Novel electric wire coating device

A coating device, wire and cable technology, used in cable/conductor manufacturing, insulation of conductors/cables, circuits, etc., can solve problems such as increased production costs, reduced production efficiency, and many seams in shielding layers, so as to extend service life. , easy to control and adjust, to meet the effect of good coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

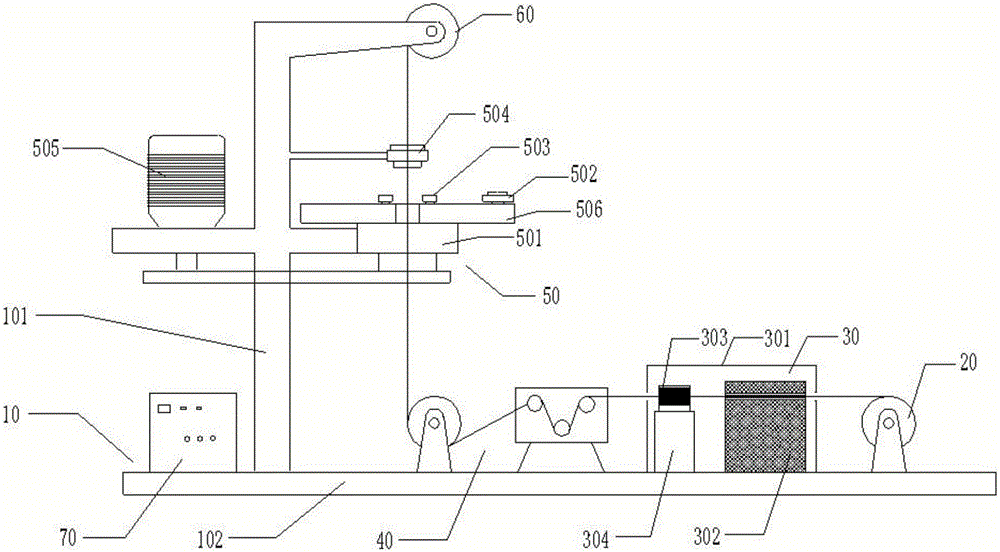

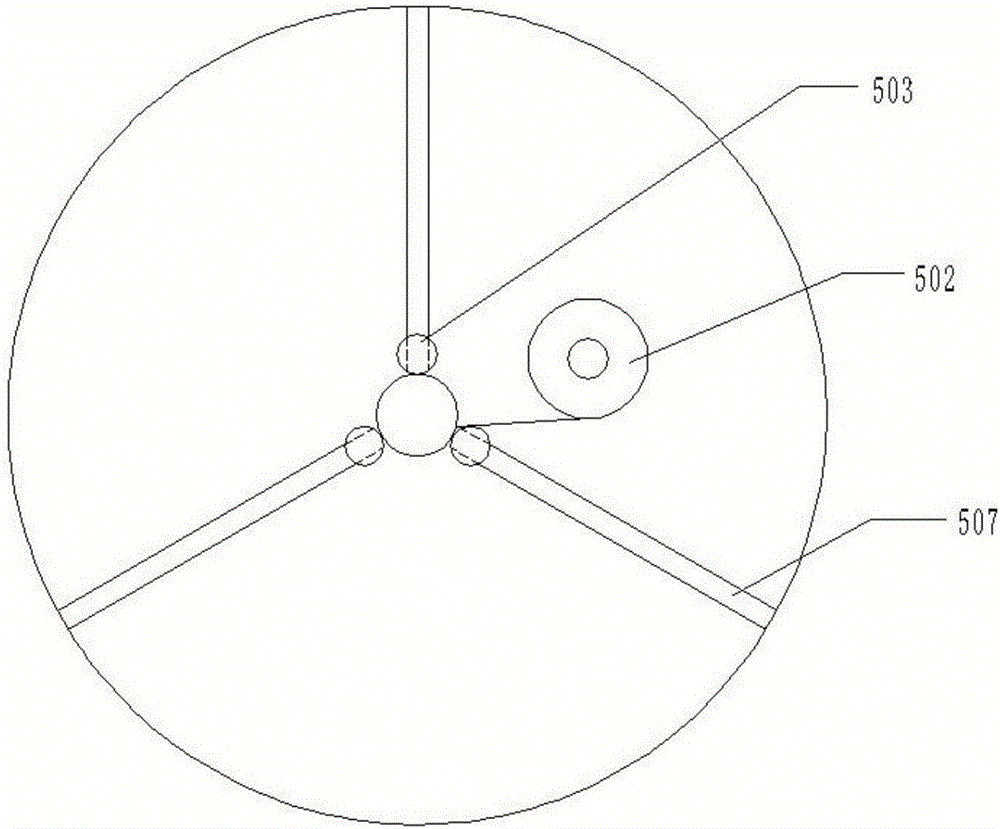

[0020] Such as figure 1 and figure 2 As shown, a new type of wire and cable coating device includes a frame 10, a wire release device 20, an impurity removal device 30, a guide device 40, a coating device 50, a wire take-up device 60 and a control device 70, and the frame 10 is provided with For being made up of a bracket 101 and a base plate 102, the bracket 101 is vertically arranged on the base plate 102, and the upper surface of the base plate 102 away from the side of the bracket 101 is provided with a wire releasing device 20, an impurity removal device 30 and a guiding device 40 in sequence, covering The device 50 is set to be composed of a winding mechanism 501 and a shielding tape holder 502. The winding mechanism 501 is horizontally arranged on the support 101, and the shielding tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com