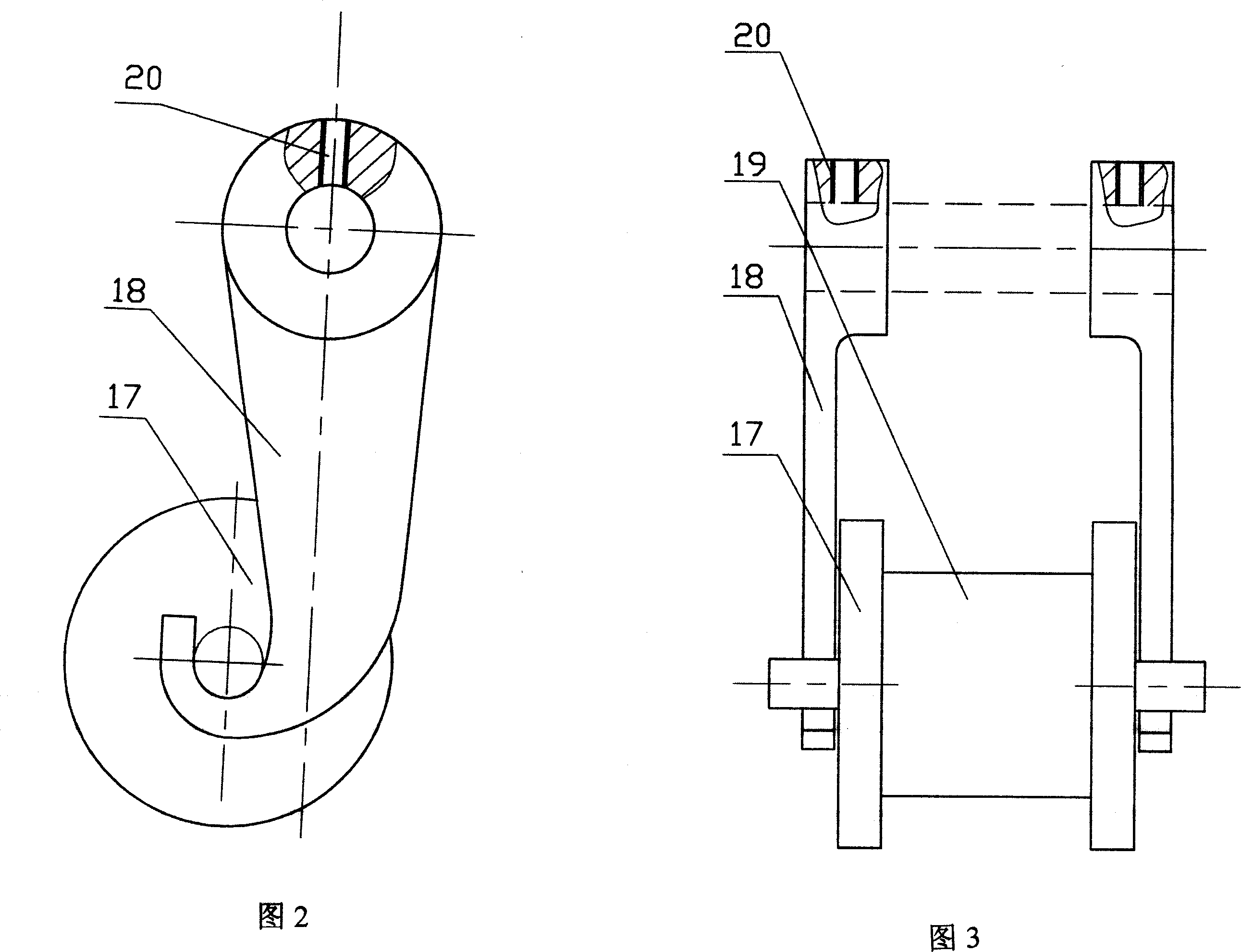

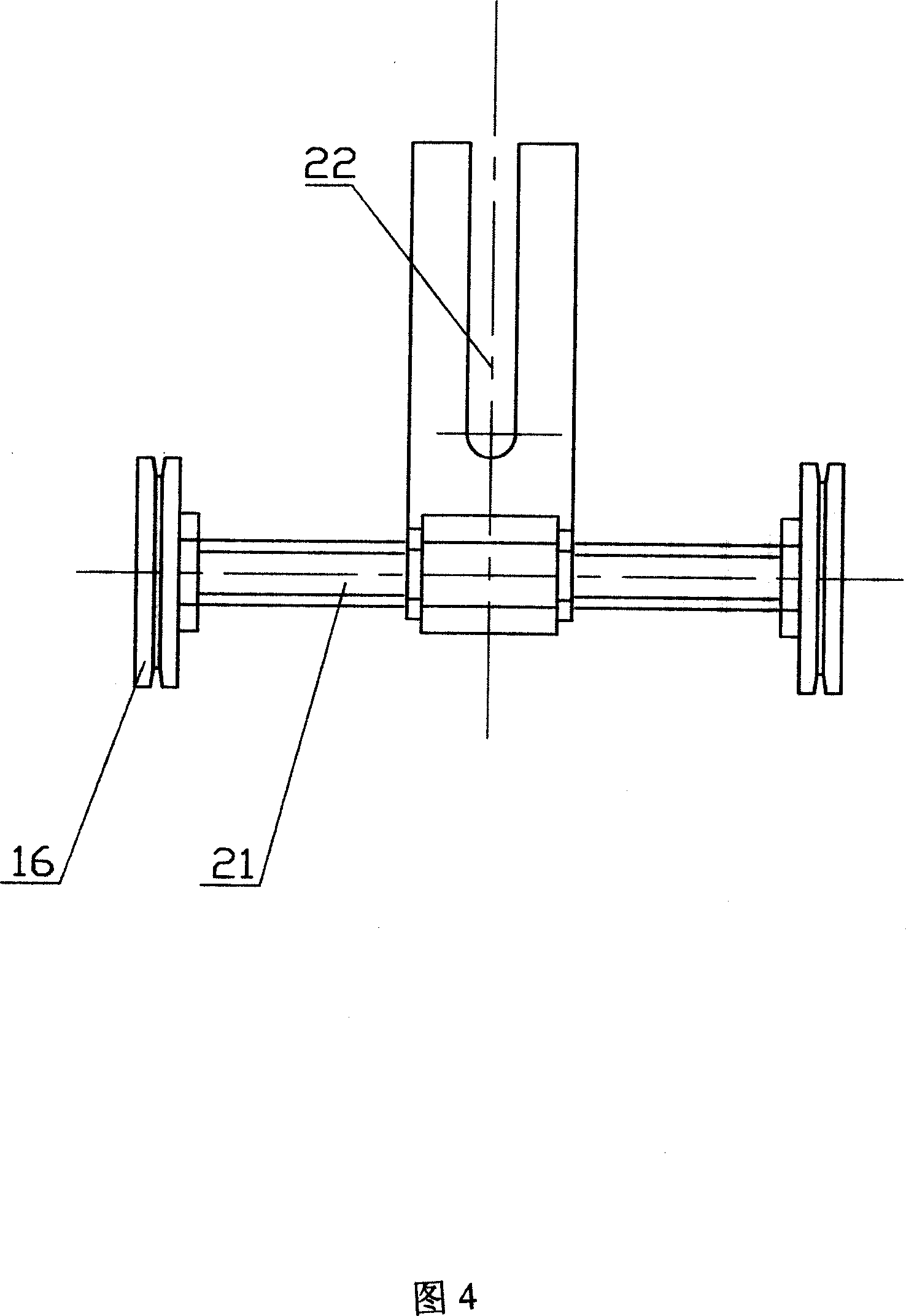

[0021] The spinning dev...

Embodiment 2

[0024] Embodiment 2: take polyester, dyed cotton and metal wire as raw material to produce colored metallic yarn as example.

[0025] Polyester and dyed cotton (proportioned according to customer requirements) are loaded into the A002D automatic disc plucking machine for mixing, and then mixed by the A045B cotton condenser, A002D automatic disc plucking machine, A045B cotton condensor are fully mixed, After being opened by the A035B hybrid opener, it is inhaled by the A045B condenser, mixed by the FA106A porcupine opener, FA046A oscillating cotton box is oscillating and mixed, and the A076E single hand lapping machine is used to make laps, and the laps are carded by A186F The machine is carded into sliver, and the sliver is drawn twice by FA304 drawing frame, and the drawn sliver is spun into colored roving by A454E roving frame.

[0026] The colored metallic yarn spinning device of the present invention is used to spin the colored rovings and metal filaments into colored meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com