Method for preparing G/Sn/PAN-base carbon nanometer fiber membrane

A technology of carbon nanofibers and nanofiber membranes, which is applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problems of battery capacity attenuation and achieve excellent conductivity, simple preparation method and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

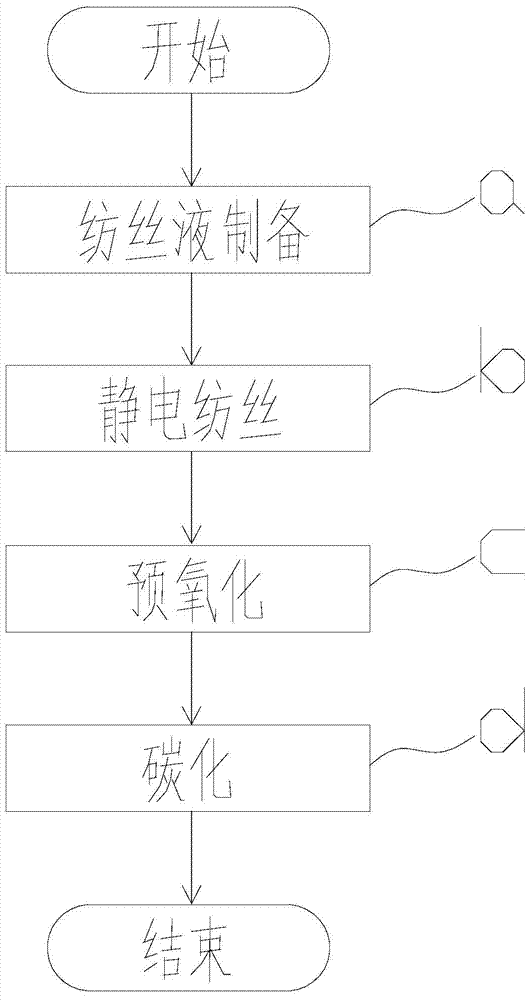

[0029] refer to figure 1 , the flow process of the method for preparing G / Sn / PAN-based carbon nanofiber film in the present invention mainly comprises the following steps:

[0030] (1) Use an electronic balance to weigh a certain amount of G / Sn / PAN powder (the mass ratio of G, Sn, and PAN is 1:3:16, and the mass fraction of PAN is 8%) and place it in a 20ml sample bottle. Pipette 10ml of N-N dimethylformamide (DMF) into the liquid tube, seal the sample bottle with raw material tape, heat to 60°C and stir for 24 hours to finally obtain a relatively uniformly dispersed solution.

[0031] (2) Use an electrospinning device for electrospinning, cut out tinfoil paper with an area of 40cm×40cm and stick it on the flat collector, take 5ml of the spinning solution sample and put it into the injection needle, connect the positive electrode of the high voltage generator with the spray Connect the wire port, connect the negative electrode to the plate receiver, adjust the flow rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com