Flame-retarding reinforced acrylonitrile-butadiene-styrene (ABS) composite containing ceramic fibers and preparation method thereof

A technology of ceramic fibers and composites, which is applied in the field of flame-retardant ABS composites and its preparation, can solve the problems of low heat resistance and low flame retardancy, and achieve high production efficiency, stable product quality, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

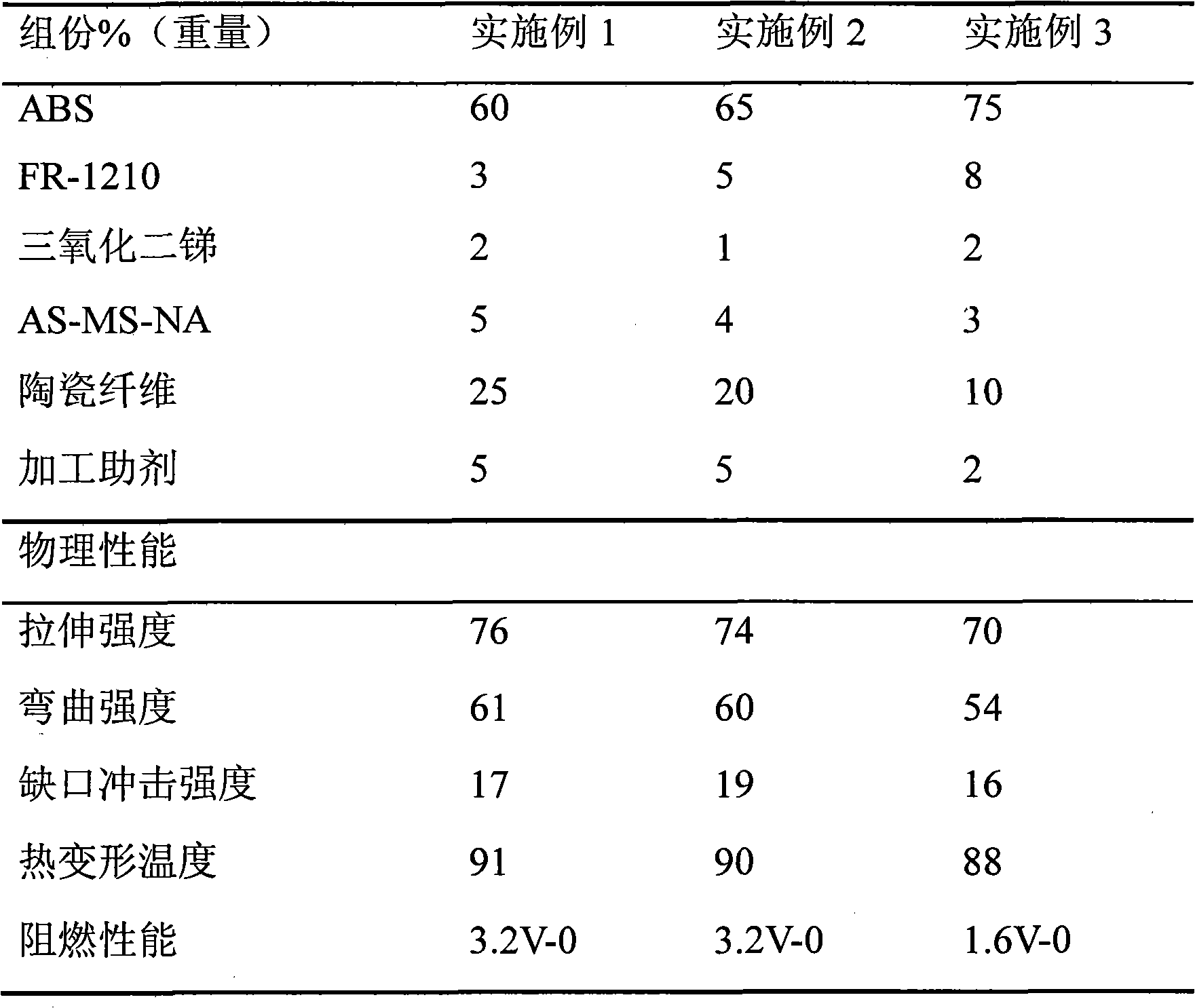

[0033] The preparation and physical properties of the flame-retardant reinforced ABS composite containing ceramic fibers of the present invention are shown in Attached Table 1, and the test method standards adopted are shown in Attached Table 2:

[0034] The ABS resin that adopts in the present embodiment is the 747 of Taiwan CHIMEI company; The heat resistance modifier is the AS-MS-NA of Nippon Denka; Antimony oxide; the ceramic fiber is a high-temperature (HT) type ceramic fiber produced by Hebei Luanping Autostin Industrial Co., Ltd., with a fiber diameter of 2 to 4 microns; the processing lubricating aid is domestic EBS, and a small amount of white mineral oil.

[0035] The preparation process of the material is as follows: According to the first processing method, the ABS resin, flame retardant, heat-resistant modifier and processing aid are mixed evenly in the high-mixer, and fed into the In the extruder with a length-to-diameter ratio of 36:1, the extruder screw has a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com